Patents

Literature

201results about How to "Reduce failure frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

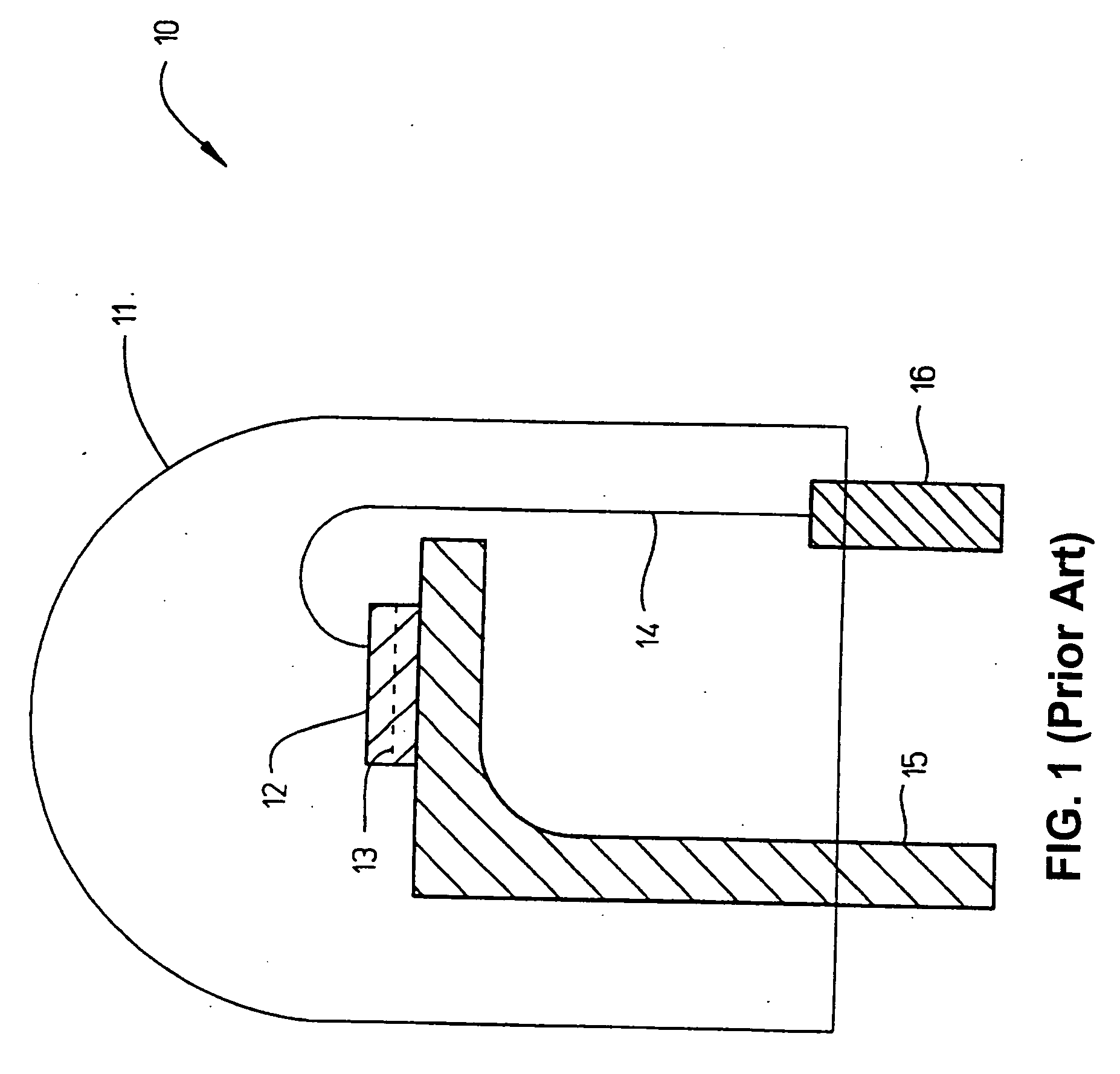

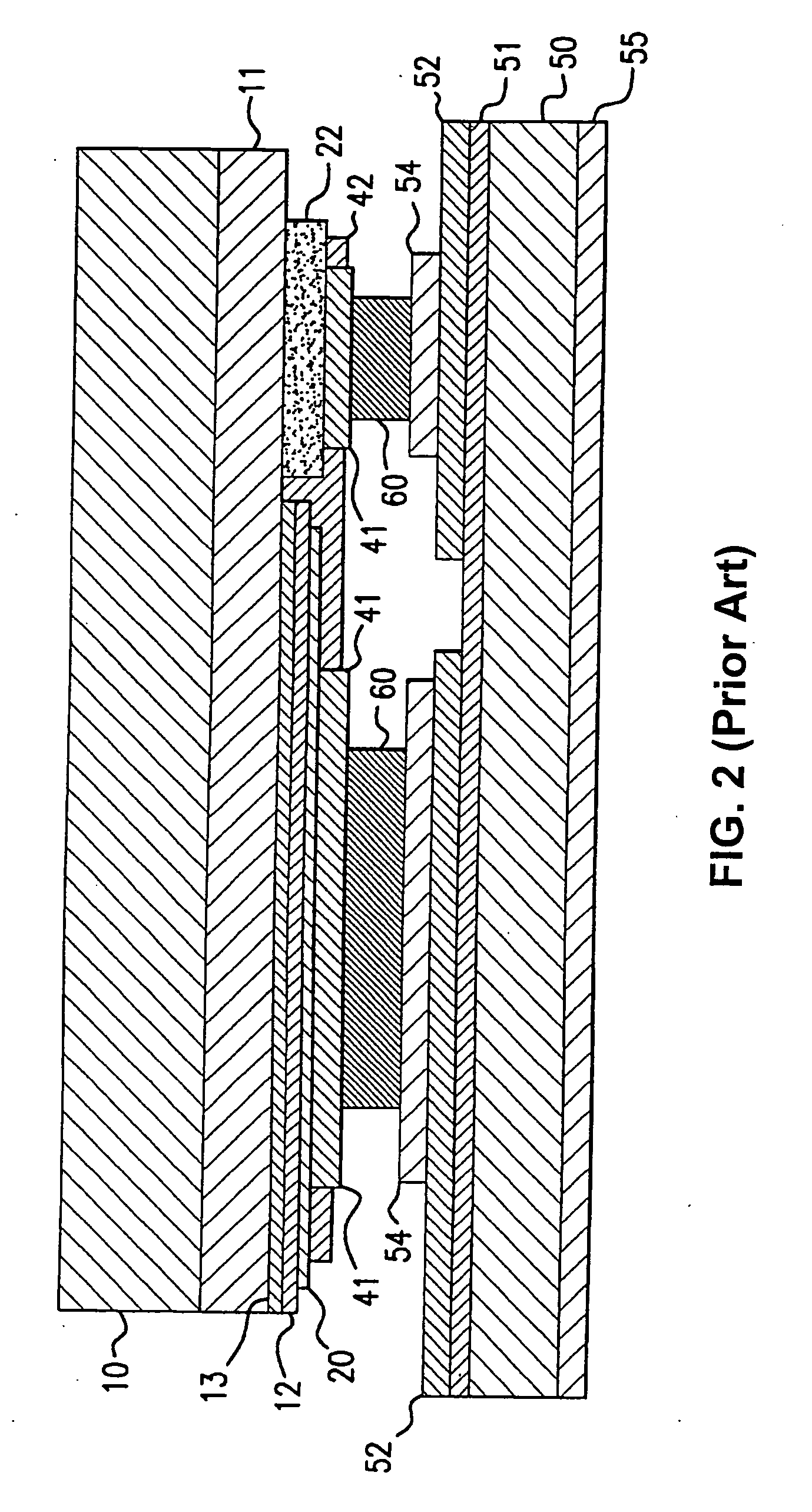

Interconnects for semiconductor light emitting devices

ActiveUS7348212B2Thermal and electrical resistanceImprove equipment reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceSemiconductor

