Patents

Literature

797 results about "Petroleum industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The petroleum industry, also known as the oil industry or the oil patch, includes the global processes of exploration, extraction, refining, transporting (often by oil tankers and pipelines), and marketing of petroleum products. The largest volume products of the industry are fuel oil and gasoline (petrol). Petroleum (oil) is also the raw material for many chemical products, including pharmaceuticals, solvents, fertilizers, pesticides, synthetic fragrances, and plastics. The extreme monetary value of oil and its products has led to it being known as "black gold". The industry is usually divided into three major components: upstream, midstream, and downstream.

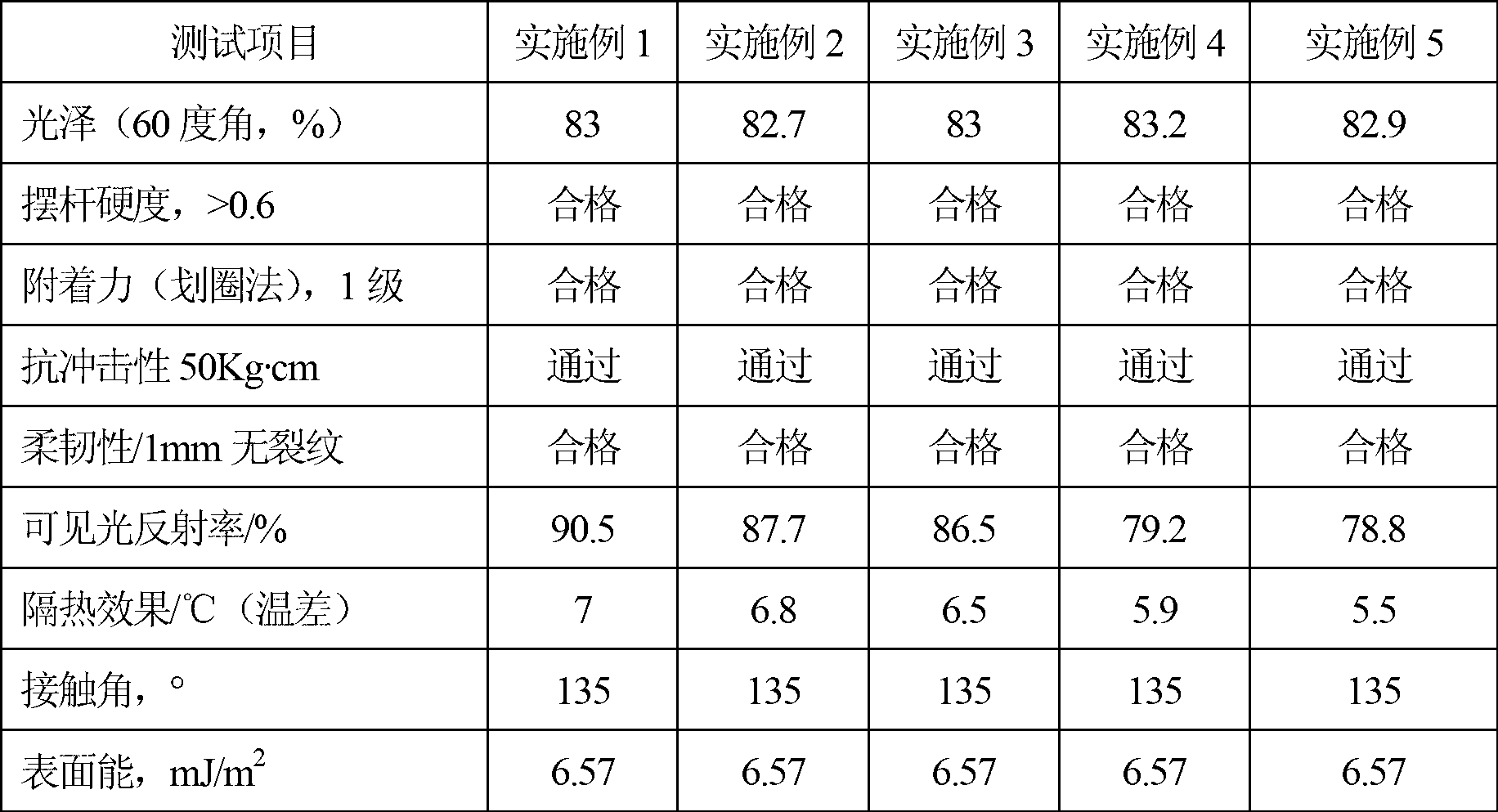

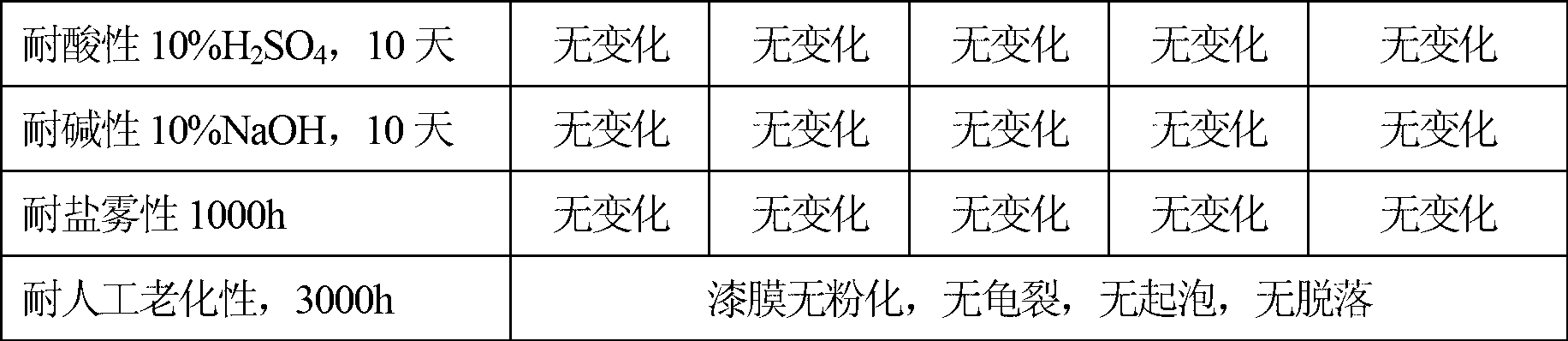

Fluorocarbon nanometer solar heat-insulation reflective paint, preparation method and using method thereof

ActiveCN103013241AImprove reflectivityImprove anti-corrosion performanceReflecting/signal paintsCross-linkInfrared

The invention relates to a fluorocarbon nanometer solar heat-insulation reflective paint, a preparation method thereof and a using method thereof. The paint can be used for roofs and glass curtain walls of the building industry, offshore drilling platforms, oil tanks and petroleum pipelines of the petroleum industry, the surfaces of cars and trains of the transportation industry, hulls and decks of the ship-building industry, and the tanks and warships of the weapon and aerospace industry. The fluorocarbon nanometer solar heat-insulation reflective paint comprises a component A and a component B, wherein the component A comprises the following materials in percentage by weight: 40%-70% of fluorocarbon resin, 1%-10% of nanometer TiO2 concentrated slurry, 10%-30% of infrared-ray reflective pigment, 3%-10% of hollow micro beads, 1%-5% of auxiliaries and 10%-20% of organic solvent; and the component B is cross-linking agent. The preparation method for the fluorocarbon nanometer solar heat-insulation reflective paint comprises the following steps: 1) preparing, dispersing and grinding the materials of the component A in proportion until the fineness is lower than 30 microns; and 2) mixing and curing the component A and the component B to prepare the fluorocarbon nanometer solar heat-insulation reflective paint. The fluorocarbon nanometer solar heat-insulation reflective paint provided by the invention is suitable for normal-temperature drying or low-temperature baking and drying; moreover, a coating film formed by the paint has the characteristics such as high reflectivity, a good heat-insulation effect, high corrosion prevention, high weather resistance, high self-cleanness, low friction and the like.

Owner:大连佳秀百隆新材料股份有限公司

Fluid loss control agents and compositions for cementing oil wells comprising said fluid loss control agent

The present invention concerns a fluid loss control agent for a petroleum industry (or analogous) cement slurry, comprising a surfactant and a micro-gel obtained by chemical cross-linking of a polyvinyl alcohol. The micro-gel and the surfactant are advantageously compatible with a wide range of petroleum industry cement additives and can also produce compositions which are gas tight.

Owner:SCHLUMBERGER TECH CORP

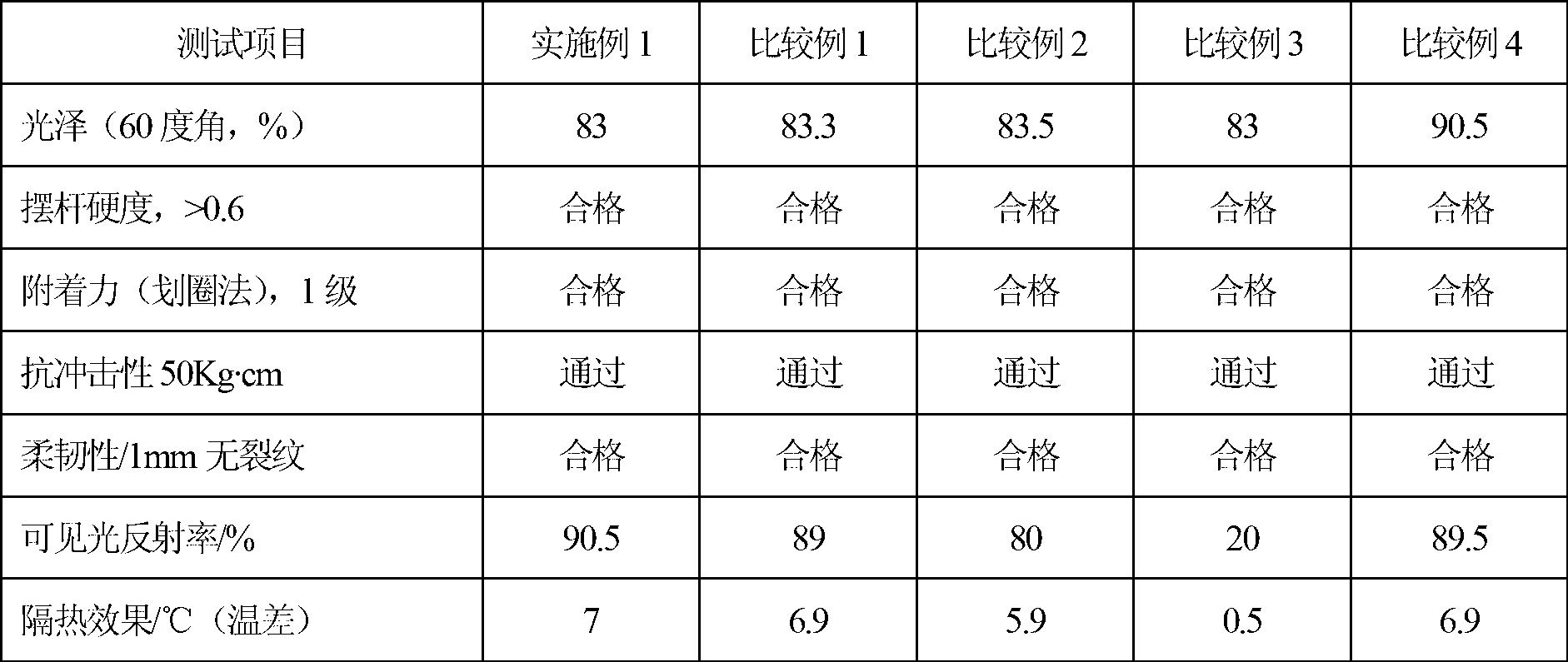

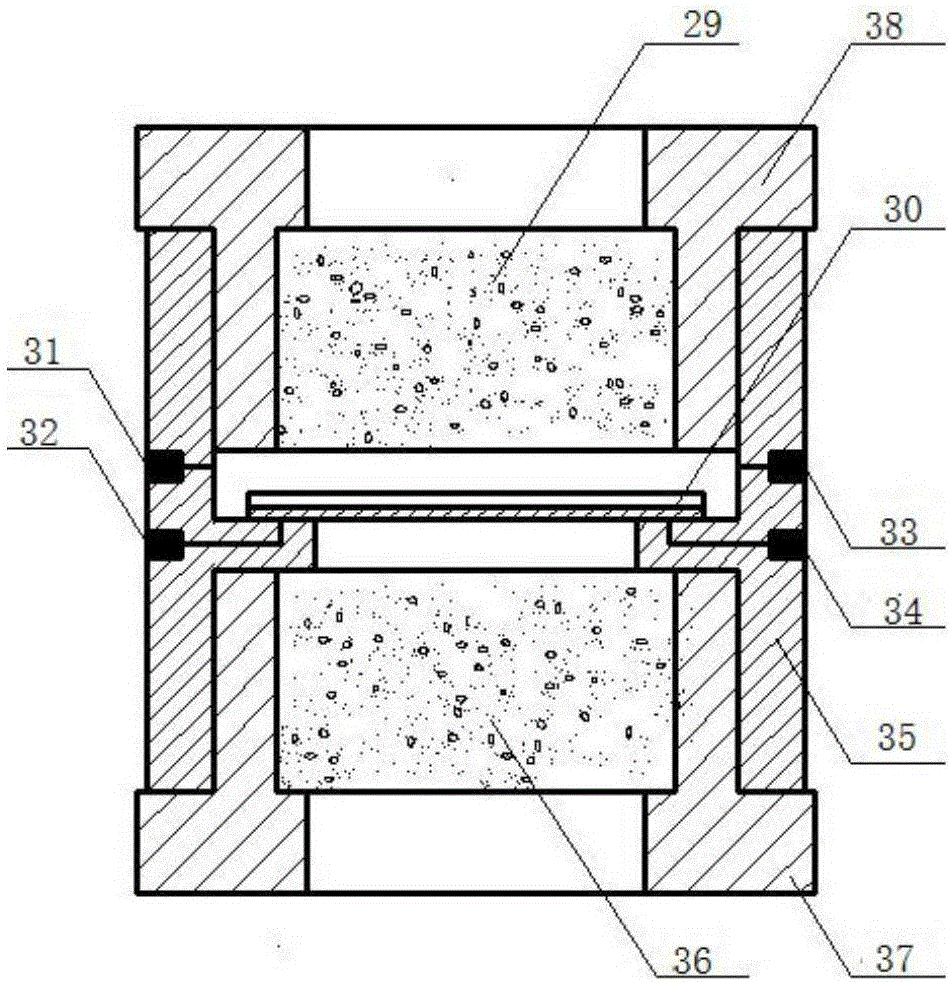

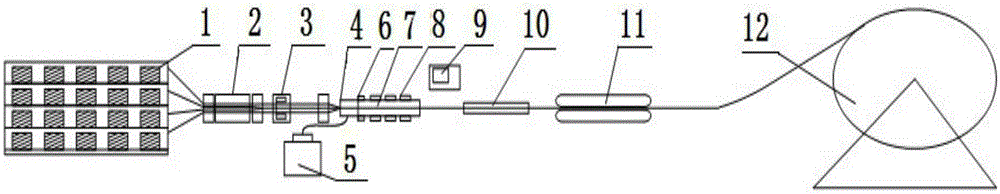

Visualization microscopic experimental device and method for displacing super heavy oil by using high-temperature high-pressure carbon dioxide

ActiveCN106437637AConvenient and effective temperatureConvenient and effective confining pressure sizeOther gas emission reduction technologiesFluid removalMicroscopic scaleHigh pressure

The invention provides a visualization microscopic experimental device and a visualization microscopic experimental method for displacing super heavy oil by using high-temperature high-pressure carbon dioxide, and belongs to the technical field of oil production. The device comprises a model clamper clamping a microscopic visual model, a replacement system, a back pressure system, a confining pressure system, a pressure monitoring system, a temperature control system and an image acquisition system. The device can control temperature and pressure simply and conveniently, has a small use space, is superior in safety performance, is simple and convenient to operate, can accurately simulate an oil reservoir actual condition, can clearly observe oil-gas action changes during carbon dioxide displacement in real time under a visual condition, and has very important significances for researching a precipitation law of asphaltene, the influence of the precipitation law on the recovery ratio, and the widespread use and promotion of a carbon dioxide displacement experiment in the petroleum industry.

