Patents

Literature

68results about How to "Suitable coefficient of thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

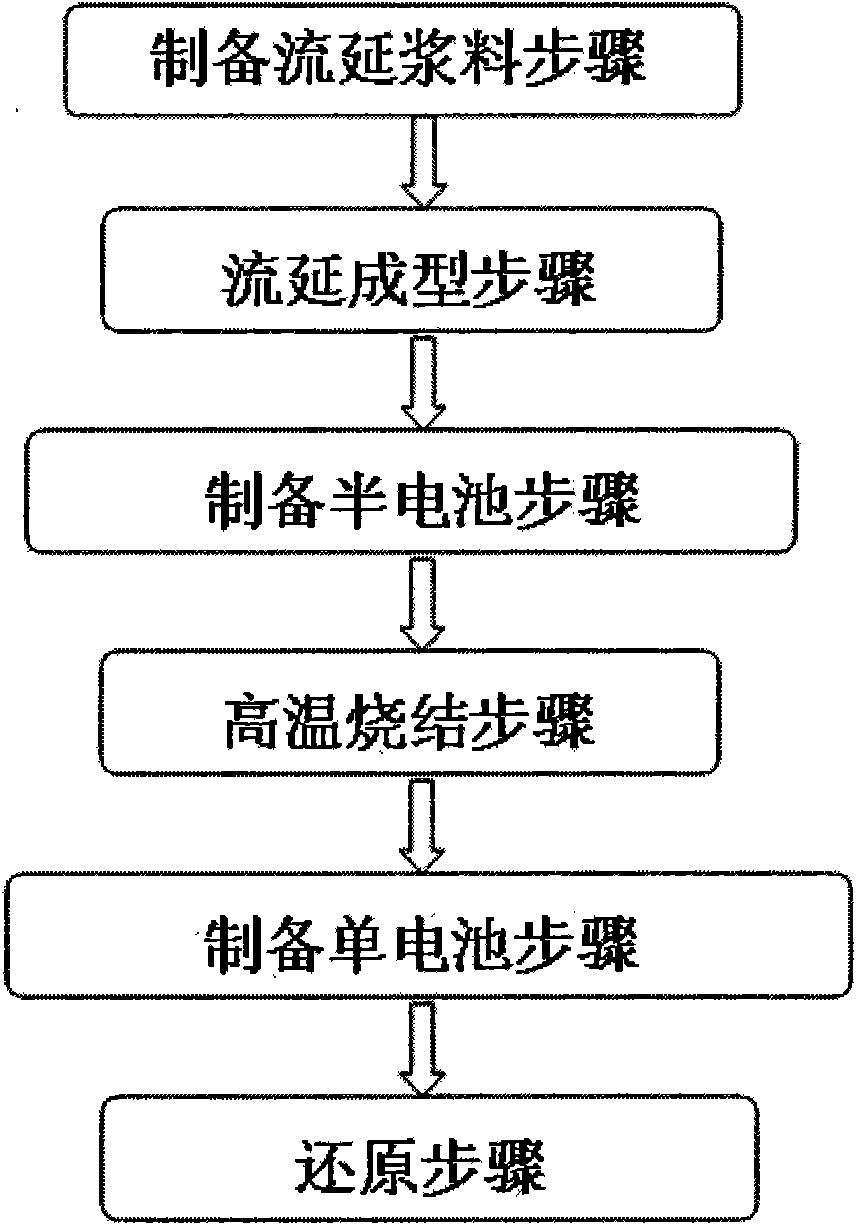

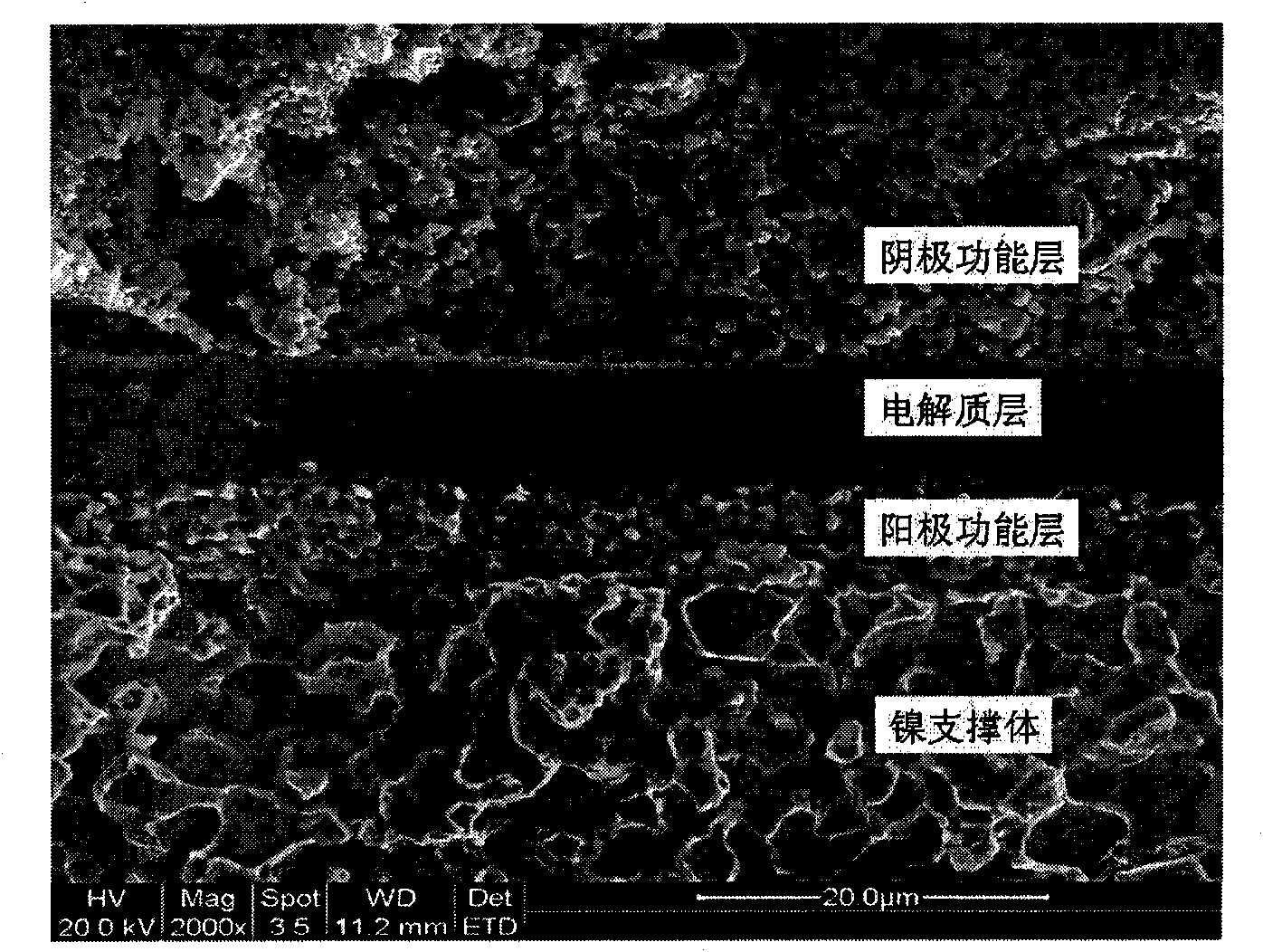

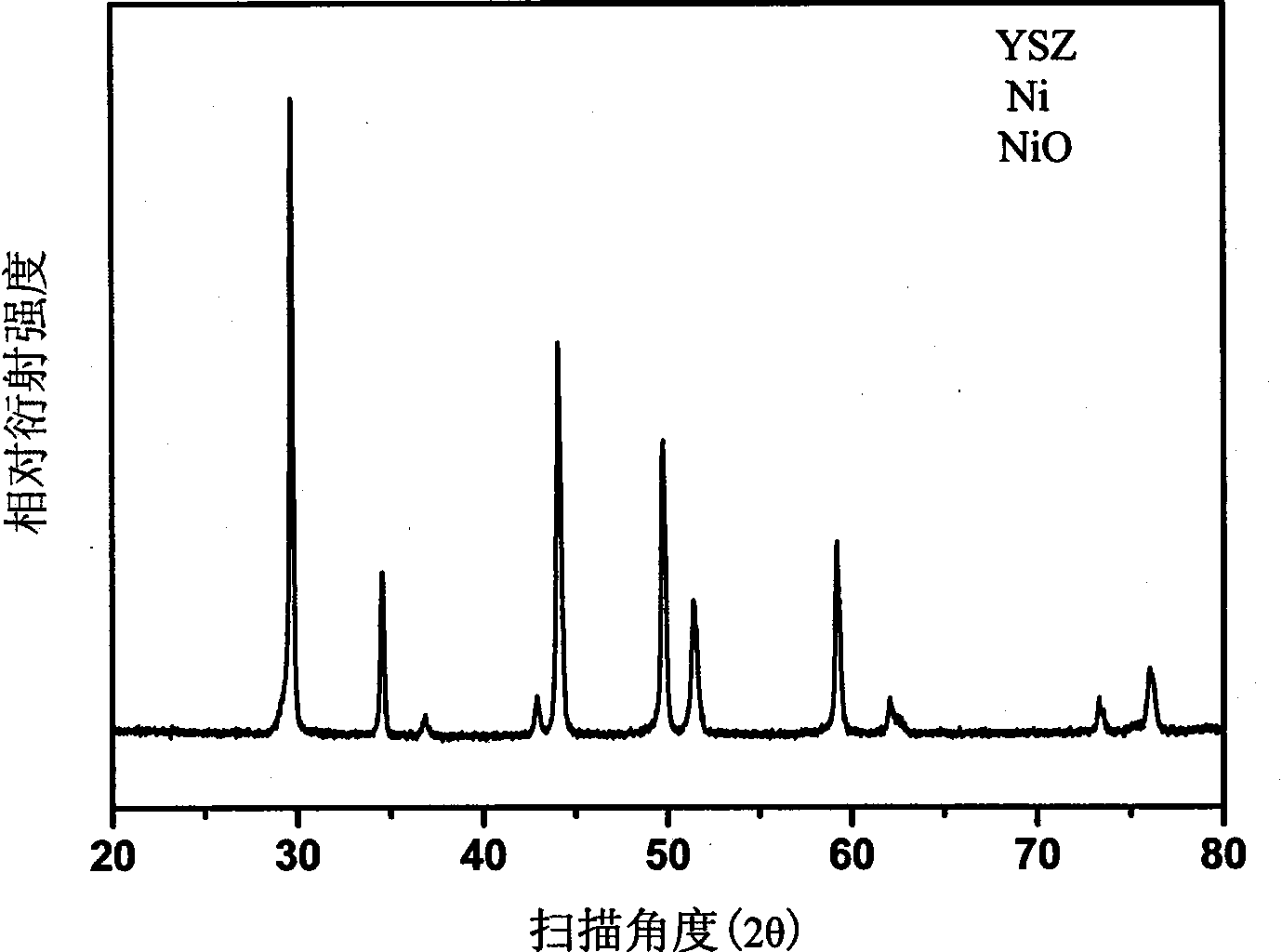

Method for preparing metallic support type solid oxide fuel cell

InactiveCN101562255AAvoid defects such as crackingAvoid cathodic activity reductionFinal product manufactureSolid electrolyte fuel cellsFuel cellsSlurry

The invention provides a method for preparing a metallic support type solid oxide fuel cell, and belongs to a method for preparing a solid oxide fuel cell (SOFC). The invention aims to simplify process, lower cost and prepare the fuel cell with excellent electric property. The method comprises the following steps: (1) a tape casting slurry preparation step; (2) a tape casting formation step; (3) a half cell preparation step; (4) a high-temperature sintering step; (5) a monocell preparation step; and (6) a reducing step. The method has the advantages of wide raw material source, simple preparation process and low cost; and the open-circuit voltage of the prepared SOFC, which is measured at a temperature of 750 DEG C, is 1.01V, the maximum power density is 0.64w / cm, so that the SOFC can be applied to the preparation of the large-area metallic support type solid oxide fuel cell.

Owner:中博源仪征新能源科技有限公司

Luminescent glaze for enamel painted porcelain and preparation method and application thereof

The invention discloses luminescent glaze for enamel painted porcelain and a preparation method and application thereof. The luminescent glaze for enamel painted porcelain comprises basic glaze for the enamel painted porcelain and a protective-glaze luminescent material, wherein the protective-glaze luminescent material is prepared by firstly mixing and then repeatedly braking the flux for the protective-glaze luminescent material and a luminescent material, and the flux for the protective-glaze luminescent material comprises the following components in percentage by weight: 42-48 percent of SiO2, 3-7 percent of SrO, 15-21 percent of B2O3, 0.2-1.2 percent of Al2O3, 3-7 percent of Li2O, 2-7 percent of Na2O, 1-3 percent of K2O, 0.6-3.8 percent of metal fluoride, 2-3.5 percent of P2O5, 0-0.5 percent of Ta2O3, 0-1 percent of Nb2O5, 0-0.5 percent of ZrO2, 0-3 percent of CeO2, 0-0.5 percent of La2O3, 0-2 percent of Y2O3, 5-10 percent of ZnO, and 0-5 percent of MgO. According to the luminescent glaze for the enamel painted porcelain provided by the invention, the thermal stability and luminescence properties of the luminescent material can be guaranteed so as to improve the luminance and luminous time of the prepared painted porcelain after irradiation, while the various characteristics of the traditional enamel painted porcelain can be maintained.

Owner:HUNAN LILING HONGYU HONGCI CERAMICS

Novel preform body for bone porcelain and preparation process of preform body

InactiveCN107032762AImprove performanceImprove thermal shock resistanceCeramic materials productionClaywaresLithiumGranularity

The invention provides a novel preform body for bone porcelain and a preparation process of the preform body. The novel preform body for bone porcelain comprises the following components in percentage by weight: 50-55% of bone meal, 24-28% of kaolin, 9-11% of quartz, 8-10% of feldspar, 0.38-0.52% of lithium chinastone, 0.8-1.6% of zircon sand and 0.4-0.8% of nano-aluminum oxide. The preparation process comprises the following steps: mixing various ground materials with proper granularity to prepare the preform body, and calcining once again before the bone meal is mixed. The preform body prepared in the invention is good in thermal shock resistance, high in strength, uniform in structure, compact in toughness and excellent in overall performance.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