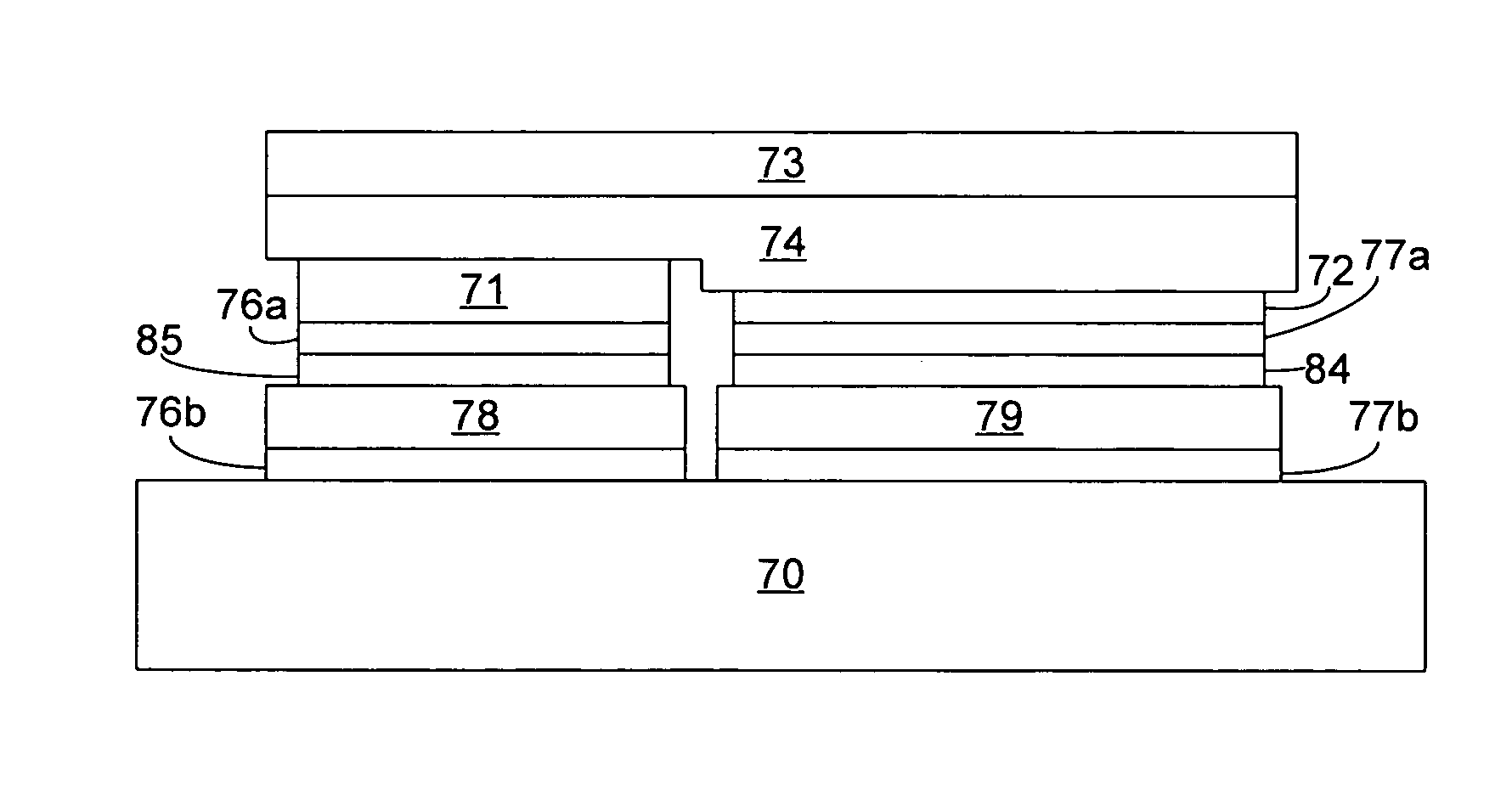

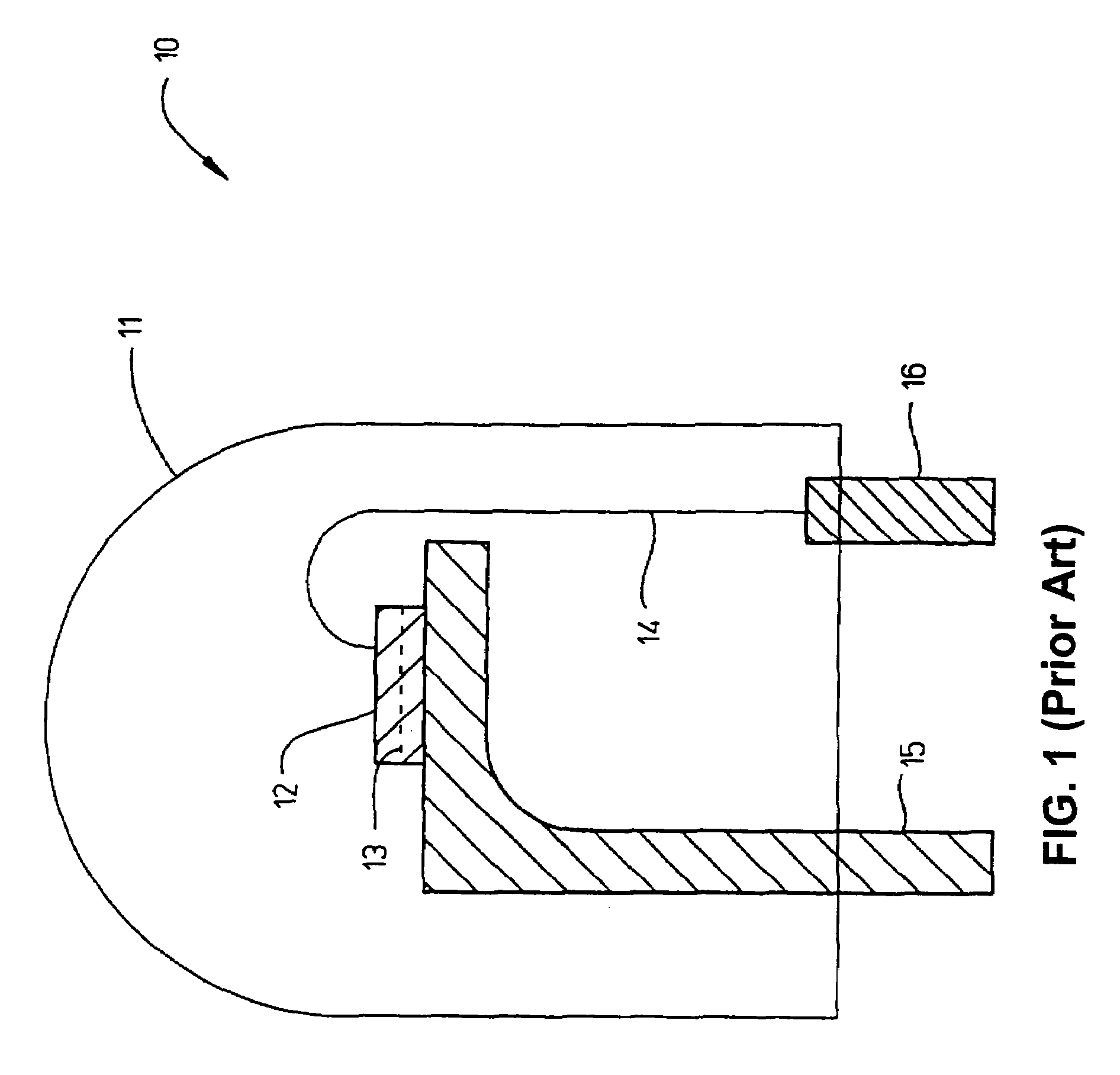

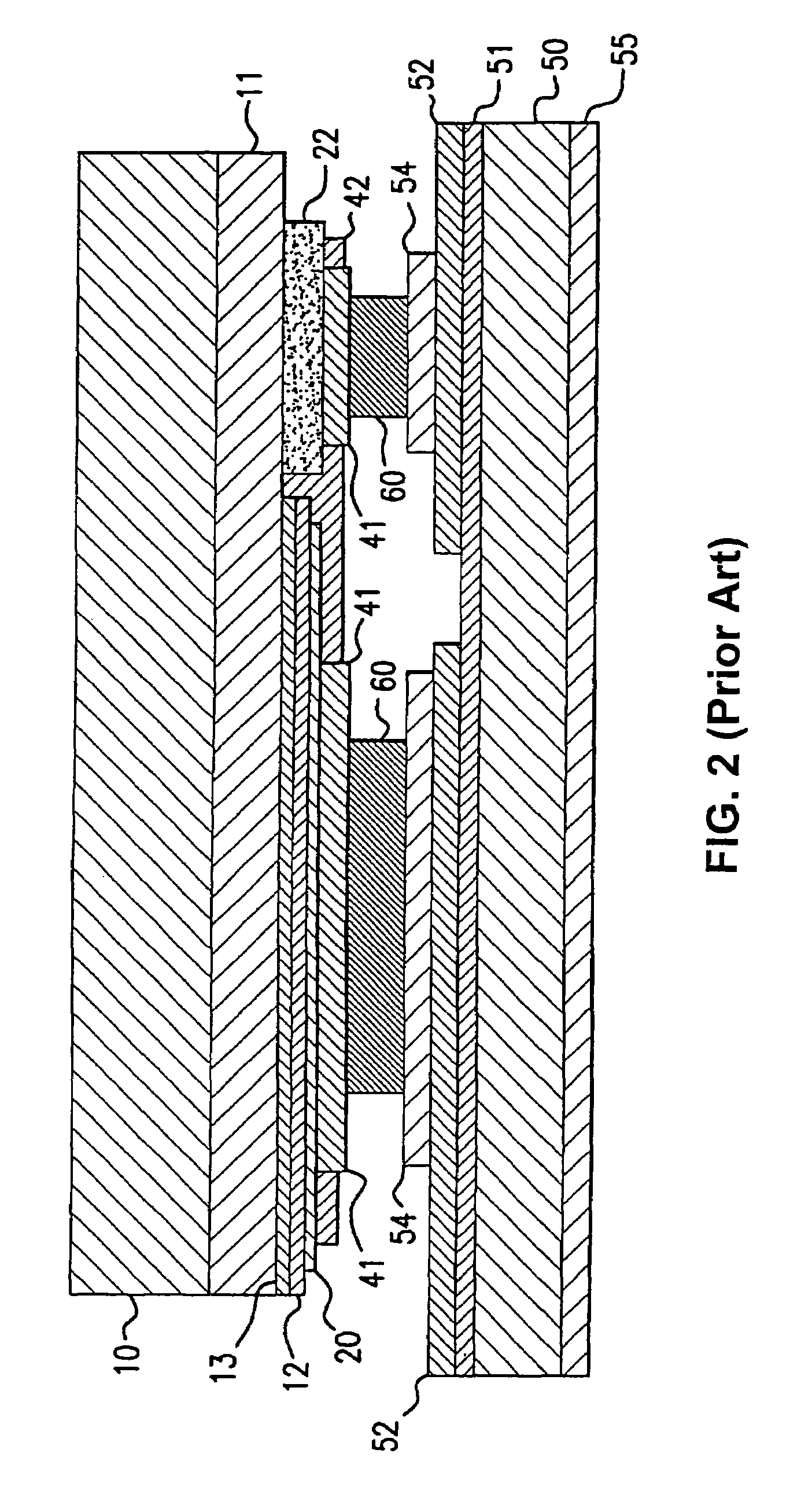

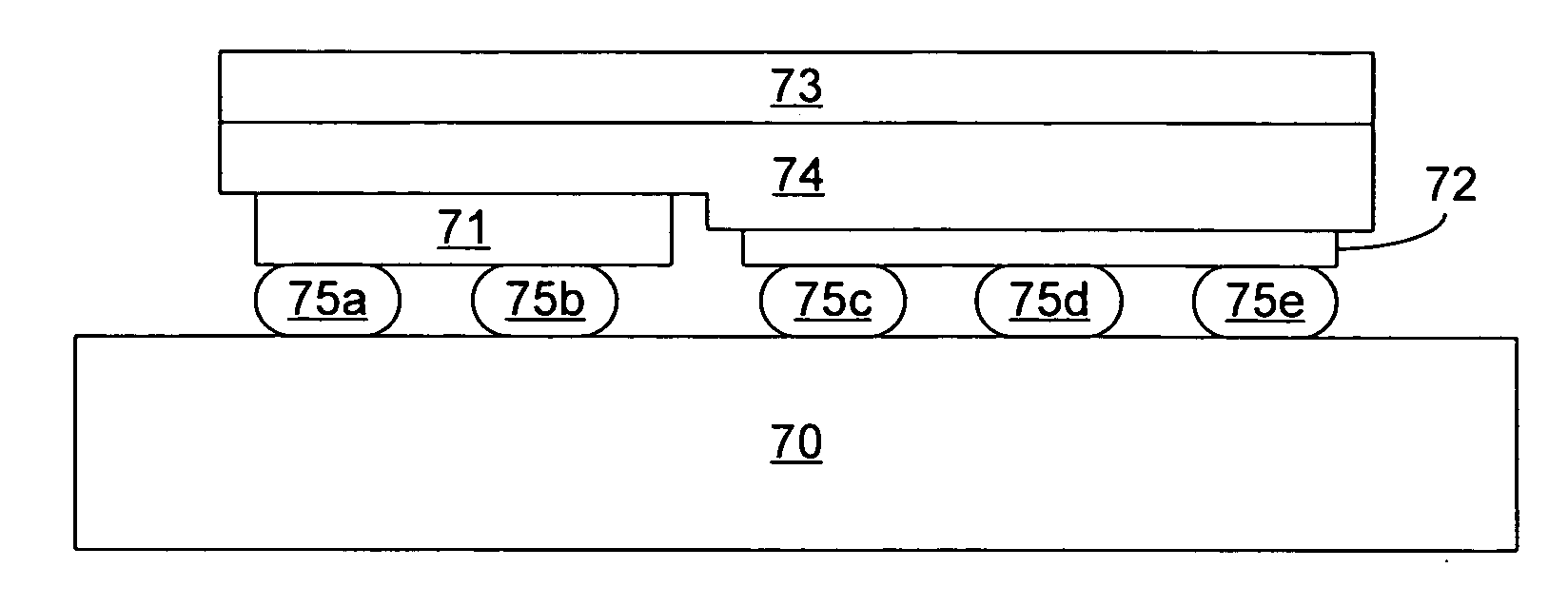

A semiconductor light emitting device including a light emitting layer disposed between an n-type region and a p-type region and contacts electrically connected to the n-type region and the p-type region is connected to a mount. A metal layer arbitrarily patterned to cover at least 20% of the area of the semiconductor light emitting device is plated on either a metal layer formed on the mount or a metal layer formed on one of the contacts. The plated metal layer may replace other known interconnecting techniques such as stud bumps. The semiconductor light emitting device is physically connected to the mount by causing interdiffusion between the contact surfaces of the metal layers. In some embodiments, a layer of solder is formed over the plated metal layer, and then the semiconductor light emitting device is physically connected to the mount by heating the solder.

Owner:LUMILEDS

Interconnects for semiconductor light emitting devices

ActiveUS20070057271A1Low thermal and electrical resistanceImprove reliability of deviceSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsElectroplating

A semiconductor light emitting device including a light emitting layer disposed between an n-type region and a p-type region and contacts electrically connected to the n-type region and the p-type region is connected to a mount. A metal layer arbitrarily patterned to cover at least 20% of the area of the semiconductor light emitting device is plated on either a metal layer formed on the mount or a metal layer formed on one of the contacts. The plated metal layer may replace other known interconnecting techniques such as stud bumps. The semiconductor light emitting device is physically connected to the mount by causing interdiffusion between the contact surfaces of the metal layers. In some embodiments, a layer of solder is formed over the plated metal layer, and then the semiconductor light emitting device is physically connected to the mount by heating the solder.

Owner:LUMILEDS

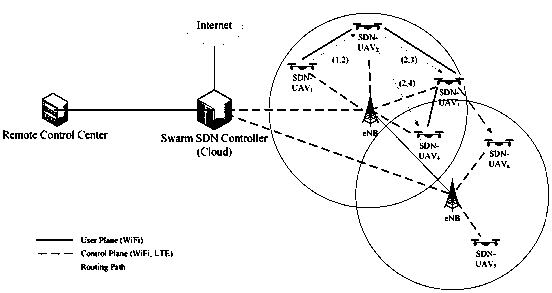

Unmanned aerial vehicle ad hoc network routing method based on link stability

InactiveCN105871717AReduce the impactReduce failure frequencyNetwork topologiesTransmission monitoringActive timeBackup path

The invention discloses an unmanned aerial vehicle ad hoc network routing method based on link stability. The link stability is jointly determined by unmanned aerial vehicle node relative speed, single-hop link transmission delay, single-hop link signal intensity and link active time. On the basis that a link life cycle is used as a routing selection restriction parameter, the effect of rapid change of unmanned aerial vehicle cluster topology on routing can be reduced to a large extent, the routing failure frequency can be reduced, and the routing stability can be improved. Meanwhile, as a routing core algorithm is deployed in a centralized server, the operation performance is higher than that of traditional distributed routing operation. A cluster controller maintains all link states of a cluster, the backup path can be selected rapidly in case of a routing failure event, and the requirement for rapid response of routing is met.