Owner:UNIV OF SCI & TECH BEIJING

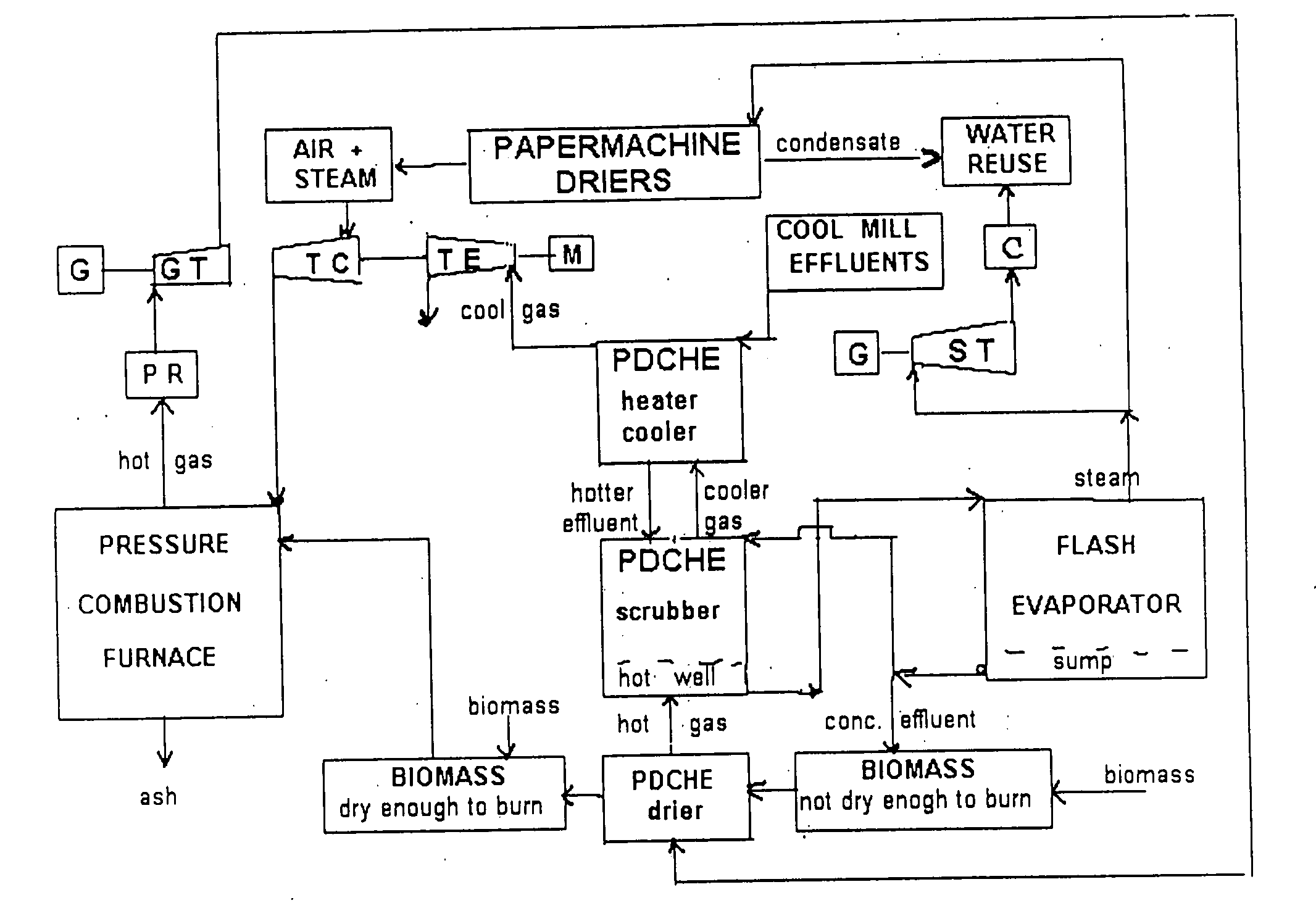

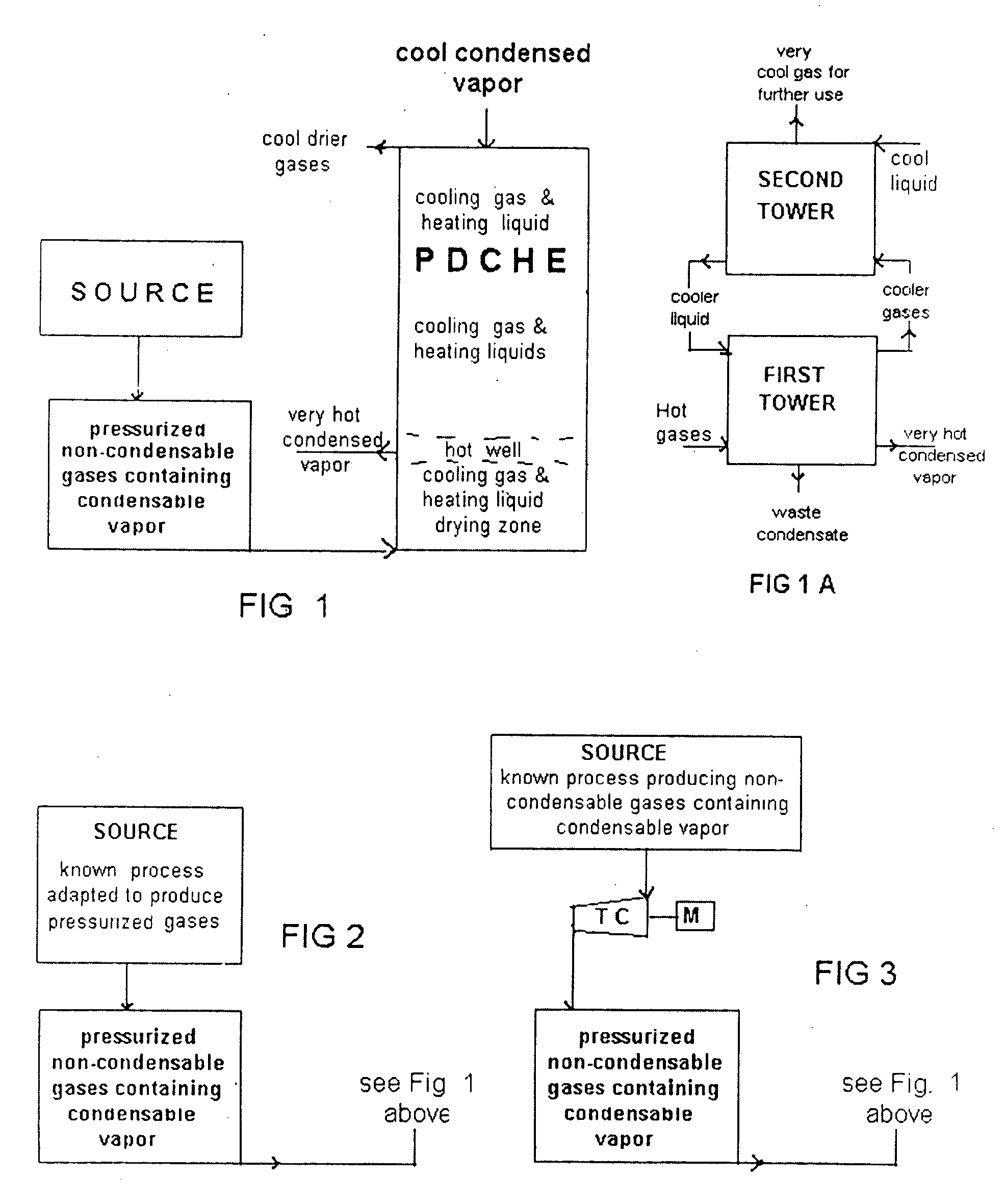

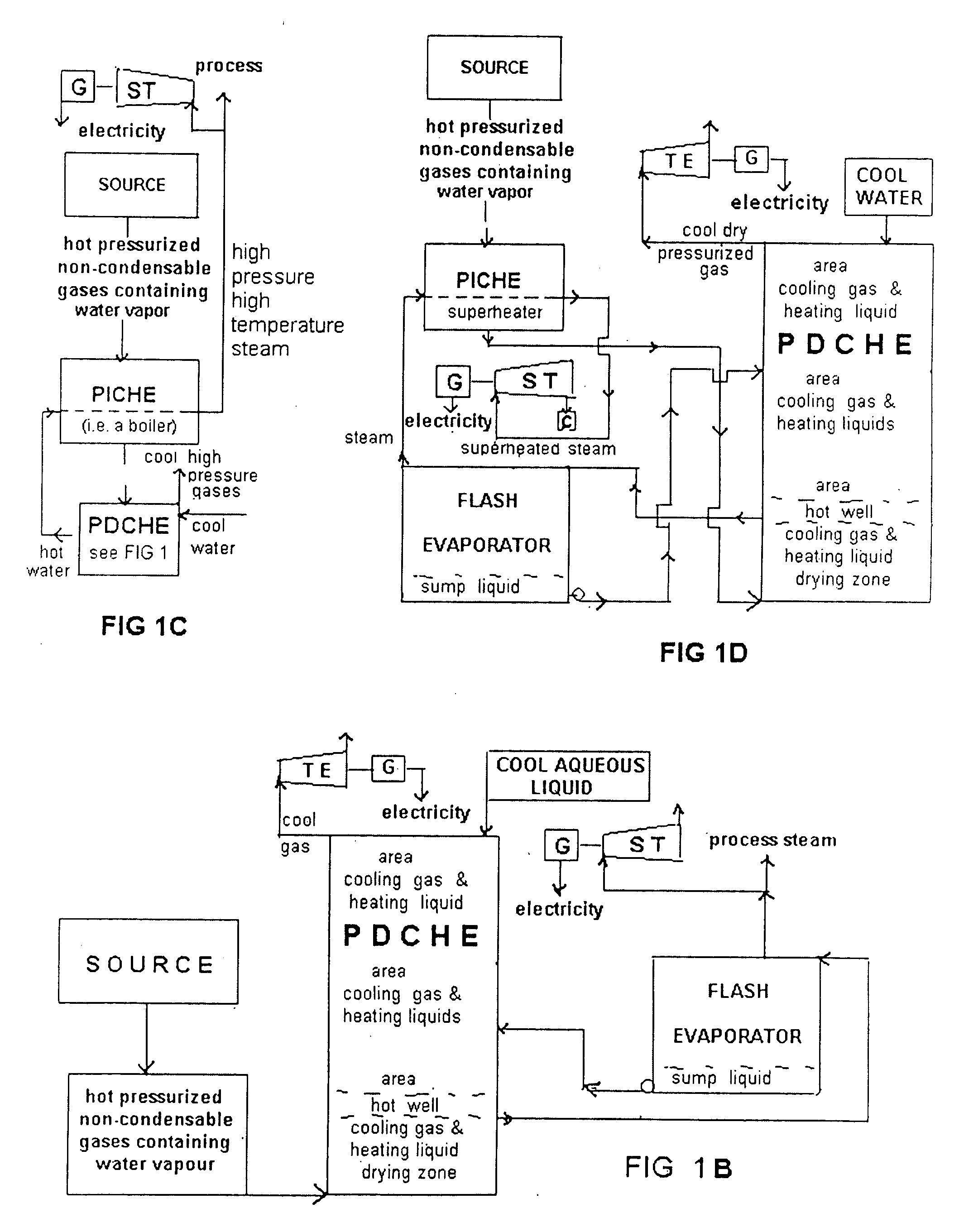

Energy reclaiming process

Owner:HELLEUR DONALD

Permanently anti-static polyolefin master batch and preparation method thereof

The invention belongs to the technical field of high polymer materials, and particularly relates to a permanently anti-static polyolefin master batch and a preparation method thereof. The polyolefin master batch is prepared from the following components in parts by weight: 40-80 parts of polyolefin, 10-50 parts of conductive polymer or a composite material thereof, 5-30 parts of reinforcing conductive powder or fiber, 1-10 parts of a compatilizer, 1-10 parts of a dispersing agent, and 0.5-1.5 parts of other additives; the preparation method comprises the following steps: mixing the materials uniformly, then adding the mixture into a co-rotating twin screw extruder with a length to diameter ratio of 36-48, and extruding and pelletizing to obtain the product. The polyolefin master batch is good in dispersibility and compatibility; the good appearance, mechanical properties and stability of polyolefin can be maintained while the excellent anti-static effect can be achieved; the polyolefin master batch can be widely applied to membrane blowing, extrusion, blow molding and injecting molding products, and promotes the high-speed development of the electronic industry, the petroleum industry, the weapon industry and the military field in China.