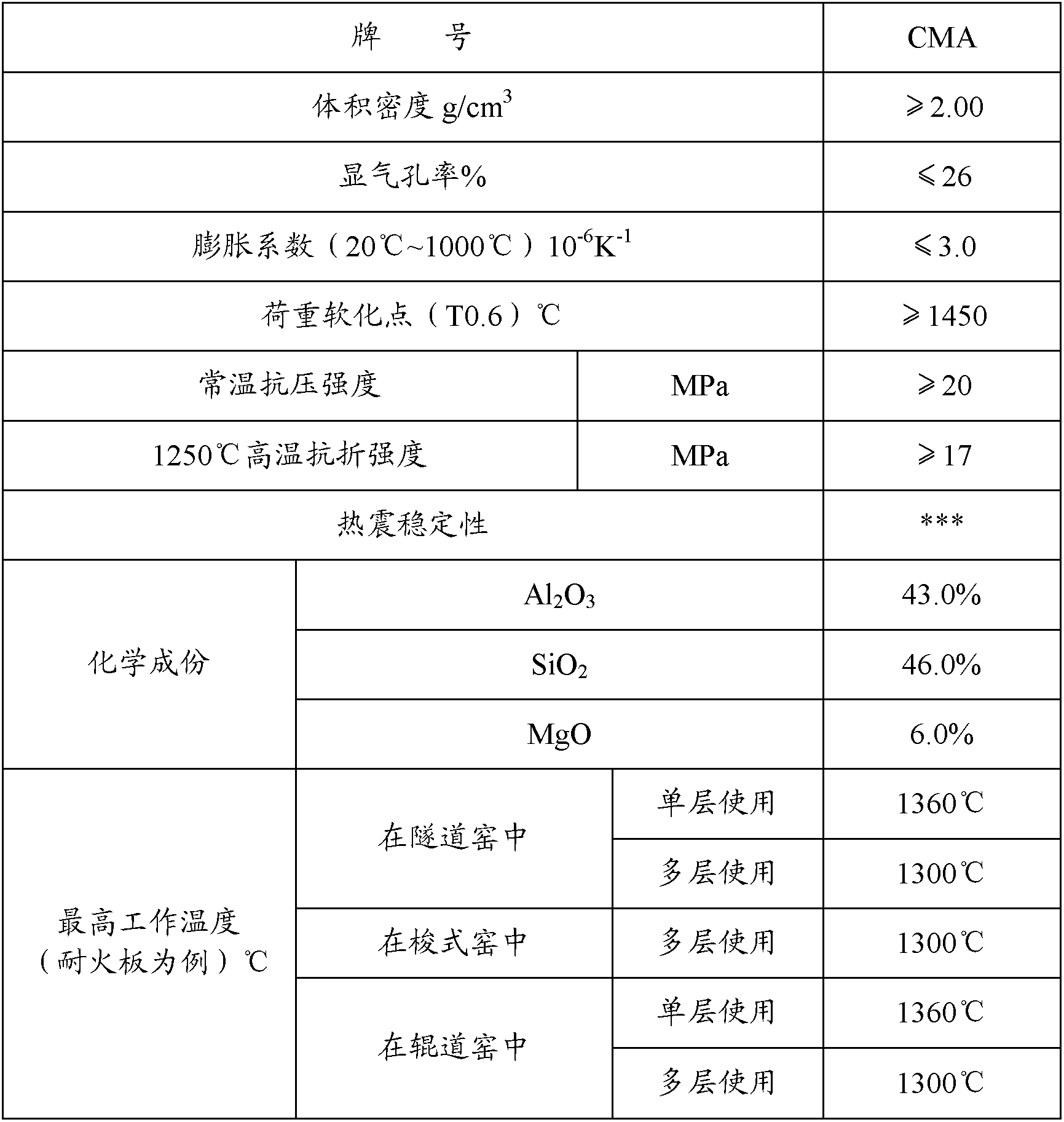

High-crystal mullite-iolite high-temperature industrial ceramic and production method for same

The invention relates to a high-crystal mullite-iolite high-temperature industrial ceramic and a production method for the same. Raw materials comprise, by weight, 40-80 parts of main crystal phase materials, 20-60 parts of combined composite substrate materials and an appropriate amount of composite microcrystal nucleating agent. A roasting process of the production method includes a two-stage constant-temperature roasting method and a two-stage composite crystallization synthetic reaction characteristic enhancing process, wherein the two-stage constant-temperature roasting method includes the steps of performing constant-temperature heat preservation for 10-15 hours at the temperature of 200 DEG C, and performing constant-temperature heat preservation for 10-15 hours at the temperature of 500 DEG C; and the two-stage composite crystallization synthetic reaction characteristic enhancing process includes the steps of sintering for 10-15 hours under the ordinary pressure and at the temperature ranging from 1100 DEG C to 1150 DEG C, and sintering for 20-25 hours under the ordinary pressure and at the temperature ranging from 1420 DEG C to 1430 DEG C. A refractory product produced bythe method has the advantages of excellent oxidation resistance, high refractoriness, high usage temperature, low thermal expansion coefficient, high compression strength, hypobarism, excellent heat stability, anti-strip performance and high high-temperature bending strength. The process of the method has the advantages of simple process, low cost and suitability for mass production, and is applicable to preparing kiln furniture, industrial ceramics and structural materials.

Owner:GUANGDONG REJINBAO NEW MATERIAL TECH +2

Low-melting glass containing nano zinc oxide and preparation thereof

The invention discloses a glass binder containing nanometer zinc oxide and a preparation method thereof. The glass binder is characterized in that the weight percentages of raw materials are as follows: Bi2O3 is 50-80 percent; B2O3 is 5-40 percent; ZnO is 5-30 percent; Al2O3 is 0.1-10 percent; SiO2 is 0.1-10 percent; MgO is 0.1-10 perent; CaO is 0.1-10 percent; and CuO is 0.1-10 percent. The preparation method comprises the following steps: the raw materials are fully mixed, wherein, the nanometer zinc oxide is finally added and mixed for producing a mixture; a crucible is put into an electric furnace at the temperature of 1100-1400 DEG C for preheating for 12-18 minutes; the mixture is added into a quartz crucible for melting at the melting temperature of 1100-1400 DEG C and heat-preserving for 5-40 minutes; the melted glass slurry is poured into water, or is milled into powder by a ball mill after tabletting, or is casted into powder, slurry, rods, powder pressed billets and the like, all of which are required when sealing is carried out; and then the detection and the package are carried out. The invention has the advantages that the application forms can be the powder, the slurry, the rods, the powder pressed billets, and the like; the cost performance is high; and the market development prospect is wide.

Owner:陈培

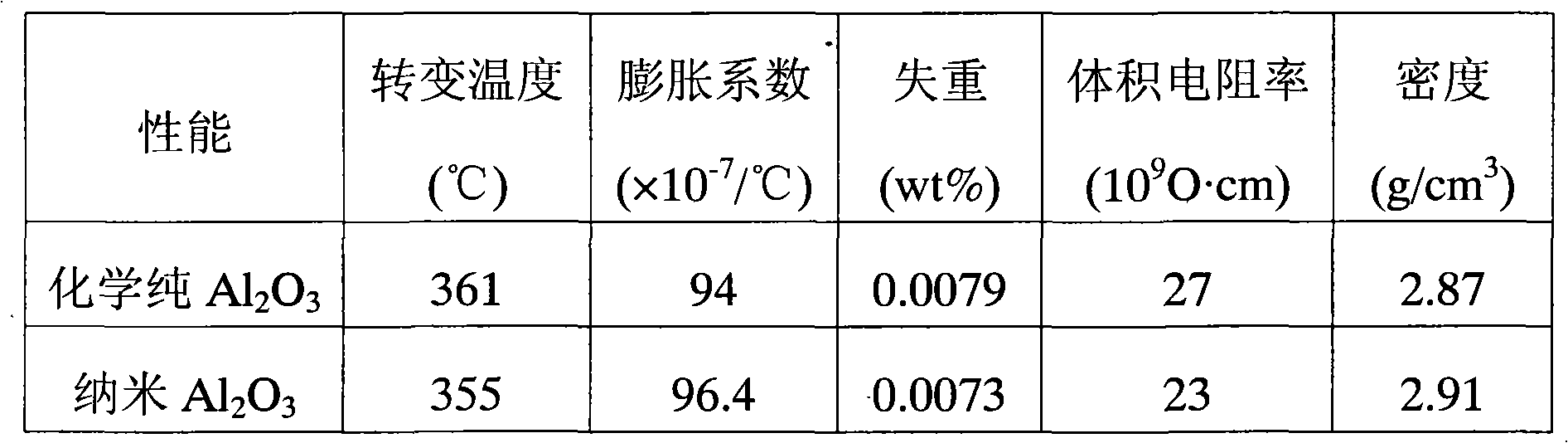

Nanooxide-doped red solder glass and preparation method thereof

The invention discloses nanooxide-doped red solder glass and a preparation method thereof. The nanooxide-doped red solder glass is characterized by comprising the following raw material components by molar percent: 35%-50% of P2O5, 20%-45% of ZnO, 0.1%-20% of B2O3, 1%-10% of Al2O3, 0.1%-10% of SiO2, 0.1%-10% of Na2O, 0.1%-10% of MgO, 0.1 %-5% of Li2O, 0.1%-4% of Fe2O3, 0.1%-4% of MnO2 and 0.1%-1% of colorant cuprous oxide. The preparation method comprises the following steps: mixing raw materials, and adding nanoalumina finally and mixing to prepare a mixture; putting a crucible into an electric furnace with the temperature of 1200-1400 DEG C, and preheating for 15 minutes; adding the mixture into the quartz crucible, melting at the melting temperature of 1200-1400 DEG C, and holding for 80 to 120 minutes; pouring the melted glass liquid into water or being ground into powder by a ball mill after tablet forming. The invention has the advantages of simple preparation process, convenient operation, high performance cost ratio and broad market development prospects.

Owner:李胜春

High temperature-resistant resistor ceramic composite material and preparation method thereof

InactiveCN106587990AHigh thermal conductivityImprove heat resistanceZirconium hydrideCeramic composite

The invention discloses a high temperature-resistant resistor ceramic composite material. The high temperature-resistant resistor ceramic composite material is prepared from barium titanate, zirconium dioxide, eucryptite, magnesium oxide, zirconium boride, hafnium diboride, lead zirconate, strontium carbonate, molybdenum disulfide, titania, yttrium oxide, calcium carbonate, thallium carbide, hafnium carbide, zirconium carbide, silicon nitride, zirconium oxide, polyvinyl alcohol, copper oxide, niobium pentoxide, tungsten trioxide, lead tetraoxide, alumina, silica and assistants. The invention also provides a preparation method of the high temperature-resistant resistor ceramic composite material. The high temperature-resistant resistor ceramic composite material has excellent high temperature resistance.

Owner:ANHUI RUIXIN AUTOMATION INSTR

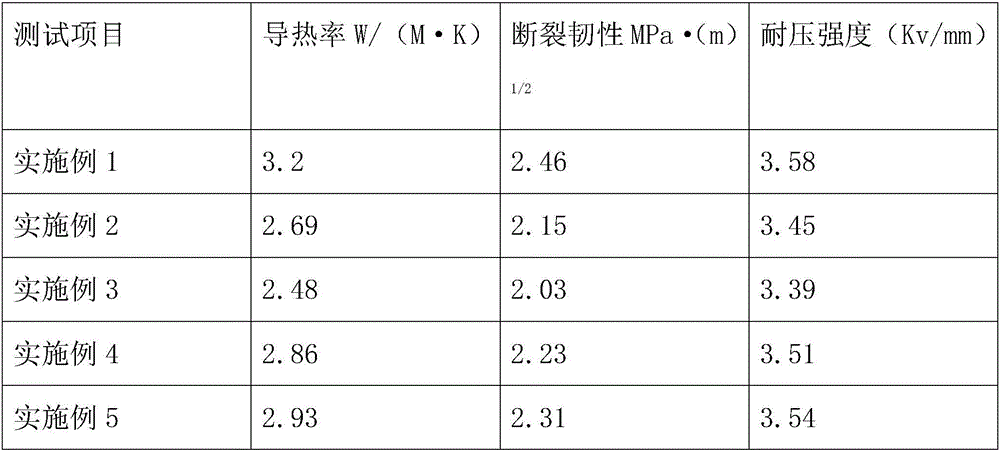

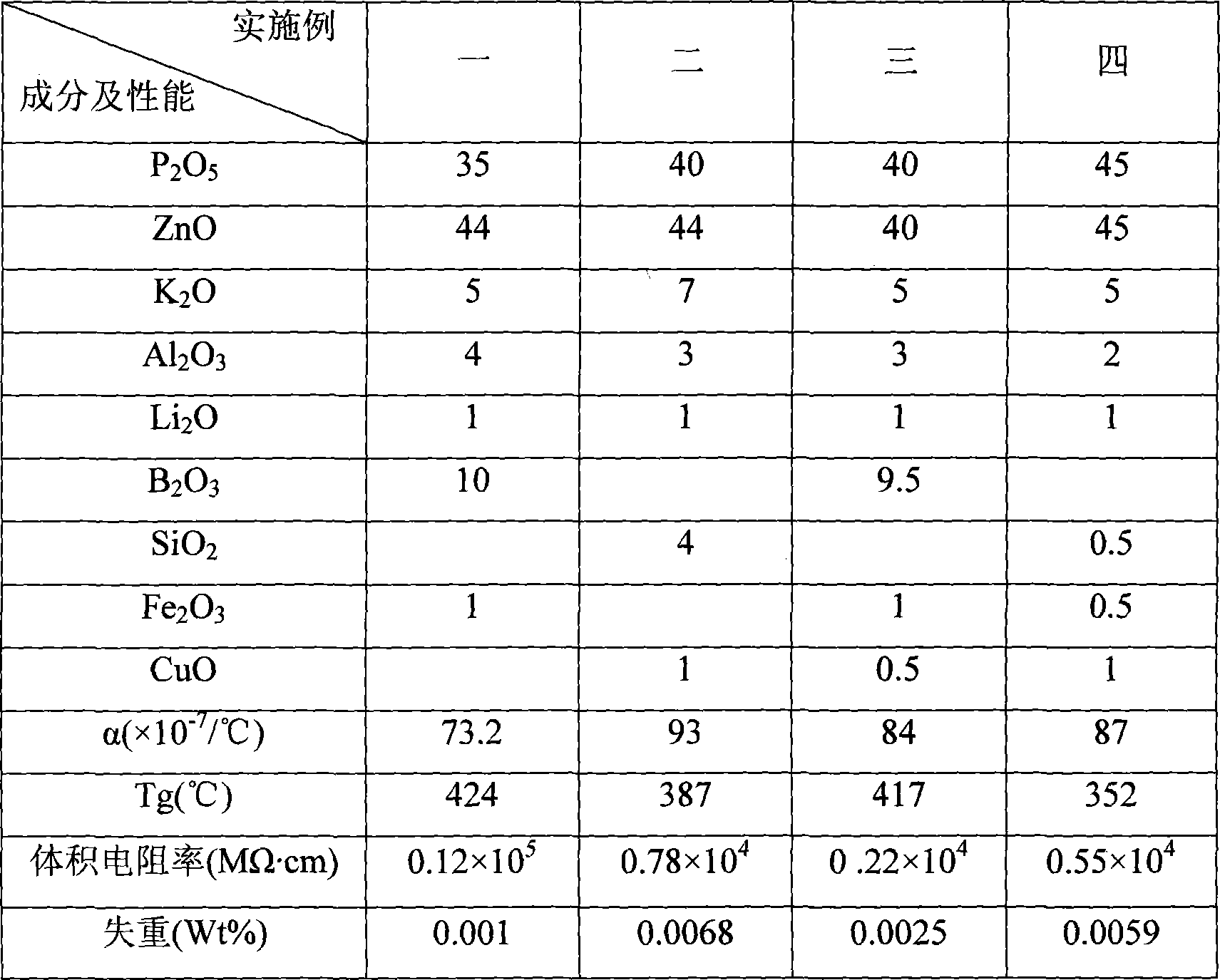

Electronic slurry lead-free low melting point glass and preparing method

InactiveCN101058478ASuitable coefficient of thermal expansionEasy to adjust thermal expansion coefficientGlass furnace apparatusGlass reforming apparatusOxideMaterials science

The invention discloses a non-lead low-fusing point glass of electronic slurry, which comprises the following parts: (1) necessary component: 30-55mol% P2O5, 20-55mol% ZnO, 2-10mol% Al2O3, 3-15mol% K2O, 0-1mol%Li2O, (2) adding component: 0-25mol% B2O3, 0-10mol% SiO2, 0-3mol%Fe2O3, 0-8mol%CuO, (3) stable component: not more than 30% two or more oxidizer compounds, wherein allocation of different components is adjusted to obtain the non-lead low-fusing point glass with bulking coefficient at 64-140X10-7 / deg. c and the sealing temperature at 430-600 deg. c.

