High-crystal mullite-iolite high-temperature industrial ceramic and production method for same

A high-temperature industry, cordierite technology, applied in the field of high-temperature industrial ceramics preparation, can solve problems such as staying in the test stage, and achieve the effects of no need for calcination, excellent interwoven network structure, and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

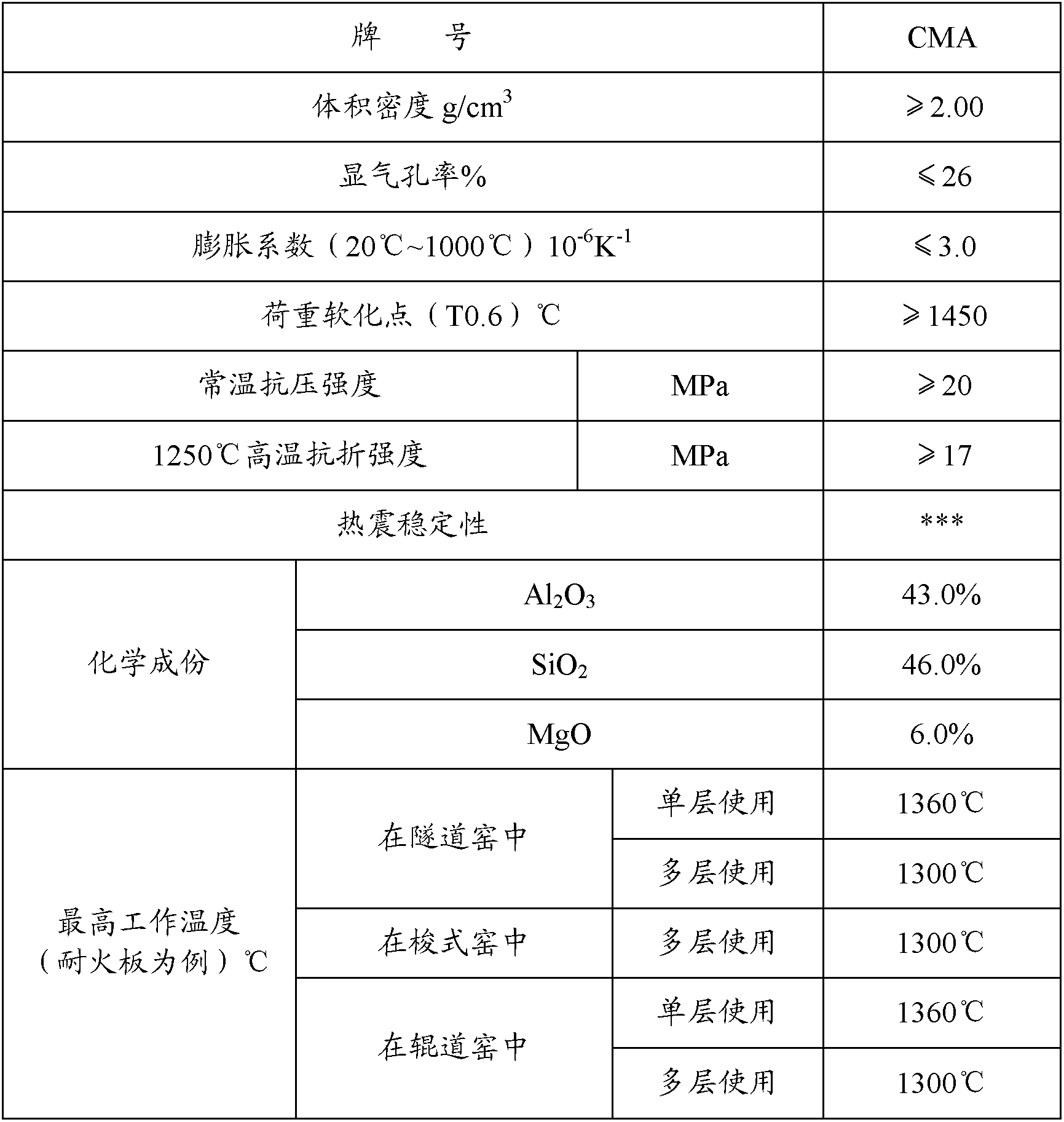

[0030] A high-crystal mullite-cordierite high-temperature industrial ceramics, including refractory kiln furniture, structural ceramics and structural materials, the raw materials prepared include 40-80 parts by weight of main crystal phase materials and 20-60 parts by weight of combined composite matrix Material, the selected main crystal phase material and the total component combined with composite matrix material reach 100 parts by weight, then add an appropriate amount of composite microcrystalline nucleating agent, wherein:

[0031] 1) The main crystal phase material is calcined kaolin, cordierite, synthetic mullite, sillimanite, andalusite aggregate, among which calcined kaolin aggregate accounts for 20-50wt% of the main crystal phase material, and cordierite aggregate accounts for the main crystal phase 5-20wt% of the phase material, synthetic mullite aggregate accounts for 30-60wt% of the main crystal phase material, andalusite or sillimanite aggregate accounts for 1-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com