Patents

Literature

51results about How to "High thermal strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear and corrosion resistant castable prepared from bauxite-based homogenous material and preparation method thereof

ActiveCN101885617AUniform structureSmall fluctuations in water addition during constructionPliabilityCement kiln

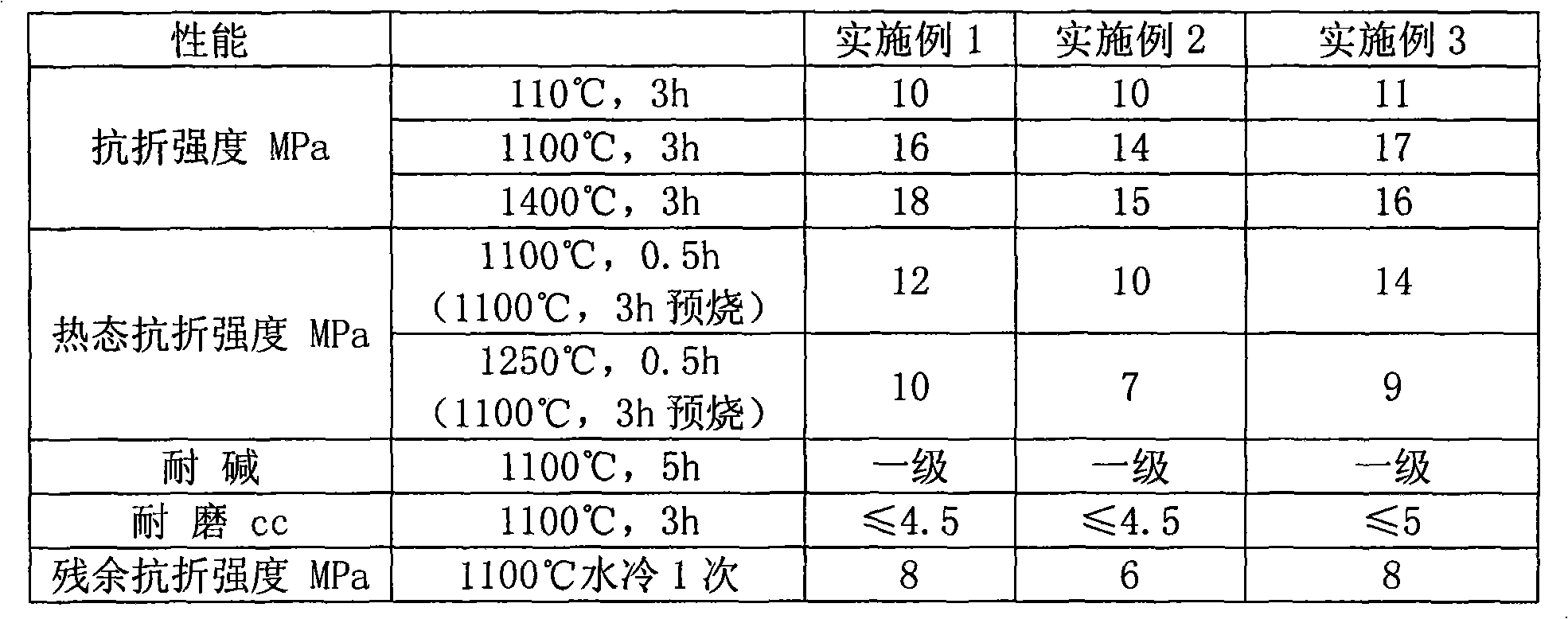

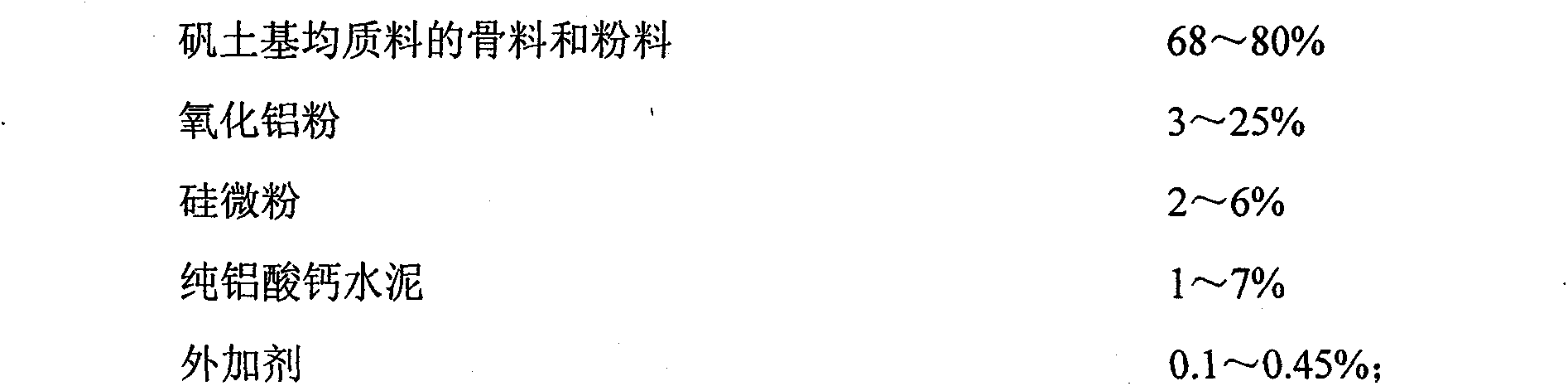

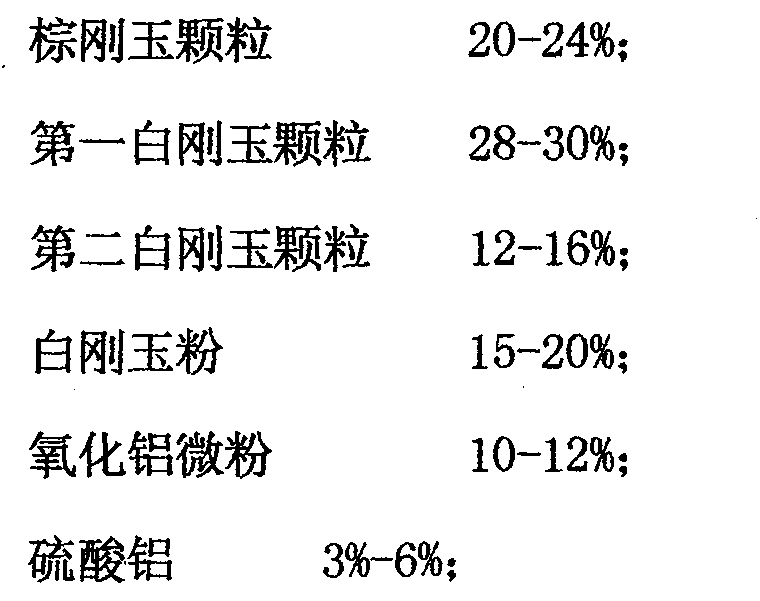

The invention discloses wear corrosion resistant castable prepared from a bauxite-based homogenous material and a preparation method thereof, which belong to the technical field of castable refractory. In the invention, by using the characteristics of the bauxite-based homogenous material, such as homogeneous chemical components and structure, stable performance, mulite main crystal phase, small linear change, high high-temperature strength and certain flexibility due to mutual insertion of micro crystals and the like, the shortcomings of low middle-temperature strength and poor wear resistance and alkali corrosion resistance of the conventional high-aluminum bauxite castable are overcome, and the problems of low middle-temperature strength, poor wear resistance and poor alkali, chloride and sulphur corrosion resistance of the conventional high-aluminum and corundum castable are effectively solved. The wear and corrosion resistant castable with high middle-temperature performance is prepared. The wear corrosion resistant castable and the preparation method thereof have the advantages of small fluctuation of water adding amount in construction, stable usability, reduction rate of partial corrosion, prolonged service life and wide application to a kiln hood, a grate cooler, a tertiary air duct and a decomposing furnace of a dry process cement kiln and relative parts of other ceramic and petrified thermo-technical kilns and the like.

