Heat exchanger, heat engine circulating system and control method thereof

A technology for heat exchangers and control methods, applied in heat exchange equipment, machines/engines, compressors, etc., can solve problems such as instability, expander vibration power output, increased thermal resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

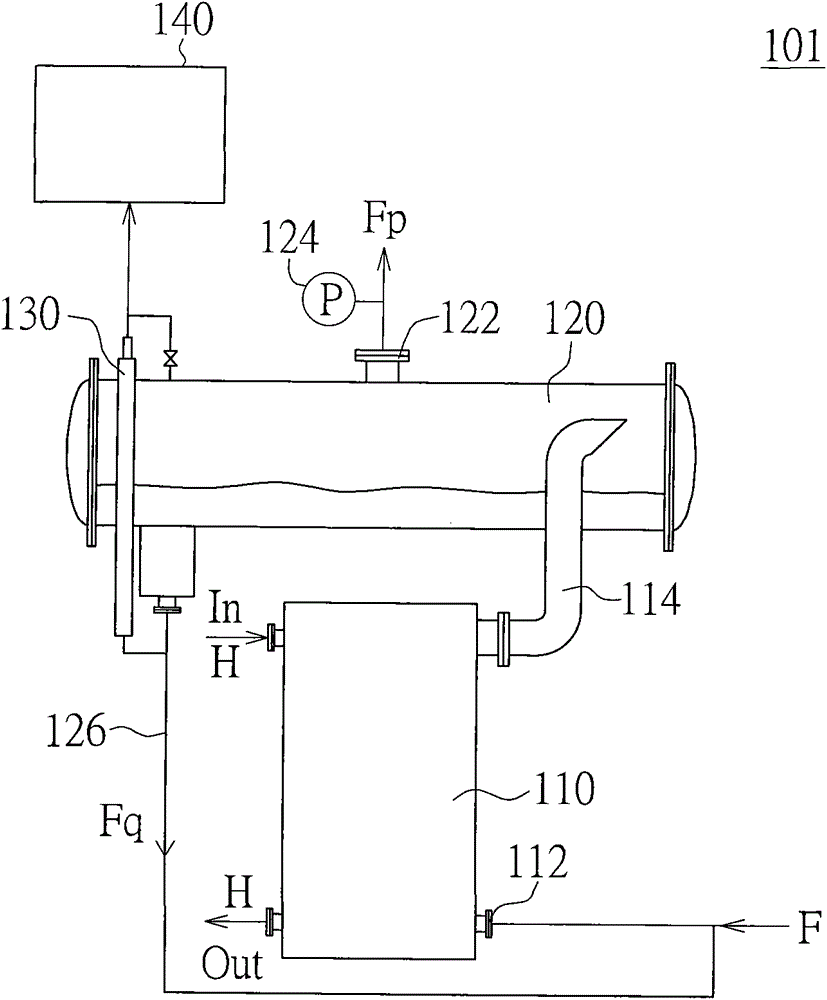

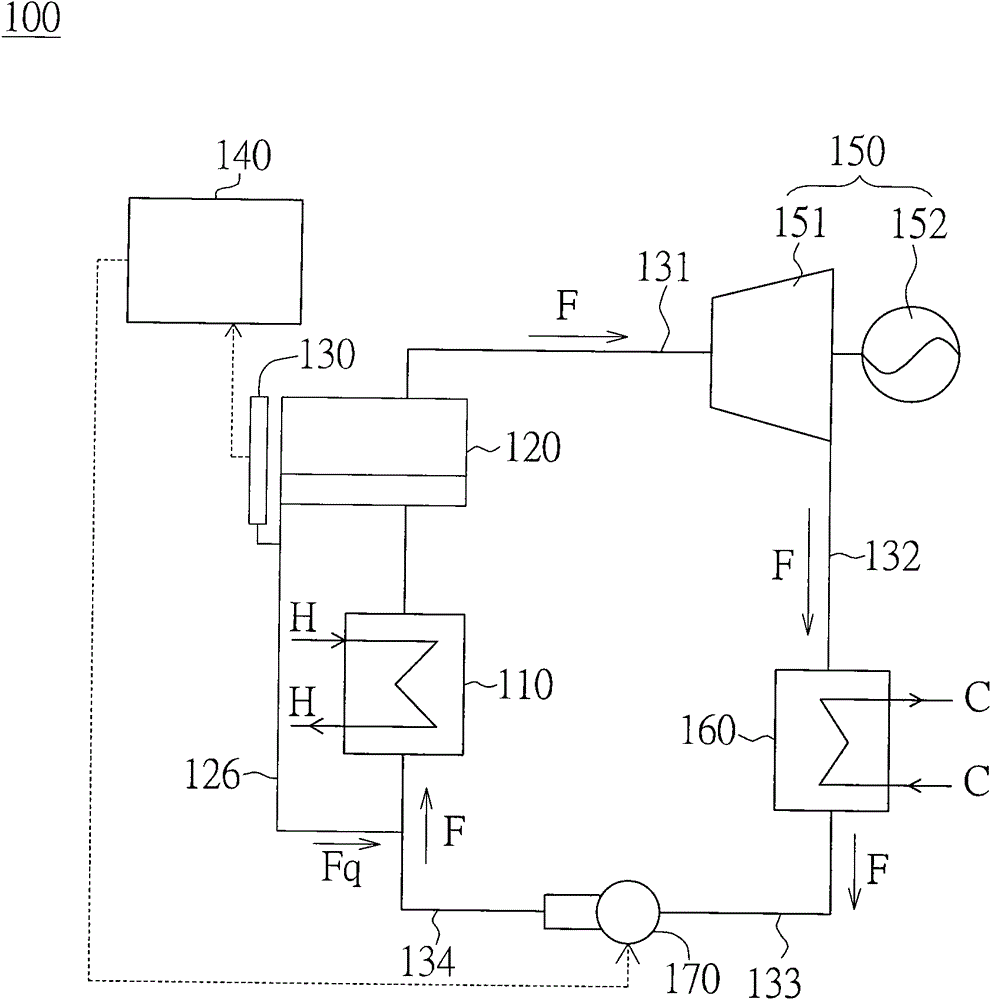

[0044] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings:

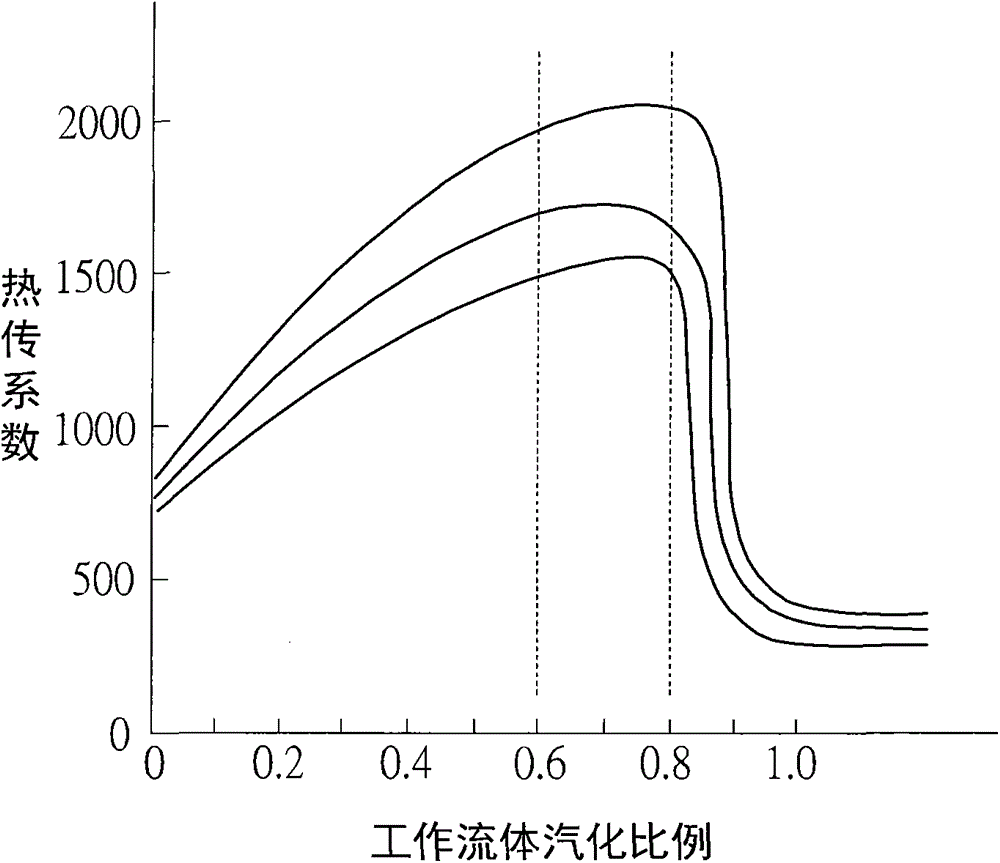

[0045] In an example of this embodiment, the heat transfer performance of the working fluid is improved by controlling the dryness of the working fluid. For example: Use an evaporator with a vapor-liquid separator, and let the vapor-liquid two-phase working fluid exit the evaporator and enter the vapor-liquid separator. When the working fluid in the evaporator is in a vapor-liquid two-phase state, the dryness of the working fluid is maintained between 60% and 80%. Compared with the liquid working medium or the superheated vapor working medium, the vapor-liquid two-phase working medium has better heat transfer coefficient and lower thermal resistance, so the dryness of the working medium is maintained between 60% and 80% , Will improve the heat transfer performance of the working fluid.

[0046] In one embodiment, if the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com