Electronic slurry lead-free low melting point glass and preparing method

A low-melting glass, electronic paste technology, applied in glass manufacturing equipment, glass furnace equipment, glass molding, etc., can solve the problems of no cost advantage, can not adapt to lead-free, large thermal expansion coefficient, etc., to achieve excellent chemical Stability, easy adjustment of thermal expansion coefficient, effect of low softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

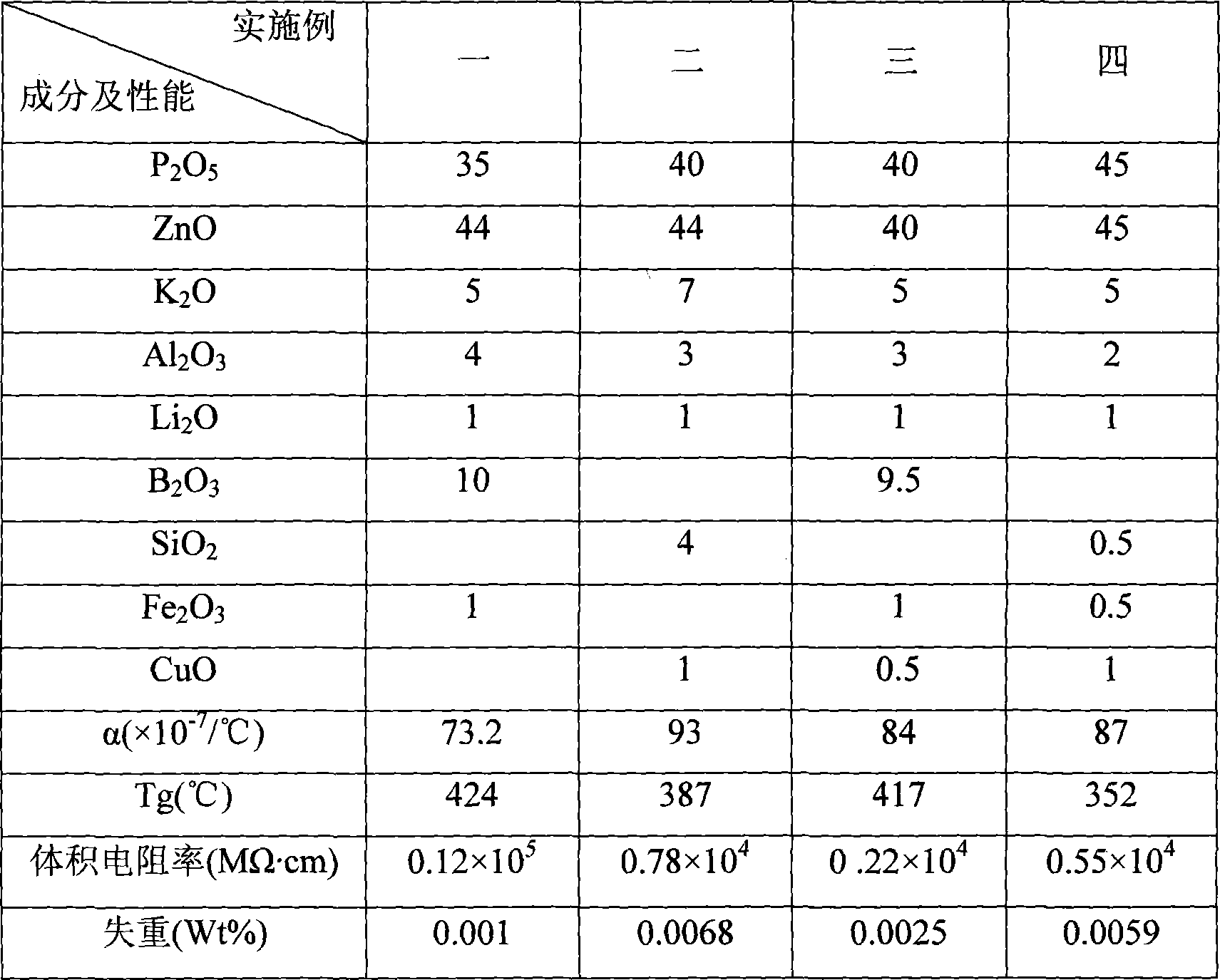

[0033] The present invention will be further described in detail through the composition of specific examples.

[0034] Table 1 (mol%)

[0035]

[0036] The preparation methods of the four lead-free sealing glasses listed in the above Table 1 are the same.

[0037] Weight loss was measured after constant temperature in deionized water at 90°C for 9 hours.

[0038] The coefficient of thermal expansion (α) is measured with a WRP-1 microcomputer thermal dilatometer. The glass sample is a cylindrical sample with a size of 5×25mm. It is raised from room temperature to 300°C with a heating rate of 5°C / min. The glass transition temperature (Tg) was measured with a CRY-IP medium temperature differential thermal analyzer, and the heating rate was 15°C / min. The volume resistivity test sample is a cylindrical glass sample with a diameter of 3 cm and a thickness of 0.5 cm. Wipe with anhydrous alcohol before the test, and then apply conductive graphite emulsion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com