Owner:DONGHUA UNIV

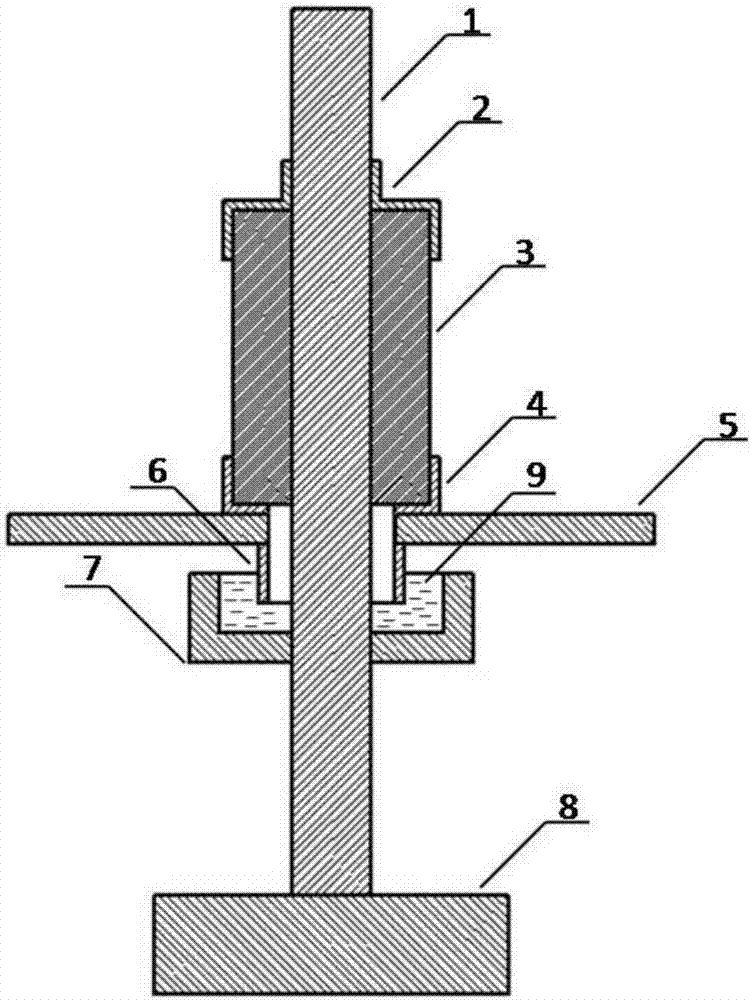

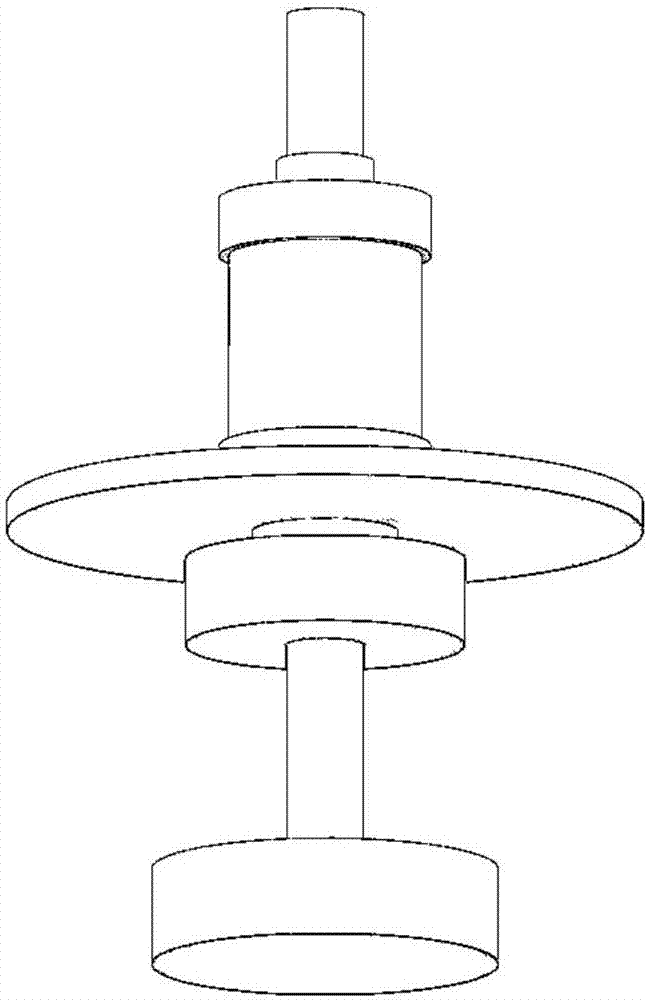

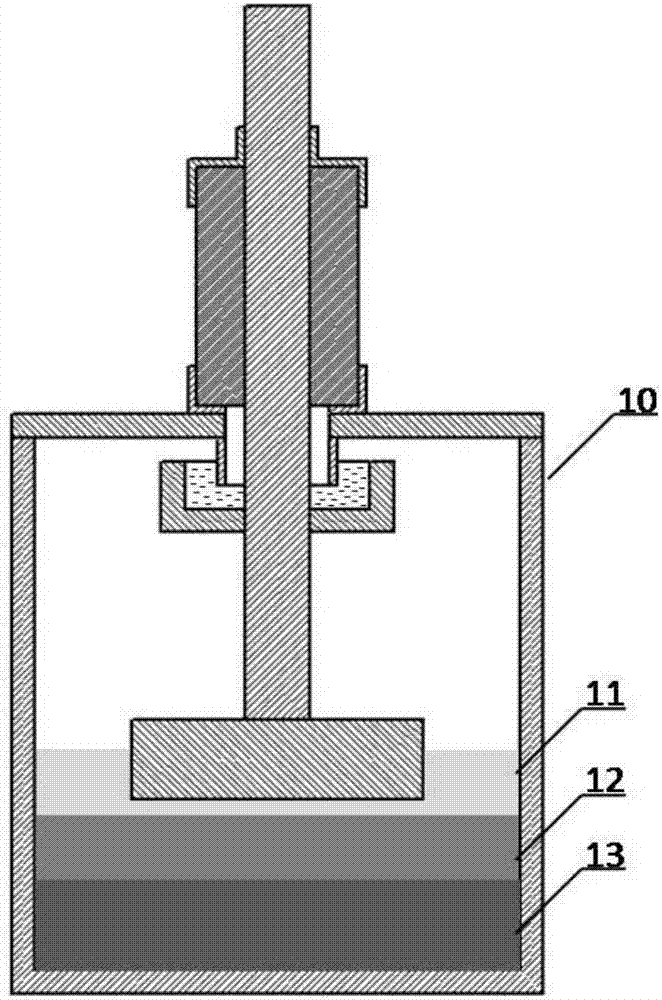

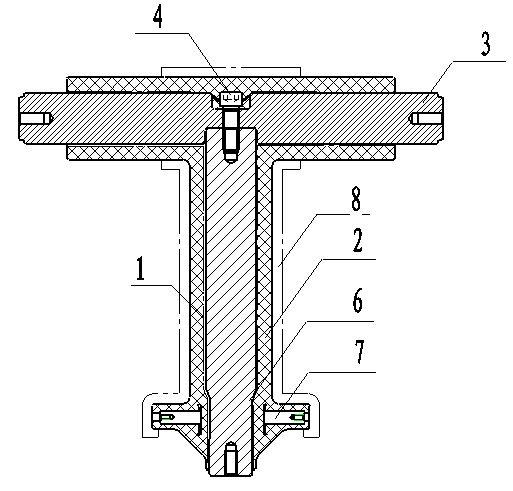

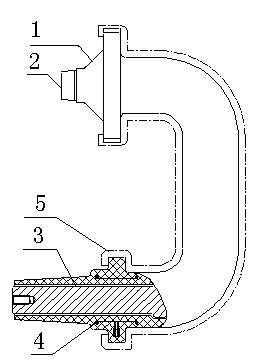

High-temperature sealed electrode and preparation method thereof

ActiveCN106972122APrevent intrusionStop erosionSecondary cellsCell sealing materialsEngineeringLiquid metal

The invention belongs to the technical field of energy storage batteries and particularly relates to a high-temperature sealed electrode. The high-temperature sealed electrode comprises a negative electrode core, an upper transition ring, an insulating sleeve, a lower transition ring, a positive electrode cover plate, a salt-sealing partition and a salt-sealing groove, wherein the upper transition ring, the insulating sleeve, the lower transition ring, the positive electrode cover plate, the salt-sealing partition and the salt-sealing groove sequentially sleeve the middle of the negative electrode core from top to bottom; a negative current collector is also welded at the bottom of the negative electrode core; the salt-sealing partition is fixed at the lower end of the positive electrode cover plate; the salt-sealing groove is also fixed in the negative electrode core at the lower end of the salt-sealing partition; the lower end of the salt-sealing partition extends into a sealed salt in the salt-sealing groove; and sealing of the electrode is achieved through heating and solidifying the sealed salt. The invention further discloses a preparation method of the high-temperature sealed electrode. According to the high-temperature sealed electrode, corrosion of steam to solder can be prevented, cracking of a connection part of the sealed electrode caused by thermal stress is prevented, long-term insulated sealing in a high-temperature condition is achieved, the sealed electrode is compact in structure and the space volume of a liquid metal battery is effectively compressed.

Owner:HUAZHONG UNIV OF SCI & TECH +2

Leadless bismuth oxide sealing glass for sealing electron device and preparation method thereof

The invention relates to lead-free bismuth oxide solder glass for sealing an electronic device and a preparation method thereof. The solder glass comprises the following components by weight percentage: 40 to 65 percent of Bi2O3, 10 to 40 percent of B2O3, 5 to 25 percent of BaO, 1 to 10 percent of ZnO, 1 to 10 percent of Al2O3, 0.1 to 10 percent of TiO2, 0.1 to 10 percent of CaO, 0.1 to 10 percent of CeO2, 0.1 to 5 percent of Sb2O3, and 0.1 to 5 percent of Cr2O3. The preparation method comprises the following steps: (1) weighing raw materials; (2) mixing the raw materials; (3) preheating the raw materials; (4) adding the mixture into a quartz crucible to melt, and preserving heat; (5) pelleting the molten glass by a pelleting machine; and (6) ball-milling, sieving, detecting and packaging the glass. The bismuth oxide solder glass contains no lead, has the characteristics of good air tightness, good sealing fluidity and wide expansion coefficient adjustment range; and the expansion coefficient of the glass is between 60*10<-7> and 100*10<-7> / DEG C, and the firing temperature is between 500 and 570 DEG C, and the glass is suitable for sealing of glass, ceramic, metal, semiconductors, and the like.

Owner:DONGHUA UNIV

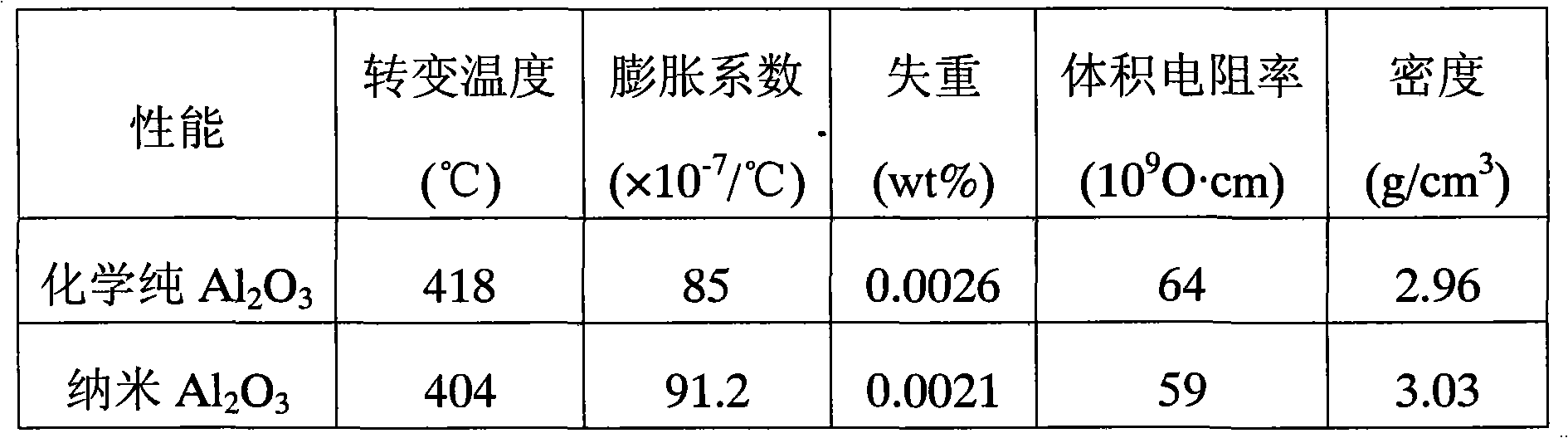

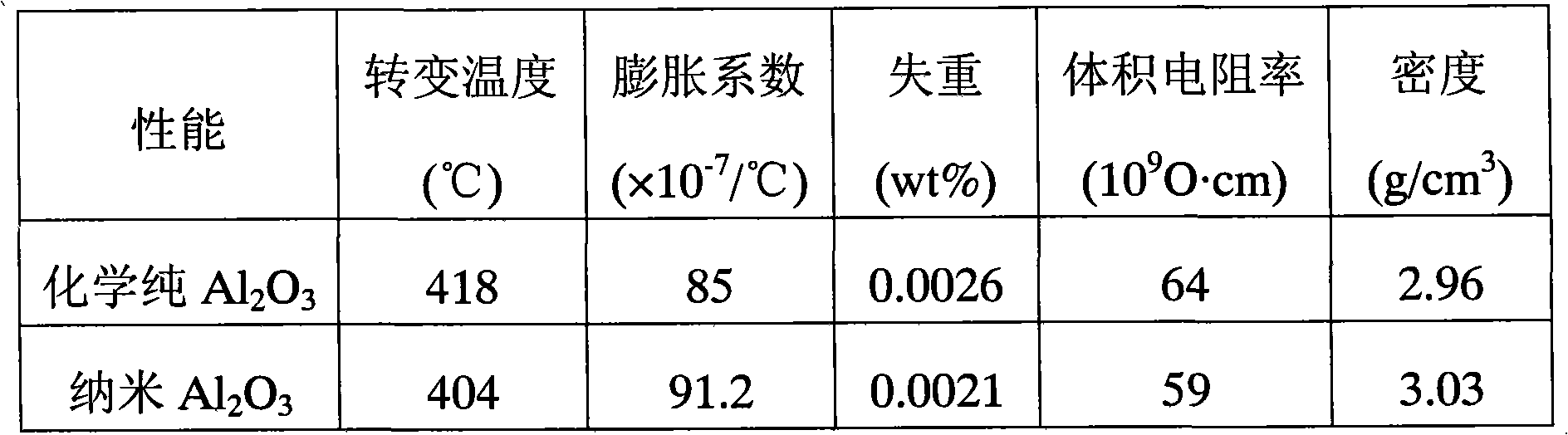

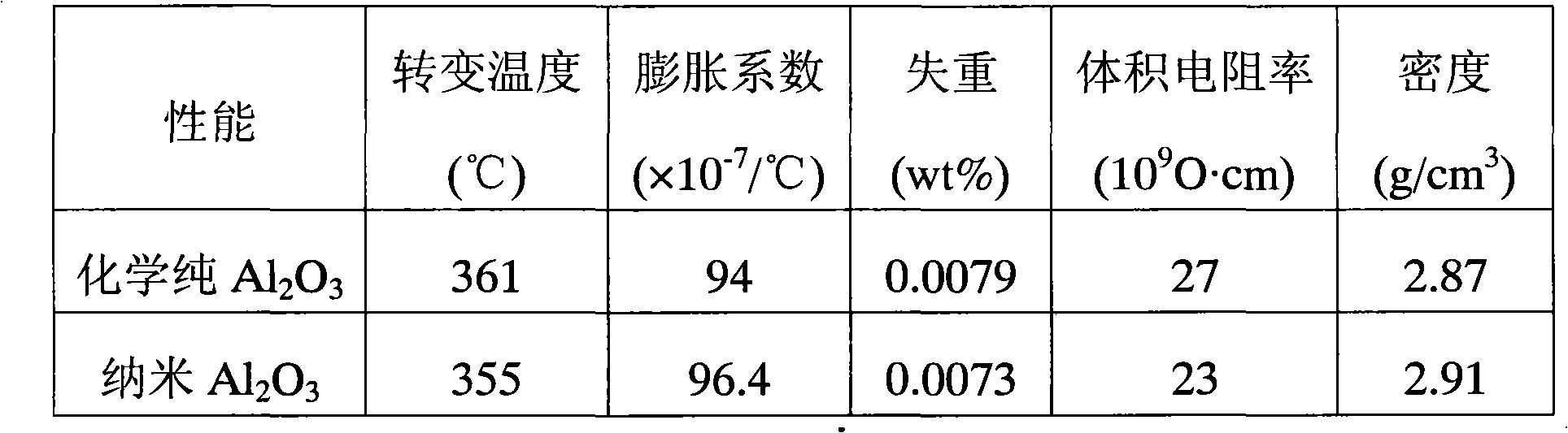

Sealing glass with additive nano-aluminum oxide and method of manufacturing the same

The invention discloses a sealing glass added with nanometer aluminum oxide and the preparation method of the sealing glass. The sealing glass is characterized in that the mol percentages of raw material components are as below: 35 percent to 50 percent of P2O5, 20 percent to 45 percent of ZnO, 0.1 percent to 20 percent of B2O3, 1 percent to 10 percent of Al2O3, 0.1 percent to 10 percent of SiO2, 0.1 percent to 10 percent of Na2O, 0.1 percent to 10 percent of MgO, 0.1 percent to 5 percent of Li2O, 0.1 percent to 4 percent of Fe2O3, and 0.1 percent to 4 percent of MnO2; the preparation method is as below: mixing the raw materials, wherein the nanometer aluminum oxide is the last to be added and then mixed to prepare a mixture; placing crucible in an electric cooker with a temperature of 1,200 to 1,400 DEG C, and the preheating for 15 minutes; adding the mixture into quartz crucible, performing smelting at the temperature of 1,200 to 1,400 DEG C, and allowing the temperature to be kept for 80 to 120 minutes; pouring the smelted glass liquid into water or tabletting the glass liquid and then grilling the tablets into powder, or casting the glass liquid into sticks, poles, tablets, and other shapes needed during the sealing; performing test and package. The invention has the advantages of simple preparation process, convenient operation and high cost performance and has wide market development prospect.

