Patents

Literature

1019 results about "Repair time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

All repair times are estimated in business days (M-F) and start from the day the unit is entered into our database. Repair times may vary depending on the type of repair or availability of parts for your unit. You may check the status of your repair online at any time during the course of your repair.

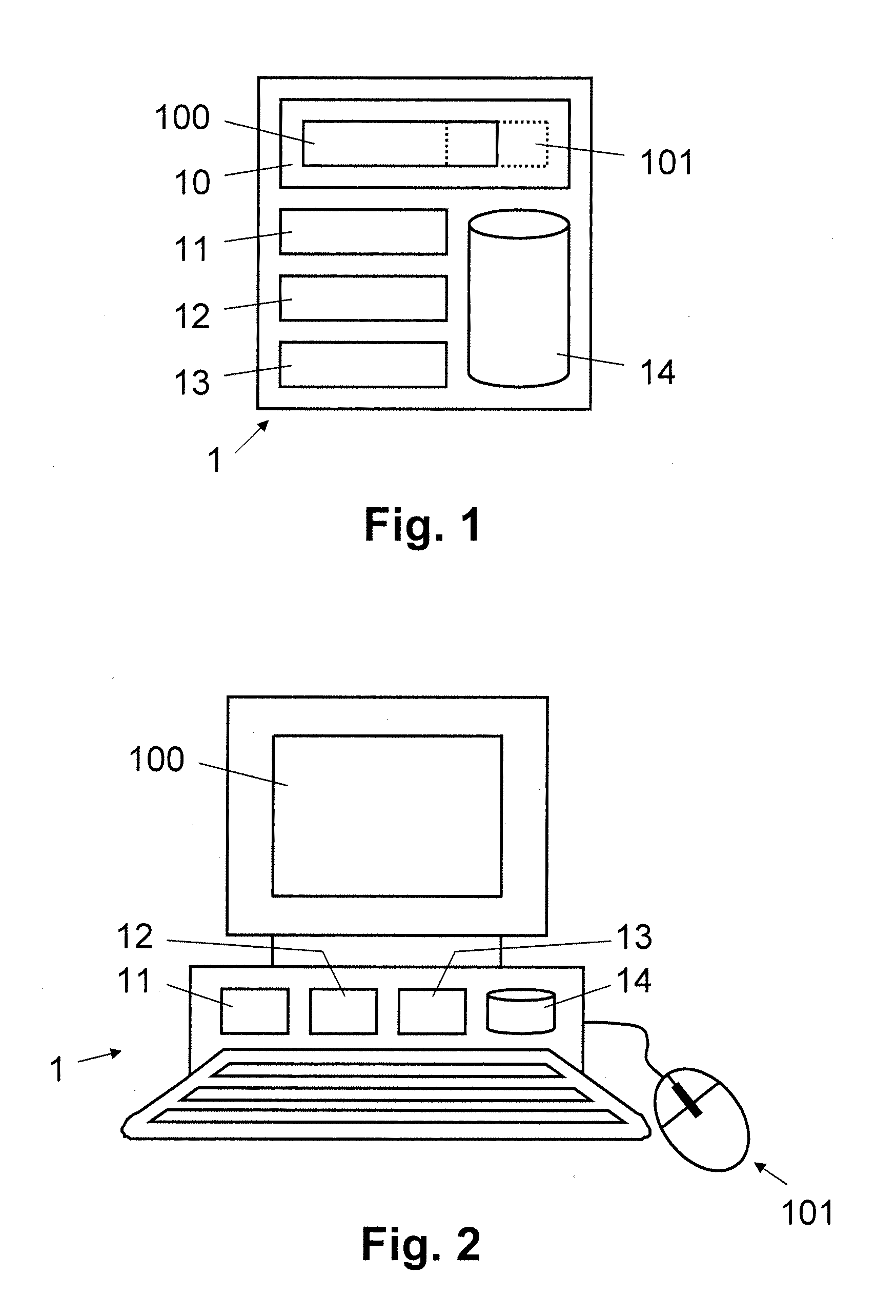

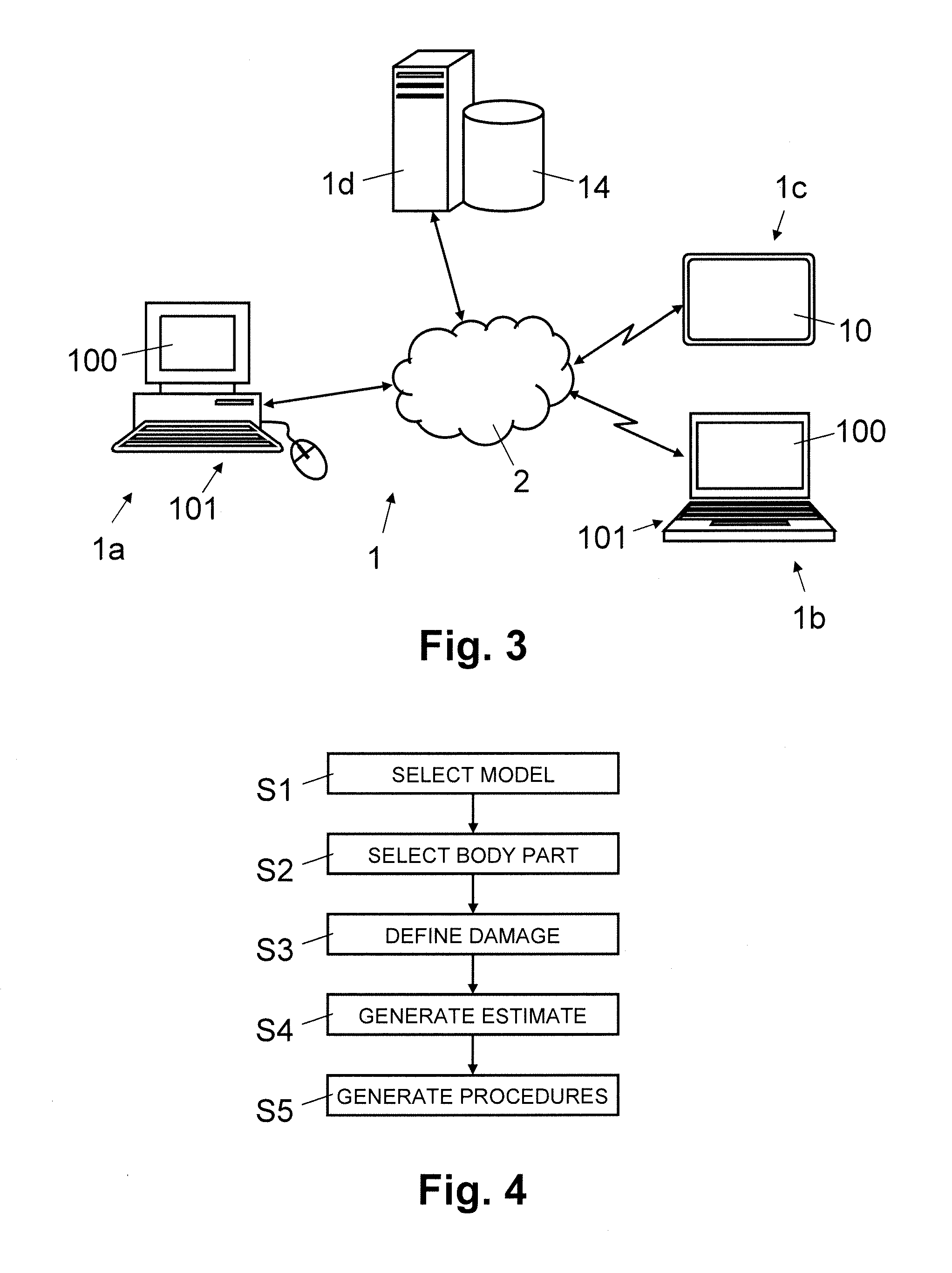

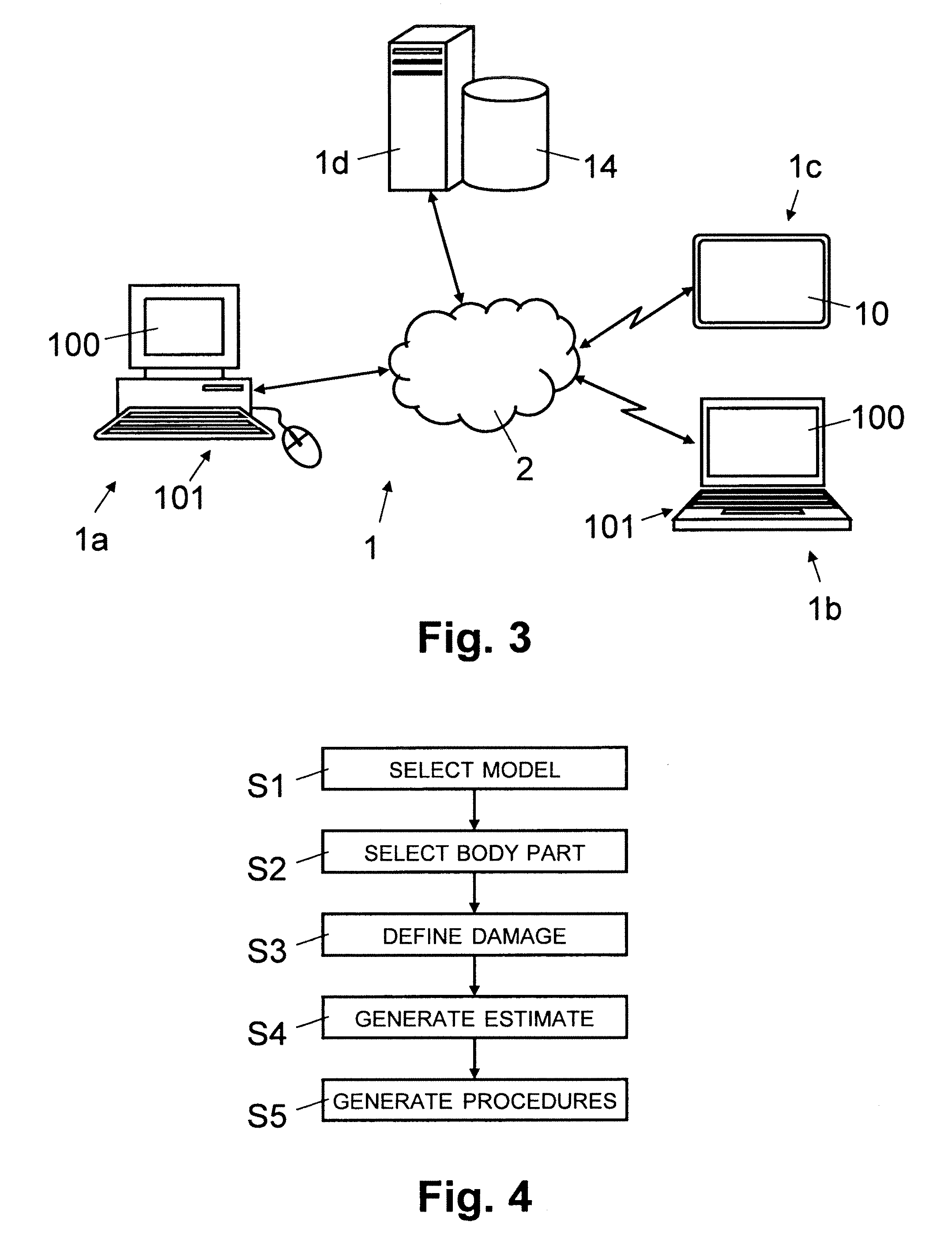

Computer-based technology for aiding the repair of motor vehicles

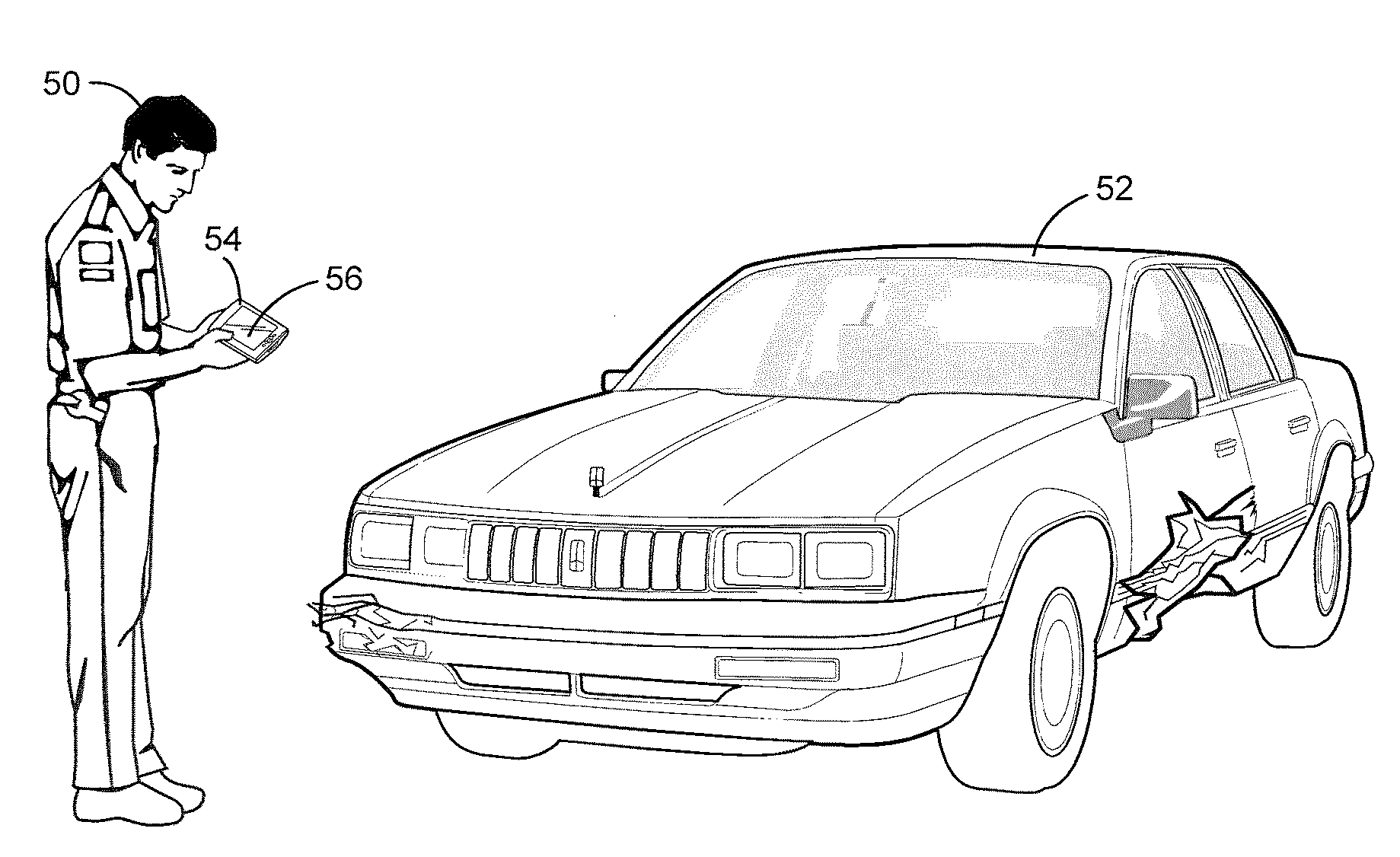

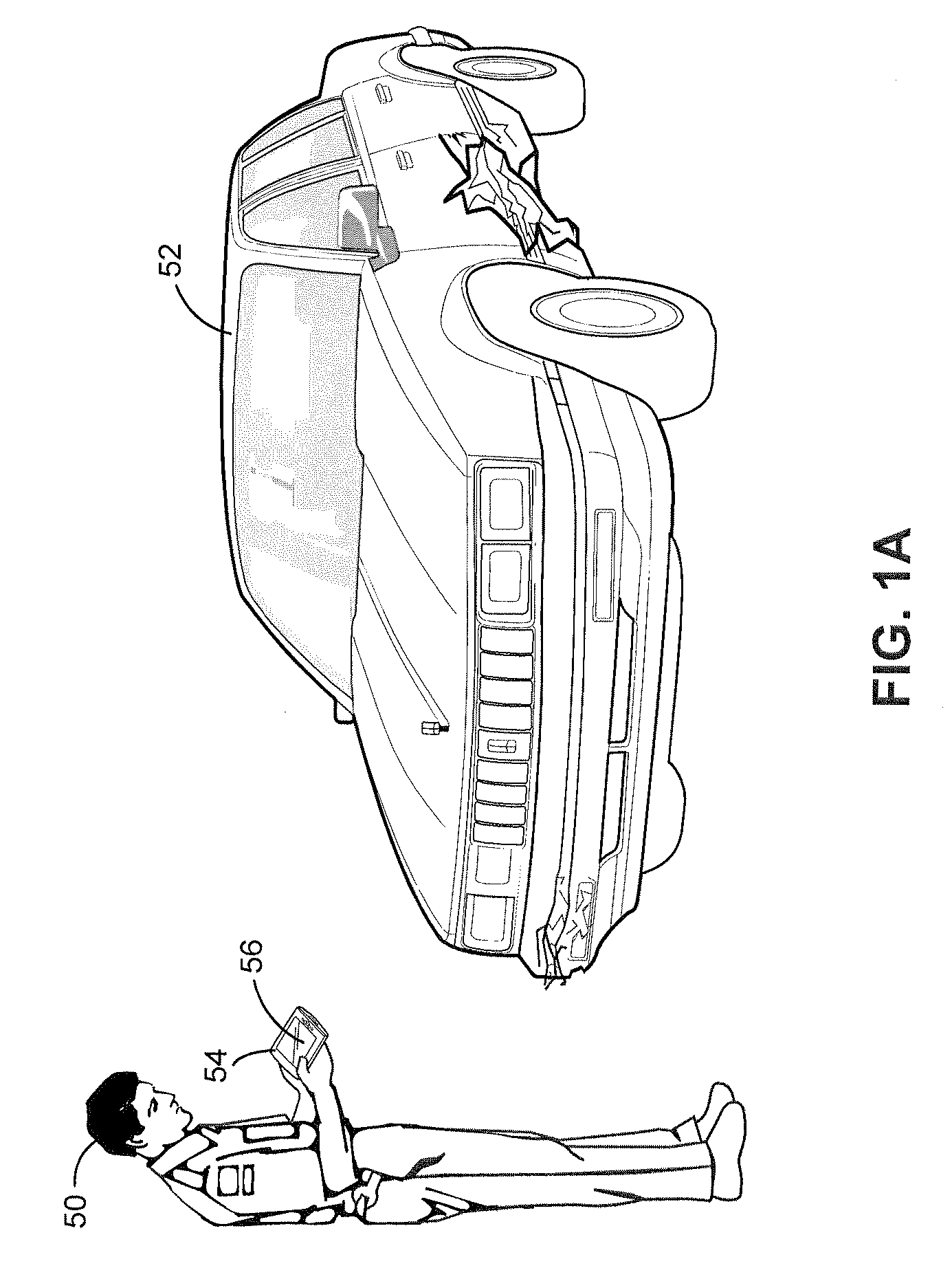

ActiveUS20120297337A1Easy to captureImpairing valueDetection of traffic movementCommerceRepair timeComputer-aided

A computer-assisted inspection system provides computer architectures and software controlled algorithms to automatically provide vehicle inspections and repair recommendations including estimated repair time and cost of depression type damage such as dents. Features provided by a handheld wireless touchscreen based inspection device include flat car part picking, auto grading including seller grading, and automatic calculation of body and bumper dent repair parameters and directions.

