Industrialization scale pyrolysis treatment system and method for oily sludge

A sludge system and pyrolysis technology, applied in the direction of sludge treatment, pyrolysis treatment of sludge, chemical instruments and methods, etc., can solve the problems of high dust concentration in flue gas, high technical requirements, and shedding of sludge residues, etc., to achieve High emission reduction capacity, improved safety factor, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings, and of course the following embodiments should not be construed as limiting the present invention.

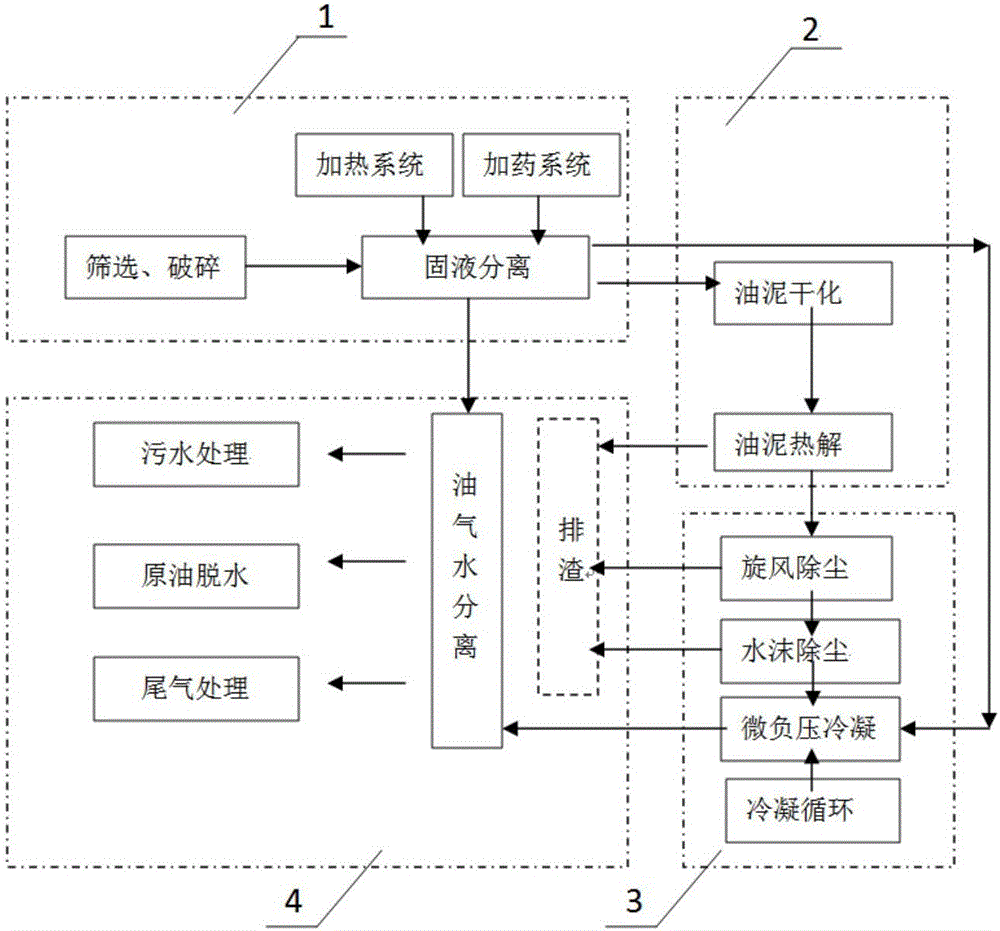

[0037] Such as figure 1 As shown, the present invention is a continuous pyrolysis treatment system and process for oily sludge, including 1-feed pre-sorting unit, 2-drying pyrolysis unit, 3-dust removal and condensation unit and 4-effluent treatment unit;

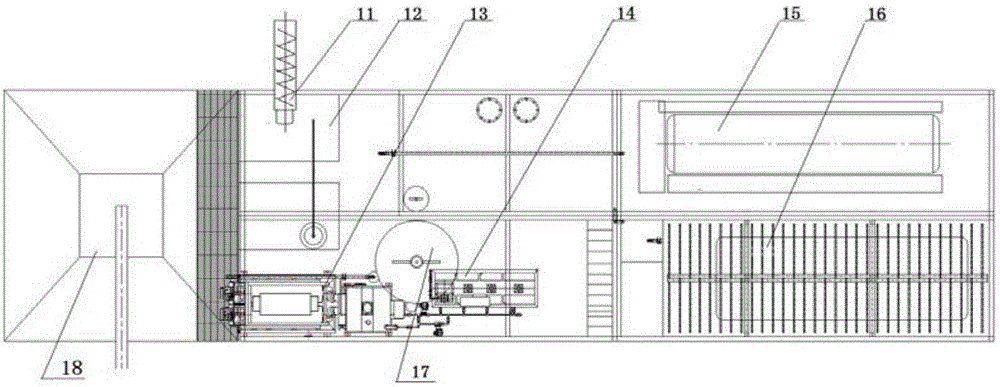

[0038] Such as figure 2As shown, the feed pre-sorting unit 1 includes a feeding screw conveyor 11 , a vibrator 12 , a centrifuge 13 , a mud pump 14 , a heating boiler 15 , an oil-water storage tank 16 , a dosing machine 17 and a sludge collection tank 18 . Firstly, the primary selection is carried out, and the oily sludge is sent to the oil sludge mixing tank by the feeding screw conveyor for dilution and heating, and then pumped into the drum screening device for rough screening, and the solid sand larger than 2mm i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com