Alumina-silicon carbide-carbonaceous cement-free castable suitable for winter construction

A silicon carbide, cement-free technology, applied in the field of alumina-silicon carbide-carbon cement-free castables, can solve the problems of difficult to control setting time, great difference in reactivity, and unsuitable for winter construction, and achieve excellent explosion-proof performance. , The effect of good density and high thermal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

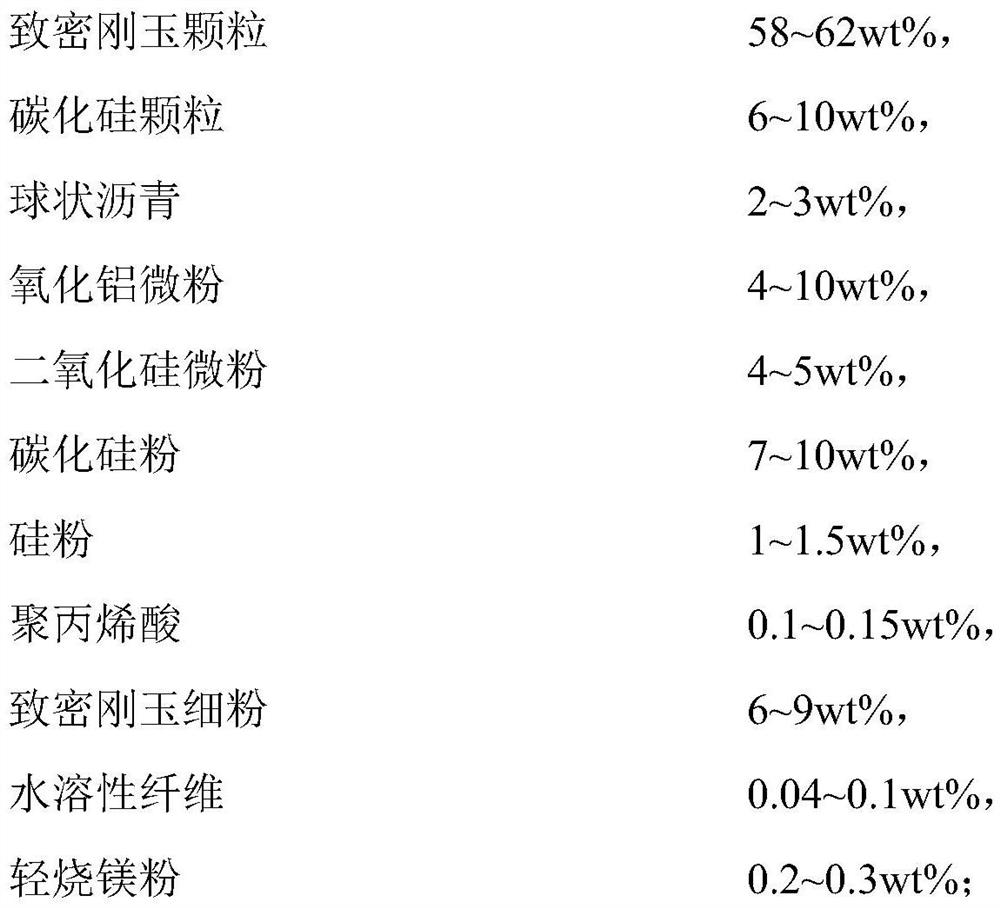

[0051] An alumina-silicon carbide-carbon cementless castable suitable for winter construction. The components and contents of the alumina-silicon carbide-carbonaceous cementless castable are:

[0052]

[0053] In this example:

[0054] The dense corundum particles: Al 2 o 3 The content is 98.7wt%; Fe 2 o 3 The content is 0.14wt%.

[0055] The silicon carbide particles: SiC content is 98.9%; Fe 2 o 3 The content is 0.15wt%.

[0056] The alumina micropowder: Al 2 o 3 The content is 99.7wt%; Na 2 The O content is 0.08 wt%.

[0057] The SiO of the silicon dioxide micropowder 2 The content is 99.9wt%.

[0058] The SiC content of the silicon carbide powder is 98.4wt%.

[0059] The Si content of the silicon powder is 98.8wt%.

[0060] The Al of the dense corundum fine powder 2 o 3 The content is 99.6wt%, Fe 2 o 3 The content is 0.07wt%.

[0061] The water-soluble fiber has a length of 10 mm and a diameter of 12 μm.

[0062] The MgO content of the lightly burne...