Owner:MANHEIM INVESTMENTS

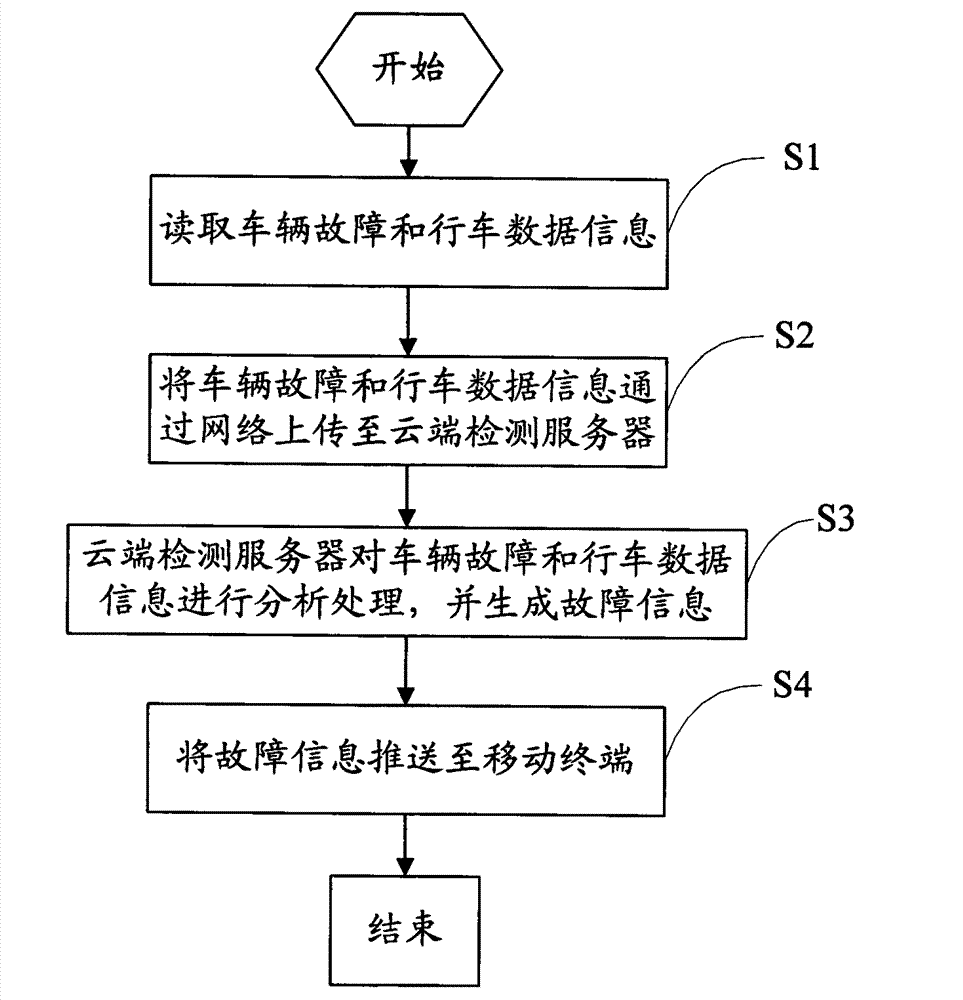

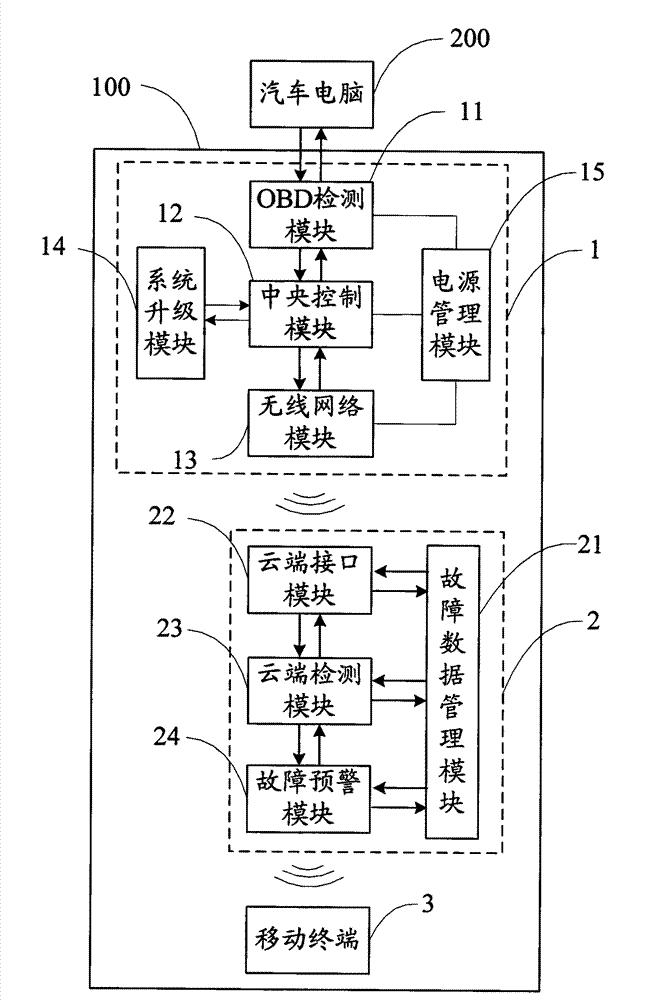

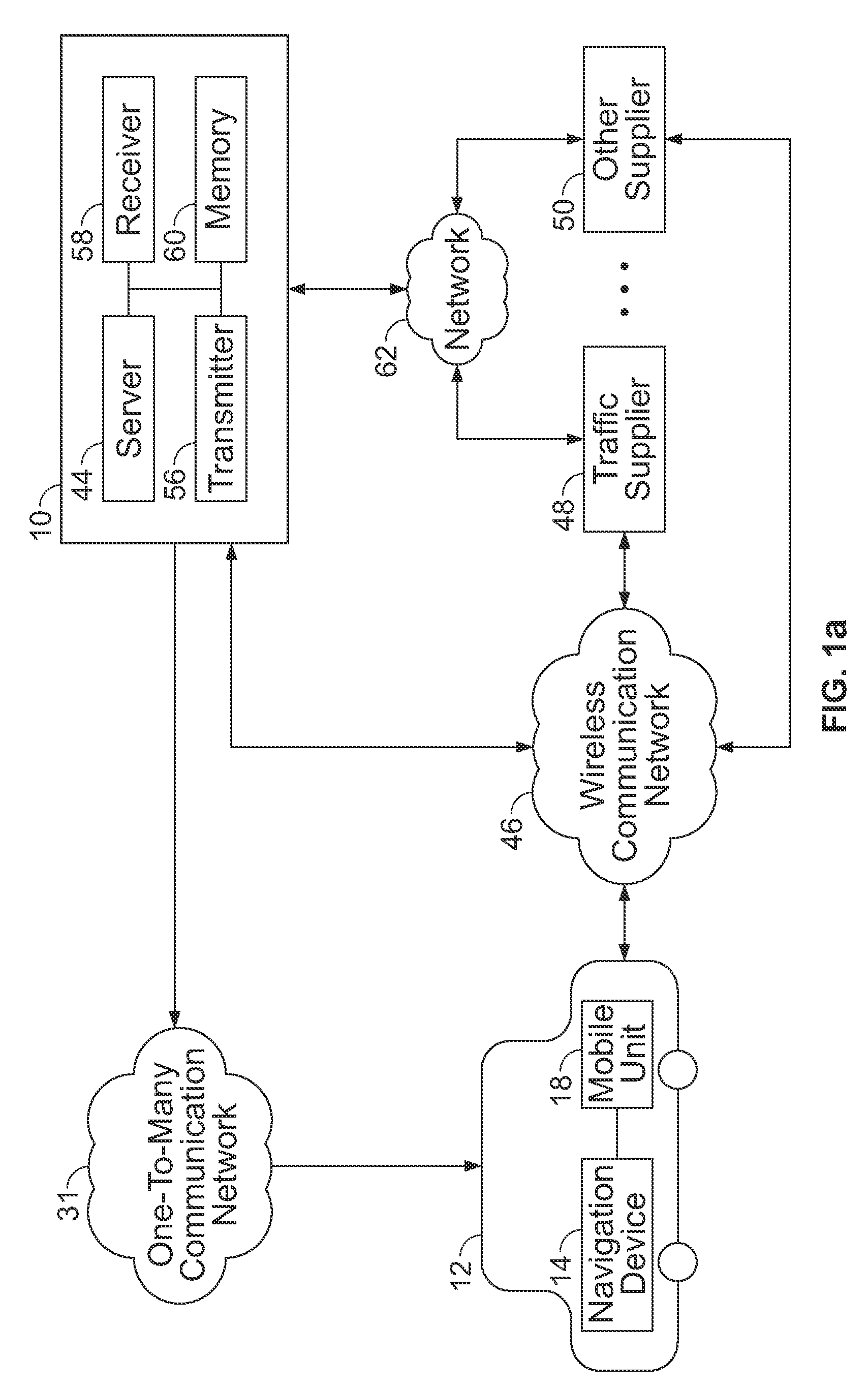

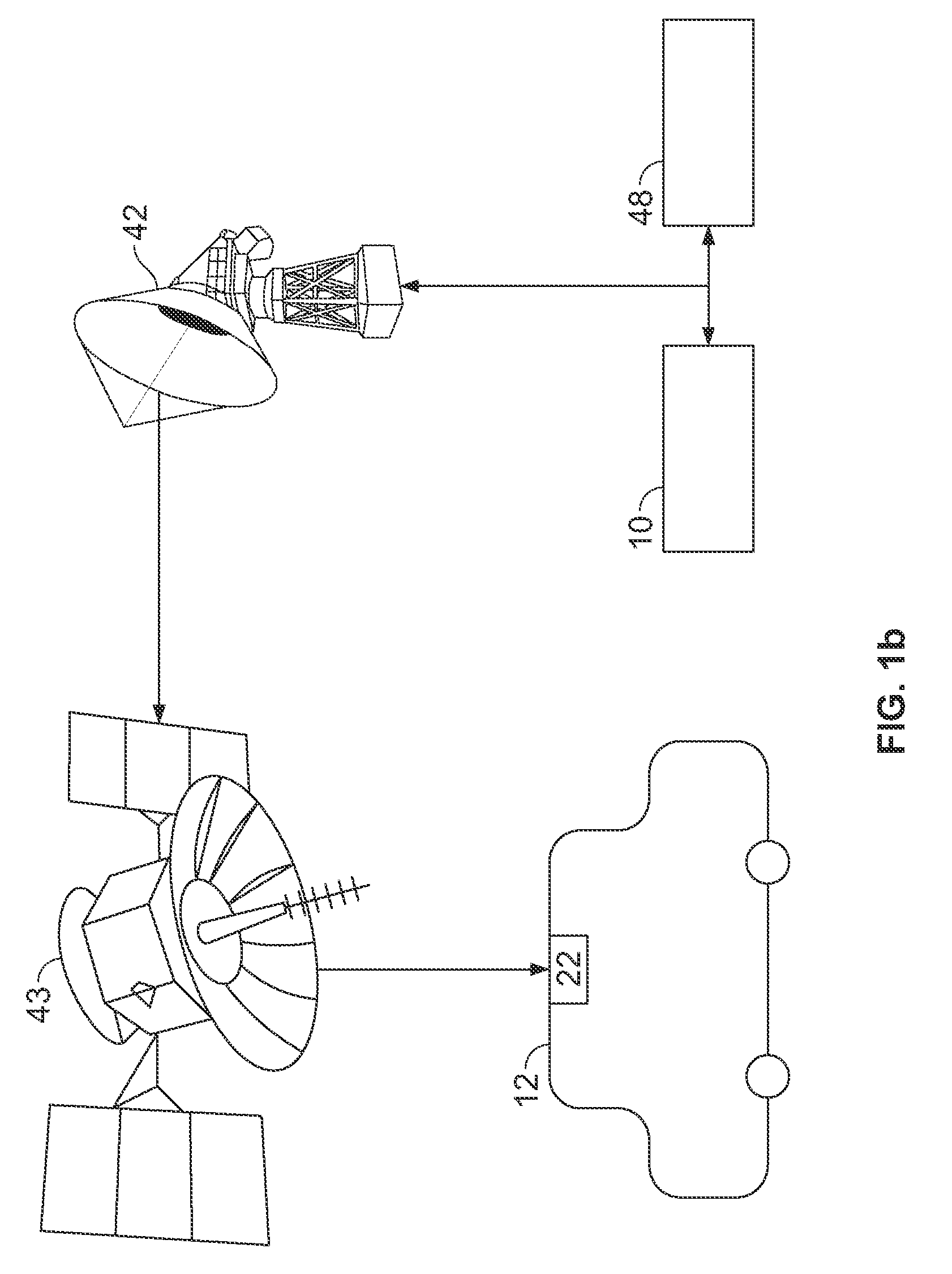

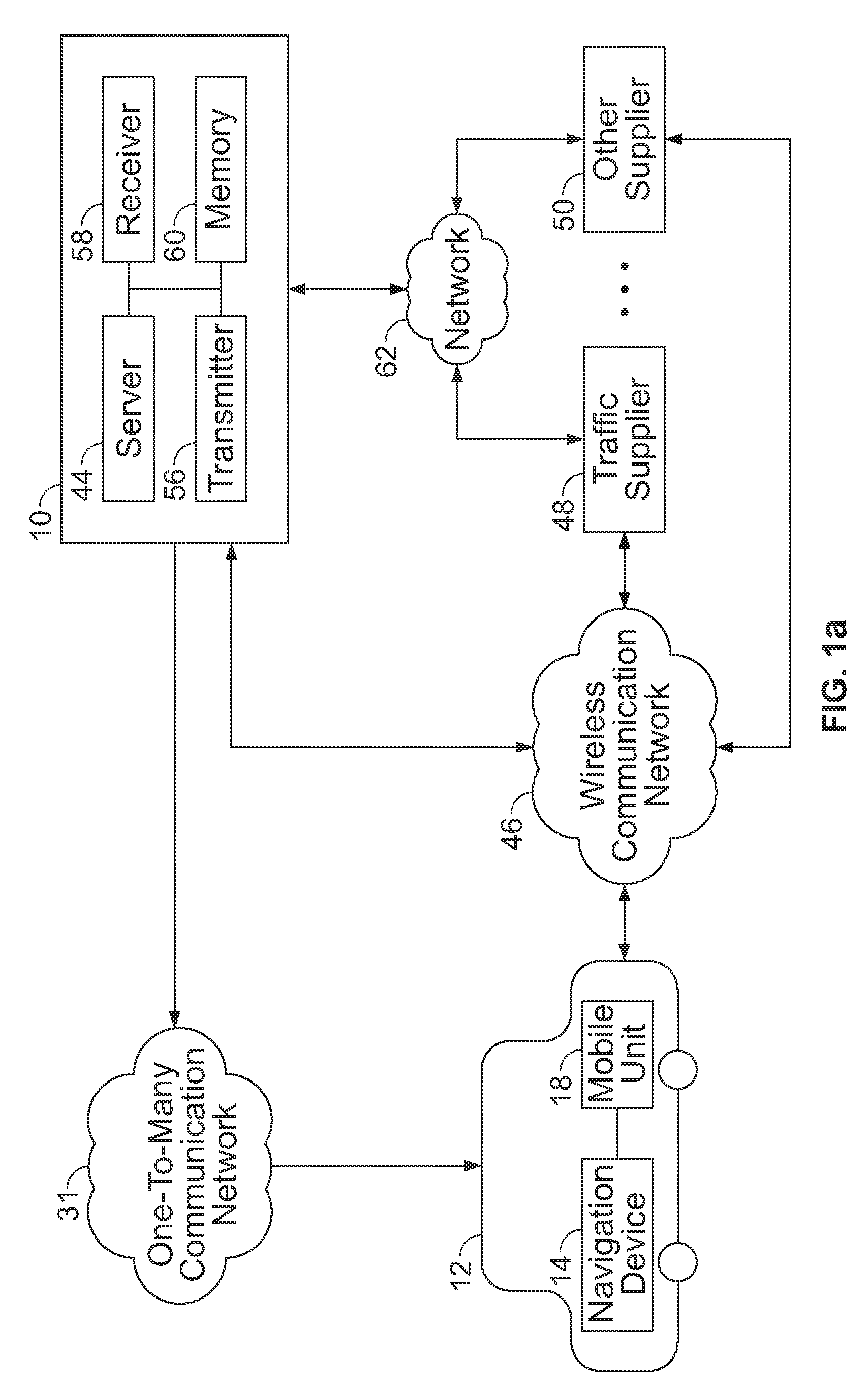

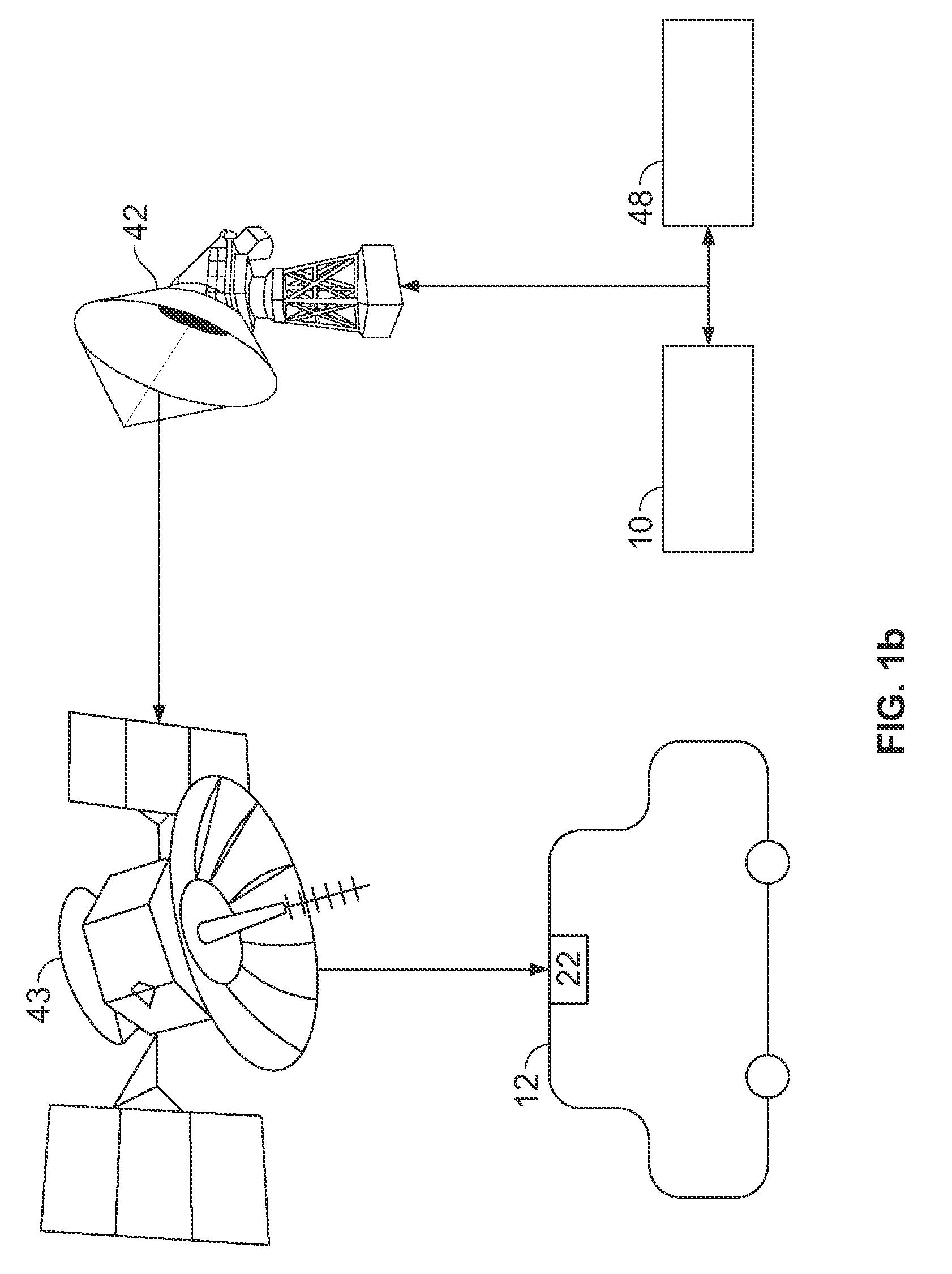

Method and system for remote monitoring and cloud diagnosis of automobile faults

InactiveCN103048992AQuick understandingAccurate understandingElectric testing/monitoringRepair timeData information

The invention relates to a method for the remote monitoring and cloud diagnosis of automobile faults. The method for the remote monitoring and cloud diagnosis of the automobile faults comprises the following steps of reading automobile fault and driving data information; uploading the automobile fault and driving data information to a cloud test server through a network; analyzing and processing the automobile fault and driving data information by the cloud test server, and then generating fault information; and sending the fault information to mobile terminals in a pushing way. With the adoption of the method and a system for the remote monitoring and cloud diagnosis of the automobile faults, the specific fault information is sent into the interiors of the mobile terminals carried by an automobile owner, a driver, repair staff and the like in the pushing way through the network, so that the automobile conditions can be learned rapidly, correctly and timely; in such a way, quite good help is provided for the smooth and rapid removal of the faults; the repair time is saved and the repair cost is decreased, and moreover, the automobile faults can be monitored remotely; and therefore, the management and the maintenance on the automobiles by people are facilitated.

Owner:张燕 +1

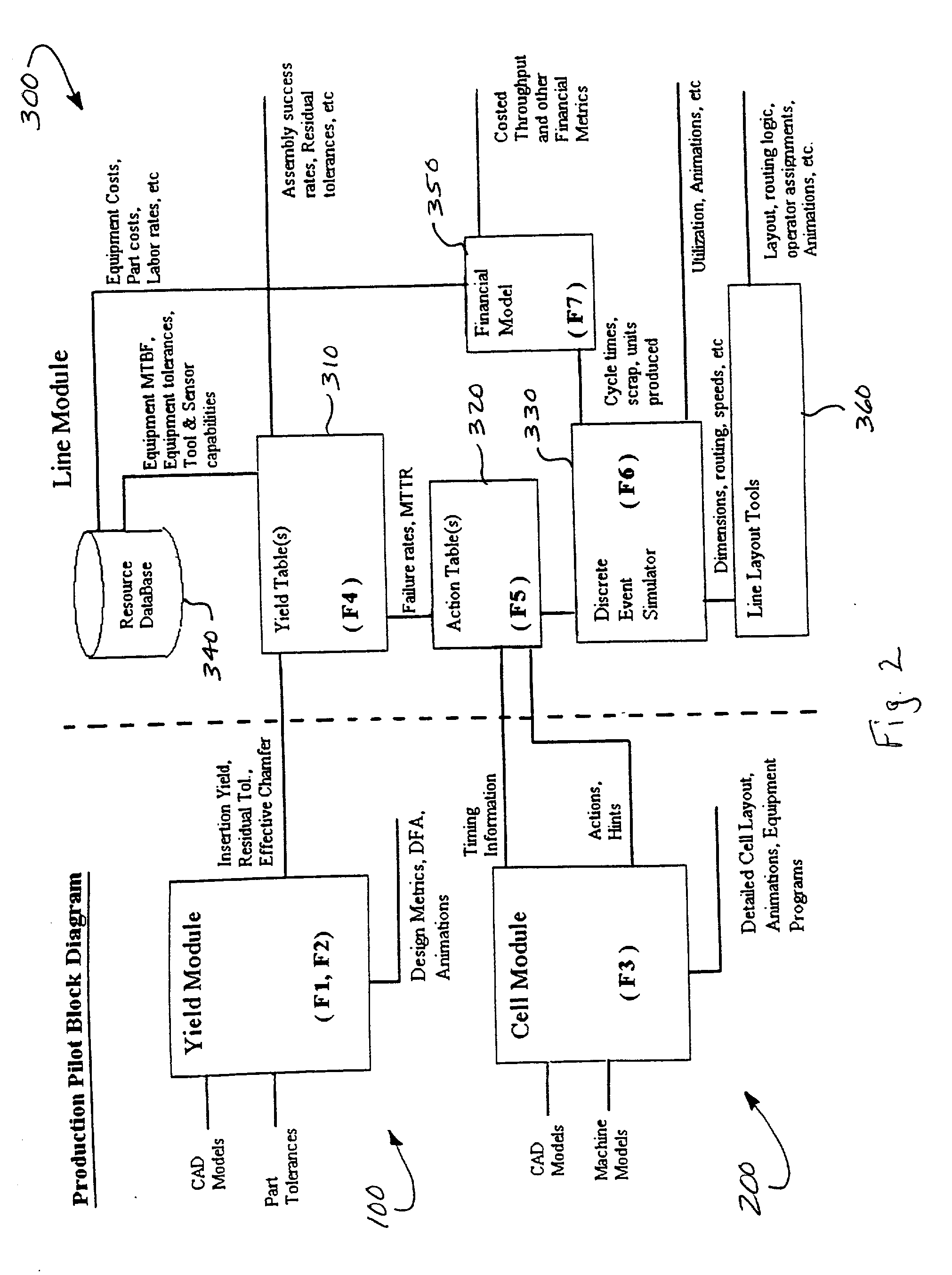

Systems and methods for simulation, analysis and design of automated assembly systems

A method for simulating, analyzing and / or designing an automated assembly system including a plurality of resources comprises: defining at least one cell from an automated assembly line; associating an action table with each cell; calculating a duration, a success rate and a repair time for each process step using fundamental data of the resources; and associating the duration, the success rate and the repair time with each process step in each action table. The action table of a respective cell specifies all process steps that are executed in the respective cell. A system for simulating, analyzing and / or designing an automated assembly system comprises a discrete event simulator and a three-dimensional kinematic and dynamic simulator coupled with the discrete event simulator. The kinematic and dynamic simulator generates timing data for the automated assembly system that is used by the discrete event simulator. A system for determining a costed-throughput is also provided.

Owner:ADEPT TECHNOLOGY

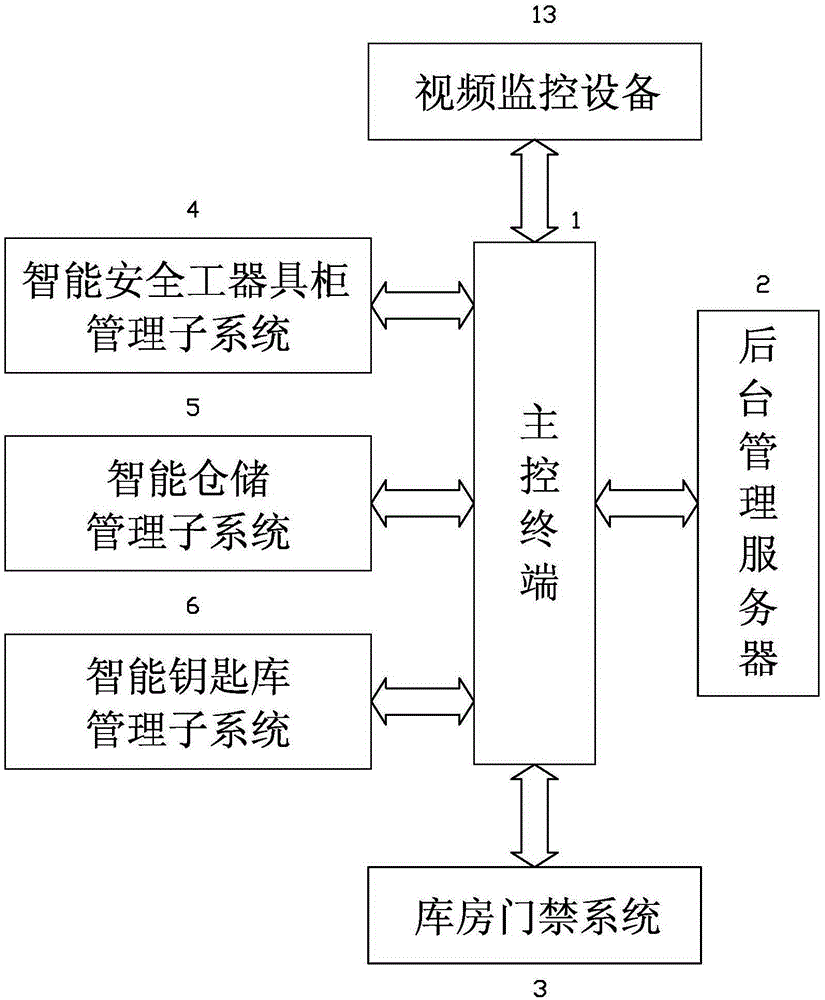

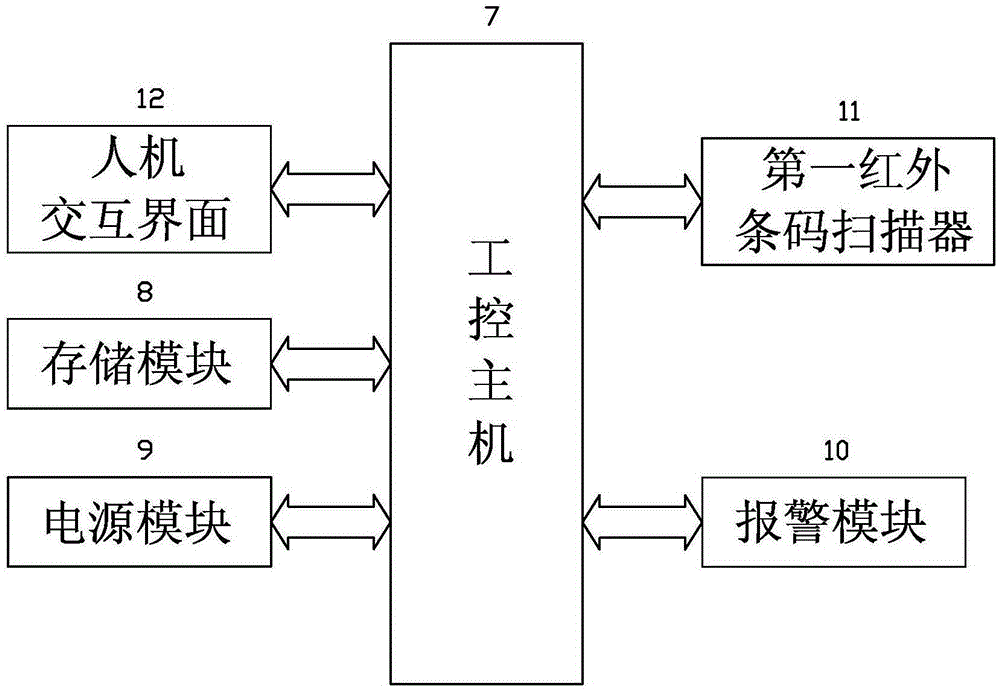

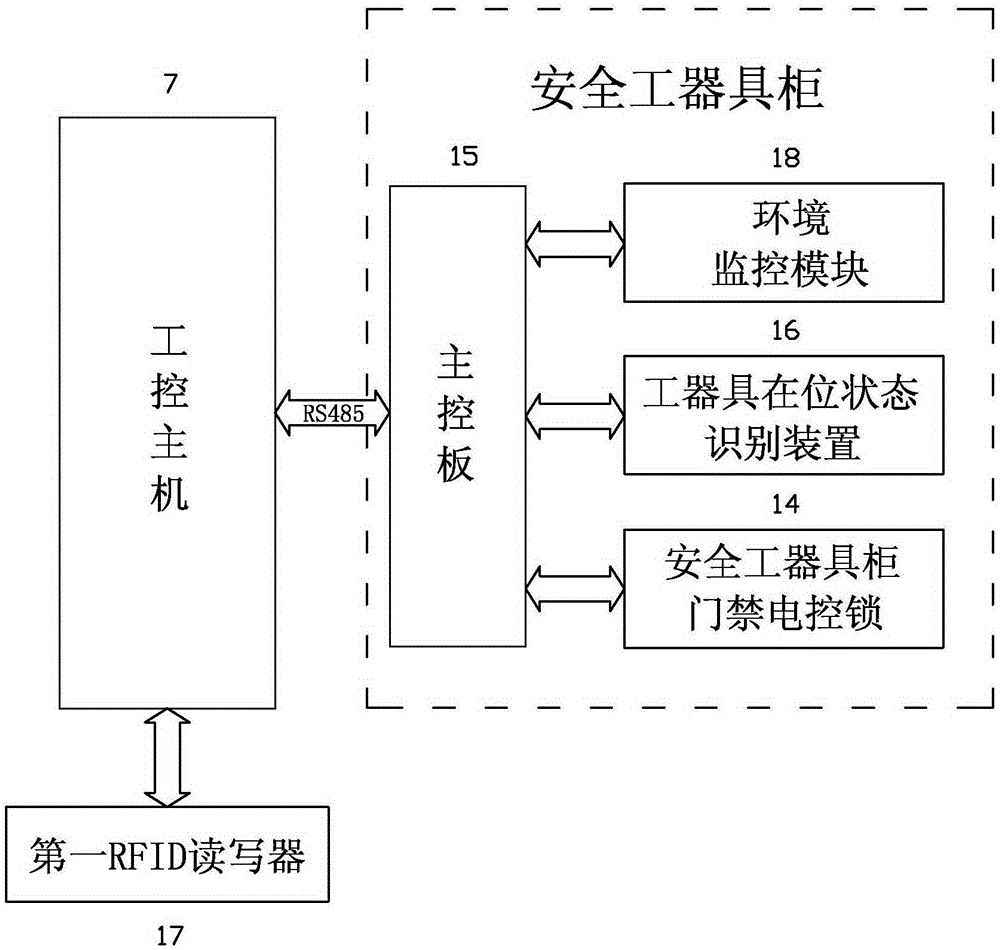

Intelligent power supply station storeroom management system and method based on internet of things

ActiveCN105160748ALearn about usageAvoid abuseData processing applicationsIndividual entry/exit registersThe InternetEngineering

The invention provides an intelligent power supply station storeroom management system and method based on the internet of things. The intelligent power supply station storeroom management system comprises a master control terminal, a background management server connected to the master control terminal, an intelligent security tool cabinet management sub system capable of being connected to the master control terminal in a communication mode, an intelligent warehouse management sub system and an intelligent key library management sub system. The master control terminal is internally provided with intelligent security tool cabinet management system software, intelligent warehouse management software and intelligent key library management system software. A three-in-one comprehensive management model of real-time voice, data and images is adopted for the system, use of a security tool, consumption of spare parts and borrowing of keys are managed through an intelligent means, the failure repair time of a response field can be effectively shortened, the failure reaction speed is increased, the agricultural distribution network construction, overhauling and repairing work efficiency is improved, the work procedure of operation personnel is standardized, the safe production awareness is enhanced, a novel intelligentized power supply station storeroom based on a technology of the internet of things is constructed, and powerful guarantee is provided for safe production of a power enterprise.