Owner:HANGZHOU DIANZI UNIV

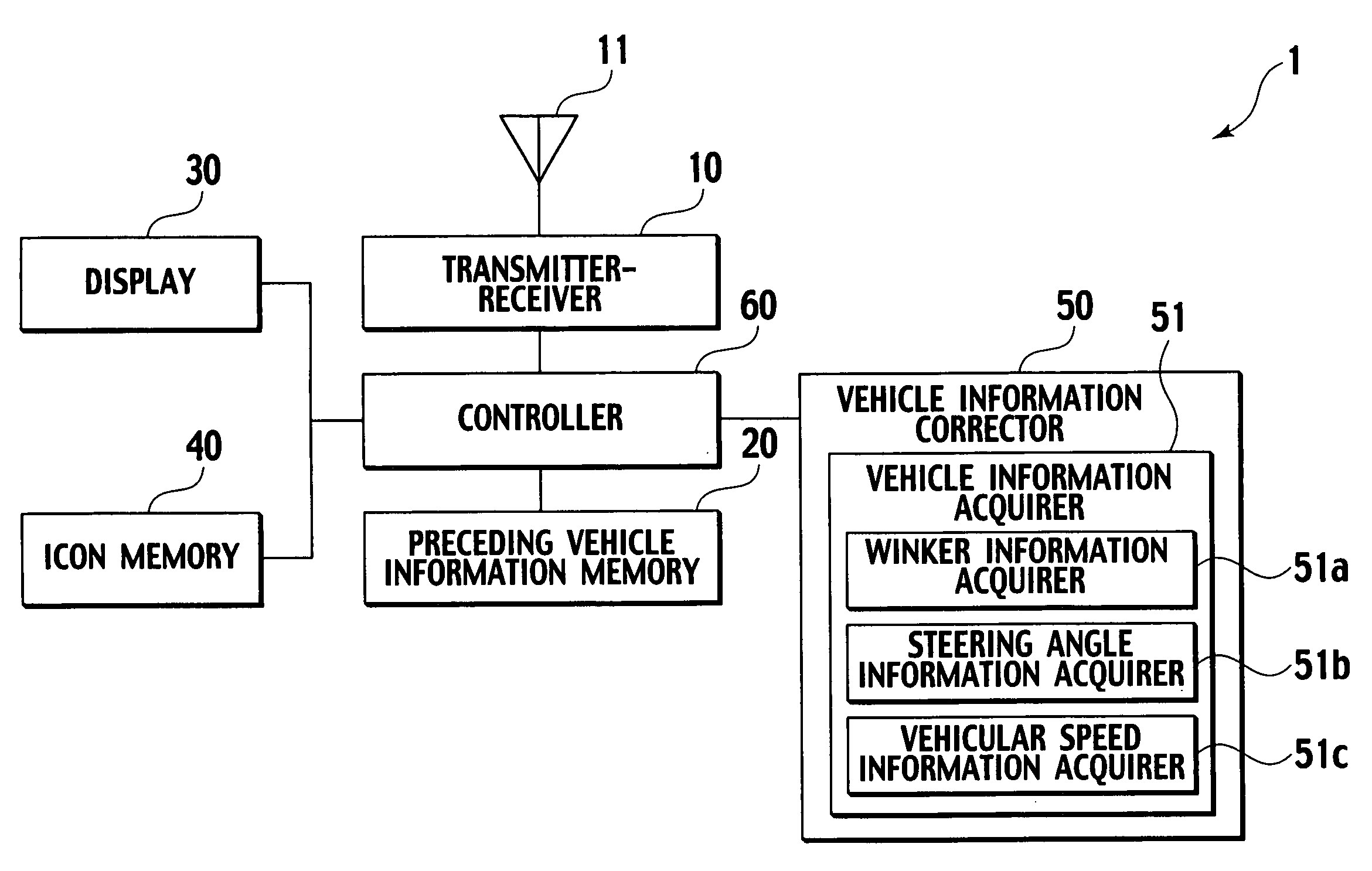

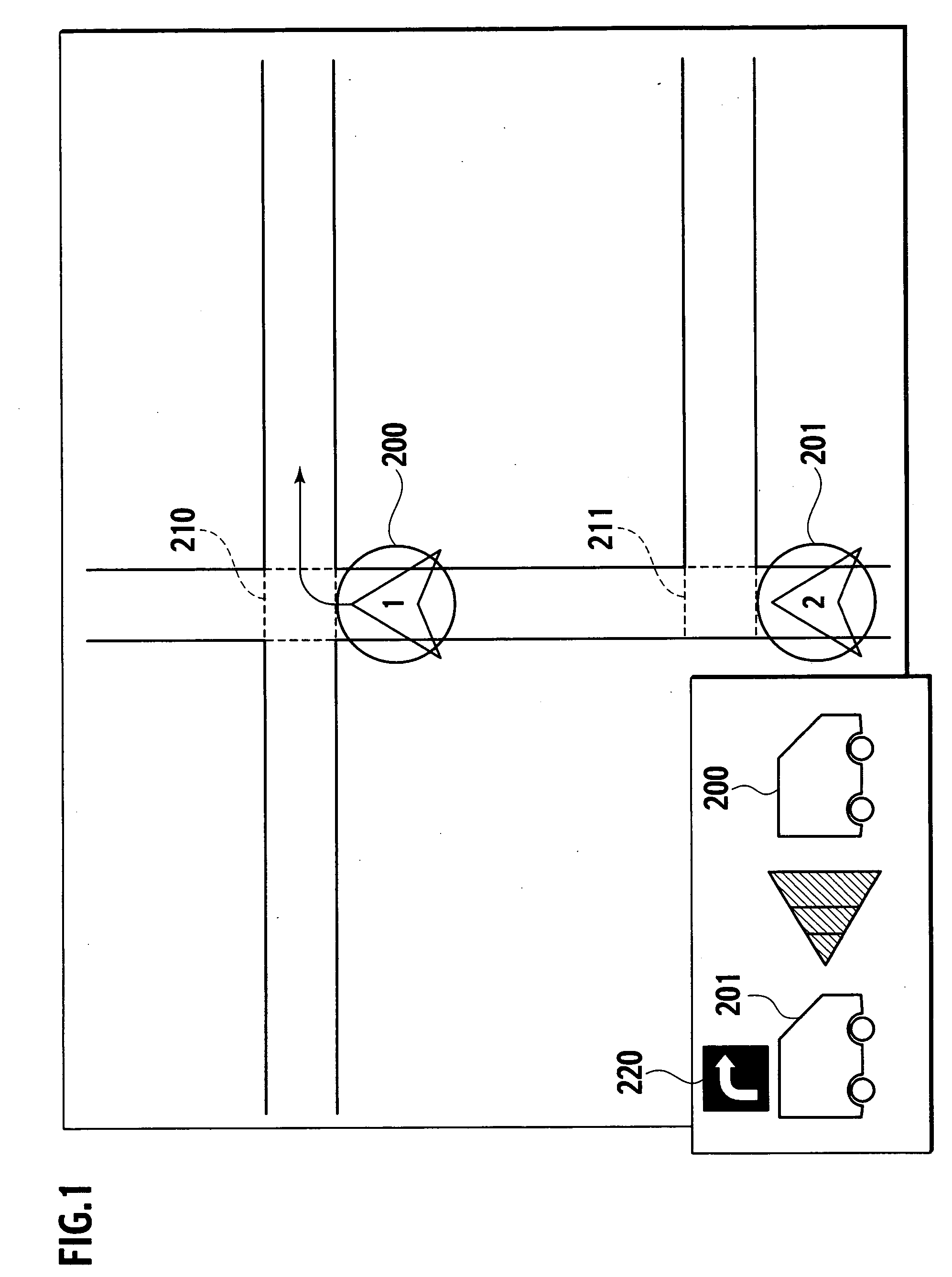

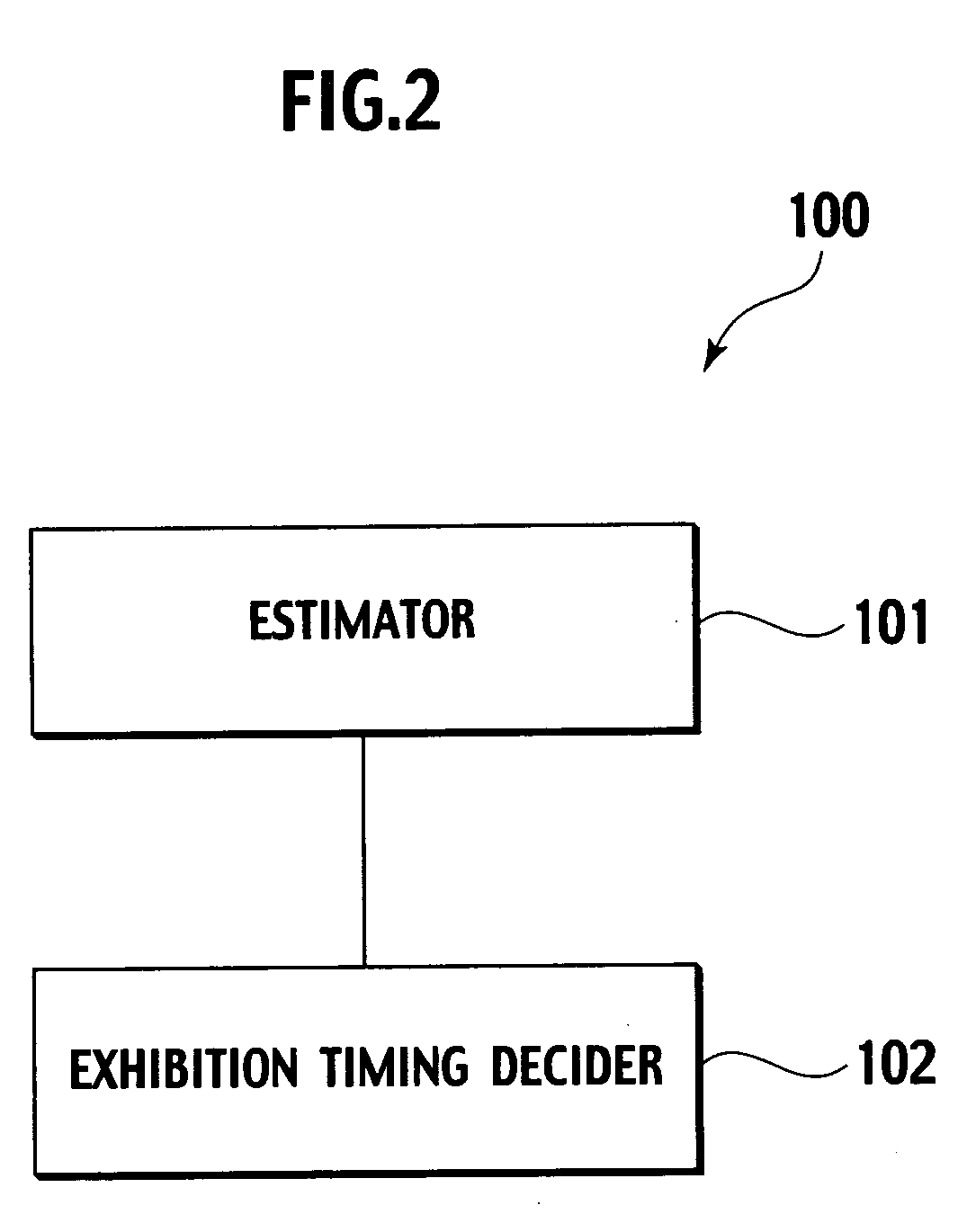

Vehicle information processing system and method

InactiveUS20060173611A1Reduce failure frequencyAnalogue computers for vehiclesInstruments for road network navigationEngineeringInformation handling system

A vehicle information processing system 100 conducts wireless communications between a preceding vehicle 200 and a succeeding vehicle 201, and exhibits information on a winker operation of the preceding vehicle 200 to a driver of the succeeding vehicle 201, and includes vehicle-mounted apparatuses 1 in the preceding and succeeding vehicles, of which one 1 in the preceding vehicle 200 wirelessly transmits information on a winker operation of the preceding vehicle, and the other 1 in the succeed vehicle 201 receives the wirelessly transmitted information on the winker state, and exhibits same to a driver of the succeeding vehicle 201, while the apparatus 1 in the succeeding vehicle 201 estimates a relationship between the preceding vehicle 200 and the succeeding vehicle 201, judges whether an exhibition liming of the information on the winker state is to be hastened or delayed based on an estimation result, and exhibits the information on the winker state at the judged timing.

Owner:NISSAN MOTOR CO LTD

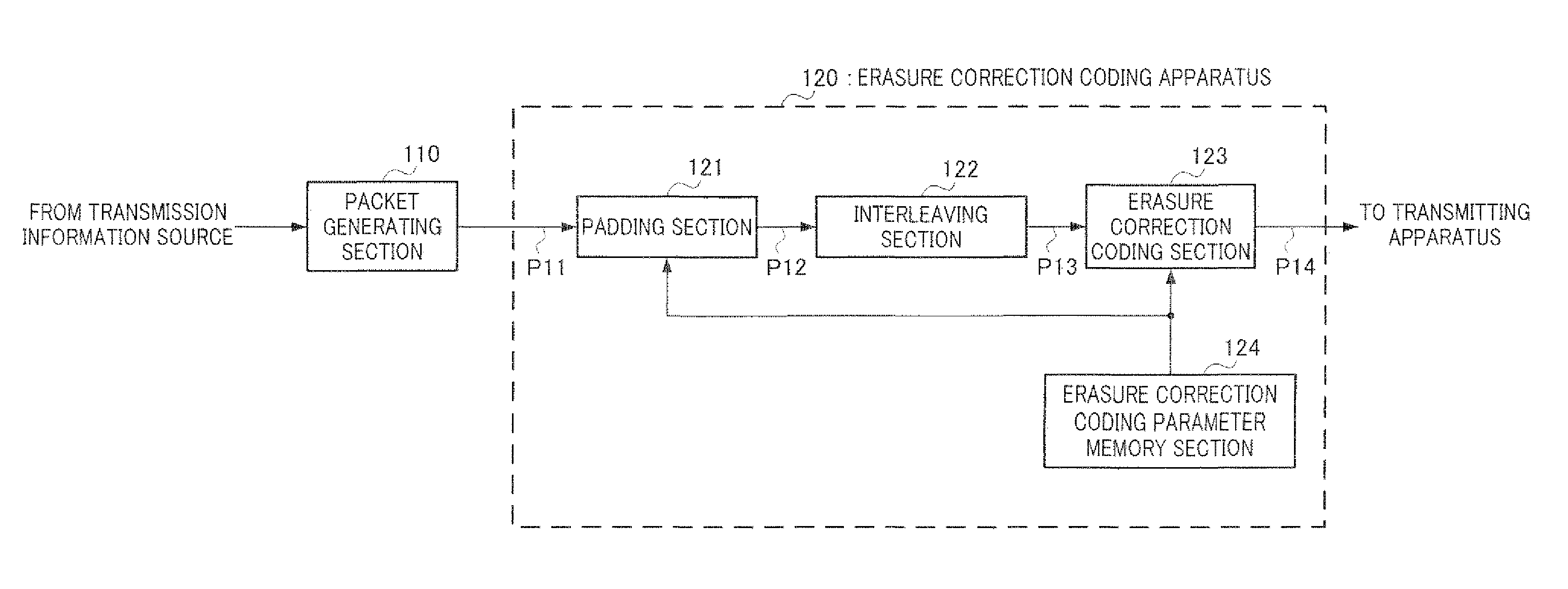

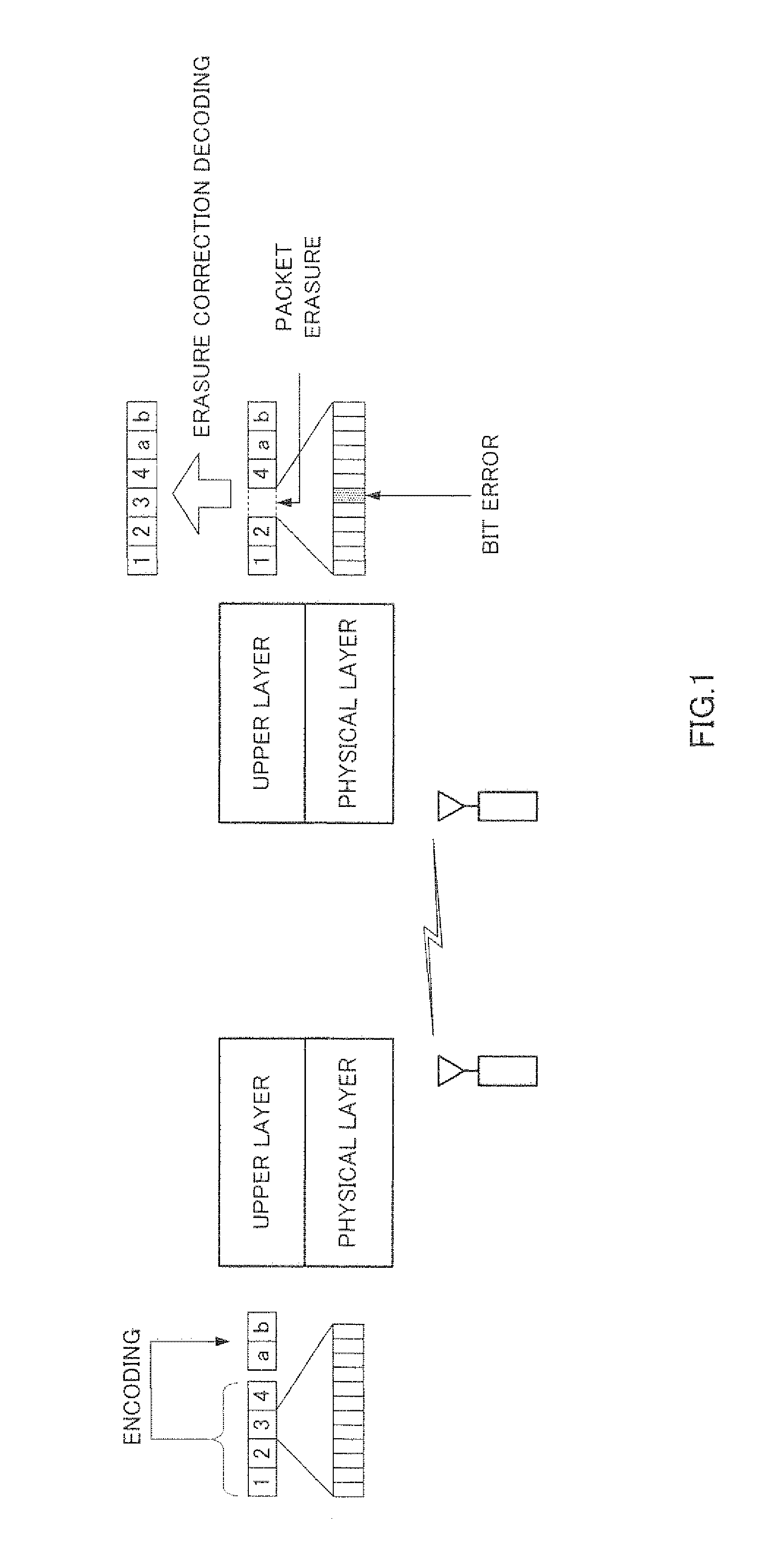

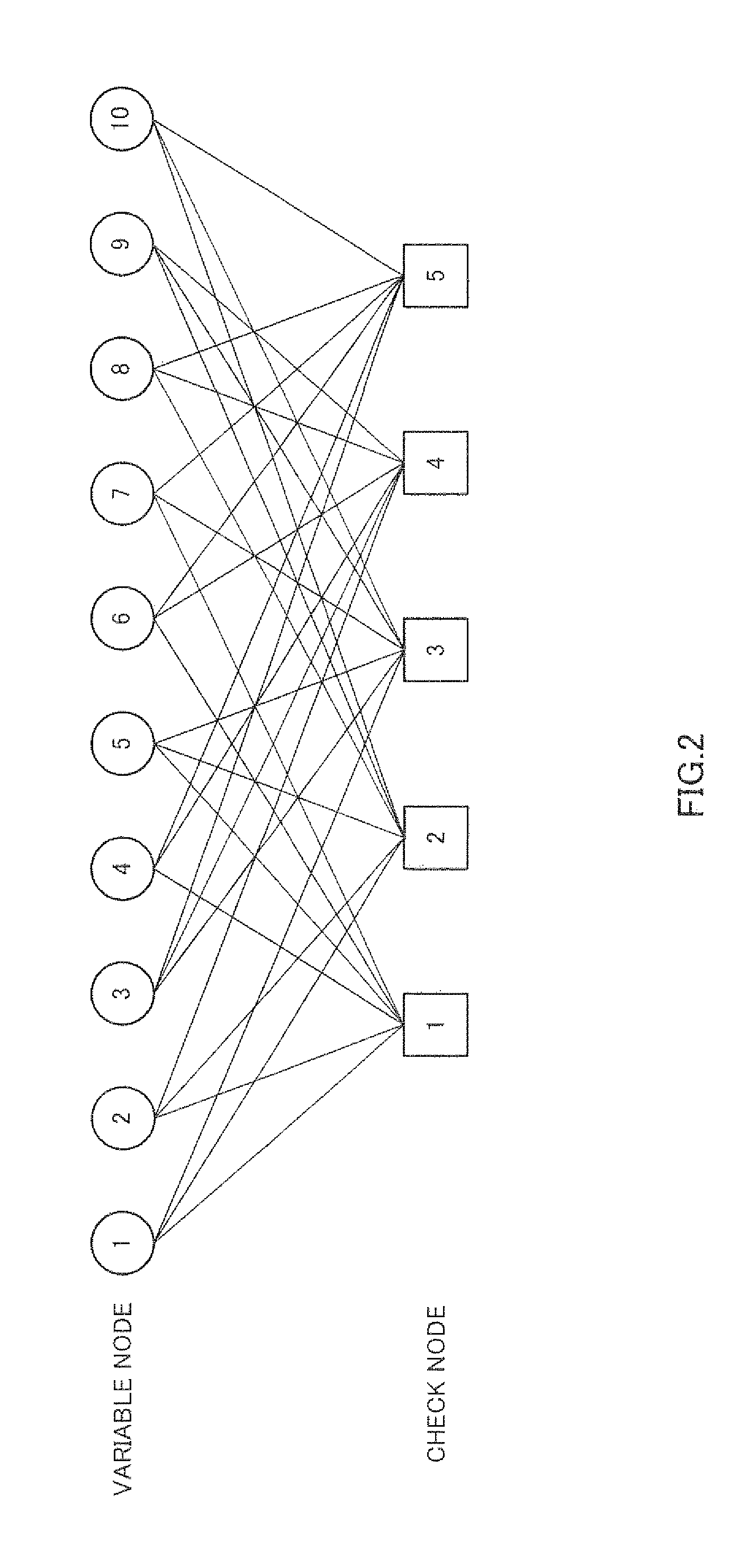

Encoding device and decoding device

ActiveUS8429503B2Reduce failure frequencyCode conversionError correction/detection using interleaving techniquesComputer hardwareLow density

