Micromechanical method and corresponding assembly for bonding semiconductor substrates and correspondingly bonded semiconductor chip

A substrate bonding and semiconductor technology, applied in semiconductor devices, microstructure devices, processing microstructure devices, etc., can solve problems such as liquid eutectic phase inflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

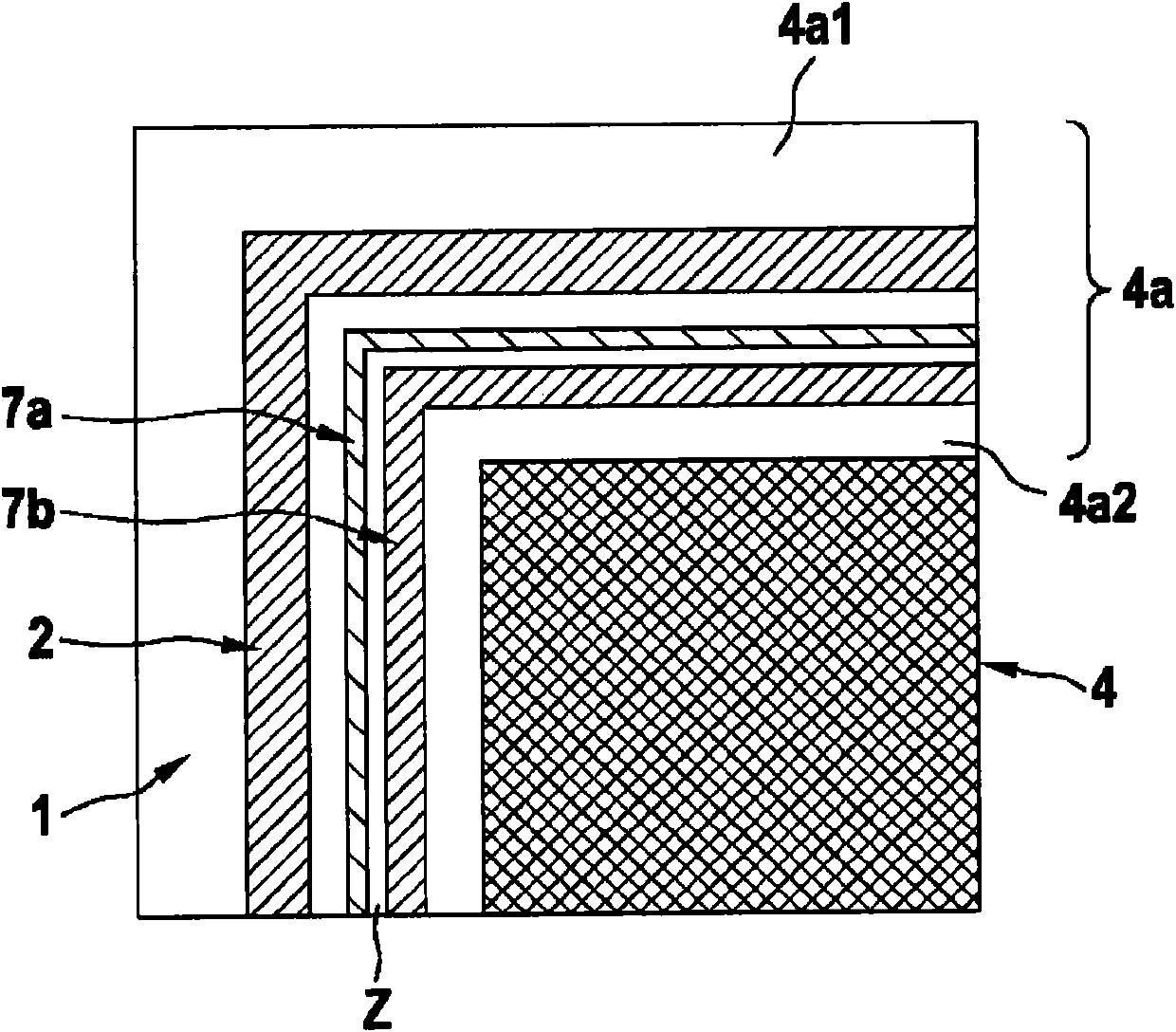

[0024] In the figures, the same reference symbols designate the same or functionally identical components.

