Patents

Literature

78results about How to "Improve high temperature flexural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

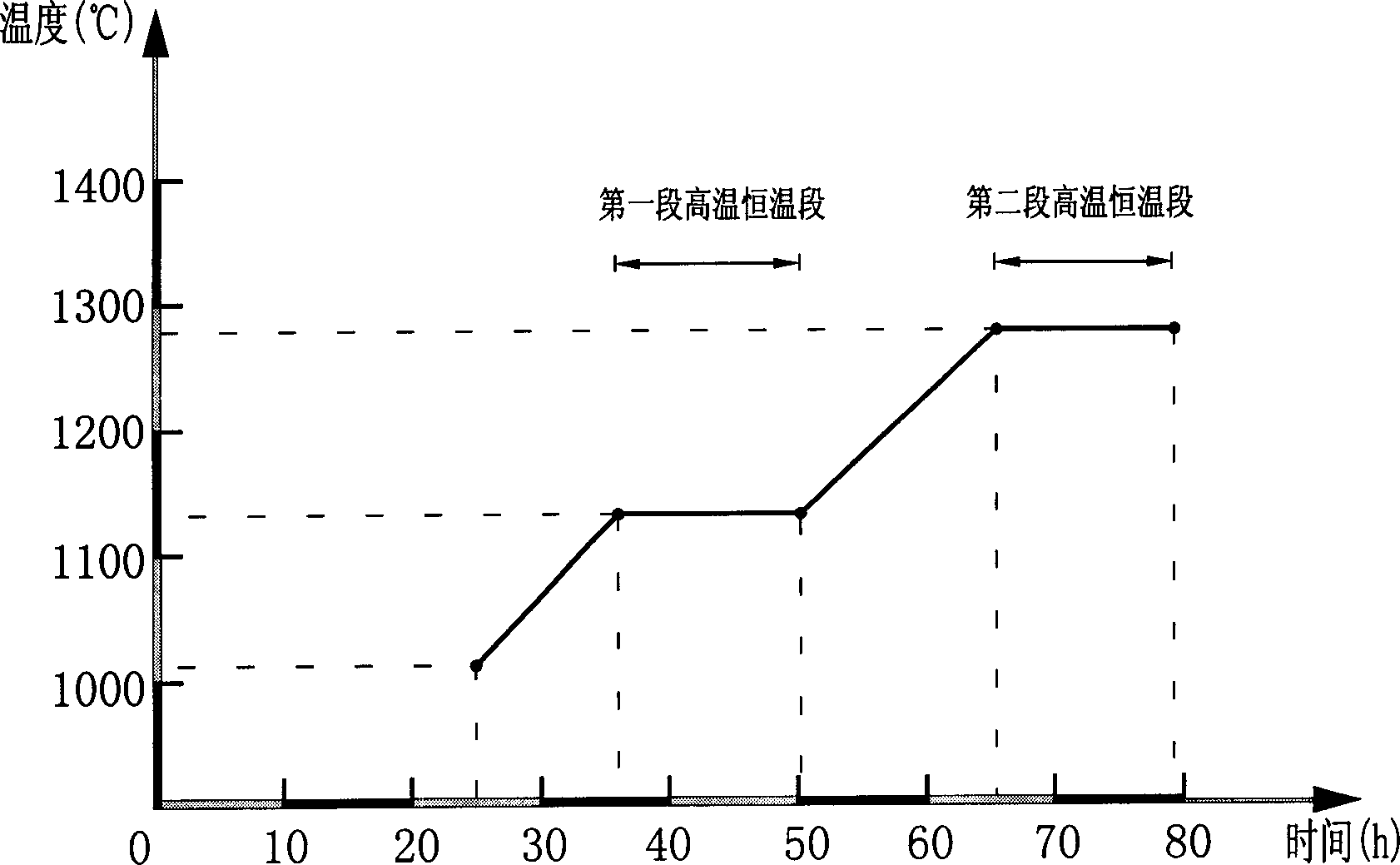

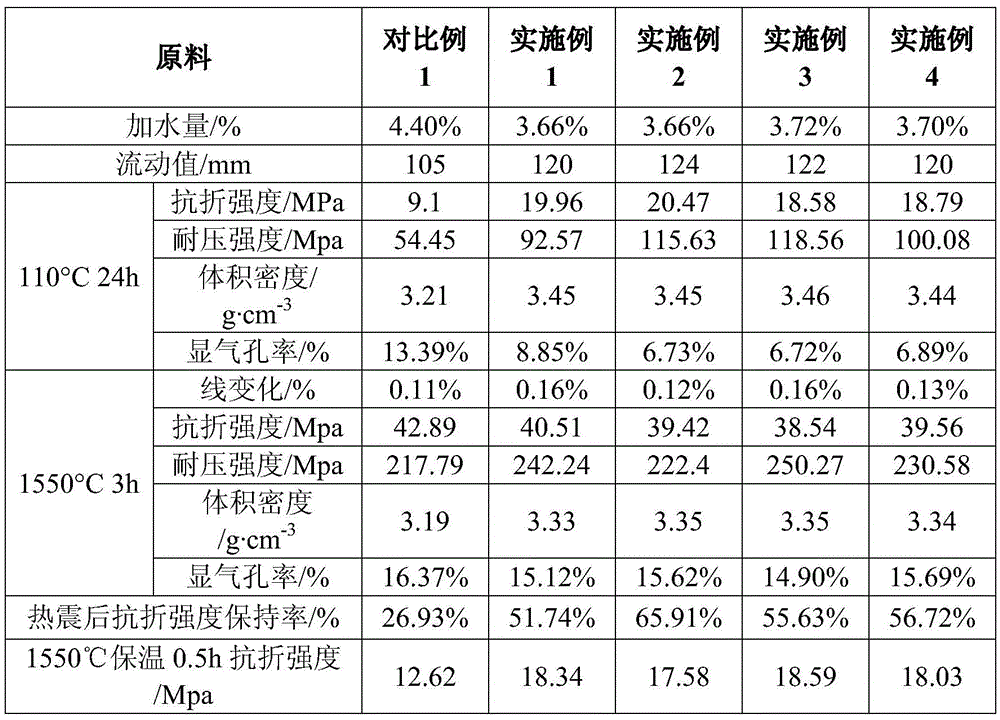

Ltigh crystalline structure iolite mullite kiln, kiln refractory product and calcining technology

The present invention relates to a kind of high crystal structure cordierite-mullite kiln furniture, kiln furnace refractory product and roasting process. Its raw material includes (by weight portion) 50-80 portions of main crystal phase material and 20-50 portions of combined compound matrix material, in the above-mentioned raw material a proper quantity of crystal nucleus formation agent can be added. Its roasting process includes two stages of high-temperature constant-temperature microcrystallization nucleation intensification treatment. Said invention also provides the concrete steps of every stage.