Owner:DONGGUAN DICOLORS PLASTIC & METAL

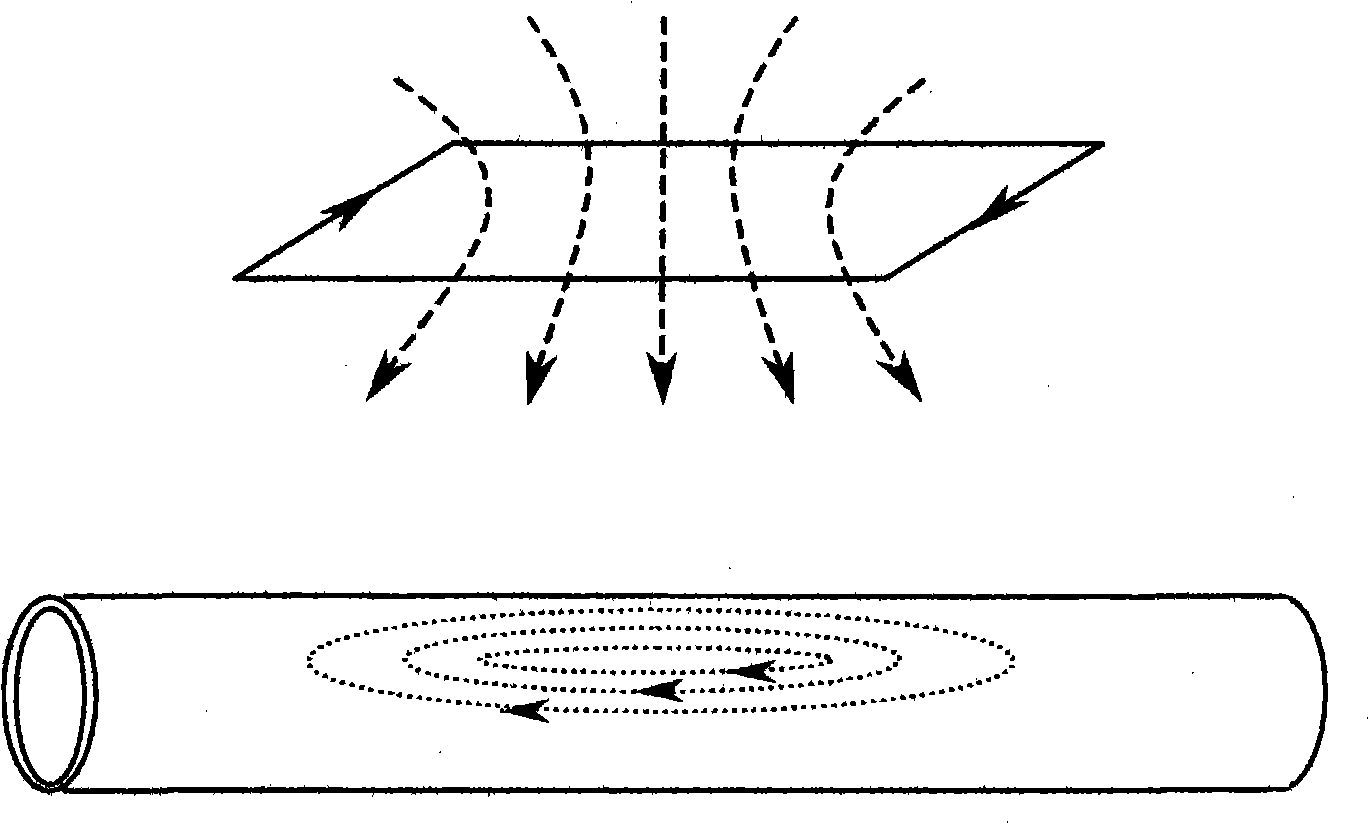

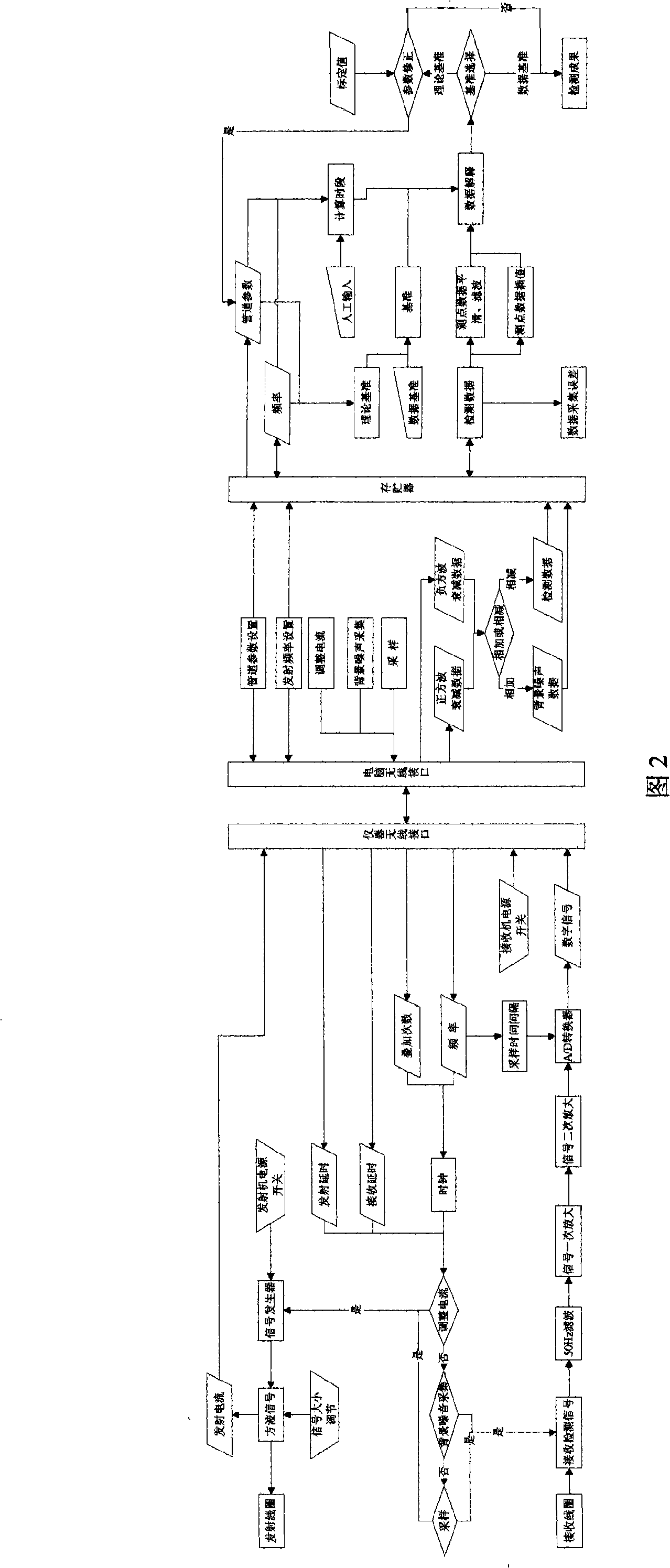

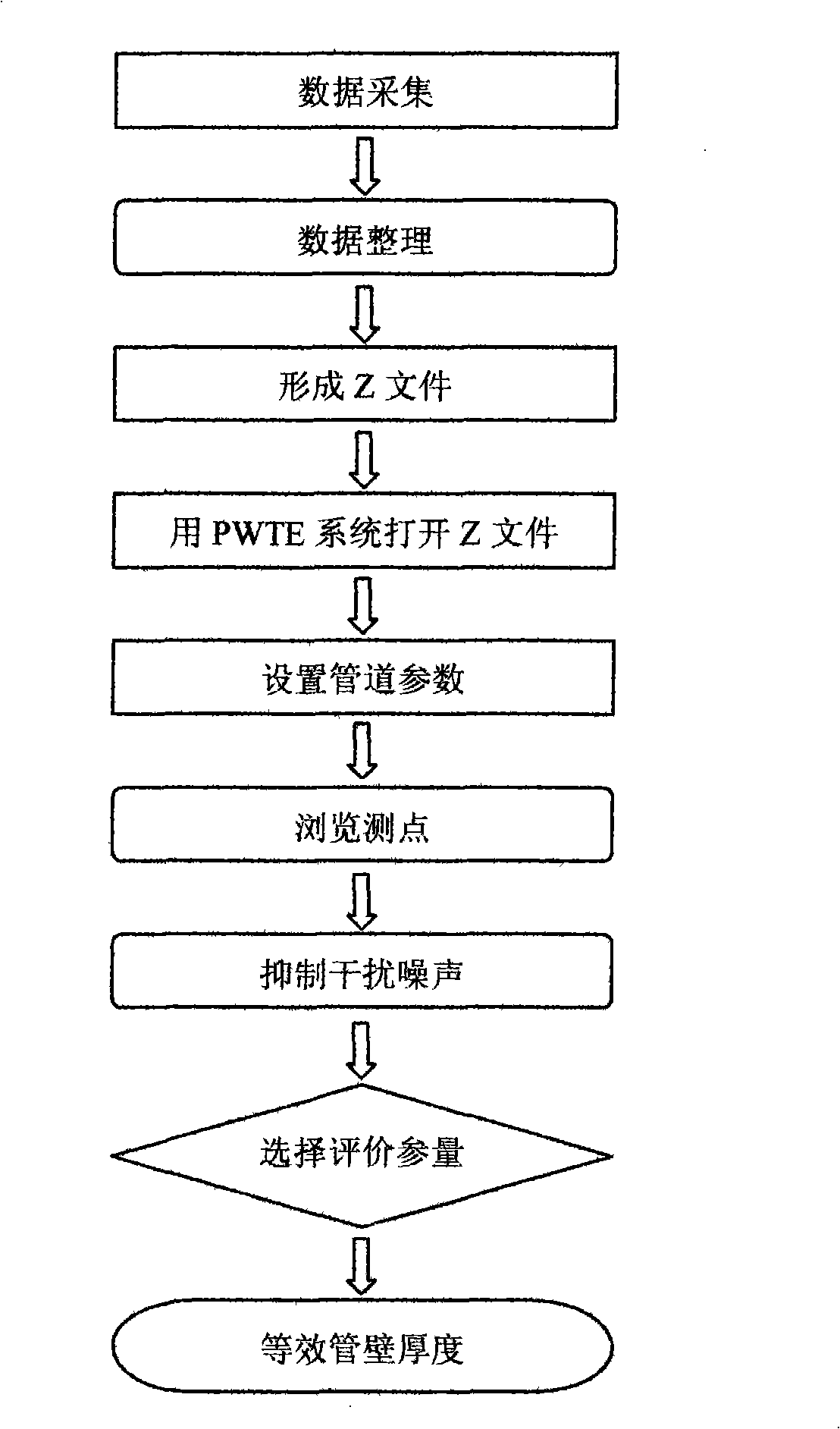

TEM detecting method for pipe wall thickness and intelligent detector for GBH pipe corrosion

ActiveCN101358827APipeline systemsElectrical/magnetic thickness measurementsPetrochemicalElectric power

The present invention relates to a corrosion examination and non-destructive examination method for a metal pipeline. The instant electromagnetic technology (TEM) is used to examine the average thickness of the wall of the pipeline under the condition that no dig is performed, no corrosion-prevention layer is damaged and the normal running of the pipeline is not influenced. The method is characterized in that when other conditions are the same, the metal pipeline with different wall thicknesses can have obvious time divisibility on a normalized pulse instant-changing responding curved line. The wall thickness of the measured section of the pipe can be obtained by the indication of the known wall thickness and the method of inversing modeling. The present invention also relates to a corrosion examination and non-destructive examination systematic device for the metal pipeline. A virtual instrument is designed and produced with the TEM examination method for the wall thickness of the metal pipeline; a data collector adopts the instant-changing electromagnetic instrument; the control of the instruments, the data processing and the results expression are realized by the software of the computer, so that the expansion property of the instrument is strengthened, and the renewing speed is accelerated, and the complicate data processing analysis can be performed instantly. The device can be widely used for examining the corrosion of the anti-corrosion heat-preservation pipeline in the industries such as the petroleum industry, the petrochemical industry, the fuel gas industry, the electric power industry, the water supply industry, and the like.

Owner:BAODING CHICHENGQIANLI SCI & TECH

Determination method of oil sources of high-maturity condensate oil

The invention provides a determination method of oil sources of high-maturity condensate oil. The method comprises the following steps: (1) an oil sample undergoes analysis and detection so as to determine whether the oil sample contains a thioadamantane compound; (2) the oil sample containing the thioadamantane compound undergoes enrichment of the thioadamantane compound; and (3) the enriched thioadamantane compound undergoes sulfur isotope testing, and the test result is compared with known sulfur isotope data of source sequence sulfate so as to determine the oil source of the oil sample. By the determination method of oil sources of high-maturity condensate oil, oil sources of condensate oil at high maturity stage are determined by determining the unique factor in condensate oil at high maturity stage. Thus, the blank that oil sources of high-maturity condensate oil cannot be determined in the present petroleum industry is filled up. By determining oil sources of high-maturity condensate oil, major hydrocarbon source rocks can be truly and objectively found and key exploration target series of strata and resources potential are determined.

Owner:PETROCHINA CO LTD

Continuous oil pipe sectional sand-blasting perforation casing fracturing pipe column and casing fracturing method

ActiveCN102691493ARemarkable effectSignificant progressDrilling rodsFluid removalSand blastingHorizontal wells

The invention discloses a continuous oil pipe sectional sand-blasting perforation casing fracturing pipe column and a casing fracturing method, which are suitable for application in vertical wells and horizontal wells in the petroleum industry, in particular for sectional fracturing of unconventional oil-gas reservoir horizontal wells such as tight sandstone wells. The fracturing pipe column comprises a safety joint, a centralizer, a hydraulic jet tool and a reverse circulation valve, which are connected to a continuous oil pipe in sequence, wherein a mechanical continuous oil pipe fracturing packer is connected below the reverse circulation valve. The sectional casing fracturing method is used for placing the fracturing pipe column provided with the mechanical continuous oil pipe fracturing packer into a casing in a well through the continuous oil pipe; and by the method, a fracturing well section closest to the bottom of the well is fractured at first, and then the fracturing well section is packed by using the mechanical continuous oil pipe fracturing packer. By the continuous oil pipe sectional sand-blasting perforation casing fracturing pipe column and the casing fracturing method, a sand stopper is not needed as an isolation section, so that the sand stopper is not needed to be subjected to back flushing, the production cost is reduced, and multi-layer section fracturing operation for a short horizontal well section or straight well section can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

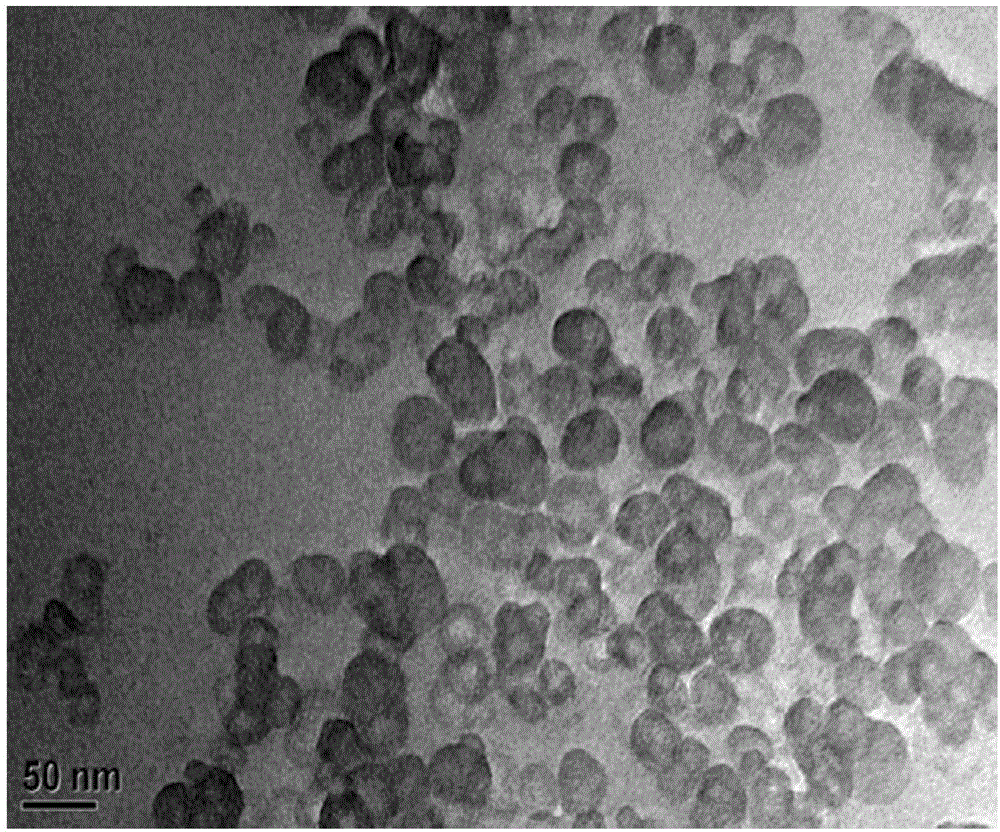

Nano-material associated clean fracturing fluid system and application thereof in oil and gas fields

ActiveCN103387827AImprove temperature resistanceTightly boundDrilling compositionAlcoholFracturing fluid

The invention provides a nano-material associated clean fracturing fluid system; the system comprises a nano-material, a clean fracturing fluid and a dispersing auxiliary liquid trihydric alcohol. The nano-material associated clean fracturing fluid system can be applied to oil and gas fields with the temperature as high as 130 DEG C above, and can still maintain a certain viscosity at the temperature. The obviously improved temperature tolerance of the prepared nano-material associated clean fracturing fluid system is beneficial to the application of the system in high temperature deep-well oil fields. Through use of the system, nanotechnology and petroleum industry are closely combined, and the market prospect is broad.

Owner:CHINA PETROLEUM & CHEM CORP +1

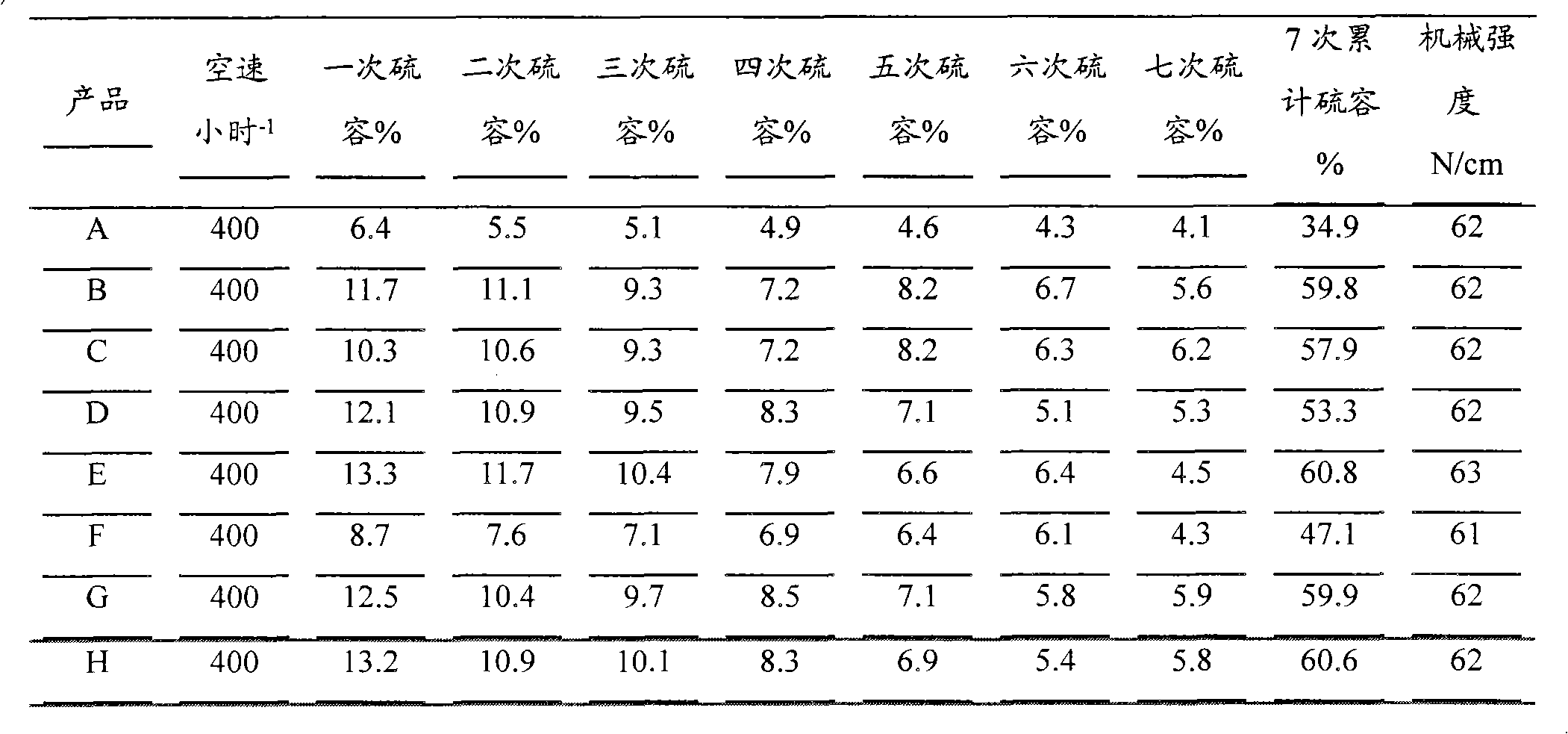

Method for preparing supported iron oxide series desulfurizing agent

ActiveCN102049179AImprove desulfurization efficiencyGuaranteed desulfurization activityDispersed particle separationSulfur preparation/purificationChemical industrySulfur

The invention discloses a method for preparing a supported iron oxide series desulfurizing agent. The preparation method comprises the following steps: a) preparing soluble iron salt solution and alkali solution; b) putting a porous material serving as a carrier into the soluble iron salt solution prepared in the step a), and soaking under the condition that the pressure is less than 3MPa and not equal to normal pressure; c) drying the carrier soaked in the step b) at the temperature of between 30 and 85 DEG C for 1 to 24 hours; d) putting the dried carrier obtained in the step c) into the alkali solution, and soaking under the condition that the pressure is less than 3MPa and not equal to normal pressure; e) drying or draining the carrier obtained in the step c), and eluting the carrier by using water of 20 to 80 DEG C till the eluted water has no negative ions; and f) drying the carrier obtained in the step e) for 1 to 24 hours at the temperature of between 30 and 85 DEG C to obtain the desulfurizing agent. The desulfurizing agent prepared by adopting the method has the advantages of high accumulative sulfur capacity, high mechanical strength, abrasion resistance and the like, is easy to regenerate, and is widely applied in the fine desulfuration process of petroleum industry, chemical industry and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Drilling fluid additive composition application thereof and water-based drilling fluid suitable for high-bearing-pressure plugging while drilling and application thereof

ActiveCN106634878AImprove pressure bearing capacityEnhance smoothness and densityDrilling compositionWell drillingDimer acid

The invention relates to the field of well drilling in petroleum industry, in particular to a drilling fluid additive composition application thereof and a water-based drilling fluid suitable for high-bearing-pressure plugging while drilling and application thereof. The composition contains a plugging agent, a nano blocking agent, a shear strength improving agent, a bionic wall fixing agent and a bionic shale inhibitor, wherein the plugging agent is a weak crosslinking copolymer, the content of a crosslinking structure in the weak crosslinking copolymer is 0.1-1% by weight, the nano blocking agent is modified silicon dioxide nano-particles, the shear strength improving agent is a dimer acid-organic amine copolymer, and the bionic wall fixing agent is carboxymethyl chitosan grafted with groups deviated from dopamine on main chains. The composition can make a water-based drilling fluid added with the composition as an additive produce an excellent plugging effect in the process of plugging while drilling through the matching effect of the plugging agent, the nano blocking agent, the shear strength improving agent, the bionic wall fixing agent and the bionic shale inhibitor.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

High-efficiency high pressure gas leak detection method

ActiveCN101598624AEasy to operateDetection of fluid at leakage pointGeneration processConfined space

The invention provides a high-efficiency high pressure gas leak detection method, comprising the generation process of high pressure tracer gas and the detection process of the leak tightness of a joint on a device or a pipeline by the high pressure tracer gas; in the generation process, a container is filled with quantitative tracer gas, then liquid with pressure is led into the container, and the liquid is used for compressing the tracer gas to facilitate the pressure of the tracer gas to be raised to a set pressure value so as to turn into constant pressure tracer gas; in the detection process, inner confined space and outer confined space are established on the joint to be detected on the device or the pipeline to be detected, the inner confined space is at least provided with an inlet for injecting the constant pressure tracer gas, the outer confined space is provided with a port which is connected with a detector, and whether the tracer gas leaking from the inner confined space exists in the outer confined space is detected by the detector. The invention finds a very reliable method for petroleum industry field high pressure gas detection and achieves the aim of field leak detection by combining various processes.

