Method for preparing elemental tellurium based composite pyroelectric material

A thermoelectric material and elemental technology, which is applied in the manufacture/processing of thermoelectric devices, and the lead wire material of thermoelectric device junctions. , the effect of high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

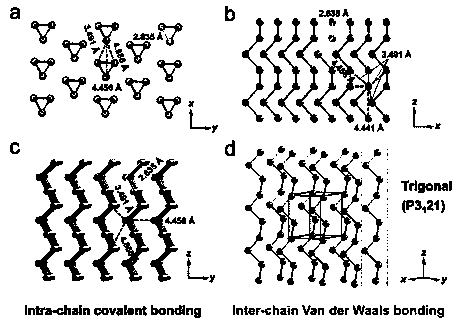

[0041] The preparation method of elemental tellurium-based composite thermoelectric material in the present invention comprises the following steps:

[0042] (1) Te block, Sb powder and Se powder with a purity of not less than 99.99%, according to Te 1-x (Sb 2 Se 3 ) x Weigh each raw material component according to the mole fraction ratio in the formula, put it into a carbon-coated quartz tube and vacuumize it;

[0043] (2) Place the quartz tube filled with simple raw materials completed in step (1) in a vertical tube furnace for heating, and slowly raise the temperature to the melting temperature, so that the raw materials can fully react in the molten state, and then quenched in water to obtain the initial Ingot;

[0044] (3) The initial ingot obtained in step (2) is vacuum-encapsulated in a carbon-coated quartz tube again, placed in a vertical tube furnace, heated and annealed, then quenched to obtain an annealed ingot;

[0045] (4) Grinding the annealed ingot obtained...

Embodiment approach 1

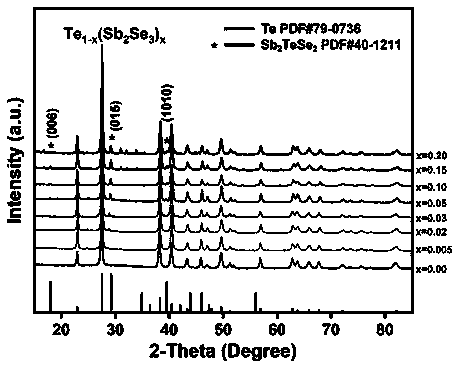

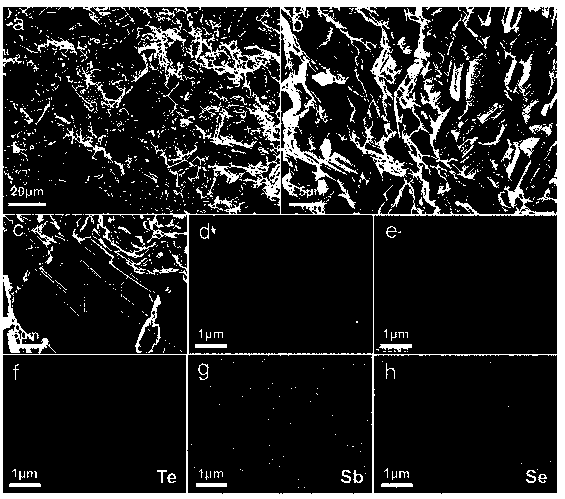

[0053] In this embodiment, an elemental tellurium-based composite thermoelectric material whose general chemical formula is Te 1-x (Sb 2 Se 3 ) x , x are 0, 0.005, 0.02, 0.03, 0.05, 0.1 and 0.15 respectively, that is, in this embodiment, a single tellurium-based composite thermoelectric material has the chemical formulas of Te, Te 0.995 (Sb 2 Se 3 ) 0.005 、 Te 0.98 (Sb 2 Se 3 ) 0.02 、 Te 0.97 (Sb 2 Se 3 ) 0.03 、 Te 0.95 (Sb 2 Se 3 ) 0.05 、 Te 0.9 (Sb 2 Se 3 ) 0.1 and Te 0.85 (Sb 2 Se 3 ) 0.15 a series of materials.

[0054] In this embodiment, a specific preparation method of an elemental tellurium-based composite thermoelectric material is as follows:

[0055] (1) In a glove box filled with an argon atmosphere, put Te block, Sb powder and Se powder with a purity of not less than 99.99%, according to the general chemical formula Te 1-x (Sb 2 Se 3 ) x The mole fraction proportioning weighs each raw material component (total mass is 8 grams), packs ...

Embodiment approach 2

[0066] This embodiment is basically the same as Embodiment 1, and the special feature is that the value of x in this embodiment is 0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com