Owner:YANGQUAN JINYU TONGDA HIGH TEMPERATURE MATERIALS +1

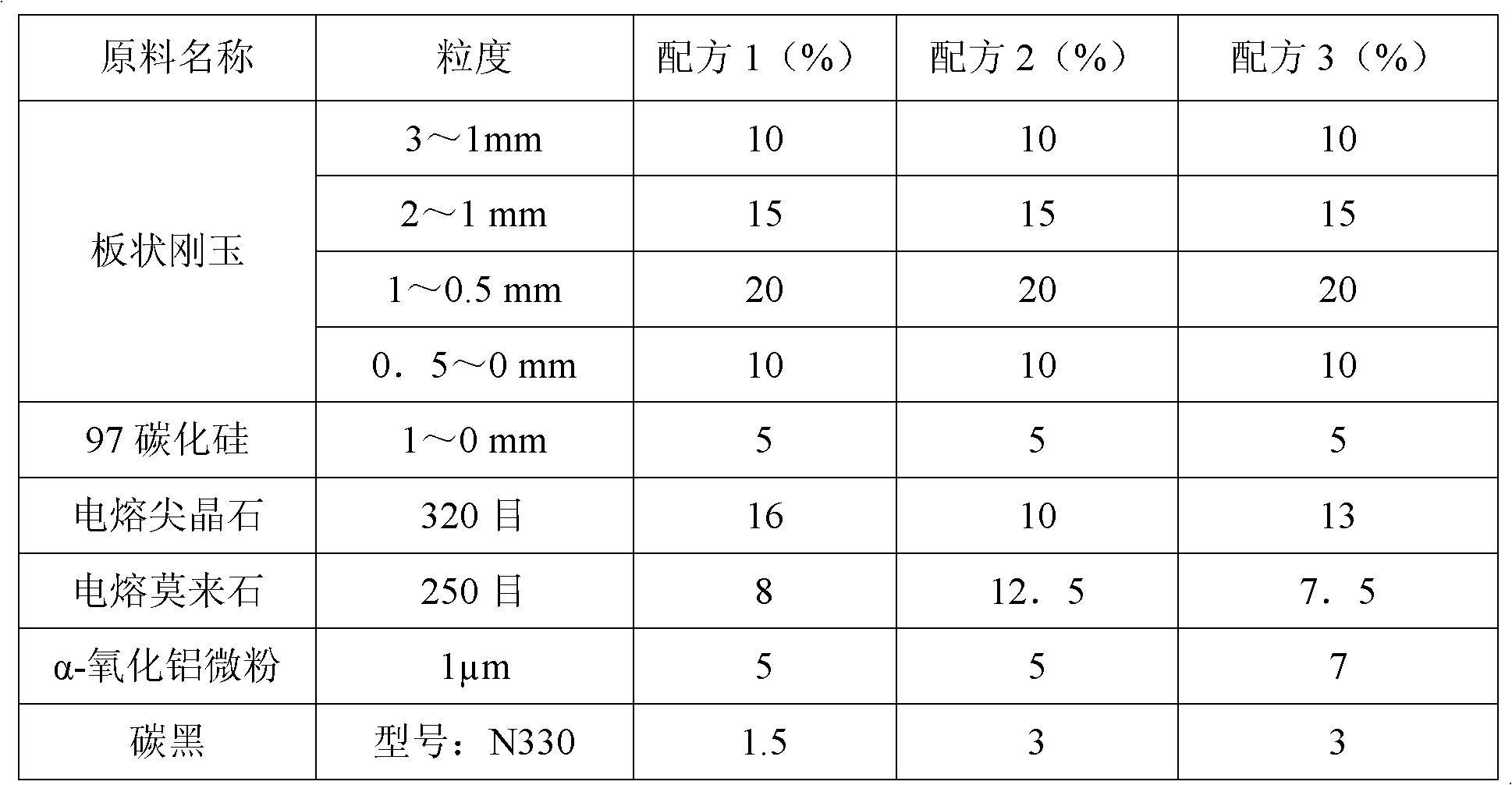

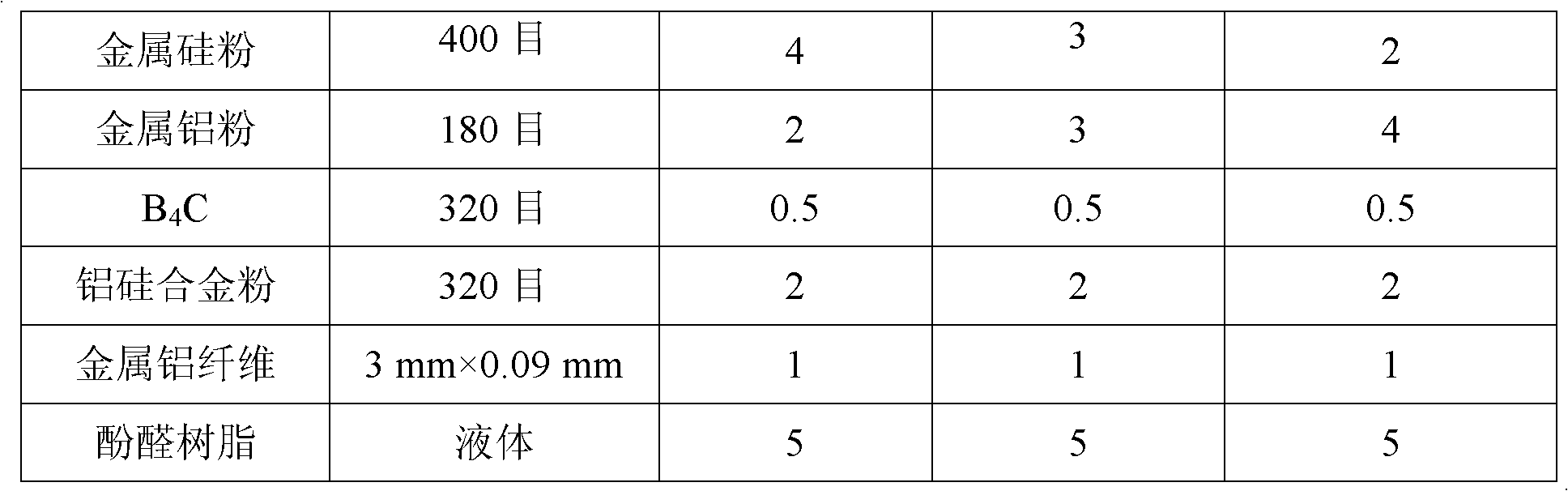

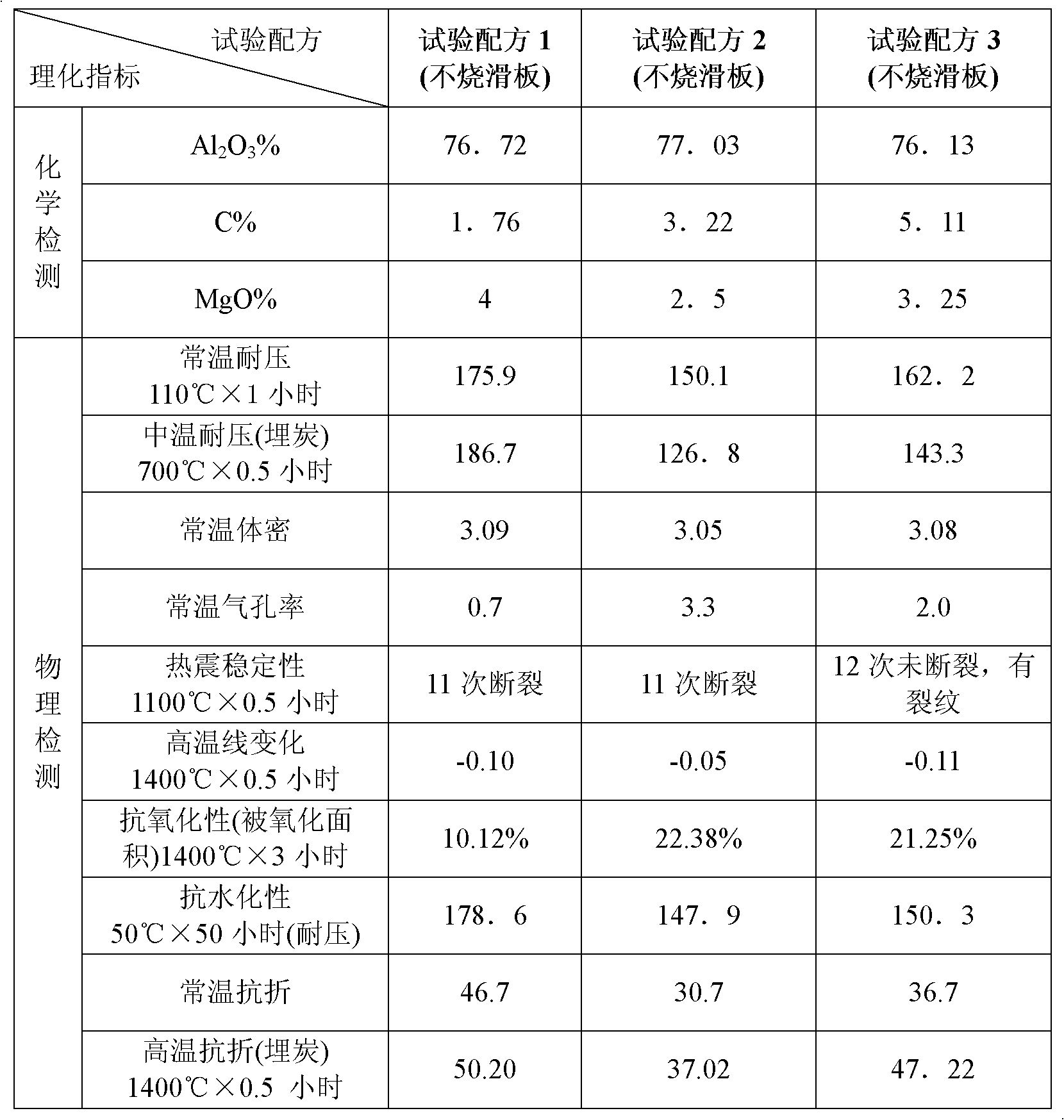

Metal ceramic combination sintering free low carbon sliding plate brick and preparation method thereof

The invention discloses a metal ceramic combination sintering free low carbon sliding plate brick and a preparation method thereof. The sliding plate brick comprises the following components according to weight percentage: 50%-60% of sintered plate shape alundum, 10%-25% of electric melting akerite, 5%-15% of electric melting mullite, 1%-3% of soot carbon, 3%-8% of Alpha- aluminum oxide micropowder, 5%-10% of silicon carbide, 2%-5% of metallic silicon powder,1%-5% of metallic aluminium powder, 0.5%-1% of boron carbide, 1%-3% of aluminum-silicon alloy powder, and 0.5%-2% of metallic aluminium fiber. In the invention, the product has low carbon, high thermal state strength, thermal shock resistance and good oxidation resistance, hole reaming is uniform, galling is less and the crack is verysmall; the process of the invention is characterized in that drying is carried out at a low temperature, the production cycle is shortened from 30 days originally to 7 days, the natural gas consumption is reduced to 2.5% of original technology, and the sintering free low carbon sliding plate brick is indeed belongs to the environmental protective and energy-saving and environmental material resistance product.

Owner:无锡市南方耐材有限公司

Cement-free in-situ silicon nitride combined silicon carbide prefabricated member and preparation method thereof

The invention discloses a cement-free in-situ silicon nitride combined silicon carbide prefabricated member and a preparation method thereof. The cement-free in-situ silicon nitride combined silicon carbide prefabricated member is formed by taking silicon carbide, metallic silicon powder, alumina micro powder, silicon dioxide micro powder and hydraulic alumina as materials and additionally adding dispersing agent, water or silica sol. The prefabricated member is formed by adopting a vibration pouring method, is cured and dried and subjected to high-temperature nitrogen treatment in a high-purity flowing nitrogen gas. The prefabricated member has the advantages of easy construction, low cost, flexible product shape, high hot strength, strong corrosion resistance, high wear resistance and the like and is widely applied to parts strictly requiring the hot-state performance, such as a wind-force pipeline of a cement kiln, a blast-furnace throat, an air port, a delivery pipeline of melt metal, a garbage incinerator and the like.

Owner:HENAN UNIV OF SCI & TECH

Anhydrous stemming and preparation method thereof

The invention provides an anhydrous stemming and a preparation method thereof. The anhydrous stemming is composed of the following raw materials: 15 to 25 % of corundum aggregate, 10 to 20 % of corundum powder, 10 to 15 % of redstone, 10 to 15 % of silicon carbide, 0 to 8 % of silicon nitride iron, 12 to 16 % of plastic clay, 13 to 18 % of coke powder, 4 to 8 % of high-temperature asphalt, 1 to 2 % of applied borax or boric acid and 14 to 20 % of applied tar. The preparation method is characterized by using a production apparatus such as a powerful mixer, and comprising steps of: blending the above raw materials, dry-mixing in the mixer for 1 to 2 minutes, adding 80 to 90 % of the tar with stirring, finely adjusting an adding amount of the tar in accordance with the stemming situation after stirring for 2 to 10 minutes, continuously stirring for 15 to 30 minutes, and molding with compression by using an extruder. The stemming provided by the invention has good performances of rapid sintering and high temperature, shrinks relatively small after being burnt, and can greatly reduce adverse phenomena of large mud, broken iron notch, long-time splashing, rapid hole reaming, etc. A new production technology is employed to ensure long-term stability of product quality, and thus the stemming has good workability and using performance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Cold bending electrical protective casing and manufacturing method thereof

ActiveCN102702644AImprove gelationImprove rigidityElectrical apparatusThermal statePolyvinyl chloride

The invention relates to a PVC (Polyvinyl Chloride) tube, in particular to a manufacturing method of a cold bending electrical protective casing. The cold bending electrical protective casing is prepared from the following components by weight: 75 kg of PVC resin, 3.8 kg of composite stabilizer, 0.5 kg of stearic acid, 0.5 kg of chlorinated polyethylene, 3 kg of titanium dioxide, 0.6 kg of paraffin, 30 kg of light calcium carbonate and 1 kg of 401 auxiliary agent. The formula of the cold bending electrical protective casing is not influenced by seasonal temperature. The 401 processing modification auxiliary agent is added after adjustment, so that plasticizing, toughening and weathering resistance of the PVC product are promoted by a low-temperature modification toughing agent. By adding 401 into the PVC product, the PVC gelling and plasticizing effects can be promoted. Through plasticizing process operation, the PVC multiple particle structure is damaged, the release of primary particles of the PVC is promoted, a PVC extrusion processing process is formed, the plasticizing is quick, the viscosity is increased, and the thermal state strength is improved.

Owner:安徽玉发塑业有限公司

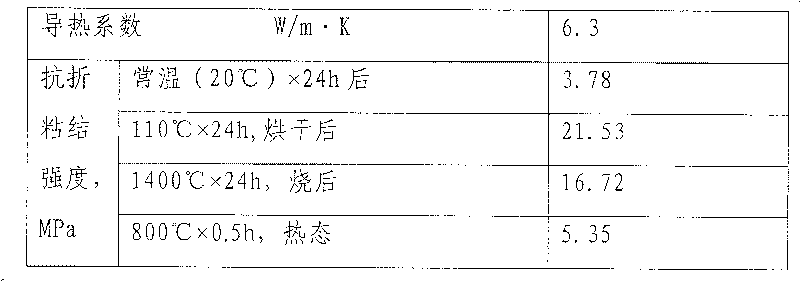

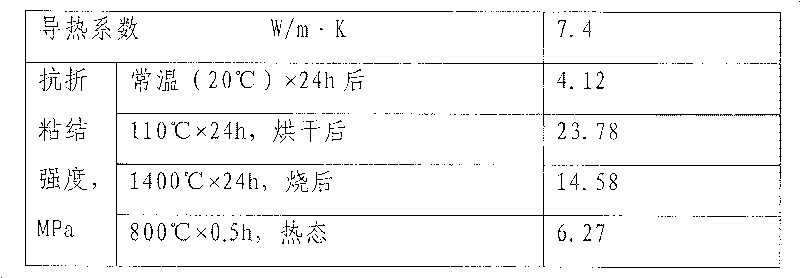

Composite mortar for building blast furnace stack graphite brick and carborundum brick

This invention discloses a composite daub of graphite bricks and SiC bricks for building stacks of furnaces, in which, the daub is composed of SiC, graphite, binder, antioxidation agent and a solidifying agent mixed in proportion, since SiC has high intensity under high temperature, the graphite material has high heat conduction performance and the binder strengthens the adhesive performance and anti-high temperature performance of the daub, the solidifying agent strengthens the plastic and self-modification function of the composite daub under high temperature, the invented daub has the property of high heat-conduction coefficient and hot state high intensity under 800-1400deg.C and can be used in building composite kiln lining composed of graphite bricks and SiC bricks.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Prefabricated part of coal injection pipe head

The invention relates to a prefabricated part of a coal injection pipe head, belonging to the field of refractory materials. The prefabricated part is prepared by the following steps: evenly mixing sintered mullite, white corundum fine powder, carborundum, sillimanite, alpha-alumina micropowder, silica micropowder, pure calcium aluminate cement and water reducing agent, which are crushed to specified granules, with water according to parts by weight; and carrying out vibration casting and conventional curing, and baking. The product has the advantages of high thermal-state strength, high temperature resistance, wear resistance, stable performance, favorable integrity, favorable anti-stripping property, favorable scour resistance and the like. The prefabricated part is directly sheathed onthe coal injection pipe head, and thus, is convenient for construction and maintenance and is safe and reliable, thereby greatly shortening the construction period.

Owner:宜兴市泰科耐火材料有限公司

Al2O3-SiC-C refractory brick for torpedo ladles and preparation method thereof

The invention discloses an Al2O3-SiC-C refractory brick for torpedo ladles and a preparation method thereof, which relate to the fields of refractory bricks and preparation methods thereof. The refractory brick is composed of the following raw materials in parts by weight: 25-35 parts of super bauxite clinker, 15-25 parts of corundum particles with a particle size of 0.2-1 mm, 3-5 parts of a phenolic resin, 12-18 parts of fine corundum powder, 10-15 parts of fine SiC powder, 3-5 parts of alumina micro-powder with a particle size of 1-5mu m, 8-15 parts of natural flake graphite and 2-4 parts of Si powder; and Si3N4, Si2N2O and Sialon nonoxide reinforced phases are generated in the refractory brick. The preparation method of the refractory brick comprises the steps of material mixing, forming and nitriding treatment. Compared with traditional Al2O3-SiC-C bricks for torpedo ladles, the Al2O3-SiC-C refractory brick for torpedo ladles disclosed by the invention can significantly improve the hot strength, scour resistance and thermal shock resistance of a brick body.

Owner:河南海格尔高温材料有限公司

Amorphous refractory and corrosion resistant material for inert anode aluminum cells and manufacturing method thereof

The invention relates to an amorphous refractory and corrosion resistant material for inert anode aluminum cells and a manufacturing method thereof. The preparation of the material is characterized by employing sintered tabular corundum particles as the aggregate, powder selected from several of sintered tabular corundum fine powder, magnesia-alumina spinel fine powder, multi-peak sintered alumina micropowder with different particle size distributions, activated alumina micropowder, activated Rho-Al2O3 micropowder, dispersion alumina micropowder and pure calcium aluminate cement as the substrate, fiber as the reinforcing and toughening agent for mixing. Able to well resist electrolyte atmosphere corrosion, the amorphous refractory and corrosion resistant material of the invention has the advantages of high hot strength, good thermal shock resistance, easy implementation, long service period, relative low cost, etc. The material provided in the invention is suitable for heat preservation and sealing of industrial inert anode aluminum cells, especially the upper parts of cells, and can be used to directly face a fused electrolyte liquid surface and areas with invaded by an electrolyte atmosphere.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

High heat conductive carbon ramming mass and preparation method thereof

InactiveCN103387401AGood construction performanceImprove thermal conductivityFlake graphiteBlast furnace

The invention relates to a high heat conductive carbon ramming mass and a preparation method thereof. According to the technical scheme of the invention, the high heat conductive carbon ramming mass comprises the raw materials in percentage by weight: 30-45wt% of industrially synthesized graphite with granularity of 1-5mm, 6-22wt% of industrially synthesized graphite with granularity smaller than 0.074mm, 10-30wt% of flake graphite with granularity of 1-5mm, 8-20wt% of high carbon composite micro powder, and 10-15wt% of modified composite thermosetting resin. The preparation method comprises the following steps: stirring the industrially synthesized graphite with granularity of 1-5mm and high carbon composite micro powder at an intermediate speed first; then, adding 5-8wt% of modified composite thermosetting resin, and stirring at an intermediate speed first and then at a high speed; and finally, pouring the balance of raw materials and residual modified composite thermosetting resin, and stirring at a high speed to prepare the high heat conductive carbon ramming mass. The heat conductive carbon ramming mass provided by the invention has the characteristic of easiness in construction; and according to the prepared heat conductive carbon ramming mass, a cooling system of a blast furnace can be used for effectively cooling a brasque, so that the blast furnace operates stably for a long time.

Owner:WUHAN WINNING TECH

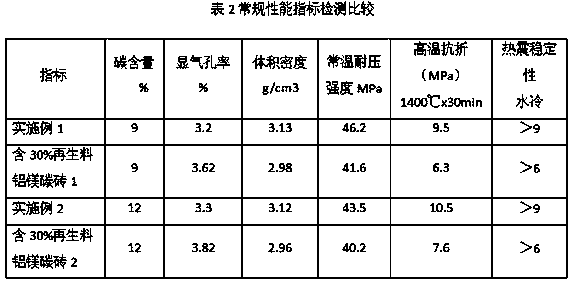

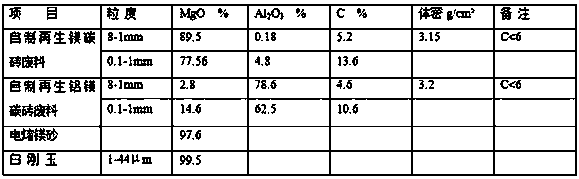

Method for making aluminum-magnesium carbon refectory brick from regenerated magnesium carbon bricks and aluminum-magnesium carbon bricks

The invention belongs to the technical field of refectory materials and in particular relates to a method for making an aluminum-magnesium carbon refectory brick from regenerated magnesium carbon bricks and aluminum-magnesium carbon bricks. The method comprises the following steps: 1, preparing aggregate; 2, preparing pre-mixed powder; 3, carrying out mixing refining; 4, carrying out a molding process; 5, drying. By adopting the method, the regenerated magnesium carbon bricks and the aluminum-magnesium carbon bricks are adopted as main raw materials, a part of an efficient additive is furtheradded, under the condition that a conventional production process is not changed, an aluminum-magnesium carbon brick which is high in medium-high temperature strength, high in volume density and excellent in corrosion resistance and thermal shock resistance is developed, and common industrial production can be carried out by using conventional experiment facilities.