Owner:通奥检测集团股份有限公司

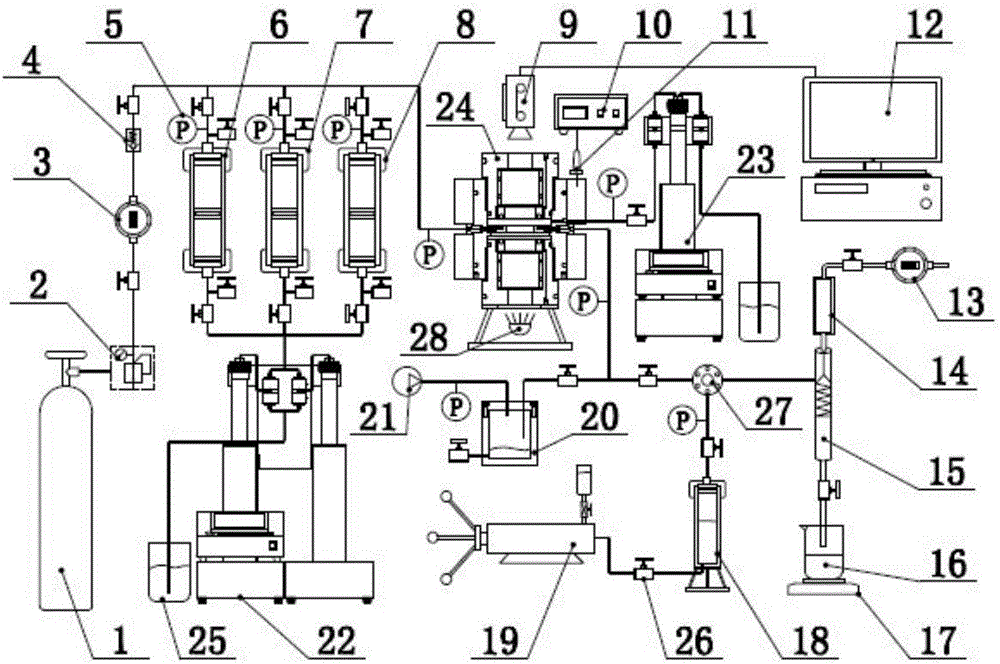

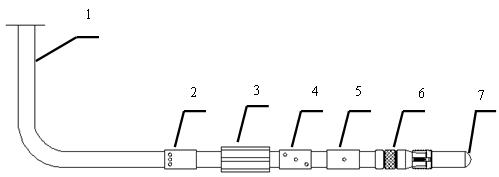

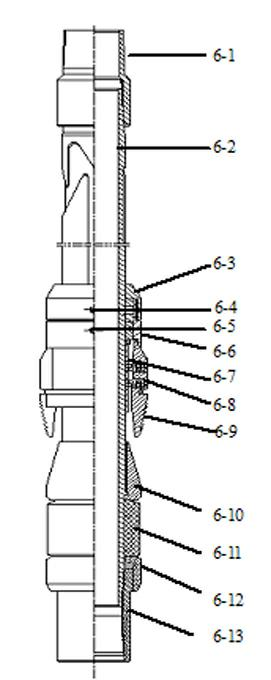

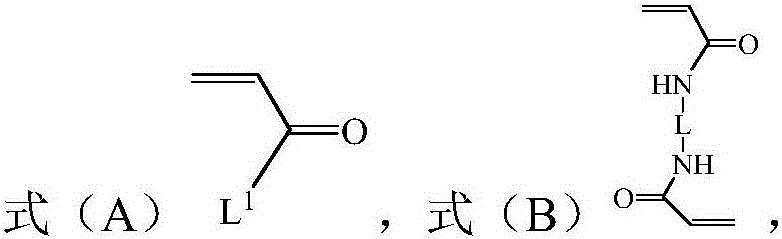

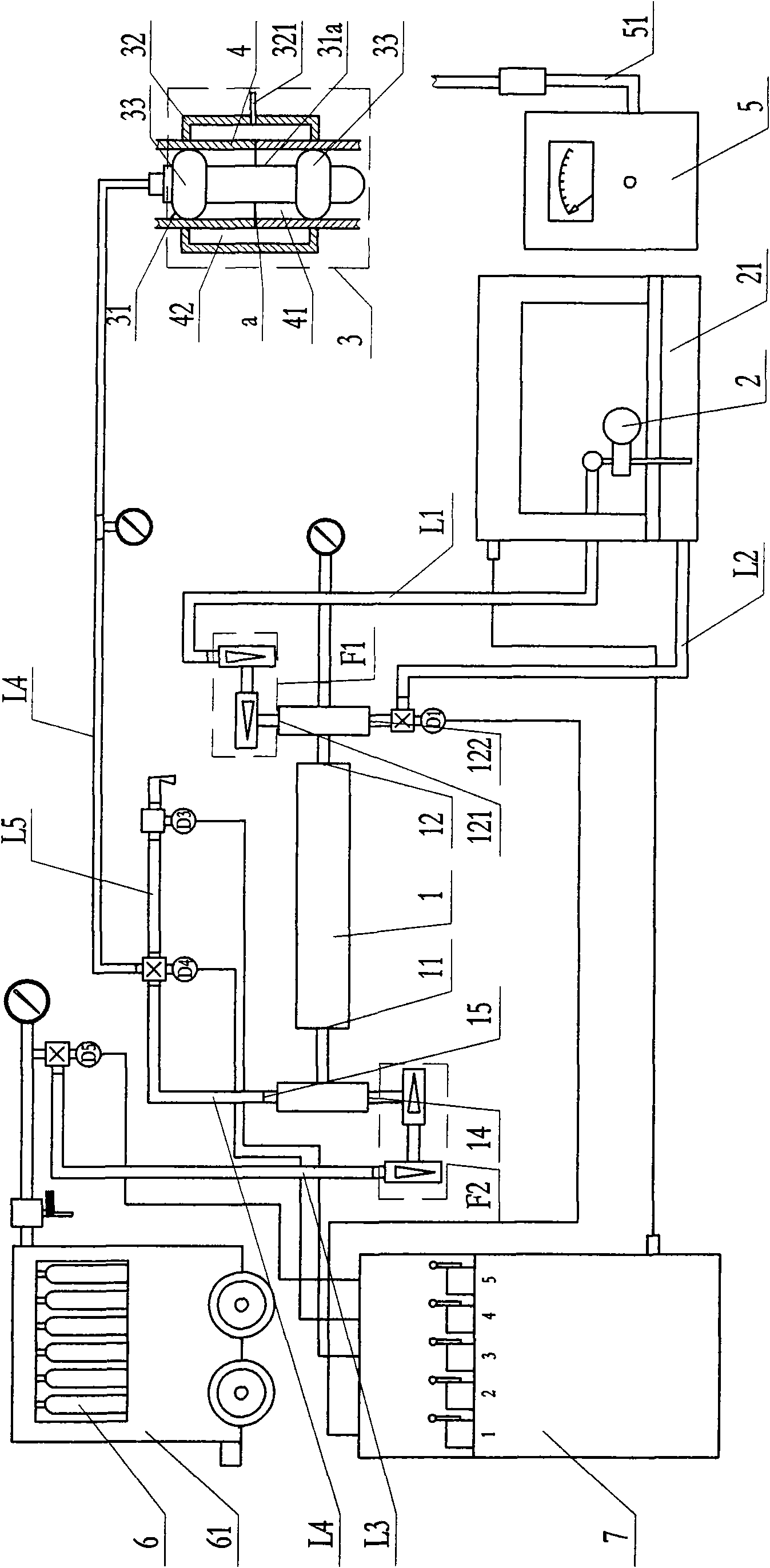

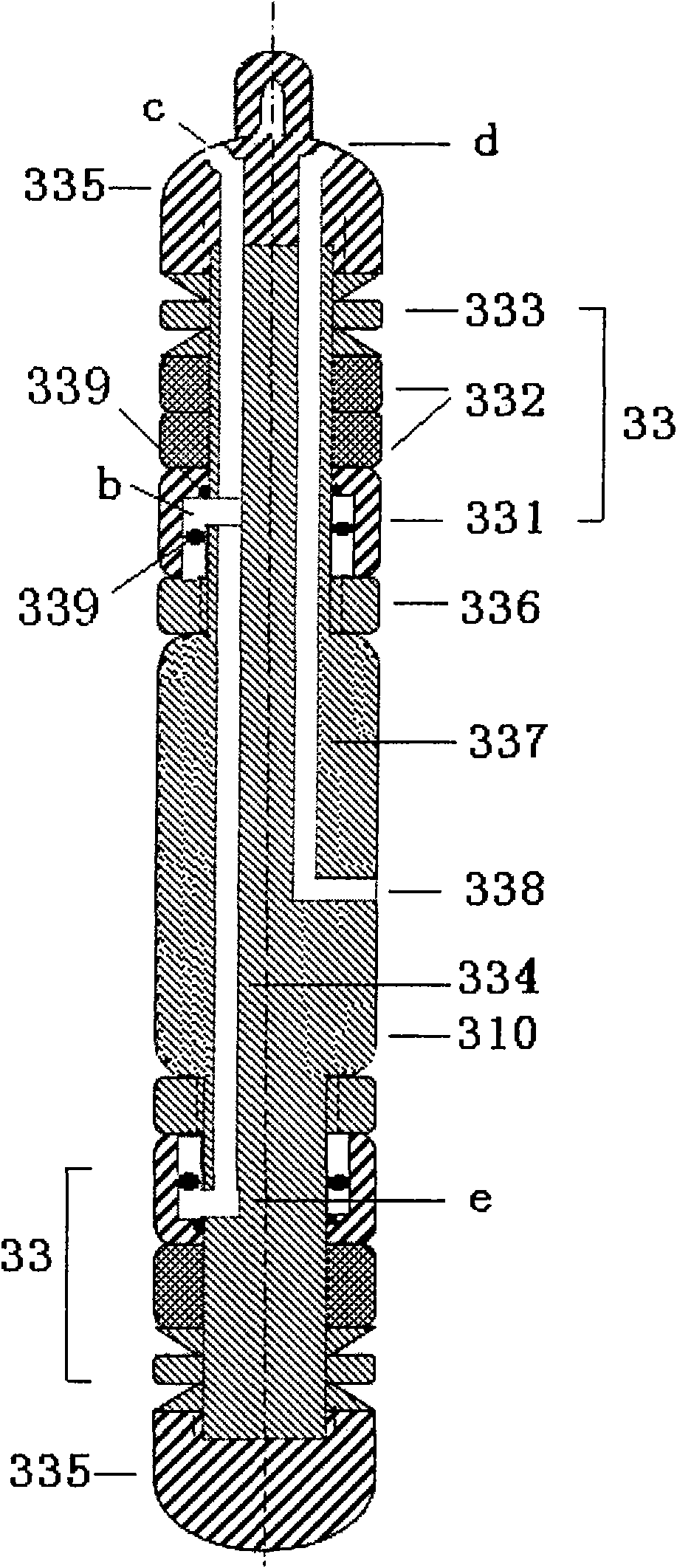

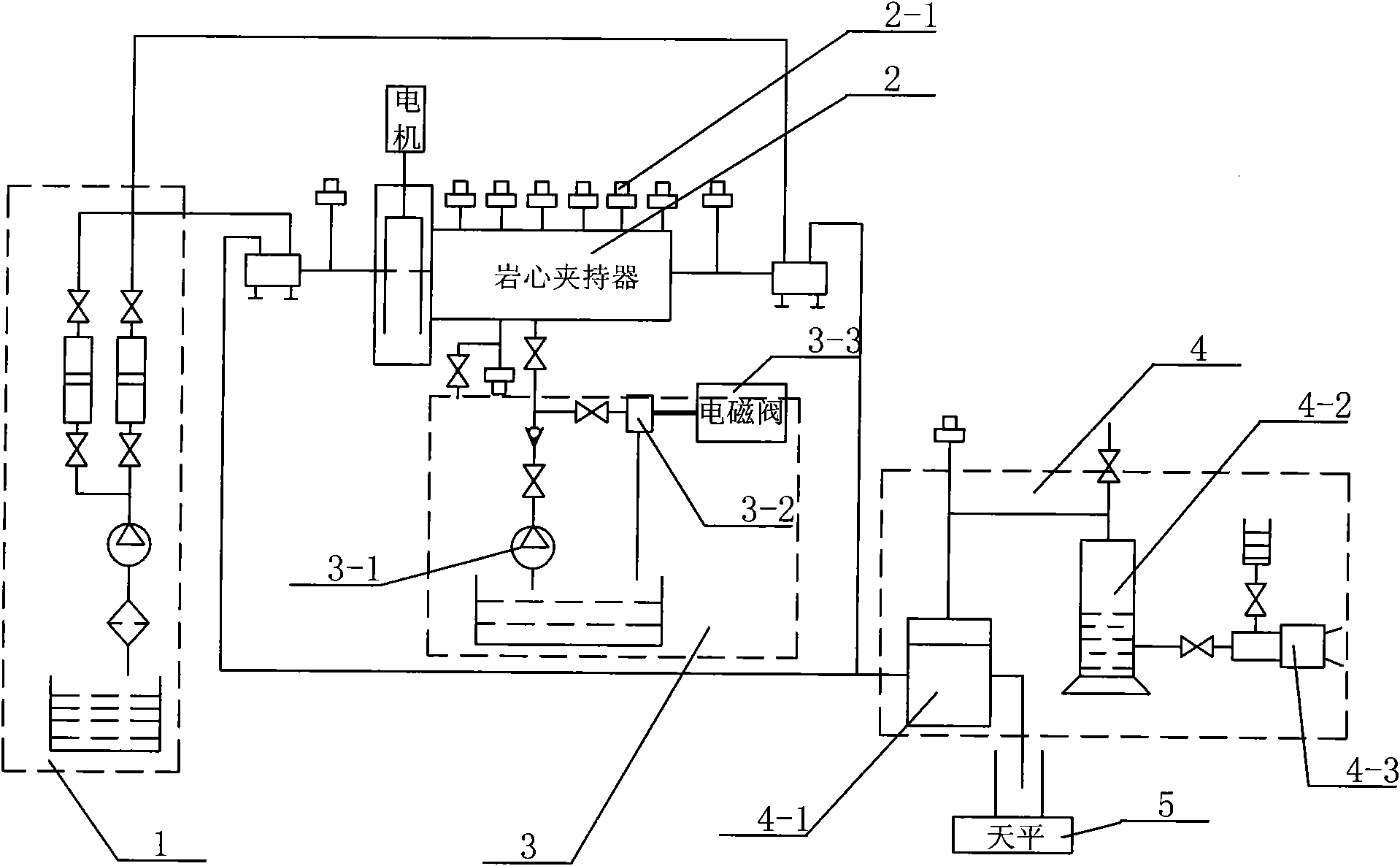

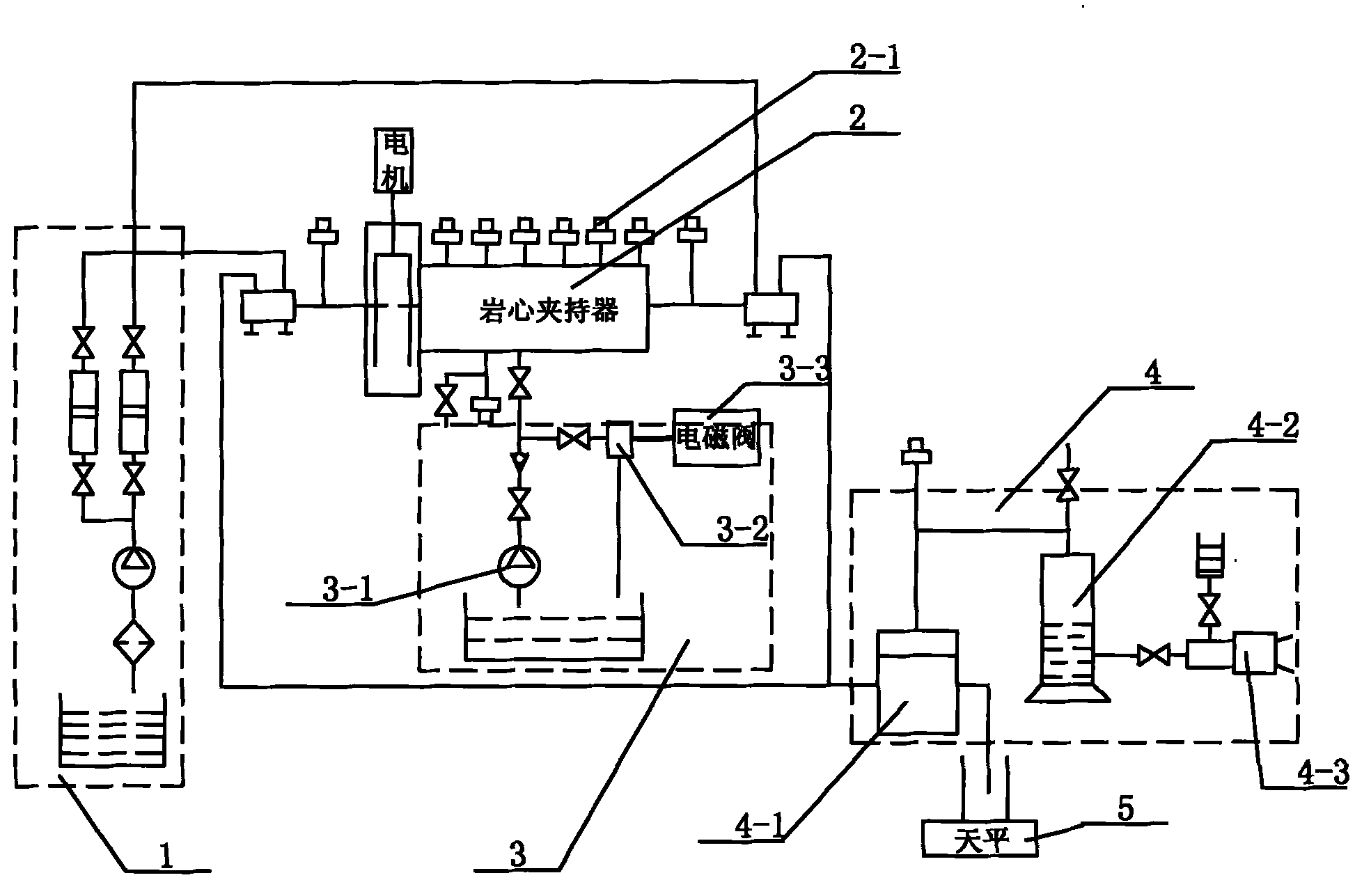

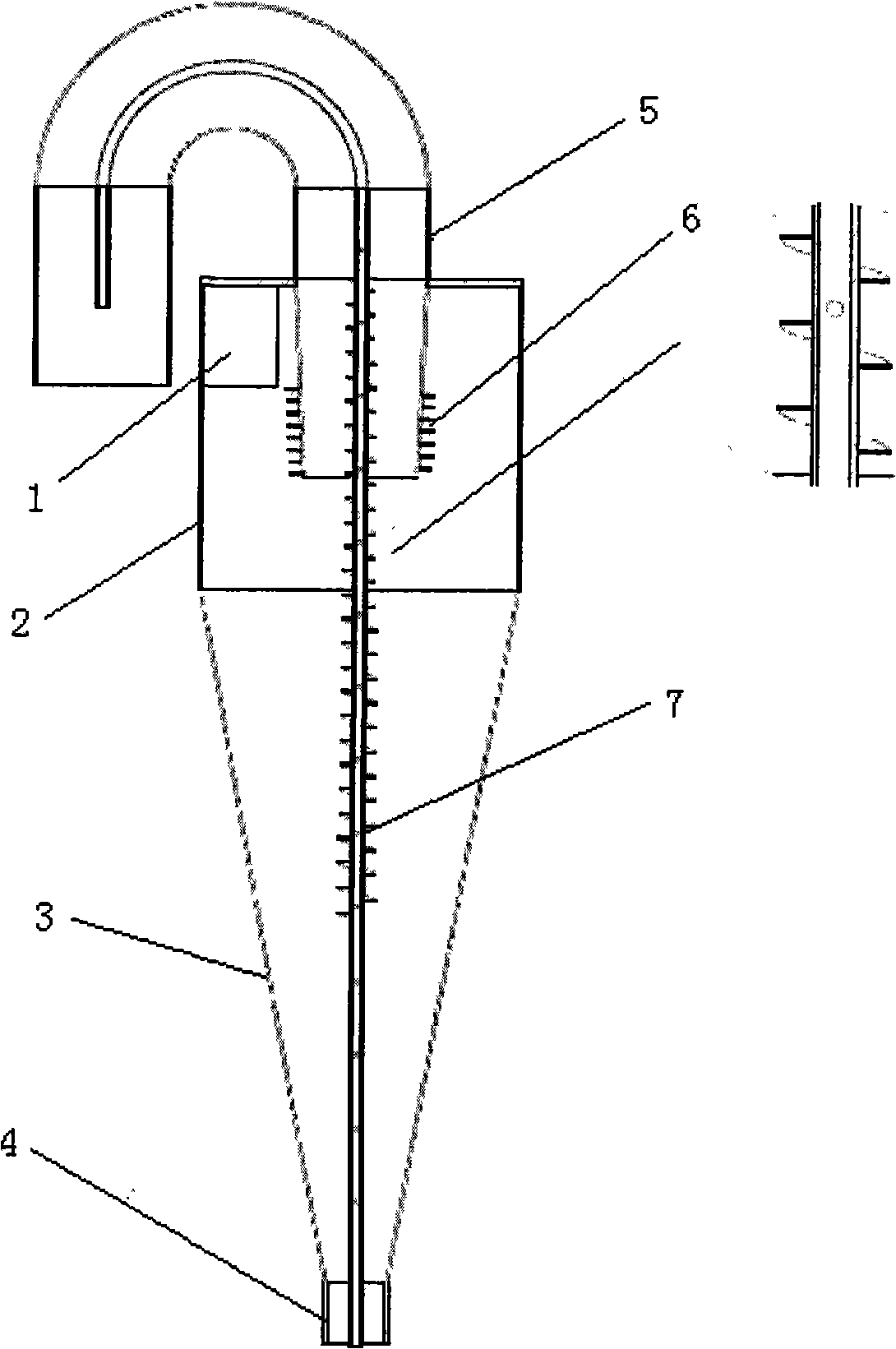

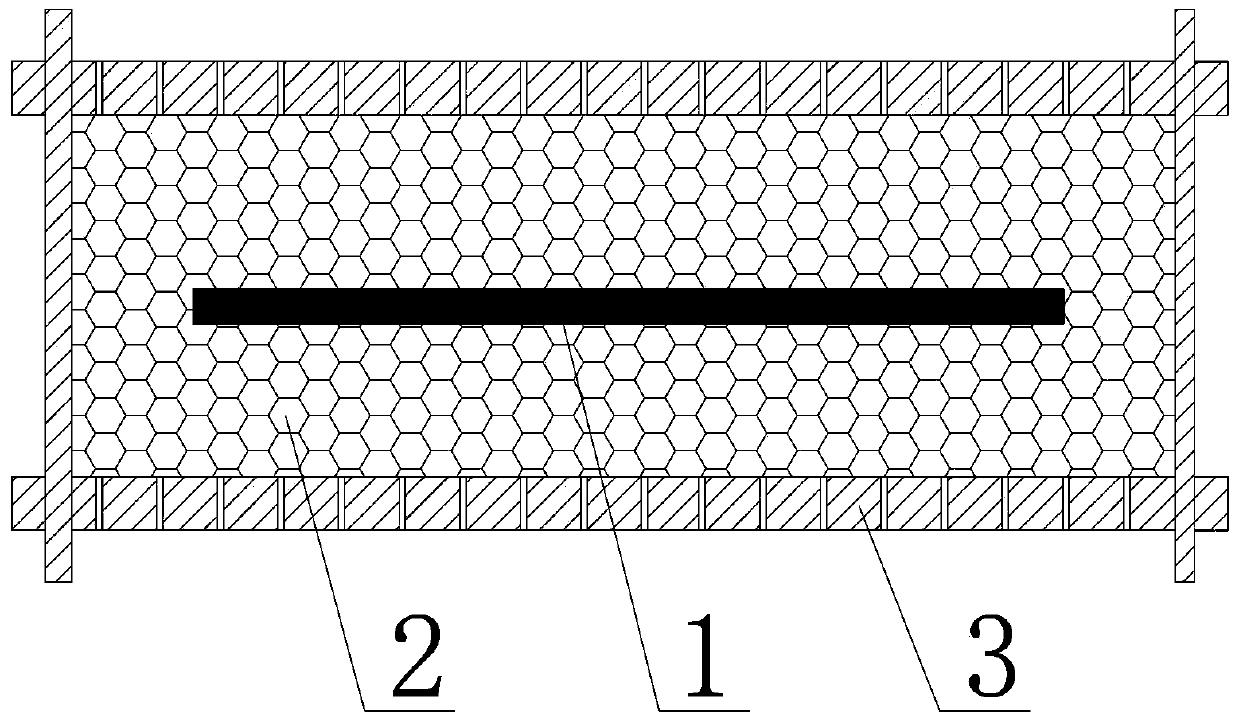

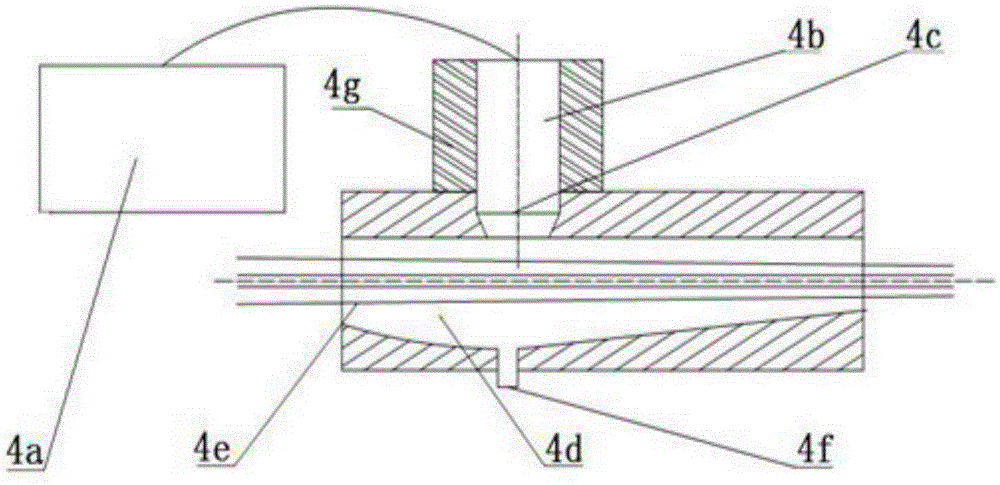

Fracturing acidification working solution dynamic filtration loss instrument

InactiveCN101864948AOptimal Reservoir Treatment SchemeReasonable structureFluid removalPermeability/surface area analysisRock coreFiltration

The invention provides a fracturing acidification working solution dynamic filtration loss instrument, which relates to the field of petroleum industry. The fracturing acidification working solution dynamic filtration loss instrument consists of a filling system (1), a rock core clamping device (2), a ring pressure tracking pump (3), a pressure return control system (4) and a metering system (5), wherein the filling system (1) is connected with the rock core clamping device (2), the rock core clamping device (2) is connected with the ring pressure tracking pump (3), the ring pressure tracking pump (3) is connected with the pressure return control system (4), and the pressure return control system (4) is connected with the metering system (5). The invention can accurately test the liquid seepage rate and the seepage rate gradient, can perfectly research formation sensitivity evaluation, oil extraction process and extraction yield improvement, and has the advantages of reasonable structure, artistic and elegant appearance, convenient operation and durability.

Owner:HAIAN GASOLINEEUM SCI RES INSTR

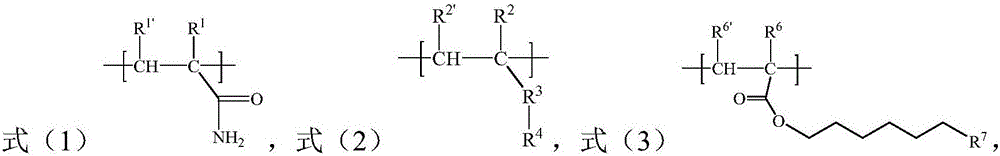

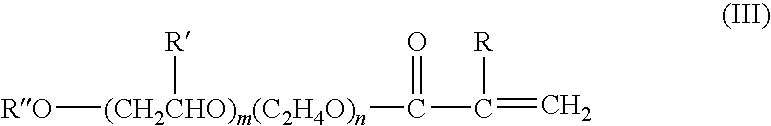

Polymers as additives for the separation of oil and water phases in emulsions and dispersions

ActiveUS20110031163A1Inhibiting and mitigating formationDewatering/demulsification with chemical meansLiquid separationOil waterCarboxylic acid