Owner:揭东县热金宝新材料科技有限公司 +2

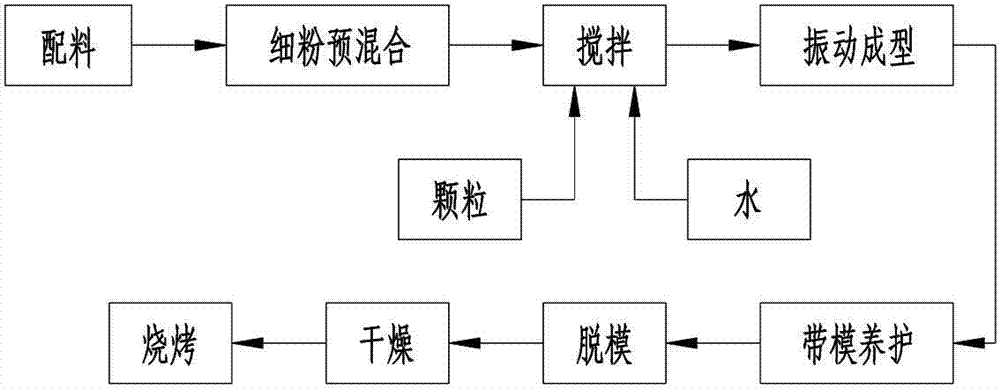

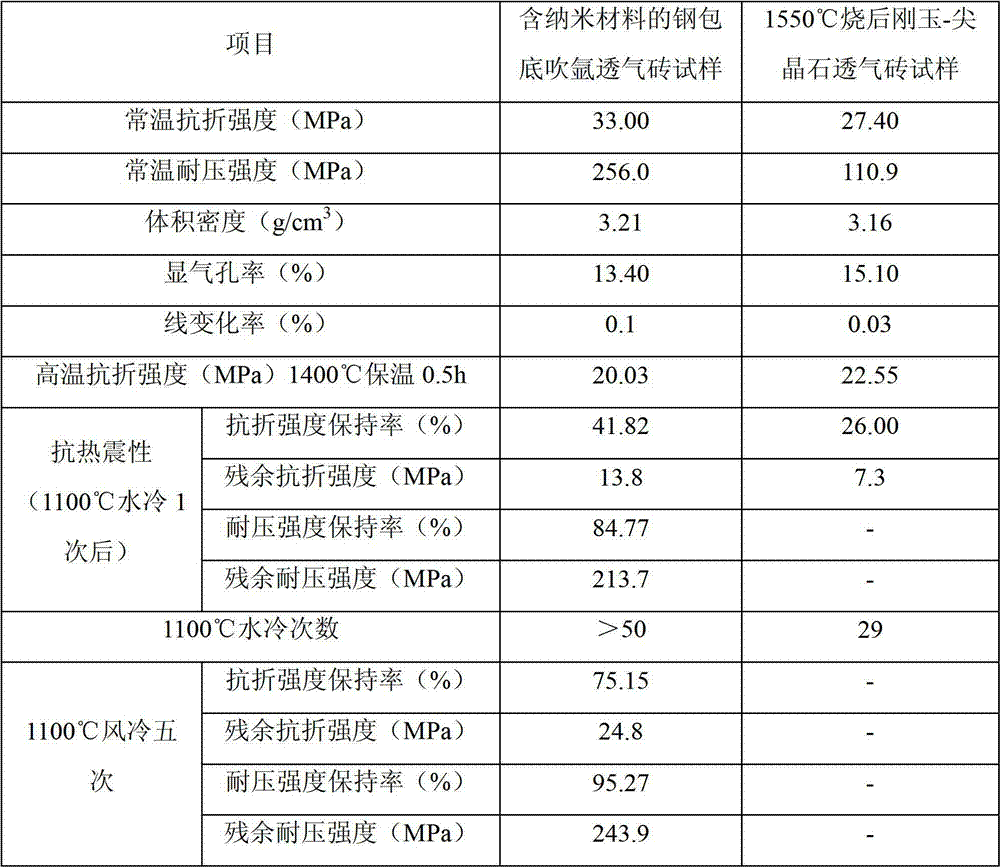

Nanometer material contained ladle bottom argon blowing permeable brick and preparation process thereof

The invention discloses a nanometer material contained ladle bottom argon blowing permeable brick and a preparation process thereof. The permeable brick comprises components of high-purity corundum, spinel, alpha-Al2O3 micro powders, nano calcium carbonate, Si powders, binding agents and antiknock agents. The preparation process of the nanometer material contained ladle bottom argon blowing permeable brick includes the following steps of dosing, fine powder premixing, stirring, vibration forming, curing with molds, demolding, drying and baking. According to the nanometer material contained ladle bottom argon blowing permeable brick and the preparation process thereof, Cr2O3 is not used, and during usage, new pollutants are not generated, so that pollution treatment costs are reduced, and high environmental benefits are achieved; micropores are evenly distributed in the brick, so that cracks are effectively prevented from continuing spreading during usage, the toughness of the permeable brick is improved, the spalling is reduced, the service life of the permeable brick is prolonged, the permeable brick is basically free from bonding slag after usage, cleaning during usage is reduced, and production costs of iron and steel enterprises are reduced.

Owner:成都府天新材料科技有限公司

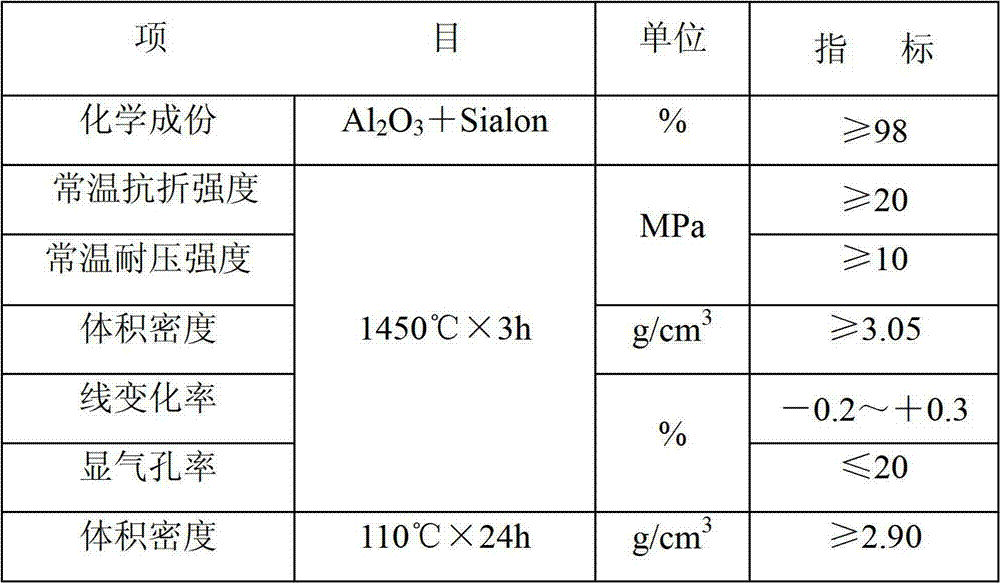

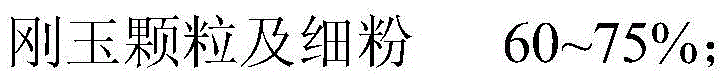

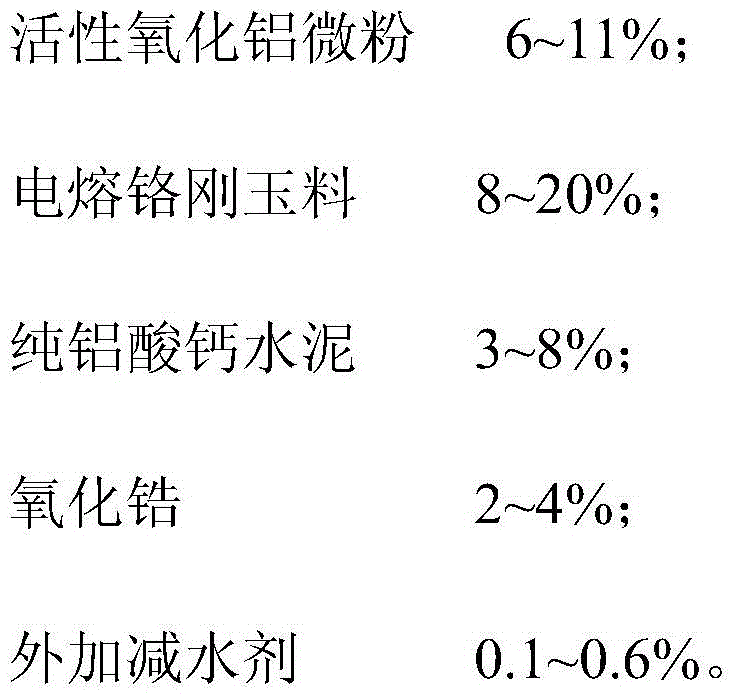

Air brick for special steel refining and preparation method thereof

InactiveCN105645977AReduce the amount of water addedImprove liquidityMelt-holding vesselsBrickCalcination

The invention relates to an air brick for special steel refining, particularly an air brick for special steel refining and a preparation method thereof. The air brick is composed of the following components in percentage by mass: 60-75% of corundum particle and fine powder, 6-11% of activated alumina micropowder, 8-20% of electrofused chrome corundum material, 3-8% of pure calcium aluminate cement, 2-4% of zirconium oxide and 0.1-0.6% of additional water reducing agent. The air brick is suitable for smelting of special steel grades, and has the advantages of excellent high-temperature properties, excellent air permeability, low breaking possibility, favorable high-temperature folding strength and favorable thermal shock resistance. By adopting the curing schedule, the cement in the material can be sufficiently hydrated, thereby enhancing the strength of the semifinished product, and avoiding generating microcracks of possible collisions in the transportation process (the cracks can further extend in the high-temperature calcination process). The firing schedule is adopted to prevent the air brick cracks from generation and enhance the yield of the air bricks.

Owner:LUOYANG LIER REFRACTORY MATERIAL

In-situ synthesized mullite whisker reinforced high-temperature ceramic roller

InactiveCN102249722AIn situ generation of composite enhancementsImprove thermal shock resistanceRefractoryWhiskers

The invention relates to an in-situ synthesized mullite whisker reinforced high-temperature ceramic roller which is prepared from natural raw mineral materials and industrial raw chemical materials. The in-situ synthesized mullite whisker reinforced high-temperature ceramic roller comprises the following compositions in percentage by weight: 15-25% of kaolin, 5-15% of refractory clay, 15-25% of alpha-Al2O3 micro-powder, 3-10% of zirconium silicate, 10-20% of zirconium-titanium mineralizer containing andalusite and 30-40% of refractory corundum; and the ceramic roller is prepared through the following steps: ball-milling, stirring, molding, drying, roasting at a temperature of 1500-1600 DEG C, carrying out heat preservation for 5-10 hours, and naturally cooling, thus obtaining a ceramic roller product (the rupture strength of the product is greater than 57.40 Mpa at a temperature of 1350 DEG C). The in-situ synthesized mullite whisker reinforced high-temperature ceramic roller provided by the invention has a wide application prospect in roasting roller kilns for products such as high-temperature and high-load domestic ceramics, building sanitary ceramics, high-grade large-sized vitrified tiles, technical ceramics and magnetic materials and the like.