Owner:STATE GRID FUJIAN JINJIANG POWER SUPPLY

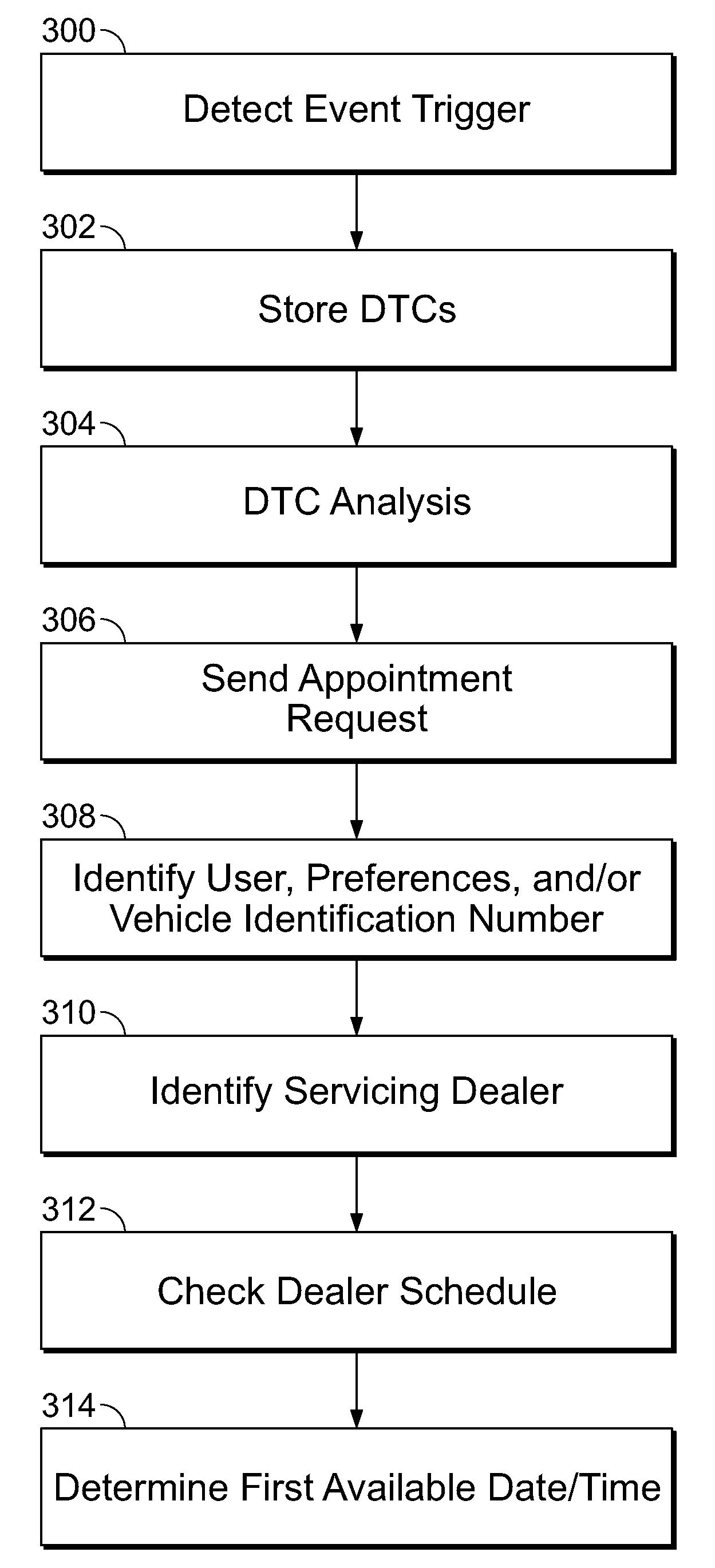

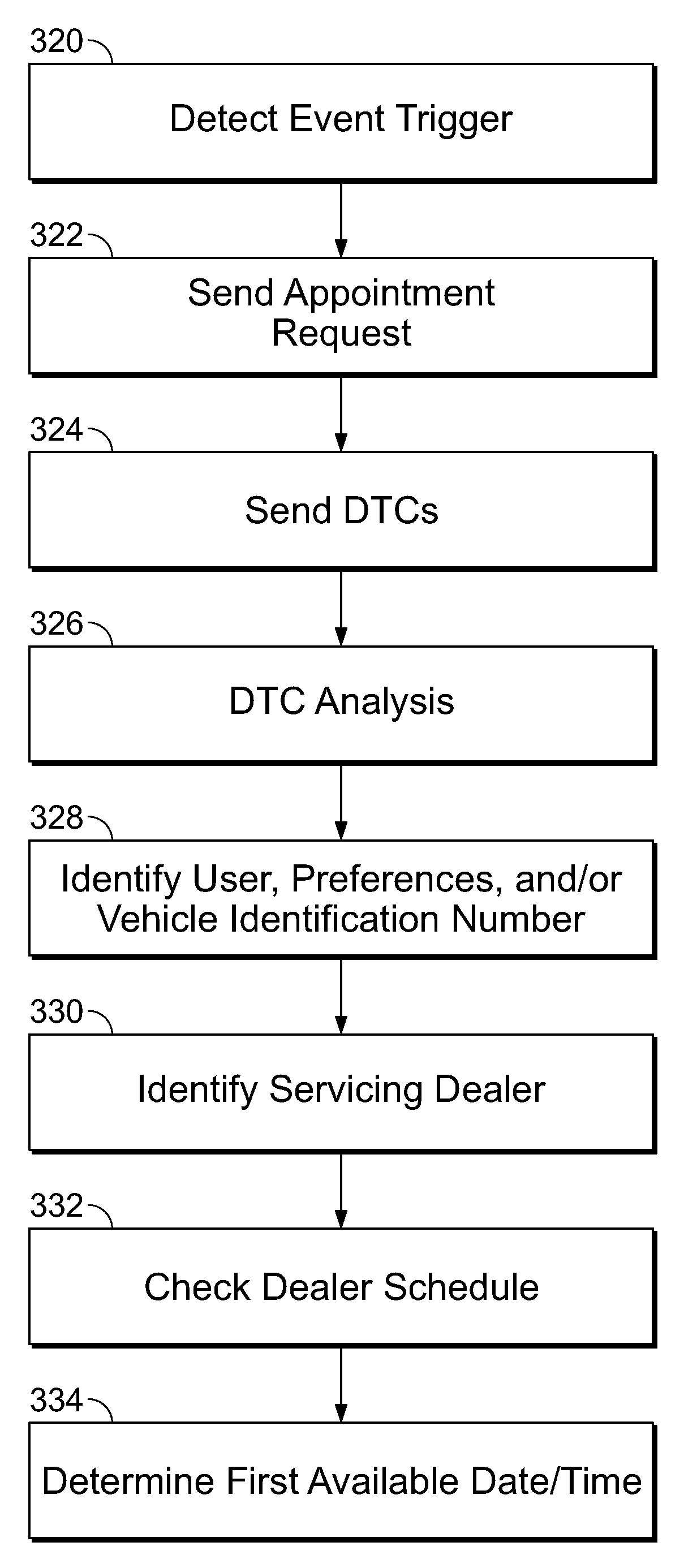

Method and system for vehicle service appointments based on diagnostic trouble codes

ActiveUS20090089134A1Ensure vehicle repairImprove efficiencyVehicle testingRegistering/indicating working of vehiclesTime scheduleRepair time

Methods and systems are provided for the analysis of one or more diagnostic trouble codes (DTCs), and for the scheduling of vehicle service appointments based at least in part on the DTC analysis. The method involves analyzing the received DTCs to determine an underlying problem. Once the underlying problem is determined, the parts and estimated repair time needed to repair the problem is determined. In one approach, the selection of the proposed slot for the service appointment involves coordinating numerous factors, such as the availability of needed parts, the user's scheduling preferences, and the availability of slots in the dealer's service schedule.

Owner:HONDA MOTOR CO LTD

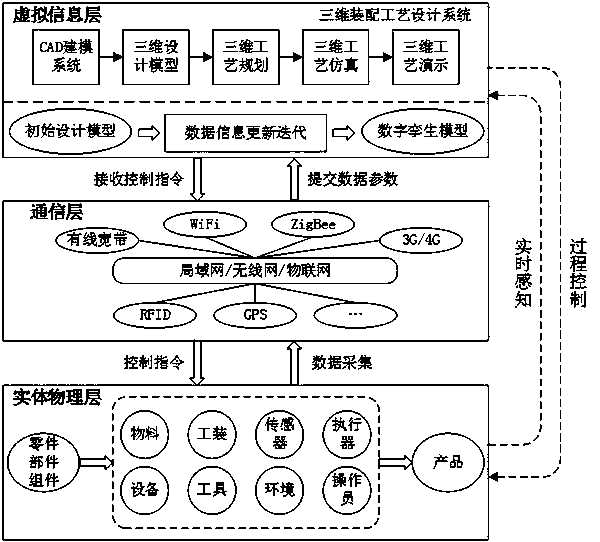

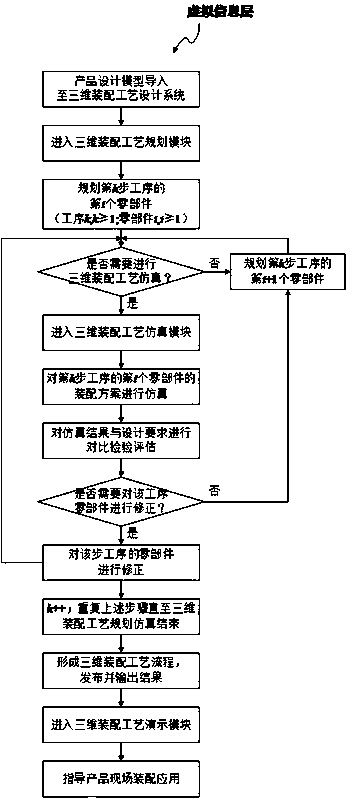

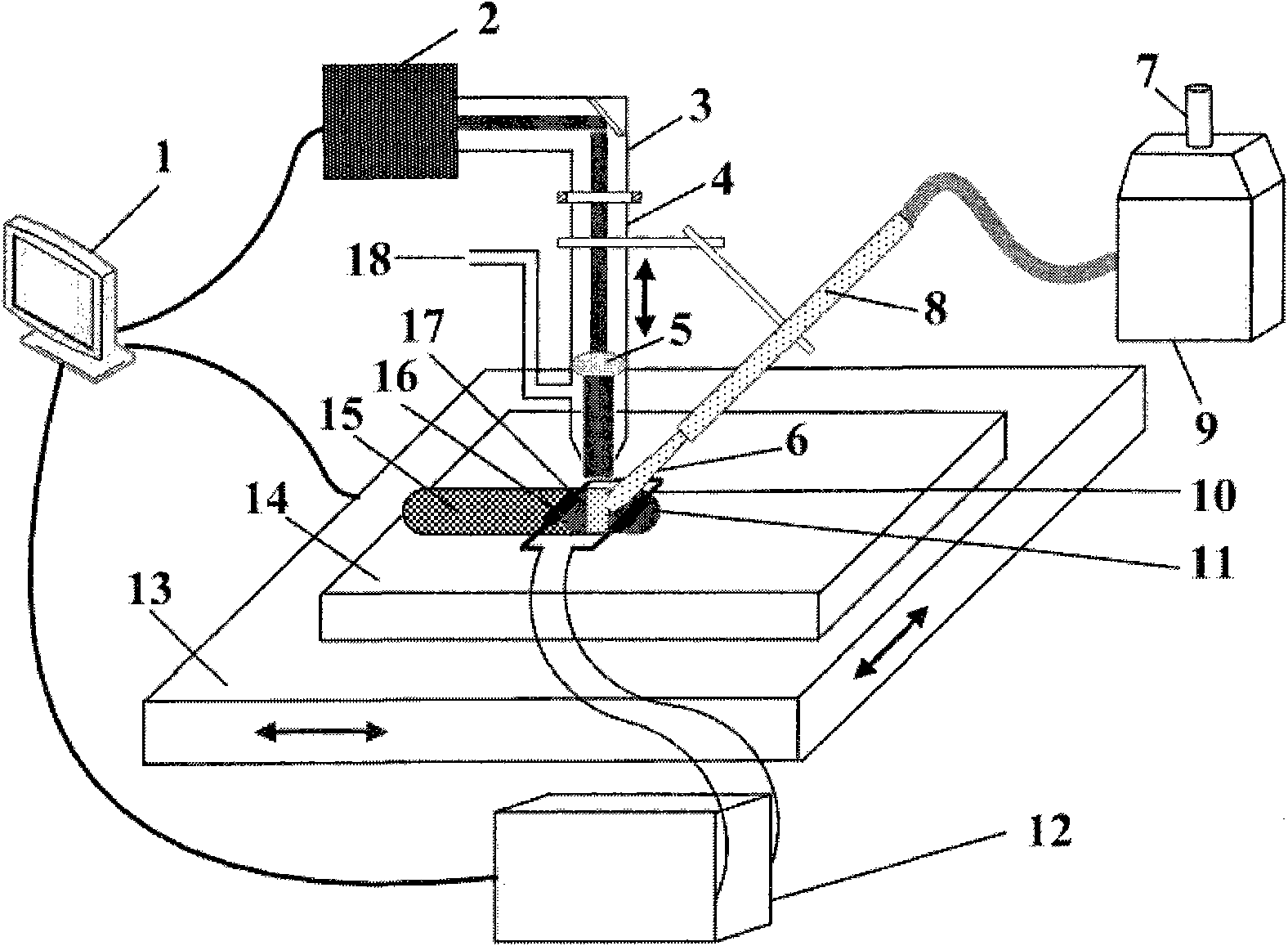

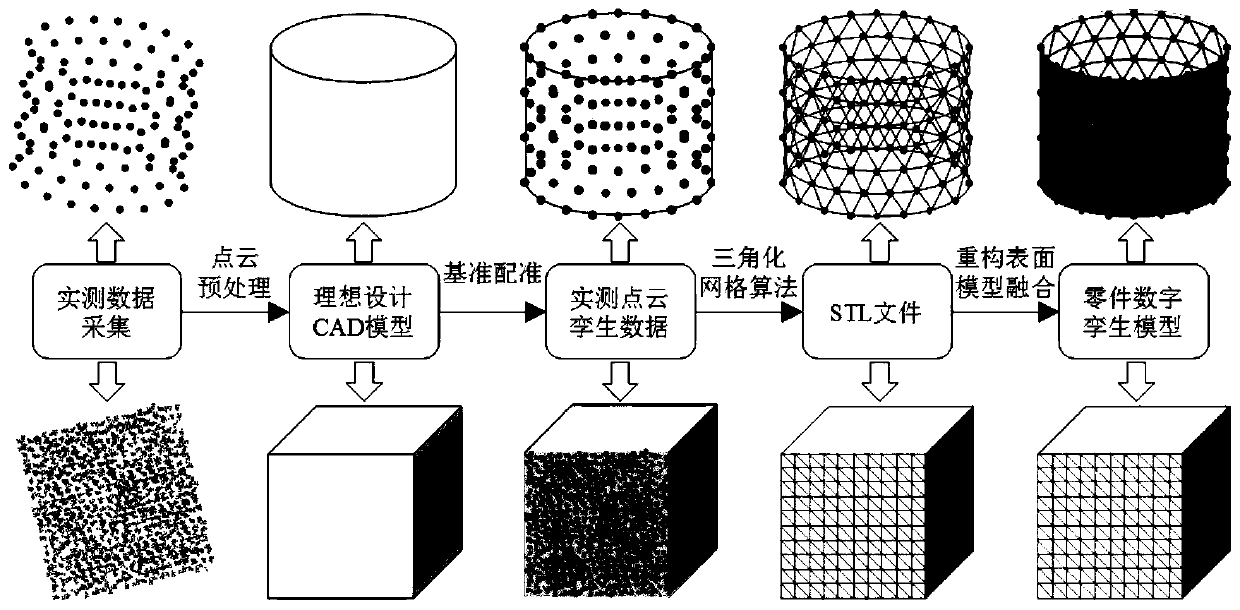

Three-dimensional assembling technology design system based on information physical fusion and operation method thereof

ActiveCN108388146AReal-time detection of problems that do not meet assembly design requirementsAvoid interferenceSimulator controlInformation layerProcess optimization

The invention discloses a three-dimensional assembling technology design system based on information physical fusion and an operation method thereof. The actual assembling environment and the virtualassembling system are combined by the system through the information physical fusion technology, the actually measured data of the critical elements / components / parts are acquired through the field equipment of the physical layer, the actually measured data are transmitted to the virtual information layer through the communication layer and used as the digital twin model data of product virtual-actual mapping to be used for virtual assembling three-dimensional technology planning and design, assembling precision prediction and the online correction instruction are given through virtual assembling simulation and process optimization and feedback control are performed on the field assembling activity so that the digital twin model can be continuously and dynamically updated to meet the product assembling design requirements, and finally the operator is guided to complete the product assembling task by three-dimensional technology demonstration. The trial assembling and repair time in theassembling activity can be reduced so that the product field assembling efficiency can be guaranteed and the product assembling accuracy and assembling accuracy can be enhanced.

Owner:SOUTHEAST UNIV

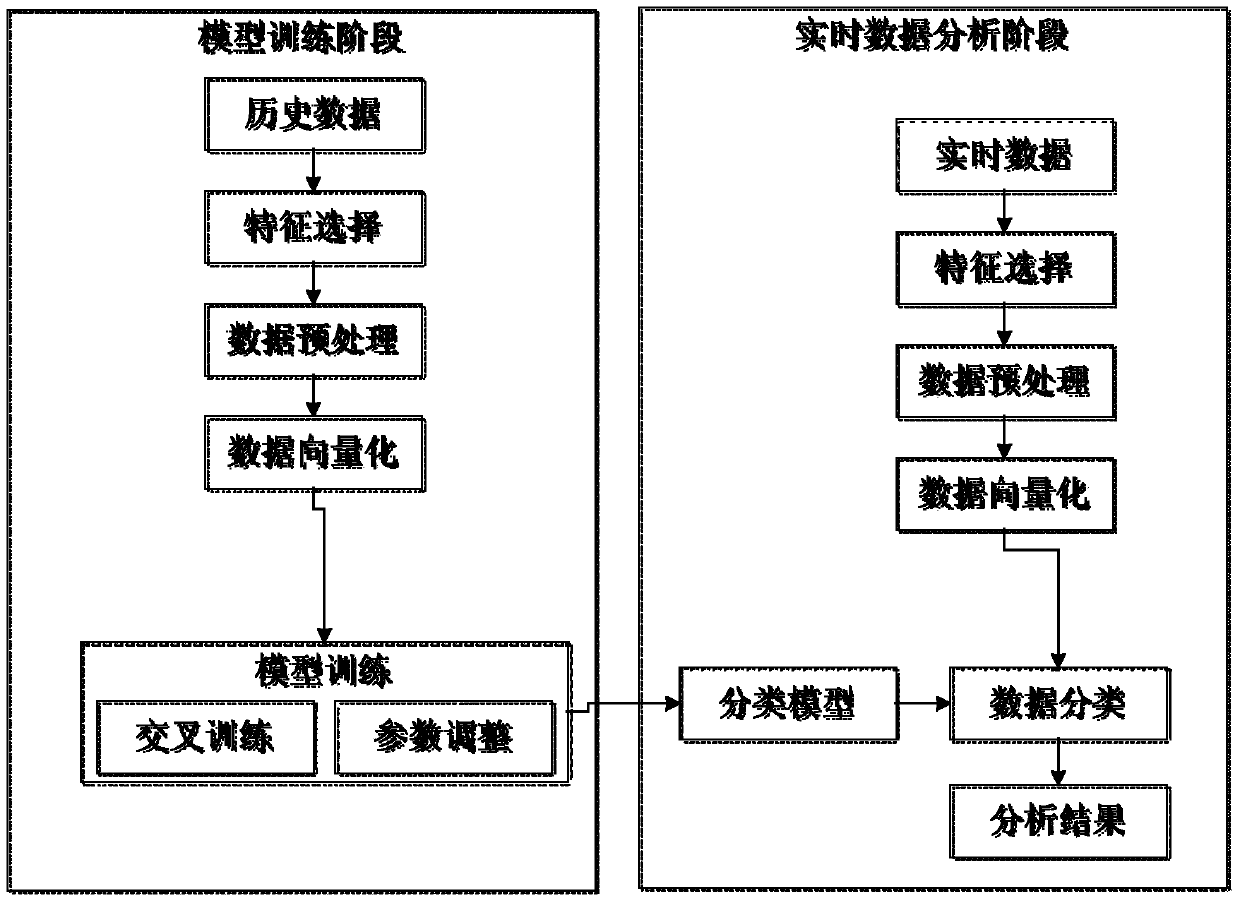

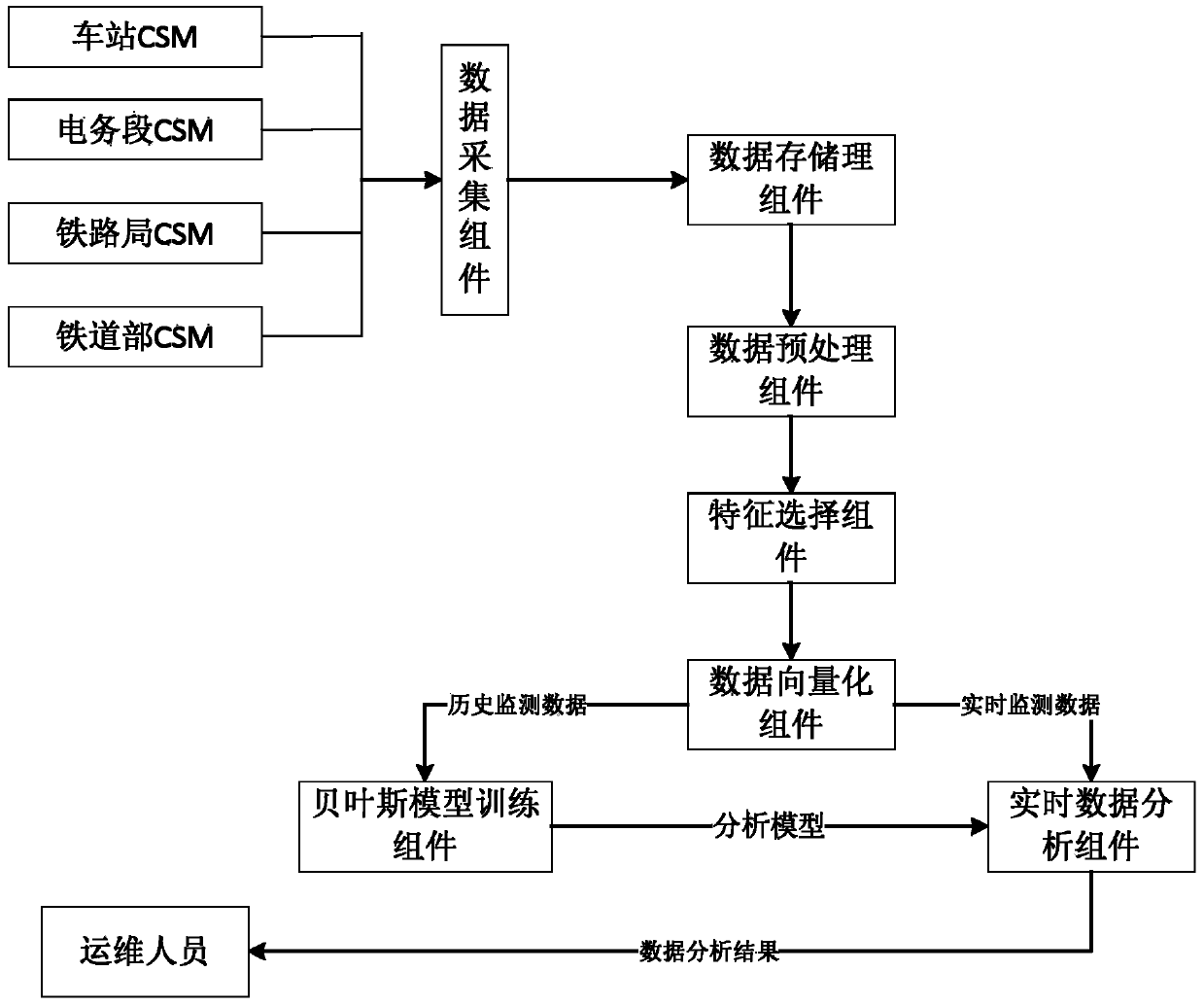

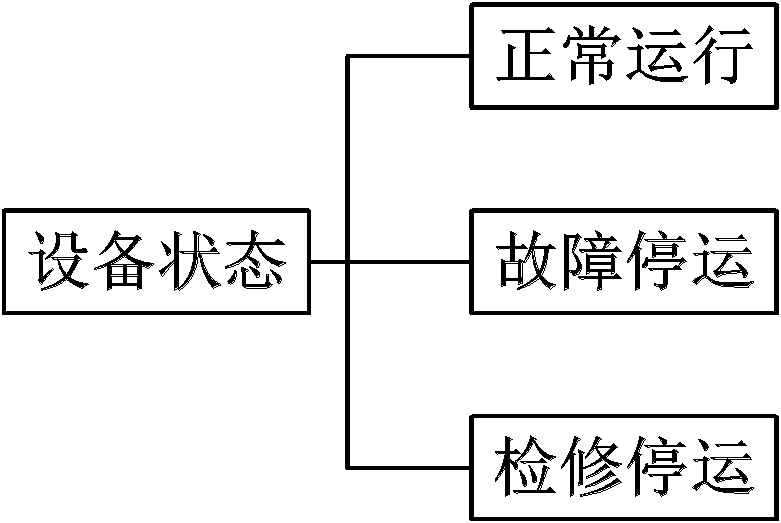

Method and system for track traffic failure recognition based on improved Bayesian algorithm

ActiveCN103699698AImprove accuracyImprove generalization abilitySpecial data processing applicationsRepair timeFault model

The invention discloses a method and a system for track traffic failure recognition based on improved Bayesian algorithm. The method comprises the following steps of: 1) determining various failure modes and corresponding monitoring values of each traffic device according to circuit structure of the traffic device, and building a failure model aiming at each failure mode and corresponding monitoring value; 2) recognizing a parent child relation among the monitoring data according to the failure model, thus obtaining a standard failure sample data; 3) training with the standard failure sample data through a Bayesian algorithm to obtain a failure recognition model, wherein weight of a parent node in the failure recognition model of each failure mode is greater than that of a child node; 4) monitoring and acquiring various monitoring values of the traffic device in real time, and recording time sequence of the monitoring values; 5) recognizing data through the failure recognition model, and determining corresponding failure. By the method and the system, accuracy of failure recognition is improved, failure repair time is reduced, the device can perform failure self-diagnosis, and traffic safety is guaranteed in the operation and maintenance aspect and the device aspect.