Owner:LIAONING ZHONGMEI HLDG

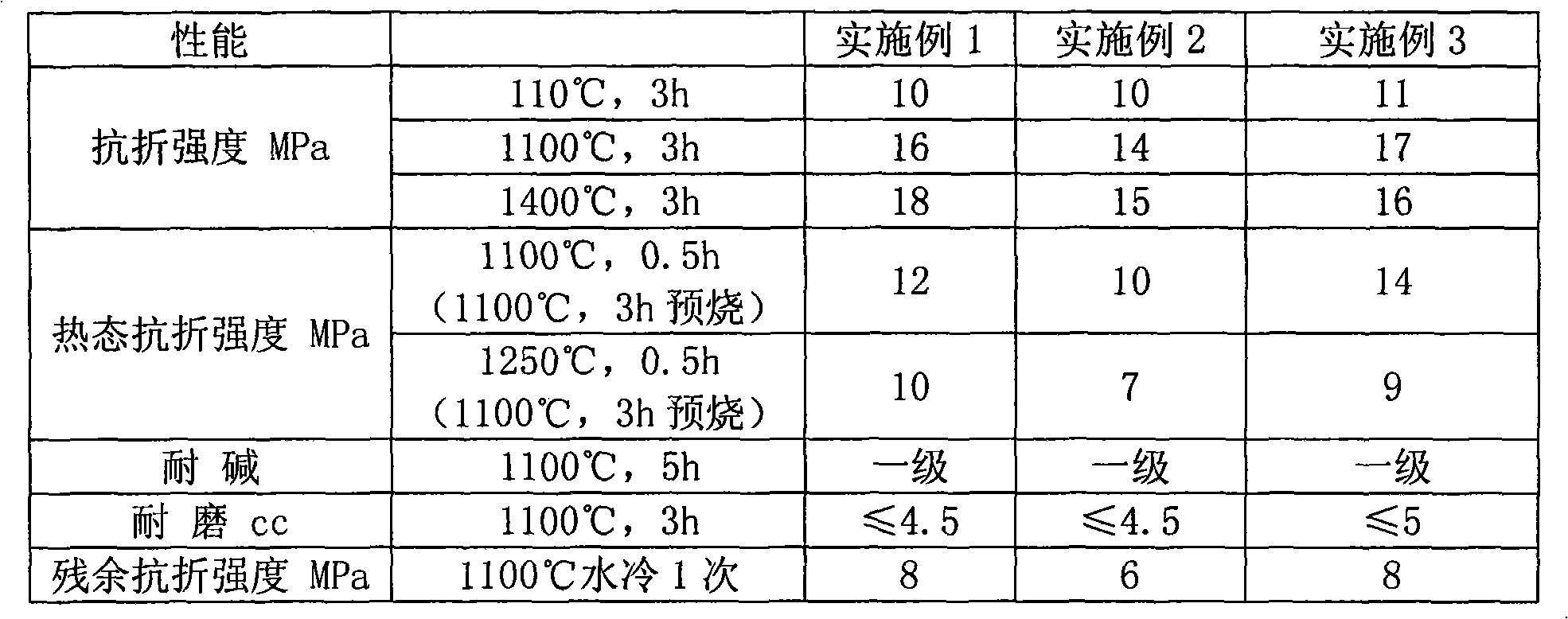

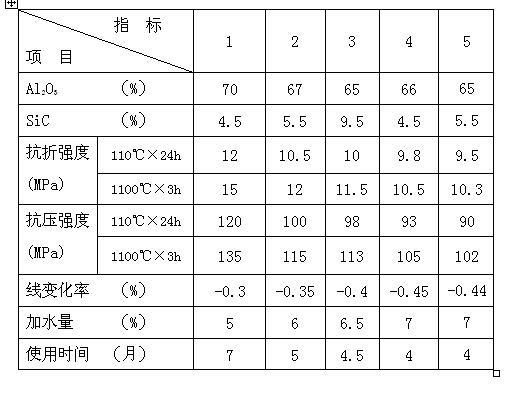

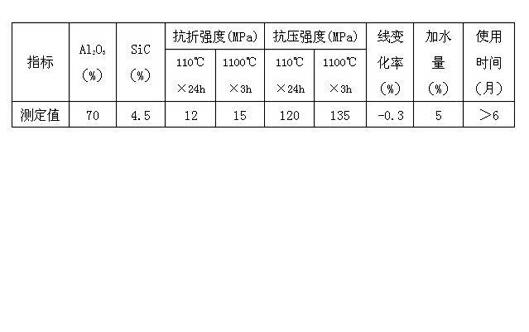

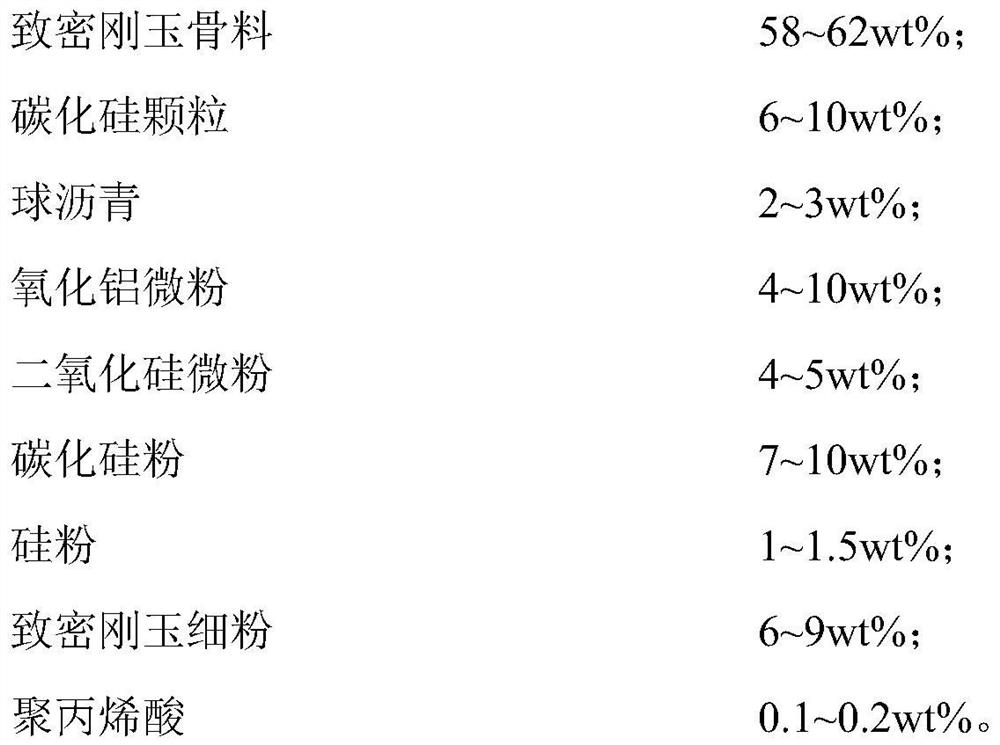

Aluminum oxide-silicon carbide-carbon castable with high hot strength

The invention relates to an aluminum oxide-silicon carbide-carbon castable with high hot strength. According to a technical scheme, the aluminum oxide-silicon carbide-carbon castable comprises the following components in percentage by weight: 58-62 wt% of compact corundum aggregate, 6-10 wt% of silicon carbide particles, 2-3 wt% of spherical asphalt, 4-10 wt% of aluminum oxide micro-powder, 4-5 wt% of silicon dioxide micro-powder, 7-10 wt% of silicon carbide powder, 1 to 1.5 wt% of silicon powder, 6-9 wt% of fine compact corundum powder and 0.1-0.2 wt% of polyacrylic acid. A preparation methodfor the castable comprises the following steps: subjecting the above components to burdening and mixing according to the respective contents; and adding water accounting for 3-3.3 wt% of the total mass of the components, performing uniform stirring, carrying out vibration molding, conducting natural drying for 24 hours, and carrying out heat treatment at 110 DEG C for 24 hours to obtain the aluminum oxide-silicon carbide-carbon castable with high hot strength. The castable has the characteristics of high hot strength, high density and good volume stability.

Owner:WUHAN UNIV OF SCI & TECH +1

Rapid repairing material prepared from waste high-aluminum brick and preparation method thereof

The invention relates to a rapid repairing material prepared from a waste high-aluminum brick and a preparation method thereof. The rapid repairing material comprises, by weight, 10-20 parts of waste high-aluminum brick, 5-8 parts of zirconium silicate sand, 20-30 parts of bauxite, 10-18 parts of clay powder, 3-5 parts of kyanite, 2-3 parts of a composite additive and 15-18 parts of a composite binder. The rapid repairing material prepared from a waste high-aluminum brick can replace a high-cost ramming material, realizes recycle of a waste high-aluminum brick, beautifies the environment and reduces a cost. The rapid repairing material is an ideal refractory material for fast first-aid repair of steel rolling and ironmaking thermal furnaces and has the characteristics of high thermal state strength, quenching and quick heating resistance, washing resistance and no baking. Compared with the existing first-aid repair material, the rapid repairing material can shorten a production period by 5-8 days and create large benefits for a client.

