Sensor element having a piezoelectric transducer

A sensor element, piezoelectric transducer technology, applied in electrical components, fluid pressure measurement using piezoelectric devices, measurement of properties using piezoelectric devices, etc., can solve the problems of high circuit technology, intractability, and cost. , to achieve the effect of high resolution and small area requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

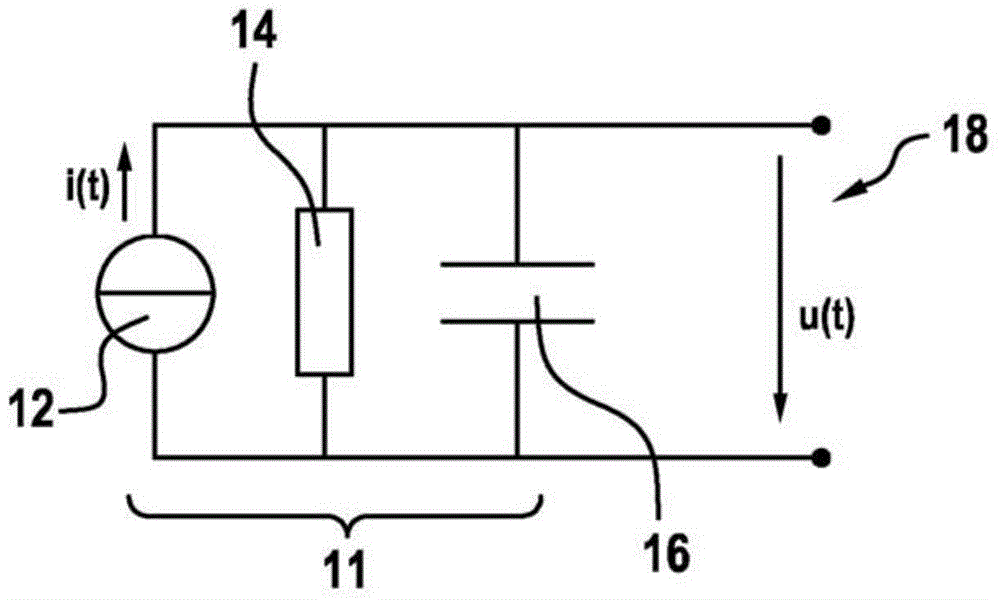

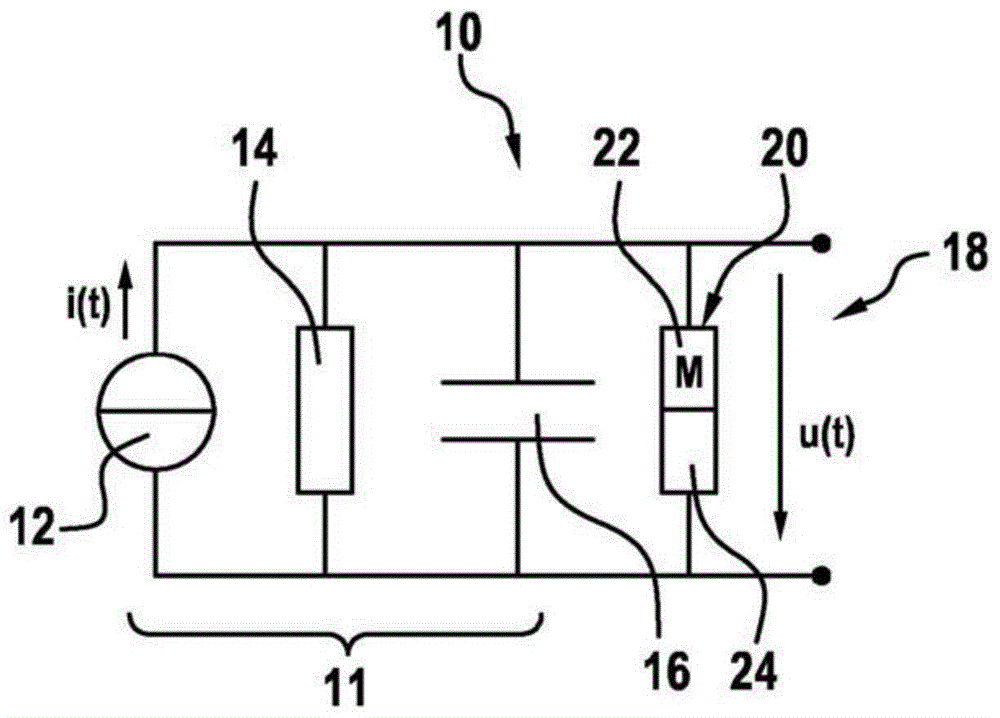

[0033] figure 1 An equivalent circuit diagram of the piezoelectric transducer 11 is shown. The equivalent circuit diagram of the piezoelectric transducer 11 includes a current source 12 simulating the piezoelectric effect. Furthermore, the current intensity i(t) has a distribution related to the piezoelectric sensitivity k and the force F to be converted:

[0034] i(t)=kδF(t) / δt.

[0035] In addition, an internal resistance 14 and a capacitor 16 are connected to the current source 12 in parallel. An output voltage u(t) of the piezoelectric converter 11 is generated at an output 18 .

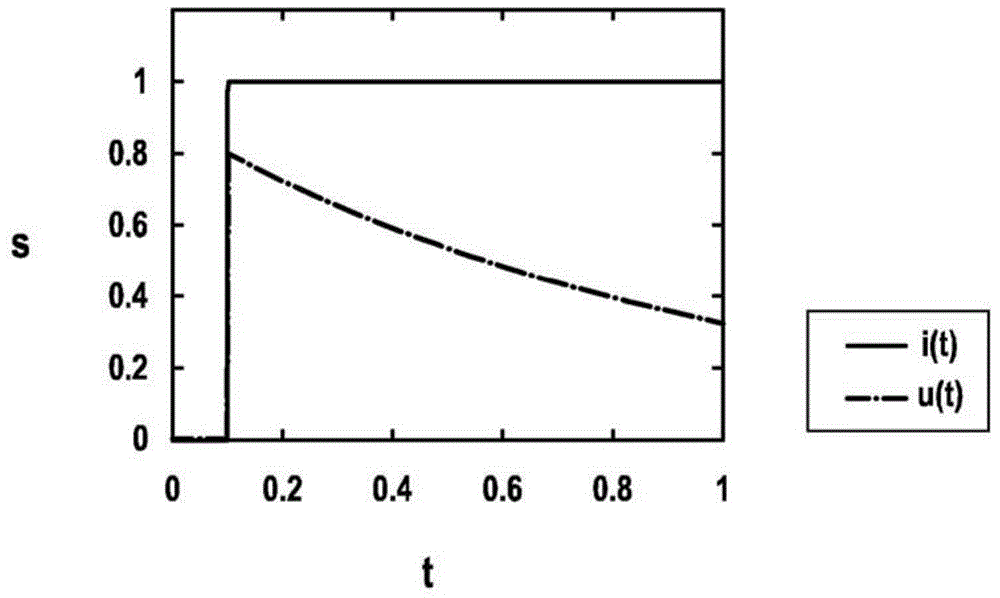

[0036] figure 2 show the basis figure 1 The step response of the piezoelectric converter 11 , that is to say the resulting output voltage u(t) at a stepped input current intensity i(t). A step response or a stepwise change of the input current intensity i(t) is achieved, for example, by exerting a force surge on the converter 11 . figure 2 The behavior of piezoelectric transducer 11 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com