Owner:BEIJING TAILEDE INFORMATION TECH

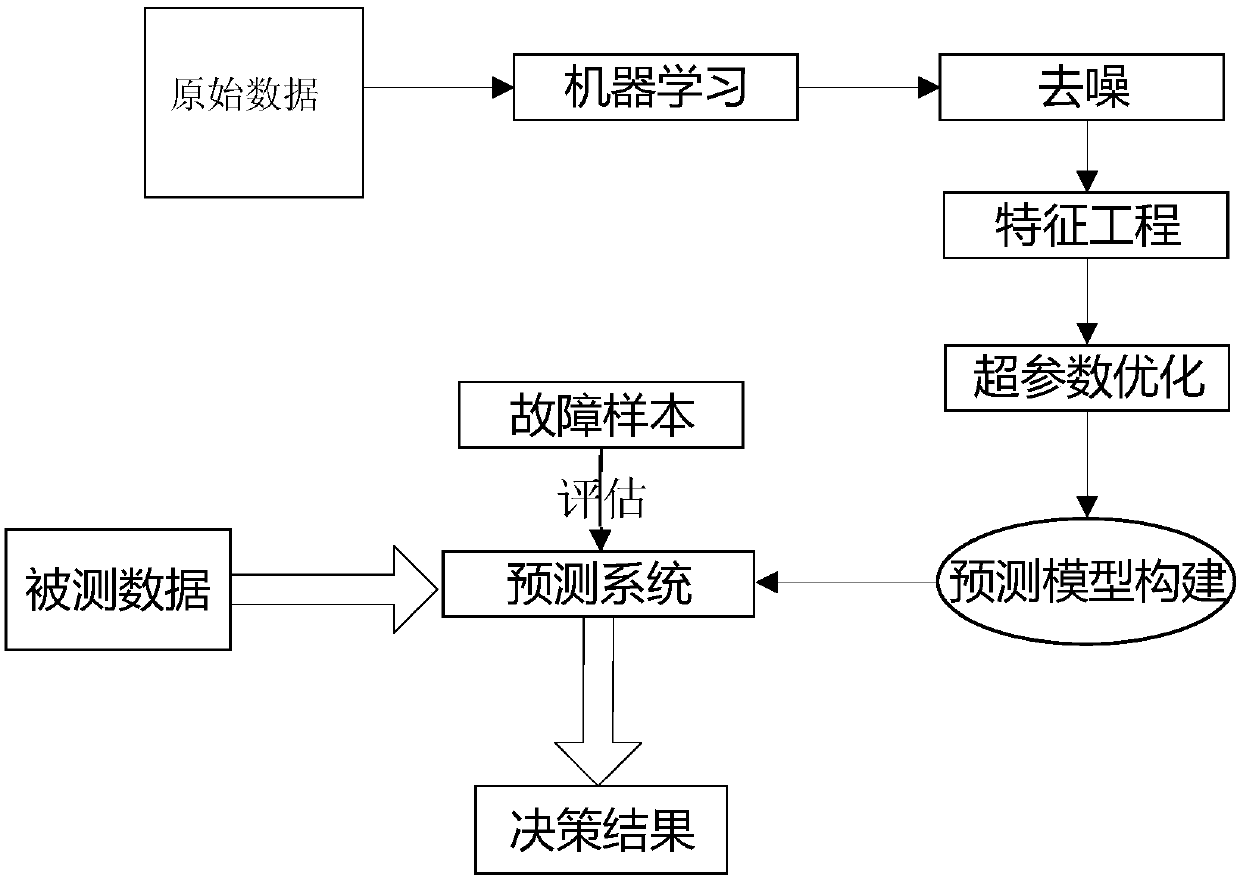

Fault prediction method based on machine learning

InactiveCN108304941ALow costReduce maintenance frequencyForecastingResourcesRepair timeReal-time data

The invention discloses a fault prediction method based on machine learning, which comprises the steps of 1) collecting set running index data of an object to be predicted, obtaining time series dataof each set running index, and collecting historical fault data of the object to be predicted; 2) respectively performing feature extraction on the data collected in the step 1), and inputting the extracted features into a machine learning system for training to obtain a basic fault prediction model; and 3) collecting real-time data of the set running indexes of the object to be predicted in running, performing feature extraction on the real-time data, inputting the extracted features into the basic fault prediction model, and predicting whether the object to be predicted has a fault or not atpresent. According to the method, the safe operation efficiency of equipment is improved, the maintenance time is shortened, the maintenance cost is reduced, the service life of the equipment is prolonged, and influences caused by the failure of some equipment are reduced or avoided.

Owner:CHINA NAT SOFTWARE & SERVICE

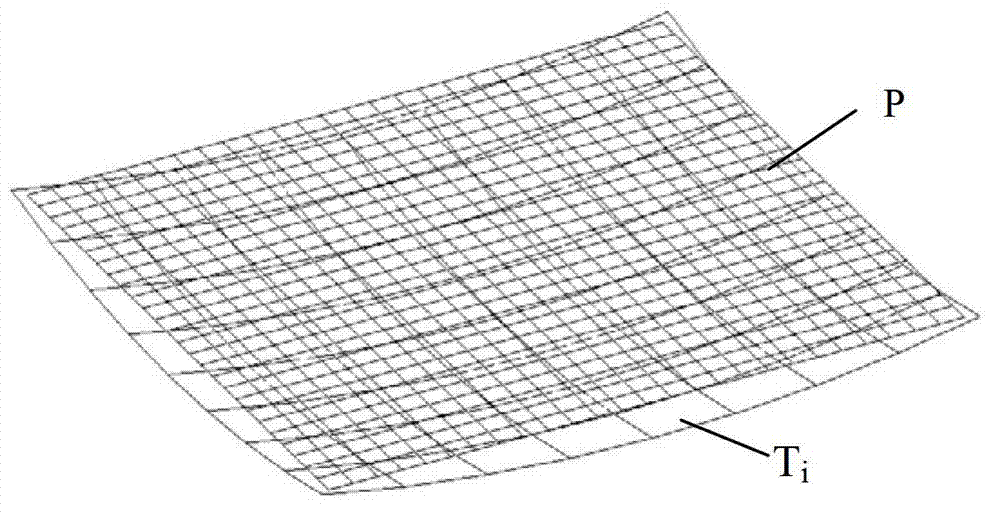

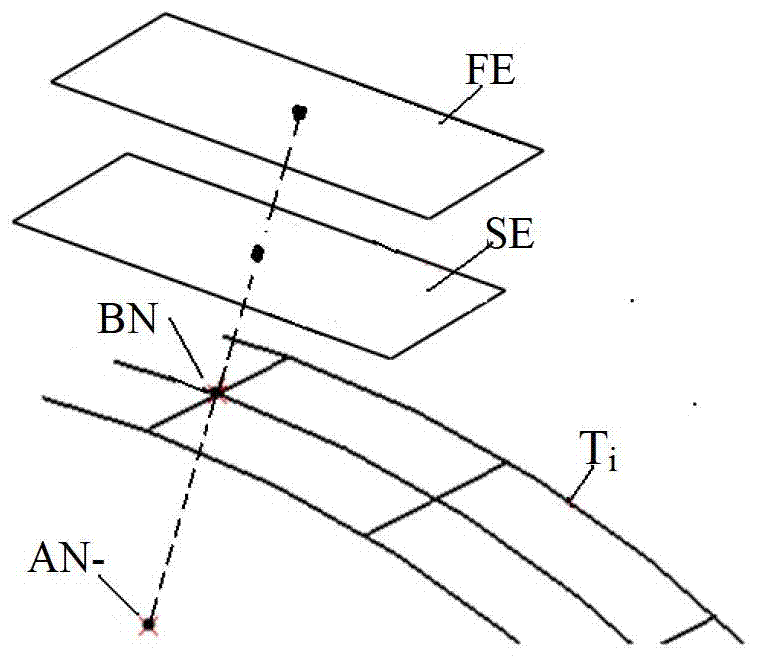

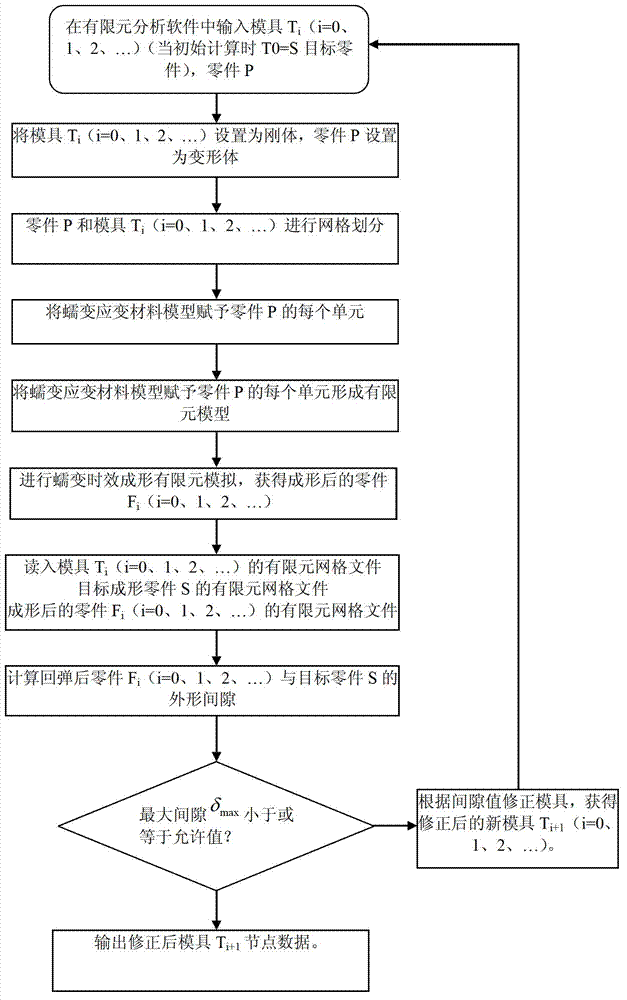

Wall board creep age forming method based on finite element mould profile rebound compensation

ActiveCN102930115AReduce auto-optimizationExtended service lifeSpecial data processing applicationsRepair timeWelding residual stress

The invention belongs to the technical field of metal plate forming, and relates to a wall board creep age forming method based on finite element mould profile rebound compensation. By the wall board creep age forming method, a finite element method is used for determining a mould profile, technological tests and mould repairing times are largely reduced, appearance control of formed parts can be realized, and forming precision is improved; according to the data through analog computation of forming process and rebound process of a formed piece, the mould profile is compensated, revised and optimized, so that rebound parts are the same as or close to the appearance of an ideal formed piece, and automatic optimization to the mould appearance during a creep age forming process is realized. The forming method can be applicable to various wallboard structures; except for overall wallboard parts, the forming method can be used for welding overall wallboards; welding residual stress can be effectively reduced, stress corrosion resistance capability is enhanced, and service lives of parts are prolonged.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Method and system for vehicle service appointments based on diagnostic trouble codes

ActiveUS8099308B2Promote repairImprove efficiencyVehicle testingRegistering/indicating working of vehiclesRepair timeComputer science

Methods and systems are provided for the analysis of one or more diagnostic trouble codes (DTCs), and for the scheduling of vehicle service appointments based at least in part on the DTC analysis. The method involves analyzing the received DTCs to determine an underlying problem. Once the underlying problem is determined, the parts and estimated repair time needed to repair the problem is determined. In one approach, the selection of the proposed slot for the service appointment involves coordinating numerous factors, such as the availability of needed parts, the user's scheduling preferences, and the availability of slots in the dealer's service schedule.

Owner:HONDA MOTOR CO LTD

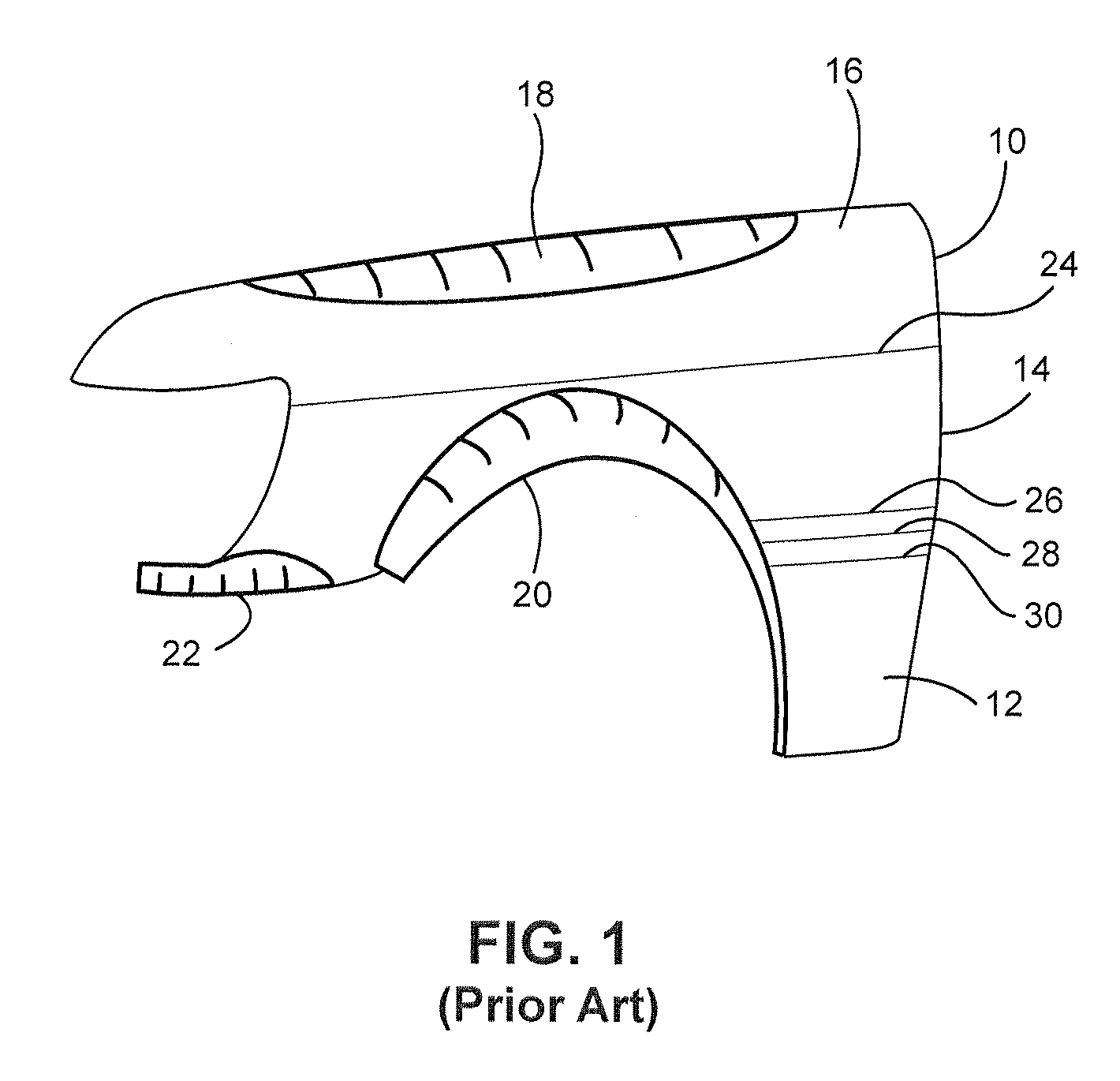

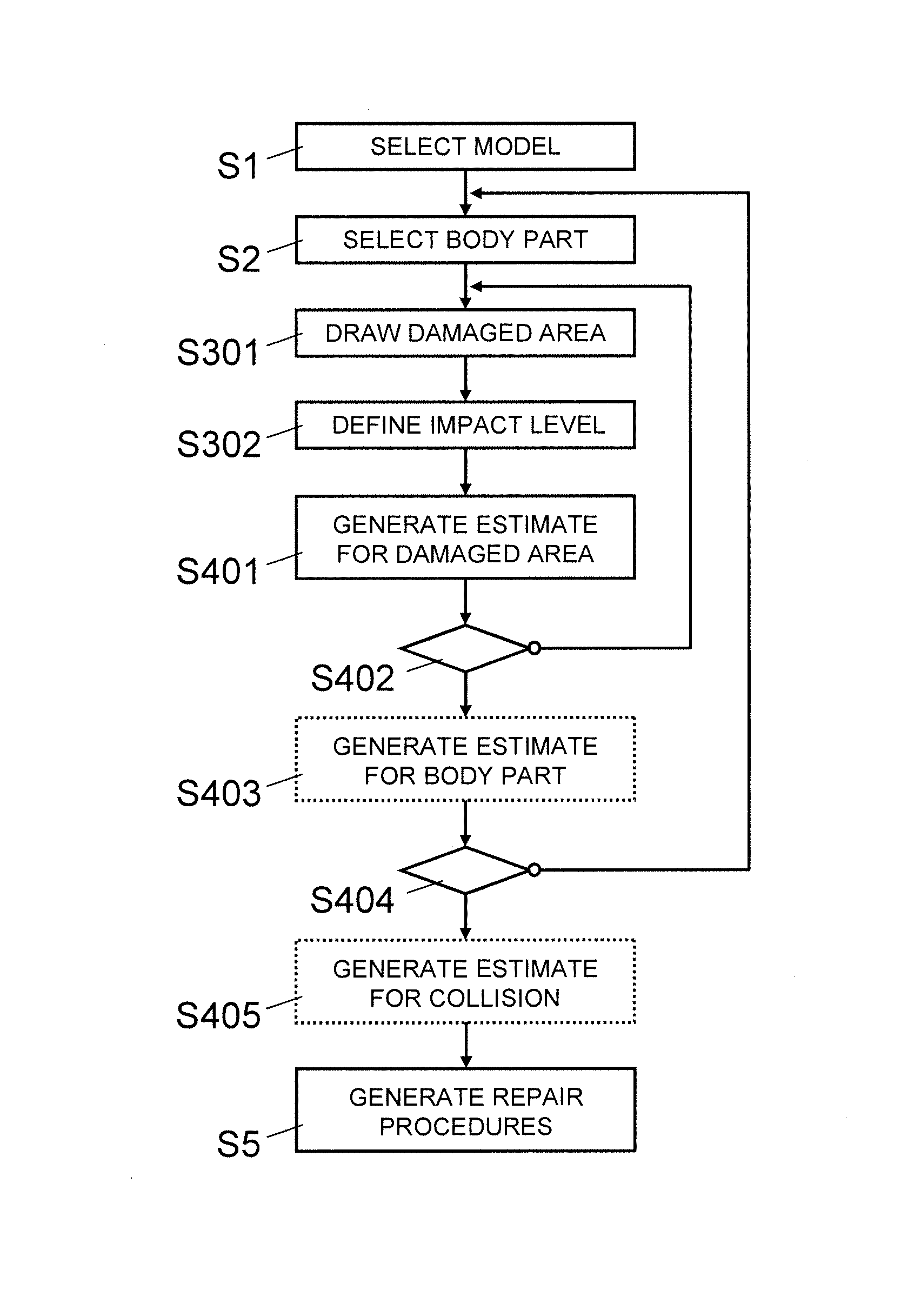

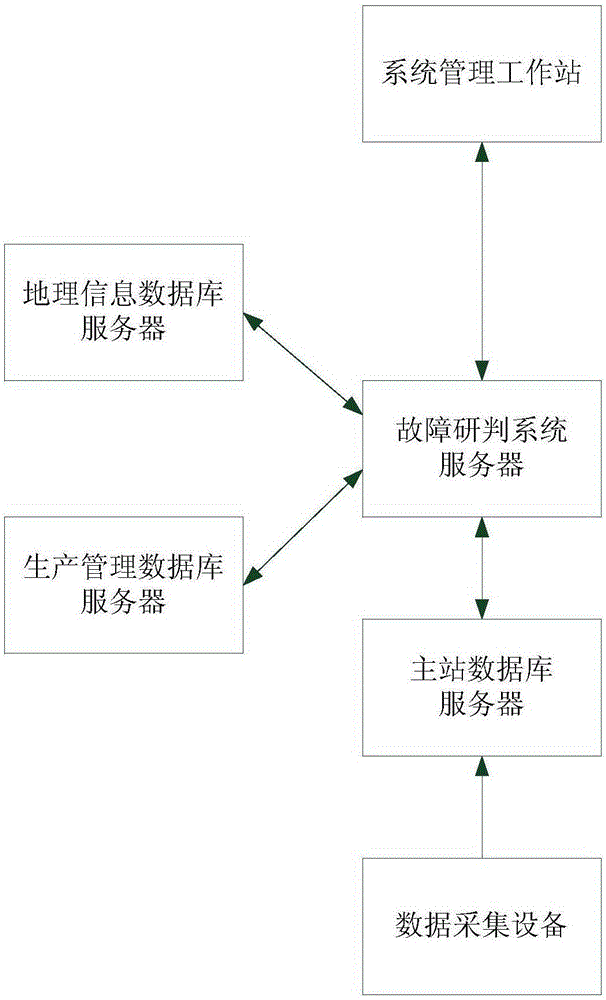

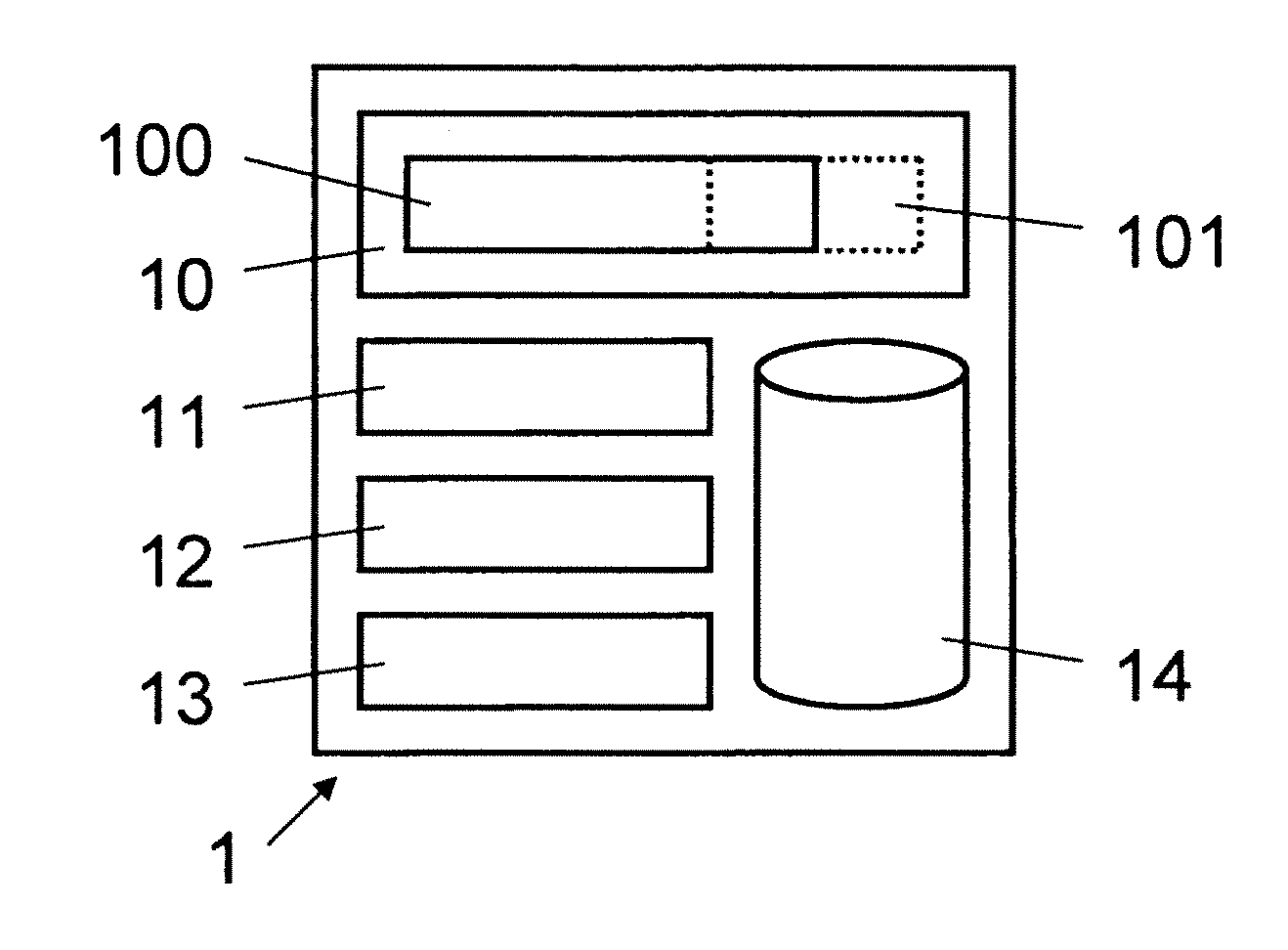

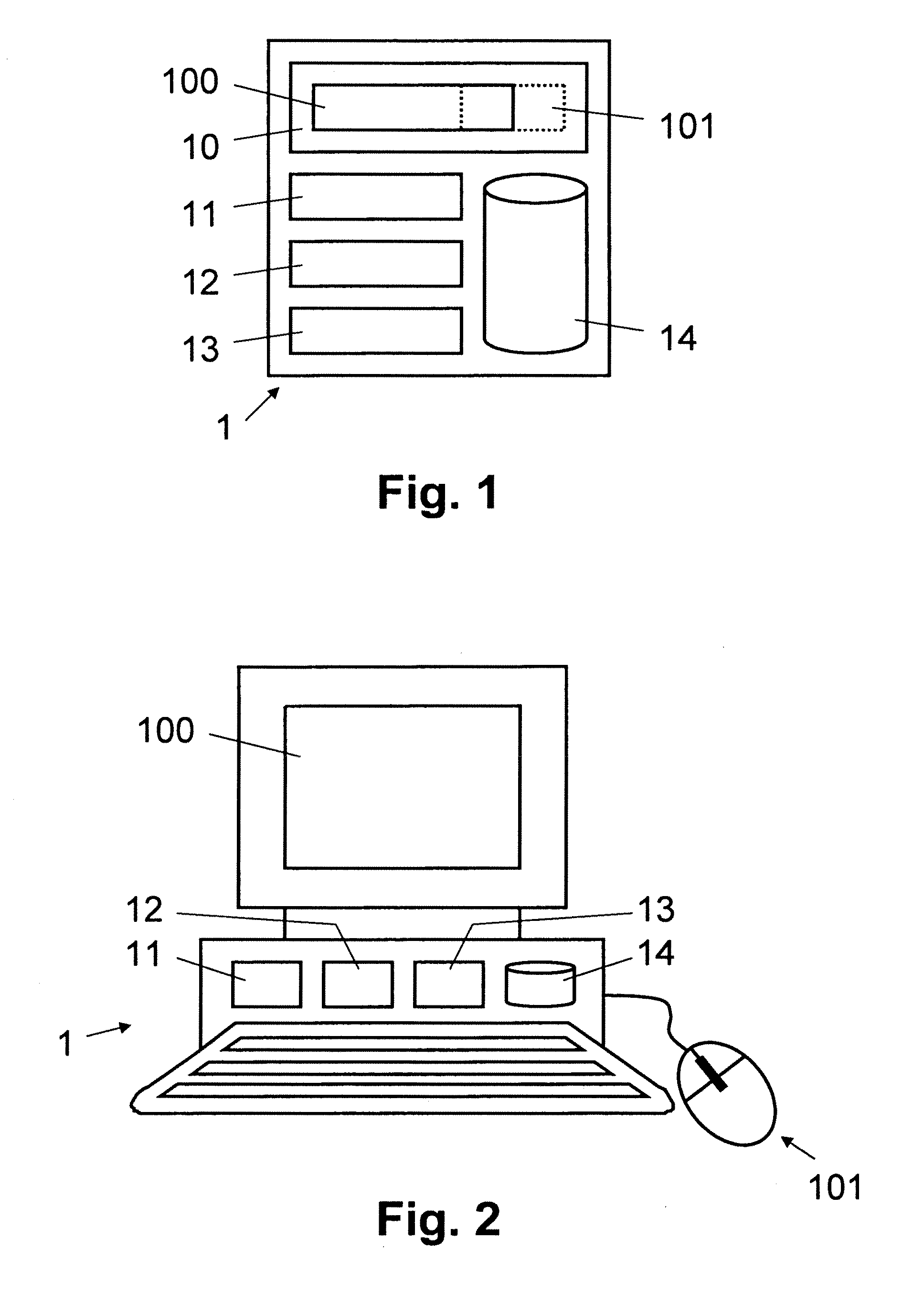

System and method for estimating collision damage to a car

InactiveUS20150294419A1Define efficiently and flexibly and accuratelyDefine efficiently, flexibly, and accuratelyVehicle testingFinanceRepair timeBody region

For determining an estimate of the collision damage to a car, a body part (3) of the car is displayed in a user interface (100). Through the user interface (100), input is received from the user for drawing on the body part (3) one or more damaged areas (4c, 5c). Specifically, the damaged areas (4c, 5c) are defined in each case by an outline of the damaged areas (4c, 5c), drawn on the body part (3) by way of a drawing tool (108, 108′), or as detected from an image. Subsequently, an estimate of the repair cost (C) and the repair time (T) is generated for the user, based on the damaged area (4c, 5c) drawn on the body part (3). Enabling the user to define the outlines of damaged areas (4c, 5c) makes it possible to define and estimate efficiently, flexibly, and accurately collision damage to a car.