Owner:JINGDEZHEN NUONAI TECH CERAMICS

High-crystal mullite-iolite high-temperature industrial ceramic and production method for same

The invention relates to a high-crystal mullite-iolite high-temperature industrial ceramic and a production method for the same. Raw materials comprise, by weight, 40-80 parts of main crystal phase materials, 20-60 parts of combined composite substrate materials and an appropriate amount of composite microcrystal nucleating agent. A roasting process of the production method includes a two-stage constant-temperature roasting method and a two-stage composite crystallization synthetic reaction characteristic enhancing process, wherein the two-stage constant-temperature roasting method includes the steps of performing constant-temperature heat preservation for 10-15 hours at the temperature of 200 DEG C, and performing constant-temperature heat preservation for 10-15 hours at the temperature of 500 DEG C; and the two-stage composite crystallization synthetic reaction characteristic enhancing process includes the steps of sintering for 10-15 hours under the ordinary pressure and at the temperature ranging from 1100 DEG C to 1150 DEG C, and sintering for 20-25 hours under the ordinary pressure and at the temperature ranging from 1420 DEG C to 1430 DEG C. A refractory product produced bythe method has the advantages of excellent oxidation resistance, high refractoriness, high usage temperature, low thermal expansion coefficient, high compression strength, hypobarism, excellent heat stability, anti-strip performance and high high-temperature bending strength. The process of the method has the advantages of simple process, low cost and suitability for mass production, and is applicable to preparing kiln furniture, industrial ceramics and structural materials.

Owner:GUANGDONG REJINBAO NEW MATERIAL TECH +2

Al2O3-SiC-C refractory brick for torpedo ladle produced by utilizing waste Al2O3-C and preparation method of Al2O3-SiC-C refractory brick

InactiveCN107555970AExtended service lifeHigh degree of densificationMelt-holding vesselsBrickMaterials science

The invention belongs to the field of refractory matters for ferrous metallurgy and in particular relates to an Al2O3-SiC-C refractory brick for a torpedo ladle produced by utilizing a waste Al2O3-C material and a preparation method of the Al2O3-SiC-C refractory brick. The Al2O3-SiC-C refractory brick comprises the following raw materials in percentage by weight: 10-40% of special grade bauxite clinker particles with the particle size of 3-5mm, 10-30% of special grade bauxite clinker particles with the particle size of 1-3mm, 5-20% of alundum particles with the particle size of 0.088-1mm, 5-20% of corundum fine powder with the particle size of less than 0.088mm, 2-8% of silicon carbon particulates with the particle size of 0.088-1mm, 2-8% of silicon carbon fine powder with the particle size of less than 0.088mm, 10-25% of waste Al2O3-C material fine powder with the particle size of less than 0.088mm, 5-15% of alumina micro powder with the particle size of less than 0.088mm, 3-10% of binding clay fine powder with the particle size of less than 0.088mm, 1-10% of crystalline flake graphite powder with the particle size of less than 0.088mm, 0.5-5% of asphalt powder with the particle size of less than 0.088mm, and 4-8% of additional phenolic resin.

Owner:UNIV OF SCI & TECH LIAONING

Heat-insulating and fire-resistant calcium alumino-titanate material and preparation method thereof

The invention relates to a heat-insulating and fire-resistant calcium alumino-titanate material and a preparation method thereof. According to the technical scheme, the method comprises the steps thatfine calcium alumino-titanate powder and coke powder are pre-mixed in a mass ratio of (8-9):1, and then placed in a tube furnace, heat preservation is conducted at the temperature of 1600-1700 DEG Cin the nitrogen atmosphere, and cooling, crushing and magnetic separation are conducted in sequence; heat preservation is conducted at the temperature of 1400-1450 DEG C, cooling and crushing are conducted, grinding is conducted until the particle size is smaller than or equal to 0.088 mm, and a mixture is obtained; sodium dodecyl benzene sulfonate accounting for 2-3 wt% of the mixture, dextrin accounting for 3-8 wt% of the mixture, sodium polyacrylate accounting for 0.2-0.5 wt% of the mixture and water accounting for 35-40 wt% of the mixture are added into the mixture, stirring, forming, maintaining and drying are conducted in sequence, heat preservation is conducted at the temperature of 1400-1500 DEG C, and the heat-insulating and fire-resistant calcium alumino-titanate material is obtained. The preparation method has the advantages of being low in cost, simple in process and high in yield. The heat-insulating and fire-resistant calcium alumino-titanate material has the advantages of being small in bulk density, high in compression strength, high in high-temperature breaking strength, small in heat conductivity coefficient and high in thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH +1

Stress buffering type fire resistive material for dry coke quenching equipment and method for manufacturing same

The present invention relates to a stress-buffering refractory material that is used for dry quenching coke equipment, and belongs to the refractory material. The stress-buffering refractory material is prepared by mixing stress-buffering raw materials, waste kiln, sintered or electrically molten mullite, micro Al2O3 powder, clay and dextrin water; wherein, the stress-buffering raw materials is molded through extrusion after andalusite, fused silica, the micro Al2O3 powder and the clay are mixed well, and is prepared after high-temperature sintering at temperature between 1400 DEG C and 1650 DEG C; the refractory material can buffer the stress produced by sudden cooling and sudden heating when in use; the thermal shock stability, high-temperature rupture strength, wear resistance and service life are greatly improved. Compared with the existing refractory material that is used for the dry quenching coke equipment, the thermal shock resistance is improved by 20 to 40 percent; the mechanical properties are improved by 10 to 20 percent; the erosion resistance is improved by 30 to 50 percent; the wear resistance is improved by 15 to 35 percent and the service life is improved by more than 50 percent.

Owner:宜兴市丁山耐火器材有限公司

Refractory castable for blast furnace tapping trough swing launder and preparation method thereof

The invention relates to a refractory castable for a blast furnace tapping trough swing launder and a preparation method thereof. The technical scheme includes: taking 50-55wt% of high-purity magnesia particles and 10-13wt% of magnesium-aluminum spinel particles as the aggregate, using 7-9wt% of used MgO-C brick fine powder, 9-11wt% of the fused magnesia fine powder, 13-18wt% of Cr7C3 micro-powder and 1-4wt% of zirconia micro-powder as the matrix material, according to the content of the aggregate and the matrix material, firstly mixing the matrix material evenly, then adding the evenly mixed matrix material into the aggregate and mixing the substances evenly, then additionally adding aluminum sol accounting for 10-12wt% of the sum of the matrix material and the aggregate, stirring the substances evenly, carrying out vibration molding and room temperature curing, and performing heat preservation at 90-110DEG C for 12-24h, thus obtaining the refractory castable for the blast furnace tapping trough swing launder. The method provided by the invention has the characteristics of low cost and simple process. The prepared refractory castable for the blast furnace tapping trough swing launder has the advantages of low heat conductivity coefficient, large high temperature bending strength, good thermal shock resistance and high iron influx.