Disclosed are an encoding device and a decoding device which can effectively reduce the decoding failure frequency in LDPC encoding / decoding. A loss correction encoding device (120) includes a padding unit (121) which adds a padding packet to an information packet sequence; an interleave unit (122) which rearranges the padding packet and the information packet; and a loss correction encoding unit (123) which performs loss correction encoding for the packet string after the interleave. The interleave unit (122) rearranges the padding packet and the information packet according to variable nodes constituting a minimum stopping set of the inspection matrix which defines a low-density parity inspection code. The interleave unit (122) uses such a rearrangement pattern that avoids a loss correction failure by the minimum stopping set of the LDPC inspection matrix so as to reduce the probability of the loss correction failure by the minimum stopping set.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

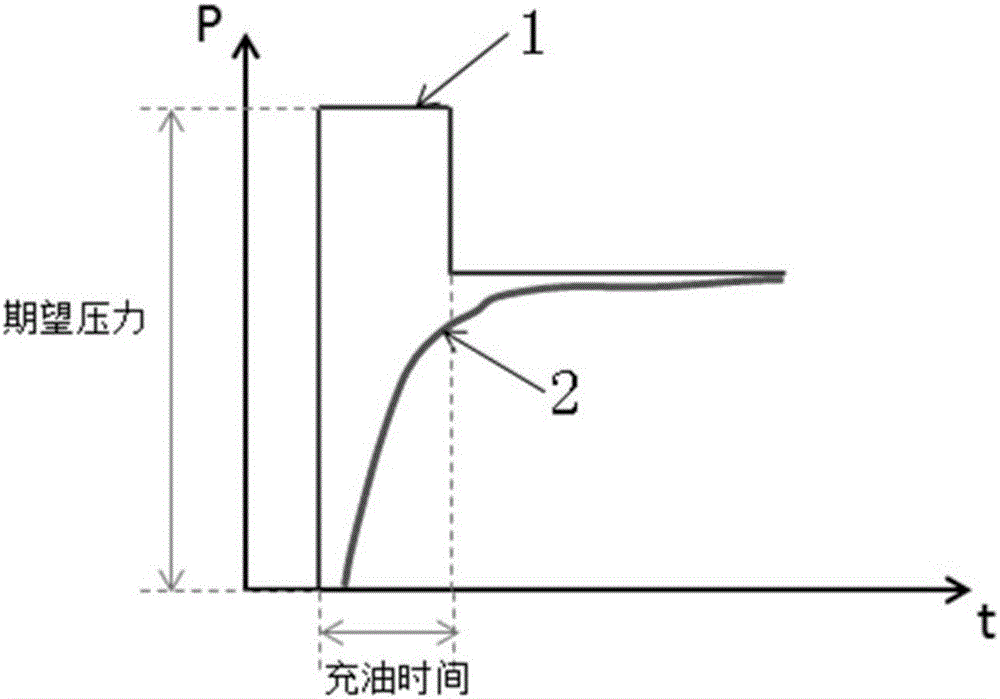

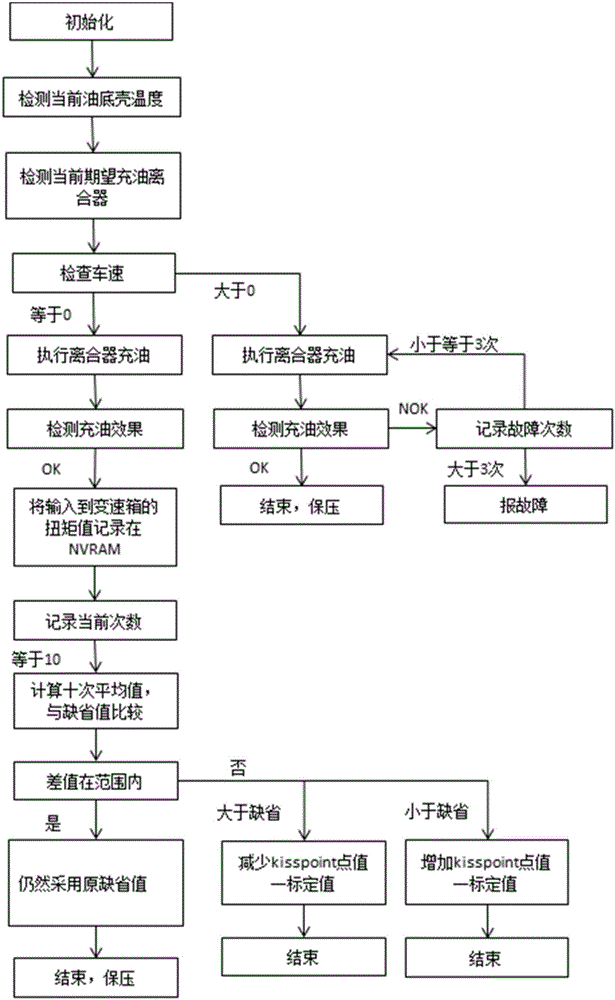

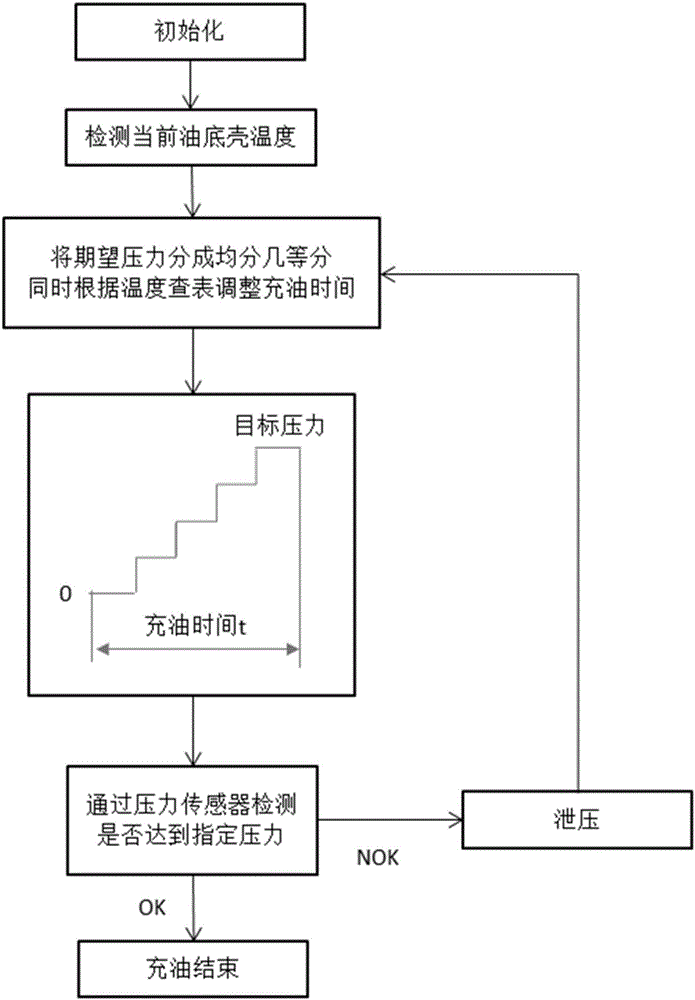

Oil charging and semi-linkage-point self-learning method of double-clutch automatic transmission

ActiveCN106224539AReduce biasImprove adaptabilityGearing controlFluid gearingsOil pressureElectromagnetic valve

The invention relates to an oil charging and semi-linkage-point self-learning method of a double-clutch automatic transmission. After an oil charging control module receives an oil charging command, the oil charging control module receives a present oil temperature detected by a sensor, and divides the oil charging pressure of a clutch into set phases according to the present oil temperature; and then, the oil charging control of the clutch is finished by an oil pressure step ascending mode. The method adopts an interpolation segmented ascending step oil charging method to reduce the clutch pressure impact problem and to prolong the service life of a hydraulic actuation unit; as the oil charging pressure is equally divided, the moving amplitude of an electromagnetic valve is relatively lower, the blockage is not easy to generate, the service life is prolonged, and the fault generation frequency is reduced; and meanwhile, the method is higher in response speed and precision.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

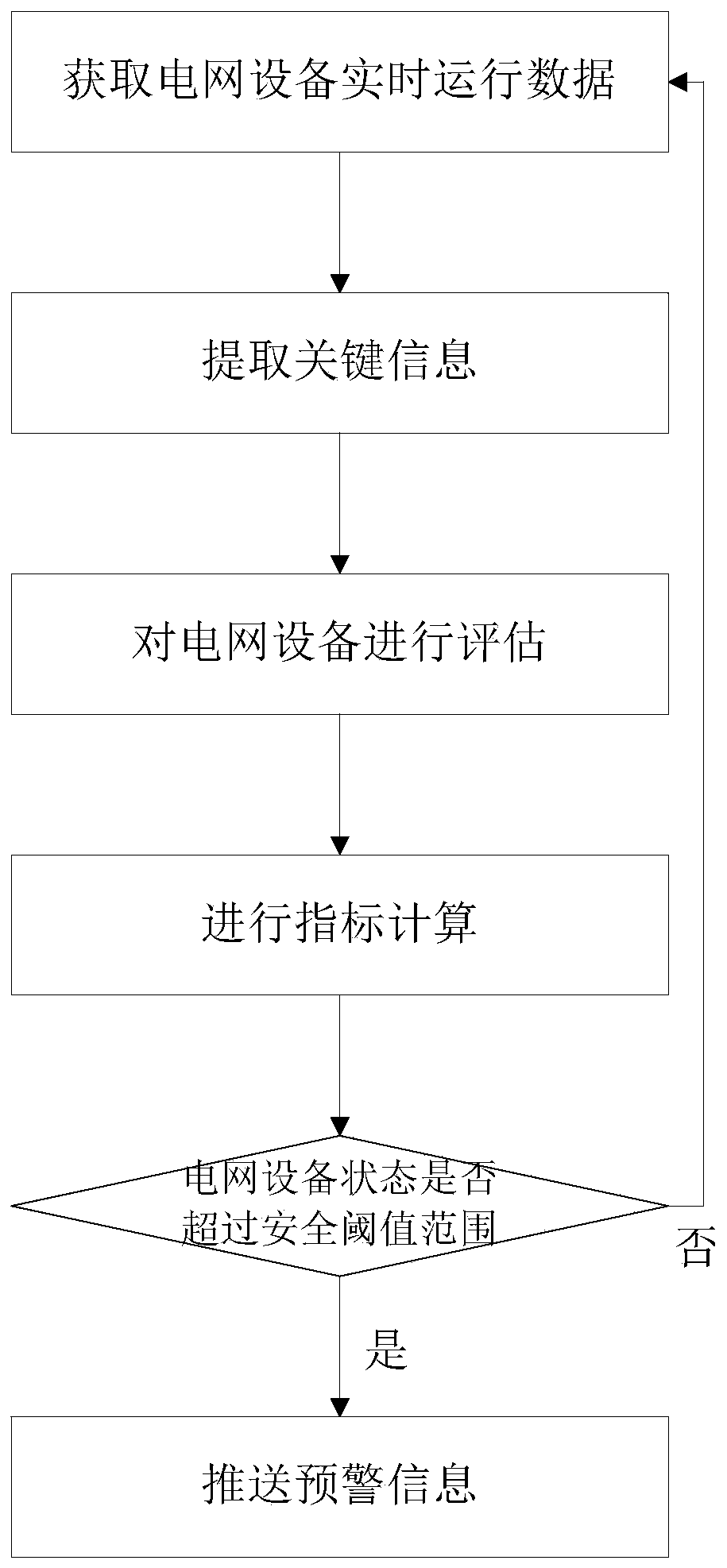

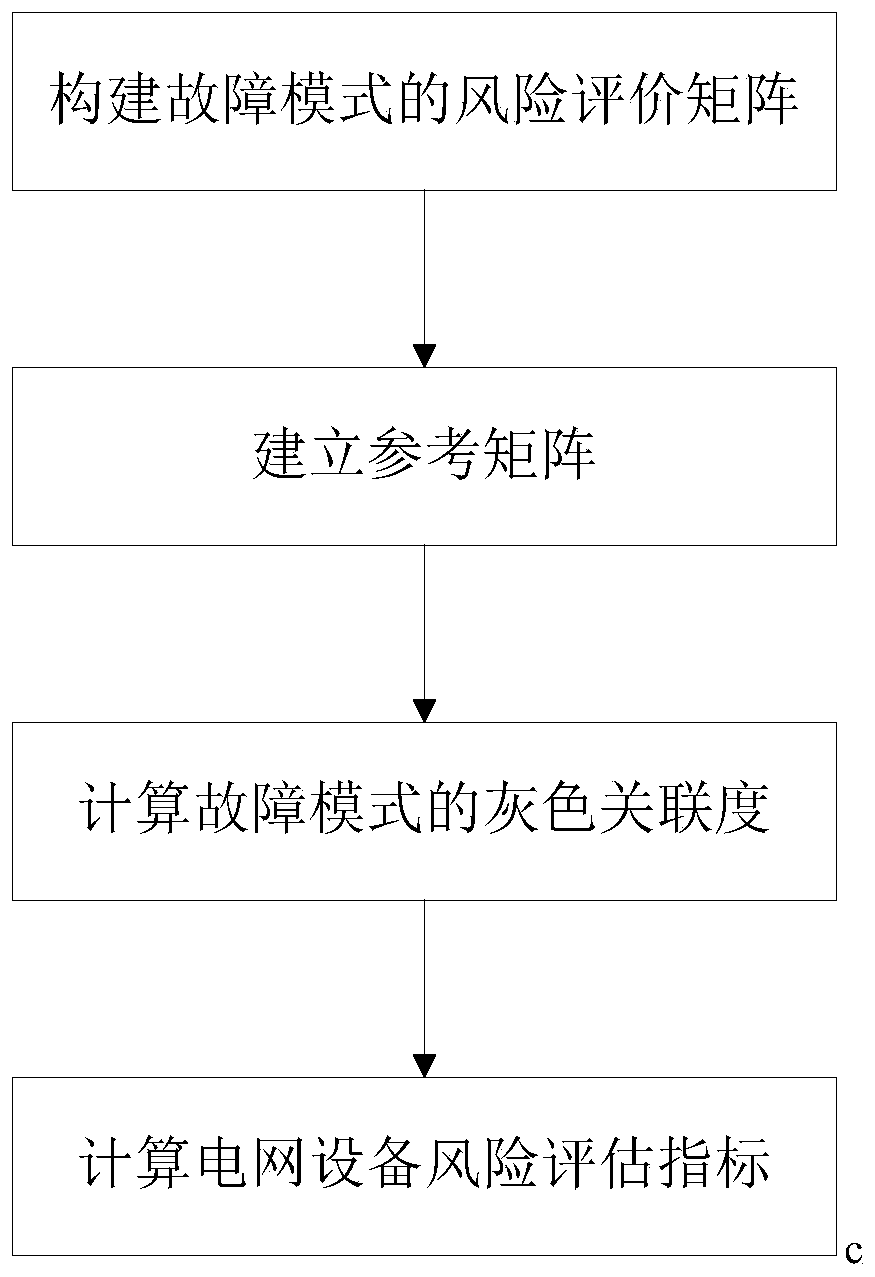

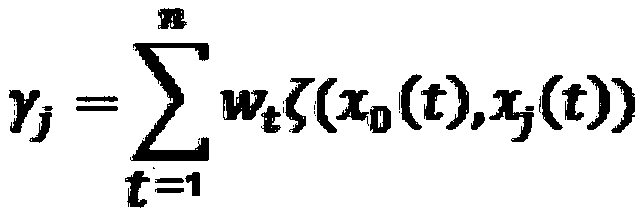

Power grid equipment risk perception method

InactiveCN110210701AImprove management levelSolve problems that cannot be effectively analyzedResourcesReal-time dataPower grid

The invention discloses a power grid equipment risk perception method, which comprises the steps of acquiring real-time operation data of power grid equipment, extracting key information, evaluating the power grid equipment, carrying out index calculation, judging whether the state of the power grid equipment exceeds a set safety threshold range or not, and pushing early warning information when the state of the power grid equipment exceeds the set safety threshold range. According to the method, by obtaining the real-time operation data of the power grid equipment, efficient data fusion is carried out on mass real-time data, key information is automatically analyzed, and the problem that monitoring personnel cannot effectively analyze a large amount of data is solved; and real-time sensing, intelligent alarming and equipment health state evaluation are carried out on the power grid equipment, so that the power grid equipment management level and the power grid safety situation supervision capability are effectively improved, the equipment fault frequency is reduced, and the operation safety is ensured.