Owner:陈培

Manufacture method of solid insulating circuit device

ActiveCN101958166ASuitable coefficient of thermal expansionNot easy to produceInsulating bodiesEmergency protective device manufactureCooking & bakingConductive coating

The invention discloses a manufacture method of a solid insulating circuit device, which comprises the steps of: cleaning the surface of an electric conductor of a circuit device, preheating and then placing into a heated mould, and injecting a liquid epoxy resin composite material composed of silicon micropowder, epoxy resin and a curing agent into the mould; and taking a molded solid insulating circuit device blank from the mould after the epoxy resin composite material in the mould is cured, placing the blank into a baking oven for post-curing treatment, then carrying out sand blasting treatment on the surface of the blank except the part of the interface of the electric conductor to be insulated, coating a layer of conductive coating, carrying out evaporation treatment in the air, and then carrying out curing treatment in the baking oven to complete the manufacture of the solid insulating circuit device. Compared with the prior art, the invention can be used for effectively decreasing partial discharge values inside the solid insulating circuit device and surface inductive voltage of a product.

Owner:GUANGXI YINHE DECOM ELECTRIC

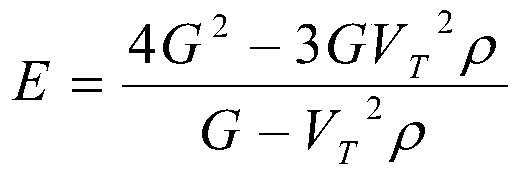

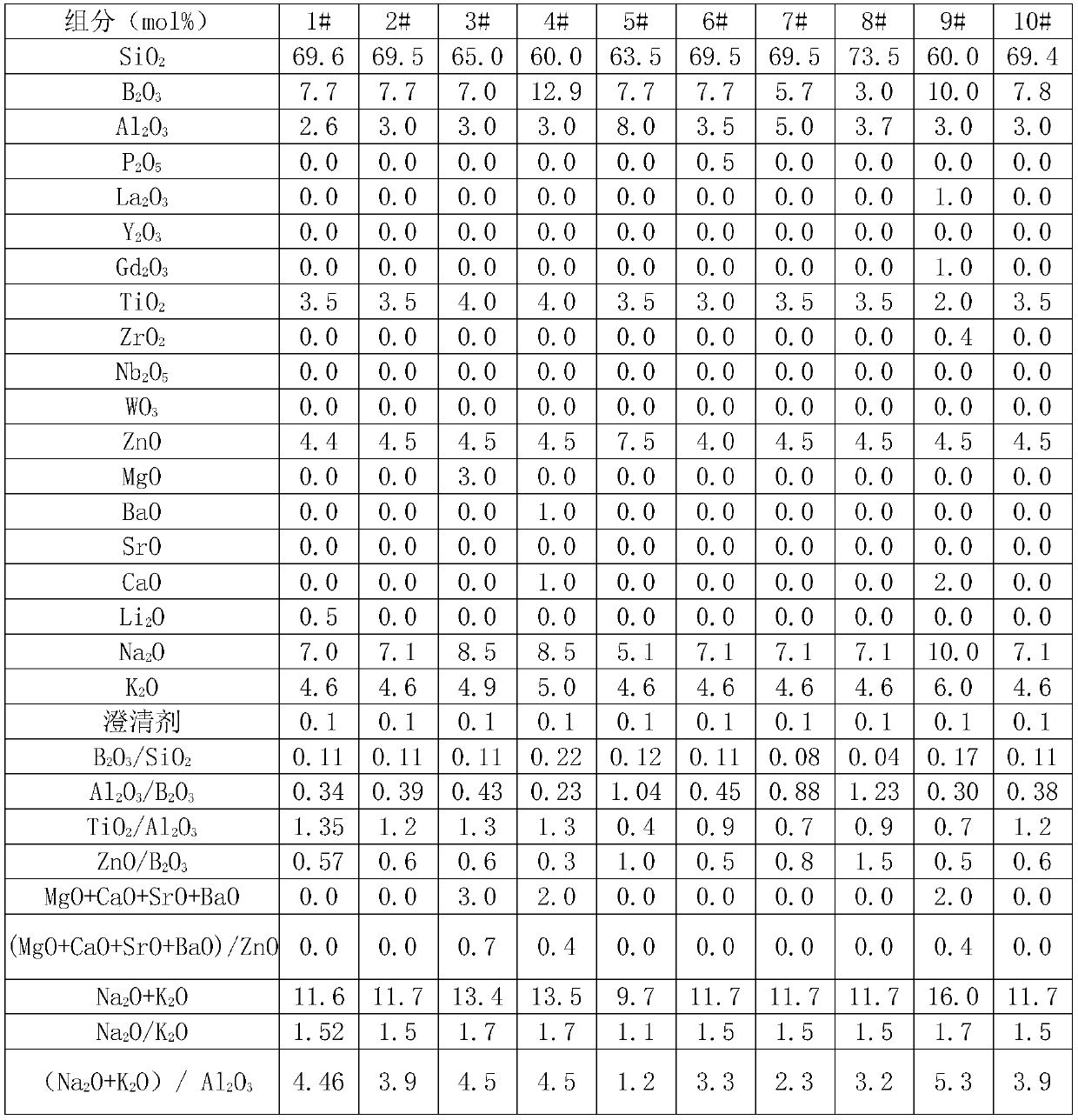

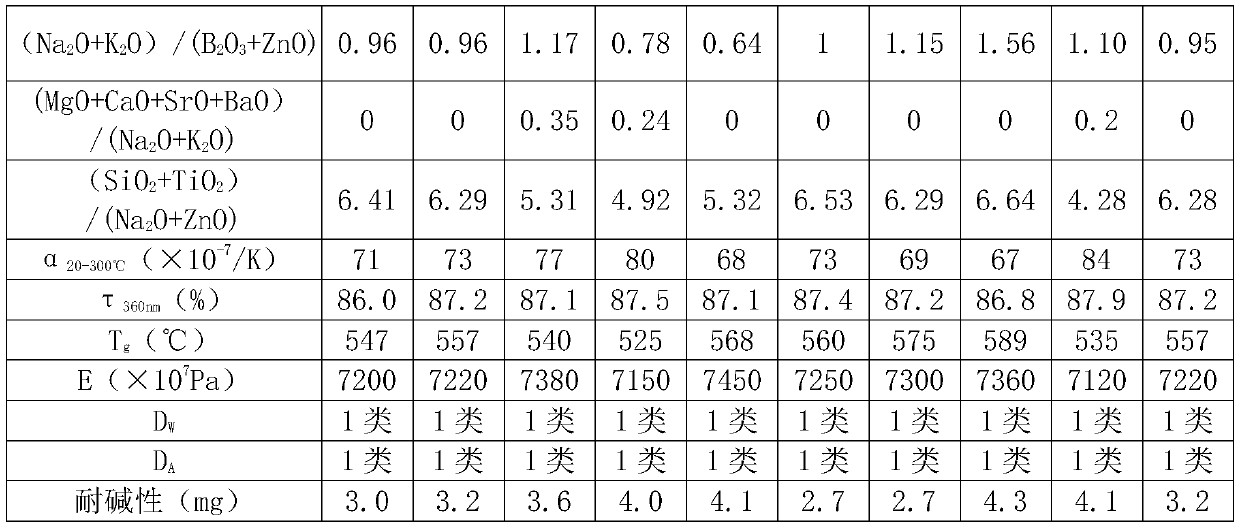

Glass composition

ActiveCN111574049ASuitable coefficient of thermal expansionImprove UV transmittanceThermal dilatationPhysical chemistry

The invention provides a glass composition. The glass composition comprises the following components in percentage by mole: 55 to 80% of SiO2, 2 to 15% of B2O3, 0.5 to 10% of TiO2, 0.5 to 12% of ZnO,0 to 10% of Al2O3, 1 to 15% of Na2O and 1-12% of K2O. Through reasonable component design, the obtained glass composition has a proper thermal expansion coefficient, high ultraviolet light transmittance and excellent water resistance, acid resistance and alkali resistance, meets the requirements of large-caliber high-quality processing, and is suitable for the fields of semiconductor manufacturingand the like.

Owner:CDGM OPTICAL GLASS +1

Glass powder for front silver paste of crystalline silicon solar cells and preparation method of glass powder

InactiveCN108083650AImprove photoelectric conversion rateSimple componentsThermal insulationThermal expansion

The invention relates to glass powder for front silver paste of crystalline silicon solar cells and a preparation method of the glass powder. The glass powder is characterized by being prepared formula raw materials in parts by mass as follows: 30-80 parts of Bi2O3, 0.1-20 parts of B2O3, 5-30 parts of ZnO, 1-15 parts of SiO2, 0.1-20 parts of BaO, 0-8 parts of Al2O3, 0-6 parts of MgO, 0-5 parts ofTiO2 and 0.1-3 parts of Ag2O. The preparation method comprises the steps as follows: a, the formula raw materials are weighed in parts by mass and uniformly mixed, and a mixture is prepared; b, a crucible is mounted in a resistance furnace, the temperature is increased to 900-1,300 DEG C, the mixture is added, thermal insulation is performed, and clear molten glass is obtained; c, the molten glassis quenched in deionized water, then taken out and dried; d, dried glass is subjected to ball milling and sieving. The glass powder has the advantages as follows: the glass powder for front silver paste of the crystalline silicon solar cells has simple raw material composition and lower cost, contains no lead, vanadium, thallium, tellurium and other harmful elements, conforms to the environmentalprotection requirement, has lower softening point and proper thermal expansion coefficient, has the expansion coefficient matched with a silicon wafer and has low shrinkage rate and high adhesion. Silver paste prepared from the glass powder has high photoelectric conversion rate after being sintered.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

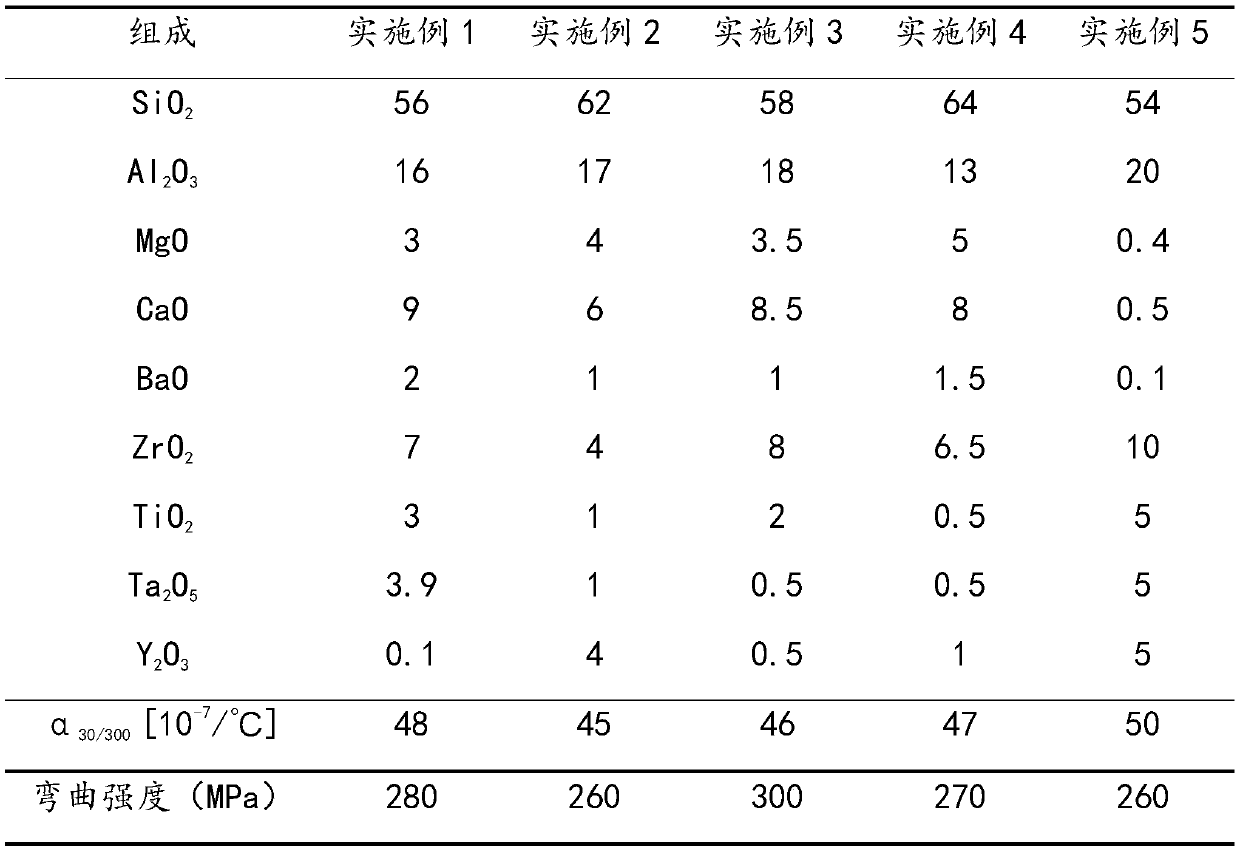

Alkali-resistant aluminosilicate glass and application thereof

The invention discloses alkali-resistant aluminosilicate glass material and an application thereof. The glass is composed of the following components, in percentages by weight: 54-64% of SiO2, 13-20% of Al2O3, 0.4-5% of MgO, 0.5-9% of CaO, 0.1-2% of BaO, 4-10% of ZrO2, 0.5-5% of TiO2, 0.5-5% of Ta2O5, and 0.1-5% of Y2O3. The alkali-resistant aluminosilicate glass provided by the invention has the advantages of a stable structure, good chemical stability, high mechanical strength and high transmittance, and does not contain elements harmful to the environment, such as lead, arsenic and cadmium, the glass has less corrosion even the glass is used in a high-temperature high-pressure environment for a long time, and the glass has excellent alkali resistance, and is suitable for use in glass of a high-temperature high-pressure liquid level meter observation window.