Owner:AUDATEX

Sol combined fire resistant repair material and repair method

The invention relates to the technical field of a refractory material, in particular to a sol-bonded refractory repair material and a repair method thereof. In order to overcome the disadvantages that the prior refractory repair material is low in high-temperature bonding strength, slow to solidify, difficult to bake fast, easy to fall off, poor in anti-erosion capability, and so on, and the invention provides the sol-bonded refractory repair material, consisting of a repair material matrix, silicon carbide, silicon oxide or alumina micropowder, sol and promoting coagulant. Compared with the prior art, the refractory repair material can increase the bonding strength of the repair material with a furnace lining of a main channel, a slag groove, a hot metal ladle, a torpedo tank or other place, has good durability, prolongs the service life of the furnace lining, decreases repair time, simultaneously raises the anti-erosion capability of the furnace lining, and reduces the refractory material consumption of iron systems.

Owner:武钢集团有限公司

Waterproof and anti-corrosion repair mortar for polymer cement-based concrete structure

The invention relates to a waterproof and anti-corrosion repair mortar for a polymer cement-based concrete structure, in particular to a cement concrete repair material for a cement concrete structure, which is used for carrying out bonding reinforcement and repair on defects of municipal roads, municipal services, bridges and water conservancy projects (dams and gates). The waterproof and anti-corrosion repair mortar is prepared by mixed materials and water, and the mixed materials comprise the following components in parts by weight: 20-30 parts of portland cement, 0.01-0.05 part of high-performance water-reducing agent, 1-5 parts of high-aluminum cement, 15-30 parts of quartz sand, 25-60 parts of gravel and 1-3 parts of acrylic adhesive powder, 1-3 parts of fiber material, while the using amount of water accounts for 5-14% of the total parts of the mixed materials. Due to the adoption of the technical scheme, the waterproof and anti-corrosion repair mortar has the characteristics of good pressure resistance, high flexural strength, high bonding strength, good durability, convenient and fast construction, fast setting and early strength shrinkage control, and can greatly shorten the repair time and quickly resume the traffic in particular to roads.

Owner:卢建华

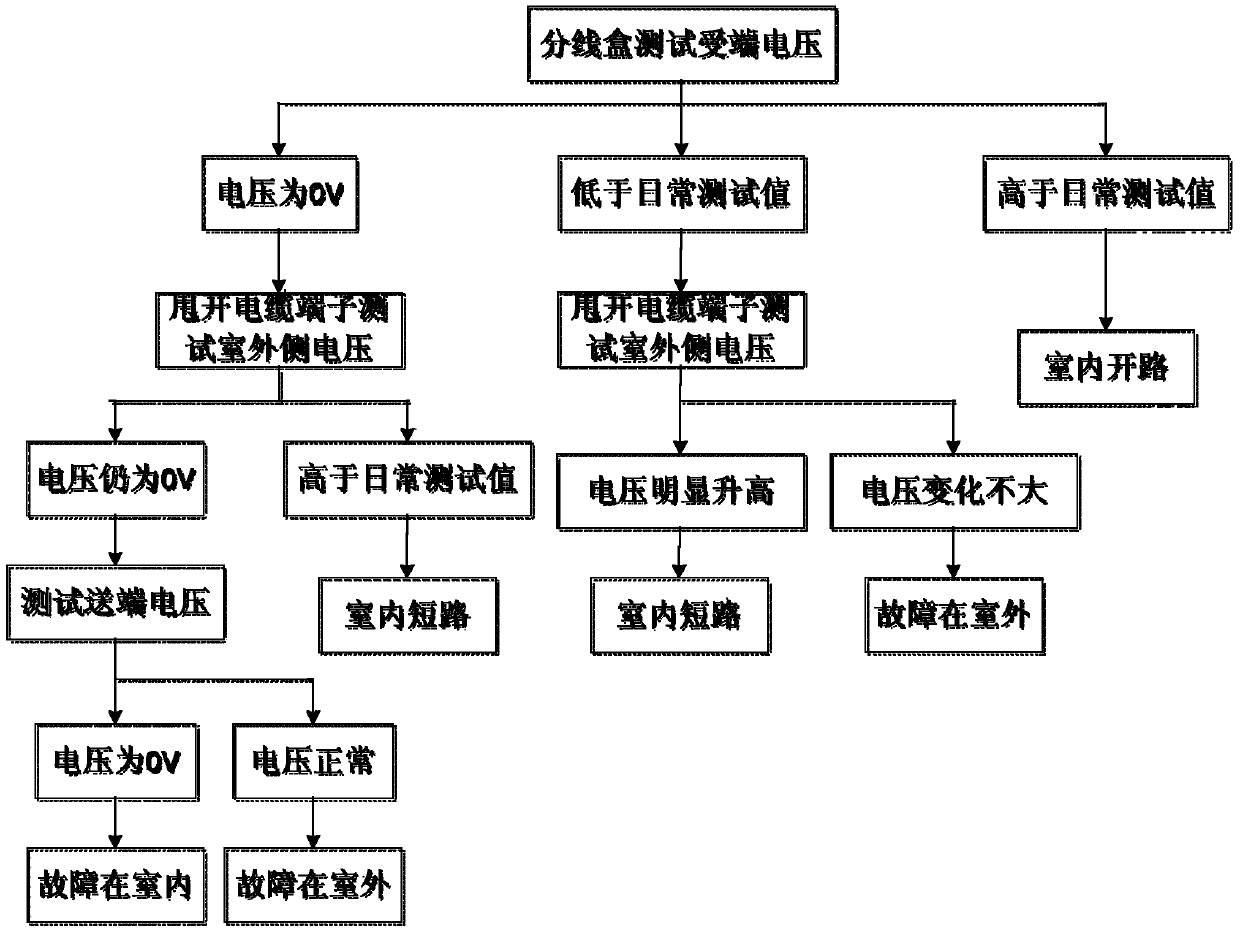

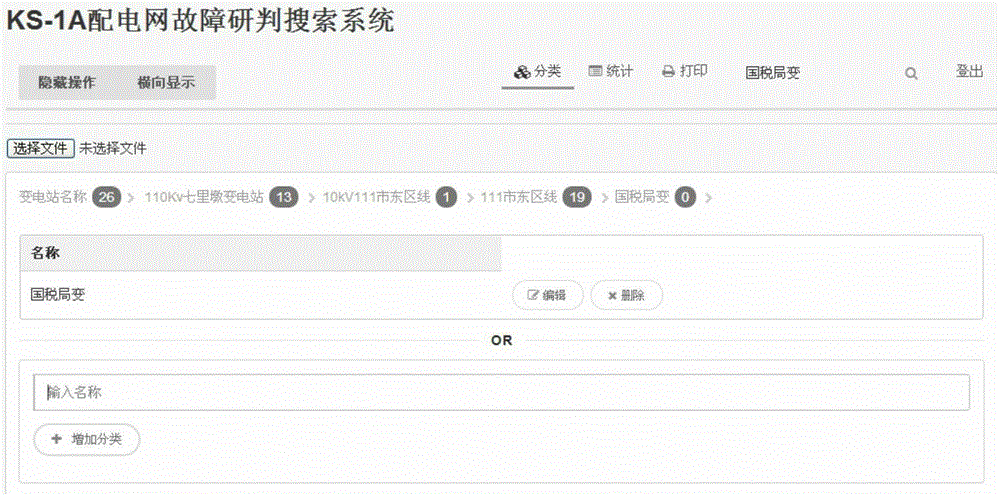

Distribution network fault judgment searching and positioning system

InactiveCN105277851AImprove power supply reliabilityEnsure safetyFault locationTransformerData acquisition

The invention provides a distribution network fault judgment searching and positioning system which belongs to the technical field of power engineering. A data acquisition device of the system is used for acquiring the state information of a distribution network, and transmitting the state information of the distribution network to a main station database server through a dedicated power communication network. GIS is used for storing and updating geographic information. PMIS is used for storing and updating the parameter information of a transformer and a transmission line. A fault judgment system server is used for providing the functions of fault information retrieval, fault diagnosis, data management analysis, graph processing and information dissemination. According to the invention, distribution network power cut and transmission information query retrieval, failed equipment searching and positioning and online graph display can be carried out; when the distribution network is failed, the system can help emergency repair staff to carry out quick fault point positioning and fault judgment; outage time is effectively shortened; outage range is prevented from expanding; valuable repair time is saved; and the system is fast, flexible and accurate.

Owner:TIANSHUI POWER SUPPLY COMPANY OF STATE GRID GANSUELECTRIC POWER

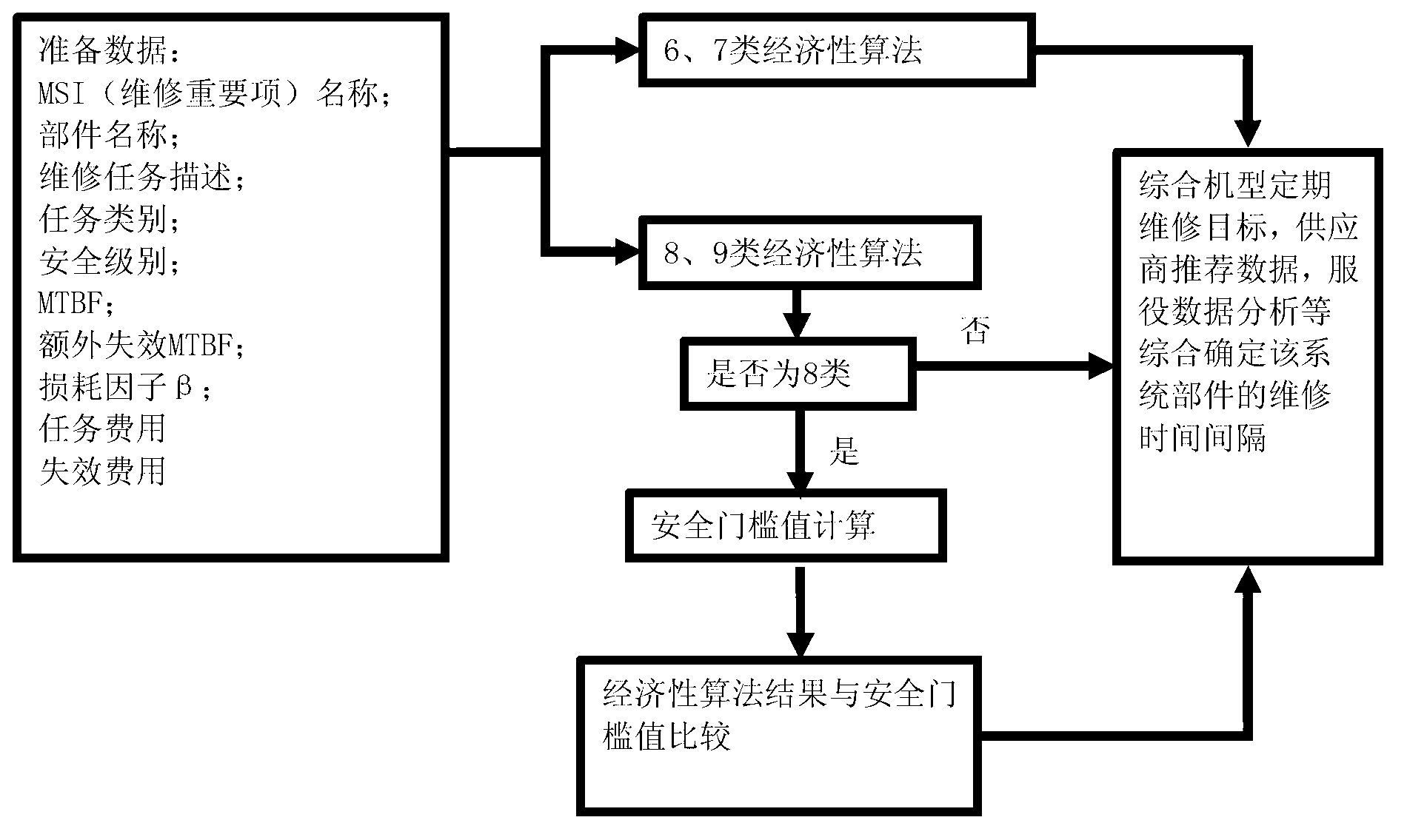

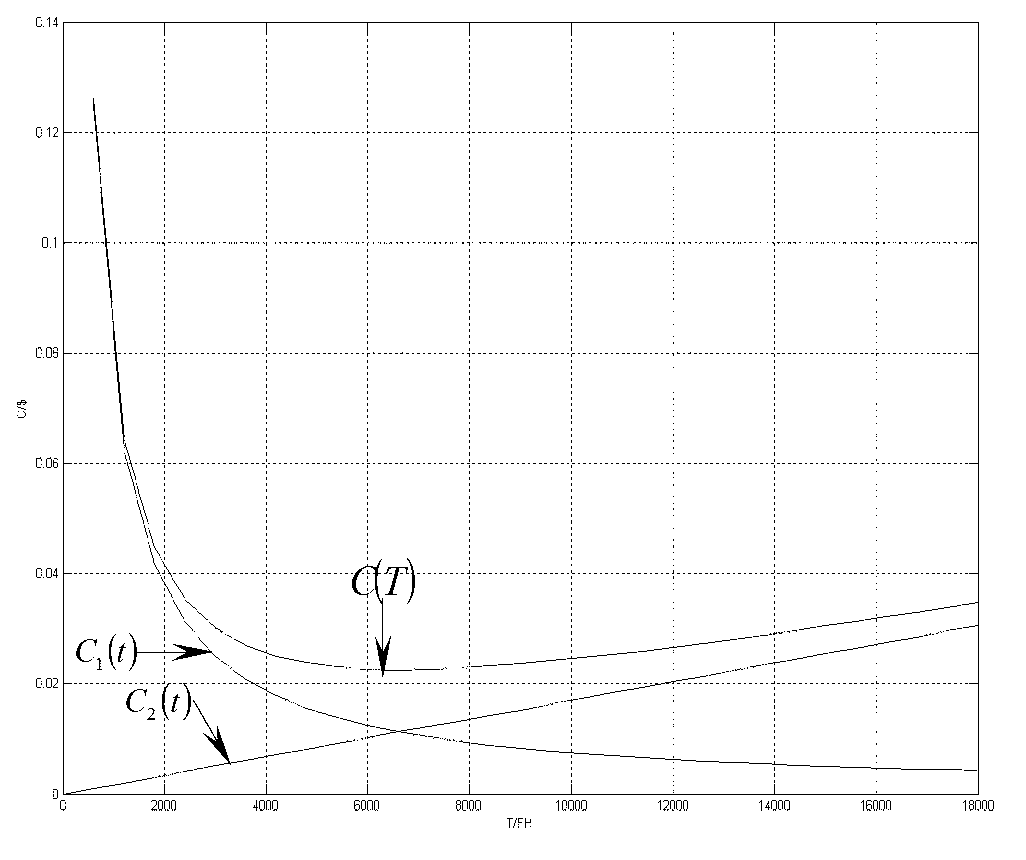

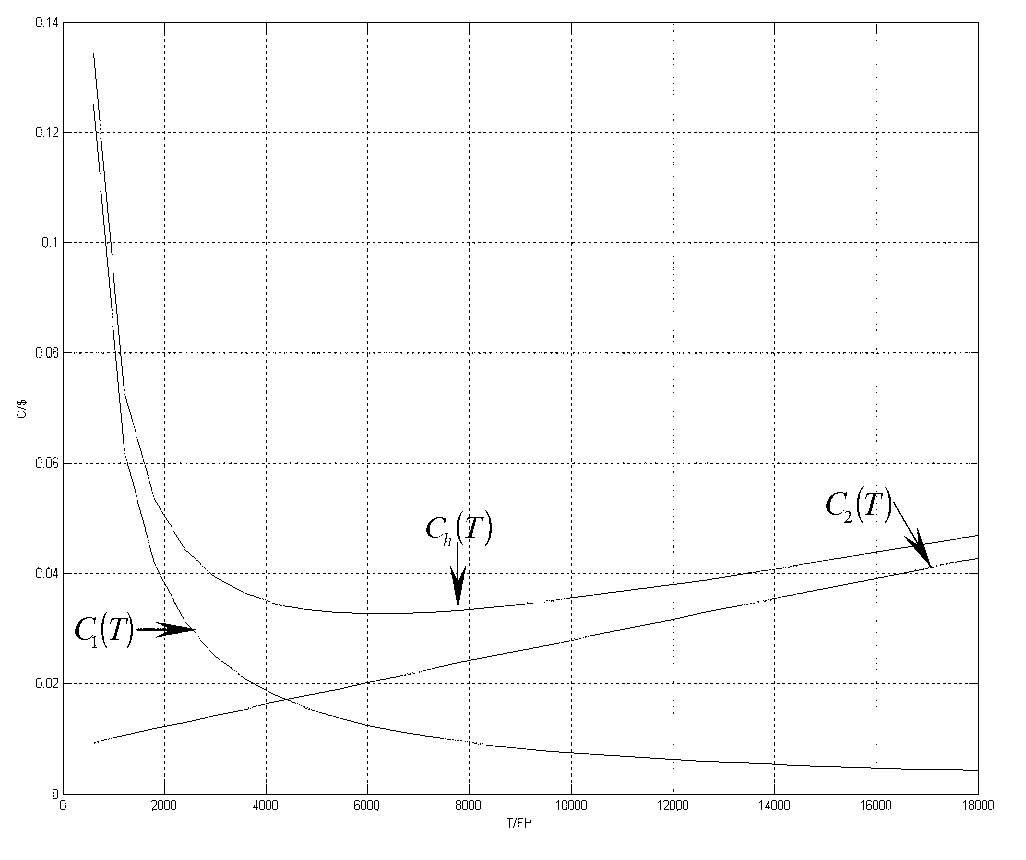

Method for calculating maintenance time interval of civil aircraft system

InactiveCN103020422ASolve the problem of maintenance intervalsSpecial data processing applicationsAviationRepair time

A method for calculating the maintenance time interval of a civil aircraft system belongs to the technical field of aviation. The method selects economy (cost / hour) as an optimization object, wherein as for safety tasks, two methods are used to calculate the time intervals of corresponding maintenance tasks, safety and economy are emphasized particularly, and the economy arithmetic recommended scope, safety threshold and product model regular checking target value are taken into comprehensive consideration to determine the task time interval. The method is economy-centered, is limited by safety and takes reliability as input idea, so as to recommend a reasonable maintenance time interval. A working group comprehensively takes supplier recommended value, engineering recommended value, history maintenance data, similar system part data, industrial experience point, the recommended value of the method and the like into consideration to make a decision, so that an optimum maintenance time interval judgment is made. The method is used for solving the problem that the civil aircraft cannot accurately judge the system part maintenance time interval due to the lack of a large number of service data during a maintenance review board report (MRBR) formulation process.

Owner:AVIC SAC COMML AIRCRAFT

Wide-band laser-induced hybrid cladding restoration and surface strengthening method for dies

InactiveCN102373468AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesRepair timeLaser scanning

A wide-band laser-induced hybrid cladding repairing and surface strengthening method for dies is characterized in that a Ni based alloy powder for wide-band laser-induced hybrid cladding is used to repair damaged areas of dies or strengthen the surface of dies. By the adoption of a wide-band scanning system, different dies such as plastic die, hot work die, cold work die and the like can be repaired and undergo surface strengthening. The width of a single track laser-induced hybrid cladding layer reaches 20-30mm; the thickness of each track cladding can reaches 3mm; laser scan speed reaches 10m / min; the powder flow reaches 15kg / h; the powder utilization rate is 90%; the efficiency is raised by 5-10 times in comparison with simple laser cladding; repairing time is shortened by 30%; energy is saved by 10-40%; defects such as pores and crack in the coating are eliminated; wear resistance, corrosion resistance, antioxidation performance and fatigue resistance of dies are greatly raised; and the service life of dies can be increased by 3-10 times.

Owner:XIAOGAN KELONG INDAL

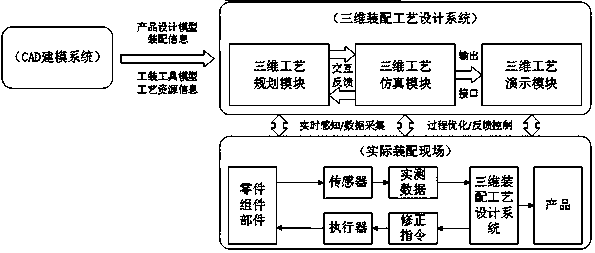

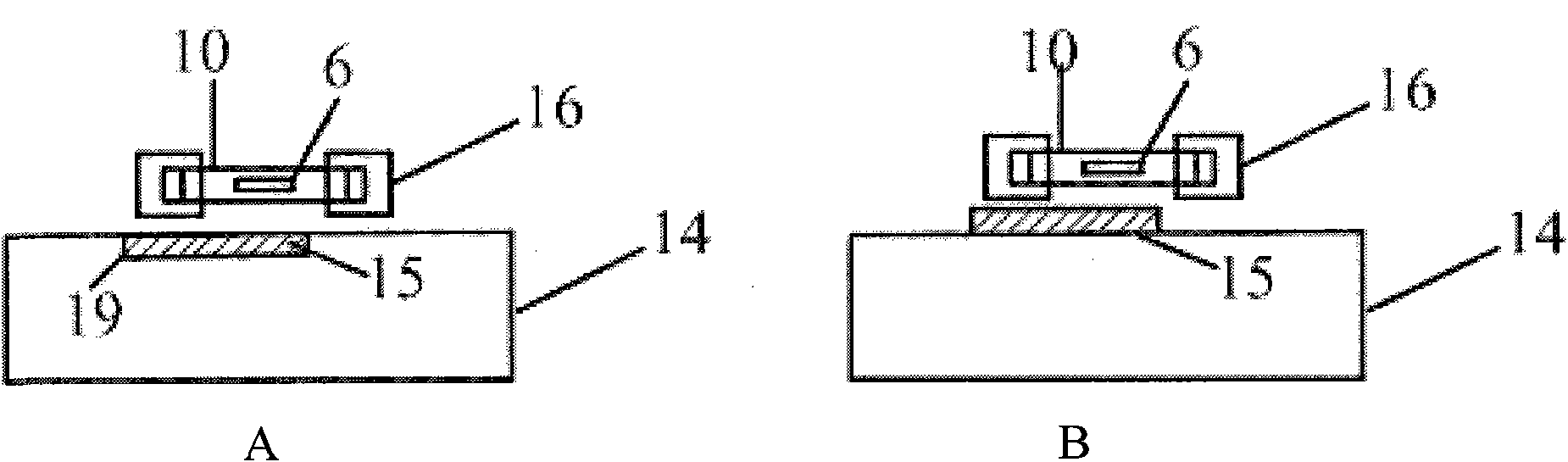

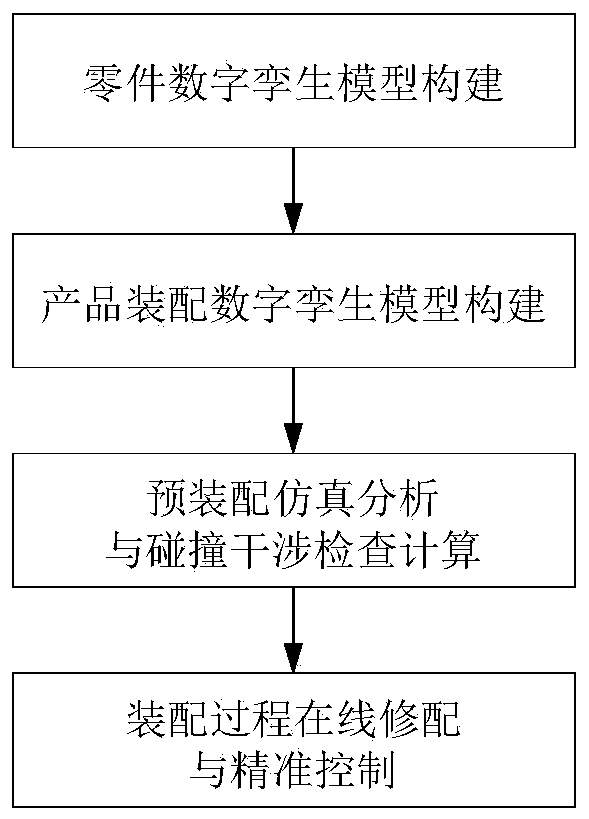

Complex product assembly process accurate repair method based on digital twinning and operation system thereof

ActiveCN111274671ARealize online precise repairRealize intelligent closed-loop controlDesign optimisation/simulationRepair timeLoop control

The invention discloses a complex product assembly process accurate repair method based on digital twinning and an operation system thereof. For the key procedures in the product assembly process, actually measured data acquisition and processing are carried out on a part assembly matching area, the actually measured data and an ideal model are deeply fused, and a part digital twinning model is constructed; solving and updating the part assembly positioning constraint in combination with the planned assembly sequence to obtain a product digital twinning model; the digital twinning model of theproduct is used for pre-assembly simulation analysis, according to an assembly simulation analysis result and an assembly collision interference check condition, position information of a matching area, needing to be repaired, of a part and the minimum repair amount are obtained through calculation, a reasonable part repair scheme is given, and online repair and precise control over the assemblyprocess are completed. Intelligent closed-loop control over the complex product assembling process can be achieved, and important engineering significance is achieved for shortening the trial assemblyand repair time in the assembling process and improving the assembling precision and efficiency.