Oil-water dispersions and emulsions derived from petroleum industry operations are demulsified and clarified using anionic polymers. Formation of such oil-water dispersion and emulsions is inhibited and mitigated using the anionic polymers. The anionic polymers comprise: A) 2-80% by weight of at least one C3-C8 α,β-ethylenically unsaturated carboxylic acid monomer; B) 15-80% by weight of at least one nonionic, copolymerizable α,β-ethylenically unsaturated monomer; C) 1-50% by weight of one or more of the following monomers: C1) at least one nonionic vinyl surfactant ester; or C2) at least one nonionic, copolymerizable α,β-ethylenically unsaturated monomer having longer polymer chains than monomer B), or C3) at least one nonionic urethane monomer; and, optionally, D) 0-5% by weight of at least one crosslinker.

Owner:ROHM & HAAS CO

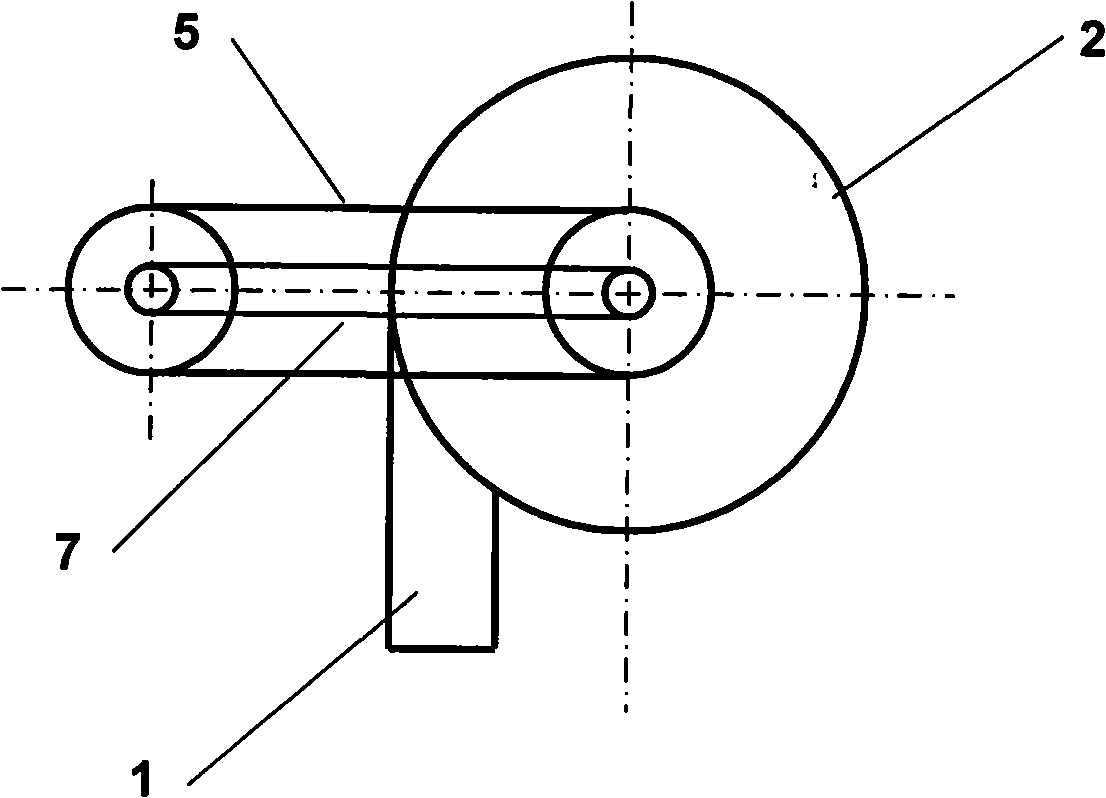

Water cyclone with improved base pipe and overflows structure

InactiveCN101254489ASimple structureReduce energy consumptionReversed direction vortexCycloneEngineering

The invention belongs to a device for solid-liquid separation / classification and non-homogeneous separation, specifically a hydraulic cyclone with improved structure of central post and overflow pipe. The device comprises a feed pipe, a cylindrical section, a coniform section, an overflow pipe and a hollow tubular central post with partial-spiral fins and spiral flow deflectors and provided outside the overflow pipe. The central post is a hollow tube provided thereon with a plurality of holes. The spiral flow deflectors are provided on the outer surface of the central post. The spiral fins are provided on the overflow pipe from the bottom of the overflow pipe to a height below the bottom of an inlet pipe. Compared with the prior art, the separation efficiency of the hydraulic cyclone is increased by 5-10% and the energy consumption is reduced by 20%. The hydraulic cyclone has high stability and reliability in separation efficiency and is suitable for solid-liquid separation in ore dressing, dredging, chemical and petroleum industries.