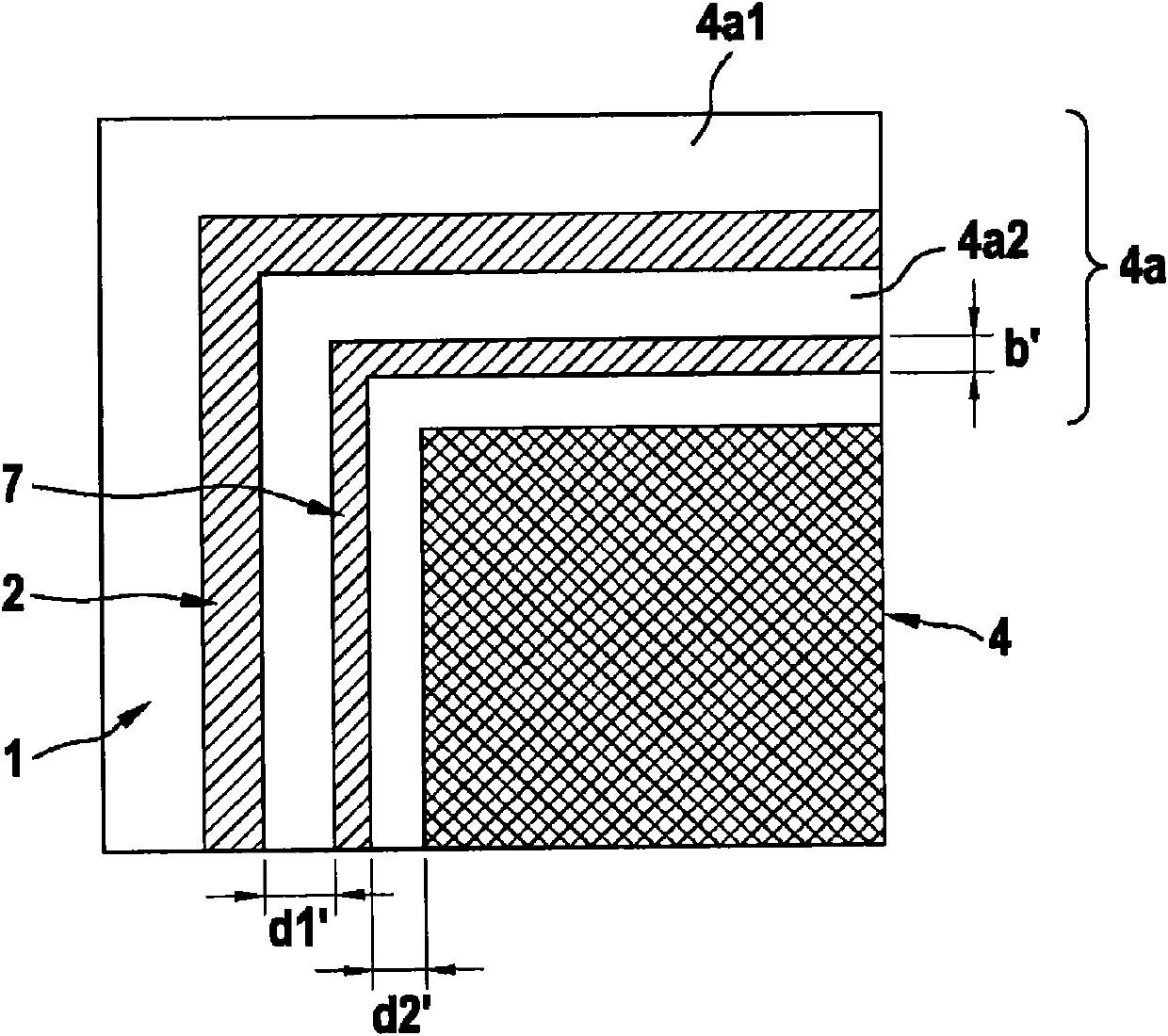

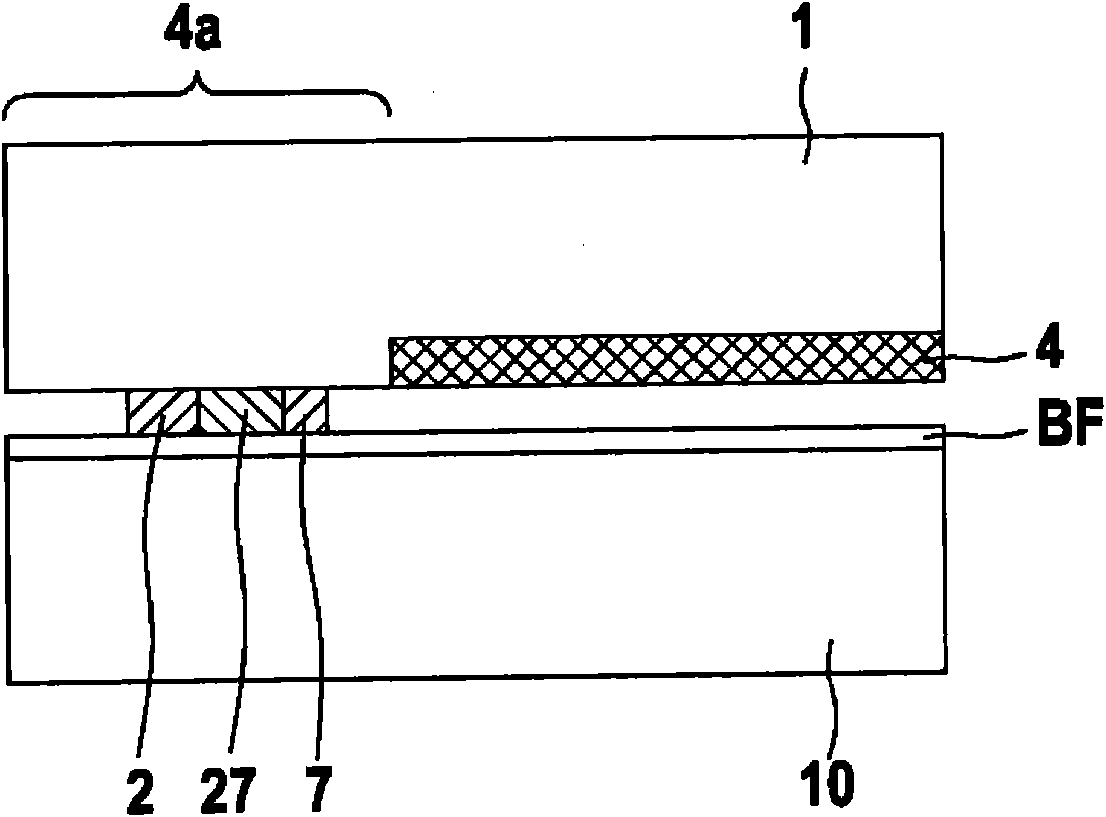

[0025] Figure 1a is a schematic partial top view of the chip region of the semiconductor substrate bonding device according to the first embodiment of the present invention.

[0026] The micromechanical sensor chip 1 has an active functional region 4 and an inactive edge region 4 a. In the edge region 4a is arranged a joint frame 2 with applied thereto a eutectic bonding alloy such as Al-Ge, which divides the edge region 4a into an inner region 4a2 surrounded by the bond frame and an outer region 4a1. In the inner region 4a2 between the junction frame 2 and the functional area 4 of the sensor chip 1 is provided a flow stop frame 7 which is formed of a non-eutectic alloy of Al and Ge and thus has a Ge content, or higher than the Al content of the corresponding eutectic alloy (up to the respective pure alloy composition).

[0027] When the attached flow stop frame 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com