Device and method for steel rail surface online measurement and laser selective repair

A repair method and laser repair technology, applied in the directions of measuring instruments, tracks, laying tracks, etc., can solve the problems of insufficient positioning accuracy, long repair time, low repair efficiency, etc., and achieve high work efficiency, high repair efficiency, and repair saving. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

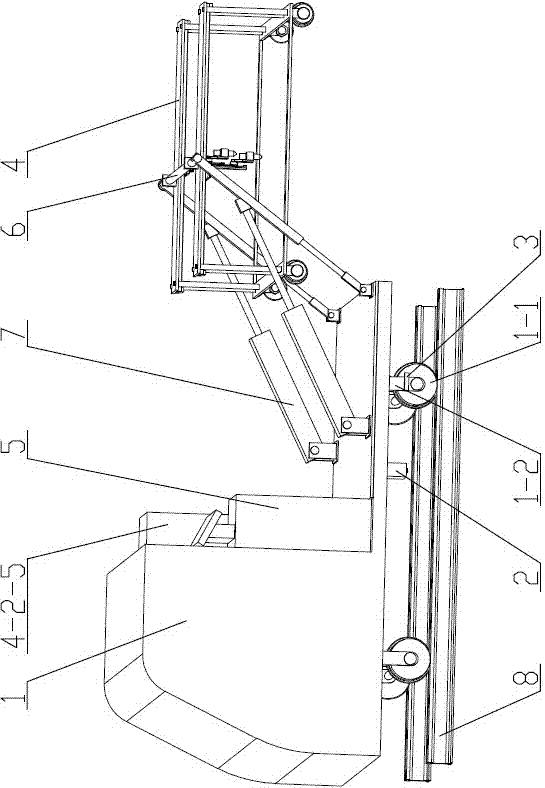

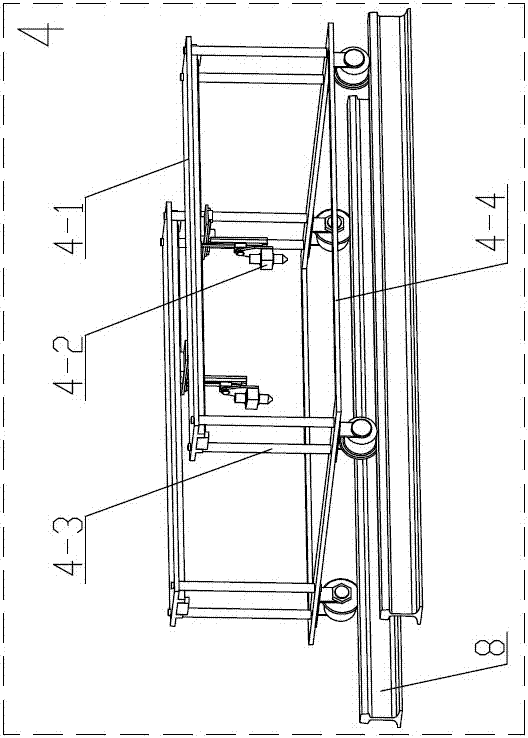

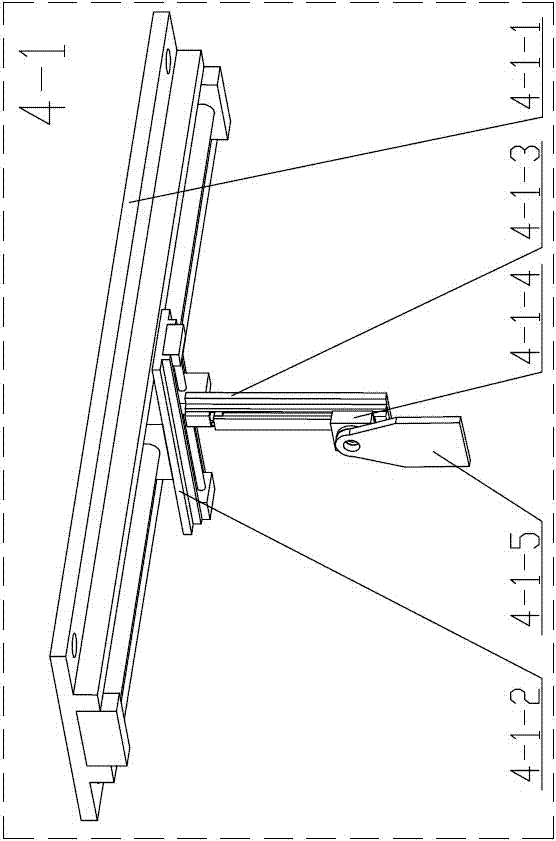

[0038] Such as figure 1 Shown is the structural schematic diagram of the device for on-line measurement of the rail surface and laser selective repair of the present invention, including a locomotive 1 arranged on the rail 8 track, and: a three-dimensional scanner 2: assembled under the body of the locomotive 1, for scanning the locomotive 1 Rapidly scan and measure the rail surface during the running process, and collect the three-dimensional profile data of the rail surface; counter 3: installed on the outside of the locomotive 1 wheel hub fixing frame, used to monitor the worn parts of the rail during the rail surface data collection process and laser repair process. Positioning; rail repair device 4: installed at the tail of the locomotive 1, pulled by the locomotive 1, locate the rail wear according to the three-dimensional conto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com