Owner:EAST CHINA UNIV OF SCI & TECH

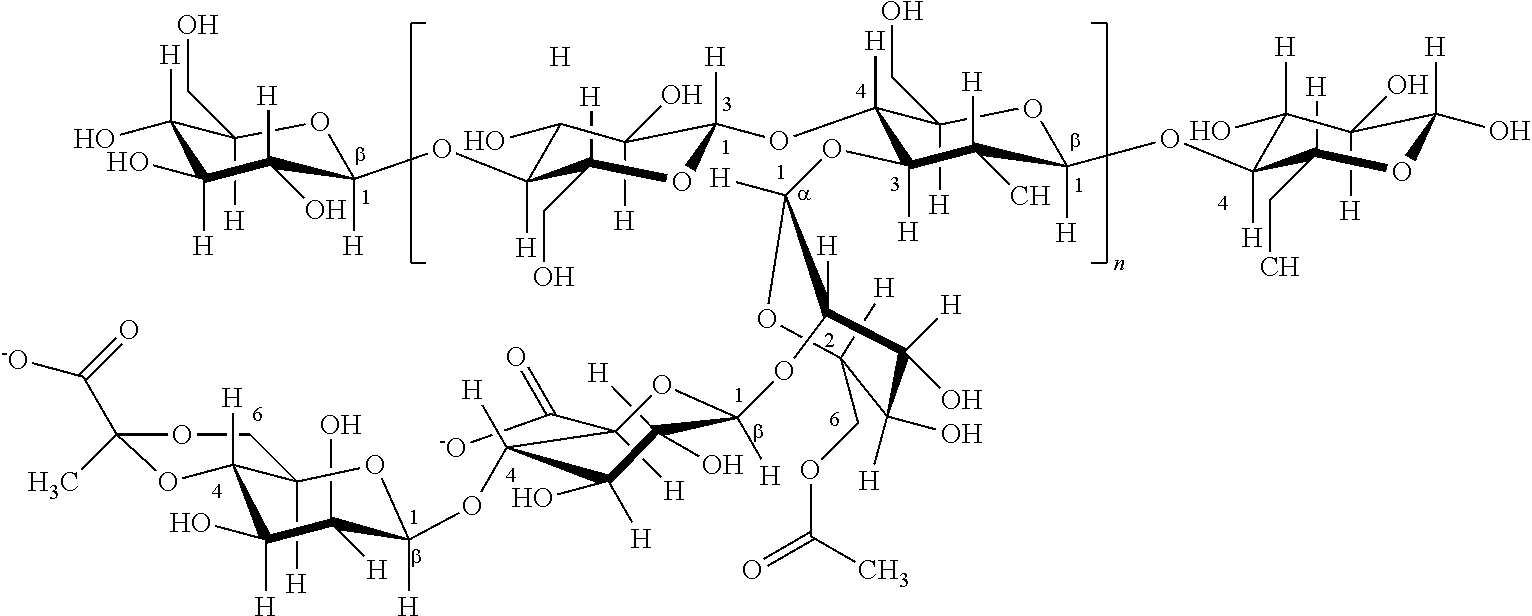

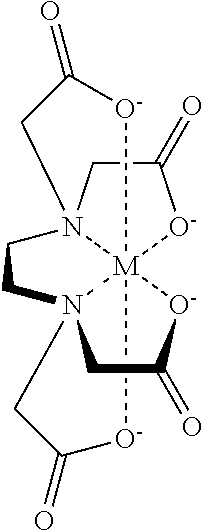

Methods for preventing or remediating xanthan deposition

InactiveUS20110053811A1Prevent polymer depositionFlushingDrilling compositionCrosslinked polymersChemical groups

Methods for remediation and / or prevention of polymer deposition on surfaces, in particular, on surfaces of drilling machinery and earth formations in the petroleum industry are described herein. Embodiments disclosed herein relate to a method of remediating xanthan deposition, the method including the steps of contacting xanthan deposition, including xanthan complexed with polyvalent metal ions, with a remediation fluid containing at least one chelating agent; and allowing the fluid to dissolve the xanthan deposition. Also disclosed is a method of preventing polymer deposition, including emplacing a wellbore fluid including a crosslinkable polymer and at least one chelating agent in a wellbore; wherein the at least one chelating agent complexes with polyvalent metal ions present in the wellbore. Also disclosed is an improved wellbore fluid including a base fluid; a polymer comprising chemical groups reactive to polyvalent metal ions found downhole; and at least one chelating agent; wherein the least one chelating agent complexes with polyvalent metal ions downhole.

Owner:MI

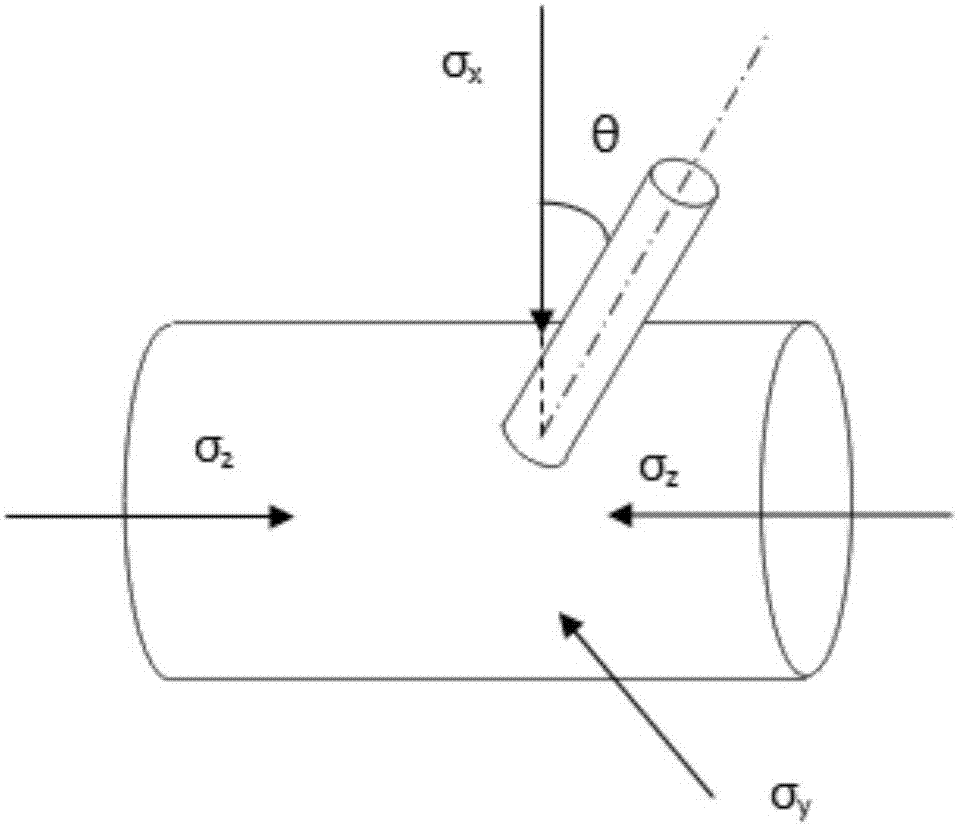

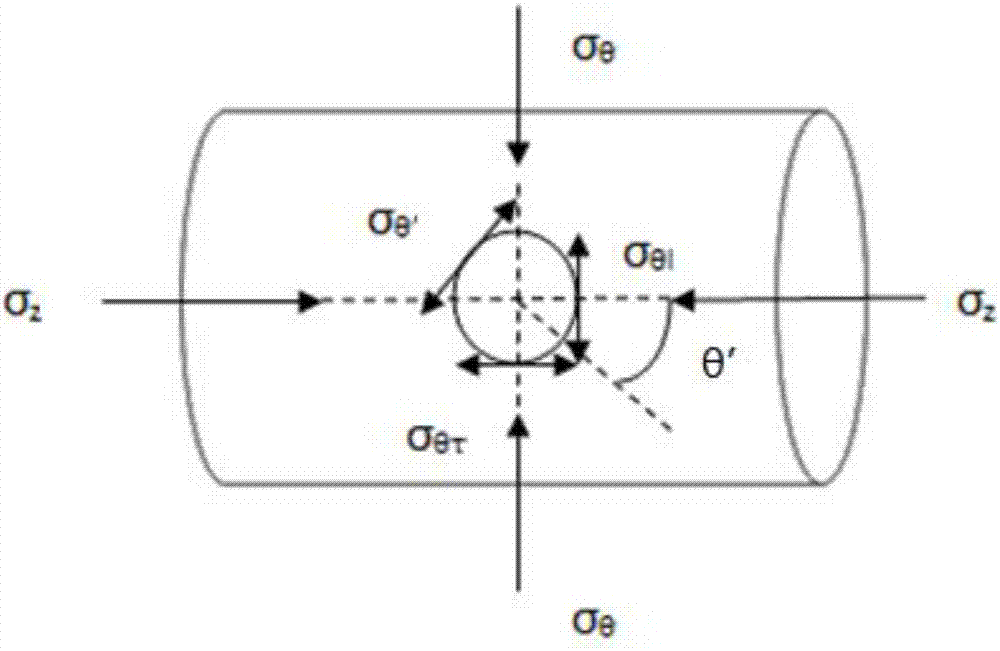

An optimization method for shale gas horizontal well perforation cluster distances

InactiveCN107506840ATo achieve the purpose of maximizingIncrease productionForecastingOil productionShale gas

Owner:CHINA PETROLEUM & CHEM CORP +1

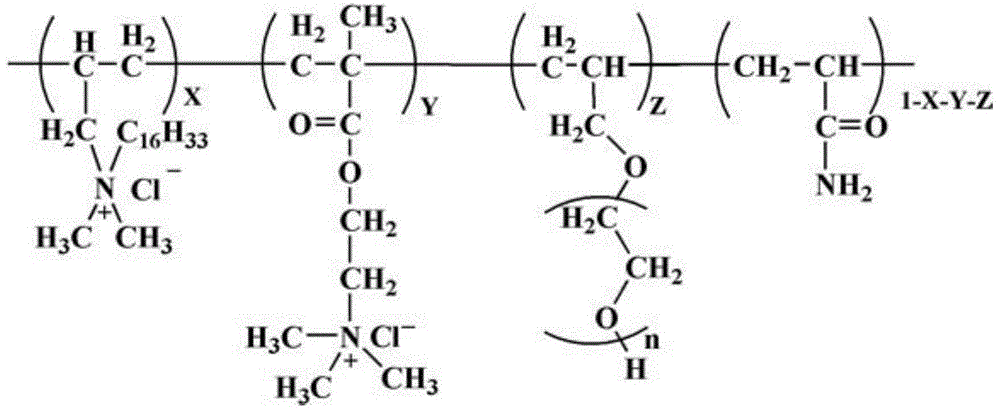

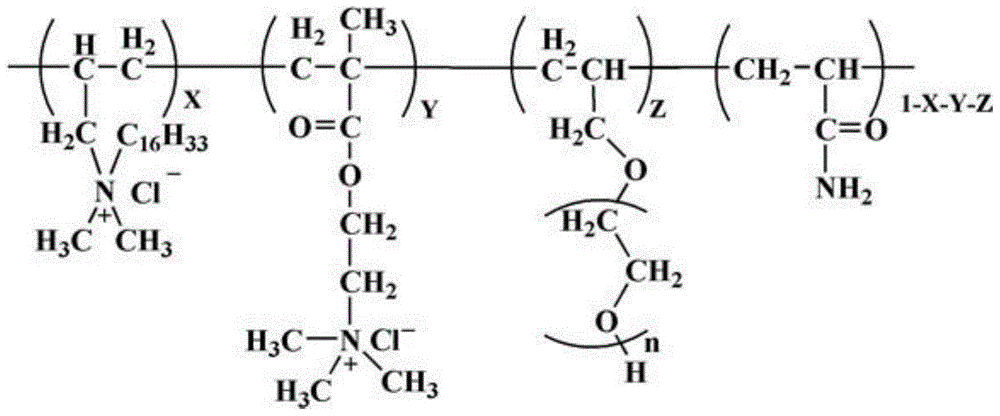

Hydrophobically associated type cation acid solution retardant and preparation method thereof

InactiveCN105001849AWide range of sourcesImprove thermal stabilityDrilling compositionEtherThermal stability

The invention relates to a hydrophobically associated type cation acid solution retardant for oil gas well acidification in petroleum industry and a preparation method thereof. According to the invention, a retarded acid is utilized for acidifying deep parts of the stratum, in order to improve the acid treatment effect. The technical scheme is as follows: the acid solution retardant is polymerized from four monomers, including acrylamide AM, allylpolyoxyethylene ether APEG-1000, methacryloxyethyltrimethyl ammonium chloride DMC, and cetyl dimethyl diallyl ammonium chloride DMAAC-16. The method of preparation is as follows: adding APEG-1000 whose mole percent is 2.00-8.00% into a flask, adding water 50.00-150.00g, carrying out stirring and dissolving, adding materials in percentage by mole including 63.40-79.60% of AM, 15.80-28.25% of DMC and 0.30-0.70% of DMAAC-16, and obtaining a solution whose concentration is 15%; finally adding an initiator, allowing reaction for 6 hours at 50 DEG C, carrying out washing by ethanol and drying, and obtaining the acid solution retardant. The retardant has a good retardance performance, so that deposition is not easy to be produced, and the retardant has good heat stability, good temperature tolerance and compatibleness.

