Environment-friendly high-refractive-index ultraviolet-permeable glass and preparation method thereof

A technology with high refractive index and outer glass, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of harsh preparation conditions of quartz glass, large difference in thermal expansion coefficient, and inability to seal the alloy. Achieve the effects of improving production and working conditions, good electrical insulation performance, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

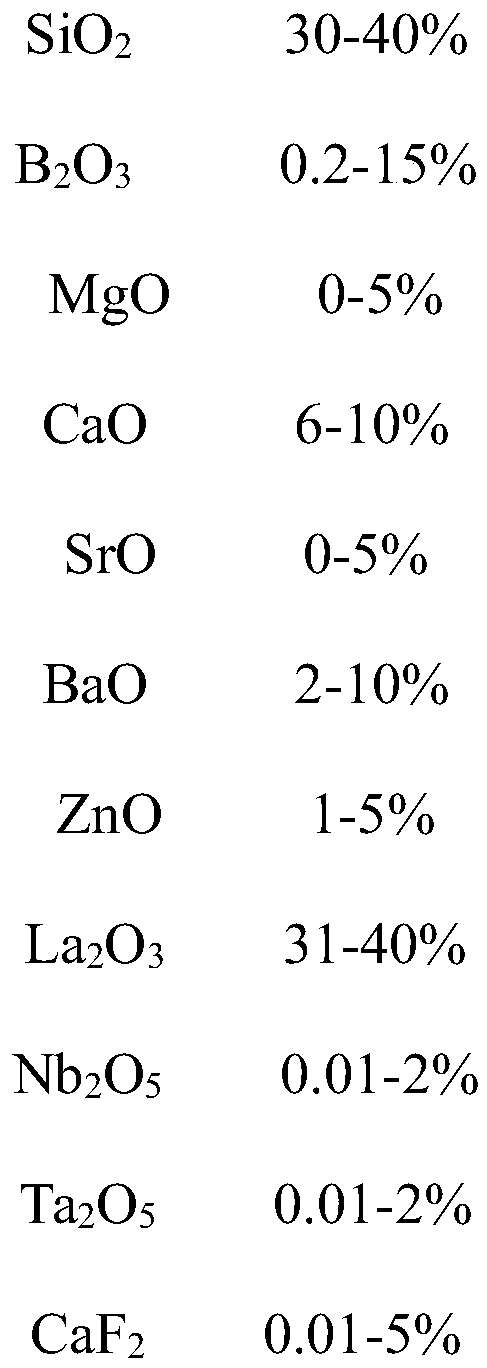

[0039] An environment-friendly high-refractive-index ultraviolet-transmitting glass, consisting of the following components in percentage by weight:

[0040]

[0041]

[0042] Raw material requirements, quartz sand (high purity, 150 μm sieve content is less than 1%, 45 μm sieve content is less than 30%, Fe 2 o 3 content less than 1PPm), boric acid or boric anhydride (400μm sieve is less than 10%, 63μm sieve is less than 10%), basic magnesium carbonate (analytical pure), calcium carbonate (analytical pure, average particle size 250μm), Strontium carbonate (analytical pure, purity ≥ 99.0%), barium carbonate (analytical pure, purity ≥ 99.0%), zinc oxide (analytical pure), lanthanum trioxide (5N), niobium pentoxide (5N), dinitrogen pentoxide Tantalum (5N), calcium fluoride (analytically pure), and the main raw materials in the glass raw materials are subjected to iron removal treatment to improve the purity of the glass raw materials, and the oxides of variable valence elem...

Embodiment 2

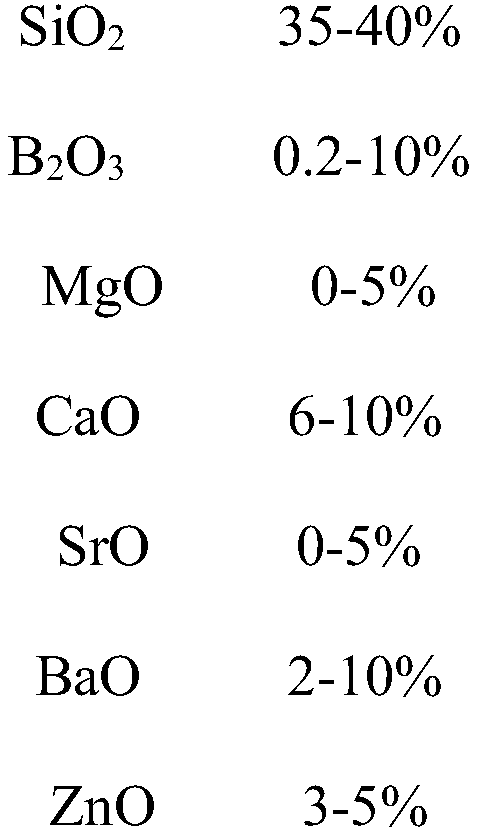

[0050] An environment-friendly high-refractive-index ultraviolet-transmitting glass, consisting of the following components in percentage by weight:

[0051]

[0052]

[0053] This example uses the same raw materials and raw material requirements as in Example 1, and adopts a melting process system of melting at 1550° C. for 4 hours and the same test conditions as in Example 1. The basic properties of the samples are shown in Table 1. (1) The refractive index is 1.78; (2) When the glass thickness is 2.0mm, the wavelength is 350nm, and the ultraviolet light transmittance reaches 87%; (3) The average linear expansion coefficient of 30-300°C is 68×10 -7 / °C; (4) Chemical stability level II. The UV-transparent glass prepared in this example is suitable for sealing with Kovar alloy, and can be used in the manufacture of UV lamps, optical windows, UV spectrometers, optical instruments and camera lenses that require high UV-visible light transmittance, and can also be used Use...

Embodiment 3

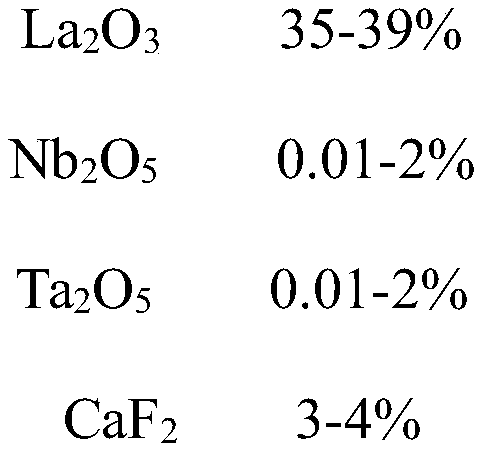

[0055] An environment-friendly high-refractive-index ultraviolet-transmitting glass consists of the following components in percentage by weight:

[0056]

[0057]

[0058] This example uses the same raw materials and raw material requirements as in Example 1, and adopts a melting process system of melting at 1350° C. for 8 hours and the same test conditions as in Example 1. The basic properties of the samples are shown in Table 1. (1) The refractive index is 1.73; (2) When the glass thickness is 2.0mm, the wavelength is 350nm, and the ultraviolet light transmittance reaches 83%; (3) The average linear expansion coefficient of 30-300°C is 78×10 -7 / °C; (4) Chemical stability level II. The UV-transparent glass prepared in this example is suitable for sealing with Kovar alloy, and can be used in the manufacture of UV lamps, optical windows, UV spectrometers, optical instruments and camera lenses that require high UV-visible light transmittance, and can also be used Used a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Average linear expansion coefficient | aaaaa | aaaaa |

| Average linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com