Owner:巩义市兴平耐火材料有限公司

Slide plate refractory with silicon nitride added and production method thereof

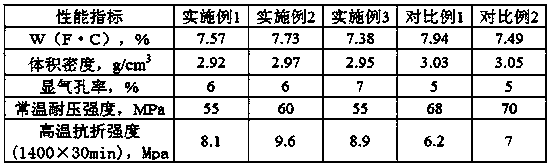

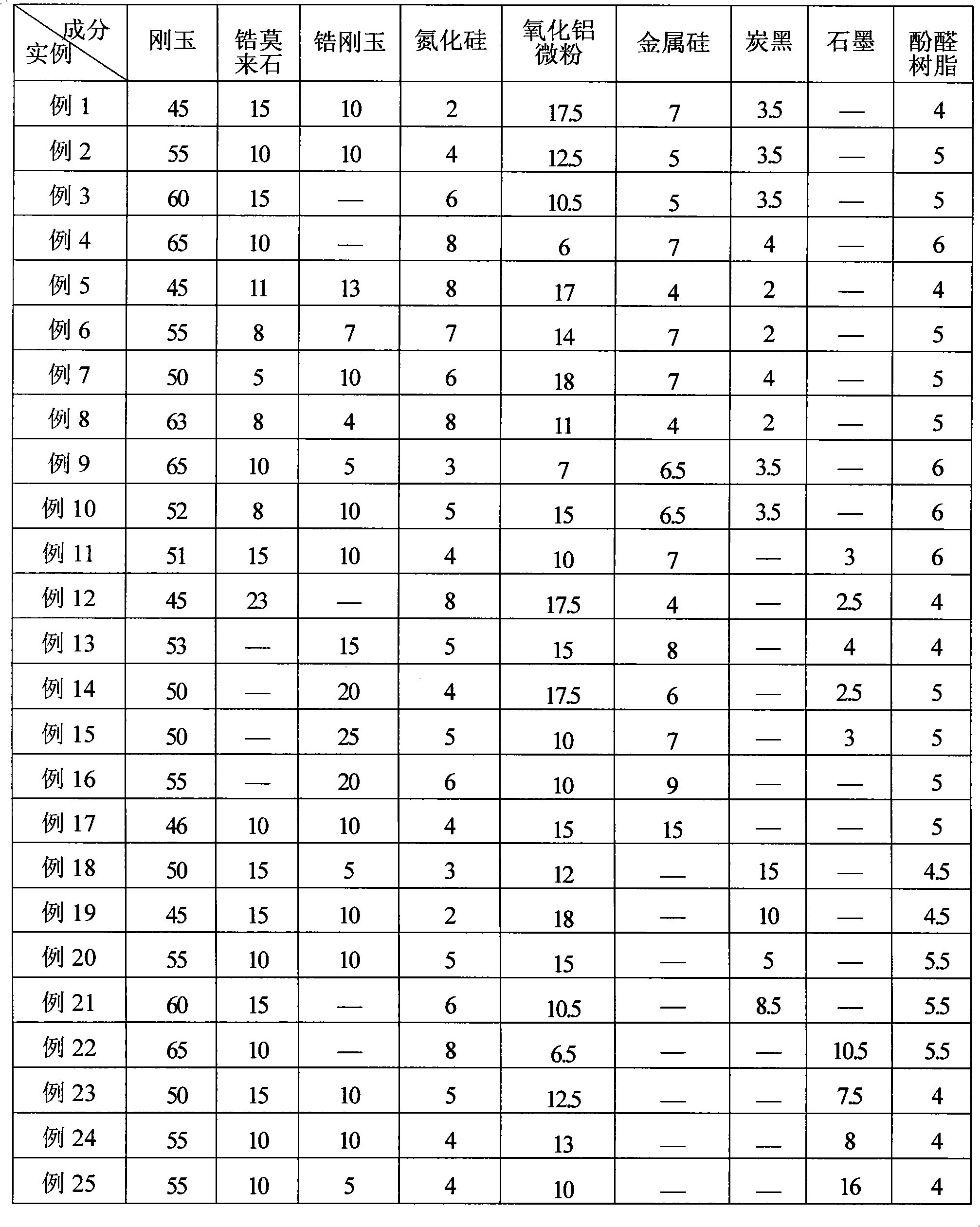

The invention relates to a slide plate refractory with silicon nitride added and a production method thereof. The slide plate is prepared by the following raw materials in percentage by weight: 45-65% of corundum, 10-25% of zirconia-mullite and / or zirconia-corundum, 2-8% of silicon nitride, 6-18% of alumina fine powder and the balance one or more of silicon metal, carbon black and graphite powder and a phenolic resin binder accounting for 4-6% of the total above raw materials. The production method is characterized by proportionally weighing the raw materials, uniformly mixing the raw materials, obtaining the mixture through mixing, press-forming the mixture, drying the formed mixture at 190-210 DEG C for 6-10h and then carrying out nitridation firing on the dried mixture at1200-1400 DEG C. The invention has the following benefits: by adding silicon nitride and reasonably adding other components according to the amount and ratios, the slide plate composite material with structure of Al2O3-ZrO2-Si3N4-C is formed, and the oxidation resistance of the slide plate is improved; and the apparent porosity of the refractory is 1-4%, the cold compression strength is 150-220MPa, the high temperature rupture strength is 28-33MPa and such performance indexes as the oxidation resistance, the scouring resistance, the thermal shock resistance and the like are all excellent or good.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

Micro-expansive brick for carbon anode baking furnace and preparation method thereof

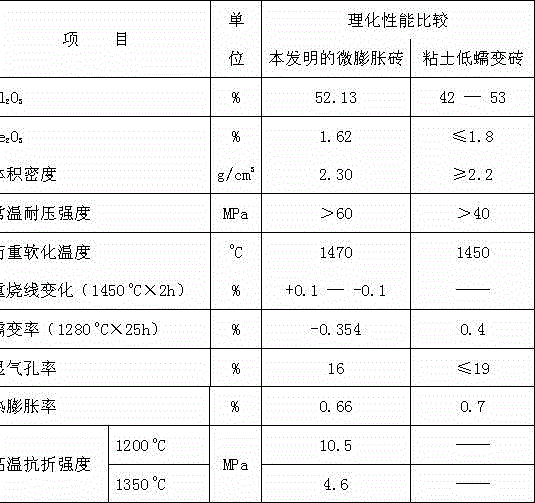

The invention discloses a micro-expansive brick for a carbon anode baking furnace and a preparation method thereof. The micro-expansive brick is prepared from the following components in percentage by weight: 6-8% of calcined bauxite clinker having the granularity of 3-5mm, 29-32% of calcined bauxite clinker having the granularity of 1-3mm, 15-20% of calcined flint clay clinker having the granularity of 0-1mm, 10-15% of Guangxi clay powder having the fineness less than or equal to 0.074mm, 14-15% of kyanite powder having the fineness less than or equal to 0.088mm, and 12-18% of calcined bauxite clinker powder having the fineness less than or equal to 0.088mm. The preparation method comprises the following steps: 1, crushing and screening the calcined bauxite clinker and the calcined flint clay clinker; 2, grinding the Guangxi clay, the kyanite and the calcined bauxite clinker; 3, mixing and stirring; 4, adding a paper pulp waste liquid and mixing; 5, pressing brick blanks; 6, drying and calcining to obtain the finished products. The prepared micro-expansive brick for the carbon anode baking furnace is low in creep rate, high in refractoriness under load, high in high-temperature bending strength and longer in service life, and therefore, the service life of the carbon anode baking furnace can be increased to the utmost extent and the maintenance cost can be reduced.

Owner:河南鑫诚耐火材料股份有限公司

MgO-Cr7C3 brick for ladle slag line and production method of MgO-Cr7C3 brick

The invention relates to a MgO-Cr7C3 brick for a ladle slag line and a production method of the MgO-Cr7C3 brick. According to the technical scheme, the production method includes: using 55-65wt% of high-purity magnesia particles as the aggregate and 15-25wt% of fused magnesia fine powder, 10-15wt% of Cr7C3 fine powder and 5-10wt% of SiC fine powder as the matrix materials; according to the contents of the aggregate and the matrix materials, evenly mixing the matrix materials first, adding the evenly-mixed matrix materials into the aggregate, and evenly mixing; adding alumina sol accounting for 3-7wt% of the sum of the aggregate and the matrix materials, mixing for 5-10 minutes, and using a semi-dry method to perform mechanical pressing; placing the formed blank into a high-temperature furnace, sintering at 1500-1600 DEG C and under the argon atmosphere, and keeping the temperature for 2-3 hours to obtain the MgO-Cr7C3 brick for the ladle slag line. The production method has the advantages that the method is simple in process, and the produced MgO-Cr7C3 brick is high in compactness, large in high-temperature bending strength, high in slag erosion resistance and low in pollution to molten steel.

Owner:WUHAN UNIV OF SCI & TECH

Mullite aluminum nitride prefabricated brick formed by nitriding sintering

The invention relates to a mullite aluminum nitride prefabricated brick formed by nitriding sintering. The mullite aluminum nitride prefabricated brick is prepared by the following steps of: adding an additive into mullite, aluminium nitride, silicon metal, aluminium metal, silica powder and aluminate cement serving as basic raw materials; uniformly mixing various raw materials and dispersing agents in a dried mode by using a stirring machine; adding water into the uniformly-mixed materials and stirring uniformly; injecting the mixed materials into a mould to be molded to form a prefabricated piece; roasting the prefabricated piece which is demoulded and naturally cured into a roasting kiln to roast; and finally putting the prefabricated piece into a high-temperature nitriding kiln at the high temperature of 1400-1500 DEG C under a nitrogen atmosphere to sinter; and after sintering the prefabricated piece, and cooling to the room temperature to obtain the prefabricated brick. Compared with the traditional product, the heat-state intensity of product disclosed by the invention is obviously improved and whole performance of the product disclosed by the invention is good.

Owner:山国强

Magnesia carbon brick for vicinity of furnace door of electric arc furnace and preparation method of magnesia carbon brick

PendingCN112125650AImprove thermal conductivityImprove toughnessThermal dilatationElectric arc furnace

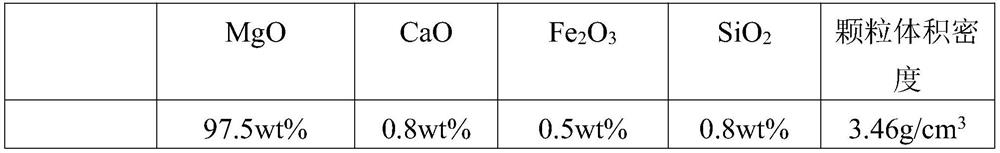

The invention relates to a magnesia carbon brick for the vicinity of the furnace door of an electric arc furnace and a preparation method of the magnesia carbon brick. The prepared magnesia carbon brick is prepared from the following raw materials in parts by weight: 20-30 parts of fused magnesia of which the granularity is more than or equal to 3mm and less than 5mm, 20-40 parts of fused magnesiaof which the granularity is more than or equal to 1mm and less than 3mm, 10-20 parts of fused magnesia of which the granularity is more than or equal to 0.1 mm, 5-20 parts of fused magnesia powder ofwhich the granularity is smaller than 0.088 mm, and 12-16 parts of flake graphite, 1-3 parts of phenolic resin binder, and 1-6 parts of additive; the content of magnesium oxide in the fused magnesiteis greater than or equal to 97.5 wt%, and the volume density of the fused magnesite is greater than 3.45 g / cm <3>. According to the magnesia carbon brick for the vicinity of the furnace door of an electric arc furnace and a preparation method of the magnesia carbon brick of the invention, the phenolic resin binder is used; the phenolic resin binder is utilized to prepare the fused magnesite and flake graphite with different particle sizes under the action of the additive, so that the magnesia carbon brick has the advantages of good heat-conducting property, low thermal expansion coefficient,high tensile strength, good toughness, oxidation resistance and scour resistance.