Owner:SOUTHWEST PETROLEUM UNIV

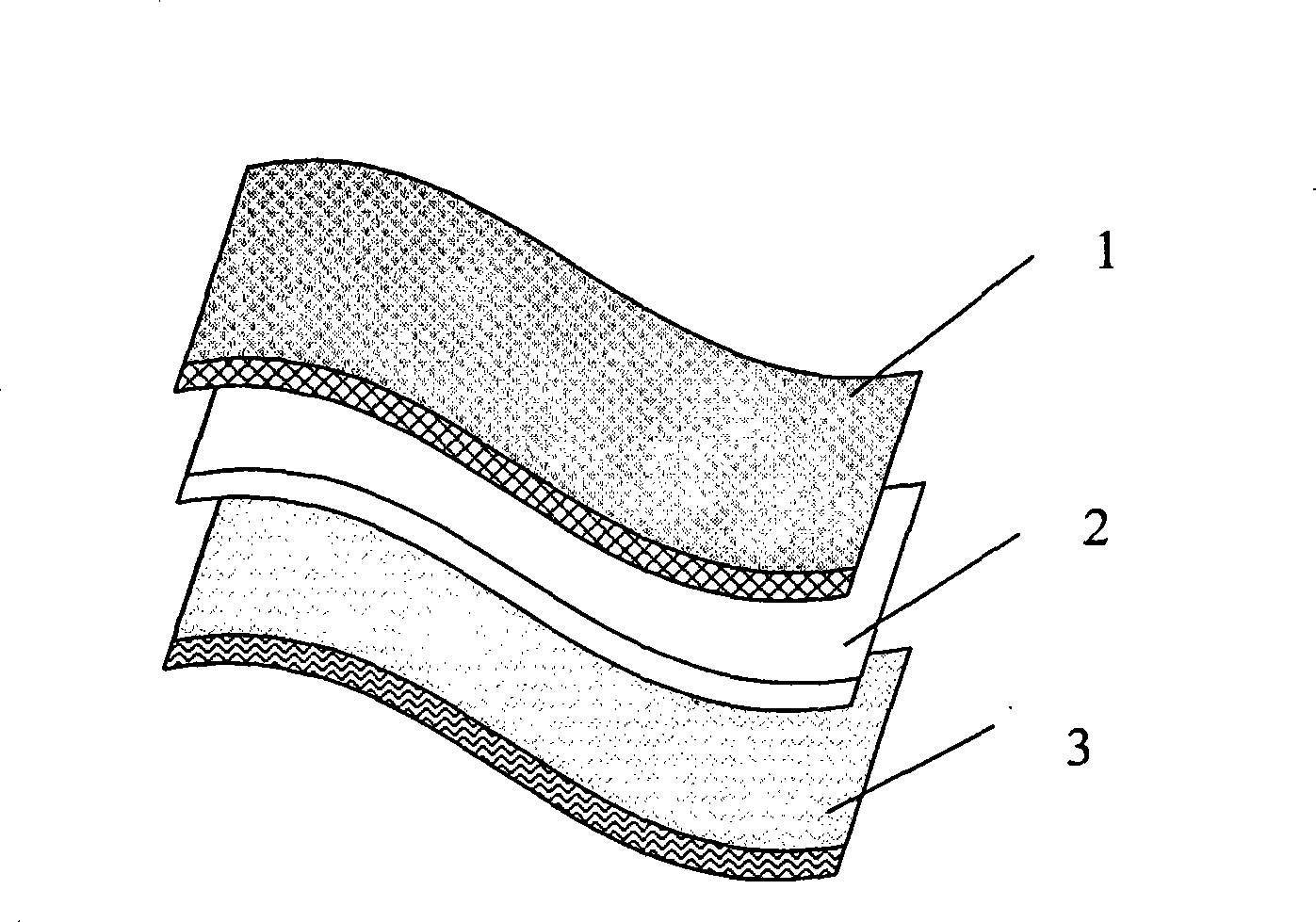

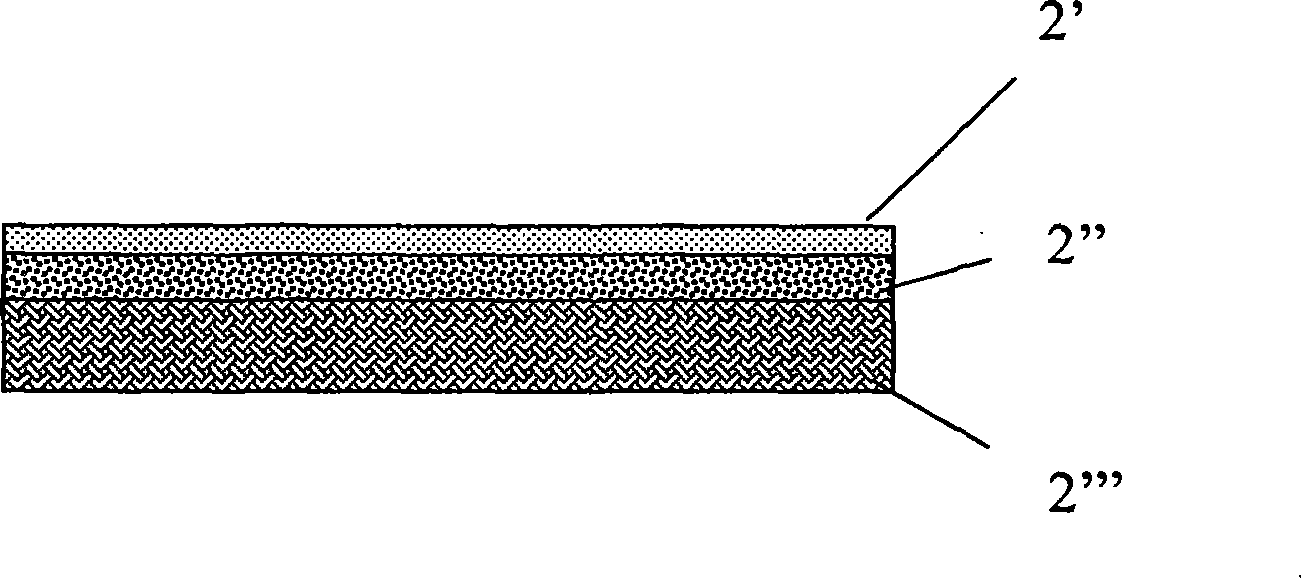

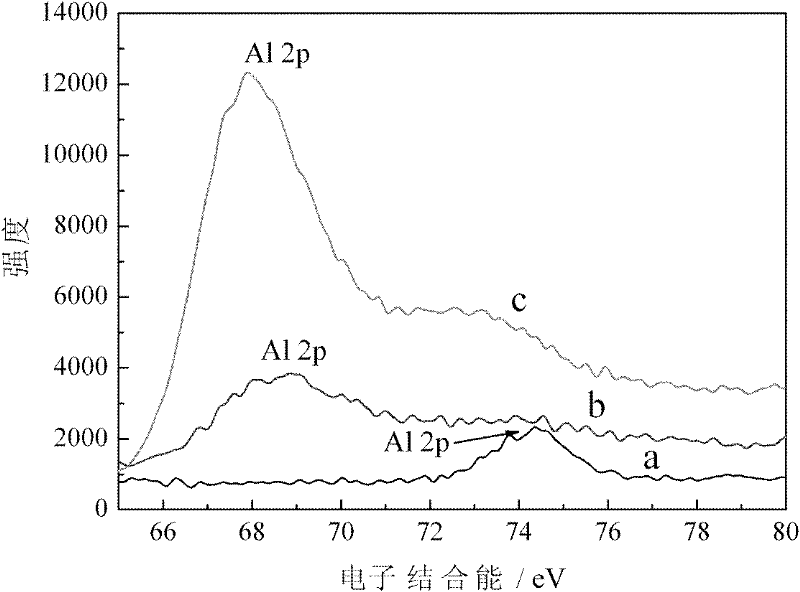

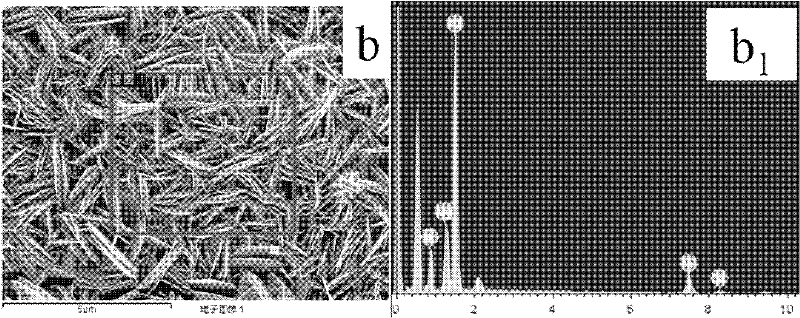

Composite facing material of fire-fighting chemical protective clothing based on electrostatic spinning fiber film

InactiveCN101248913ALarge body surface areaReduce weightProtective garmentSpecial outerwear garmentsActivated carbonFilm base

The invention relates to fire resistant, electrostatic preventing, moisture permeable, anti-chemical and anti-gas composite fabric based on electro-spinning fibers for chemical protective clothing for firefighters, which sequentially comprises, from outside to inside, a fire resistant and electrostatic preventing layer, an anti-chemical isolating layer and a thermal insulating layer, wherein the fire resistant and electrostatic preventing layer is natural fire-resistant fabric or fabric after fire-resistant finish; the anti-chemical isolating layer is composed of an electro-spinning fiber film, a film base cloth and an activated carbon non-woven fabric that are sequentially arranged from outside to inside; the thermal insulating layer is composed of non-woven fabric or felt made of fire-resistant fiber; and the anti-chemical isolating layer is laminated together with the fire resistant and electrostatic preventing layer and then quilted with the thermal insulating layer. The inventive composite fabric has the advantages of good gas permeability, good electrostatic prevention, waterproof, anti-chemical, anti-gas and moisture permeability, good degradation liability, no toxicity, no pollution; and can be used for fire fighting and chemical defense, and can be used in the fields needing personal protection such as military, petroleum industry, decontamination, and dangerous chemicals.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Chromium 23 nickel 6 ferrite-austenitic stainless steel pipe and fabrication process thereof

ActiveCN101353769AEasy to useHigh tensile strengthRoll mill control devicesWork treatment devicesChemical industryManufacturing technology

The invention relates to a Cr 23 Ni 6 ferrite-austenitic stainless steel which is manufactured from stainless steel materials containing components by weight percentage as follows: 22 percent to 24 percent of Cr, 5 percent to 7 percent of Ni, 3 percent to 4 percent of Mo, 0.15 percent to 0.25 percent of N, less than or equal to 0.03 percent of C and 1 percent to 2 percent of Mn, and the rest is Fe. The manufacturing technology of the Cr 23 Ni 6 ferrite-austenitic stainless steel of the invention is characterized in that: in hot piercing process, the hot piercing temperature is controlled to be 1150 DEG C to 1200 DEG C; the prior compression coefficient of a piercing plug is controlled to be 5 percent; the reduction of roller waist is controlled to be 12 percent and the ovality is controlled to be 1.08 to 1.11; in cold drawing / cold rolling process, cold deformation quantity is controlled to be below 50 percent; in heat treatment process, the solid solution temperature of products is controlled to be 1080 DEG C to 1100 DEG C and the solid solution temperature of finished products is controlled to be 1050 DEG C to 1100 DEG C. The Cr 23 Ni 6 ferrite-austenitic stainless steel has good chloride stress corrosion resistance, good pit corrosion resistance, high tensile strength and yield strength and good corrosion fatigue resistance and erosion corrosion resistance, and is widely used in the fields such as petroleum industry, chemical industry, natural gas industry and marine shipping and the like.

Owner:上上德盛集团股份有限公司

Short-injection water injection well acidation injectivity process

The invention discloses a short-injection water injection well acidation injectivity process for petroleum industry, which is applied to a short-injection water injection well, improves the acidation effect and improves the water injection success rate. The process comprises the following steps: a prepose acid liquor soaking oil layer is inputted; the well is backwashed at high flow rate so as to discharge the prepose acid liquor; main acid is squeezed in; the well is backwashed by water mixed with gas, the back pressure on the bottom of the well is reduced, the ground layer is induced to flow, and the deep stoppage reactant can be discharged under the effect of the strata pressure. The prepose acid liquor is discharged through the repeated washing of the well, so the effect of the main acid is adequately played, the secondary pollution of the oil layer can be prevented, the deep acidation can be realized, the injectivity valid period is prolonged, the measure success rate is improved, and the recovery rate of the low-permeability reservoir can be improved. The effect of the used acid can be effectively played, the underground tube pile can be free from damaged, the consumption of the main acid can be reduced on the premise of ensuring the construction effect, and the production cost can be saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

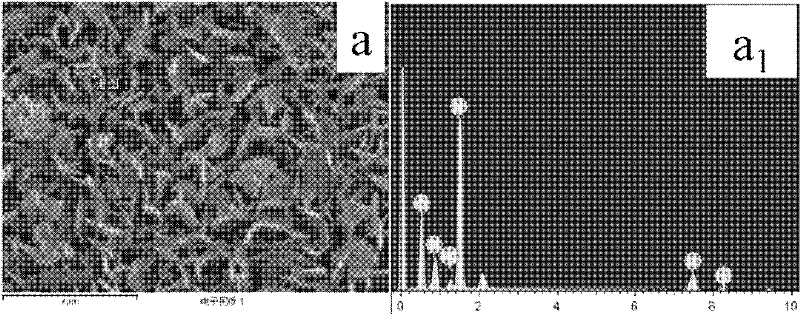

Vertically aligned layered double hydroxides (LDHs) film and application thereof in structured catalysis

ActiveCN102343283AAvoid churnControl shapeOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils refiningThiolCatalytic oxidation

The invention discloses a vertically aligned layered double hydroxides (LDHs) film and a preparation method thereof, and belongs to the technical field of an inorganic functional material and controlled preparation thereof. The vertically aligned LDHs film has the characteristics of good stability, high catalysis efficiency, longer catalysis life, easy regeneration procedure and the like in the event that the film is applied to structured catalytic oxidation deodorization of mercaptan. The preparation method of a structured catalyst comprises the following steps: preparing vertically aligned binary and ternary LDHs films on a pure aluminum substrate by an in-situ growth method; calcining the obtained LDHs films at the temperature of 400-500 DEG C to obtain a complex metal oxide film; and then loading cobalt sulfonated phthalocyanine (CoSPc) on the complex metal oxide film to obtain the structured catalyst. The obtained catalyst can be applied to catalytic oxidation of mercaptan and shows the advantages of high catalytic activity and longer catalysis life, thus having potential application prospect in deodorization in petroleum industry.

Owner:BEIJING UNIV OF CHEM TECH

High-strength toughness steel for continuous sucker rod and method for manufacturing same

InactiveCN101245436AReduce failure frequencyReduce work stressTemperature control deviceHeat treatment process controlChemical compositionToughness

The invention discloses steel with high strength and toughness applied in a coiled rod and a manufacturing method thereof, solving the problems of the existing coiled rods that the strength and the plasticity are low and not well matched, and fatigue crack occurs frequently. The manufacturing method comprises the following steps: 1) the chemical components of the steel by weight percentage are: 0.12-0.22 percent of C, 0.15-0.40 percent of Si, 0.30-0.60 percent of Mn, 0.20-0.40 percent of Mo, 1.30-1.95 percent of Ni, 0.40-0.60 percent of Cr, 0.20-0.35 percent of V, 0.015-0.050 percent of Al, less than or equal to 0.30 percent of Cu, less than or equal to 0.0 15 percent of S, less than or equal to 0.020 percent of P and the rest of Fe; 2) smelting, ladle refining and continuous casting to form blocker: the (O) is less than or equal to 0.0025 percent and the (H) is less than or equal to 0.00015 percent; 3) casting blank and heating: the soaking temperature is 1130-1180 DEG C, heat preservation is more than or equal to 2.5 h, and the tapping temperature is 1100-1180 DEG C; 4) control of rolling: the temperature of finishing rolling is 820-860 DEG C; 5) control of cooling: the cooling speed is 40-80 DEG C per hour. The steel of the invention improves the comprehensive mechanical performances and fatigue life of the coiled rod and fulfils the development of the petroleum industry.