Owner:鞍山市永恒特种耐火材料制造有限公司

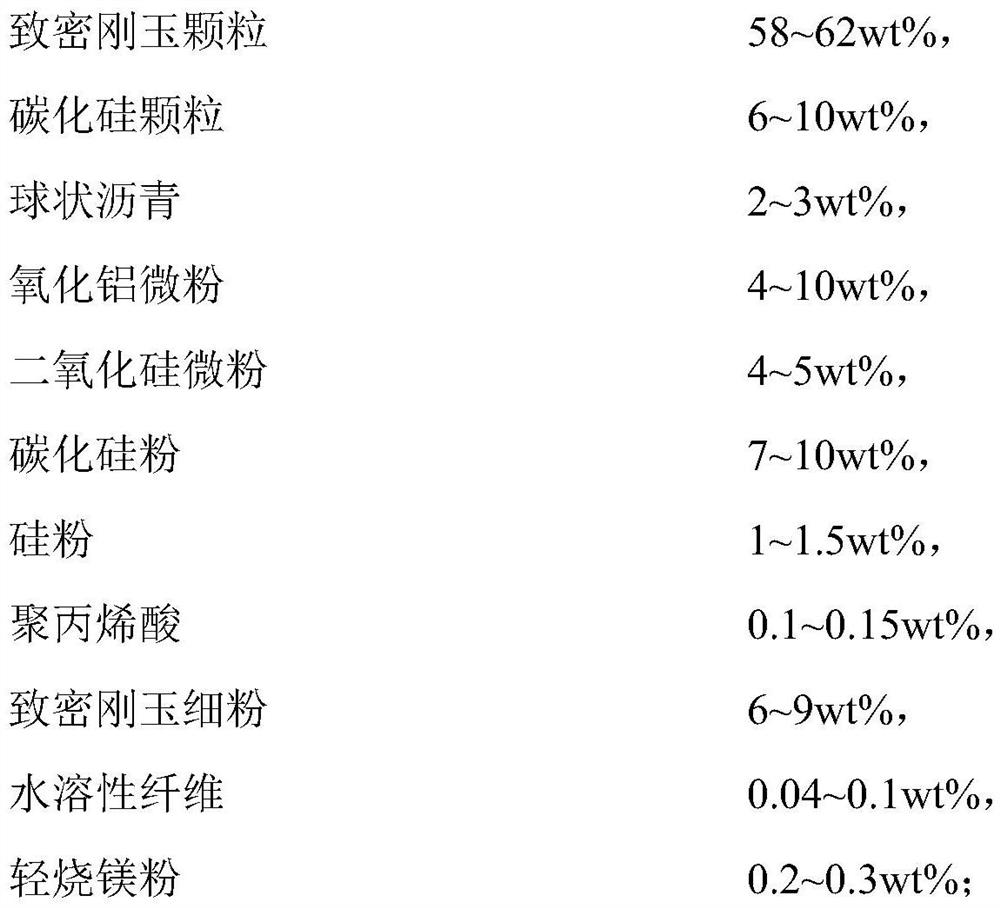

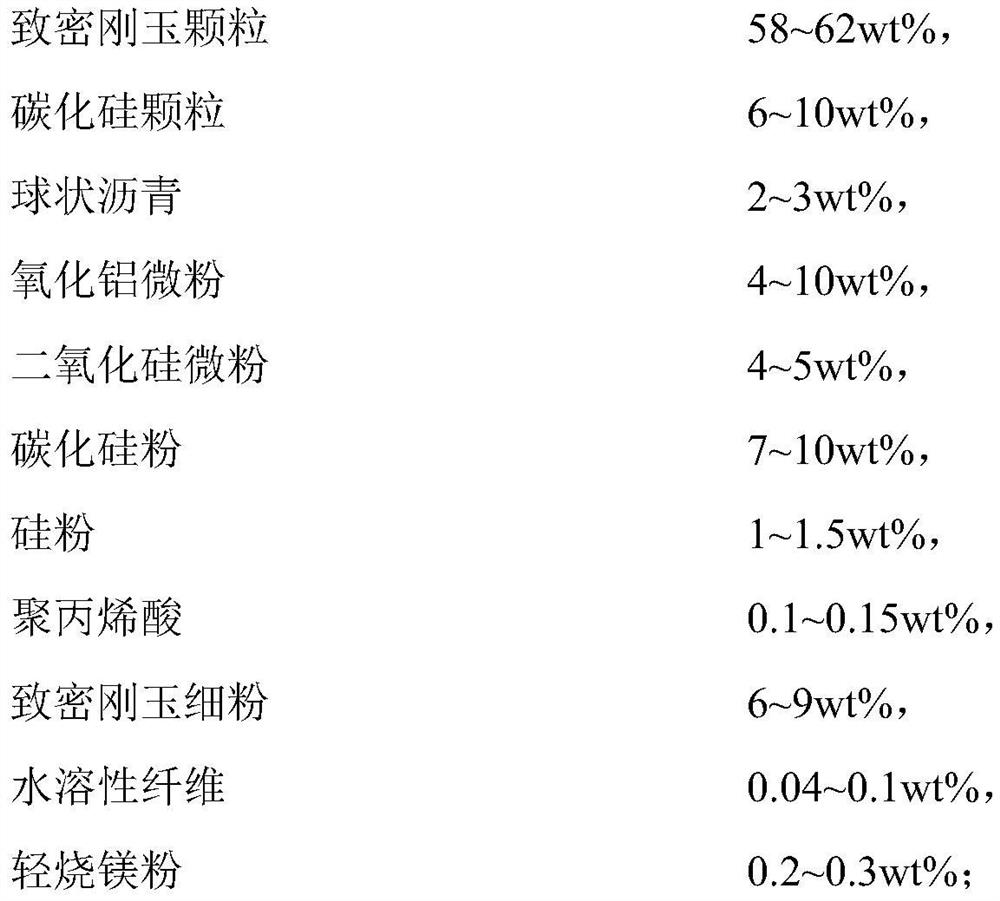

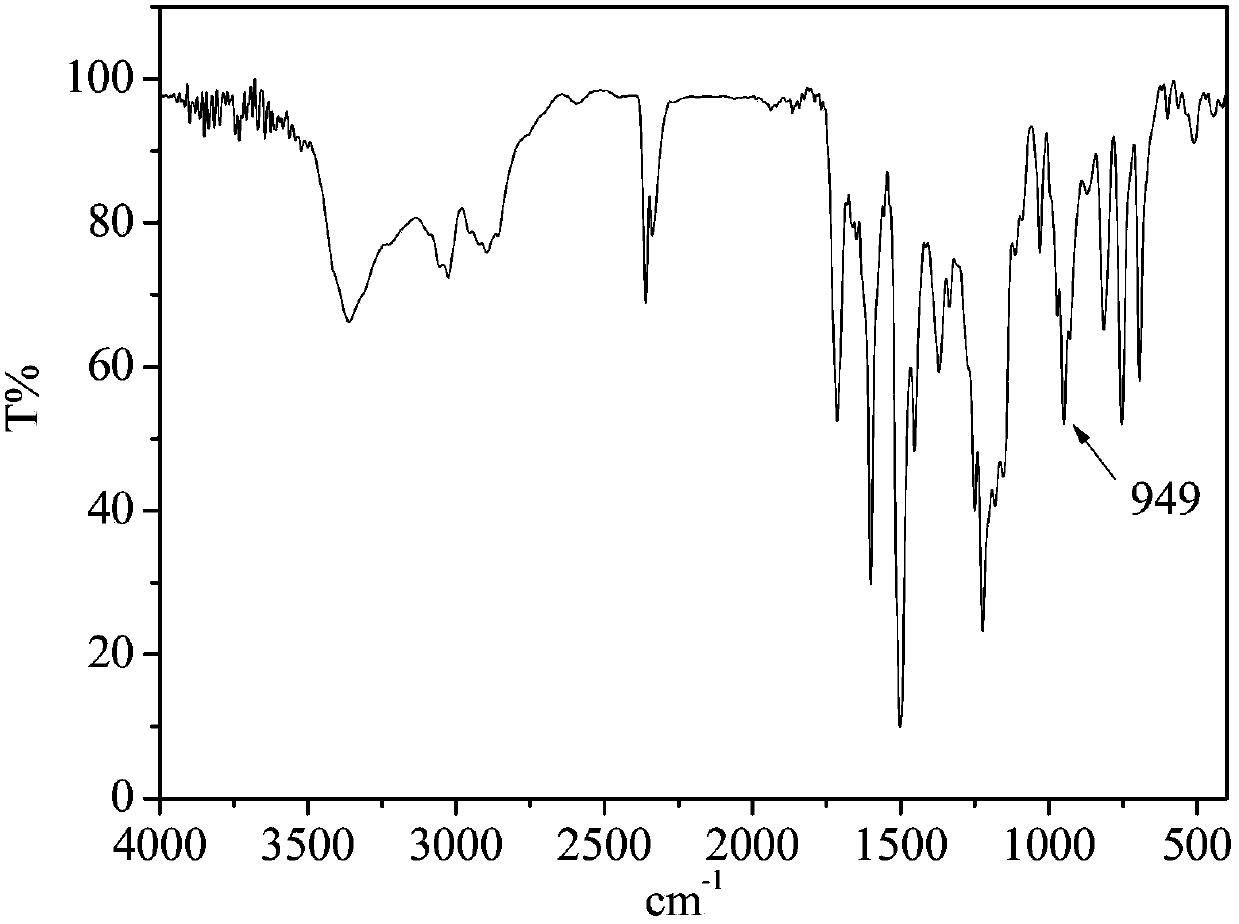

Alumina-silicon carbide-carbonaceous cement-free castable suitable for winter construction

PendingCN113087500AReduce the amount of water addedSufficient early strengthCarbide siliconSoluble fiber

The invention relates to an aluminum oxide-silicon carbide-carbonaceous cement-free castable suitable for construction in winter. The technical scheme is as follows: the castable comprises the following components in percentage by weight: 58-62wt% of dense corundum particles; 6-10 wt% of silicon carbide particles; 2-3 wt% of spherical asphalt; 4-10 wt% of alumina micro powder; 4 to 5 wt% of silicon dioxide micro powder; 7-10 wt% of silicon carbide powder; 1 to 1.5 wt% of silicon powder; 0.1-0.15 wt% of polyacrylic acid; 6-9 wt% of dense corundum fine powder; 0.04-0.1 wt% of water-soluble fibers; and 0.2-0.3 wt% of caustic-burned magnesia powder. During construction, when the environment temperature and the water temperature are both lower than 15 DEG C, after construction is completed, a pouring body is cured at 33-38 DEG C until the pouring body is completely cured. The concrete has the advantages of being small in water adding amount, short in setting time and high in construction site safety, is good in compactness, free of cement, high in thermal strength and good in various technical indexes, and particularly completely meets the requirements of construction in winter.

Owner:WUHAN UNIV OF SCI & TECH +1

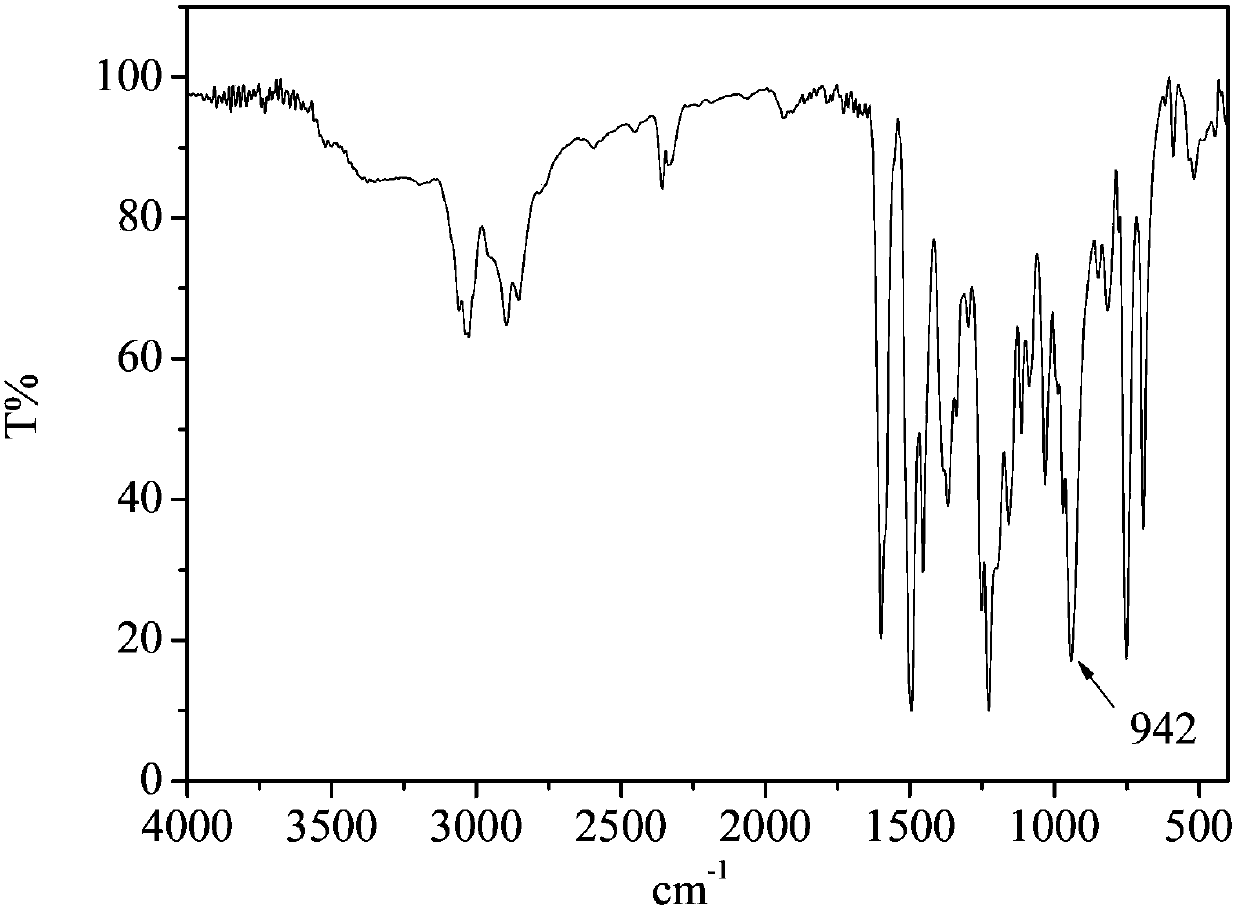

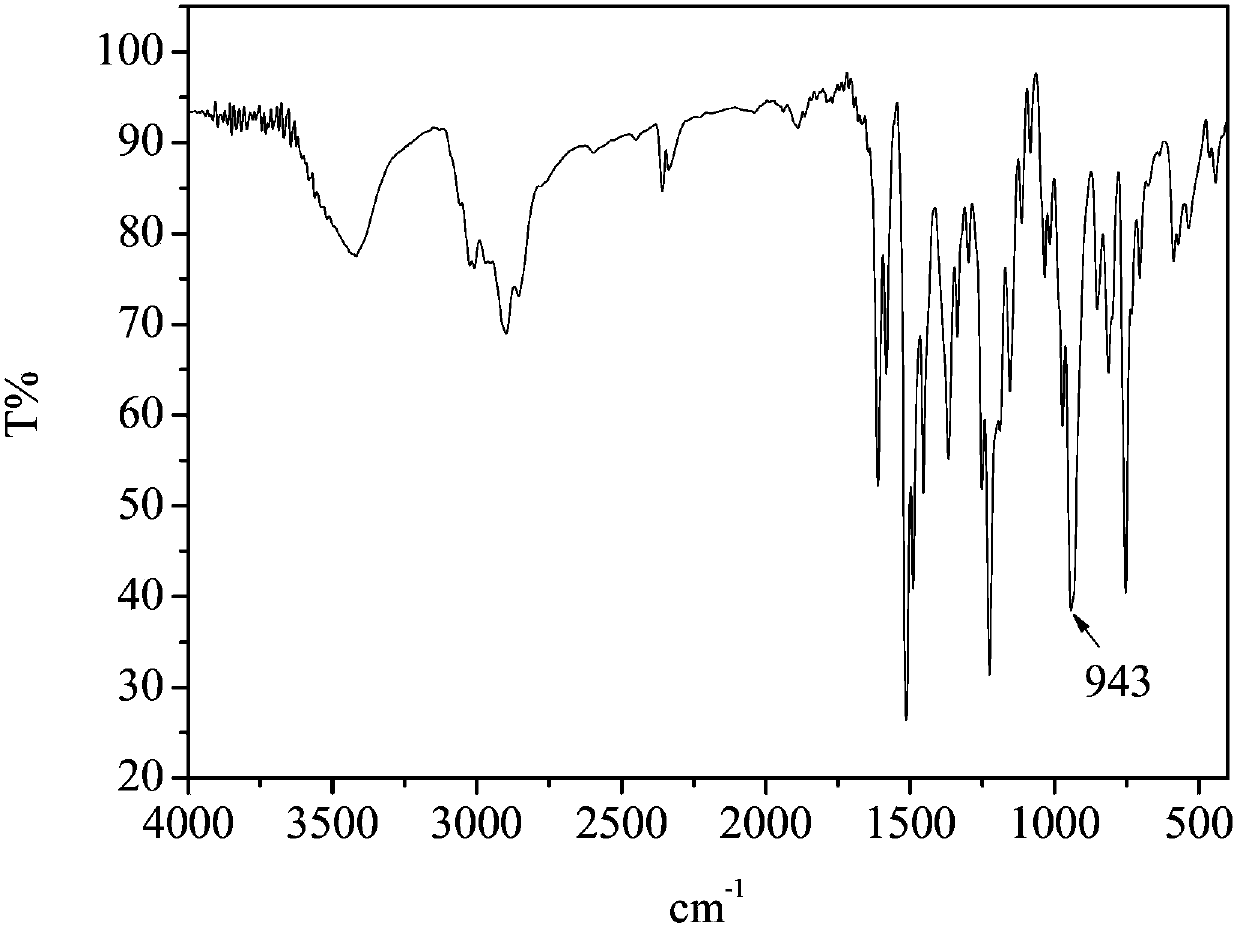

Plant oil benzoxazine copolymer elastomer preparation method

The invention discloses preparation method of a plant oil benzoxazine copolymer elastomer. The elastomer is obtained by copolymerization of a plant-oil-based prepolymer, an amino-comprising benzoxazine monomer, a monocyclic benzoxazine monomer, and a bicyclic benzoxazine monomer. According to the invention, epoxy vegetable oil is heated to 85-120 DEG C in an oil bath, polyamine and tertiary amine catalyst are added, the oil temperature is increased to 95-125 DEG C, and constant-temperature reaction is carried out for 1.5-3.5h, such that the plant-oil-based prepolymer is prepared. The amino-comprising benzoxazine is prepared through a dehydration condensation reaction of an amino-substituted phenol compound, aniline and paraformaldehyde. Benzoxazine is prepared through a dehydration condensation reaction of a phenol compound, aniline and paraformaldehyde. According to the invention, the plant-oil-based prepolymer is adopted as a soft segment, polybenzoxazine is adopted as a hard segment, and the amino-comprising benzoxazine is adopted as a grafting agent, such that the prepared plant oil benzoxazine copolymer elastomer has the advantages of high modulus, high glass transition temperature, high hot strength, excellent thermal stability, and excellent thermal mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