Owner:北京利尔高温材料股份有限公司

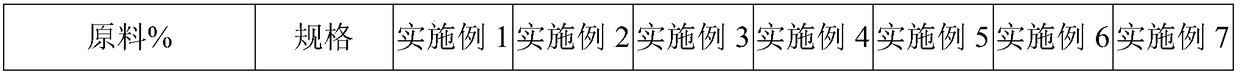

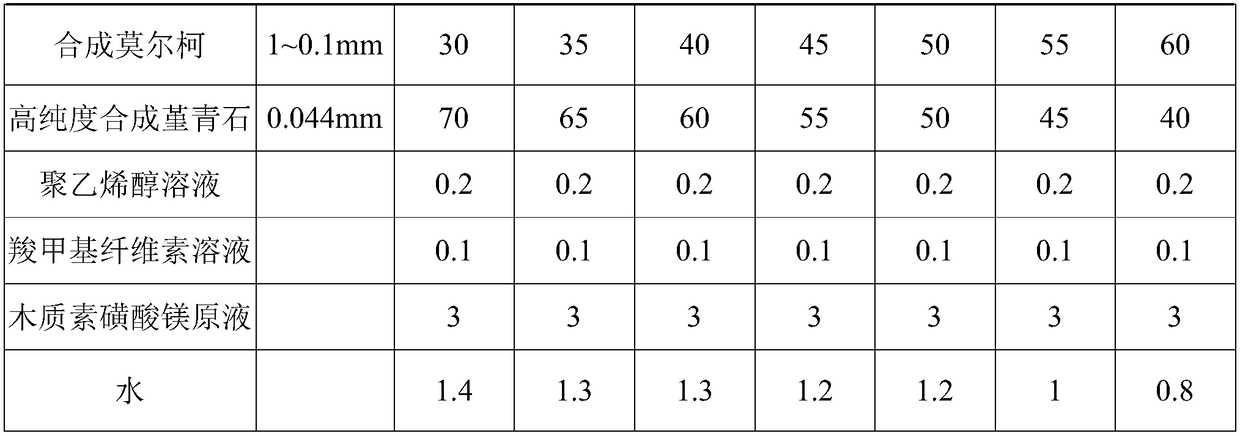

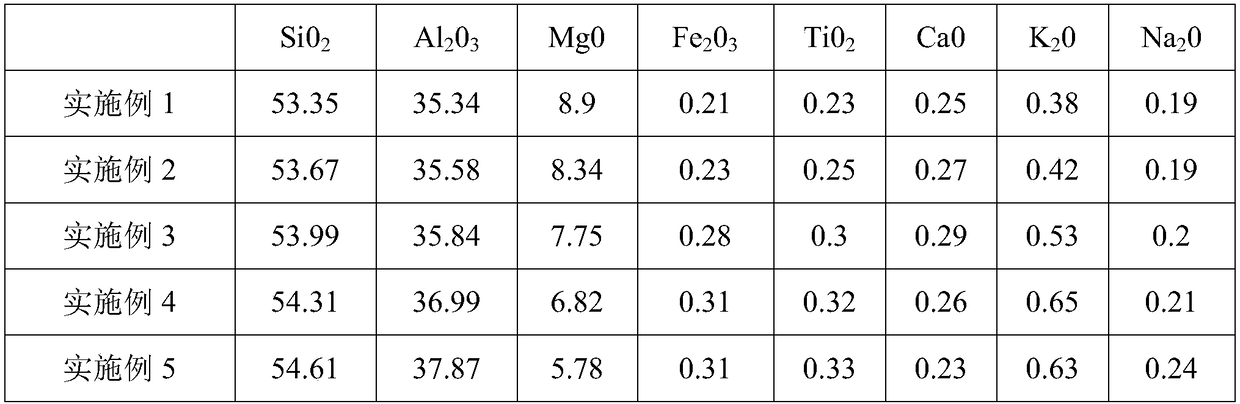

High-purity cordierite-combined mullite material and preparation method thereof

The invention belongs to the technical field of novel ceramic materials, and relates to a high-purity cordierite-combined mullite material and a preparation method thereof. Synthesized mullite is usedas aggregate, high-purity synthesized cordierite is used as matrix, a compound organic additive is used for solving formability, and no clay is added. The high-purity cordierite has higher high-temperature bending strength, lower thermal expansion coefficient and lower impurity content; the matrix of the cordierite-mullite material adopts the high-purity cordierite, and therefore the prepared cordierite-mullite material has the outstanding advantages of high high-temperature bending strength, low thermal expansion coefficient, high recycling frequency under high temperature, little deformation and long service life.

Owner:ZIBO GT INDAL CERAMICS

Sintered high-alumina refractory brick and preparation method thereof

The invention relates to a sintered high-alumina refractory brick and a preparation method thereof. The technical scheme of the preparation method comprises the following steps: mixing high-alumina bauxite in a planetary forced mixer, and screening to obtain a material A of which the granularity is 3-5mm; mixing titanium-iron slags in the planetary forced mixer, and screening to obtain a material B of which the granularity is 0.088-2.5mm; burdening material A, material B, Guangxi white clay, silicon carbide and Rho-aluminium oxide according to the weight ratio of 1 to (0.75 to 0.80) to (0.05 to 0.10) to (0.25 to 0.30) to (0.30 to 0.35), evenly stirring, adding silica solution, stirring, ageing mixture, carrying out mechanical pressing, demoulding and drying; then, keeping the temperature for 2-4 hours at the temperature of 1480-1500 DEG C in air atmosphere in a muffle furnace, and carrying out furnace cooling to the room temperature to obtain the sintered high-alumina refractory brick. The preparation method has the characteristics of simple technology and low cost, and the prepared sintered high-alumina refractory brick has the advantages of high compactness and high high-temperature breaking strength and slag corrosion resistance.

Owner:淄博恒森耐火材料有限公司

Corundum-spinel refractory brick and preparation method thereof

The invention relates to a corundum-spinel refractory brick and a preparation method thereof. The corundum-spinel refractory brick comprises 55 to 60% by weight of brown fused alumina particles as aggregates, 20 to 25% by weight of aluminum-magnesium spinel fine powder as a base material, 15 to 20% by weight of caustic calcined magnesite powder as a base material, 1 to 2% by weight of aluminum powder as a base material and 1 to 4% by weight of iron powder as a base material. The preparation method comprises uniformly mixing the base materials, adding the aggregates into the base materials, mixing the mixture for 5 to 8 minutes, adding 3 to 6 wt% of thermosetting phenolic resin into the base materials and aggregates, mixing the mixture for 10 to 15 minutes, carrying out mechanical pressing molding, carrying out maintenance at a temperature of 200-250 DEG C for 12 to 18 hours, putting the molded material into a muffle furnace, carrying out heating to 1500-1600 DEG C under nitrogen atmosphere conditions, carrying out thermal insulation for 2 to 3 hours, and carrying out furnace cooling to obtain the corundum-spinel refractory brick. The preparation method has the characteristics of low cost and simple processes. The corundum-spinel refractory brick has high sintered density, large high temperature flexural strength and strong anti-slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Thermal-shock-resistant magnesian sliding plate brick and production method thereof

InactiveCN111960805AHigh bonding strengthGood detection of coating strengthMelt-holding vesselsAluminium chlorideThermal dilatation

The invention discloses a thermal-shock-resistant magnesian sliding plate brick which is prepared from the following raw materials in percentage by weight: 55-70% of modified magnesia particles, 30-45% of magnesia fine powder and 3-5% of paper pulp waste liquid. The preparation method comprises the following steps: firstly, preparing alpha-Al2O3 micro-powder coated modified magnesia particles by taking a saturated solution of aluminum chloride or aluminum sulfate as a binding agent, weighing the components according to the weight, mixing for 0.5 hour, forming by selecting a press machine according to the single weight of a sliding plate, drying a green body for 24 hours at the temperature of 110 DEG C, loading into a kiln, firing at 1500 DEG C for 8 hours, hooping the fired green body, adhering a steel shell, grinding, coating, finishing, checking and accepting, and storing in a warehouse. According to the thermal-shock-resistant magnesium sliding plate produced by the invention, low-expansion spinel is generated around magnesia particles to absorb thermal expansion of the magnesia particles, so that the internal thermal stress of the material is reduced and the thermal shock resistance is improved, through modification, the surface activity of magnesia particles is improved, sintering is promoted, combination of the particles and a matrix is strengthened, and the high-temperature strength is improved, so that the service life of the magnesian skateboard is prolonged and the sintering temperature is reduced.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Joint refractory material for heat exchange of converter bottom and construction method

ActiveCN108439958ASatisfy the requirement of service life of 1000~2000 furnacesEnsure safe productionAlcoholRefractory

The invention discloses a joint refractory material for heat exchange of the converter bottom and a preparation method and a construction method of the joint refractory material. The joint refractorymaterial is prepared from a first constituent part and a second constituent part, wherein the first constituent part comprises following components in percentage by weight: 63wt%-85wt% of magnesia, 0-10wt% of asphalt, 0-10wt% of graphite and 2wt%-17wt% of metal powder; the second constituent part is prepared from resin accounting for 5wt%-15wt% of weight of the first constituent part, alcohol substances accounting for 5wt%-15wt% of weight of the first constituent part and a curing agent accounting for 0.5wt%-1.5wt% of weight of the first constituent part. The joint refractory material can meetthe requirement of 1000-2000 furnaces of service life when the converter bottom is replaced in new furnace campaign and medium term of furnace campaign and guarantees normal and safe production of aconverter.