Owner:SOUTHEAST UNIV

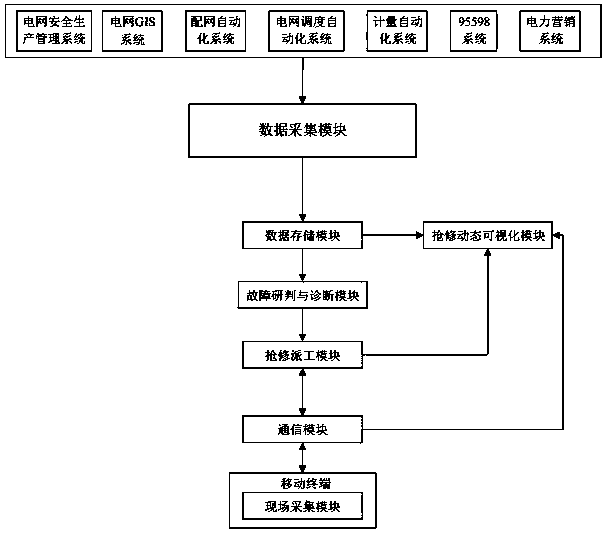

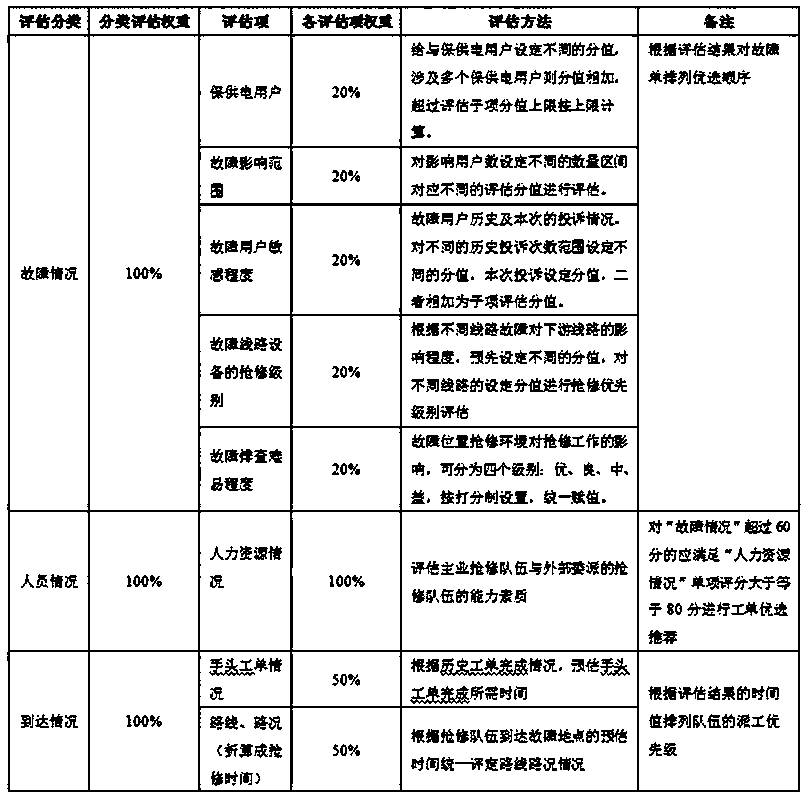

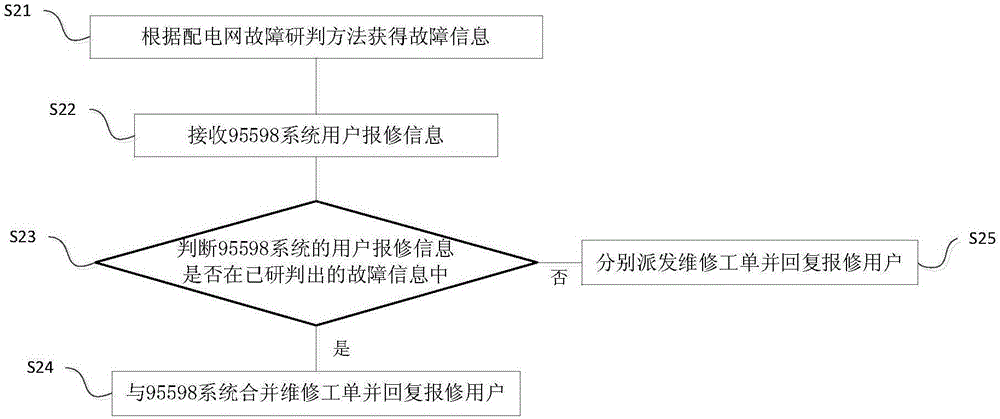

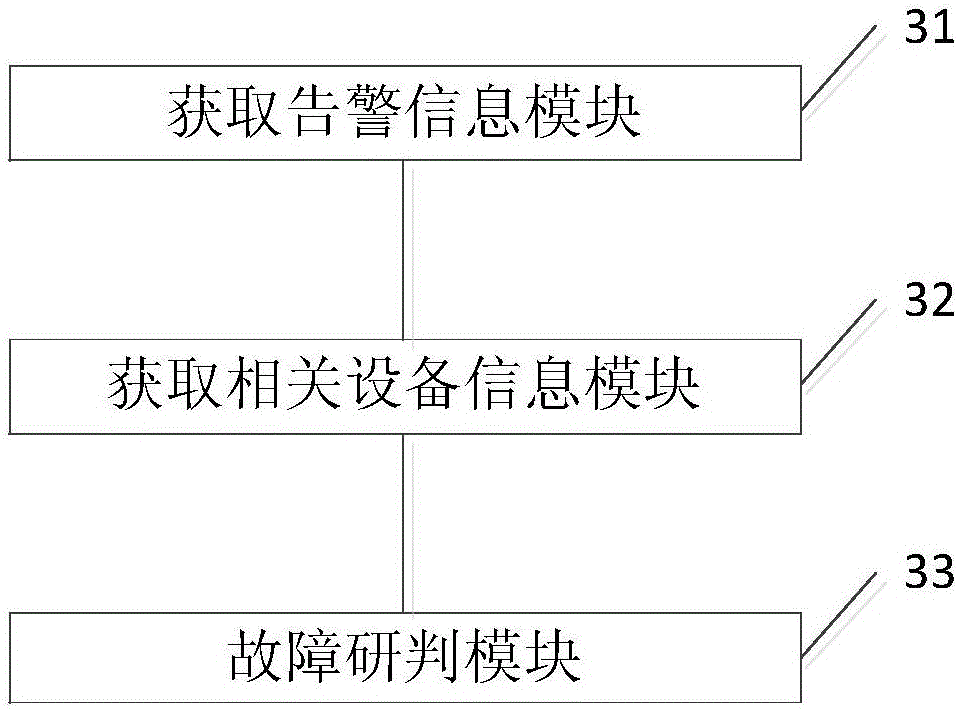

Distribution network repair assistant decision-making and intelligent management and control system

PendingCN110289682AImprove basic management levelImprove troubleshooting efficiencyEmergency protective circuit arrangementsInformation technology support systemRepair timeControl system

The invention relates to the technical field of distribution network repair, in particular to a distribution network repair assistant decision-making and intelligent management and control system, which comprises a data acquisition module, a data storage module, a fault study and judgment and diagnosis module, a repair dispatching module, and a repair dynamic visualization module. In view of information interaction and integration, the problems of fast and accurate fault positioning, repair resource dispatching optimization and the like can be solved; resources in all aspects are called thoroughly to study distribution network fault intelligent search and positioning, fault repair and recovery technologies, the fault repair time is reasonably arranged, a fault repair strategy and a scheme are scientifically formulated, the fault repair efficiency is improved, the fault repair cost is effectively reduced, a health fault repair comprehensive management system can be established conveniently, and the basic management level of power grid repair and operation are thus improved.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU

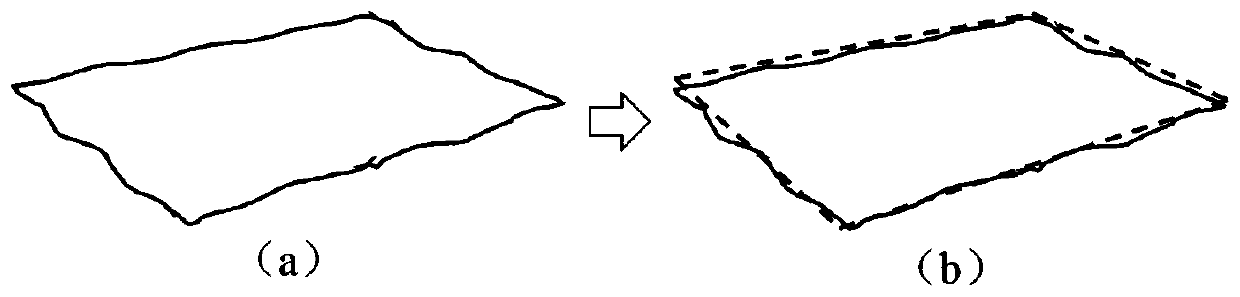

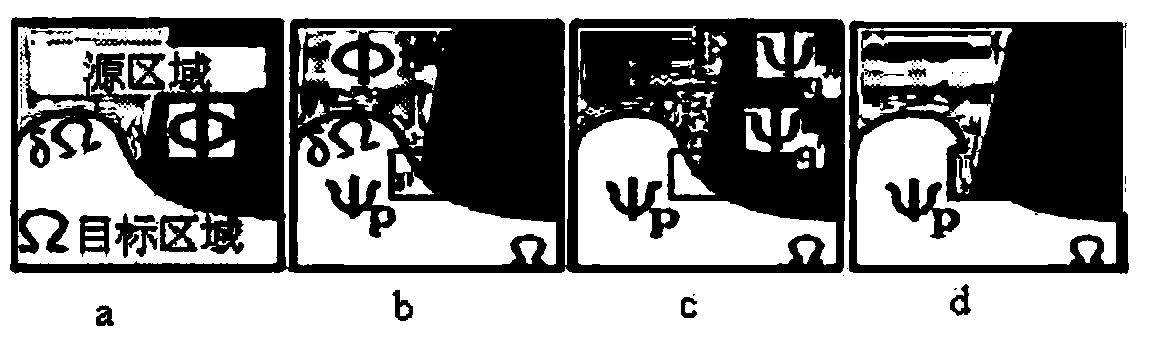

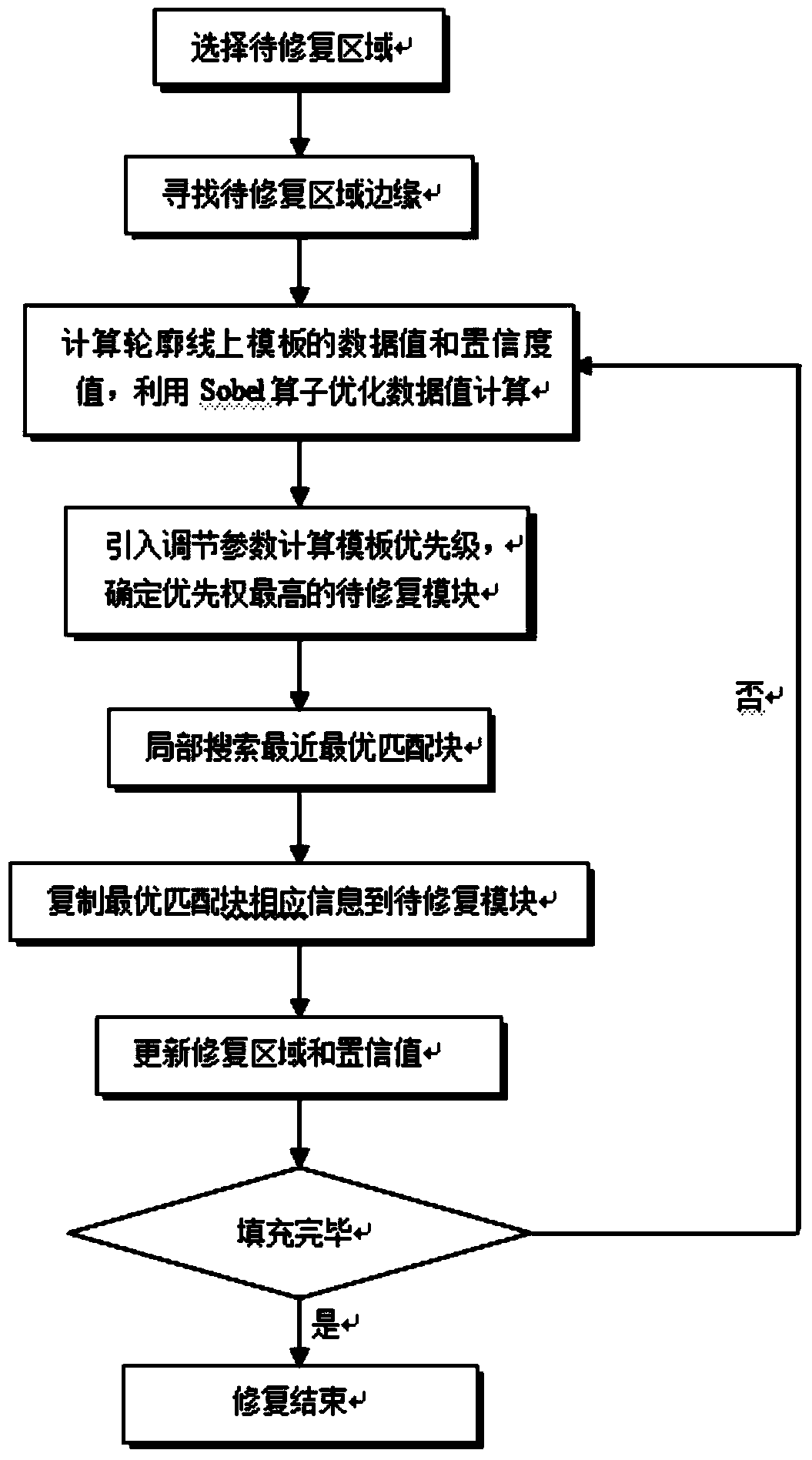

Rapid image repairing method based on sample

ActiveCN104376535ASolve the problem of repair lagEasy to eliminateImage enhancementRepair timeAlgorithm

The invention discloses a rapid image repairing method based on a sample. The rapid image repairing method includes the steps that a to-be-repaired area is determined through marks; a contour line of a boundary of the to-be-repaired area and a known area is selected; a data value and a confidence coefficient value of a template are calculated; adjusting parameters are introduced to determine a to-be-repaired module with the highest priority; in the known area adjacent to the to-be-repaired module, conducting searching from the near to the distant to obtain an optimal matching block according to the distance between the optimal matching block and a center point of the to-be-repaired module; filling the corresponding position of the to-be-repaired module with a pixel point corresponding to the optimal matching block, and meanwhile updating the confidence value of the newly-updated pixel point; repeatedly executing the steps on the to-be-repaired area until the to-be-repaired area is filled completely. The rapid image repairing method is optimized from priority operation, data valve calculation, matching area and optimal matching block searching and confidence value updating, and the repairing effect is more natural; meanwhile, matching only needs to be carried out on a local part during repairing, so that the repairing time is greatly shortened.

Owner:XUZHOU UNIV OF TECH

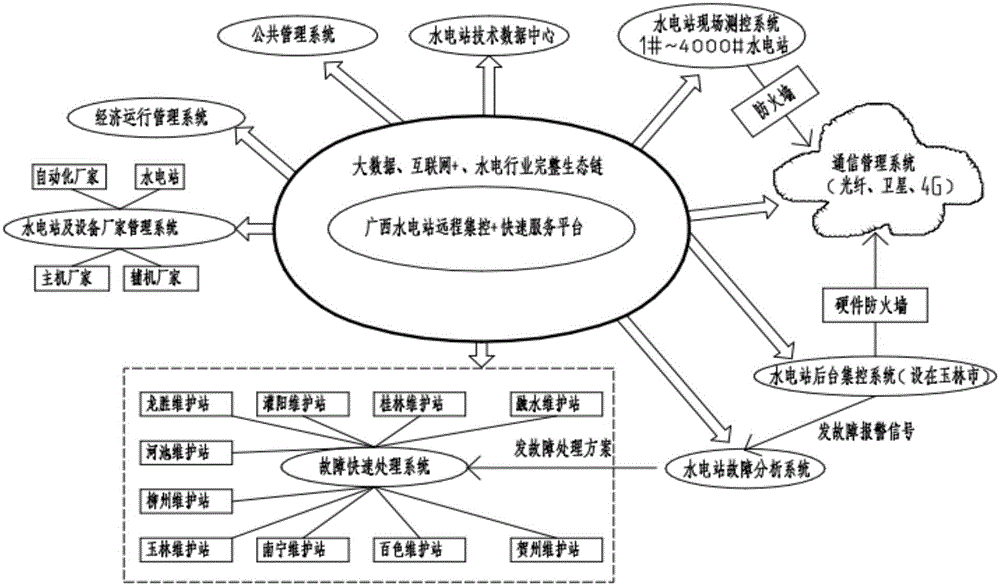

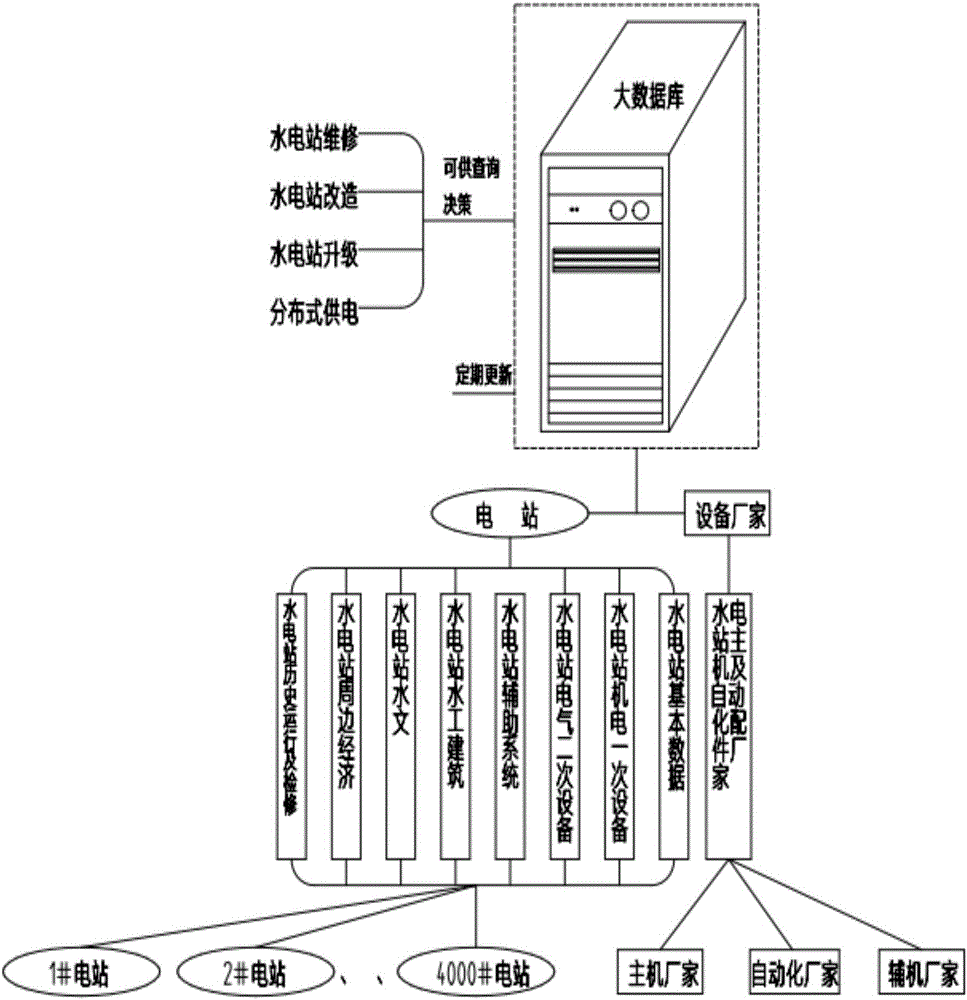

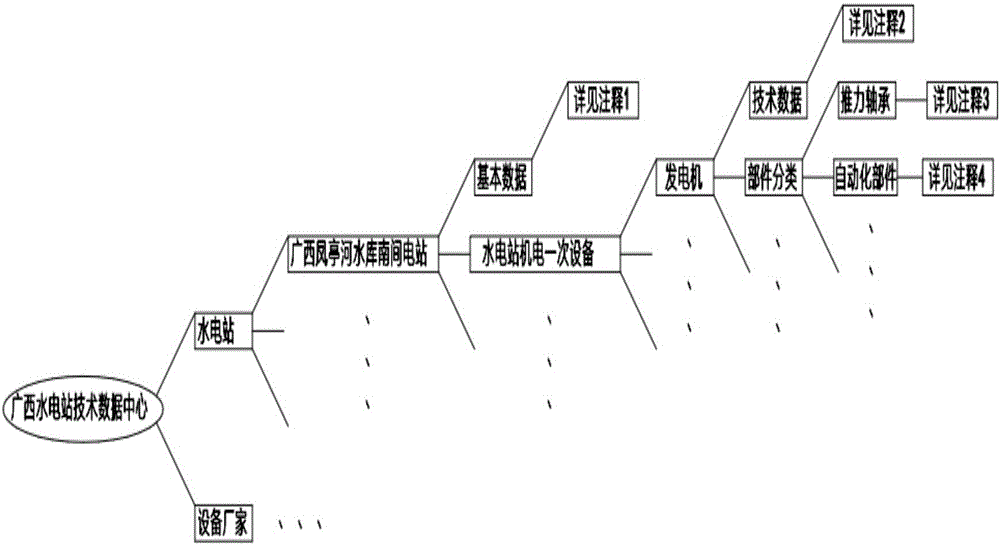

Hydropower station remote centralized control and quick service platform

InactiveCN106527367ASolve problemsRapid responseData processing applicationsProgramme total factory controlData centerThird generation

The invention discloses a hydropower station remote centralized control and quick service platform, which comprises a hydropower station technical data center, a hydropower station field measurement and control system, a hydropower station and equipment manufacturer management system, a hydropower station backstage centralized control system, a communication management system, a hydropower station fault analysis system, a fault quick processing system, an economic operation management system and a public service system. The communication management system uses an optical fiber channel, satellite or 3G / 4G network communication mode to build complete communication channels among systems for mutual connection. Based on a big data and cloud computing condition, an Internet + mode is used for realizing no man on duty or few men on duty for the hydropower station, design, production, selling, mounting, maintenance, operation and the like in the hydropower industry can be merged organically, and a complete ecological industry chain for the industry is formed; and after remote centralized control management and quick repair service are realized on a hydropower station cluster, the shipment inspection persons are reduced by 98%, the fault repair time is shortened, and the economic benefits are improved significantly.

