Leadless bismuth oxide sealing glass for sealing plate glass and preparation method thereof

A technology for sealing glass and flat glass, which is applied in the field of lead-free sealing glass and its preparation, can solve the problem of low melting point of sealing glass, and achieve the effects of high cost performance, wide performance adjustment range, and broad market development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

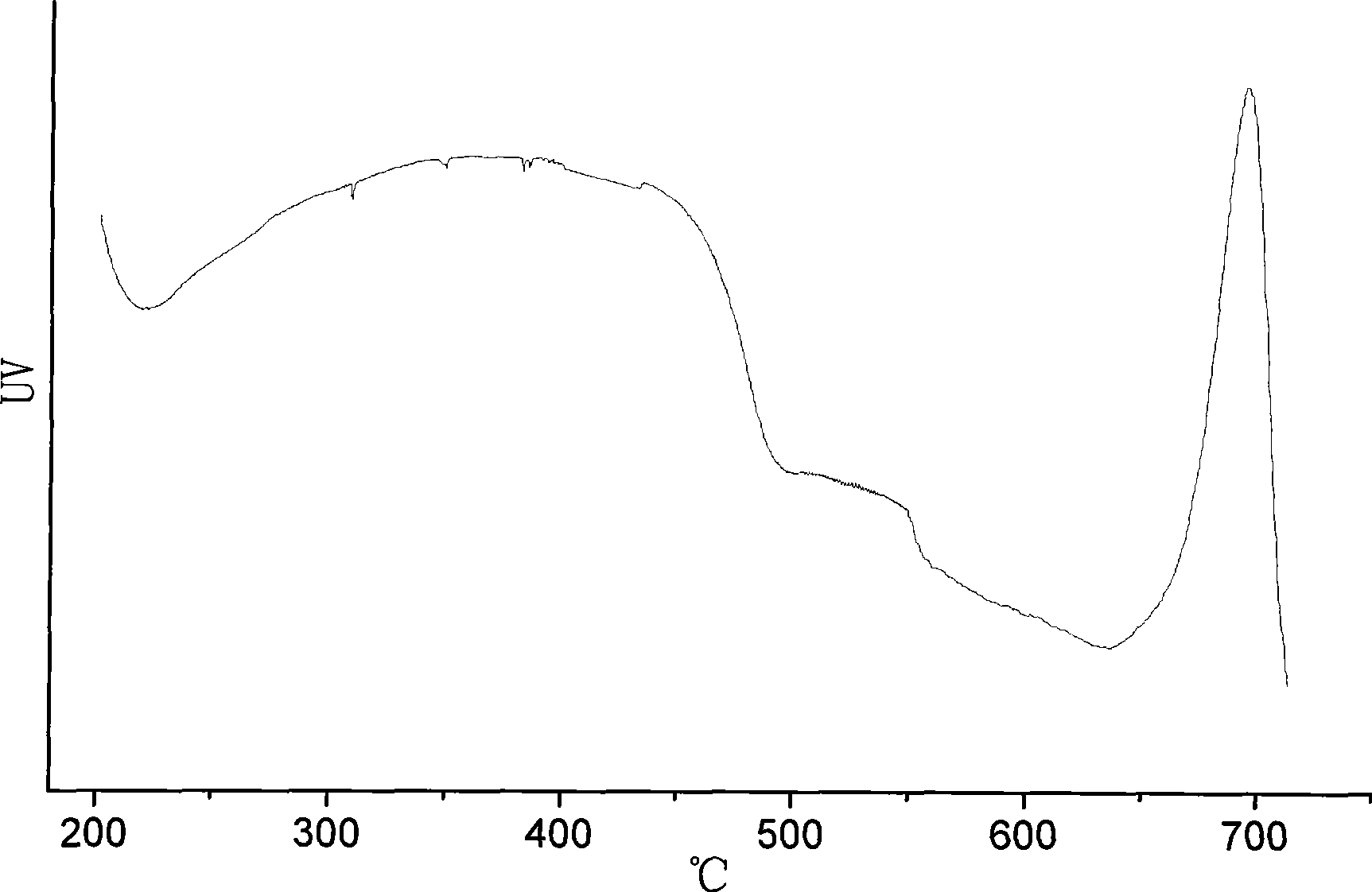

Image

Examples

Embodiment 1-5

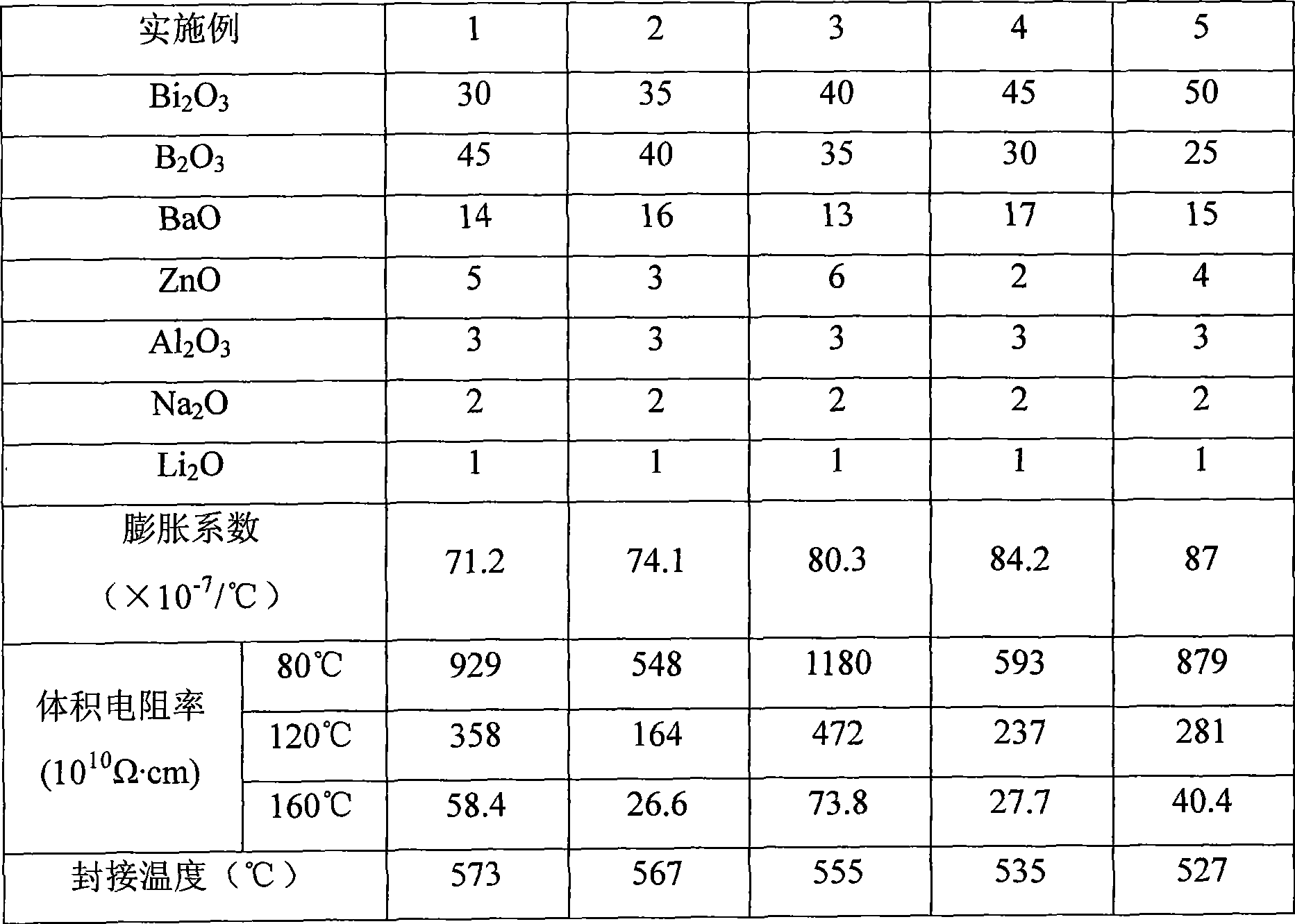

[0047] Below are five lead-free sealing glasses with different components and different expansion coefficients, and their components and performance parameters are listed in Table 1 below.

[0048] Table 1

[0049]

[0050] In the above Table 1, each lead-free sealing glass is prepared according to the following method:

[0051] (1) take each raw material according to the weight percentage of each component;

[0052] (2) Fully mix the raw materials taken;

[0053] (3) Put the mixed mixture into a crucible, then put it into an electric furnace with a furnace temperature of 1200 ° C, and keep it warm for 2 hours;

[0054] (4) Pour the melted glass liquid into a tablet press and press it into thin slices or pour it into cold water or cast it into a certain shape;

[0055] (5) Put the flake or granular glass and the pigment into the ball mill for ball milling;

[0056] (6) Sieve, test and pack the ball-milled glass powder.

[0057] Bi here 2 o 3 When 2 o 3 When >60%, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com