Owner:SHOUGANG CORPORATION

High-aluminum pull brick for carbon anode roasting furnace flame paths and preparation method thereof

The invention discloses a high-aluminum pull brick for carbon anode roasting furnace flame paths and a preparation method thereof. The high-aluminum pull brick for carbon anode roasting furnace flame paths is prepared by mixing, calcining and pressing calcined mullite, calcined high-aluminum bauxite, andalusite granules, alumina powder, Gangxi clay powder and andalusite fine powder. The preparation method comprises the following steps: 1. crushing and screening the calcined mullite and calcined high-aluminum bauxite; 2. selecting 10-16 wt% of alumina powder, 10-12 wt% of Gangxi clay powder and 15-21 wt% of andalusite fine powder, mixing and grinding; 3. mixing the co-ground powder with 8-12 wt% of calcined mullite, 17-23 wt% of calcined high-aluminum bauxite and 25-29 wt% of andalusite granules; 4. adding pulp waste, and compounding; 5. pressing to be green bricks; and 6. drying and calcining to obtain the finished product. The high-aluminum pull brick for carbon anode roasting furnace flame paths has the advantages of low creep rate, high refractoriness under load, favorable high-temperature folding strength and small physical dimension deformation, and can prolong the service life of the carbon anode roasting furnace and lower the maintenance cost.

Owner:河南鑫诚耐火材料股份有限公司

Non-oxide enhanced material for slag line of submersed nozzle

The invention relates to a submersed nozzle for steel making and continuous casting tundish, in particular to a non-oxide enhanced material for a slag line of a submersed nozzle. The material comprises the components in percentage by mass as follows: 5.5%-8% of ZrB2, 75%-78% of m-ZrO2, 6%-8% of graphite, 2%-3% of Al, 5%-6.5% of O'-Sialon, 1.0%-2.0% of Y2O3-PSZ and the balance of impurities; and 8-10% of a modified resin binding agent is additionally added. The non-oxide enhanced material for the slag line of the submersed nozzle has excellent corrosion resistance and plugging resistance, can effectively reduce carbureting of molten steel, and is more suitable for producing low -carbon steel and ultra-low carbon steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Zirconium composite high-performance electrofused magnesium-calcium zirconium brick and manufacturing method thereof

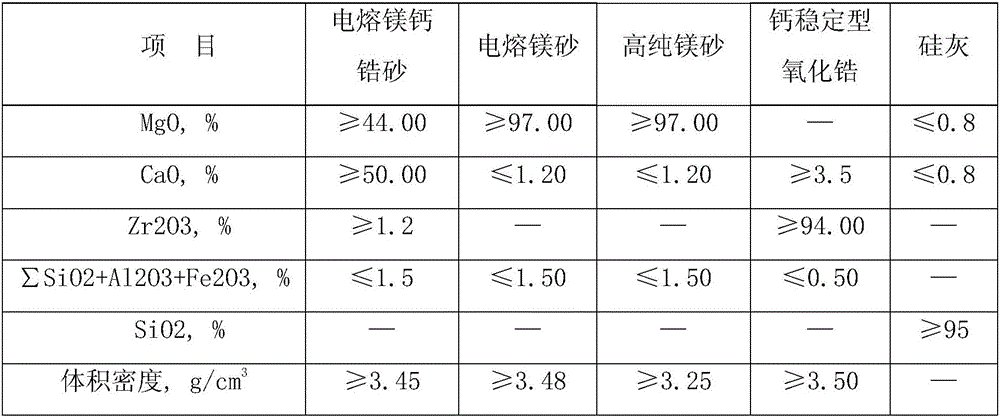

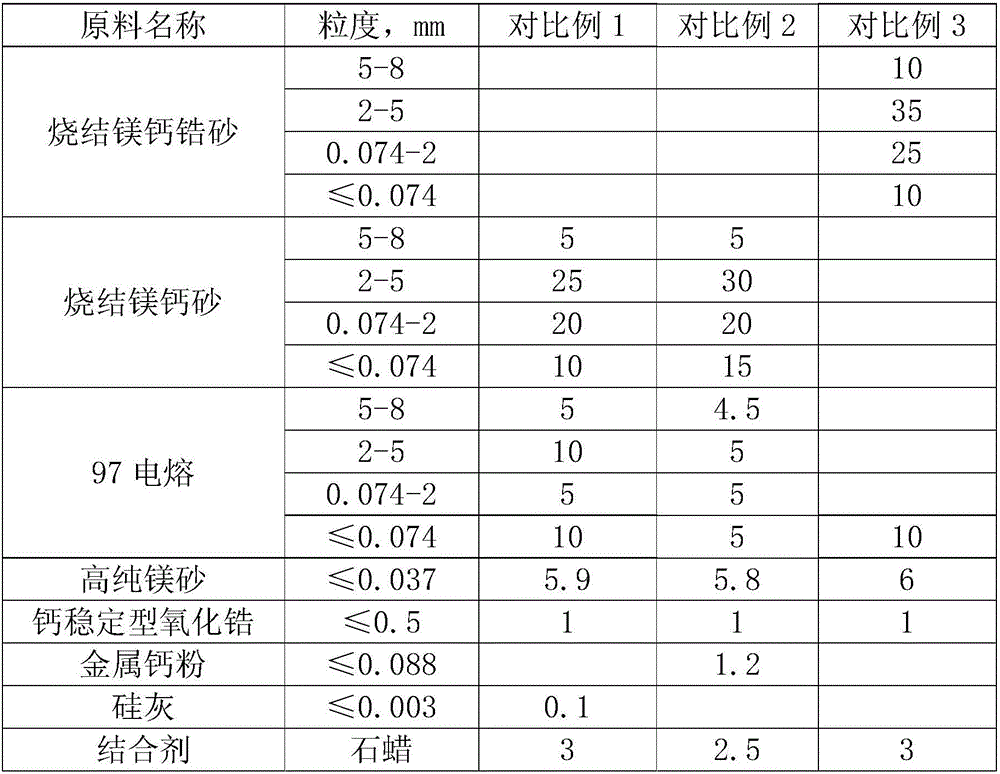

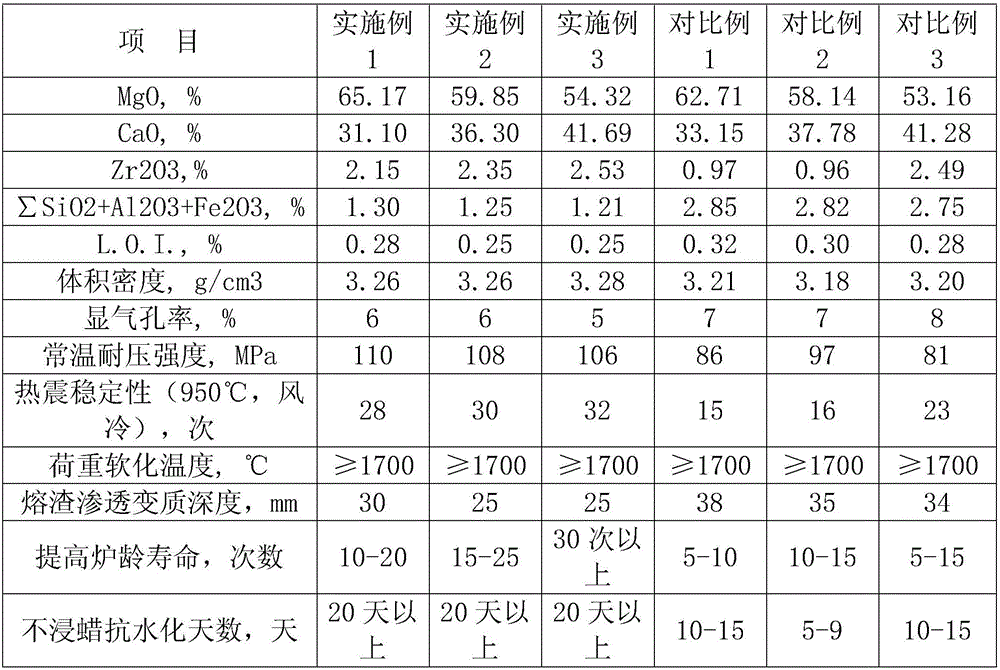

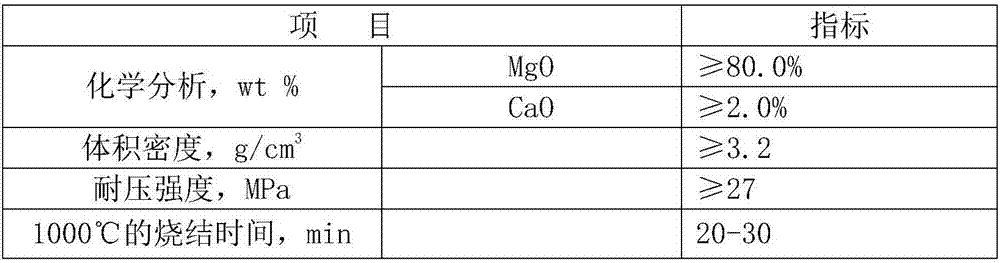

The invention belongs to the technical field of refractories for steel smelting furnaces, and in particular relates to a zirconium composite high-performance electrofused magnesium-calcium zirconium brick and a manufacturing method thereof; the zirconium composite high-performance electrofused magnesium-calcium zirconium brick comprises 5-10% of electrofused magnesium-calcium zirconium sand with a partical size of 5-8mm, 20-35% of electrofused magnesium-calcium zirconium sand with a partical size of 2-5mm, 20-30% of electrofused magnesium-calcium zirconium sand with a partical size of 2-0.074mm, 10-15% of electrofused magnesium-calcium zirconium sand fine powder with a partical size of 0.074mm or less, 1-5% of electrofused magnesium sand with a partical size of 5-8mm, 1-10% of electrofused magnesium sand with a partical size of 2-5mm, 1-5% of electrofused magnesium sand with a partical size of 2-0.074mm, 5-10% of electrofused magnesium sand fine powder with a partical size of 0.074mm or less, 5-10% of electrofused magnesium sand super-fine powder with a partical size of 0.037mm or less, 0.5-1.2% of calcium stabilized zirconia with a partical size of 0.5mm or less, 0.5-2% of metal calcium powder with a partical size of 0.088mm or less, 0.1-0.5% of silica fume with a partical size of 0.003mm or less and 2-5% of a binder. The method can obviously improve the physical and chemical performance indexes of the magnesium-calcium zirconium brick, anti-penetration, anti-erosion, anti-erosion and anti-spalling and other use performances of the magnesium-calcium zirconium brick can be improved, and most importantly, the magnesium-calcium zirconium brick can meet the requirements of current smelting conditions.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Multifiber reinforced magnesia-alumina-carbon refractory material and preparation process thereof