Owner:GUIZHOU POWER GRID CO LTD

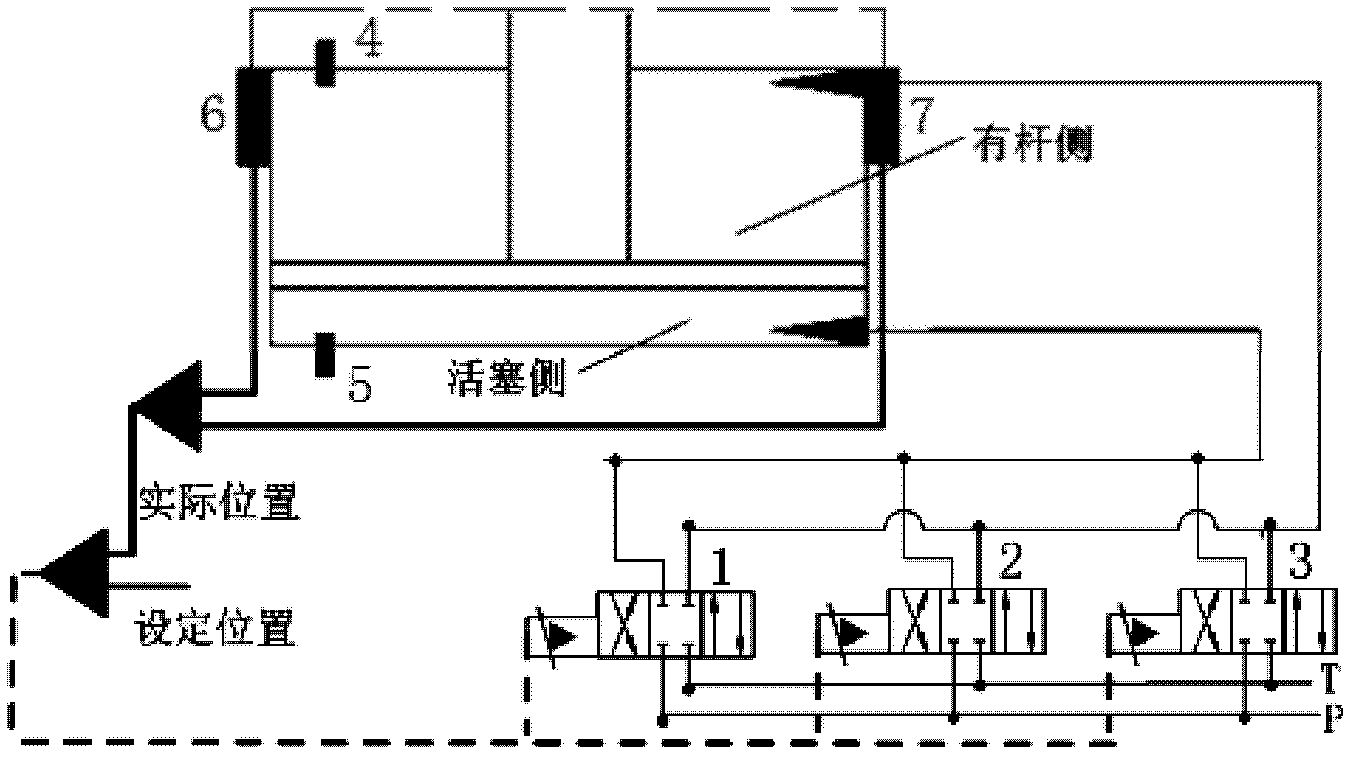

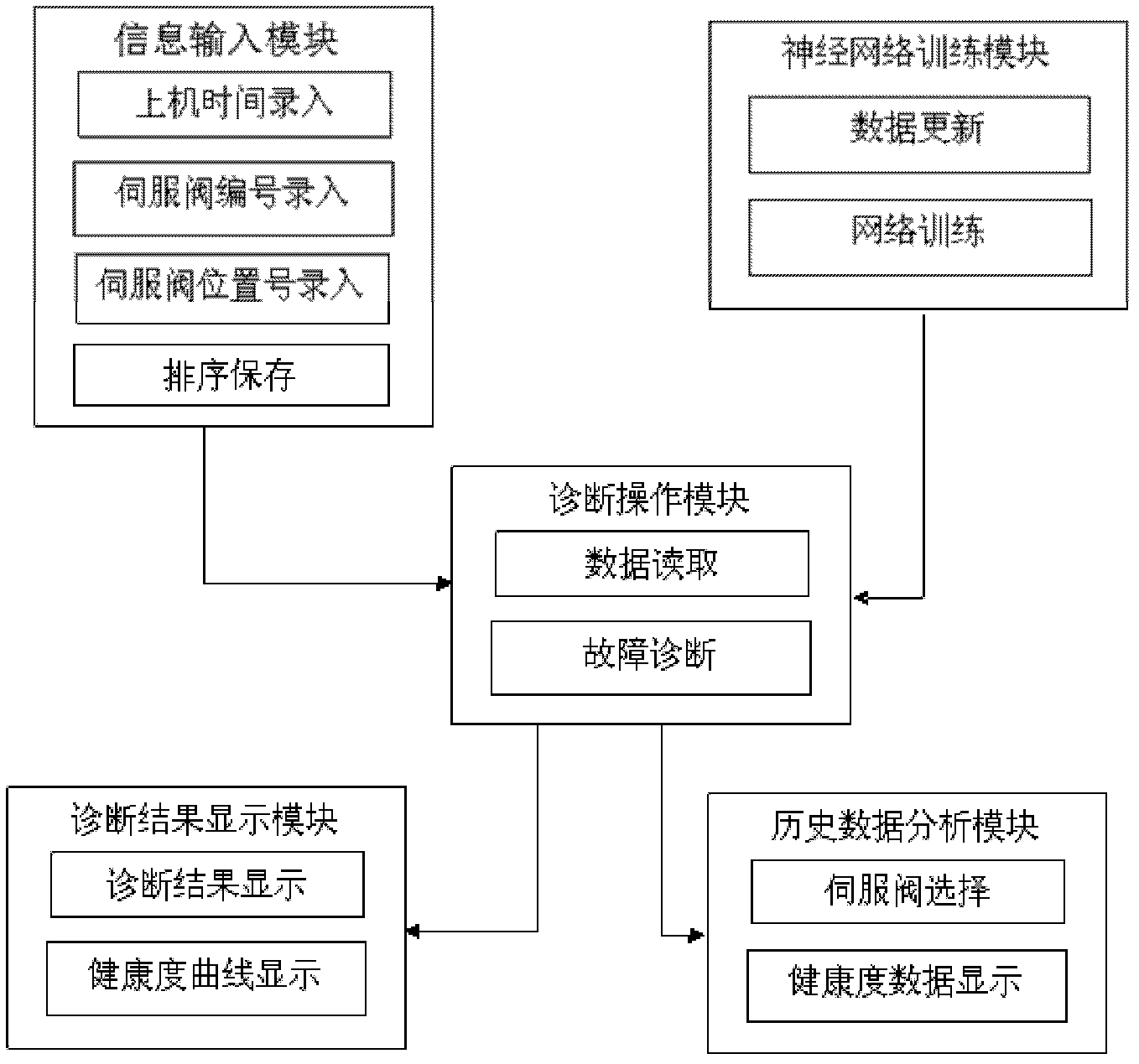

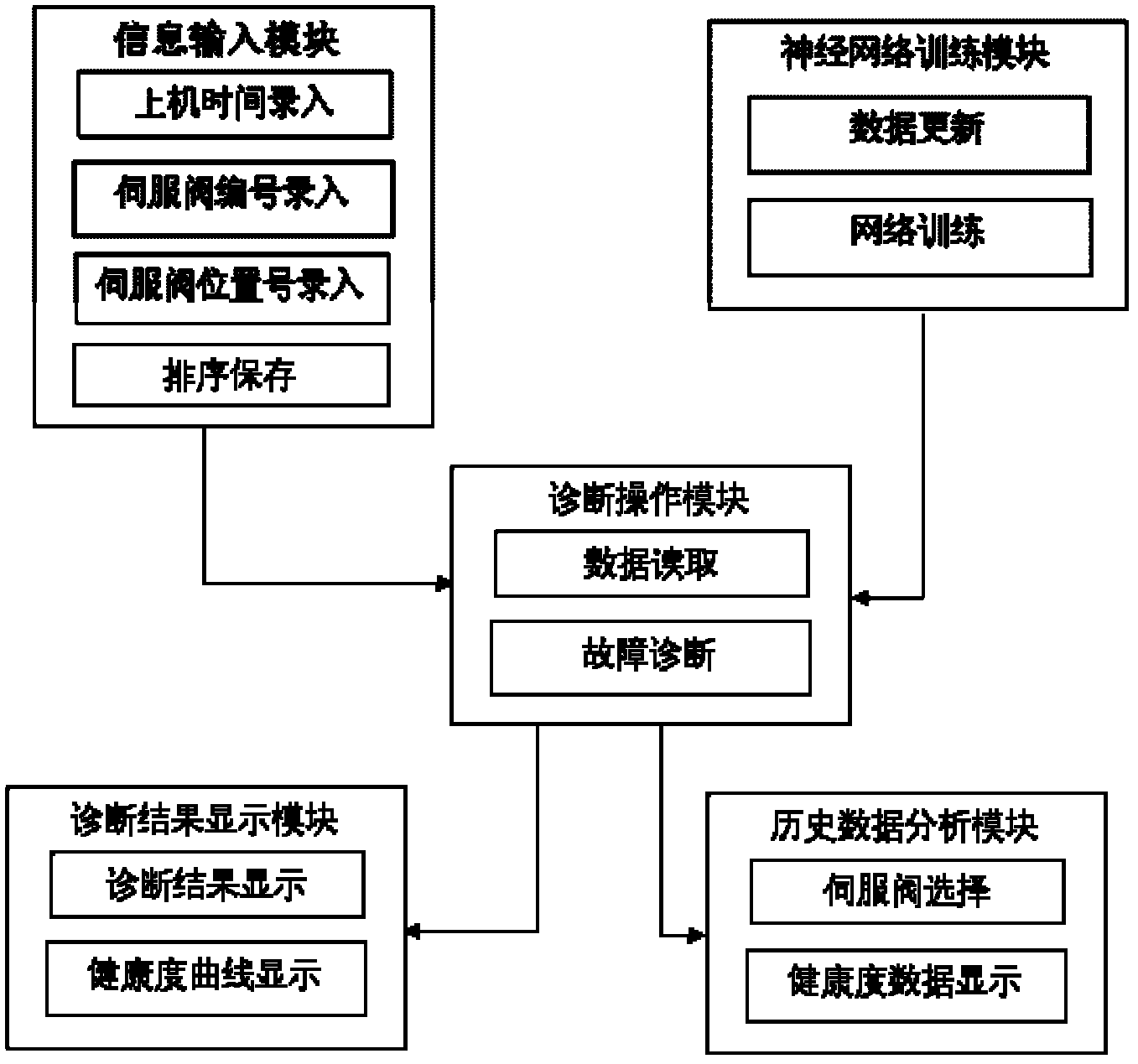

State monitoring and failure diagnosis system for thick plate mill AGC servo valve

InactiveCN102628738AEnsure safetyReduce failure frequencyMachine part testingNeural learning methodsThick plateRelevant information

The invention relates to a state monitoring and failure diagnosis system for a thick plate mill AGC servo valve. The system comprises a diagnosis operation module, a diagnosis result display module, an information input module, a historical data analysis module and a neural network training module, wherein the diagnosis operation module reads the text file to be tested, performs diagnosis and transmits the diagnosis result to the diagnosis result display module; the diagnosis result comprises the health degree tendency of the servo valve and the current operation state represented by the health degree; the information input module inputs the information of a new valve when the mill exchanges the new servo valve; the neural network training module is used for training the data of the new servo valve and inputting the result into a knowledge base; and the historical data analysis module can check the related information such as the historical operation state and the like of the selected valve. The system has the functions of automatically diagnosing state failure and storing and checking historical data and provides real-time guarantee for finding system failure and exchanging the servo valve timely so as to reduce loss caused by equipment failure to the maximum degree.

Owner:SHANGHAI JIAO TONG UNIV

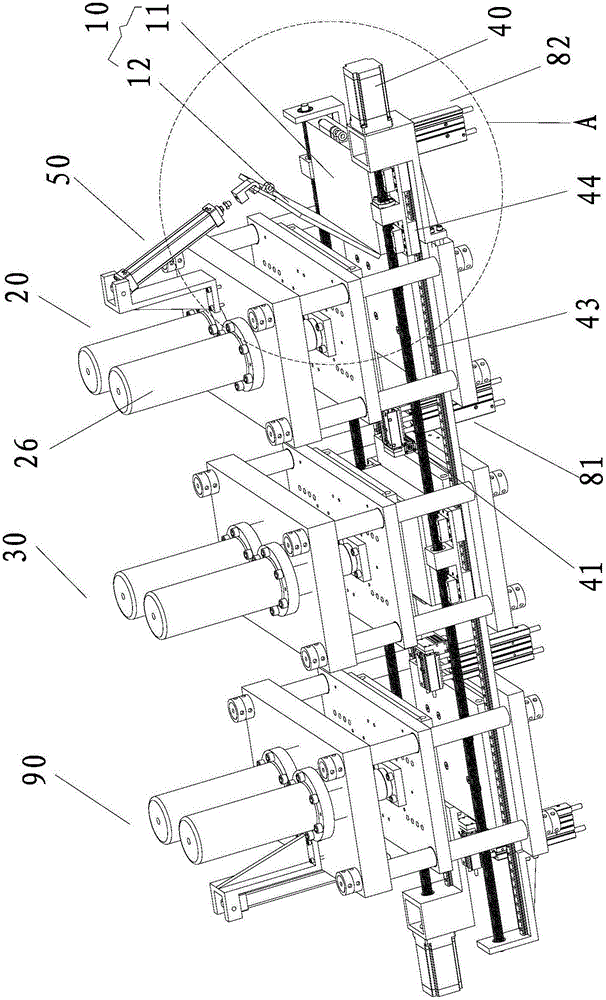

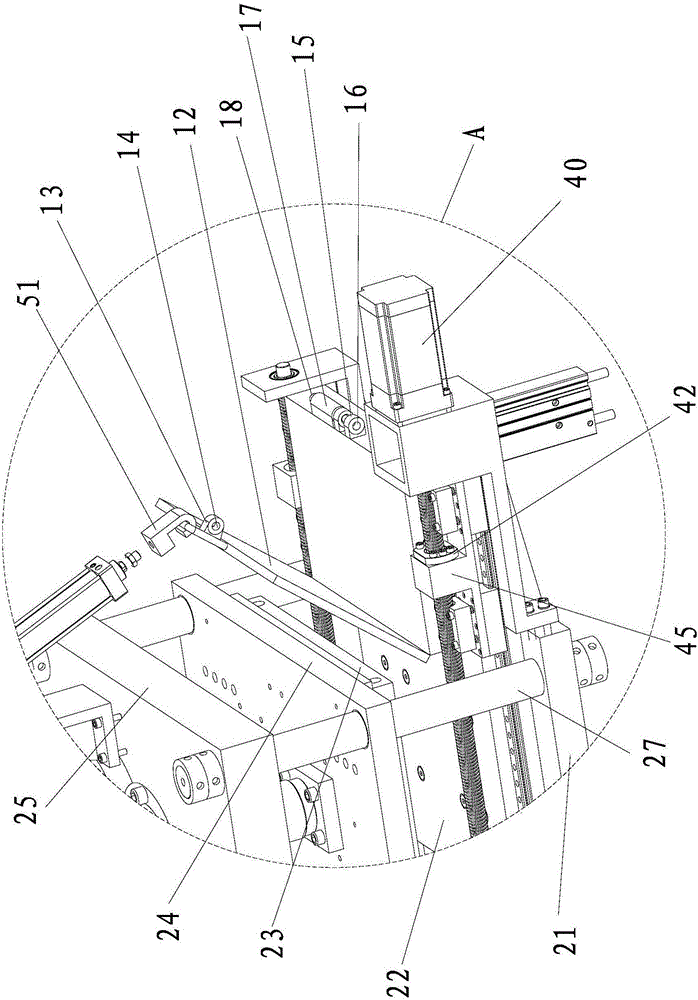

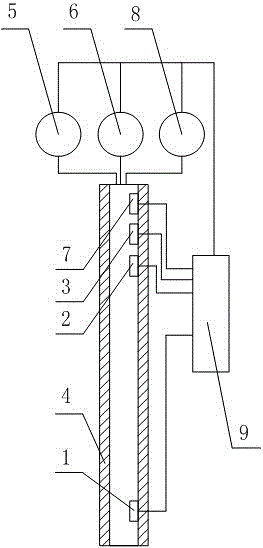

Secondary fast forming machine for sole material

The invention relates to a secondary fast forming machine for a sole material. The secondary fast forming machine for the sole material comprises a mold for containing the sole material, a heating mold station for heating the mold, and a first cooling mold station for cooling the mold and further comprises a second cooling mold station for cooling the mold; the first cooling mold station and the second cooling mold station are arranged on the two sides of the heating mold station; the mold comprises a first mold body corresponding to the first cooling mold station and a second mold body corresponding to the second cooling mold station; an automatic transferring mechanism is further included; the first mold body can be arranged on the automatic transferring mechanism in the manner that the first mold body moves between the first cooling mold station and the heating mold station; and the second mold body can be arranged on the automatic transferring mechanism in the manner that the second mold body moves between the second cooling mold station and the heating mold station. The forming machine can greatly improve the work environment of an operator, relieve the workloads of the operator and achieve automatic forming of soles; and meanwhile the energy utilizing rate is increased, and efficient, energy-saving, environment-friendly and reasonable energy transmission is achieved.