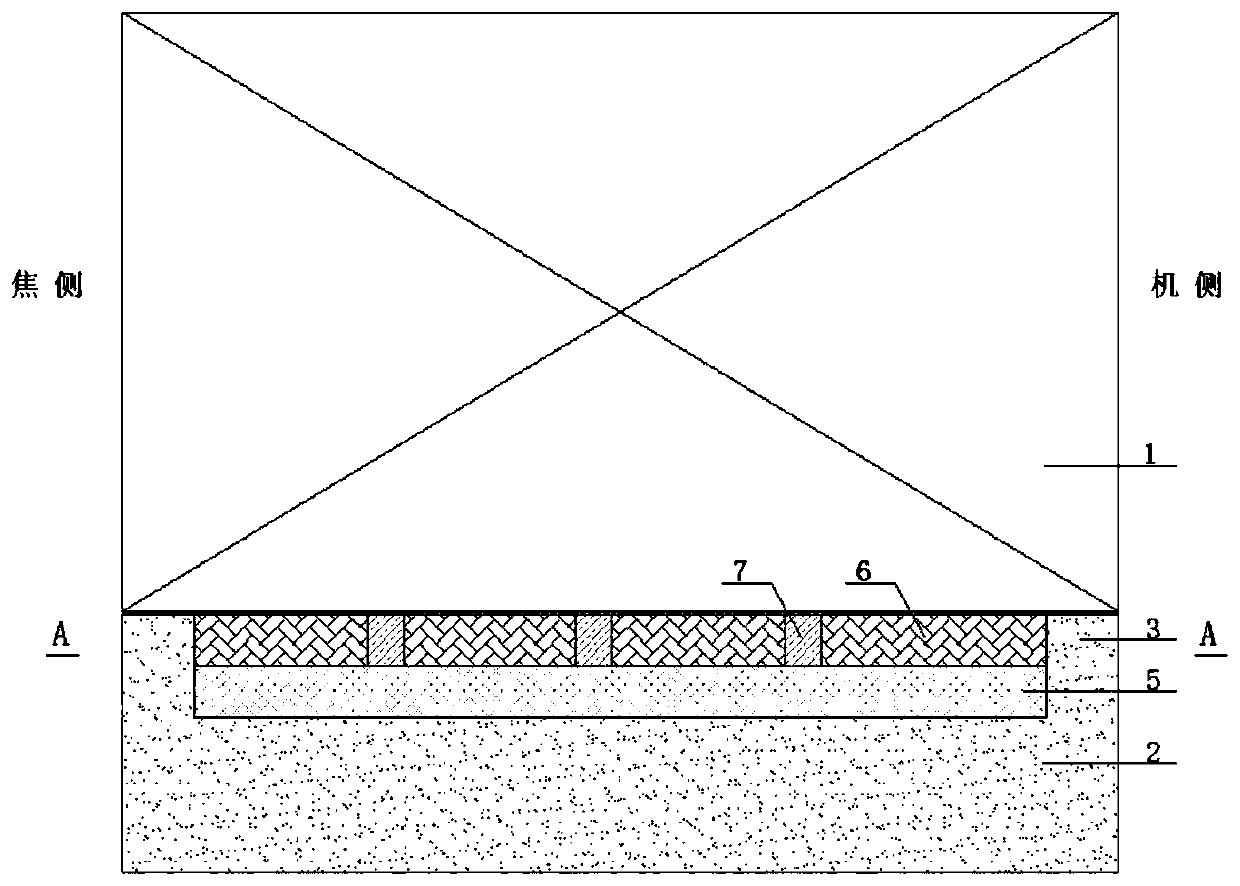

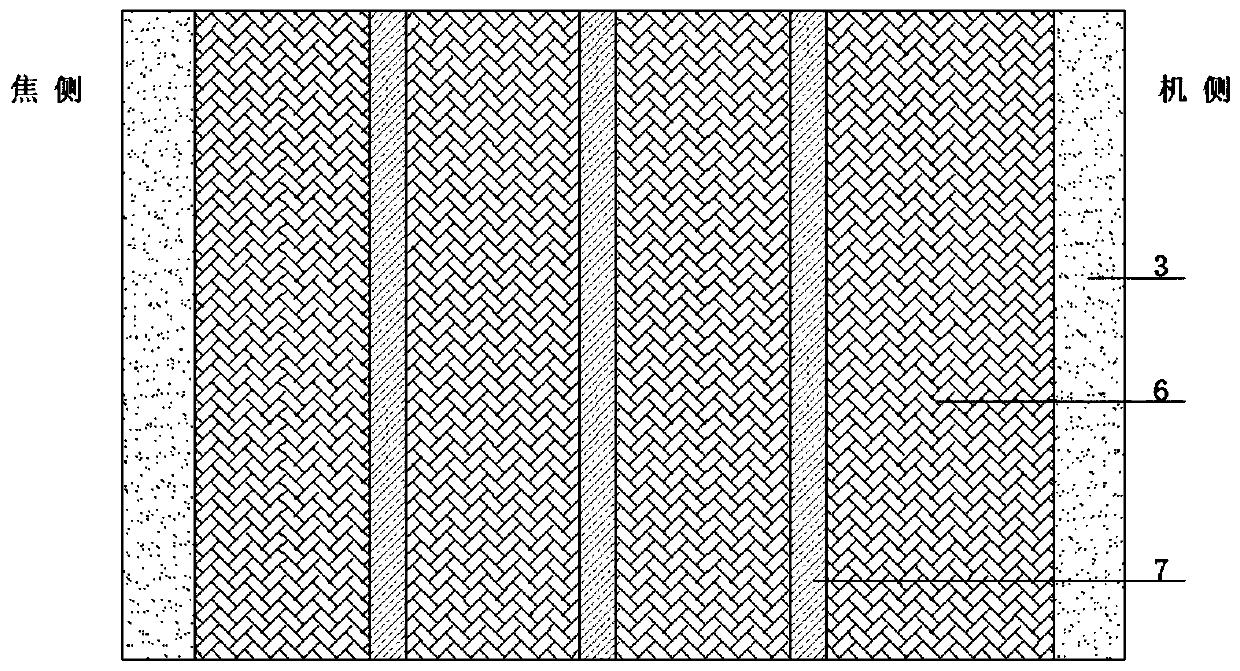

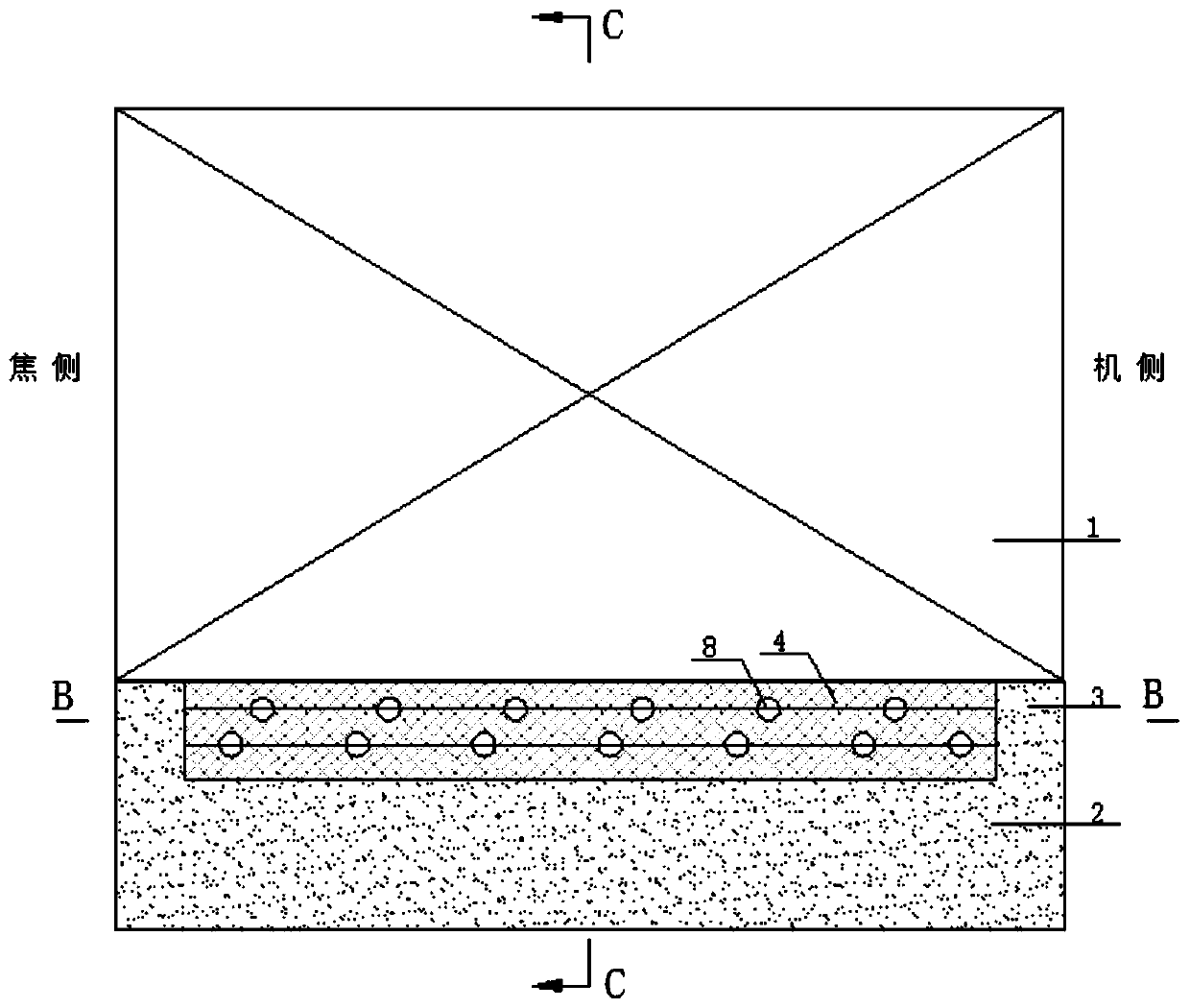

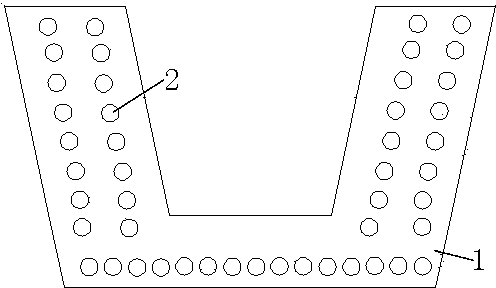

Novel heat insulation structure of coke oven foundation top plate

PendingCN111575026AEasy construction in cold stateGood heat insulationCoke oven brickworkBrick masonryFire brick

The invention relates to a novel heat insulation structure of a coke oven foundation top plate. The novel heat insulation structure comprises an integral castable layer, transverse preformed holes andlongitudinal preformed holes. Side beams are arranged on the two sides of a foundation top plate, and the top faces of the side beams are higher than the top face of the foundation top plate, so thata groove structure is formed in the top of the foundation top plate. The integral castable layer is arranged in a groove structure; the integral castable layer is provided with at least one layer oftransverse preformed holes and at least one layer of longitudinal preformed holes, and each of the transverse preformed holes and the longitudinal preformed holes includes a plurality of preformed holes formed in parallel. The refractory castable layer is adopted to replace a traditional refractory brick masonry structure, and a protective layer is formed on the coke oven foundation top plate in apouring mode; in the pouring process, holes are reserved through pre-buried plastic pipes, and the longitudinally and transversely arranged hole structures can play a good role in heat insulation, sothat the temperature of foundation top plate concrete is reduced, and the service life of the foundation top plate concrete is prolonged; meanwhile, the coke oven basement temperature is reduced, andcoke oven operation conditions are improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Preparation method of iron runner sialon casting body

The invention discloses a preparation method of an iron runner sialon casting body. The method comprises the following step: embedding a pipe easy to burn out in an iron runner casting body; and forming a pipe inlet and a pipe outlet in the wall of an iron runner. When the iron runner is used, the pipe easy to burn out is burnt out to form a channel, nitrogen is fed in the channel; and when the flows of the inlet and the outlet of the nitrogen channel are the same, the outlet of the channel is closed and the feeding of the nitrogen is stopped; and a filling material is pressed into the channel. The air-cooled iron runner sialon casting body prepared by using the method is high in cooling efficiency, so that the service life of the iron runner is further prolonged. The integrated iron runner sialon casting body can be used for improving the whole thermal state strength of the iron runner by dozens of times; and the iron runner material contains nitrides, so that a wetting angle of the iron runner material to slag iron is enlarged. Thus, the slag erosion resistance and the penetration resistance of the iron runner are greatly improved. Therefore, the service life of the iron runner is prolonged. As a result, the cost of an enterprise is reduced; and the generation of industrial wastes and the waste of fire-resistant raw material resources are reduced, namely, the environmental-friendly effect is achieved.

Owner:巩义市时创新材料孵化器有限公司

Pouring material for furnace wall built-in channel heat-accumulating type heating furnace

The invention discloses a pouring material for a furnace wall internal regenerative heating furnace with 65-95 percent of high alumina bauxite, 1-10 percent of alumina powder, 1-10 percent of silica ultrafine powder and 0.5-15 percent of cement as raw materials by weight percentage as well as sodium polyphosphate being 0.01-0.3 percent of the total weight of the raw materials. The product of the invention has excellent performance with refractoriness under load T0.6 equal to or more than 1500 DEG C, 1350 DEG C multiplied by 1h high temperature break resistant intensity equal to or more than 3MPa and heat-shake stability more than 40 times under 1100 DEG C and cool water condition. The invention adds active rho-alumina in the Al2O3.SiO2 system refractories, therefore, in-situ reaction can happen under comparatively low temperature to form lots of column mullite, thus leading the pouring material to have the characteristics of high soft load capacity, high hot strength and excellent heat-shake stability, etc. and prolonging more than 2 times of service life compared with that of low cement pouring material.