The invention relates to a multifiber reinforced magnesia-alumina-carbon refractory material and a preparation process thereof. A refractory brick is prepared from the following raw materials in percentages by weight: 8 to 10% of A-grade dead-burnt magnesia fine powder, 5 to 7% of B-grade dead-burnt magnesia fine powder, 19 to 22% of C-grade dead-burnt magnesia fine powder, 11 to 13% of D-grade dead-burnt magnesia fine powder, 8 to 10% of E-grade dead-burnt magnesia fine powder, 15 to 18% of F-grade dead-burnt magnesia fine powder, 7 to 8% of a binder A, 5.5 to 7.5% of a binder B, 1.3 to 1.7% of a binder C, 6 to 8% of metal aluminum powder and 0.3 to 0.5% of an additive. According to the invention, products and raw materials are safe and non-toxic, and may not cause harmful effects to users and the environment; good physical properties and wide application prospects in the fields of metallurgy and steelmaking are realized; the refractory material is improved in mechanical properties of the substrate thereof by mixed application of dead-burnt magnesia fine powder with different particles sizes, and is superior to a substrate material prepared from the dead-burnt magnesia fine powder with single particle size; the fiber structure greatly improves the mechanical properties of the material; meanwhile, carbon is difficult to be diffused into molten steel after carbon nanotube fiber is formed, so the pollution of the refractory materials to the molten steel is greatly reduced.

Owner:营口宏远耐火材料有限公司

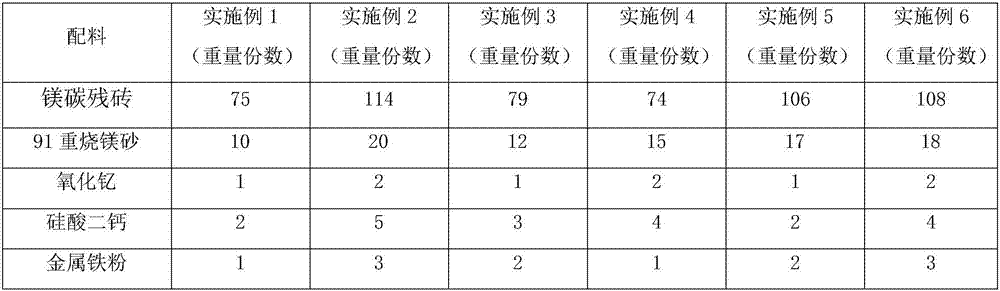

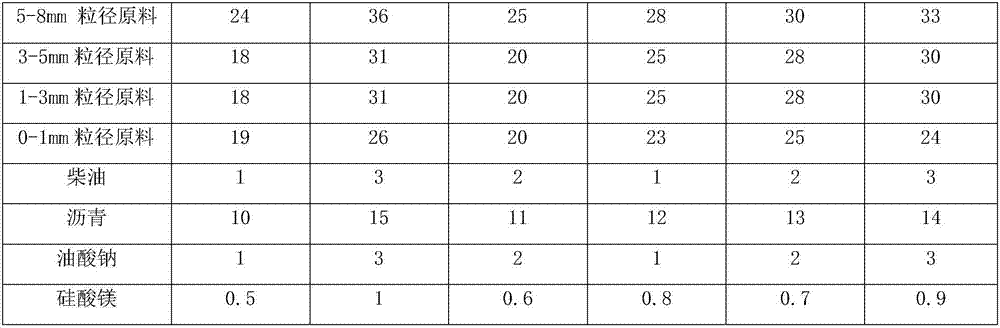

Converter bedding face repair material with magnesia-carbon residue bricks serving as main raw material and preparation method of converter bedding face repair material

ActiveCN106977215AImprove high temperature flexural strengthImproved thermal shock stabilitySteelmakingBrick

The invention discloses a converter bedding face repair material with magnesia-carbon residue bricks serving as a main raw material. The magnesia-carbon residue bricks are used as the main raw material; the physical and chemical property of the raw material is improved through a pre-sintering method, so as to improve the high-temperature mechanical property of prefabricated materials; meanwhile, the prefabricated materials with different grain compositions are premixed with refired magnesia; modified asphalt is used as a binding agent, and the magnesia-carbon residue bricks are fully used as secondary resources; therefore, on the premise of guaranteeing high thermodynamic property of the converter bedding face repair material, the cost of a refractory material and the steelmaking cost are reduced.

Owner:海城利尔麦格西塔材料有限公司 +1

High temperature nanometer non-burning slide plate and processing technique thereof

ActiveCN106986619AImprove high temperature performanceImprove antioxidant capacitySlide plateEngineering

The invention relates to a high temperature nanometer non-burning slide plate and a processing technique thereof. By applying a method for shaping for many times, namely, a primary shaped slide plate is prepared firstly, and then slide plates in line of dimension requirement are shaped through gradually expanding outwards for several times on this basis; the slide plate is integrated structure. By applying the method of shaping for many times and the progressive way, the slide plate is more compactly pressed, and the primary shaping dimension is big; thus the primary shaped slide plate is not easy to deform and damage even through being pressed during the secondary shaping; meanwhile, the slide plate is provided with a reinforcing pipe to provide stress load during the pressing process, thus the shaping quality of the slide plate is further guaranteed; meanwhile, the reinforcing pipe is further arranged to be a hollow pipe, thus the reinforcing pipe can play a certain bearing effect during the secondary shaping and the third shaping; the reinforcing pipe also can be deformed and compactly inlaid in the groove for being pressed, thus the shaping quality and compact consistence of the slide plate are guaranteed.