Owner:宝钢特钢有限公司

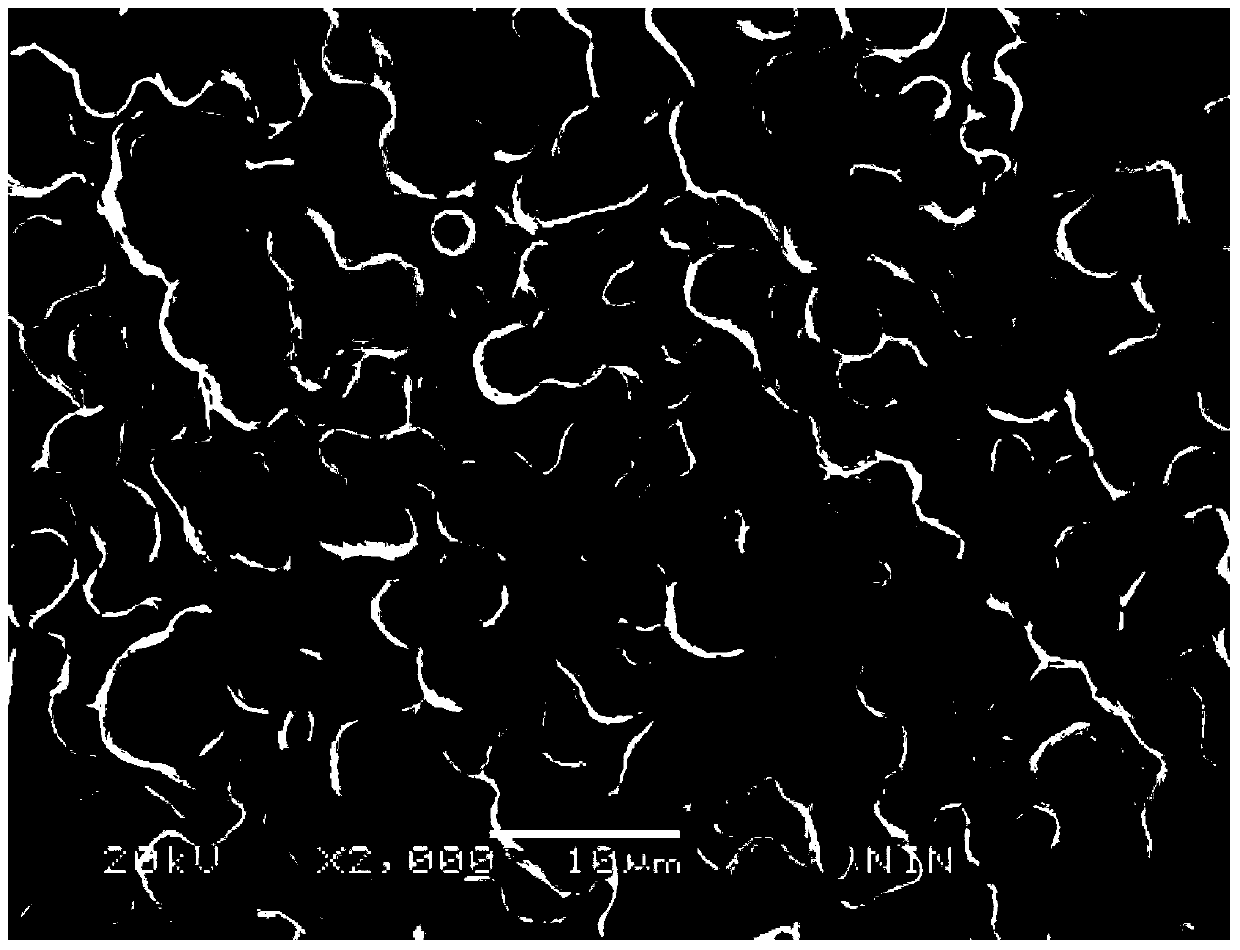

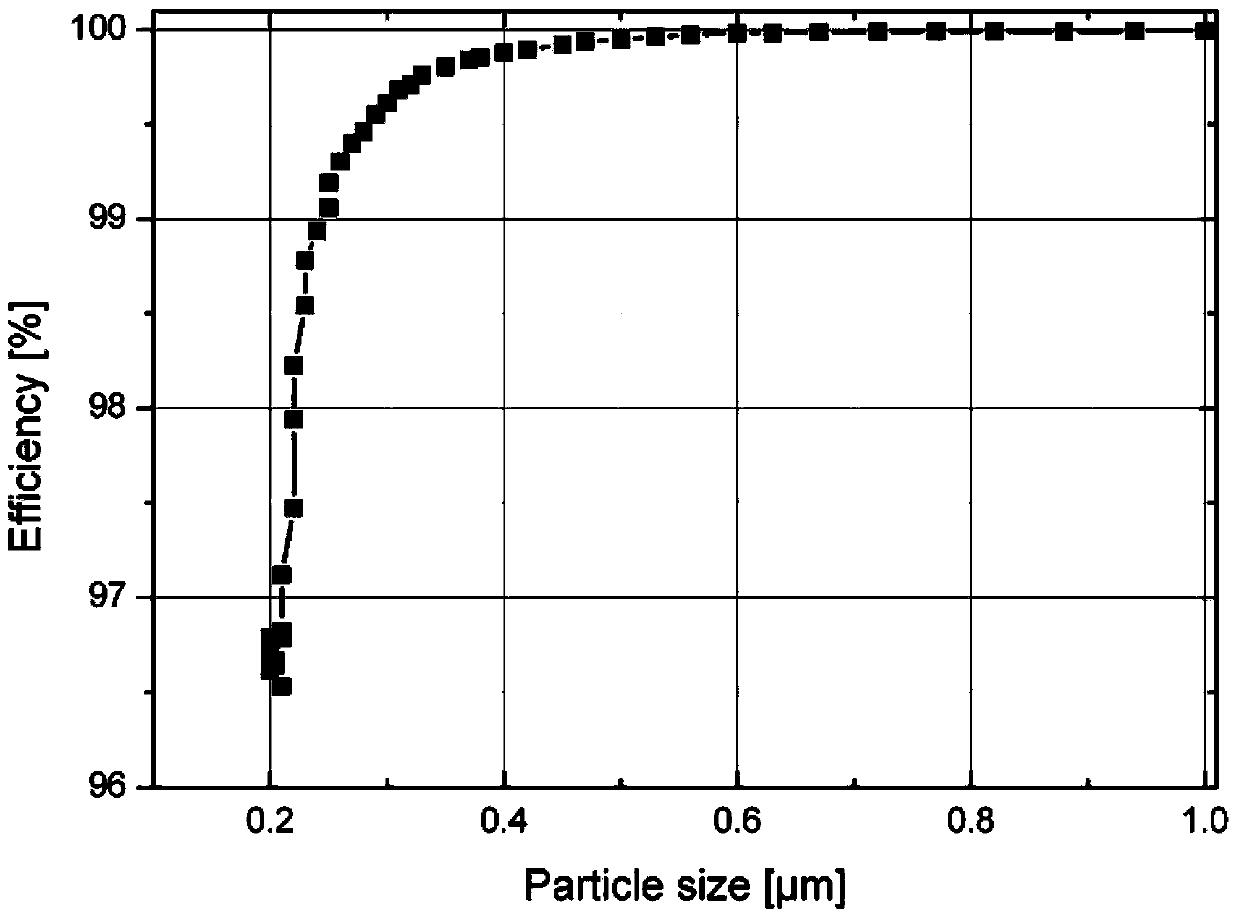

Support-free perforated metal film preparation method

ActiveCN103386486AAddress stressSolve the problem of organic matter residue after sinteringLow demandPolyvinyl alcohol

The invention provides a support-free perforated metal film preparation method, comprising the steps of 1, uniformly mixing metal powder and poval in a ball-milling mode to obtain slurry; 2, coating the slurry onto a basal body face, and stripping after drying to obtain a support-free metal film blank; 3, placing ceramic padding and the support-free metal film blank into a sintering die, enabling the ceramic padding to fully wrap the support-free metal film blank, and then performing processes of pre-sintering preprocessing, pre-sintering, sintering and cooling to obtain the support-free perforated metal film. The support-free perforated metal film preparation method is simple in process and low in production cost, has lower demands on production equipment, and is suitable for large-scale industrial production; and the support-free perforated metal film produced according to the preparation method is small and uniform in aperture, high in porosity, and far higher in filtering efficiency compared with a traditional metal film, and can be widely applied in industrial fields such as petroleum industry, bio-pharmaceuticals, food, beverage and water treatment.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

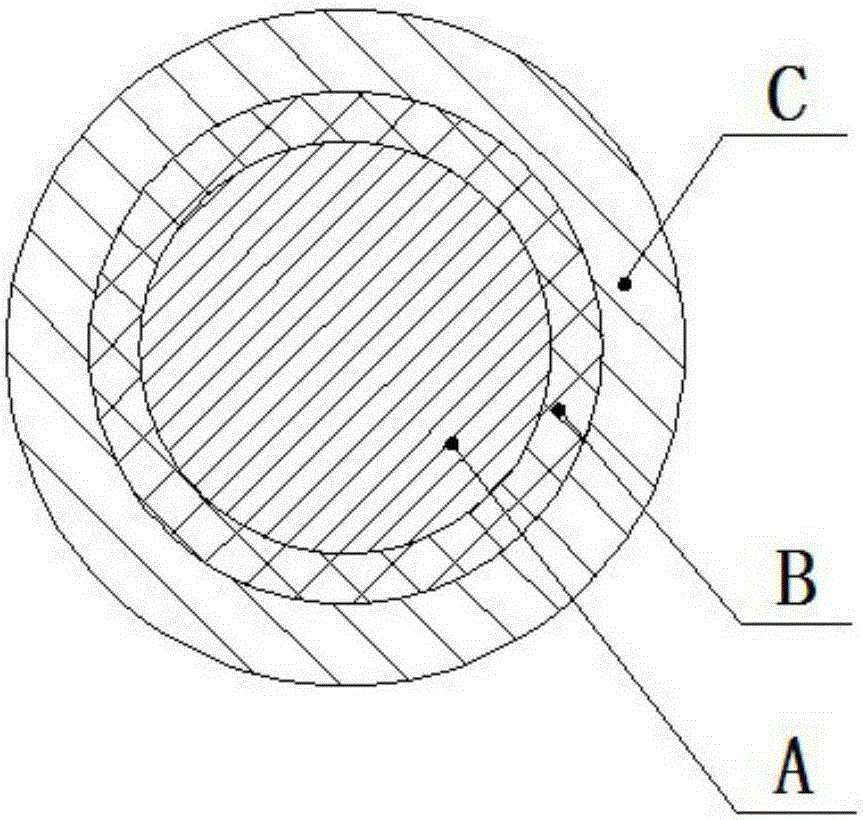

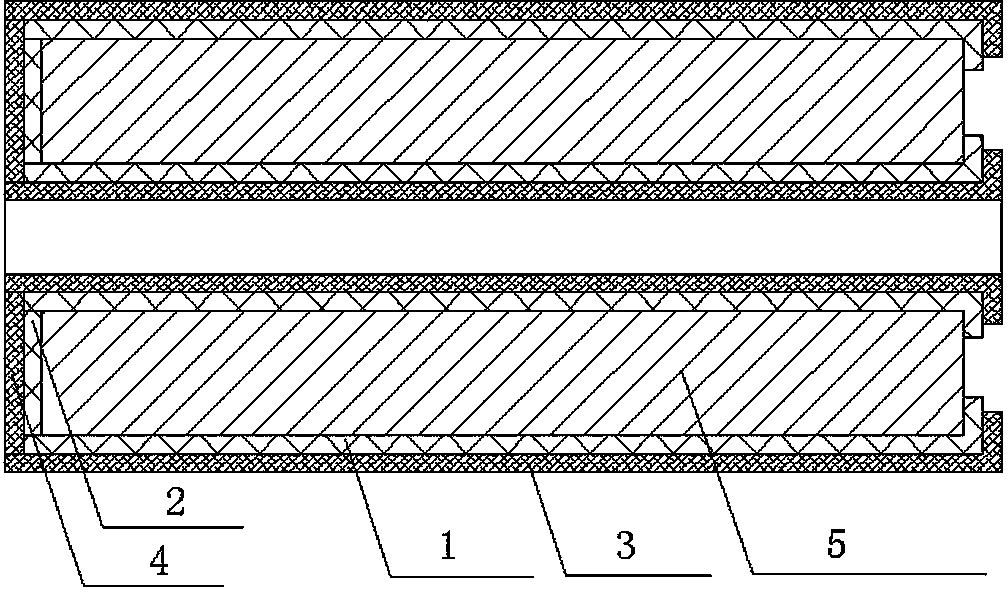

Fiber-reinforced composite coiled sucker rod and production apparatus and method thereof

ActiveCN105178878ALow costLittle impact on performanceDrilling rodsGlass/slag layered productsEpoxyGlass fiber

The invention discloses a fiber-reinforced composite coiled sucker rod and belongs to the technical field of oil production equipment in the petroleum industry. The fiber-reinforced composite coiled sucker rod has three structural layers stacked in order, namely an inner carbon fiber layer (A), an intermediate glass fiber layer (B) and an outer glass fiber layer (C) orderly from inside to outside. The inner carbon fiber layer is made of unidirectional carbon fibers arranged axially along a rod body. The intermediate glass fiber layer is made of H-grade glass fibers arranged transversely along the rod body and is bidirectionally wound or knitted to the inner carbon fiber layer. The outer glass fiber layer is made of unidirectional H-grade glass fibers arranged axially along the rod body. The sucker rod is made of resin matrix which is an epoxy resin system; the carbon fibers and the H-grade glass fibers are used as reinforcing materials. The invention further provides a production apparatus and method of the sucker rod. The sucker rod is good in corrosion resistance, has few connectors, is low in cost and low breaking rate, has slight piston effect and moderate modulus and is convenient to curl, transport, operate and use.

Owner:江苏众成复合材料有限责任公司

Leakage-proof type temporary blockage additive for low-pressure thin oil well

The invention discloses a leakage-proof type temporary blockage additive for a low-pressure thin oil well, which belongs to the field of workover treatment for a thin oil well in petroleum industry. The temporary blockage additive comprise the following raw materials in weight percentage: 0.4-0.6% of hydroxypropyl guar gum, 0.2-0.4% of organic titanium, 5-10% of petroleum resin, 0.3-0.5% of dodecyl dimethyl betaine, 0.1% of sodium sulfite, 0.02-0.04% of ammonium persulfate and 88.5-93.5% of water. The leakage-proof type temporary blockage additive of the invention crosslinks the hydroxypropyl guar gum with the organic titanium to form a gel system, and at the same time adds a certain amount of petroleum resin to form a compound temporary blockage system. The temporary blockage system can immediately break gel without blocking off the oil well, and avoids the accident of stuck pump caused by broken gel fragment. In addition, the leakage-proof type temporary blockage additive has the advantages of no pollution, no harm to a reservoir and low cost.

Owner:PETROCHINA CO LTD

High-performance TC11 tube and preparation thereof

The invention relates to a high-performance TC11 tube and a preparation thereof. According to the preparation method, the finished product TC11 tube is prepared by firstly preparing a TC11 titanium alloy cast ingot from a first-class titanium sponge, an aluminum-vanadium alloy, an aluminum-zirconium alloy and scrap zirconium by virtue of strict control of materials and the melting process, forging the cast ingot to obtain a black-rust sheared billet, then machining and carrying out surface grinding to obtain a extruded ingot billet, drilling the ingot billet, sheathing, heating and extruding to obtain a tube billet, then carrying out hot straightening, surface treatment and heat treatment and finally machining, such as boring and turning to obtain the finished product TC11 tube. The TC11 titanium alloy tube prepared by the preparation method disclosed by the invention has the characteristics that (1) the TC11 titanium alloy tube has very high strength, ductility and impact properties; (2) the tube having relatively high tolerance level can be obtained; (3) the microstructure of the TC11 titanium alloy tube is uniform and stable; and (4) the TC11 titanium alloy tube has excellent corrosion performance. The TC11 titanium alloy tube can meet the high-standard application requirement in the petroleum industry.

Owner:NINGXIA ORIENT TANTALUM IND

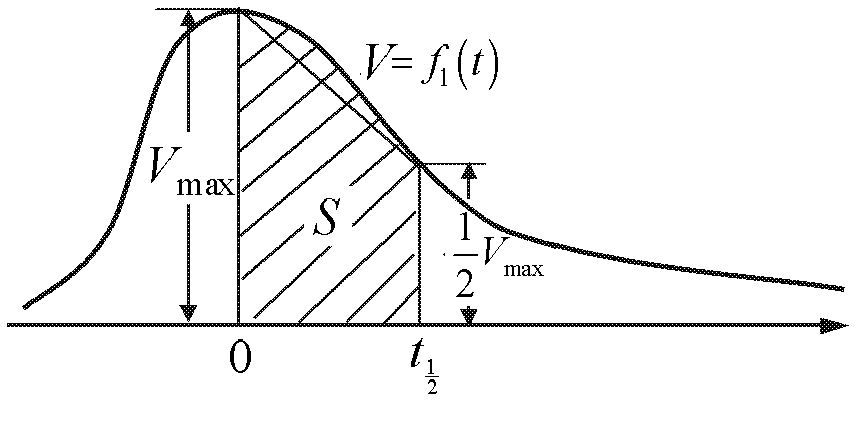

Measuring method for performance of foaming agent

The invention belongs to the technical field of petroleum industry, relates to a measuring method for performance of foaming agent, specifically relates to measurement of high temperature performance of foaming agent. By measuring the foam volume and half-life of the foaming agent under different temperature conditions, the method obtains average foam comprehensive index as the measurement result of the foaming performance and foam stabilizing performance of the foaming agent; on this basis, by measuring the resistance factor of the foaming agent under different temperatures conditions, an average foam resistance factor is obtained to be used as the measurement result of the sealing and blocking performance of each foaming agent. The method can objectively measure the foaming performance, foam stabilizing performance and sealing and blocking performance of the foaming agent under varying temperature conditions, thus realizing the optimal selection of the foaming agent used for blocking and profile adjusting under high temperature vapor conditions on the site of oil field.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Automatic assembly mechanism for perforating bullet

ActiveCN103801930AProtection securityGuaranteed isolationMetal working apparatusProduction lineEngineering

The invention provides an automatic assembly mechanism for a perforating bullet. The automatic assembly mechanism is characterized in that a powder liner (arranged on an upper-layer conveyor belt) and a casing filled with an explosive (arranged on a lower-layer conveyor belt) are respectively taken from an dual-layer plane turning loading conveyor belt 1 by a dual-claw pneumatic loading mechanical arm 3; the casing and the powder liner are sequentially placed in a hydraulic press 4; after the casing and powder liner are compressed by the hydraulic press, a product is taken down by a pneumatic product-taking mechanical arm 6 and is placed into a die 2 of a plane turning product-taking conveyor belt 7. According to the automatic assembly mechanism disclosed by the invention, the assembly process of loading, conveying, pressing explosive and taking product is realized, the safety coefficient is improved, the work condition of a production line can be monitored by an isolating explosion-proof wall window 5 while the isolation of an operator and an explosive pressing scene is ensured, potential safety hazards are eliminated and the assembly precision and efficiency are improved. The automatic assembly mechanism is suitable for assembly and production of perforating bullets in the petroleum industry.

Owner:严格集团股份有限公司

Anti-scaling multi-hydrogen retarded acid for highly argillaceous sandstone reservoir

The invention provides an anti-scaling multi-hydrogen retarded acid for a highly argillaceous sandstone reservoir. The retarded acid is prepared from the following raw materials by weight: 3 to 5 parts of hydrochloric acid, 3 to 5 parts of amino trimethylene phosphonic acid, 3.5 to 6 parts of ammonium bifluoride, 1 to 2.2 parts of a corrosion inhibitor, 0.5 to 1 part of a ferric ion stabilizing agent, 0.2 to 1 part of a clay stabilizing agent, 0.3 to 1 part of a de-emulsifier, 0.2 to 1 part of a mutual solvent and 78 to 87 parts of water. The anti-scaling multi-hydrogen retarded acid is used in the petroleum industry to control a reaction speed of hydrofluoric acid and clay so as to realize deep acidization of the highly argillaceous reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com