Owner:广西凯悦新源电力科技有限公司

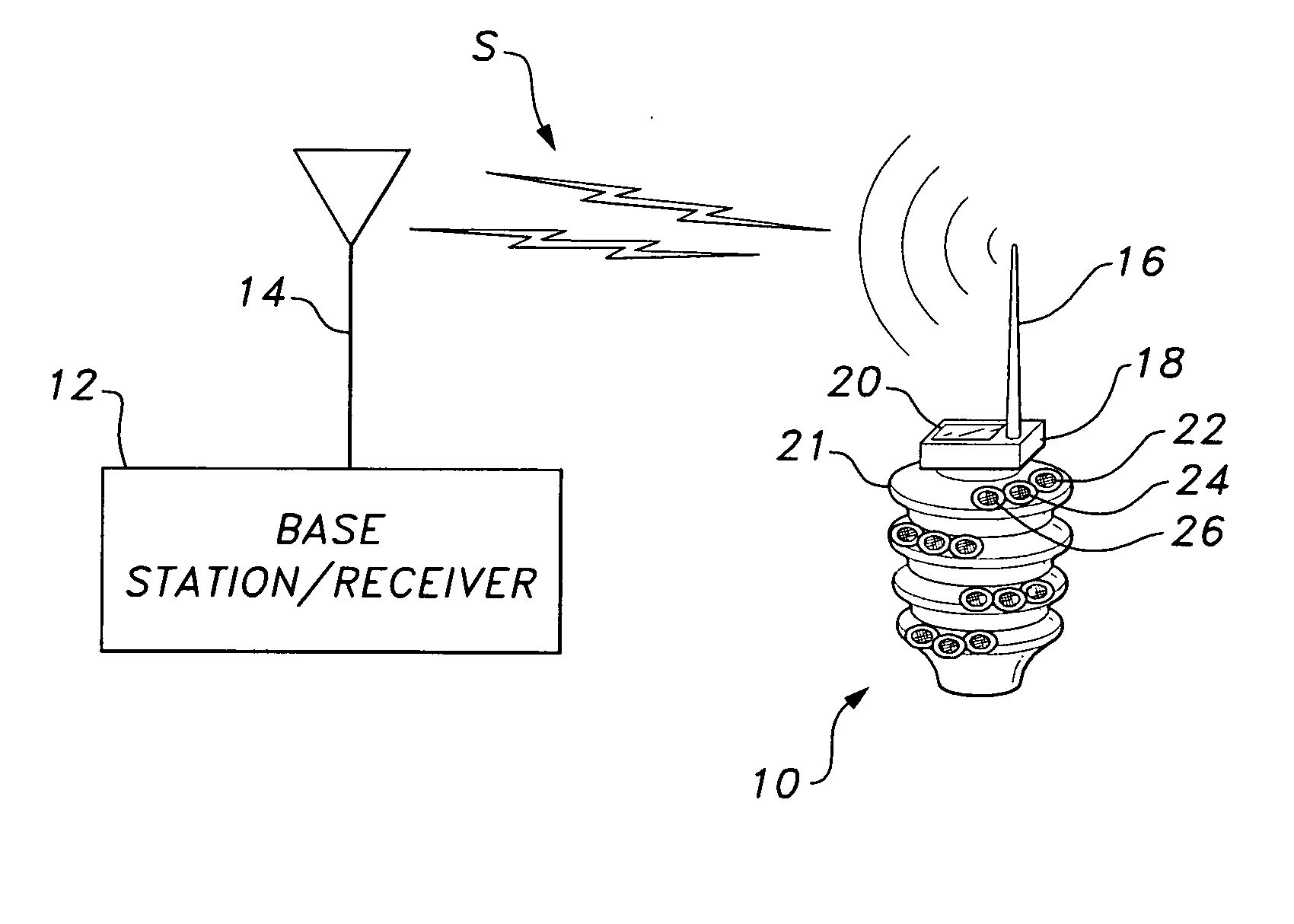

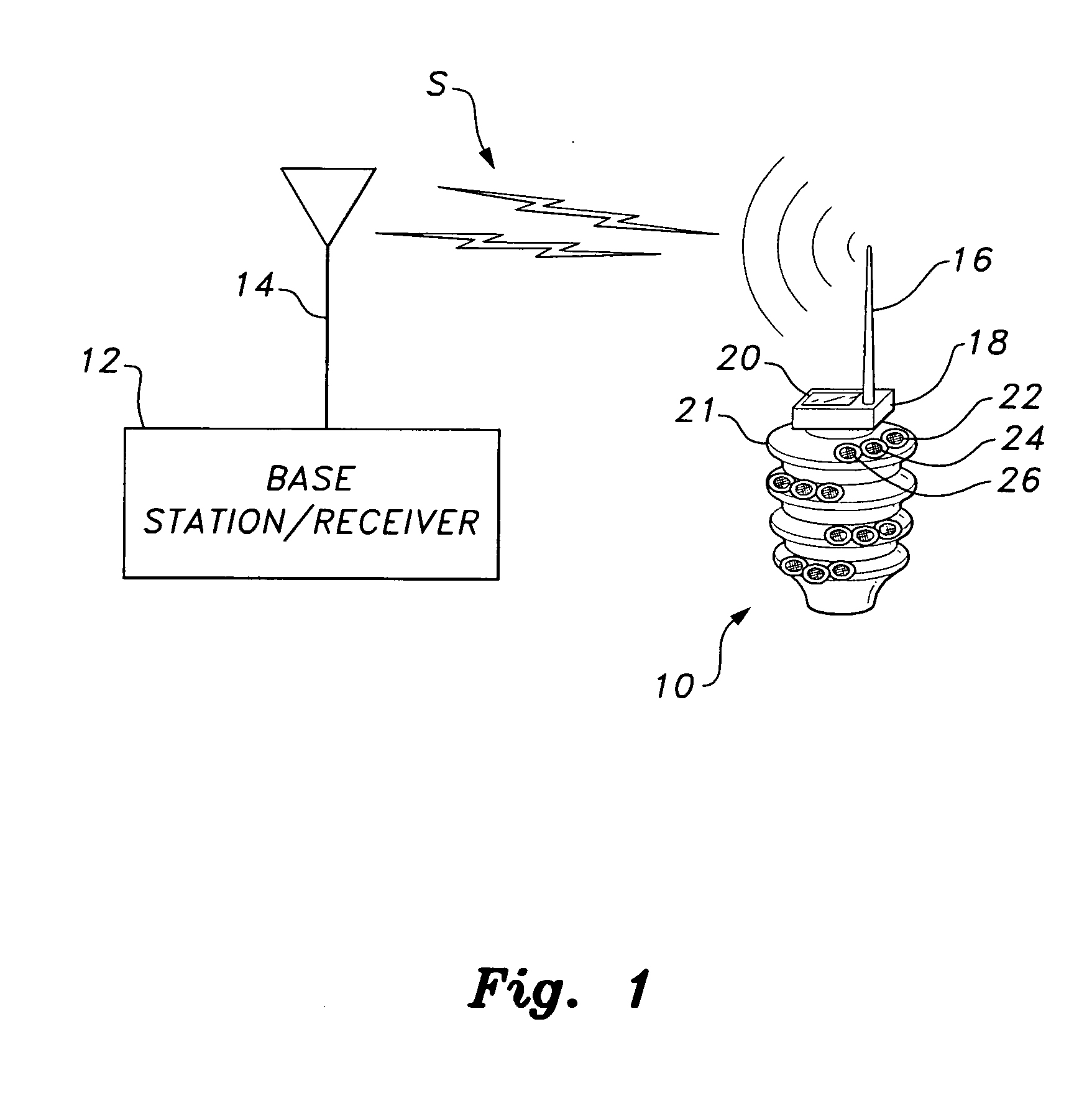

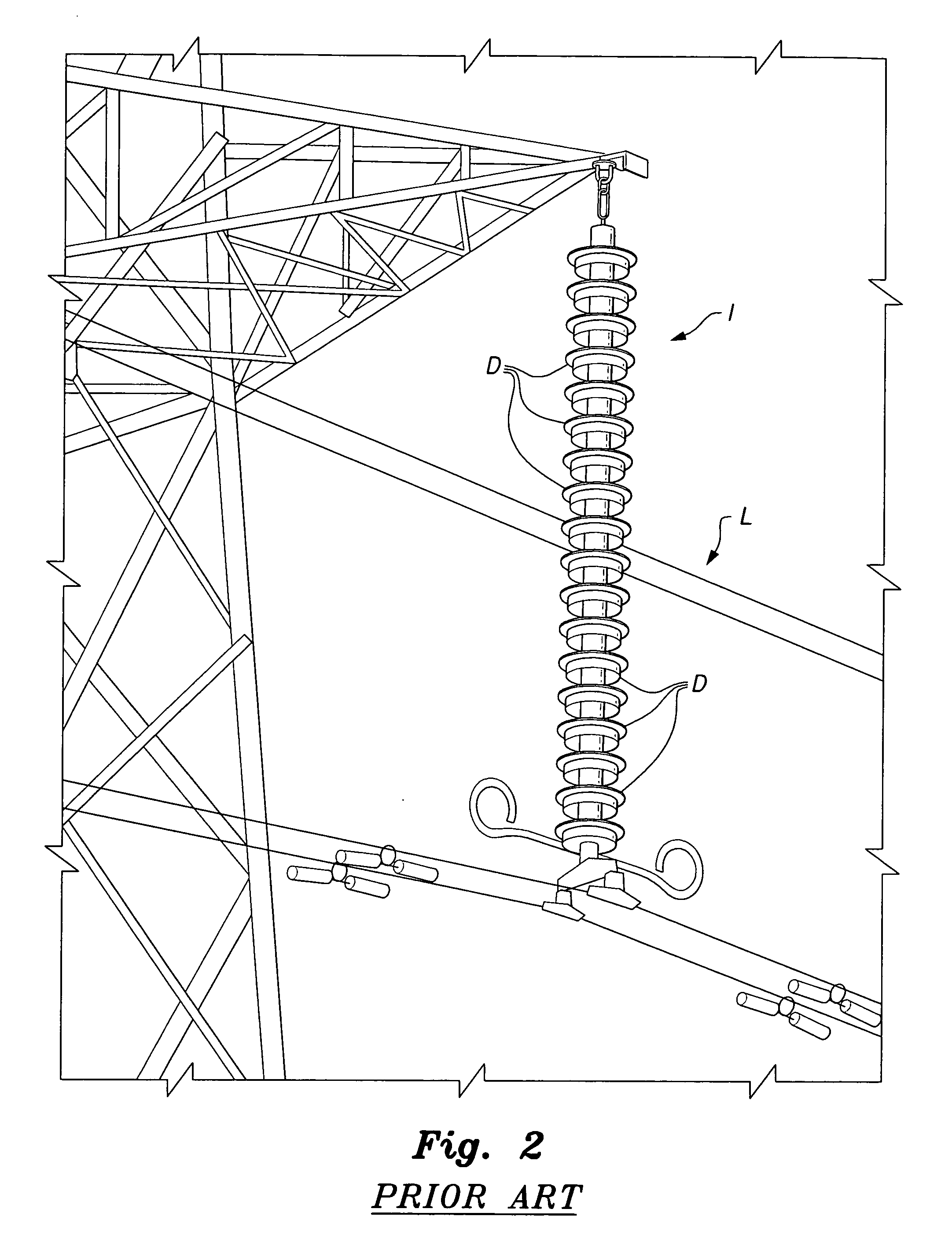

Monitoring and early warning alarm system for high voltage insulator failure

The monitoring and early warning alarm system for high voltage insulator failure provides an early predictor for high voltage insulator failure, allowing repairmen to either already be on site when a high voltage insulator fails in order to expedite repair time, or allowing repair and / or replacement of a faulty insulator before the failure actually occurs. The monitoring and early warning alarm system includes a housing adapted for mounting on a high-voltage power line in proximity to a high voltage insulator associated therewith. A temperature sensor, a contamination sensor, a humidity sensor, or combinations thereof are mounted on the housing and the measured ambient temperature, pollutant contamination and humidity are compared with pre-selected threshold values of temperature, humidity and pollutant contamination. A transceiver transmits an alarm signal when the measured ambient temperature, the measured humidity and / or the measured ambient pollutant contamination are greater than the respective pre-selected threshold values.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

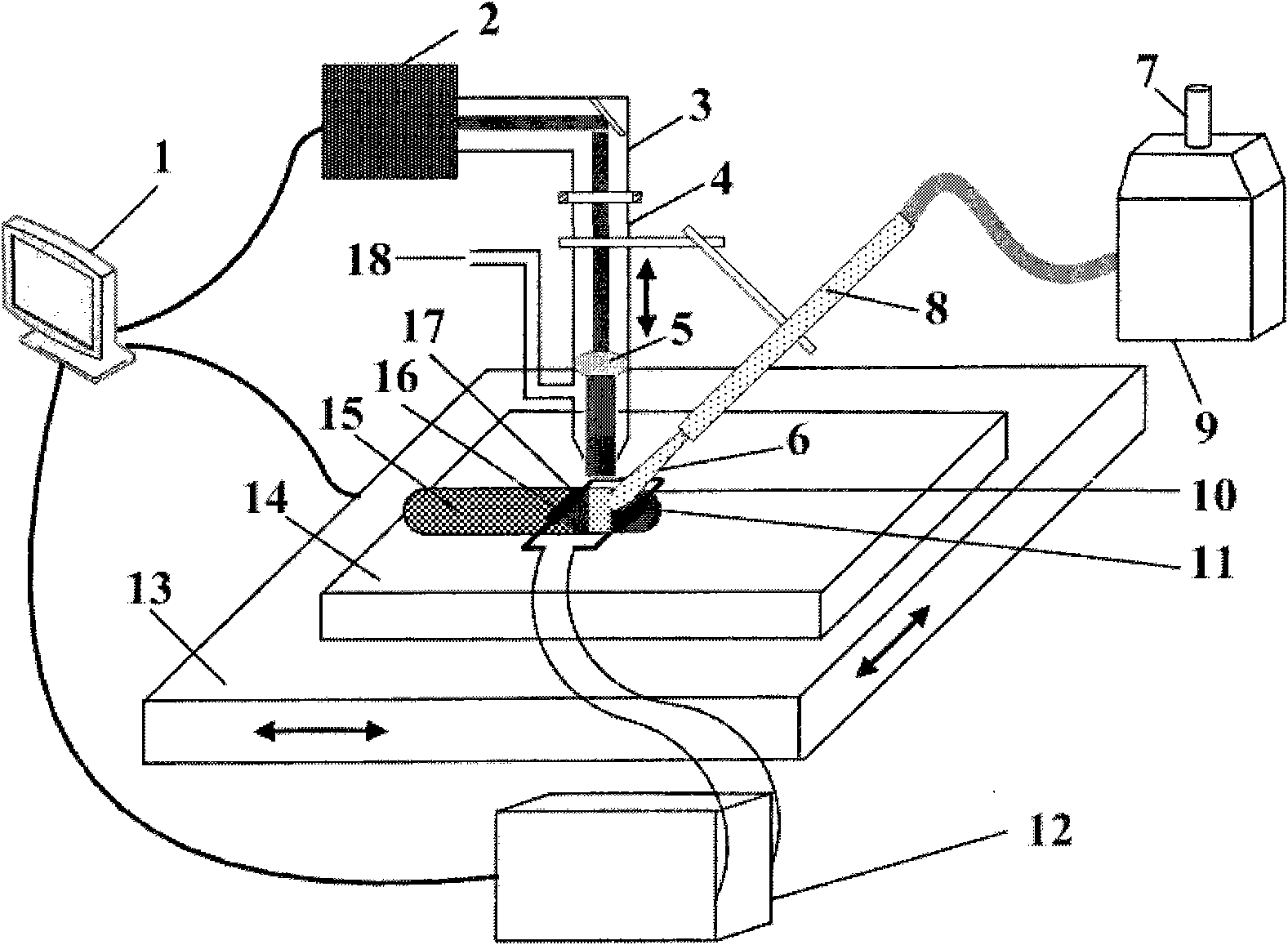

Device and method for steel rail surface online measurement and laser selective repair

ActiveCN102864704AExtended service lifeGuaranteed machining accuracyRailway track constructionMeasuring apparatusComplete dataHead movements

The invention discloses a device for steel rail surface online measurement and laser selective repair, which comprises a machine cart arranged on a steel rail, a three-dimensional scanner, a counter, a laser repairing device and a control device, wherein data measurement is processed for a steel rail surface by dint of the three-dimensional scanner mounted below a power engine body; the three-dimensional CAD graph of a to-be-repaired part is acquired through the comparison between the steel rail surface and a standard steel rail surface; and a complete data chain between the three-dimensional CAD graph of the to-be-repaired part and numerical control codes capable of controlling laser head movement is realized by a layering software. According to the invention, steel rail surface abrasion online measurement is associated with laser online repair equipment by the counter; high-precision selective repair is processed to the steel rail surface abrasion by dint of a high-power laser; repair time is saved; hardly-repaired parts such as a steel rail lateral face, a rail head bottom surface and the like are repaired by dint of filler wire laser repair technology; field adaption capacity is strong; working efficiency is high; and the repair of different steel rail abrasion types can be completed.

Owner:JIANGSU YONGNIAN LASER FORMING TECH

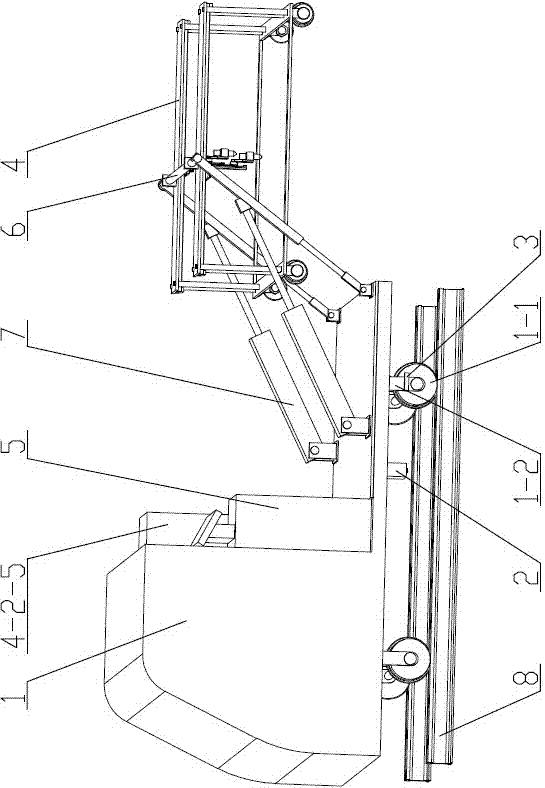

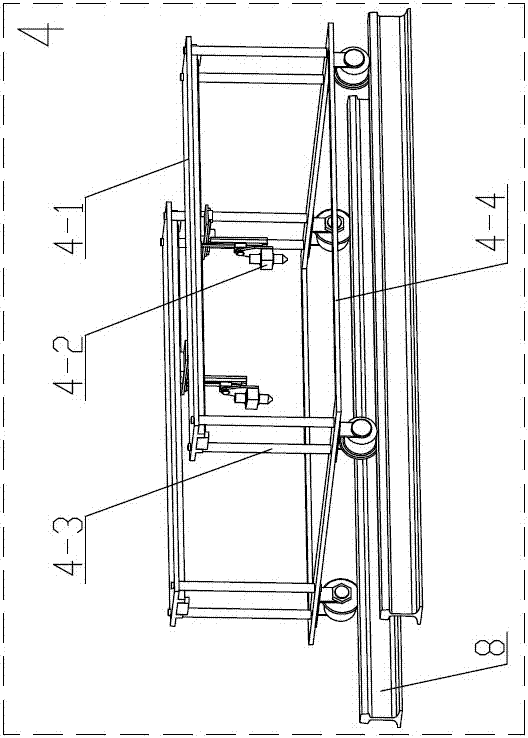

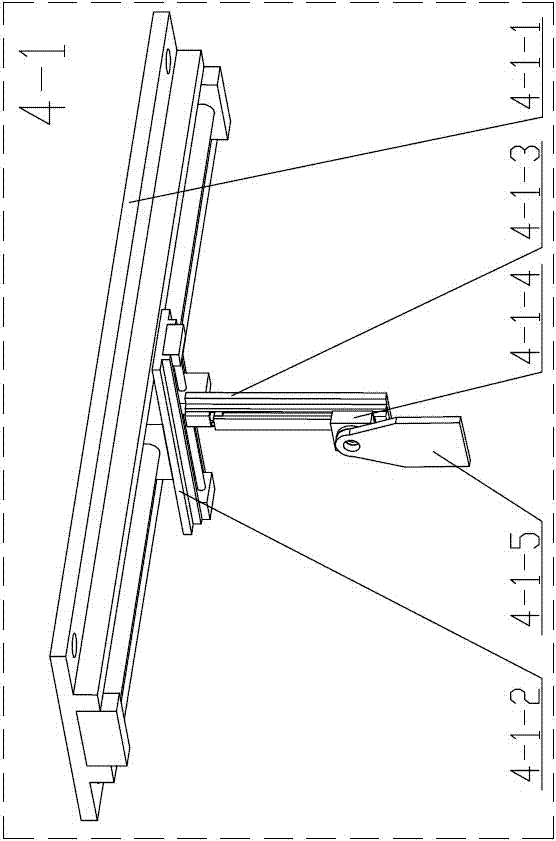

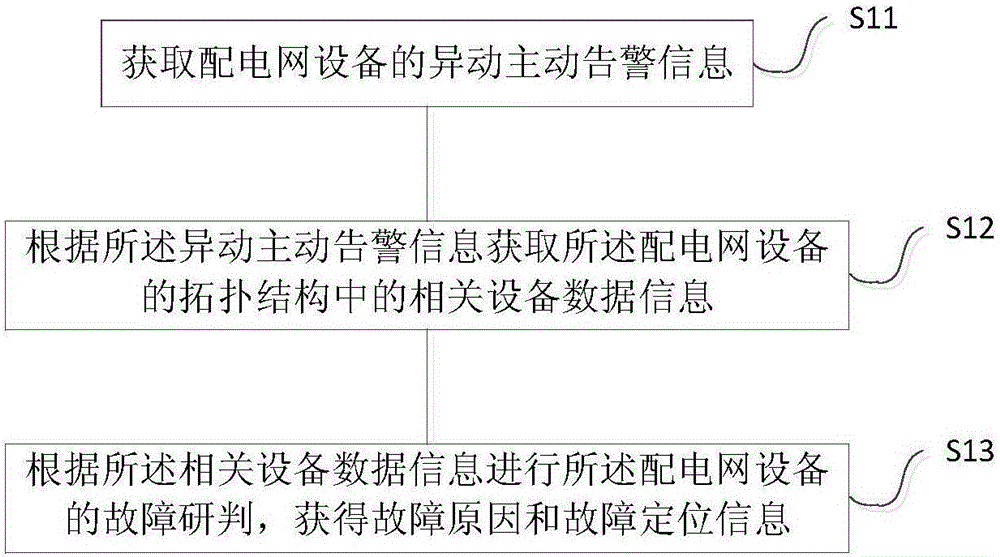

Power distribution network fault active generation and repair scheduling method and apparatus

InactiveCN106291245ASolve blind assignmentSolve invalid dispatchData processing applicationsFault location by conductor typesRepair timeItem generation

The invention discloses a power distribution network fault active generation and repair scheduling method and apparatus. The power distribution network fault active generation and repair scheduling method comprises the following steps: obtaining abnormity active alarm information of distribution network equipment; according to the abnormity active alarm information, obtaining correlation equipment data information in a topology structure of the distribution network equipment; and according to the correlation equipment data information, performing fault study and determining on the distribution network equipment so as to obtain fault causes and fault positioning information. According to the invention, the problems of long fault first-aid repair time and low working efficiency due to blind and ineffective labor distribution of a power supply company are solved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

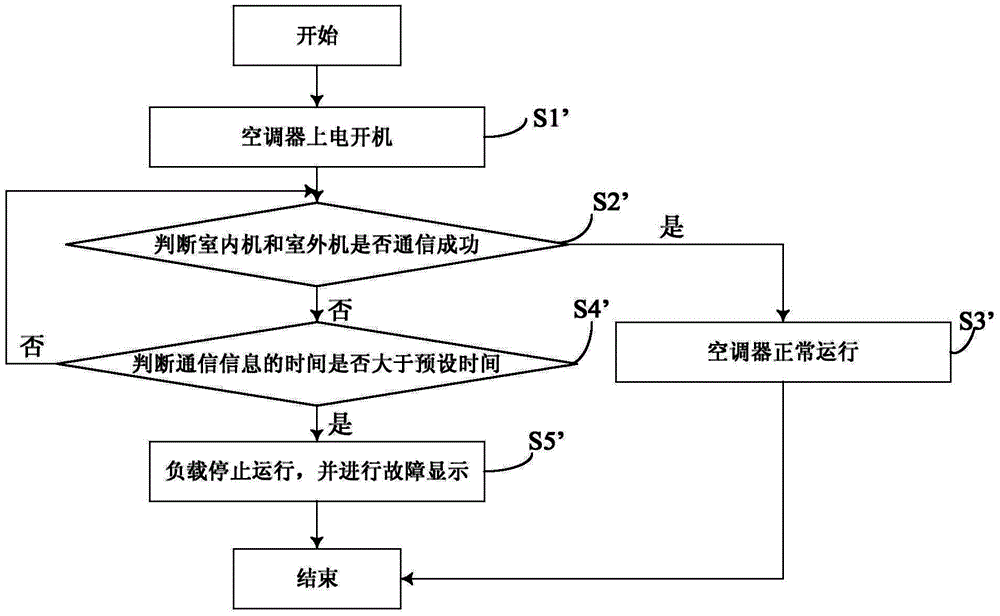

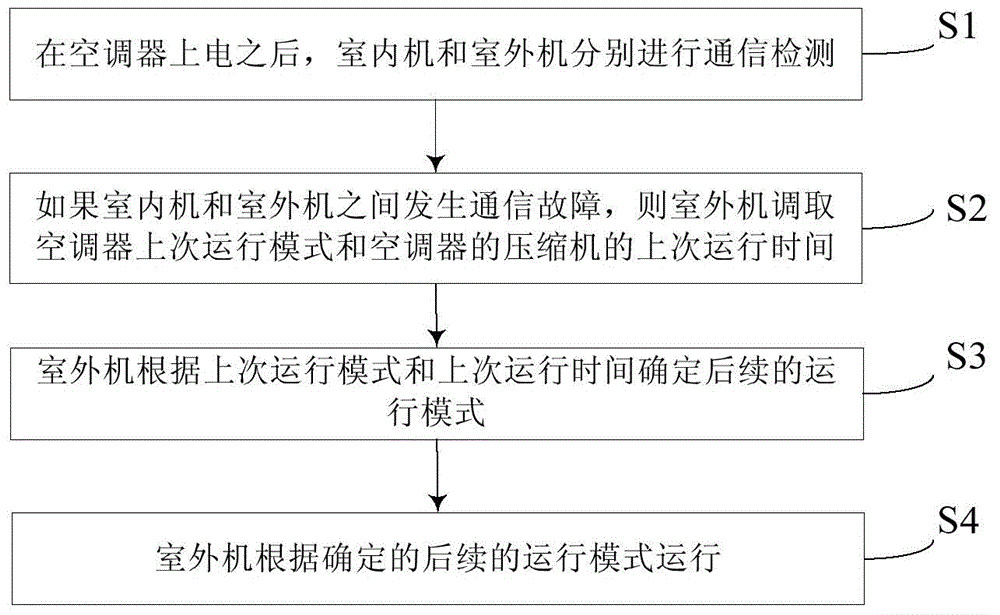

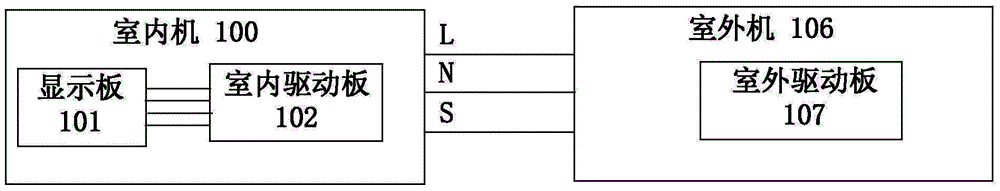

Control method of air conditioner

ActiveCN104807129AGuaranteed uptimeMeet needsMechanical apparatusSpace heating and ventilation safety systemsElectricityRepair time

The invention provides a control method of an air conditioner. The air conditioner comprises an indoor unit and an outdoor unit which communicate with each other. The control method comprises the steps of respectively performing communication detection for the indoor unit and the outdoor unit after the air conditioner is electrified; in case of communication fault between the indoor unit and the outdoor unit, calling the previous operation module of the air conditioner and the previous operation time of a compressor of the air conditioner through the outdoor unit; determining the subsequent operation mode through the outdoor unit according to the previous operation mode and the previous operation time; running the outdoor unit according to the determined subsequent operation mode. According to the method, the indoor unit and the outdoor unit can continuously run in case of communication fault, and a fault code can be displayed, so that the comfort of a user in use can be ensured, the repair time is gained for the after-sell service people of a manufacturer, the complaint can be reduced, and the satisfaction of the user can be increased.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