Embodiment 2

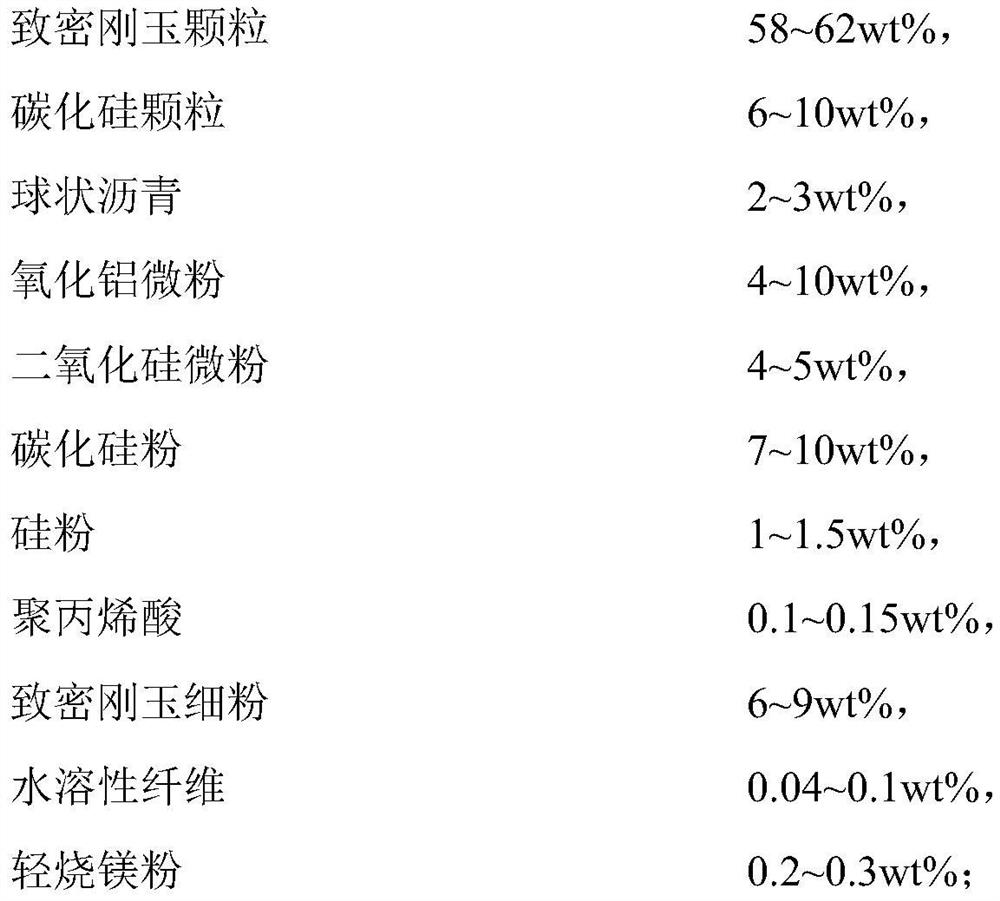

[0069] An alumina-silicon carbide-carbon cementless castable suitable for winter construction. The components and contents of the alumina-silicon carbide-carbonaceous cementless castable are:

[0070]

[0071] In this example:

[0072] Al of dense corundum particles 2 o 3 The content is 99.3wt%, Fe 2 o 3 The content is 0.12wt%.

[0073] SiC content of silicon carbide particles is 99.2%, Fe 2 o 3 The content is 0.24wt%.

[0074] Al 2 o 3 The content is 99.9wt%, Na 2 The O content is 0.06 wt%.

[0075] Silica powder SiO 2 The content is 99.94wt%.

[0076] The SiC content of the silicon carbide powder was 98.7 wt%.

[0077] The Si content of the silicon powder was 99.1 wt%.

[0078] Al of dense corundum fine powder 2 o 3 The content is 99.3wt%, Fe 2 o 3 The content is 0.04wt%.

[0079] The water-soluble fibers had a length of 8 mm and a diameter of 14 μm.

[0080] The MgO content of lightly burned magnesium powder is 96wt%.

[0081] The construction metho...

Embodiment 3

[0086] An alumina-silicon carbide-carbon cementless castable suitable for winter construction. The components and contents of the alumina-silicon carbide-carbonaceous cementless castable are:

[0087]

[0088] In this example:

[0089] Al of dense corundum particles 2 o 3 The content is 98.8wt%, Fe 2 o 3 The content is 0.11 wt%.

[0090] SiC content of silicon carbide particles is 99.2%, Fe 2 o 3 The content is 0.27wt%.

[0091] Al 2 o 3 The content is 99.7wt%, Na 2 The O content is 0.09 wt%.

[0092] Silica powder SiO 2 The content is 99.88wt%.

[0093] The SiC content of the silicon carbide powder was 98.4 wt%.

[0094] The Si content of the silicon powder was 99.3 wt%.

[0095] Al of dense corundum fine powder 2 o 3 The content is 99.2wt%, Fe 2 o 3 The content is 0.06wt%.

[0096] The water-soluble fibers had a length of 6 mm and a diameter of 13 μm.

[0097] The MgO content of lightly burned magnesium powder is 92wt%.

[0098] The construction meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com