Owner:鲁米星特种玻璃科技股份有限公司

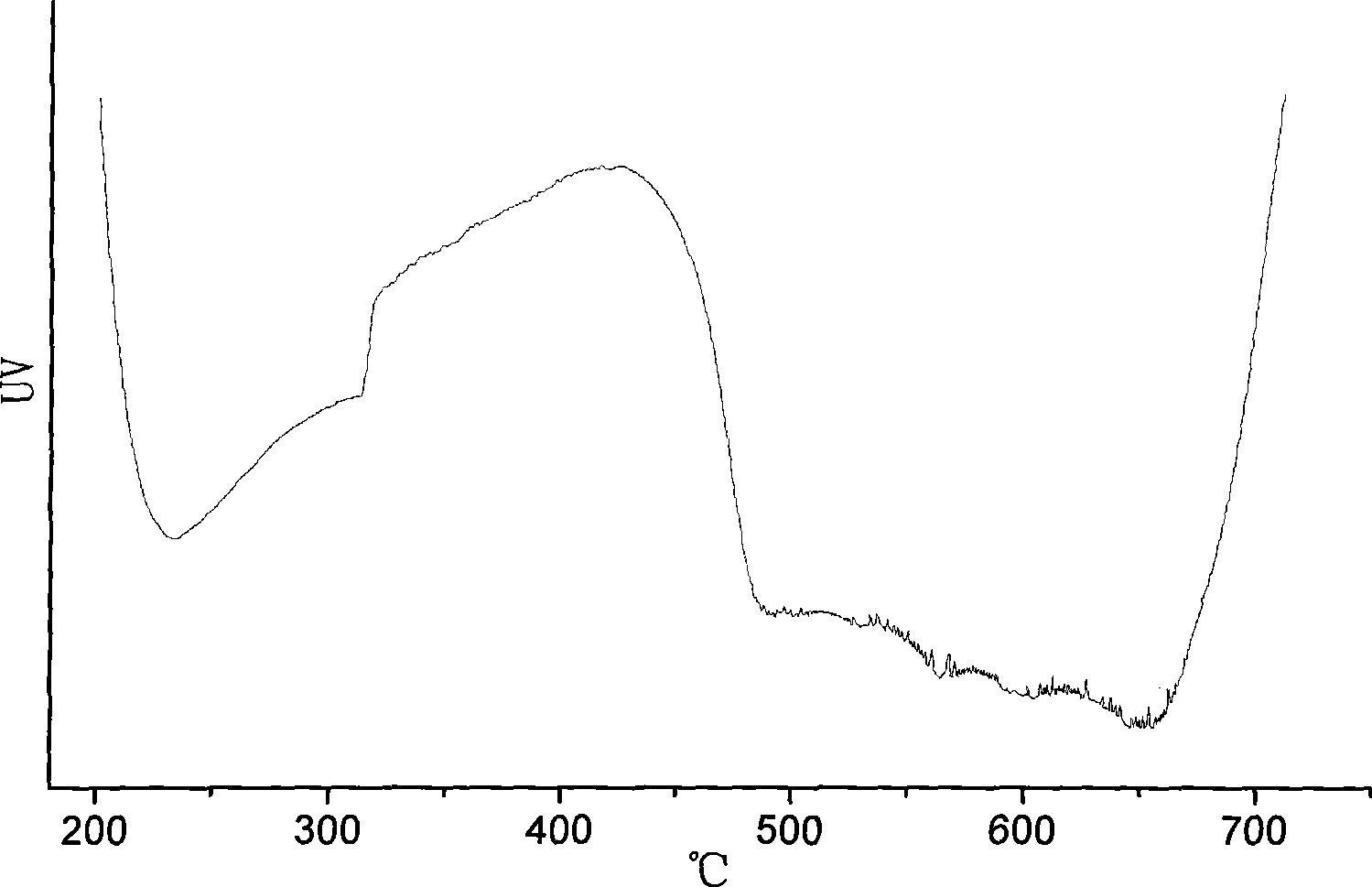

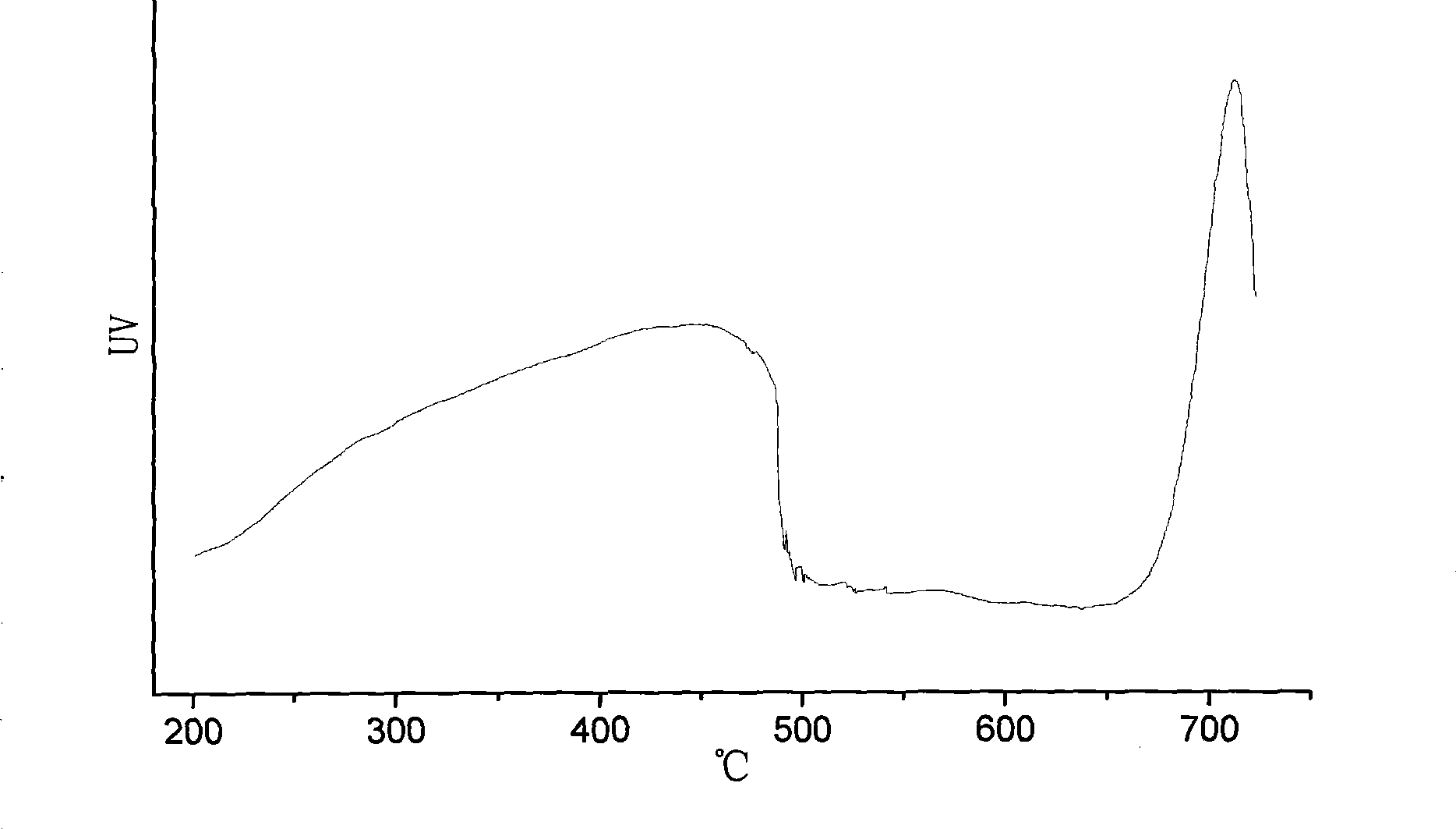

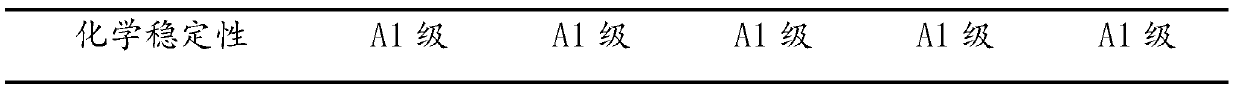

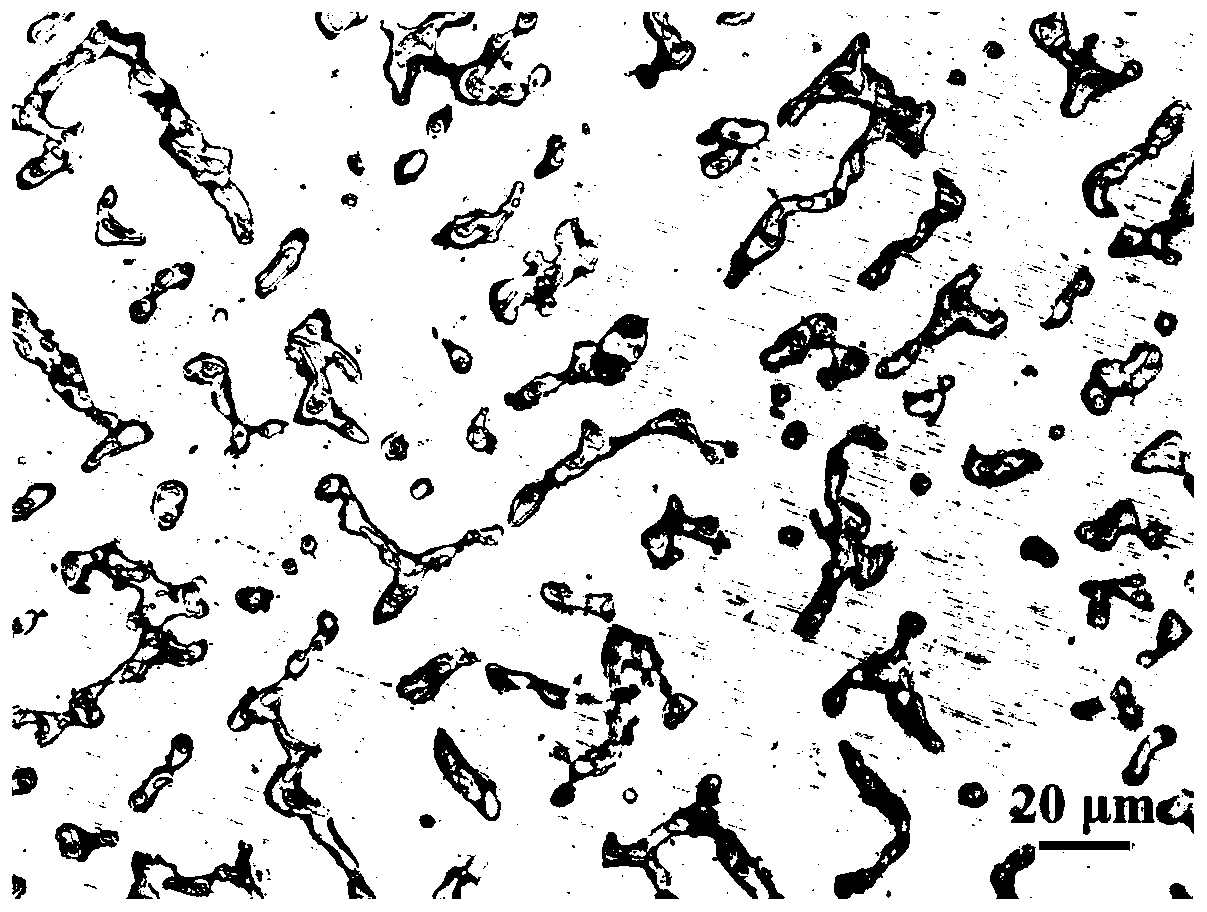

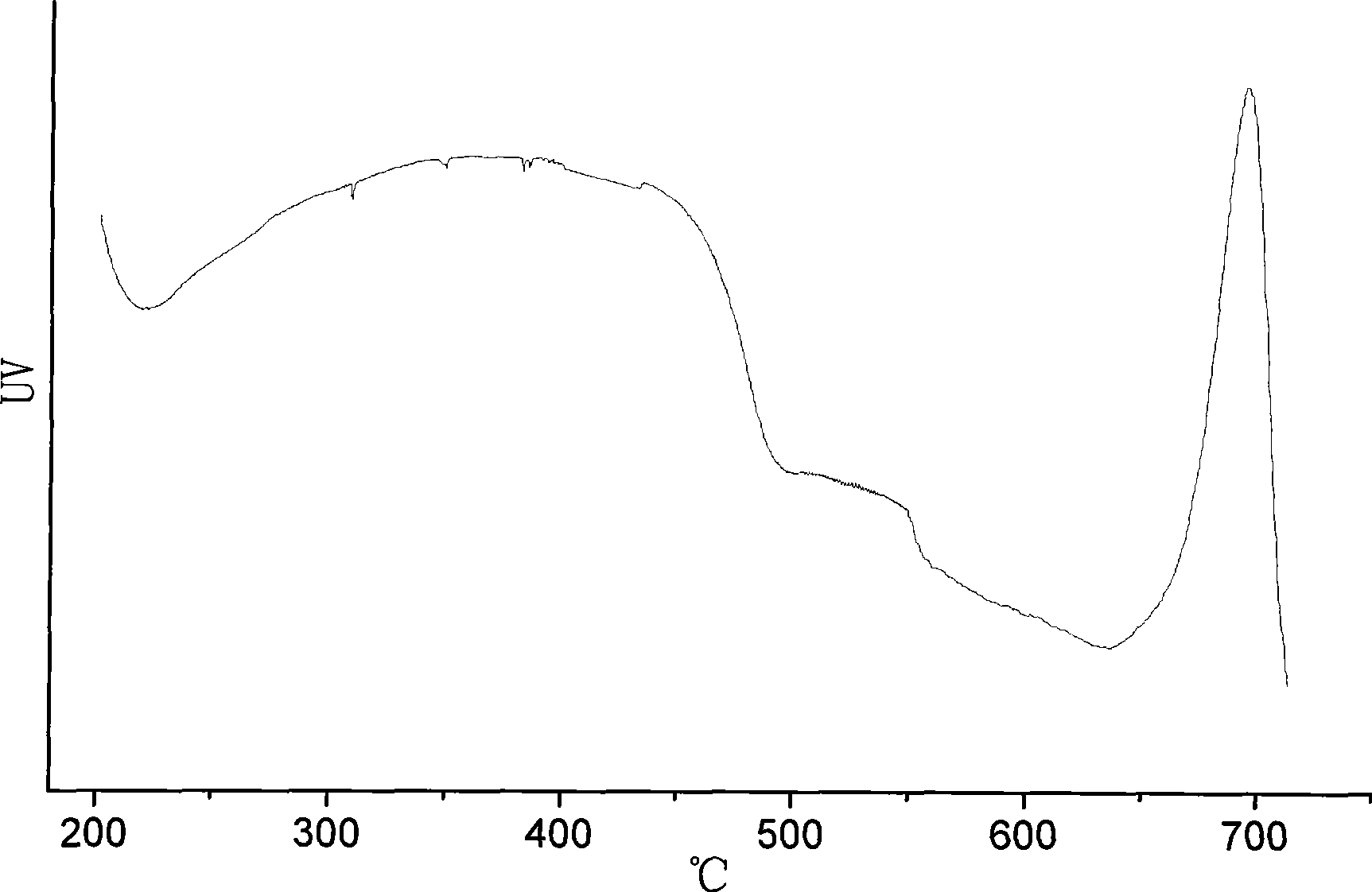

Crystallizing glass material for 4J29 kovar alloy sealing-in and method of producing the same

InactiveCN101152973ASuitable coefficient of thermal expansionSimple process conditionsKovarHeat treated

The composition of a microlite glass material for sealing with 4J29 kovar alloy is Li2O-ZnO-Al2O3-SiO2; a crystal nucleating agent is P2O5; a clarifying agent is Sb2O3; raw materials are mixed according to a ratio to prepare a uniform batch; the batch is put into a corundum crucible and melted at a temperature between 1350 and 1400 DEG C in a high-temperature electric cooker for three hours; then the batch is injected and molded. At a constant temperature of about 520 DEG C, anneal is done for 1 hour; in the end, the batch is processed to be microcrystal. The present invention uses the complementary principle of thermal performances; with the composition design and crystallization process of base glass, the Li2Al2Si3O10 main crystal phase of low heat expansion coefficient or negative thermal expansion coefficient can be separated in the base glass. The present invention uses a little P2O5 as the crystal nucleating agent; the betaII'-LZS is first separated when the base glass is micro-crystallized; then a plurality of Li2Al2Si3O10 crystal phase are separated to get the microlite glass; a large amount of tiny dendrite are mutually connected to form a network; thus the microlite glass has a higher mechanical strength.