Owner:HENAN GENGSHENG REFRACTORIES

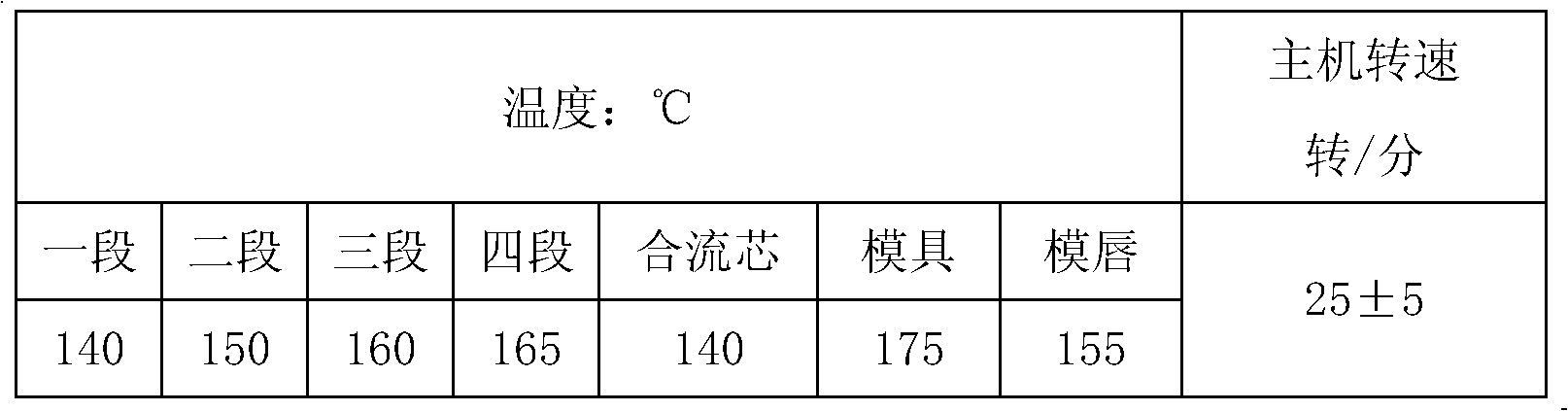

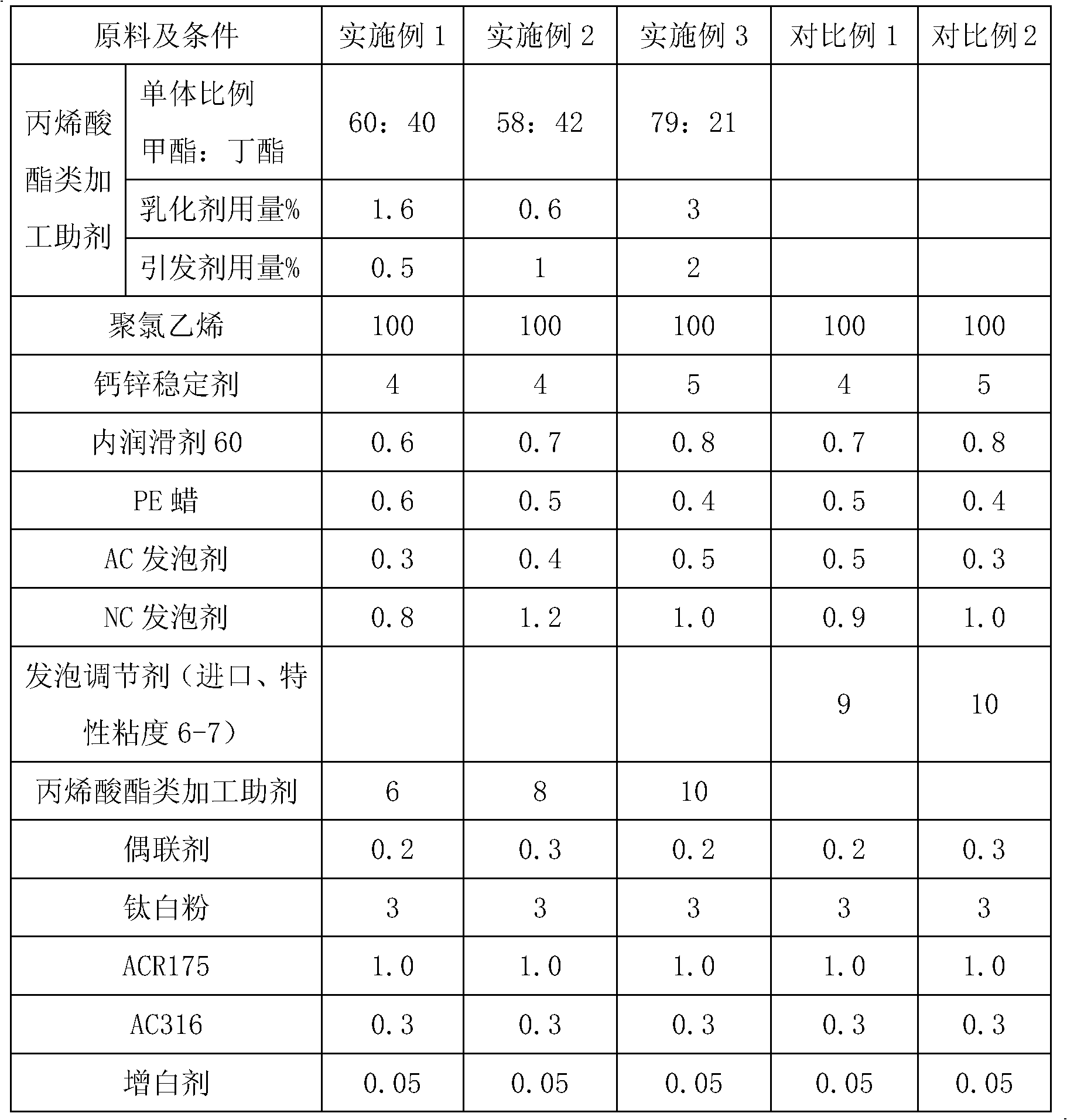

Acrylate processing aid as well as preparation method and application thereof

The invention belongs to the field of chemical engineering and particularly relates to an acrylate processing aid as well as a preparation method and an application thereof in production of polyvinyl chloride foam boards. Calculated by taking the total weight of polymerization monomers as 100%, the acrylate processing aid is formed by polymerization reaction of 58-79% of methyl methacrylate and 39-18% of butyl acrylate via emulsion; a surfactant adopts a mixture of sodium dodecyl sulfate and OP-10 at the weight ratio of 5:1, the using quantity of the surfactant accounts for 0.5%-3% of the total weight, an initiator adopts potassium persulfate, and the using quality of the initiator is 0.3-2% of the total weight of the processing aid. When the acrylate processing aid disclosed by the invention is used as a foam regulator for polyvinyl chloride, the viscosity can be up to 12-13; and an acrylate polymer is good in powder fluidity and can be used for preparing polyvinyl chloride foam board products with uniform foam holes.

Owner:SHANDONG RUIFENG CHEM

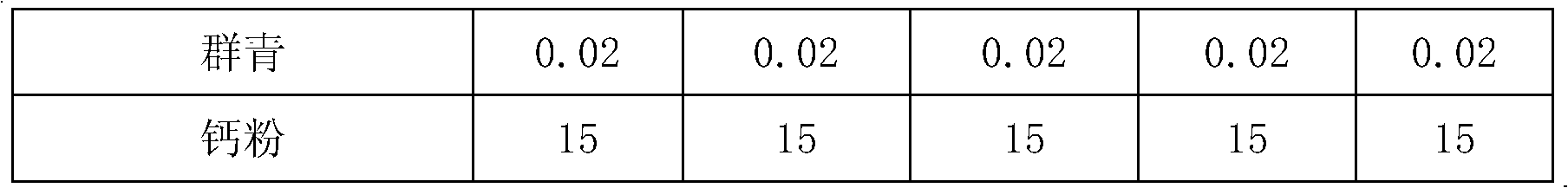

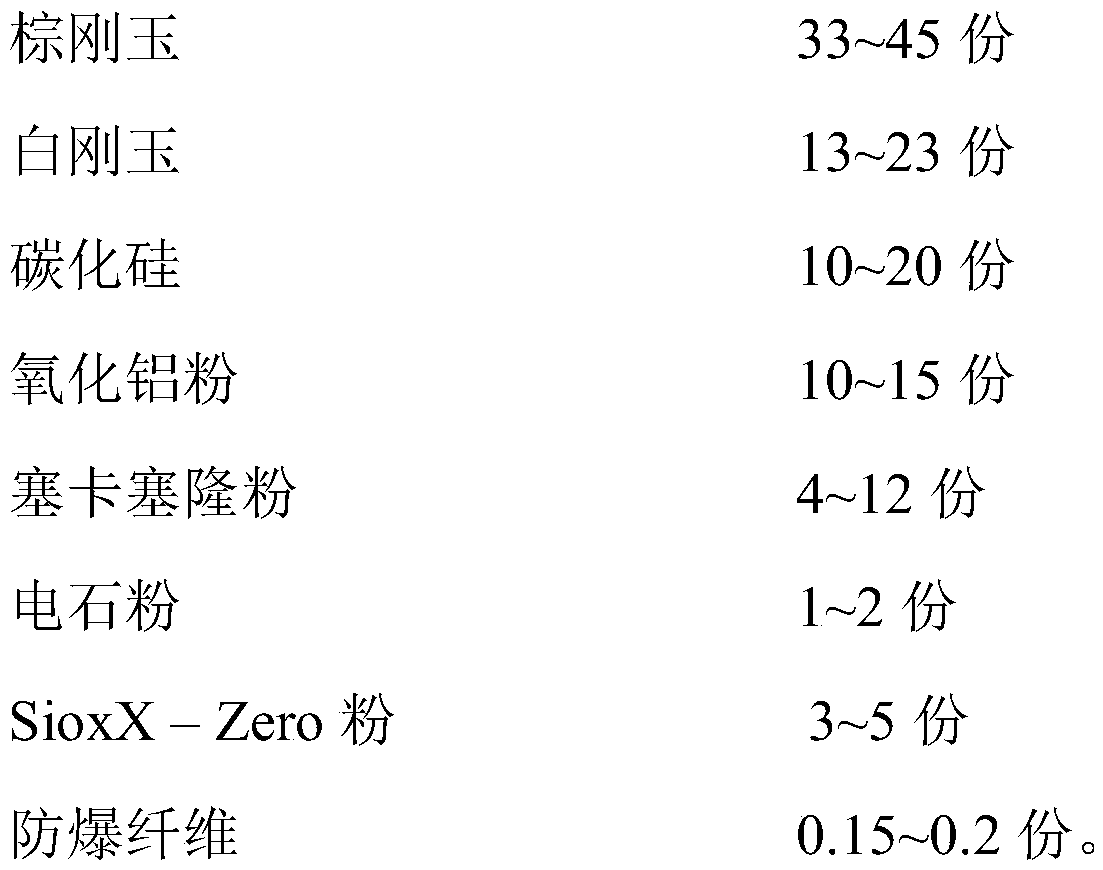

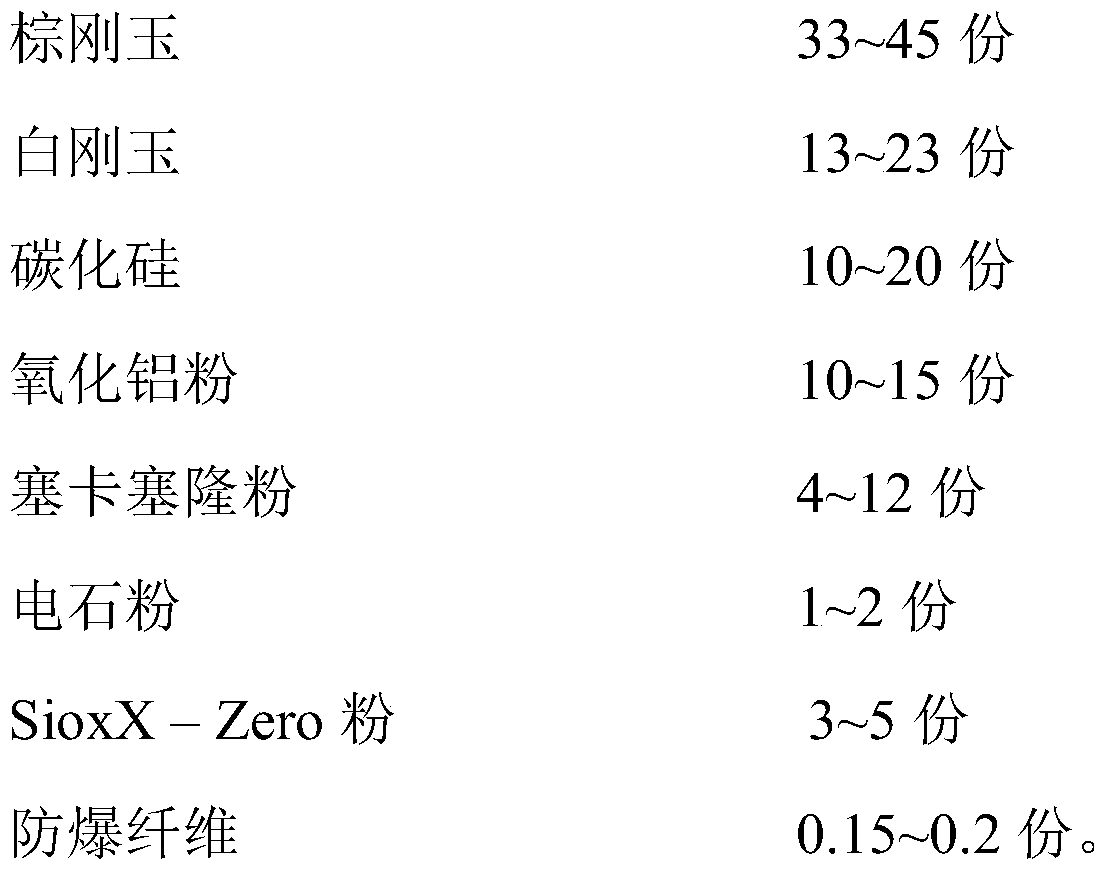

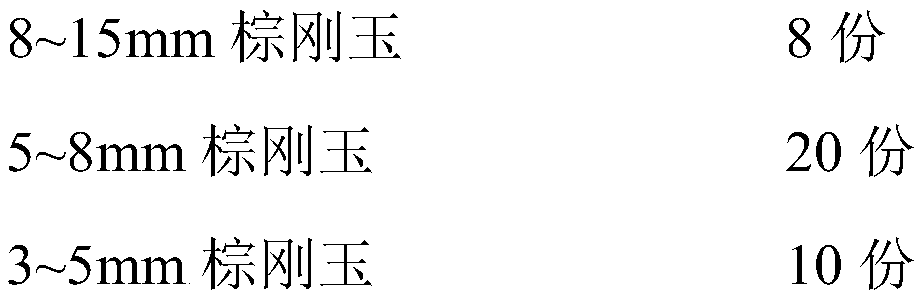

Cement-free iron runner castable

The invention relates to a cement-free iron runner castable including, by weight, 33-45 parts of brown corundum, 13-23 parts of white corundum, 10-20 parts of SiC, 10-15 parts of alumina powder, 4-12parts of SiC-SiAlON powder, 1-2 parts of calcium carbide powder, 3-5 parts of Siox X-Zero powder and 0.15-0.2 parts of explosive-proofing fibers. The castable has good high temperature mechanical strength and strong anti-slag scouring performance, is good in breathability and can achieve rapid constructure of an iron runner.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

