Poly aryl ether ketone composite material and preparing method thereof

A polyaryletherketone and composite material technology, which is used in medical science, tissue regeneration, prosthesis, etc., can solve the problems of complex force direction and enhanced bending strength, and achieve consistent mechanical strength, suitable grinding performance, and polishability. suitable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

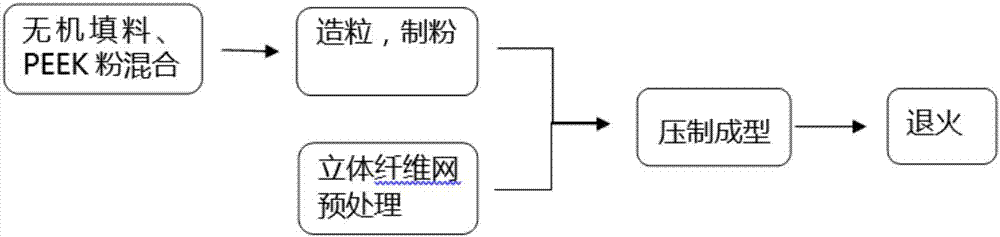

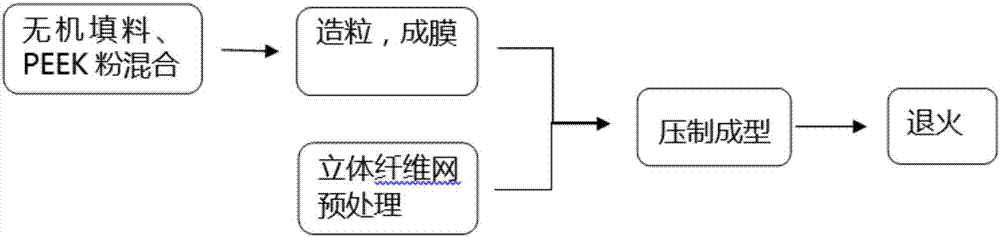

[0026] Next, the preparation method of the polyaryletherketone composite material according to the second aspect of the present invention is described, which includes the steps of: (1) mixing polyaryletherketone powder and inorganic filler in a weight ratio of 100:5 to 40 to obtain a mixture (2) granulate the compound extruder, grind it into powder, and obtain the powder to be formed with a particle size of 1 to 9 μm; (3) powder spreading: pave the three-dimensional fiber net in the mold and spread the The powder to be formed is vibrated at a frequency of 100-5000 Hz for 10 minutes, so that the powder to be formed is filled in the pores of the three-dimensional fiber net to obtain the material to be pressed; (4) pre-press the material to be pressed with a pressure of 5-300MPa Exhaust, heat up to 150-250°C, keep the pressure at 10-20MPa, keep the pressure for 5-20 minutes, then raise the temperature to 350-450°C for sintering, keep the pressure at 2-10MPa, keep the pressure for ...

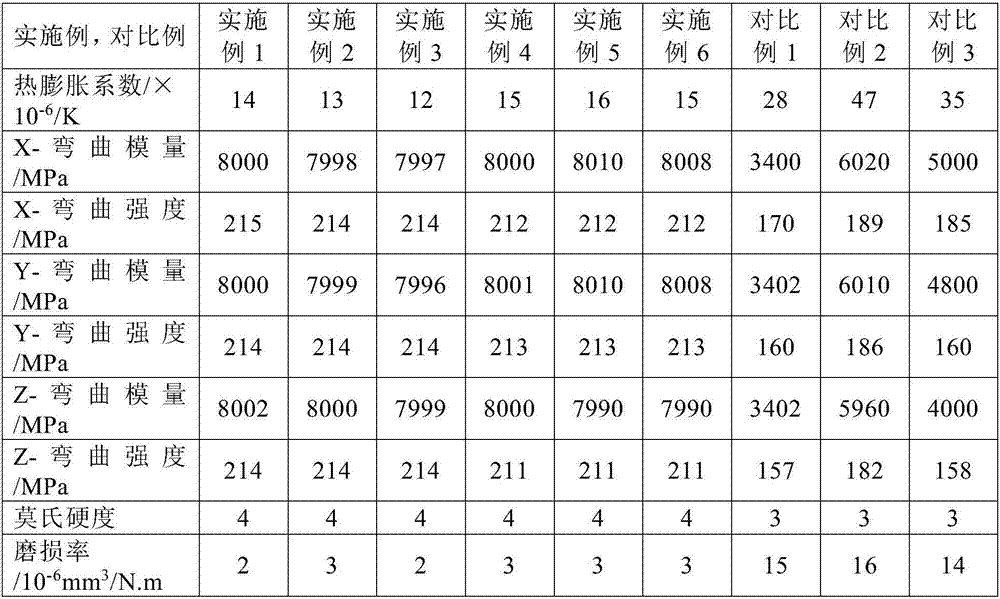

Embodiment 1

[0035] Mix zirconia powder with 10% silane coupling agent KH550 ethanol solution at a weight ratio of 2:1, mix at high speed for 10 minutes at 50°C, heat and dry in an oven at 120°C for 30 minutes, and obtain treated zirconia .

[0036] Soak the carbon fiber mesh in acetone for 10 hours, dry it in vacuum at 100°C for 10 minutes, then immerse it in a mixture of concentrated sulfuric acid and concentrated nitric acid with a weight ratio of 3:1 for 10 minutes, clean it with deionized water ultrasonic vibration for 10 minutes, and dry it in vacuum at 120°C for 30 minutes , to obtain a processed three-dimensional carbon fiber mesh.

[0037] Mix the treated polyether ether ketone powder and zirconia in a weight ratio of 100:20 to obtain a mixture, granulate with an extruder, and grind into powder to obtain a powder to be formed with a particle size of 1 μm; After the three-dimensional carbon fiber net, spread the powder to be formed, and vibrate at a frequency of 3000 Hz for 10 min...

Embodiment 2

[0039] Mix alumina powder with silane coupling agent KH550 ethanol solution with a content of 10%, the weight ratio is 2:1, mix at a high speed for 10 minutes at 50°C, heat and dry in an oven at 120°C for 30 minutes, and obtain treated alumina .

[0040] The three-dimensional glass fiber net is soaked in 10% KH550 ethanol solution for 1 hour, and vacuum-dried at 120° C. for 10 minutes to obtain a treated three-dimensional glass fiber net.

[0041] Mix polyether ketone ketone powder and treated alumina according to the weight ratio of 100:5 to obtain a mixture, extruder to granulate, grind into powder, and obtain a powder to be formed with a particle size of 9 μm; After the three-dimensional glass fiber mesh, spread the powder to be formed, and vibrate at a frequency of 100 Hz for 10 minutes to obtain a material to be pressed that is fully filled with the powder to be formed in the pores of the three-dimensional glass fiber mesh; After pressing the material, raise the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com