Owner:CENT SOUTH UNIV

Inorganic adhesive used in field of computers and preparation method thereof

InactiveCN101701136AMeet environmental protection requirementsWide Performance Tuning RangeInorganic adhesivesAdhesiveAir tightness

The invention relates to an inorganic adhesive used in the field of computer and a preparation method thereof. The inorganic adhesive comprises the following raw materials, by weight percent: 20-40% of SiO2, 5-20% of Al2O3, 5-30% of MgO, 1-20% of B2O3, 1-20% of BaO, 1-10% of ZnO, 1-10% of V2O5, 0.1-5% of SrO, 0.1-5% of Li2O, 0.1-2% of Sb2O3 and 0.1-1% of Co3O4; the preparation process comprises the following steps: weighing, material mixing, melting, tabletting, ball milling and sieving; and the invention has the characteristics of complete elimination of gas, good airtightness and strong bonding force.

Owner:HENAN UNIV OF URBAN CONSTR

Phosphate controlled-release fertilizer with sterilizing effect and preparation method thereof

InactiveCN102190510ADissolution rate controlLow investment costClimate change adaptationExcrement fertilisersControlled releasePhosphate

The invention relates to a phosphate controlled-release fertilizer with a sterilizing effect and a preparation method thereof. The fertilizer is prepared from the following raw materials by molar percent: 30-60% of P2O5, 15-40% of K2O, 1-15% of CaO, 1-10% of MgO, 1-10% of Fe2O3, 1-10% of MnO2, 1-10% of CuO, 0.1-10% of Y2O3, 0.1-10% of Sm2O3 and 0.1-10% of La2O3, wherein the sum of P2O5 and K2O is 50%-80%, and the sum of Y2O3, Sm2O3 and La2O3 is 2%-7%. The preparation method comprises the following steps: weighing, mixing, smelting, pouring, ball-milling and packaging. The fertilizer has the characteristics of less dosage and high and long fertilizer efficiency, is not easy to run off, cake and deteriorate, and is convenient for application, storage and transportation; and the required release amount is achieved through controlling the dissolution rate and granularity of a glass fertilizer.

Owner:郑庆云

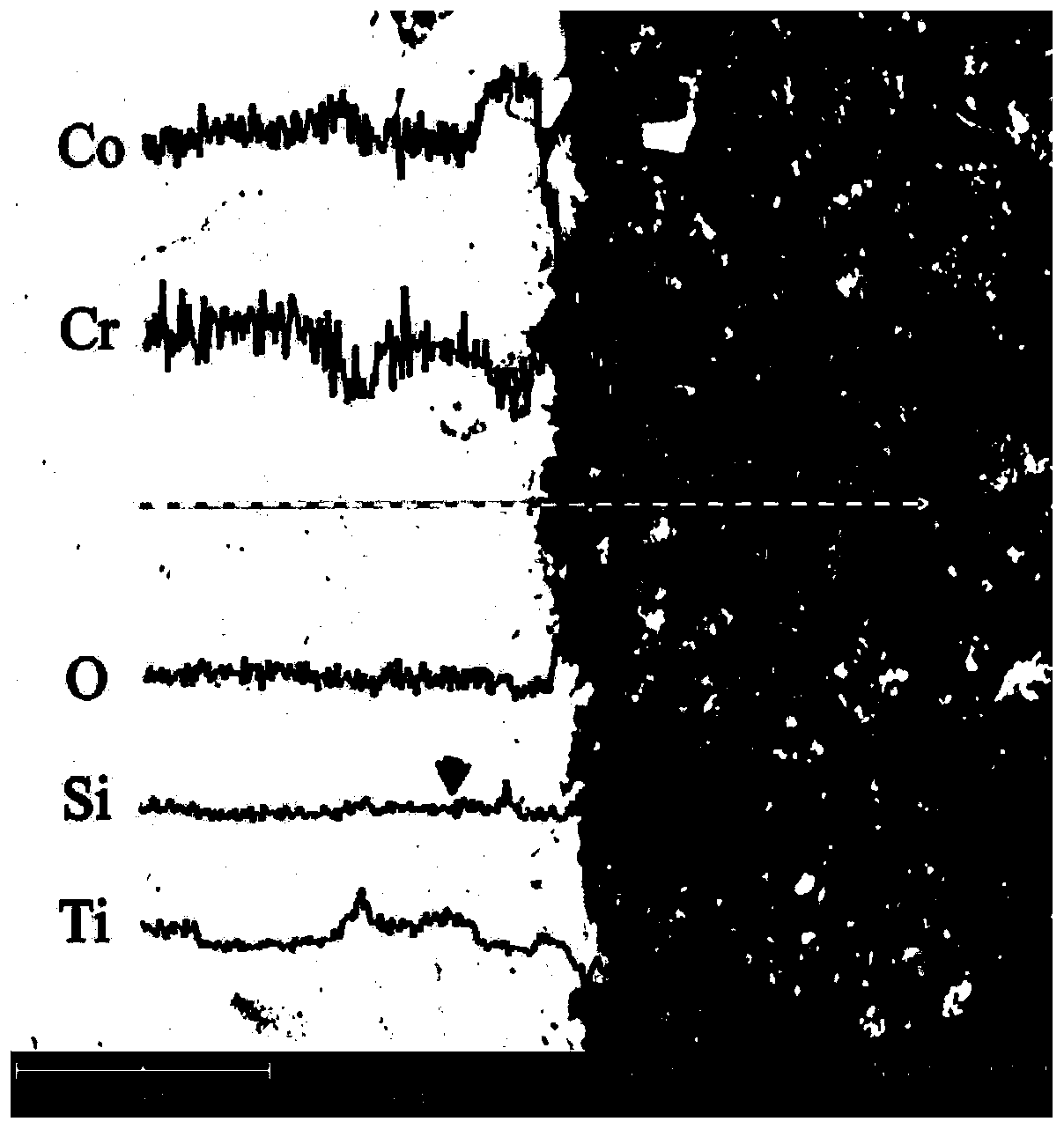

Titanium-containing cobalt-chromium alloy, preparation method and application thereof

InactiveCN111057909ALow priceGood biocompatibilityTooth crownsArtificial teethThermal dilatationShrinkage rate

The invention relates to the technical field of alloys, in particular to a titanium-containing cobalt-chromium alloy, a preparation method and application thereof. The titanium-containing cobalt-chromium alloy comprises the following components according to the weight percentage: 23.0-30.0% of Cr, 5.0-8.0% of Mo, 1.5-3.5% of Ti, 0-1.0% of Mn, 0-2.0% of Si, 2.0-4.0% of Cu, and the balance being Co.The titanium-containing cobalt-chromium alloy has the tensile strength of 828 MPa, the yield strength of 632 MPa, the elongation percentage of 8%-15%, the Vickers hardness of HV 270-330, and the casting shrinkage ratio of 1.5%-2.0 %, and has a suitable coefficient of thermal expansion with earthenware, can be used for making a denture movable repairing bracket, a porcelain base crown and the like.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Dielectric layer lead-less glasses material for plasma display screen

The invention discloses a lead-free glass frit for the dielectric layer of a plasma display, and the glass frit comprises the following raw materials according to the weight percentage: 30%-50% of Bi2O3, 5%-40% of B2O3, 5%-30% of BaO, 0.1%-10% of Al2O3, 0.1%-10% of ZnO, 0.1%-10% of MgO and0.1%-5% of La2O3. The invention has the advantages that the glass frit belongs to environment-friendly materials; various performances are excellent; the cost performance is high; the glass frit has suitably and easily adjusted thermal expansion coefficient and proper sintering temperature, and also has good chemical stability and high dielectric strength; the competitive power is very strong in lead-free performance and cost performance; and the glass frit has wide market development prospect.

Owner:陈培

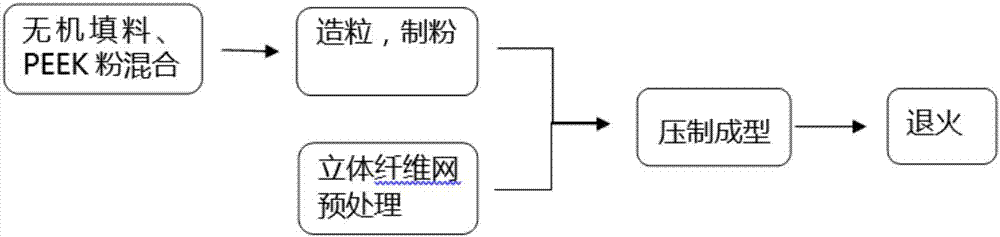

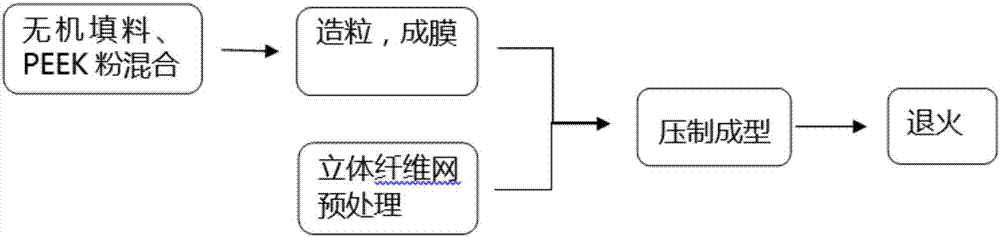

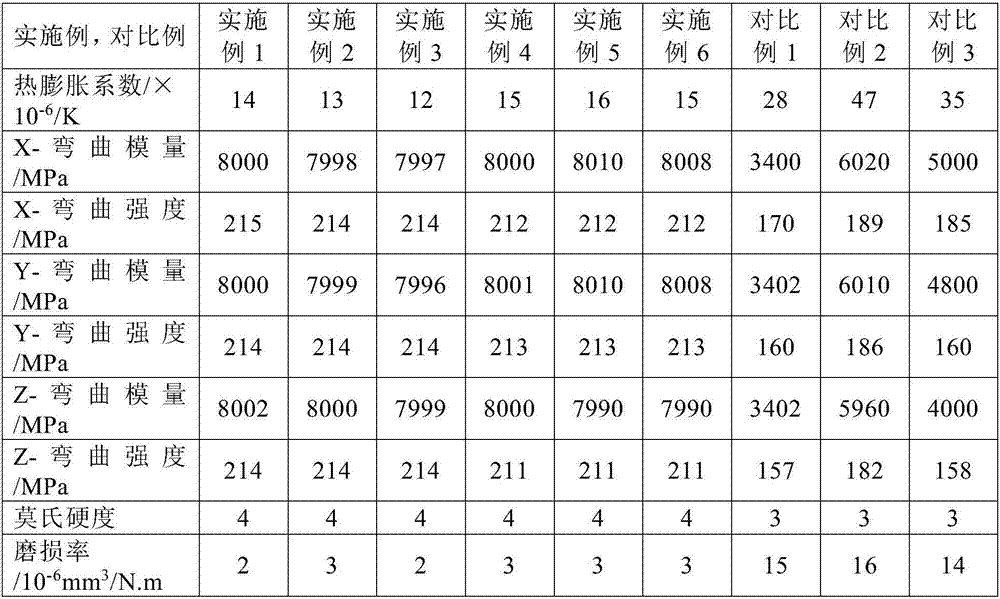

Poly aryl ether ketone composite material and preparing method thereof

InactiveCN107412848AConsistent mechanical strengthSatisfy complex stress situationsTissue regenerationProsthesisFiberBiocompatibility Testing

The invention provides a poly aryl ether ketone composite material and a preparing method thereof. The poly aryl ether ketone composite material comprises poly aryl ether ketone resin, three-dimensional fiber net and inorganic filler in the weight ratio of 100: 10-20: 5-40. The preparing method for the poly aryl ether ketone composite material comprises the steps of mixing, powdering, laying powder, pressing for molding and annealing. Another preparing method for the poly aryl ether ketone composite material comprises mixing, granulating, film forming, pressing, annealing and other steps. According to the poly aryl ether ketone composite material and the preparing method thereof, the poly aryl ether ketone matrix resin is synergistically strengthened in the three-dimensional direction by using the three-dimensional fiber net and the inorganic filler, and the prepared composite material has the same mechanical strength in all directions and the flexural strength is greater than 200Mpa, so that the complicated stress condition of teeth can be met, and thermal expansion coefficient, hardness, abrasion resistance, machinability, grinding performance and polishing performance are relatively suitable, the poly aryl ether ketone composite material is a high strength non-metallic dental restoration material; and no extra processing additives are need to be added in the preparing process, and biocompatibility is good.

Owner:陈明翠 +4

Inorganic adhesive used for slurry, and preparation method thereof

InactiveCN102190443AMeet environmental protection requirementsWide Performance Tuning RangeAdhesiveSlurry

The invention relates to an inorganic adhesive used for slurry, and a preparation method thereof. The inorganic adhesive is composed of the following raw materials in percentage by weight: 20-40% of SiO2, 5-20% of Al2O3, 5-30% of CaO, 1-20% of B2O3, 1-20% of BaO, 1-10% of ZnO, 1-10% of V2O5, 0.1-5% of CuO, 0.1-5% of Li2O, 0.1-2% of Sb2O3 and 0.1-1% of Co3O4. The preparation method comprises the following processes: weighing, mixing materials, melting, tabletting, ball-milling and screening. The inorganic adhesive has the advantages of complete removal of gas, high airtightness, and high adhesive force.

Owner:李胜春

Energy-saving LED lamp lampshade material and preparing method thereof

ActiveCN109796560ASimple manufacturing methodLow priceChemical industryGlobesAddition polymerAging resistance

The invention discloses a preparing method of an energy-saving LED lamp lampshade material. The preparing method comprises the steps of 1, preparing carbonic ester-based polycondensation monomers, 2,preparing polycondensates, 3, preparing addition polymers, and 4, shaping the energy-saving LED lamp lampshade material. The invention further discloses the energy-saving LED lamp lampshade material prepared by adopting the preparing method. The energy-saving LED lamp lampshade material is good in comprehensive performance, not fragile, excellent in aging resistance, abrasion resistance, toughness, high temperature resistance and flame resistance, good in light transmittance, small in transmittance lumen depreciation, even in fog face and long in service life.

Owner:江门市塑禾照明科技有限公司

Nanooxide-doped green solder glass and preparation method thereof

The invention discloses nanooxide-doped green solder glass and a preparation method thereof. The nanooxide-doped green solder glass is characterized by comprising the following raw material components by molar percent: 35%-50% of P2O5, 20%-45% of ZnO, 0.1%-20% of B2O3, 1%-10% of Al2O3, 0.1%-10% of SiO2, 0.1%-10% of Na2O, 0.1%-10% of MgO, 0.1 %-5% of Li2O, 0.1%-4% of Fe2O3, 0.1%-4% of MnO2 and 0.1%-1% of colorant chromium oxide. The preparation method comprises the following steps: mixing raw materials, and adding nanoalumina finally and mixing to prepare a mixture; putting a crucible into an electric furnace with the temperature of 1200-1400 DEG C, and preheating for 15 minutes; adding the mixture into the quartz crucible, melting at the melting temperature of 1200-1400 DEG C, and holding for 80 to 120 minutes; pouring the melted glass liquid into water or being ground into powder by a ball mill after tablet forming. The invention has the advantages of simple preparation, convenient operation, high performance cost ratio and broad market development prospects.