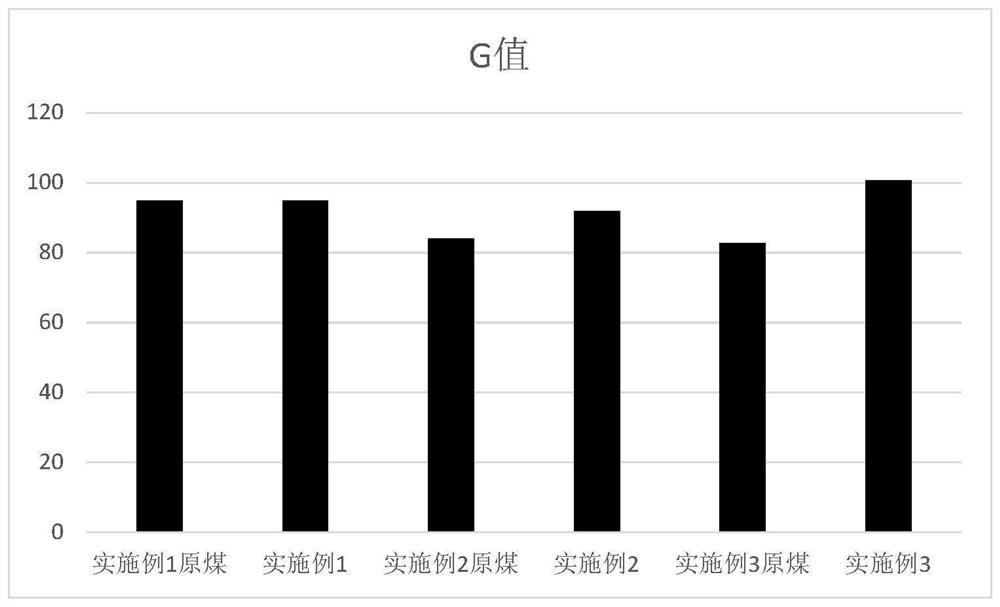

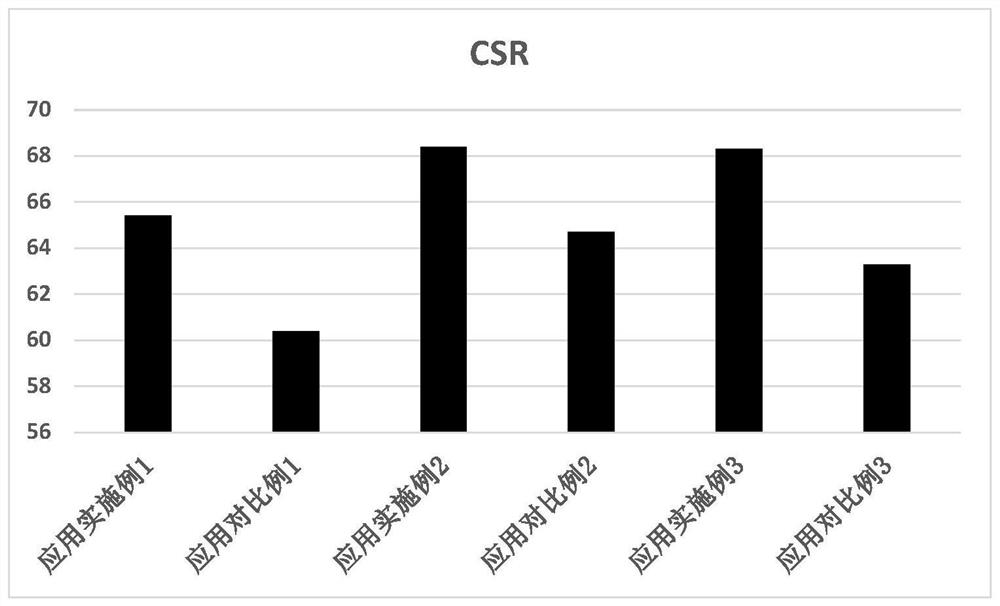

A method for preparing high-strength metallurgical coke by upgrading Xinjiang coal

The invention discloses a method for preparing high-strength metallurgical coke from modified Xinjiang coal, belonging to the technical field of coal processing. A modifier for the modified Xinjiang coal is boron (B), calcium boride (CaB6) and a boron carbon compound; the boron carbon compound can be one or more than one of boron-enriched boron carbon compounds (B3C, B5C, B6C, B7C, B8C, B12C, B12C2, B13C, B13C2, B13C3 and B25C) and carbon-enriched boron carbon compounds (B12C13, BC2 and BC3). The modifier can consist of one, or any two or all of boron (B), calcium boride (CaB6) and the boron carbon compound. The use amount of the modifier is 0.1%-1.3% of the mass of coking coal. By adding the modifier into the coking coal to realize co-carbonization with the Xinjiang coal, the purpose of greatly improving the thermal strength of the Xinjiang coal coke can be reached, the thermal strength of the Xinjiang coal coke can be improved by 5%-26%, and the quality of the coke can meet high-quality requirement of a modern large blast furnace for coke.

Owner:CHONGQING UNIV

Wear and corrosion resistant castable prepared from bauxite-based homogenous material and preparation method thereof

The invention discloses wear corrosion resistant castable prepared from a bauxite-based homogenous material and a preparation method thereof, which belong to the technical field of castable refractory. In the invention, by using the characteristics of the bauxite-based homogenous material, such as homogeneous chemical components and structure, stable performance, mulite main crystal phase, small linear change, high high-temperature strength and certain flexibility due to mutual insertion of micro crystals and the like, the shortcomings of low middle-temperature strength and poor wear resistance and alkali corrosion resistance of the conventional high-aluminum bauxite castable are overcome, and the problems of low middle-temperature strength, poor wear resistance and poor alkali, chloride and sulphur corrosion resistance of the conventional high-aluminum and corundum castable are effectively solved. The wear and corrosion resistant castable with high middle-temperature performance is prepared. The wear corrosion resistant castable and the preparation method thereof have the advantages of small fluctuation of water adding amount in construction, stable usability, reduction rate of partial corrosion, prolonged service life and wide application to a kiln hood, a grate cooler, a tertiary air duct and a decomposing furnace of a dry process cement kiln and relative parts of other ceramic and petrified thermo-technical kilns and the like.

Owner:YANGQUAN JINYU TONGDA HIGH TEMPERATURE MATERIALS +1

Machine pressing carbon-free lining brick for steel ladles

Owner:JINAN IRON & STEEL GRP REFRACTORY CO LTD

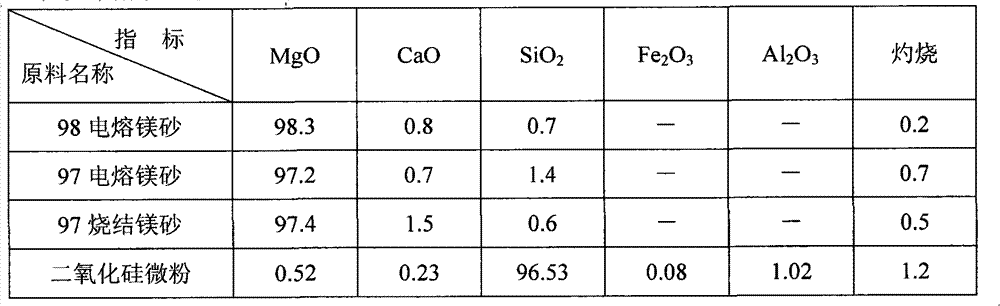

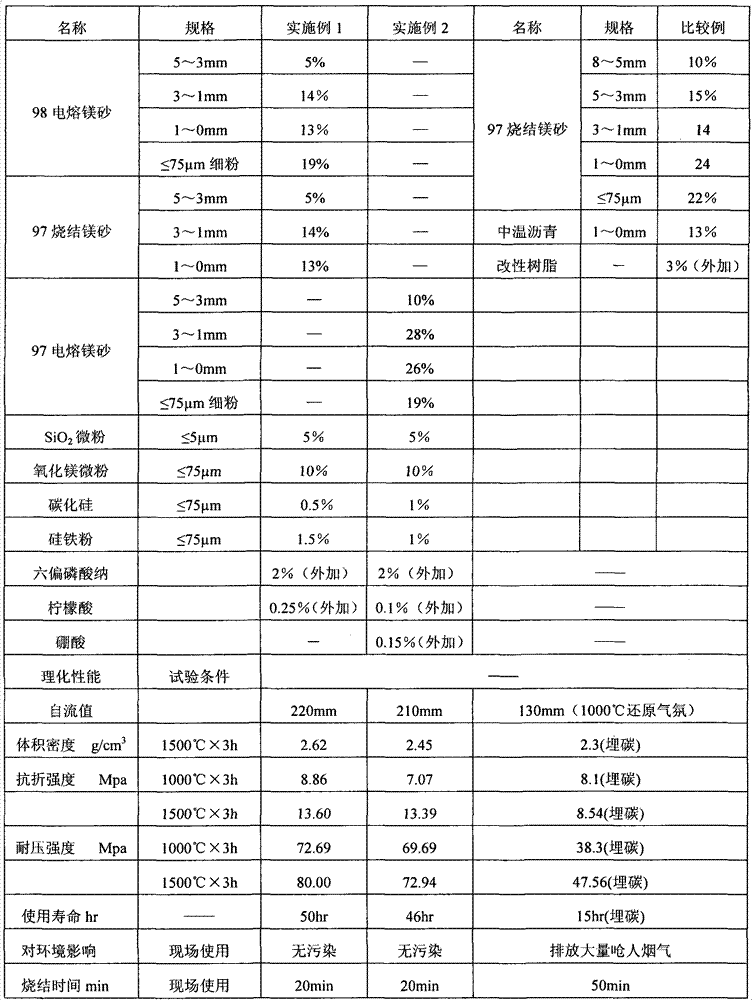

Environment-friendly aqueous long-life self-flowing repairing mix for converter and preparation method thereof

ActiveCN101792322BImprove high temperature performanceNo pollution in the processCeramic shaping apparatusSteelmakingContinuous use

The invention relates to environment-friendly aqueous long-life self-flowing repairing mix for a converter and a preparation method thereof. The invention is characterized by utilizing high purity fused magnesia, high purity sintered magnesia and fine silica powder as the main raw materials; utilizing one or more of ferrosilicon powder, silicon carbide powder, fine metal powder and the like as the burning accelerating agent to realize rapid sintering of the self-flowing repairing mix; utilizing one or two of citric acid, boric acid, tartaric acid, oxalic acid and the like as the retarders to realize the construction time of the self-flowing repairing mix; and utilizing fine MgO and SiO2 powder, thus improving the mobility and the sintering property of the material, enhancing the medium and high temperature strength and boosting the washing resistance and the impact resistance of the material. The self-flowing repairing mix has high hot strength and excellent erosion resistance and liquid steel washing resistance and can be continuously used for 50h after once repairing under the condition of smelting multi-variety steel in the converter, thus greatly improving the efficiency of converter steelmaking, reducing the consumption of refractories and prolonging the lives of the lining materials of the converter.

Owner:上海柯瑞冶金炉料有限公司

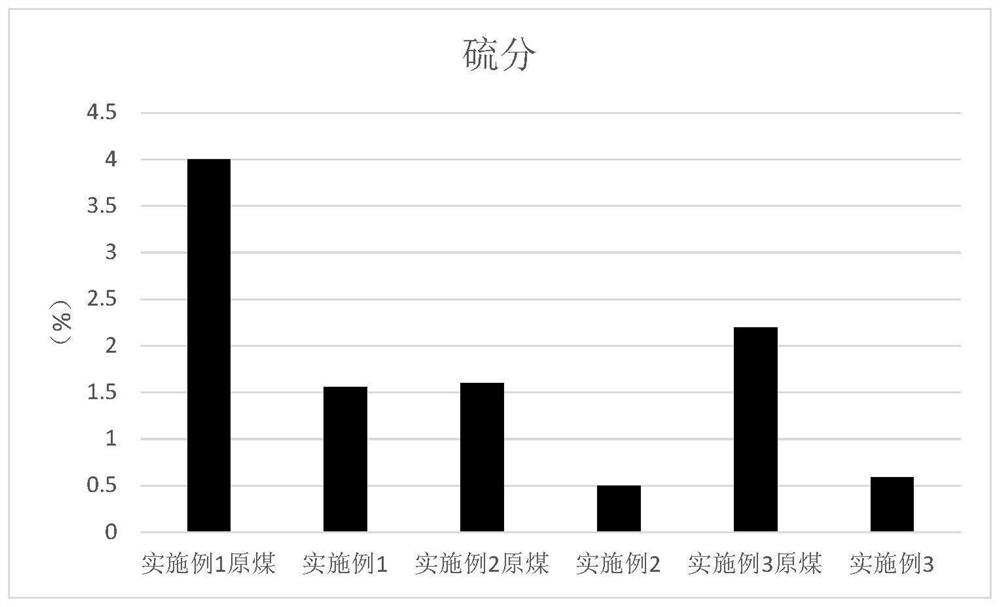

Method for upgrading and desulfurizing high-sulfur fat coal

ActiveCN114437851AHigh thermal strengthImprove cohesion indexSolid fuelsOrganic solventPhysical chemistry

The invention provides a method for upgrading and desulfurizing high-sulfur fat coal, which relates to the technical field of coking and comprises the following steps: (a) mixing high-sulfur fat coal, an organic sulfur removal agent, titanium dioxide and nickel fluoborate to form first slurry; (b) carrying out heating reaction on the first slurry, and separating to obtain a first liquid material and a first solid material; (c) mixing the first solid material and washing oil to form second slurry; (d) carrying out heating and pressurizing reaction on the second slurry, and separating to obtain a second liquid material and a second solid material; (e) carrying out flash evaporation on the second liquid material to obtain an organic solvent and a third solid material; and drying the third solid material to obtain desulfurized coal. According to the method, 50% of organic sulfur and 100% of inorganic sulfur can be removed on the premise that the caking property of the high-sulfur fat coal is not damaged, the utilization rate of precious high-quality coking coal is reduced while the utilization rate of inferior coke is increased, and good economic benefits and environmental benefits are achieved.

Owner:BEIJING RISUN TECH CO LTD

Briquette containing composite binder and burning synergistic agent and preparation method thereof

The invention discloses a briquette containing a composite binder and a burning synergistic agent. The briquette contains raw material components of coal powder, the composite binder and the burning synergistic agent, wherein the composite binder comprises pregelatinized starch, clay and polyvinyl alcohol; and the burning synergistic agent comprises potassium permanganate, sodium chloride and sodium carbonate. The briquette has the advantages of being easy to burn, high in cold-hot strength, high in heat efficiency, little in equipment investment, low in production cost, friendly to environment and the like.