Owner:JIANGSU YUEZHAN NEW MATERIALS

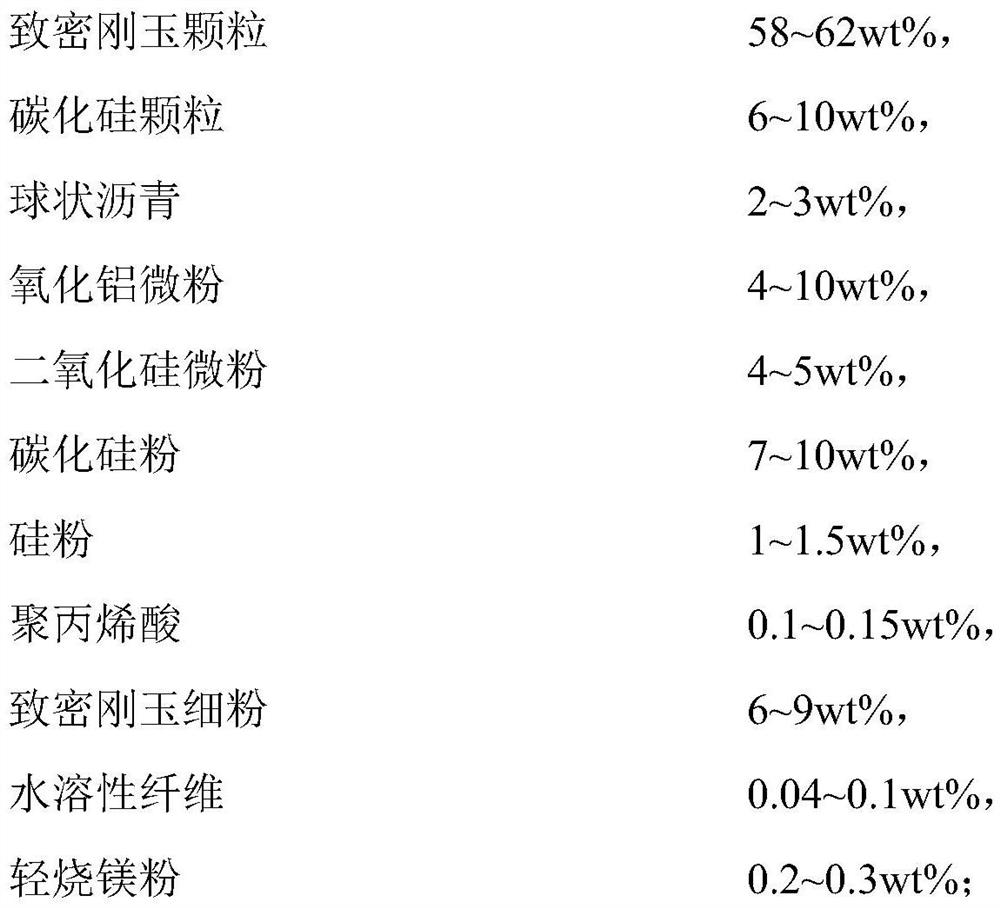

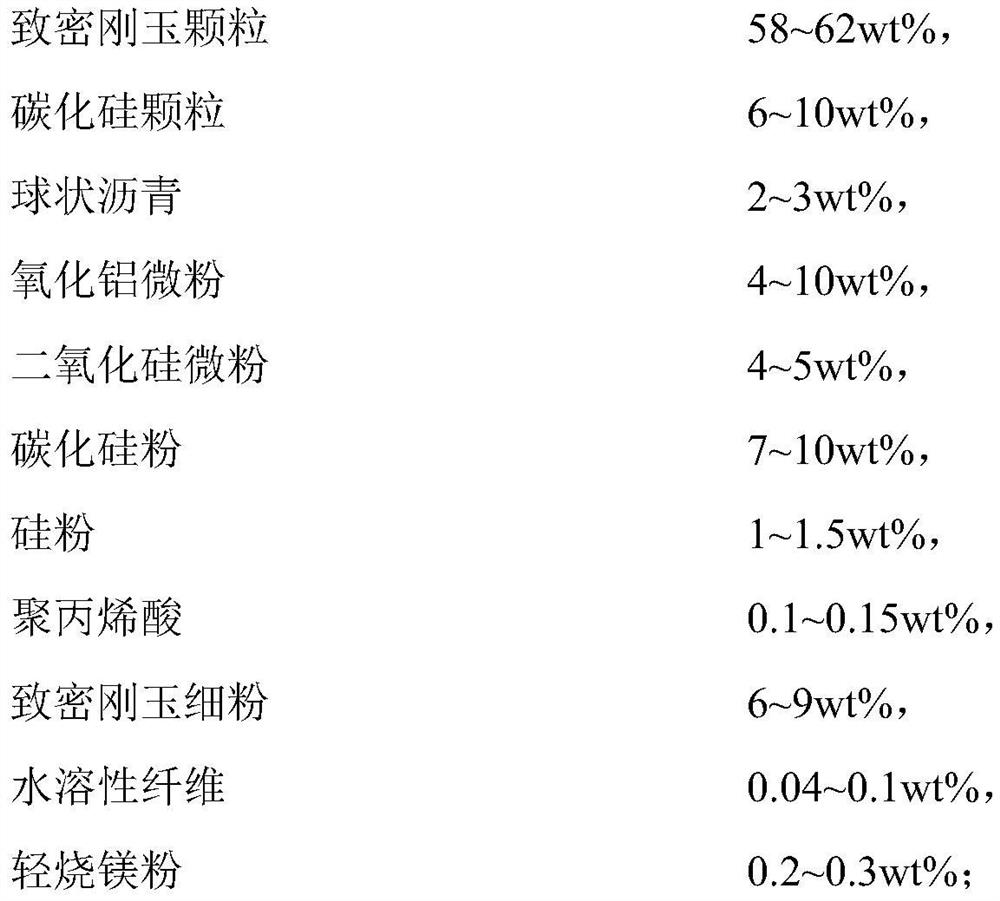

Alumina-silicon carbide-carbonaceous cement-free castable suitable for winter construction

PendingCN113087500AReduce the amount of water addedSufficient early strengthCarbide siliconSoluble fiber

The invention relates to an aluminum oxide-silicon carbide-carbonaceous cement-free castable suitable for construction in winter. The technical scheme is as follows: the castable comprises the following components in percentage by weight: 58-62wt% of dense corundum particles; 6-10 wt% of silicon carbide particles; 2-3 wt% of spherical asphalt; 4-10 wt% of alumina micro powder; 4 to 5 wt% of silicon dioxide micro powder; 7-10 wt% of silicon carbide powder; 1 to 1.5 wt% of silicon powder; 0.1-0.15 wt% of polyacrylic acid; 6-9 wt% of dense corundum fine powder; 0.04-0.1 wt% of water-soluble fibers; and 0.2-0.3 wt% of caustic-burned magnesia powder. During construction, when the environment temperature and the water temperature are both lower than 15 DEG C, after construction is completed, a pouring body is cured at 33-38 DEG C until the pouring body is completely cured. The concrete has the advantages of being small in water adding amount, short in setting time and high in construction site safety, is good in compactness, free of cement, high in thermal strength and good in various technical indexes, and particularly completely meets the requirements of construction in winter.

Owner:WUHAN UNIV OF SCI & TECH +1

Bending-resistant high-temperature composite load bearing board and preparation method thereof

ActiveCN111056825AImprove high temperature flexural strengthEffectively reflect the bending functionCharge supportsTougheningHigh heat

The invention discloses an anti-bending type high-temperature composite load bearing board, and belongs to the field of preparation of fire-resistant kiln furniture; an outer surface layer is a load-bearing isolation layer composed of aluminum oxide as a main body, an inner surface layer is a load-bearing support layer composed of silicon carbide as a main body, and a toughening interface layer composed of zirconium oxide as a main body is arranged between the outer surface layer and the inner surface layer. At the same time, the invention also discloses a preparation method of the load bearing plate. Compared with the prior art, on the basis of fully mastering the use environment requirement of the composite load bearing plate and the main cause of damage, through the arrangement of the interface layer, the bonding strength of the inner layer and the outer layer is enhanced, the high-temperature breaking strength of the middle layer is improved, the high-temperature strength of the composite load bearing board is improved, the improvement of the bending resistance of the composite load bearing board is effectively reflected, the service life of the composite load bearing board isprolonged, and the manufacturing cost of a using unit is reduced.

Owner:江苏三恒高技术窑具有限公司

Low-carbon magnesia carbon brick and preparation method thereof

The invention relates to a low-carbon magnesia carbon brick and a preparation method thereof. The technical scheme is as follows: 78-93 wt% of magnesia particles, 0.1-2 wt% of organic additives and 5-20 wt% of absolute ethyl alcohol are placed in a stirrer, stirred for 2-6 hours at a rotating speed of 300-600 rpm, dried at 80-110 deg c for 12-24 hours, and sieved to obtain pretreated magnesia particles with a particle size of 1-5 mm. Then, 63-75 wt% of the pretreated magnesia particles, 20-32 wt% of magnesia fine powder, 2-5 wt% of flake graphite, 1-3 wt% of an antioxidant and 2-5 wt% of thermosetting phenolic resin are used as raw materials to be uniformly mixed, pressed and molded at 150-200 MPa, and then cured at 180-240 deg c for 18-24 hours to prepare the low-carbon magnesia carbon brick. The invention has the characteristics of low production cost, simple process and easy industrial production, and the prepared low-carbon magnesia carbon brick has high thermal shock stability, high high-temperature bending strength and good slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

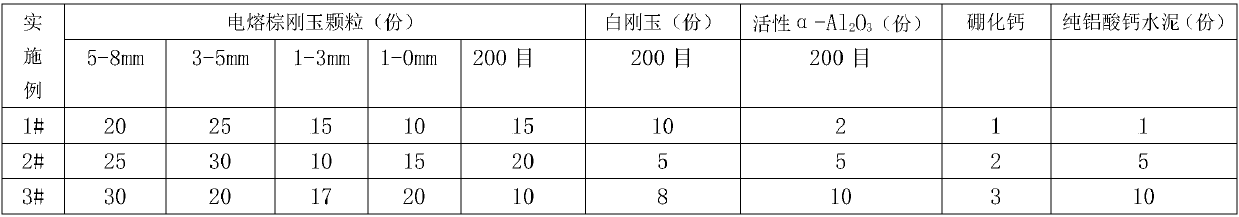

Anti-oxidation high-bending-resistance iron runner castable

The invention provides an anti-oxidation high-bending-resistance iron runner castable. The components of the castable comprise, in parts by weight, 20-30 parts of fused brown corundum with a particlesize of larger than 5 mm and less than or equal to 8 mm, 20-30 parts of fused brown corundum with a particle size of larger than 3 mm and less than or equal to 5 mm, 10-20 parts of fused brown corundum with a particle size of larger than 1 mm and less than or equal to 3 mm, 10-20 parts of fused brown corundum with a particle size of larger than 0 mm and less than or equal to 1 mm, 1-3 parts of calcium boride, and 1-10 parts of binder. Compared with the prior art, the beneficial effects of the present invention comprise that 1) the addition of calcium boride improves the strength and bulk density after treatment of each temperature section of the castable; 2) the addition of calcium boride promotes the high-temperature densification of the castable, so that the castable can obtain better oxidation resistance and higher high-temperature flexural strength; and 3) the addition of calcium boride can significantly improve the various properties of the iron runner castable, and when 2 parts of calcium boride is added, the castable has better comprehensive performance.

Owner:海城利尔麦格西塔材料有限公司

Chromium-free magnesium composite brick used for VOD furnace and preparation method thereof

ActiveCN107010967AExcellent high temperature mechanical propertiesImproved thermal shock stabilityYttriumMagnesium

The invention relates to a chromium-free magnesium composite brick used for a VOD furnace and a preparation method thereof. The preparation method comprises the following steps: firstly sintering macrocrystalline magnesium sand with yttrium oxide and dicalcium silicate at the temperature of about 1550 DEG C, firstly preparing a pre-prepared material with excellent high temperature mechanical properties by adopting a presintering method, taking the pre-prepared materials in different grain gradations as an aggregate of a mending material, also adopting electrically smelted zirconia and calcined alumina as additives to make an unfired chromium-free magnesium composite brick for replacing an existing fired magnesium chromium brick to be used, pollution of the magnesium chromium brick to the environment is avoided, and thermal shock resistance and high temperature bending strength of a refractory material used for the VOD furnace are improved, so that the service life of the VOD furnace is guaranteed.

Owner:海城利尔麦格西塔材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com