Owner:李胜春

Novel environment-friendly glass powder with nano-metal oxide and preparation method thereof

InactiveCN109369027ASolve the problem of poor chemical stabilityLow softening temperatureLead oxideMoisture resistance

The invention relates to the technical field of high-temperature coatings, in particular to novel environment-friendly glass powder added with nano-metal oxide and used for a high-temperature coatingand a preparation method thereof. In the novel environment-friendly glass powder, according to mass percent, Bi2O3 is 60-85%, ZnO is 5-20%, B2O3 is 5-30%, Sb2O3 is 0.5-5%, SiO2 is 1-10%, Al2O3 is 1-10%, TiO2 is 0.5-3%, CaO is 0.5-8%, MgO is 0.5-10%, BaO is 0.5-10%, Na2O is 0-5%, K2O is 0-5%, Li2O is 0-5%, Y2O3 is 0.5-5%, SrO is 0.5-5%. The low-temperature lead-free environment-friendly glass powder does not contain lead oxide, has low softening point, good adhesion, good chemical stability and strong moisture resistance, and can be used for high-temperature resistant coatings.

Owner:江西合创光电技术有限公司

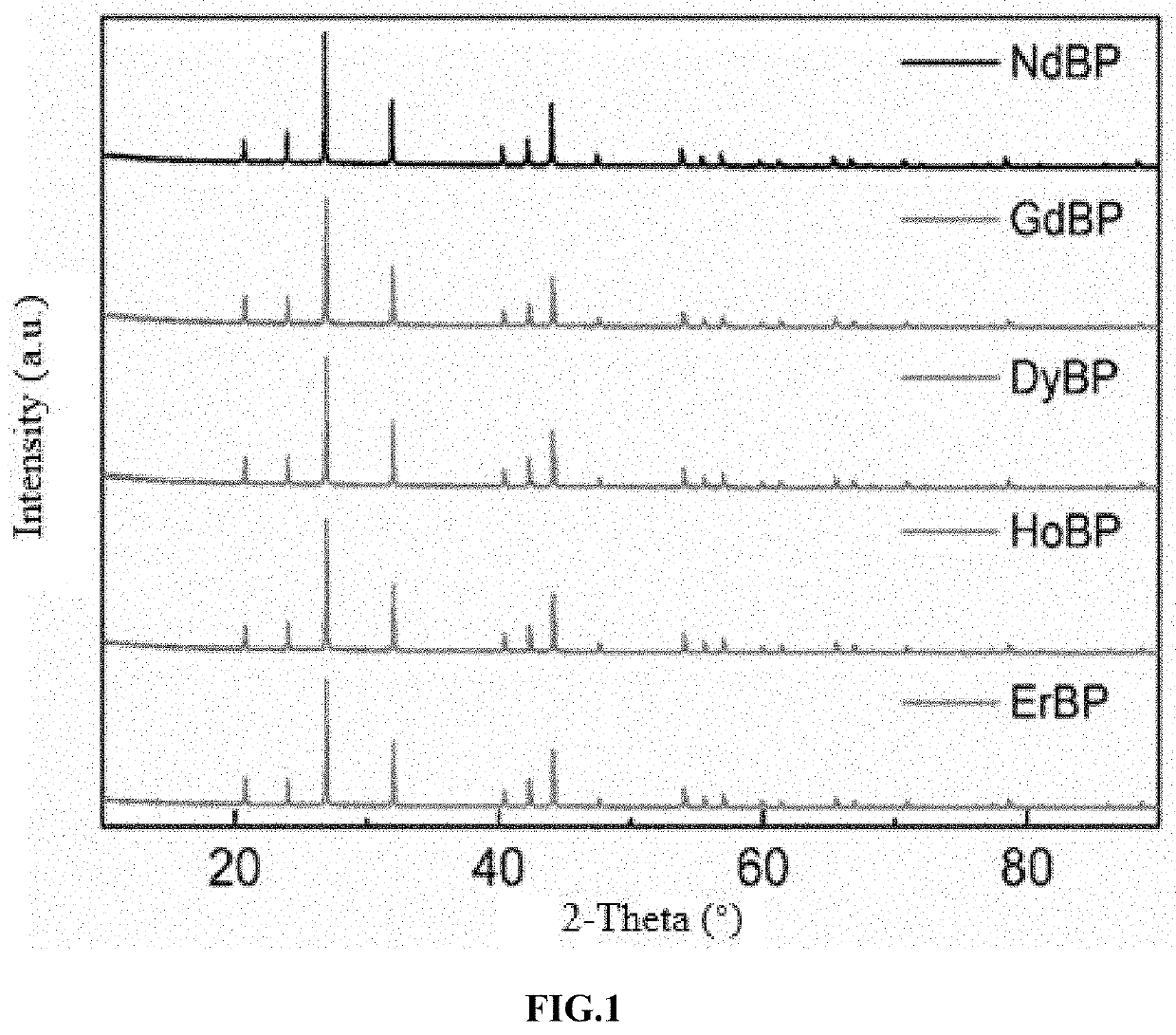

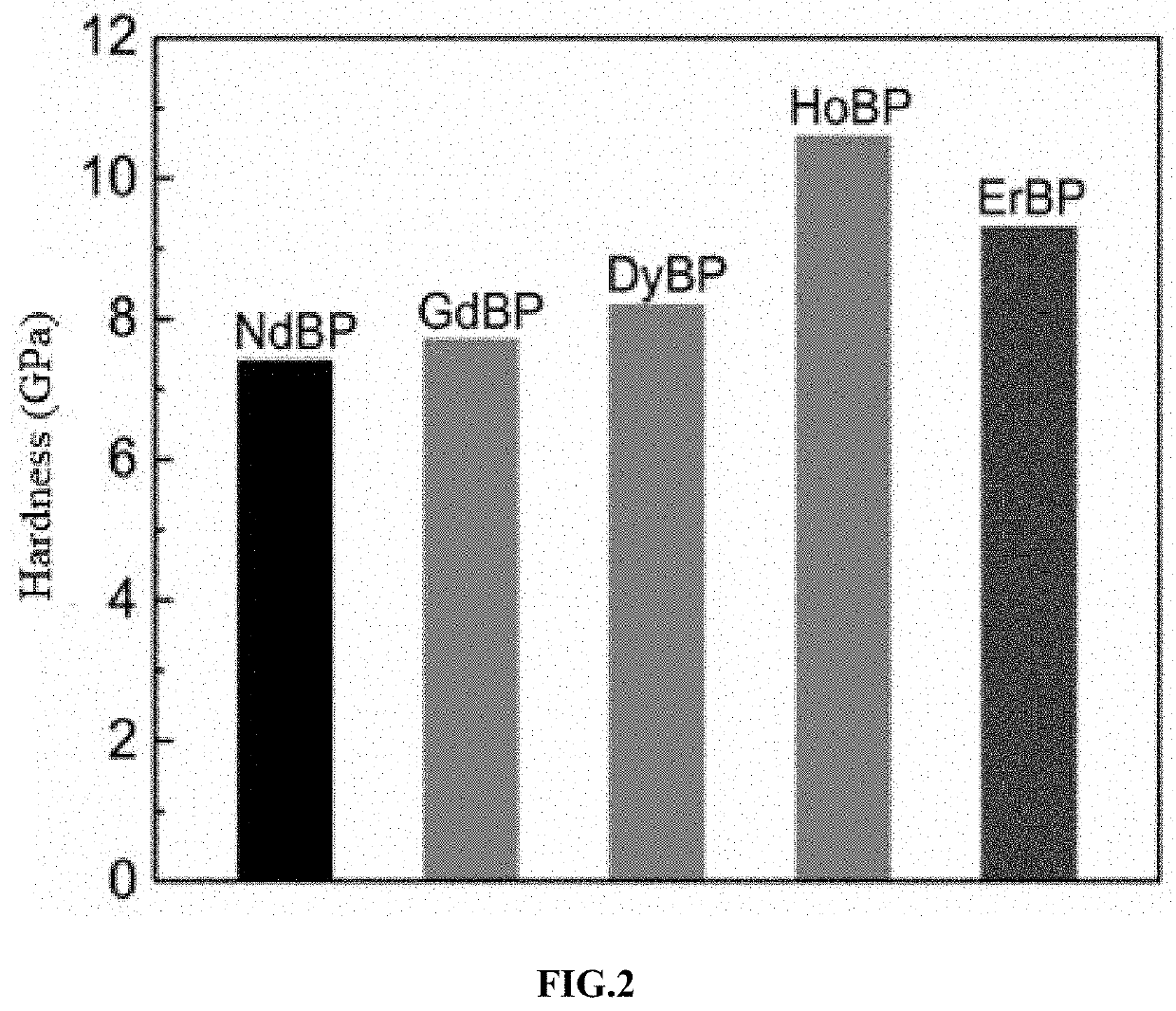

Orthophosphate thermal barrier coating material with high coefficient of thermal expansion and preparation method thereof

PendingUS20220306472A1High melting pointHigh phase stabilityEfficient propulsion technologiesCoatingsThermal dilatationCrystal system

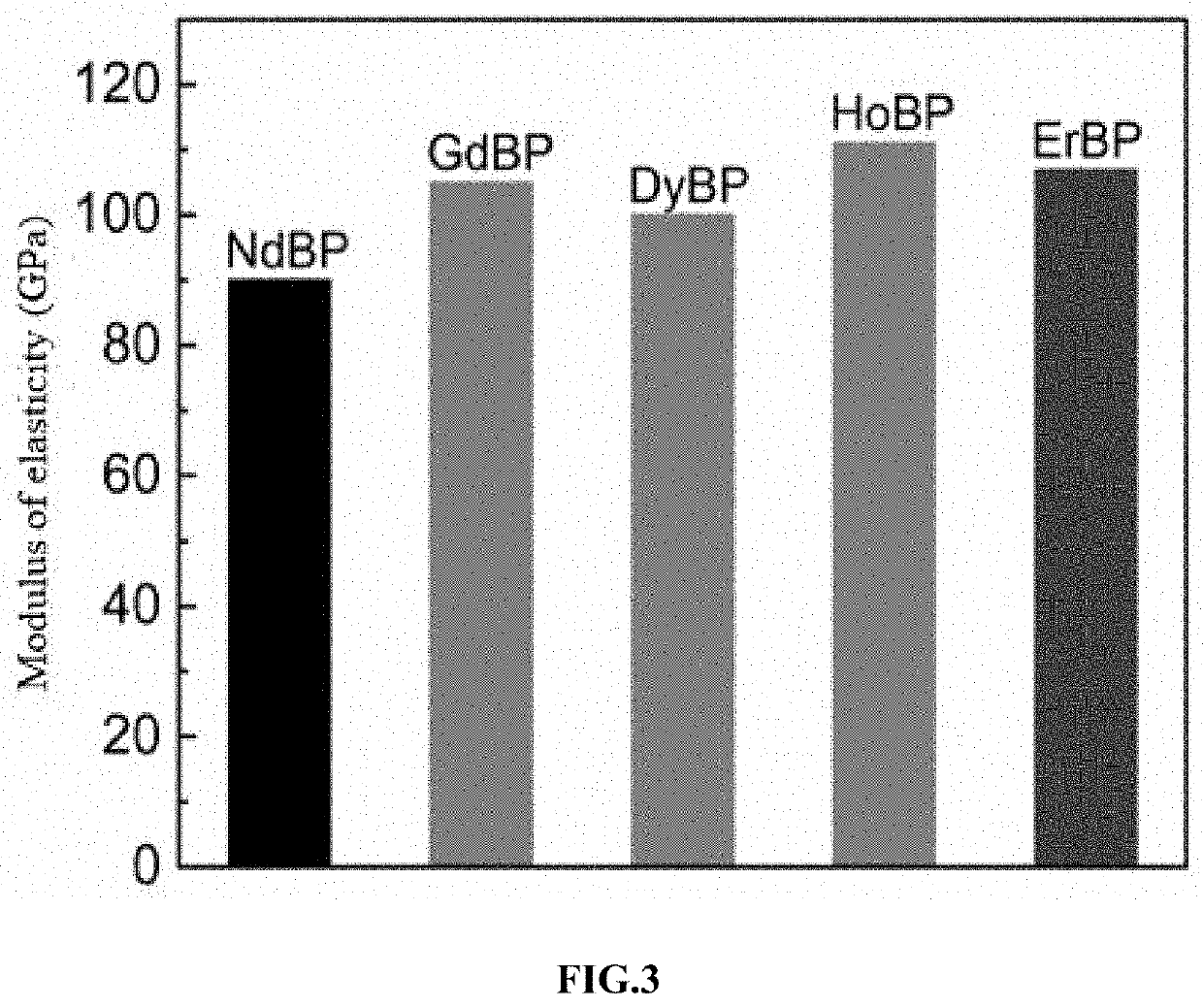

The present disclosure relates to an orthophosphate thermal barrier coating material with high coefficient of thermal expansion and a preparation method thereof. ReM3P3O12 series ceramics with an eulytite crystal structure are prepared by a high-temperature solid-phase reaction for the first time. The ReM3P3O12 ceramic belongs to a −43 m space group of a cubic crystal system, which not only has a higher melting point and excellent high-temperature phase stability, but also has a lower thermal conductivity and a suitable coefficient of thermal expansion. It can effectively alleviate the stress caused by the mismatch of the coefficient of thermal expansion of the base material and the ceramic layer, so as to meet the requirements of thermal insulation and high-temperature oxidation and corrosion resistance of the hot end parts in long-term service, which has application prospects in the field of thermal barrier coatings.

Owner:SHANDONG UNIV

Environment-friendly high-refractive-index ultraviolet-permeable glass and preparation method thereof

ActiveCN110128006AStable glass structureGood chemical stabilityGlass shaping apparatusTransmittanceMolten glass

