Axial pre-tightening mechanism for transformer

A technology of axial preloading and transformers, applied in the field of transformers, can solve problems such as endangering the safe operation of the power grid, and achieve the effect of uniform force and consistent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

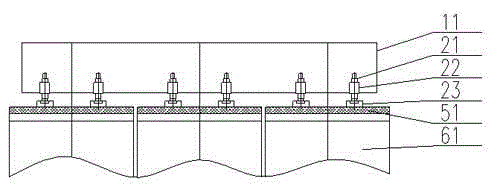

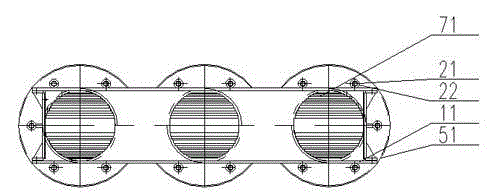

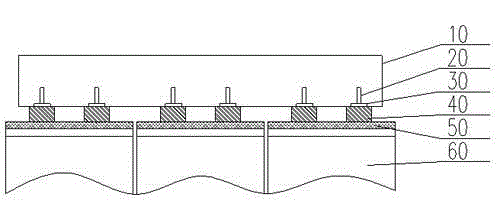

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0013] see figure 1 with figure 2 , the embodiment of the present invention includes:

[0014] An axial pretension mechanism for a transformer, including an upper clamp 10, a pressure plate 50 and several compression points (not marked), each of which includes a reinforcement plate 20, a support plate 30 and a spacer 40, the The reinforcing plate 20 and the supporting plate 30 are connected with the upper clamping piece 10 , and the spacer 40 is located between the supporting plate 30 and the pressing plate 50 .

[0015] Preferably, the cushion block 40 is a laminated wood block.

[0016] Preferably, the spacer 40 has different specifications...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com