Owner:泉州大展机械有限公司

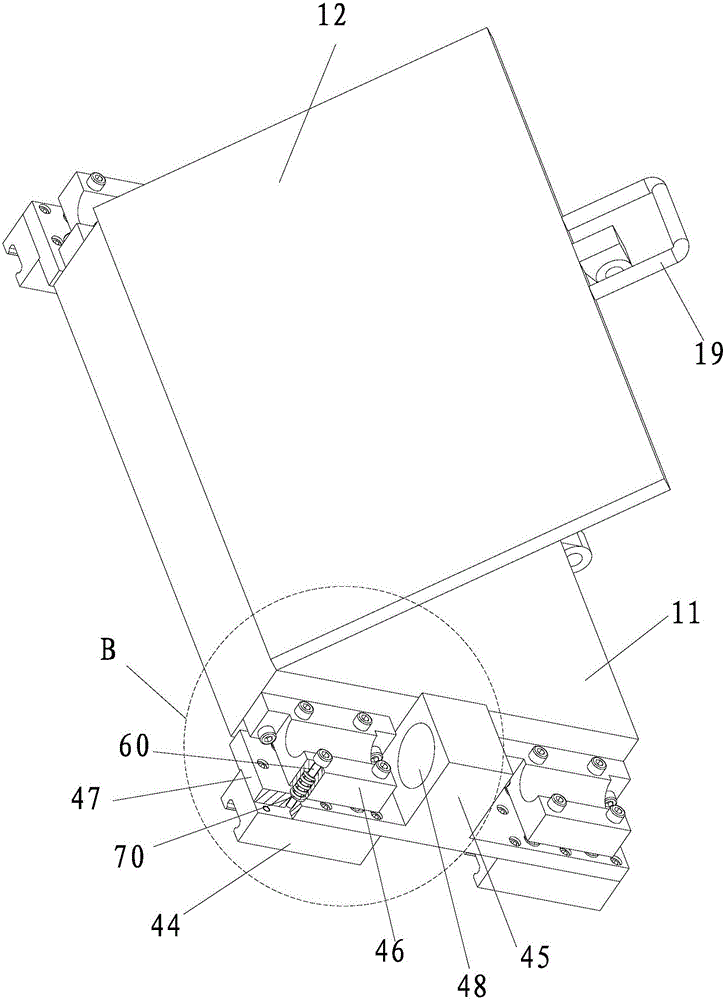

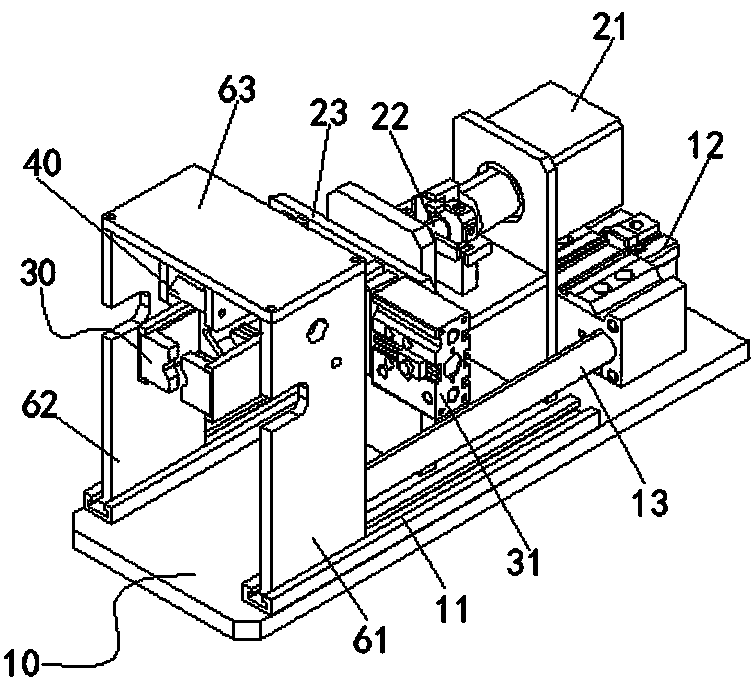

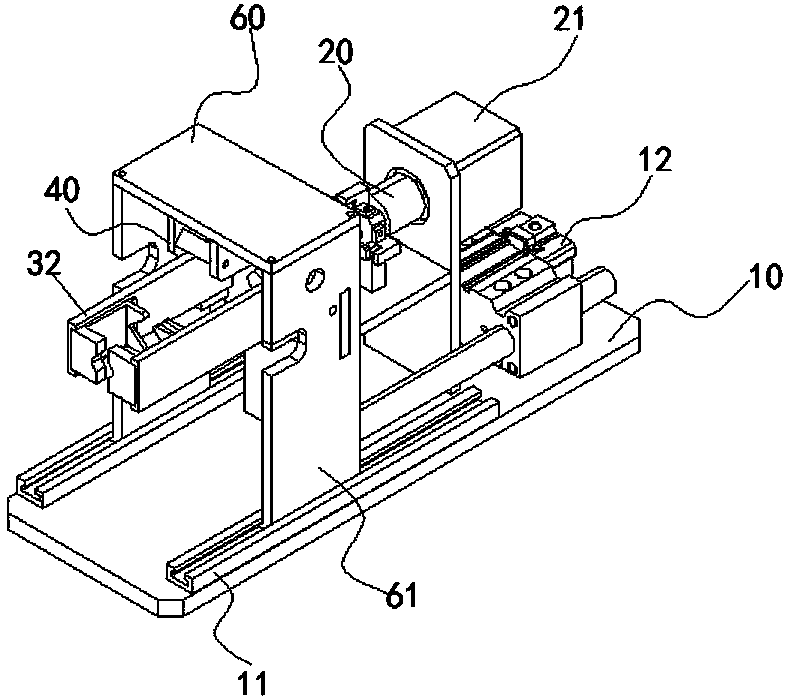

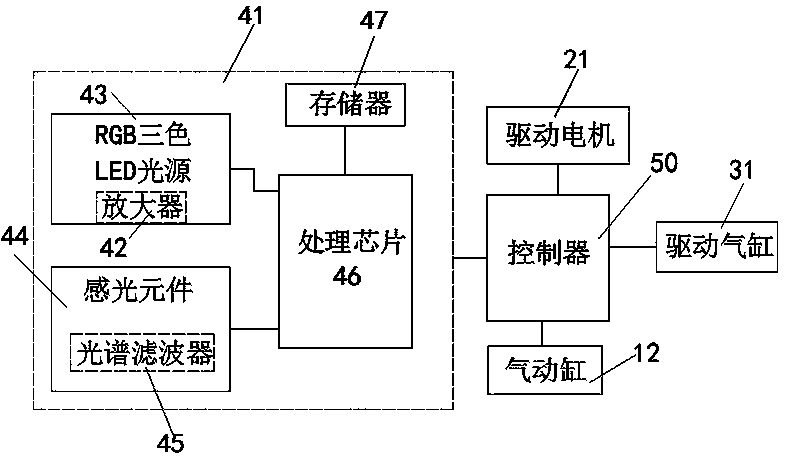

Three-core power line visual deconcentrating system detected by optical fiber sensor

ActiveCN103872551AAffect qualityAvoid inconvenienceLine/current collector detailsAudio power amplifierEngineering

A three-core power line visual deconcentrating system detected by an optical fiber sensor comprises a bottom plate, a rotating device, a line clamping device, a visual deconcentrator and a controller, wherein the rotating device, the line clamping device, the visual deconcentrator and the controller are installed on the bottom plate. The line clamping device is fixedly installed on the rotating device. The rotating device can drive the line clamping device to rotate. The rotating device comprises a driving motor for driving the line clamping device to rotate. An installation frame for installation of the visual deconcentrator is further arranged on the bottom plate, is movably installed on the bottom plate and can slide forward and backward relative to the line clamping device. The visual deconcentrator comprises an RGB color sensor which is electrically connected with the controller through an optical fiber. The RGB color senor comprises an RGB three-color LED light source with a built-in amplifier and a photosensitive element for receiving reflected light rays. The RGB color sensor is arranged over the portion, clamped by the line clamping device, of a power line. The three-core power line visual deconcentrating system detected by the optical fiber sensor is simple in structure, accurate and reliable in sampling and convenient to operate.