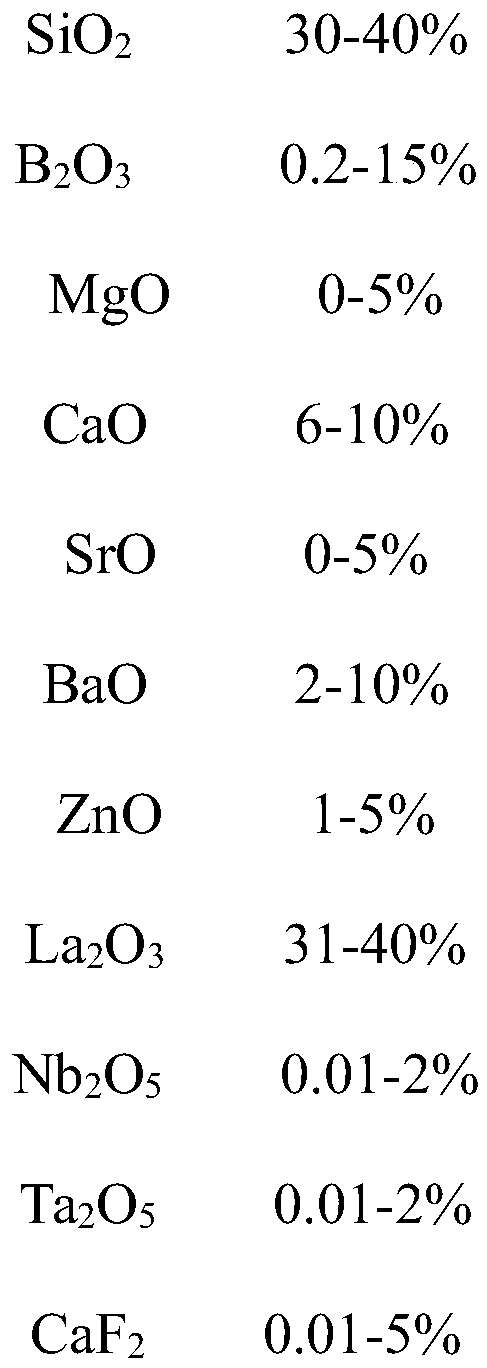

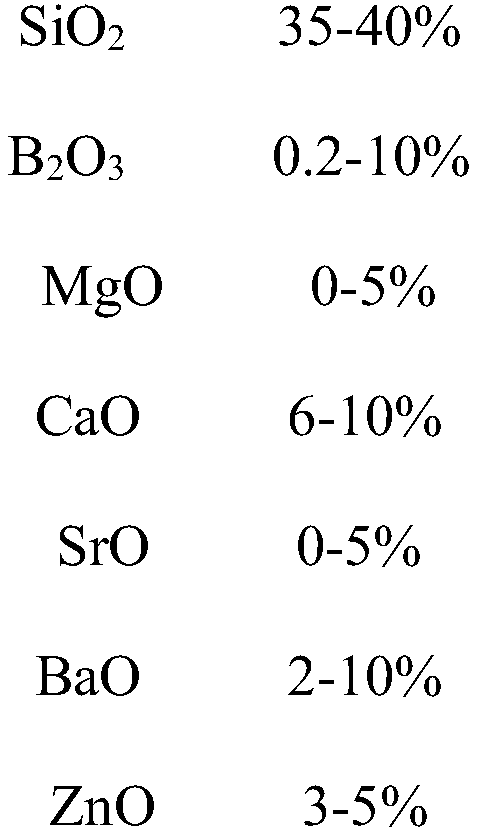

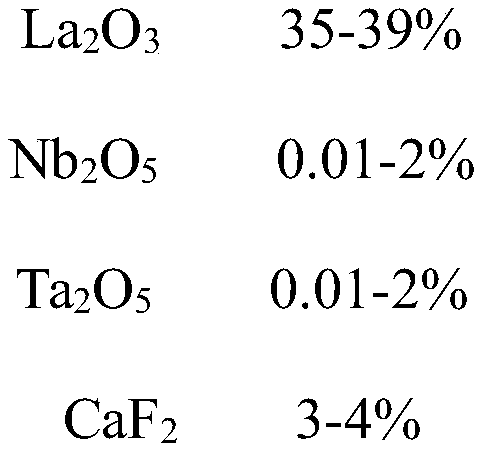

The invention discloses environment-friendly high-refractive-index ultraviolet-permeable glass and a preparation method thereof. The ultraviolet-permeable glass is prepared from the following components in percentage by weight: 30-40% of SiO2, 0.2-15% of B2O3, 0-5% of MgO, 6-10% of CaO, 0-5% of SrO, 2-10% of BaO, 1-5% of ZnO, 31-40% of La2O3, 0.01-2% of Nb2O5, 0.01-2% of Ta2O5 and 0.01-5% of CaF2.the preparation method comprises the following steps: carrying out iron removal treatment on the main raw materials, then weighing the high-purity raw materials according to weight percentages of thecomponents, carrying out ball-milling and uniform mixing to prepare a mixture, heating the mixture, then carrying out mixing, stirring the molten glass liquid for multiple times in a melting processof the glass mixed material, then taking out the glass molten liquid out from a furnace and quickly pouring the glass molten liquid into a preheated heat-resistant steel mold to obtain glass with a specified specification by pouring, then putting the glass into an annealing furnace for annealing treatment, and carrying out cooling to obtain the environment-friendly high-refractive-index ultraviolet-permeable glass material. The ultraviolet-permeable glass has the advantages of environmental protection, high refractive index, high ultraviolet transmittance, appropriate thermal expansion coefficient, good chemical stability and simple preparation method, and has a wide market application prospect.

Owner:鲁米星特种玻璃科技股份有限公司

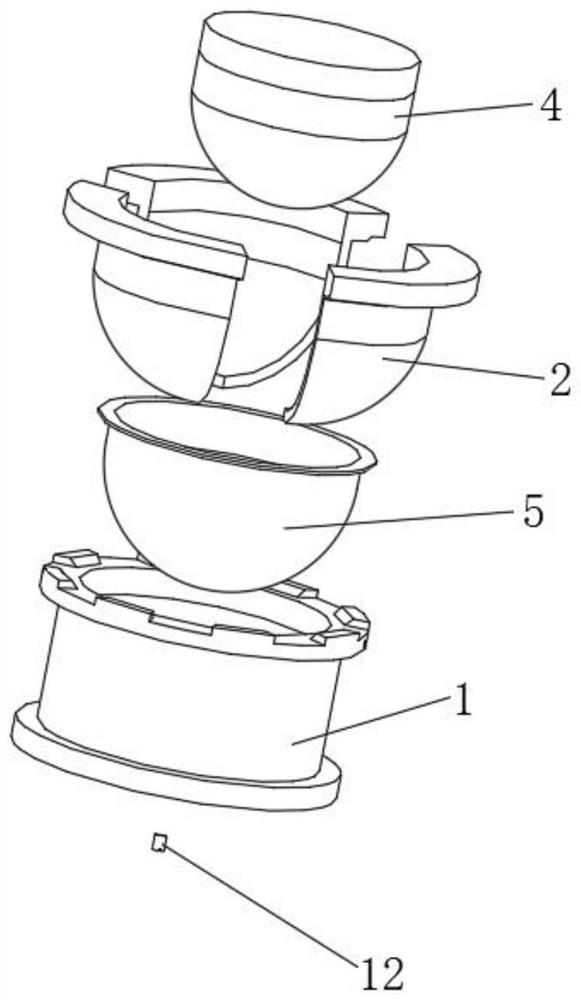

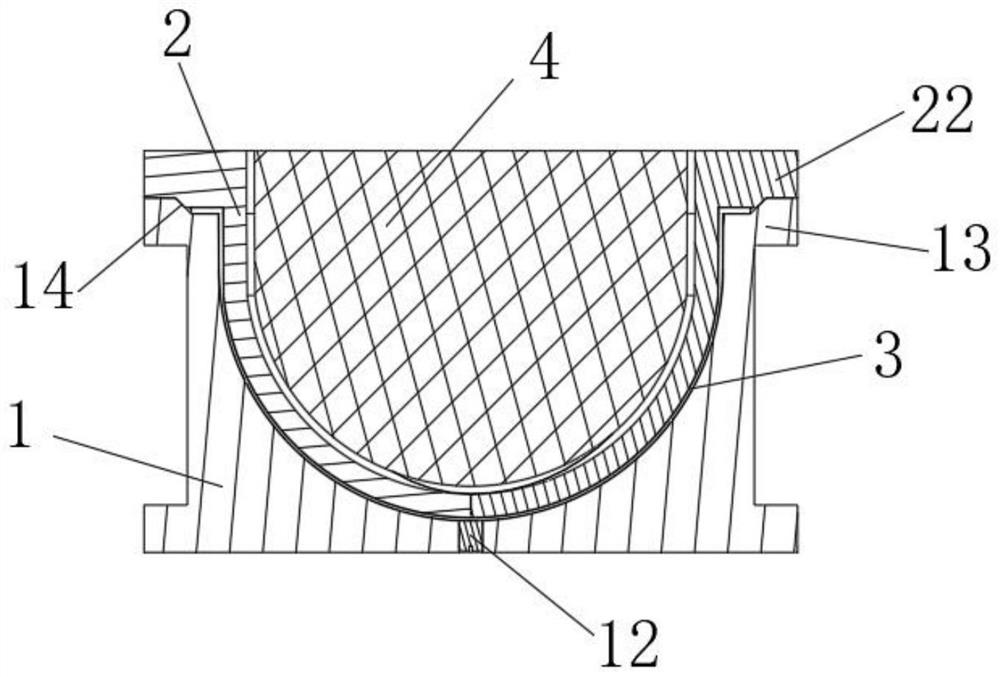

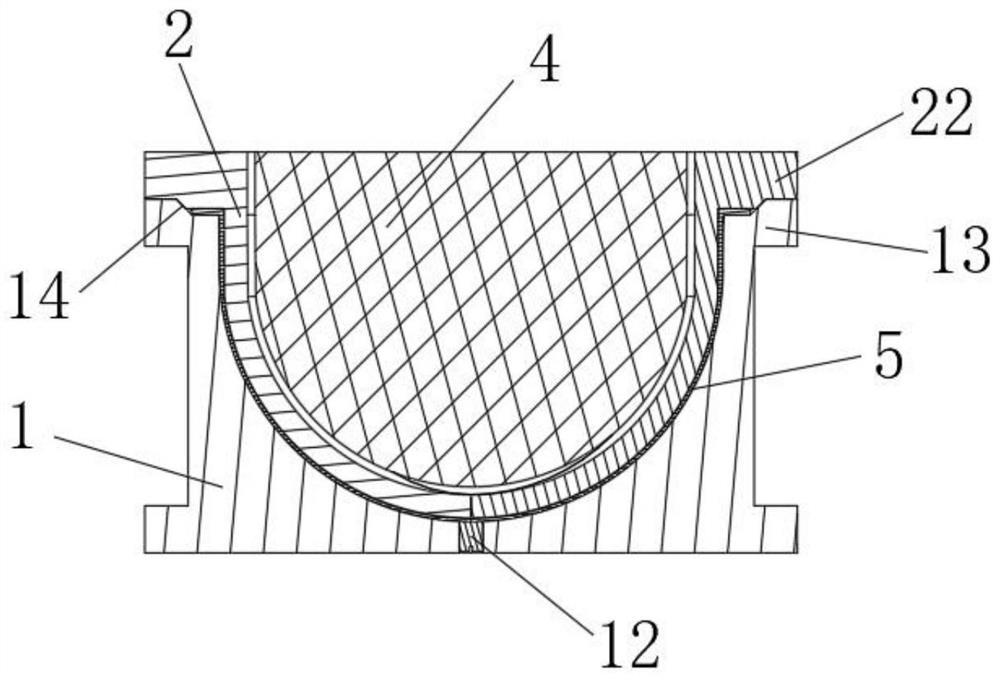

Forming die and method for high-precision thin-shell structure composite material wave-transparent antenna housing

The invention provides a forming die and method for a high-precision thin-shell-structure composite material wave-transparent radome, the forming die comprises a female die and a male die which are matched with each other, a forming cavity used for forming a radome product is formed between the female die and the male die, the male die is of a shell structure and is formed by combining a plurality of male die units, and the male die units are connected with the female die and the male die. A thermal expansion core mold is arranged in the male mold in a matched mode, and the thermal expansion core mold expands after being heated and can extrude the male mold. The forming method comprises the following steps: 1) preparing a forming mold; 2) paving a composite material for the antenna housing on the inner surface of the female die corresponding to the forming cavity; placing the male die in the female die, and placing the thermal expansion core die in the male die; 3) heating, pressurizing and curing; 4) cooling and taking out; and taking out the thermal expansion core mold and demolding. The male die formed by combining the multiple male die units is arranged, and the thermal expansion core die is combined to increase the die assembly auxiliary pressure, so that the compactness and the uniformity of an antenna housing product can be effectively improved.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

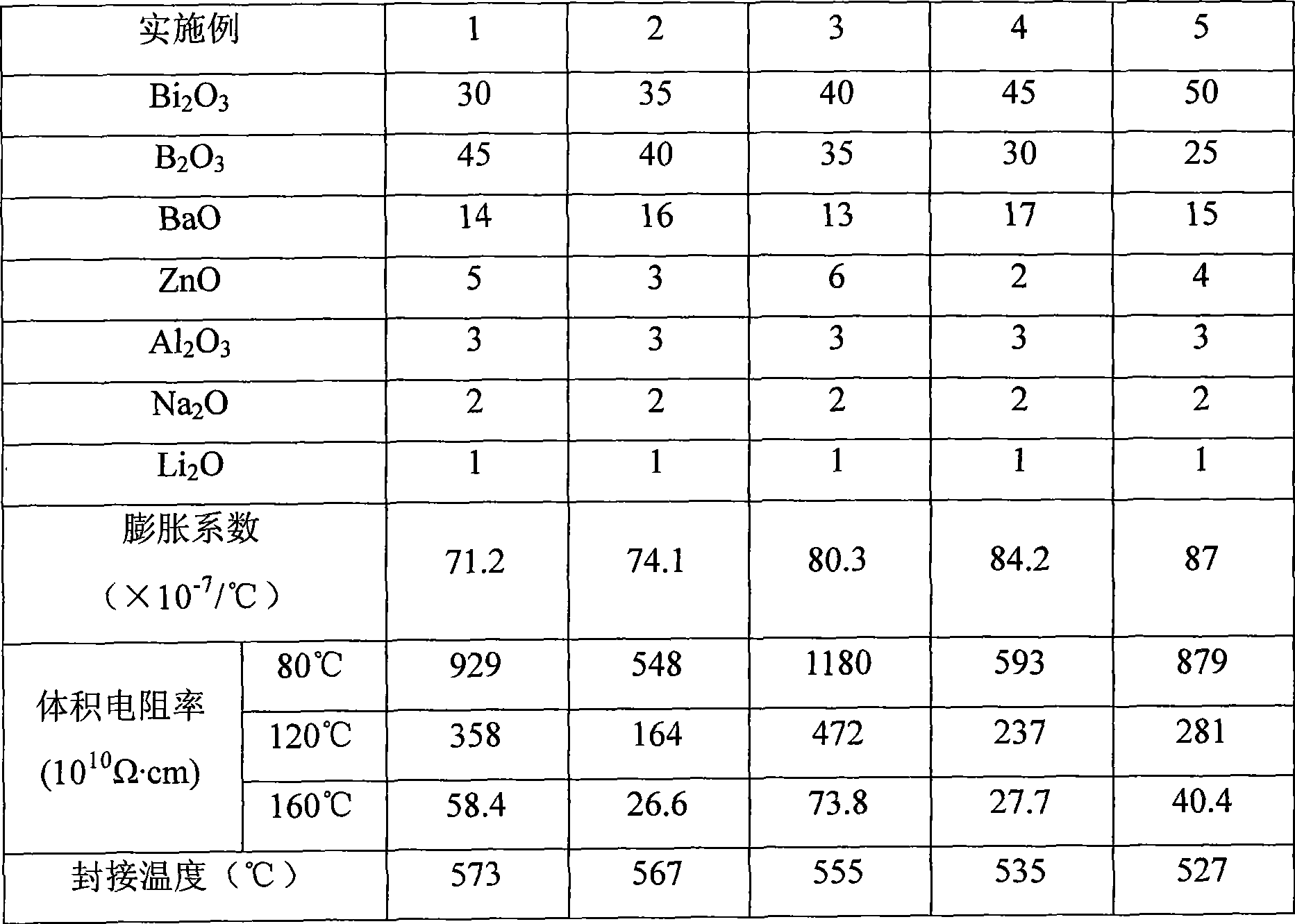

Leadless bismuth oxide sealing glass for sealing plate glass and preparation method thereof

The invention relates to lead-free bismuth oxide sealing glass for sealing flat glass and a preparation method thereof. The sealing glass comprises the following components by weight percentage: 30 to 60 percent of Bi2O3, 15 to 50 percent of B2O3, 5 to 25 percent of BaO, 0.1 to 10 percent of ZnO, 0.1 to 5 percent of Al2O3, 0.1 to 5 percent of Na2O, and 0.1 to 5 percent of Li2O. The preparation method comprises the following steps: (1) weighing raw materials; (2) mixing the raw materials; (3) melting the raw materials in an electric furnace at a temperature of between 1,100 and 1,300 DEG C; (4) pelleting the molten glass by a pelleting machine; (5) ball-milling the glass; and (6) sieving, detecting and packaging the ball-milled glass powder. The expansion coefficient of the lead-free bismuth oxide sealing glass is between 68*10<-7> and 90*10<-7> / DEG C, and the sealing temperature is between 510 and 600 DEG C; and the lead-free bismuth oxide sealing glass is suitable for sealing of multiple kinds of flat glass, has the advantages of low melting point, environmental protection, innocuousness and no pollution, can be added with pigments to generate diversified colors, and meets personalized requirement.

Owner:DONGHUA UNIV

Silicon wafer back metallization structure and manufacturing process thereof

InactiveCN110783292AImprove yieldImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesThermal dilatationManufacturing technology

The invention belongs to the semiconductor device and integrated circuit process technology field, and especially relates to a silicon device back metallization structure and process. In the structure, at least first metal layer hafnium is deposited on a surface of a back substrate silicon wafer, and then other layers are deposited. The process comprises process steps of front surface protection,back surface thinning, back surface polishing, cleaning, physical vapor deposition and the like. By using a characteristic that hafnium and silicon form ohmic contact, a layer of hafnium is prepared on the back surface of the silicon wafer so that a lower contact resistance and better adhesion are possessed, and simultaneously good electrical conductivity, good thermal conductivity and a proper thermal expansion coefficient are achieved. A yield in a manufacturing process of a silicon device and reliability in use are effectively improved.

Owner:NANJING INST OF PROD QUALITY INSPECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com