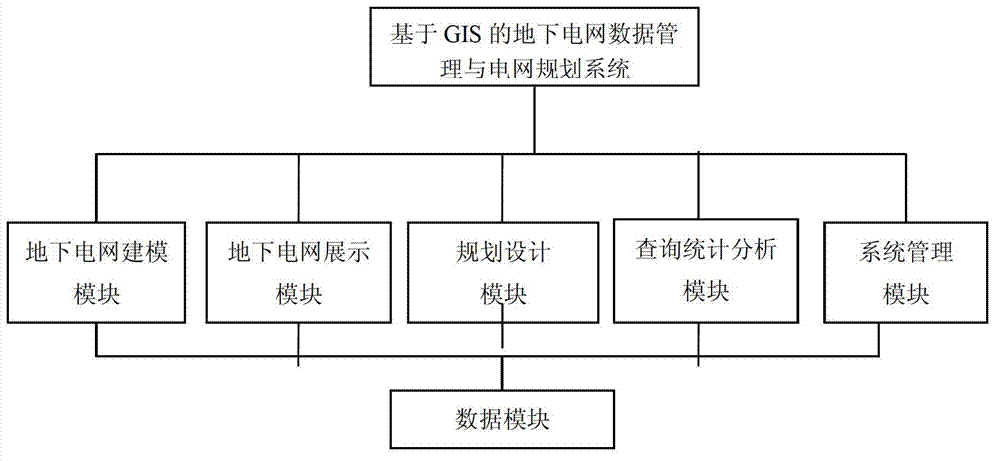

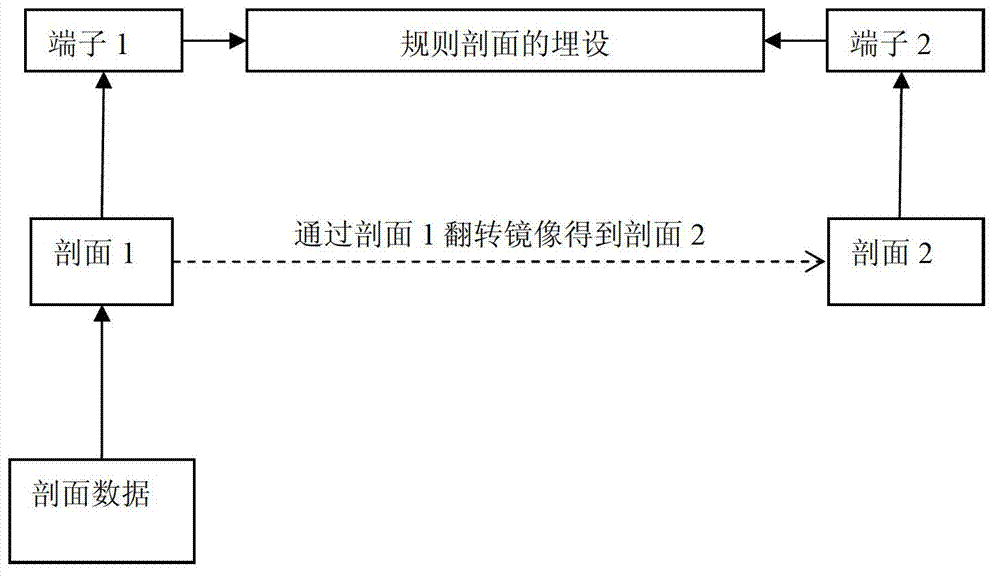

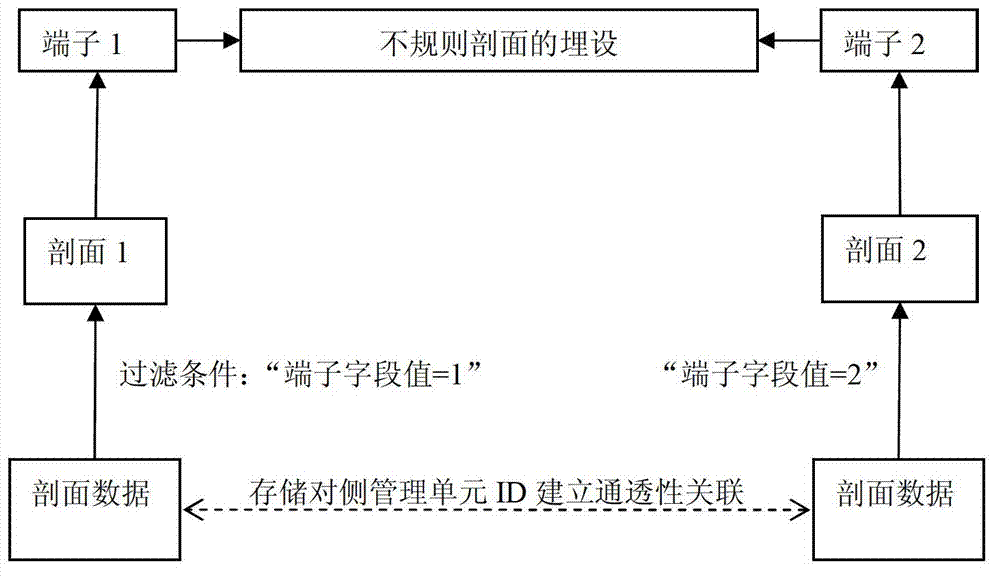

Underground power network data management and power network planning system and management method

The invention provides an underground power network data management and power network planning system and a management method. The system includes a data module, wherein the data module is connected with an underground power network modeling module, an underground power network display module, an inquiry statistics analysis module, a planning design module and a system supervision module respectively. The underground power network data management and power network planning system and the management method, provided by the invention, provide an information management platform for production management personnel to comprehensively master the present situation of the underground power network, guarantee the safe operation of the underground power network and reduce the economic loss caused by electric cable accidents; the informatization construction of the underground power network is facilitated, the power cable management level is improved; the conventional resources are utilized to the utmost extent, land occupied for electric power construction is saved, and duplicate construction is reduced; the speed for emergency rescue is improved, the failure emergency repair time is shortened, power supply volume is increased; and the working efficiency and working quality are improved, and cost of human resources is saved.

Owner:STATE GRID CORP OF CHINA +1

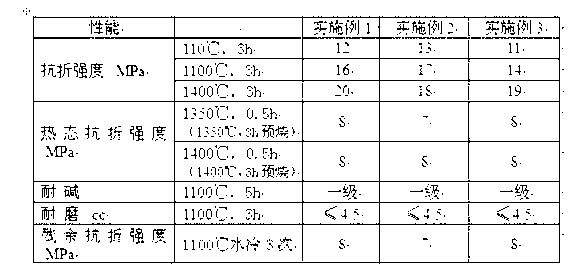

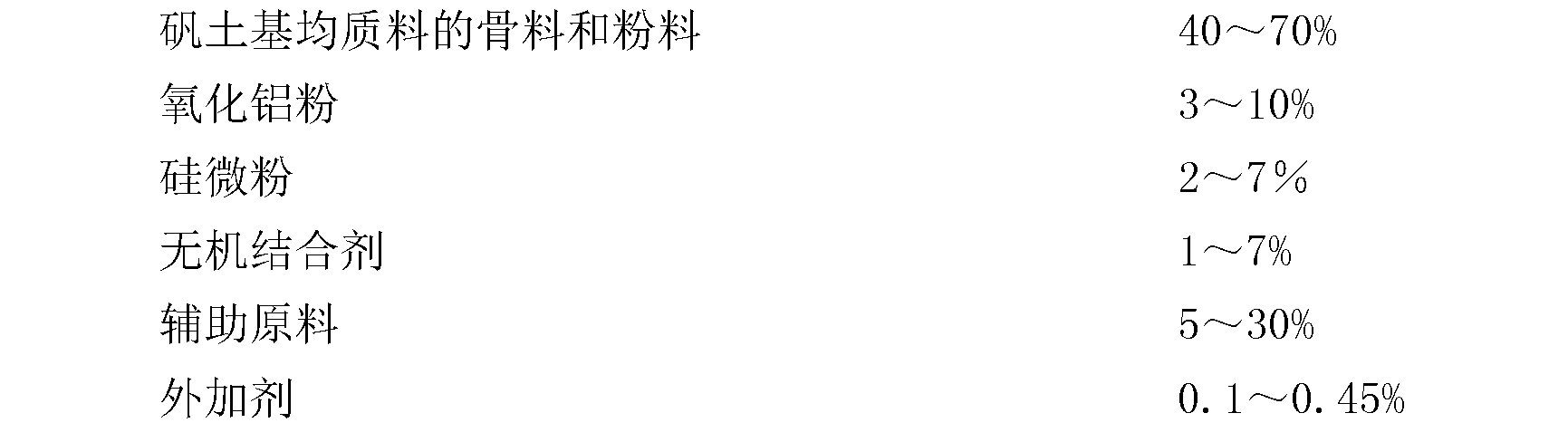

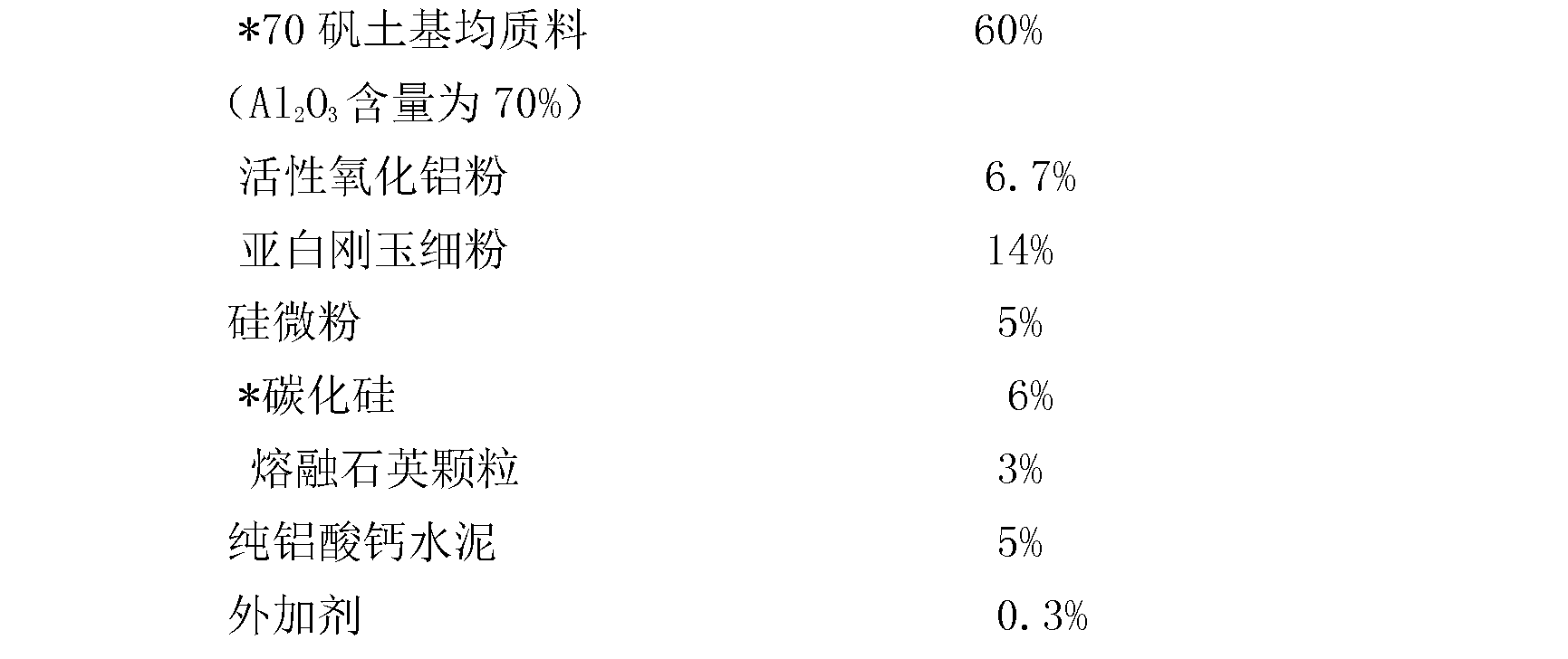

High-strength and anti-stripping type homogenous composite castable and preparation method

The invention provides a high-strength and anti-stripping type homogenous composite castable and a preparation method, and belongs to the technical field of refractory castables. The composite castable comprises the following raw materials by mass percent: 40 to 70% of aggregate and powder of bauxite-based homogenized grogs, 3 to 10% of alumina powder, 2 to 7% of silica powder, 1 to 7% of inorganic binding agent, 5 to 30% of auxiliary raw material, and 0.1 to 0.45% of additive. An efficient dispersing agent and proper additive components are adopted and are prepared into the high-strength and anti-stripping type homogenous composite castable through the blending technique. The high-strength and anti-stripping type homogenous composite castable has the advantages that the composition and structure are uniform, the problems that the conventional high-alumina and corundum castables are low in high-temperature strength, easy to desquamate and crack at high temperature, and poor in resistance to corrosion due to alkali, chlorine and sulfur, can be effectively solved, the life cycle is prolonged, and the plannable performance respect to the maintenance and repair time is improved at the same time.

Owner:YANGQUAN JINYU TONGDA HIGH TEMPERATURE MATERIALS +1

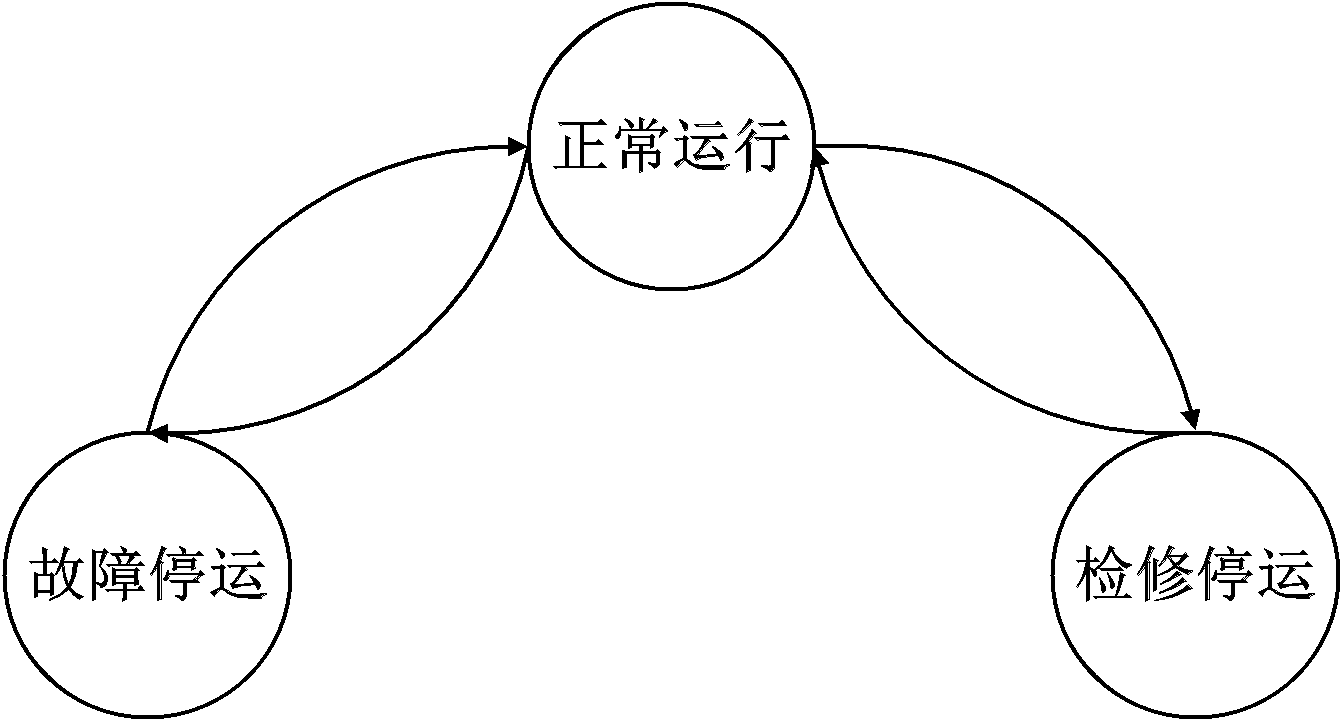

Method for calculating repair cycle of power transformer in operation

ActiveCN102495967AThe maintenance cycle is economical and reasonableImprove usabilitySpecial data processing applicationsSwitchgearFailure rateWork period

The invention discloses a method for calculating a repair cycle of a power transformer in operation. The method has the advantages that: influence of failure-rate level and a repair time interval on the residual life cost of the power transformer is fully considered, a reasonable repair cycle is determined, and equipment management cost is reduced. The method comprises the following steps of: firstly, establishing a power transformer failure rate and average no-failure operation time estimation model on the basis of operating reliability data of equipment; secondly, according to a calculation result of the estimation model, establishing an in-operation power transformer residual life cost model for comprehensively considering the failure-rate level of the equipment and the repair time interval, and classifying the residual life cost into operating cost, repair cost, failure cost, failure loss, operating period indirect cost and disposal cost according to operation type; and finally, with the aim of optimizing the residual life cost, calculating a suggested time interval of the repair cycle of the power transformer.

Owner:JINING POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

System and method for estimating collision damage to a car

InactiveUS20160292759A1Define efficiently and flexibly and accuratelyDefine efficiently, flexibly, and accuratelyBuying/selling/leasing transactionsInput/output processes for data processingRepair timeBody region

For determining an estimate of the collision damage to a car, a body part (3) of the car is displayed in a user interface (100). Through the user interface (100), input is received from the user for drawing on the body part (3) one or more damaged areas (4c, 5c). Specifically, the damaged areas (4c, 5c) are defined in each case by an outline of the damaged areas (4c, 5c), drawn on the body part (3) by way of a drawing tool (108, 108′), or as detected from an image. Subsequently, an estimate of the repair cost (C) and the repair time (T) is generated for the user, based on the damaged area (4c, 5c) drawn on the body part (3). Enabling the user to define the outlines of damaged areas (4c, 5c) makes it possible to define and estimate efficiently, flexibly, and accurately collision damage to a car.

Owner:AUDATEX

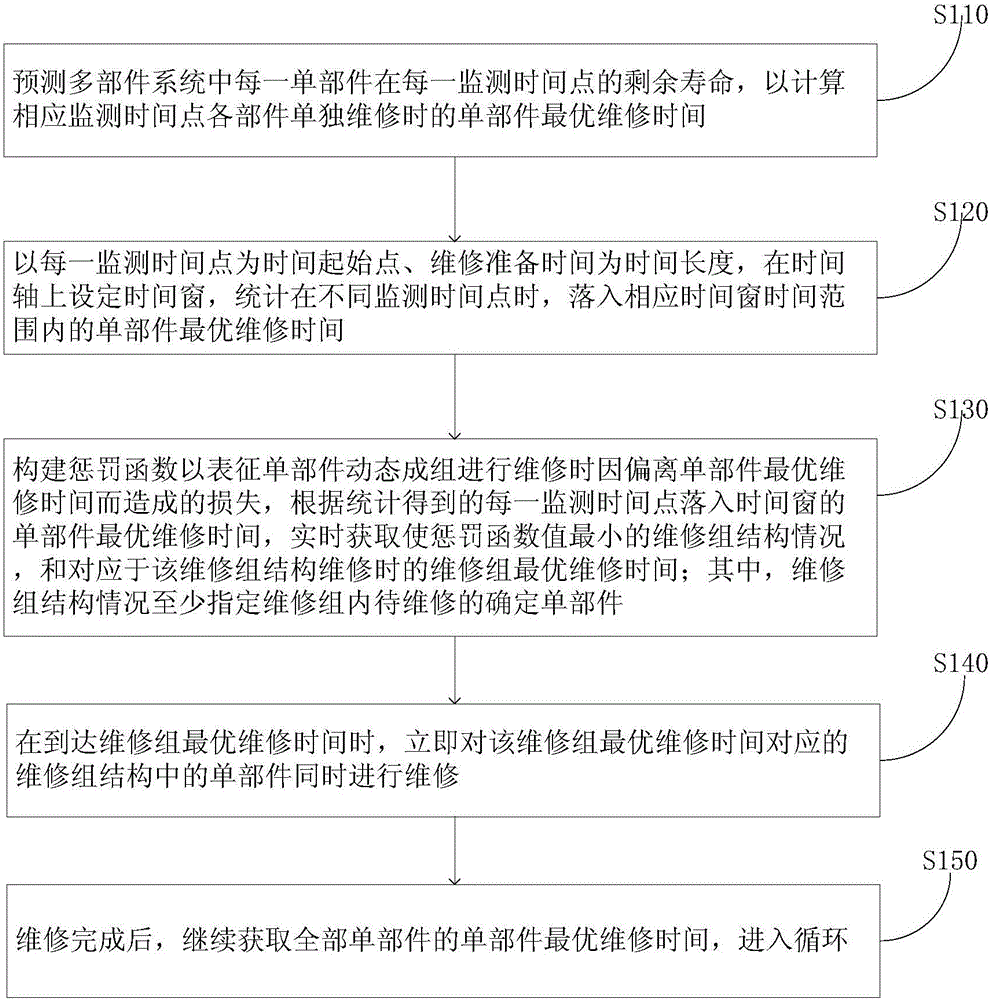

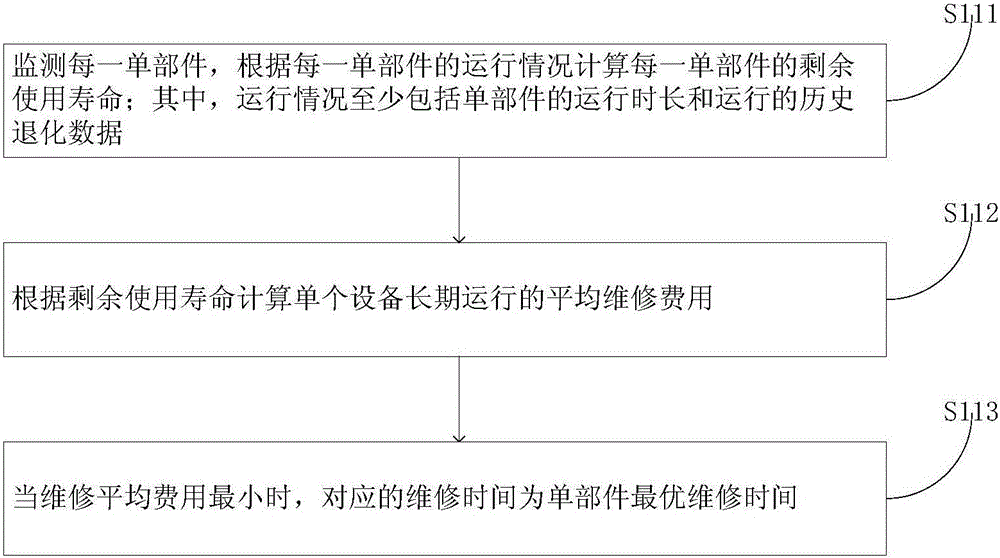

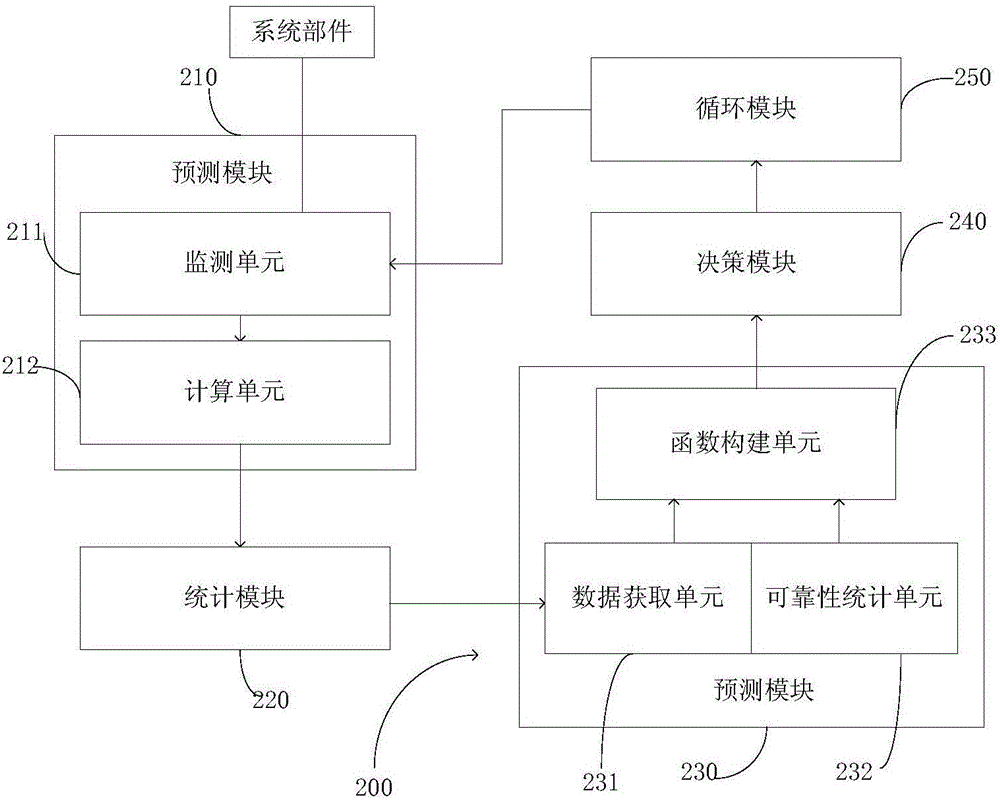

Multi-component system group maintenance decision method and multi-component system group maintenance decision device based on prediction

The invention discloses a multi-component system group maintenance decision method and a multi-component system group maintenance decision device based on prediction. The method comprises the following steps: predicting the residue life of single components at a monitoring time point, and calculating the single-component optimal maintenance time; setting a time window with each monitoring time point as the starting time point and the maintenance preparation duration as the time length, and calculating the single-component optimal maintenance time falling into the time range of the time window; building a penalty function, and acquiring a maintenance group structure with minimum penalty function value and the maintenance group optimal maintenance time according to the calculated single-component optimal maintenance time falling into the time window for each monitoring time point; grouping-maintaining the single components in the maintenance group structure; and after maintenance, continuing acquiring the single-component optimal maintenance time, and so on. According to the invention, the most saving group maintenance mode for maintenance of a multi-component system can be decided according to the predicted single-component residue life, so that the maintenance cost is saved, the downtime is reduced, and the loss is reduced.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

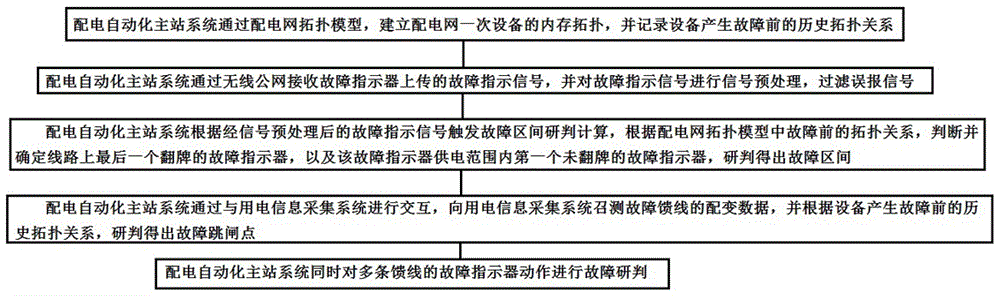

Grid fault research and judge method based on fault indicator and public/specific transformer

ActiveCN105606957AImprove utilizationEfficient integrationFault location by conductor typesFault indicatorGrid fault

The invention relates to a grid fault research and judge method based on a fault indicator and a public / specific transformer, the method comprises the steps: a distribution network topology model in a distribution automation master station system establishes the internal storage topology of distribution network primary equipment and records the historical topological relation before the equipment fault; when the fault occurs on a feeder, the distribution master station system performs preprocessing on a received fault indication signal to filter false information; combined with the historical topological relation, the distribution master station system performs researching and judging to quickly position a fault section according to flip operation of the preprocessing; combined with the historical topological relation and distribution transform historical data, the distribution master station system uses collected data interoperated with an usage and collection system to quickly position tripping equipment. According to the invention, the method can timely and quickly prompt a dispatcher and point out the fault section and tripping equipment, the efficiency and intellectuality during the fault emergency repairing process are improved, so that the line patrol range is greatly narrowed, the fault repairing time is shortened, and the efficiency of the power distribution repairing work is improved.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com