Owner:浙江海宁普赛自动化科技有限公司

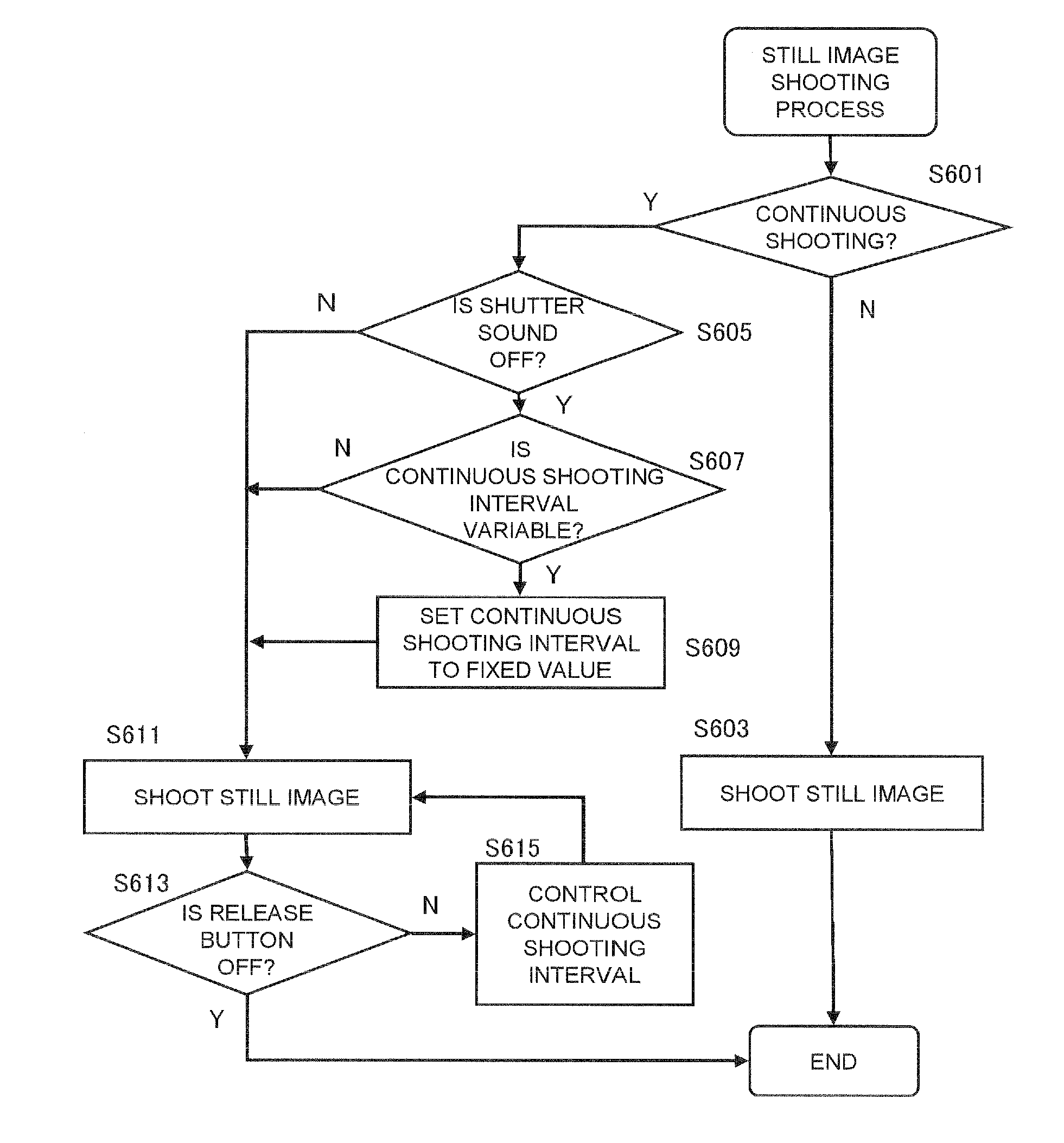

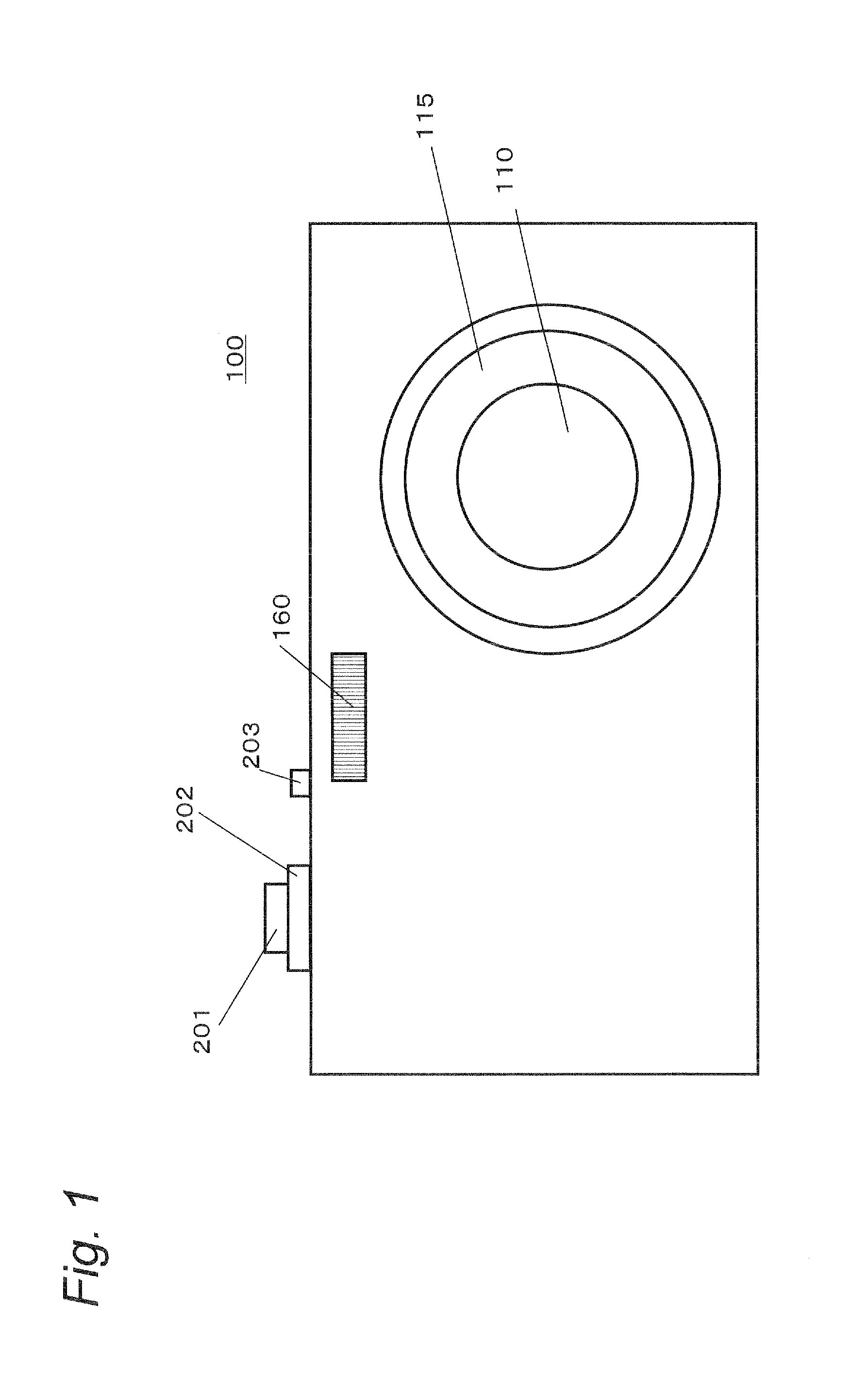

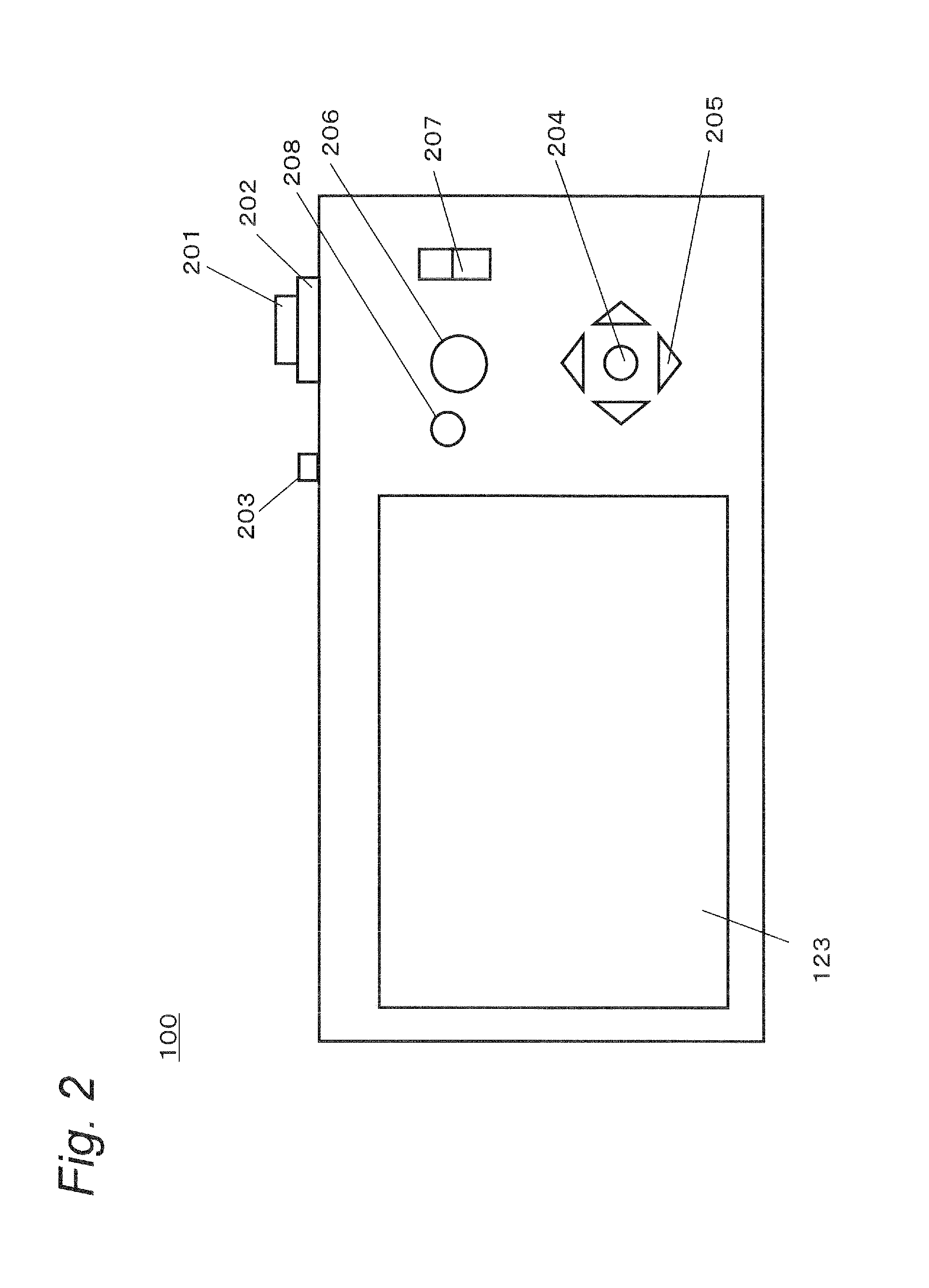

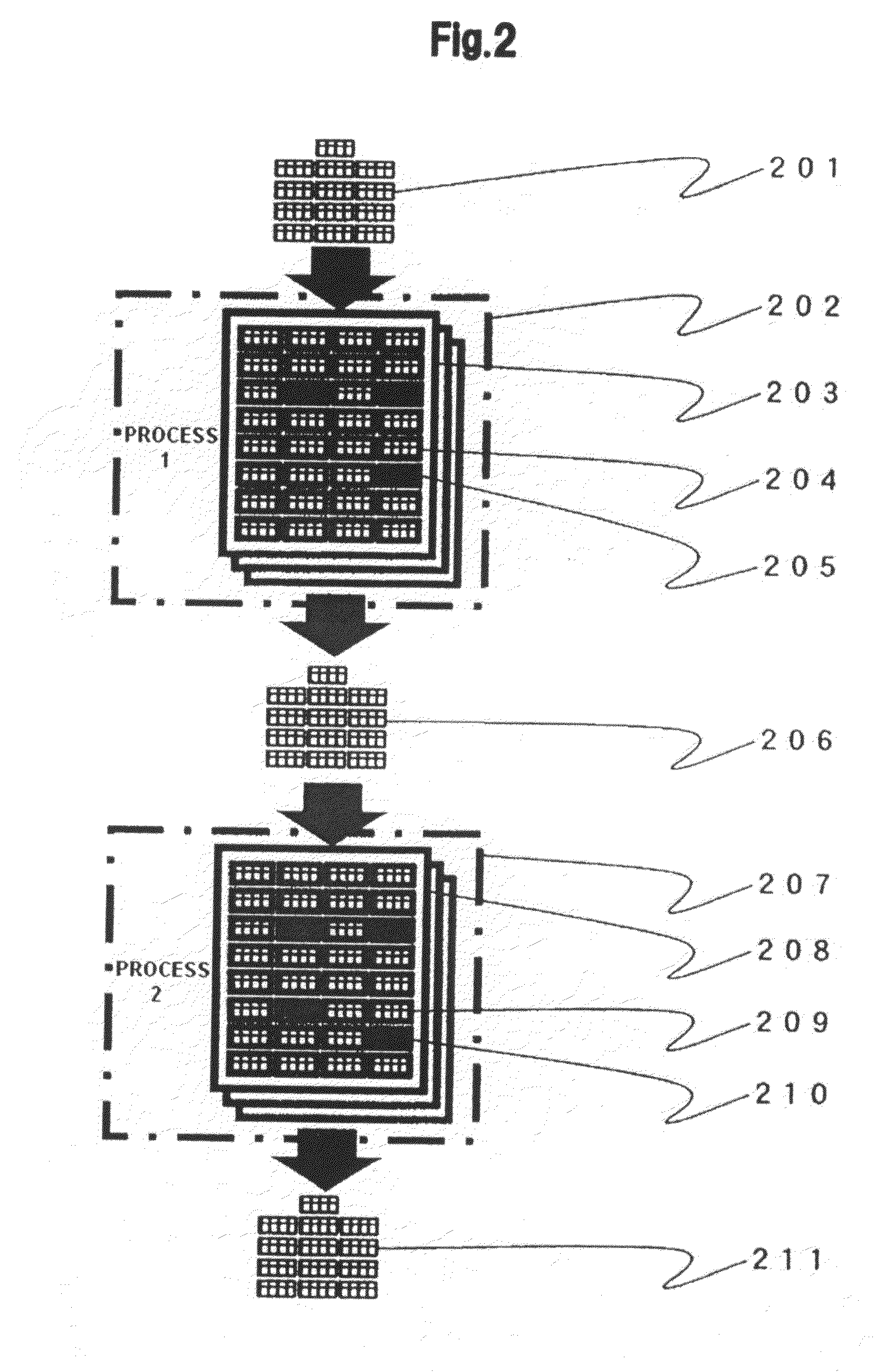

Imaging apparatus

InactiveUS20120033958A1Reduce failure frequencyImprove convenienceTelevision system detailsColor television detailsExecution controlEngineering

Owner:IMAGE PROCESSING TECH

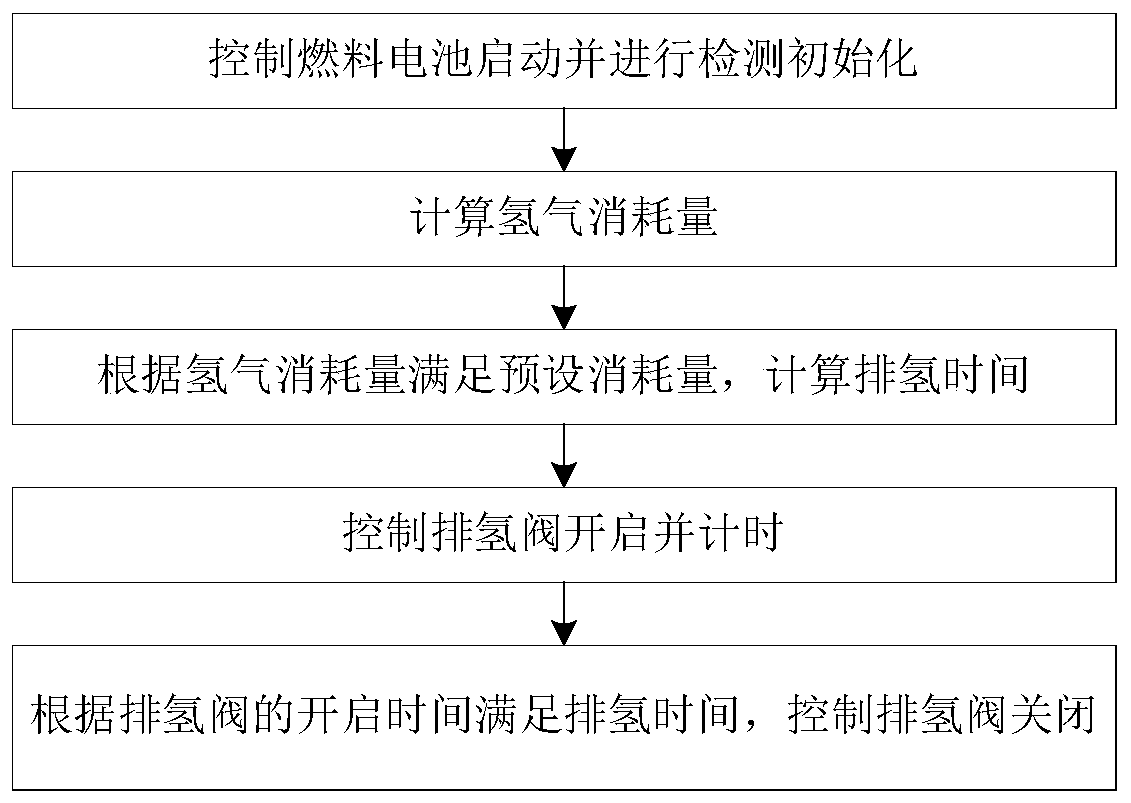

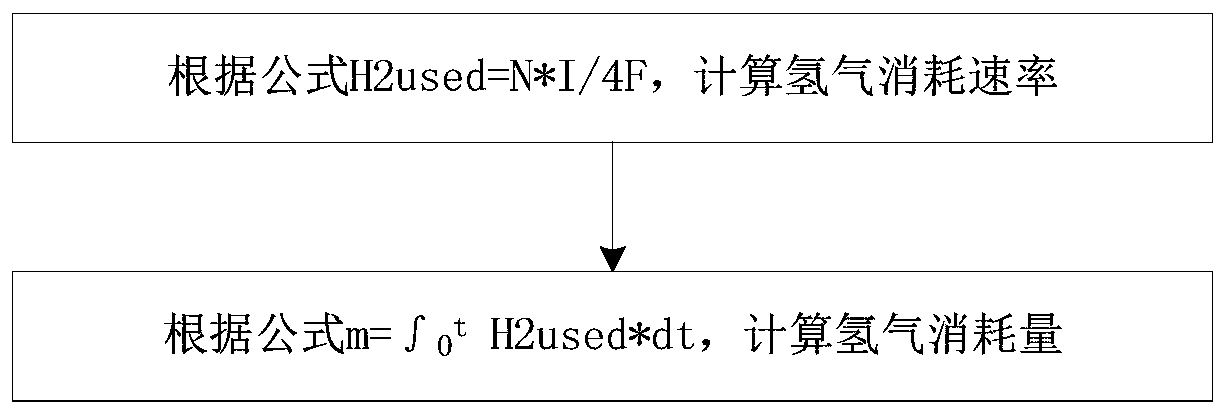

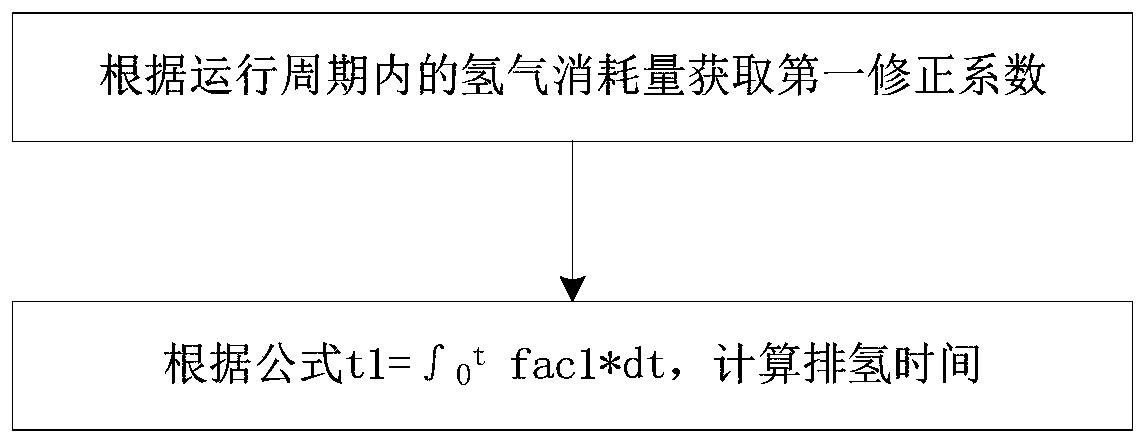

Control method of fuel cell hydrogen exhaust valve

The invention belongs to the technical field of fuel cells, and in particular relates to a control method of a fuel cell hydrogen exhaust valve. The control method of the fuel cell hydrogen exhaust valve comprises the steps that the start of a fuel cell is controlled, and detection initialization is carried out; the hydrogen consumption amount is calculated; if the hydrogen consumption amount satisfies the preset consumption amount, the hydrogen exhaust time is calculated; the hydrogen exhaust valve is controlled to start, and timing is carried out; and if the start time of the hydrogen exhaust valve meets the hydrogen exhaust time, the hydrogen exhaust valve is controlled to close. According to the control method of the fuel cell hydrogen exhaust valve, which is provided by the embodimentof the invention, the hydrogen consumption amount can reflect the content of impurities in a hydrogen pipeline, and hydrogen is discharged according to the content of impurities; and hydrogen waste caused by unreasonable hydrogen discharge time is reduced, and the frequency of stack failure caused by insufficient hydrogen concentration is reduced.