Owner:广西桂晟新能源科技有限公司

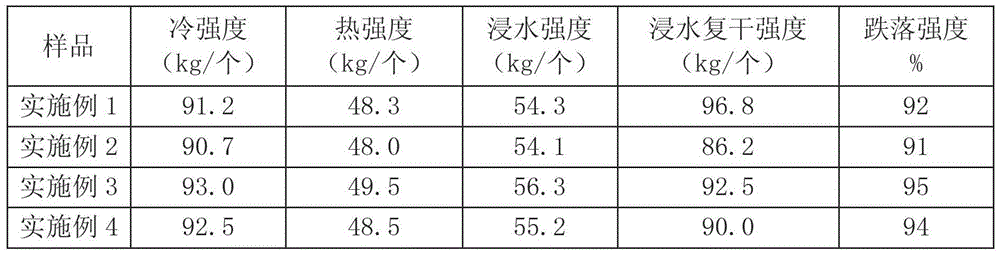

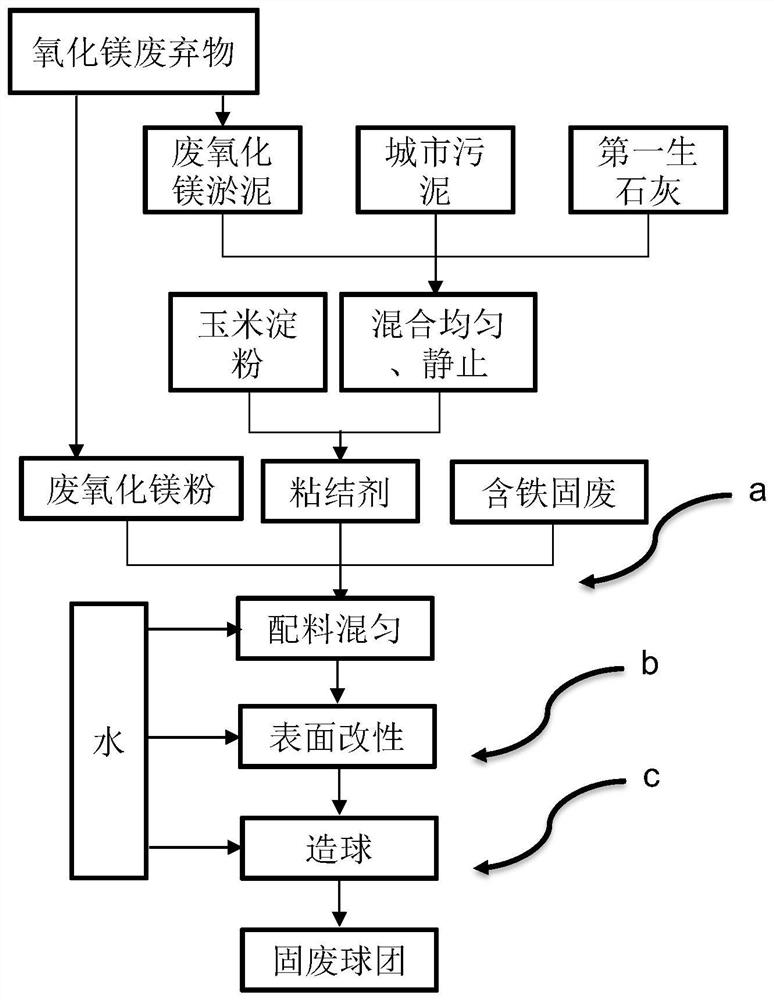

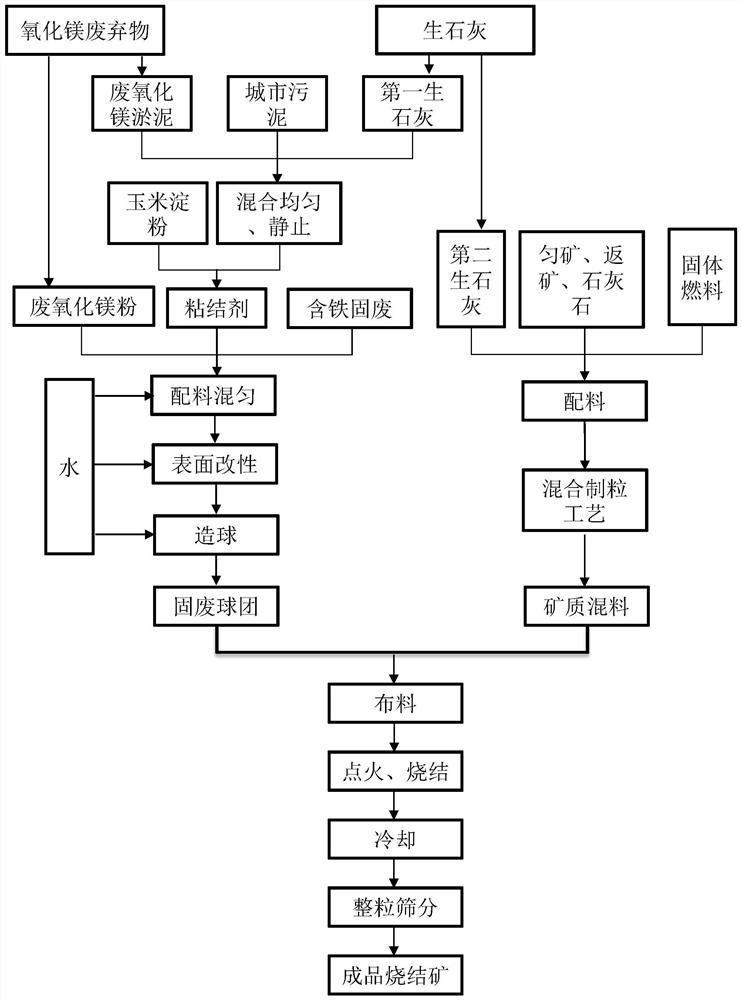

Solid waste pelletizing process and efficient sintering method thereof

PendingCN114763581AHigh thermal strengthAvoid sinter productivity impactProcess efficiency improvementFine powderCorn starch

The invention discloses a solid waste pelletizing process and an efficient sintering method thereof, waste magnesium oxide powder, iron-containing solid waste and a binder are adopted as raw materials, and solid waste pellets are prepared after burdening, surface modification and pelletizing; and mixing the solid waste pellets and a mineral mixture prepared by adopting a mixing granulation process as sintering raw materials, and sequentially carrying out material distribution, ignition, sintering, cooling and whole grain screening to obtain a finished product of sintered ore, the binder is prepared from waste magnesium oxide sludge, municipal sludge, first quick lime and corn starch; the waste magnesium oxide powder and the waste magnesium oxide sludge are magnesium oxide wastes. According to the method, the magnesium oxide waste, the municipal sludge, the rotary hearth furnace fine powder and other solid wastes inside and outside the steel plant are fully recycled, local concentrated heterogeneous sintering of magnesium oxide is realized, the adverse effect of uniform distribution of MgO on the sintering productivity is avoided, the quality of solid waste pellets is improved, and the production cost is reduced. Therefore, the quality index and the heat energy utilization efficiency of the finished sinter are remarkably improved, and fuel consumption and CO2 emission are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Unburned carbon-free brick for generating MgAlON/beta-Sialon complex phase in situ under smelting condition

The invention discloses an unburned carbon-free brick for generating an MgAlON / beta-Sialon complex phase in situ under a smelting condition. According to the adopted technical scheme, the MgAlON / beta-Sialon complex phase consists of the following raw materials in parts by weight: 60-70 parts of fused magnesite, 5-10 parts of MaO.Al2O3 spinel with a fiber netlike structure, 3-12 parts of metal aluminum powder and 0-5 parts of metal silicon powder, 2-6 parts of aluminum oxide micro powder and 4-6 parts of a magnesium aluminate cementing agent; and the unburned carbon-free brick is prepared by mixing the raw materials above according to a certain weight proportion, molding and drying at 100-200 DEG C for 24-30 hours. Environmental protection is facilitated, the production period is shortened greatly, and production cost is reduced. An MgAlON / beta-Sialon complex phase refractory material is generated in situ under a smelting condition, and has the advantages of small linear expansion, low apparent porosity, high volume density, high thermal shock resistance, high erosion resistance, high scouring resistance, high oxidation resistance, self-repairing capacity and the like.

Owner:辽宁青花耐火材料股份有限公司

Composite mortar for building blast furnace stack graphite brick and carborundum brick

This invention discloses a composite daub of graphite bricks and SiC bricks for building stacks of furnaces, in which, the daub is composed of SiC, graphite, binder, antioxidation agent and a solidifying agent mixed in proportion, since SiC has high intensity under high temperature, the graphite material has high heat conduction performance and the binder strengthens the adhesive performance and anti-high temperature performance of the daub, the solidifying agent strengthens the plastic and self-modification function of the composite daub under high temperature, the invented daub has the property of high heat-conduction coefficient and hot state high intensity under 800-1400deg.C and can be used in building composite kiln lining composed of graphite bricks and SiC bricks.

Owner:BAOSHAN IRON & STEEL CO LTD +1

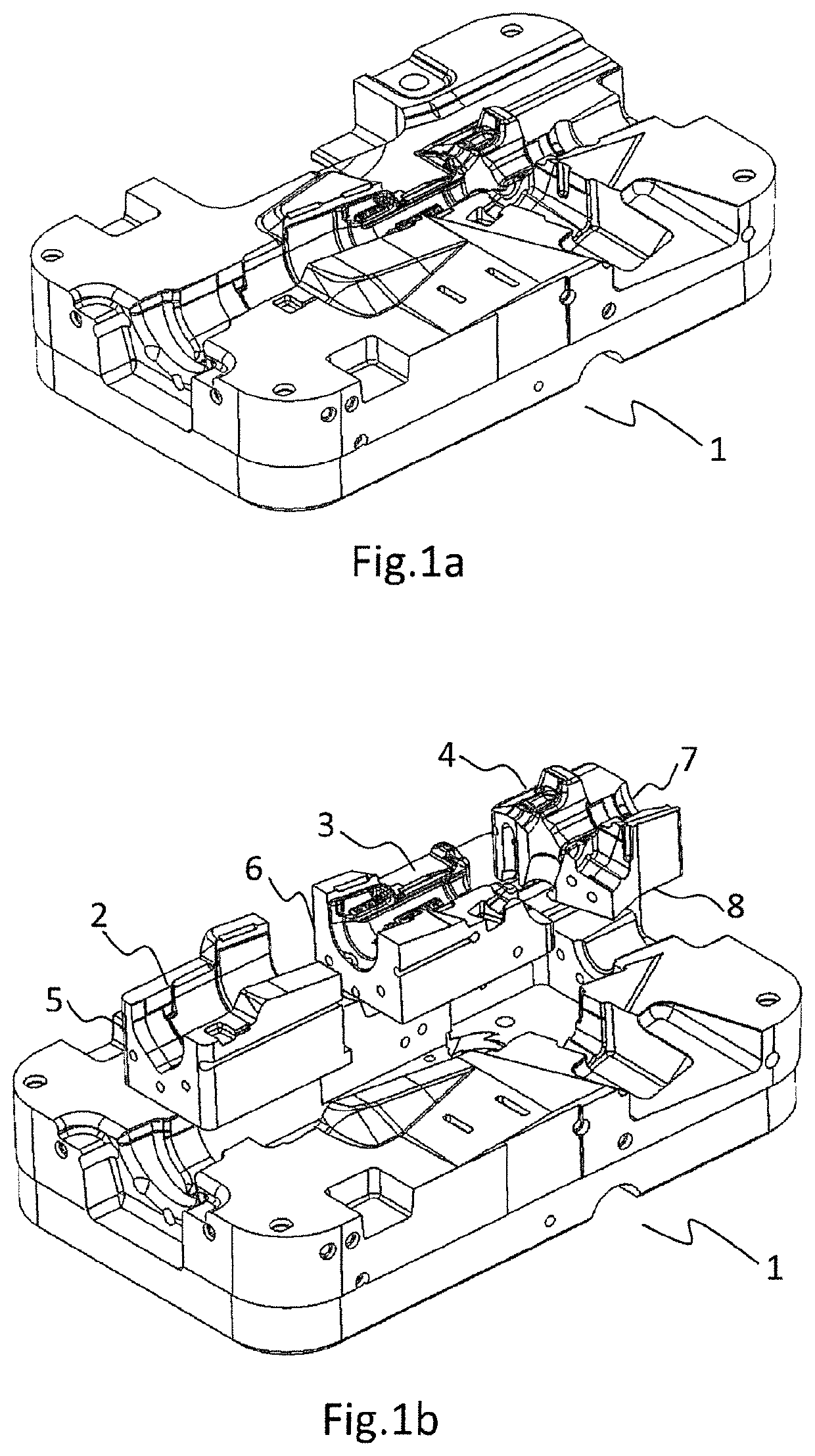

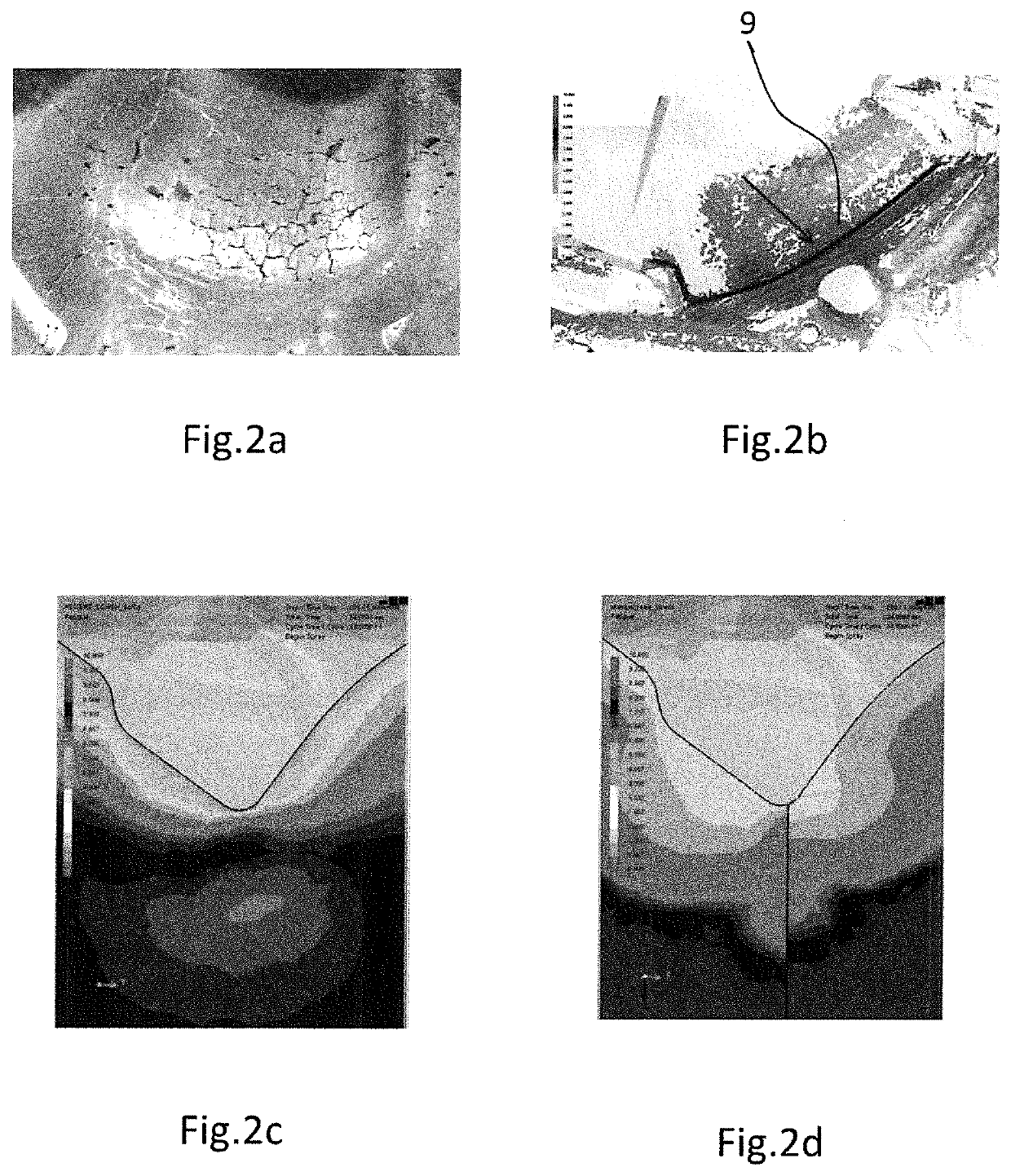

Method for designing dies for die casting and die

ActiveUS20200175214A1High mechanical strengthHigh thermal strengthDesign optimisation/simulationSpecial data processing applicationsDie castingMechanical engineering

A method for making dies for die casting, and relative die, includes designing moulding parts of the die as plurality of sub-inserts. Each sub-insert of the plurality is bordered by boundary lines defined on the basis of a simulation of thermo mechanical behaviour of the die in operation. The simulation is performed by a processor of a computer and the behaviour is the behaviour of the die if the die were a single piece. The method also includes producing the plurality of sub-inserts and assembling the sub-inserts of the plurality with attachment means, so as to form the die.

Owner:COSTAMP GRP SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com