Owner:WEICHAI POWER CO LTD

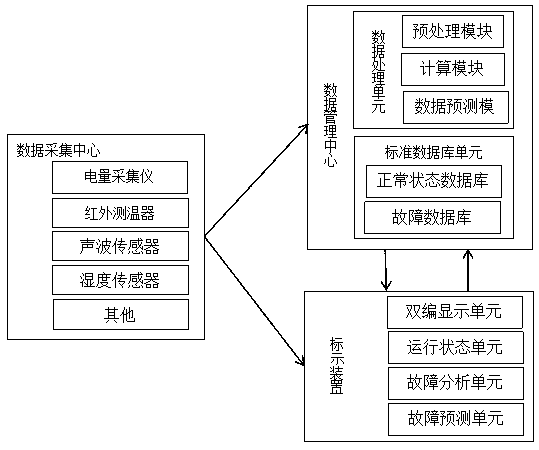

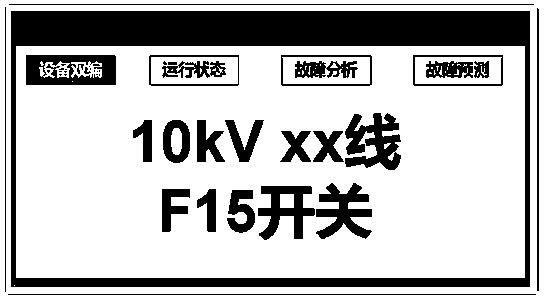

Switch cabinet intelligent marking device and system based on Internet of Things

ActiveCN111525694AAchieve normalizationFailure Detection GuaranteeBiological neural network modelsCharacter and pattern recognitionTroubleshootingData processing

The invention provides a switch cabinet intelligent marking device and system based on the Internet of Things. Specifically, fault detection and prediction are carried out on collected equipment operation parameters by constructing an SML model; the invention further provides an information interaction technology platform integrating a data acquisition module, a data processing center module and amarking device. The defects that an existing signboard is prone to shifting or information is not updated in time or information is disordered are overcome. The maintenance and troubleshooting efficiency of field operation personnel and the fault detection and judgment capability are effectively improved; a neural network algorithm is adopted to optimize the SML model, the accuracy and authenticity of the SML model are improved, a Bayesian prediction model is further constructed for fault risk prediction, faults are effectively restrained before happening, scientific and intelligent management is achieved, and safe and stable operation of a power system is guaranteed.

Owner:广东电网有限责任公司惠州供电局 +1

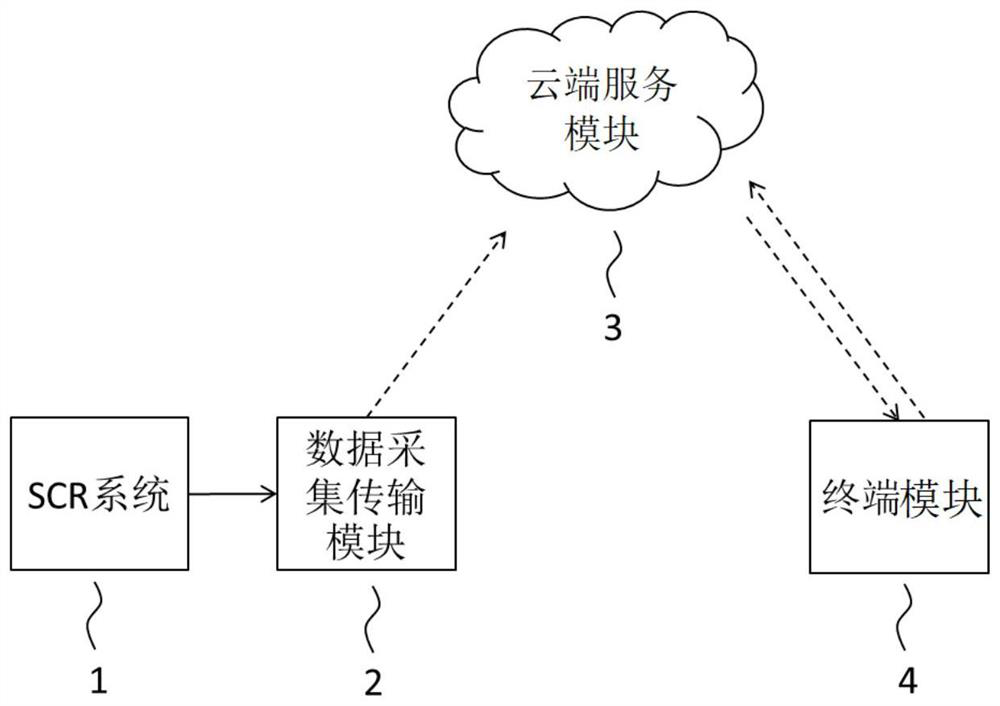

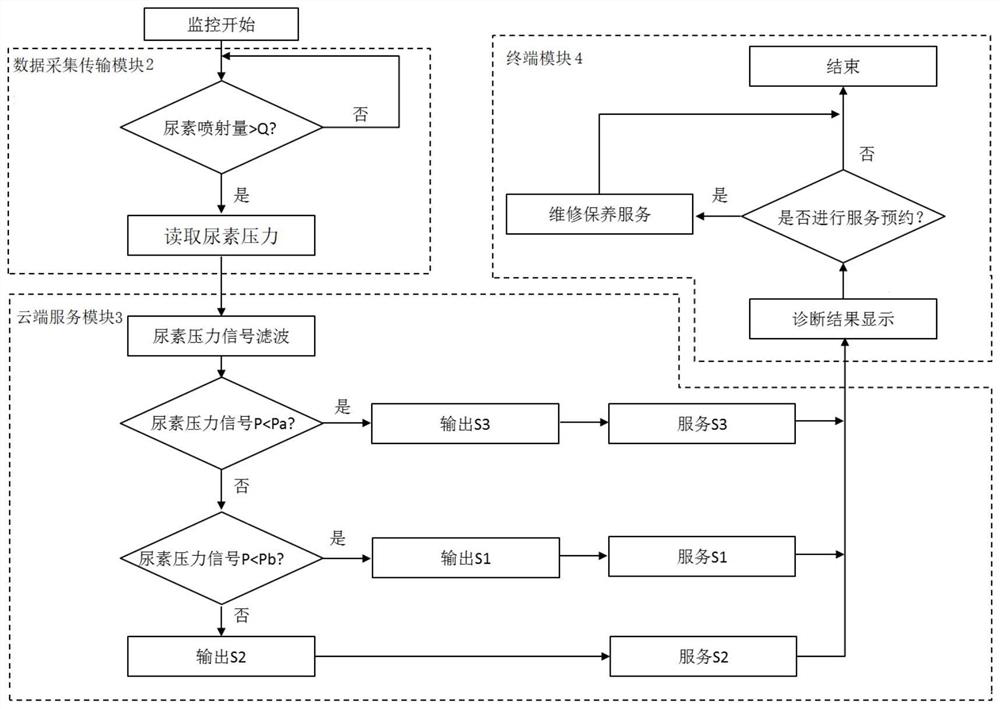

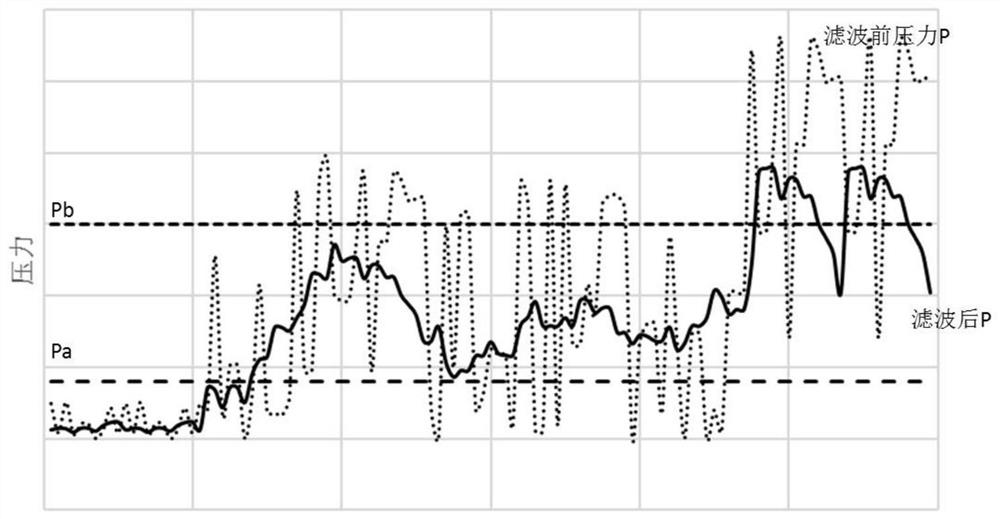

Predictive maintenance system and method for SCR (Selective Catalytic Reduction) urea injection system

InactiveCN111677577ALow costImprove reliabilityInternal combustion piston enginesExhaust apparatusIn vehicleControl engineering

The invention discloses a predictive maintenance system and method for an SCR (Selective Catalytic Reduction) urea injection system. The predictive maintenance method comprises the following steps of:periodically collecting the urea injection volume and urea pressure of the SCR system; judging whether the current urea pressure is selected according to the current urea injection volume; comparingthe selected urea pressure within a certain period of time with a threshold value; and determining different maintenance service plans according to different comparison results; and determining whether a maintenance service appointment is made according to the maintenance service plan. The predictive maintenance system monitors the status of the urea injection system in real time, including various abnormalities such as blocking and leakage. When the system is found to deviate from the normal running status, the information is transmitted to the cloud through a vehicle-mounted platform; afterthe cloud performs information analysis and processing, and the terminal notifies a vehicle user of the information of the urea injection system; and the vehicle user can make the maintenance serviceappointment through the terminal for eliminating the system abnormalities, thereby reducing the frequency of occurrence of failures, the chain reaction caused by failures and the maintenance cost.

Owner:DONGFENG COMML VEHICLE CO LTD

Emulsified liquid supply device

InactiveCN106988982AAvoid wasting energySave power resourcesPositive displacement pump componentsPump controlThermal insulationLiquid temperature

The invention discloses an emulsified liquid supply device. A liquid level sensor, a liquid temperature sensor and a stirring component are arranged in an emulsified liquid box; the emulsified liquid box, a liquid imbibition filter, an energy accumulator group and a working face bracket are sequentially communicated through a liquid delivery pipeline; a mechanical unloading valve and a pressure sensor are arranged on the liquid delivery pipeline; the mechanical unloading valve is further connected with a liquid return pipeline; a liquid outlet of the liquid return pipeline stretches into the emulsified liquid box; a buffer is arranged on the liquid return pipeline; a liquid return filter communicates with the working face bracket and the emulsified liquid box through a pipeline; a thermal insulation sleeve is connected onto the periphery of the emulsified liquid box in a sleeving manner and forms a backflow passage with the emulsified liquid box; and a cold and hot water supply device communicates with a water flow passage through a pipeline. The emulsified liquid supply device, disclosed by the invention, saves plenty of electric power resource and reduces the failure rate of an emulsified liquid pump and the overhaul cost; and stability of the emulsified liquid temperature ensures the usability of the emulsified liquid pump and the working stability of a hydraulic system.

Owner:安徽恒源煤电股份有限公司

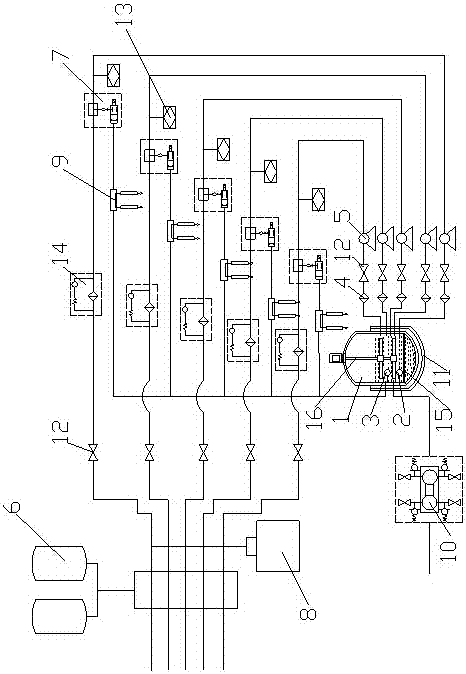

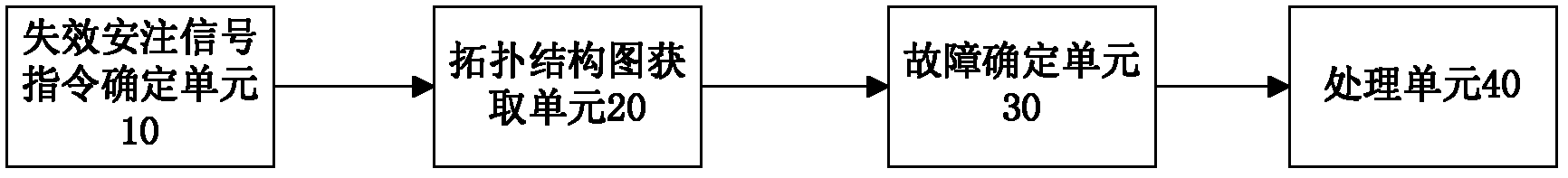

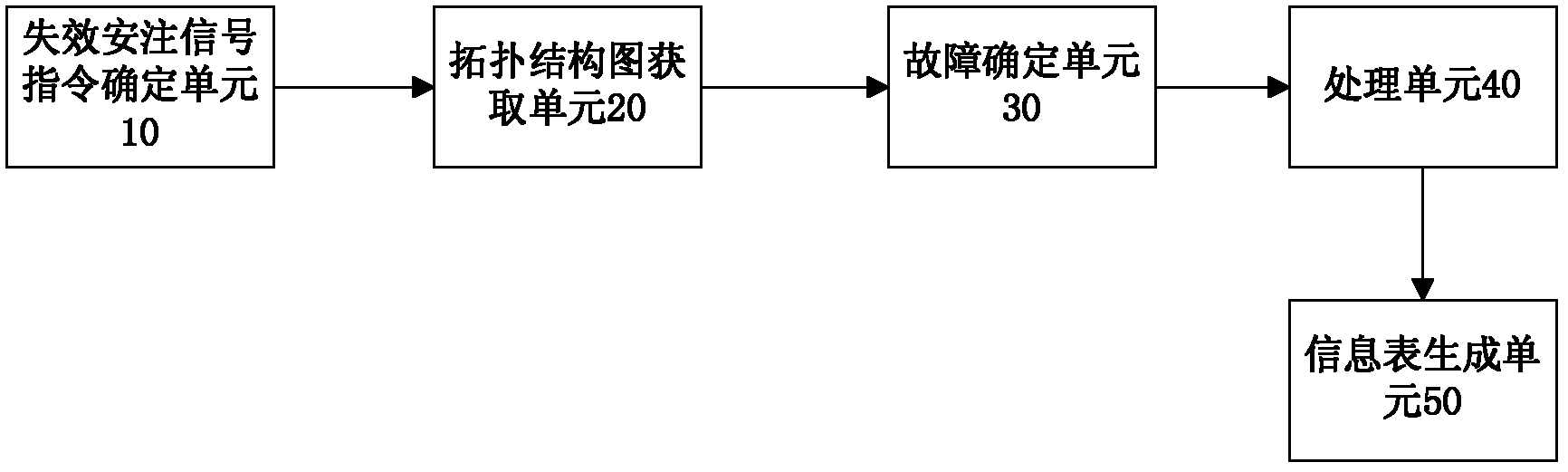

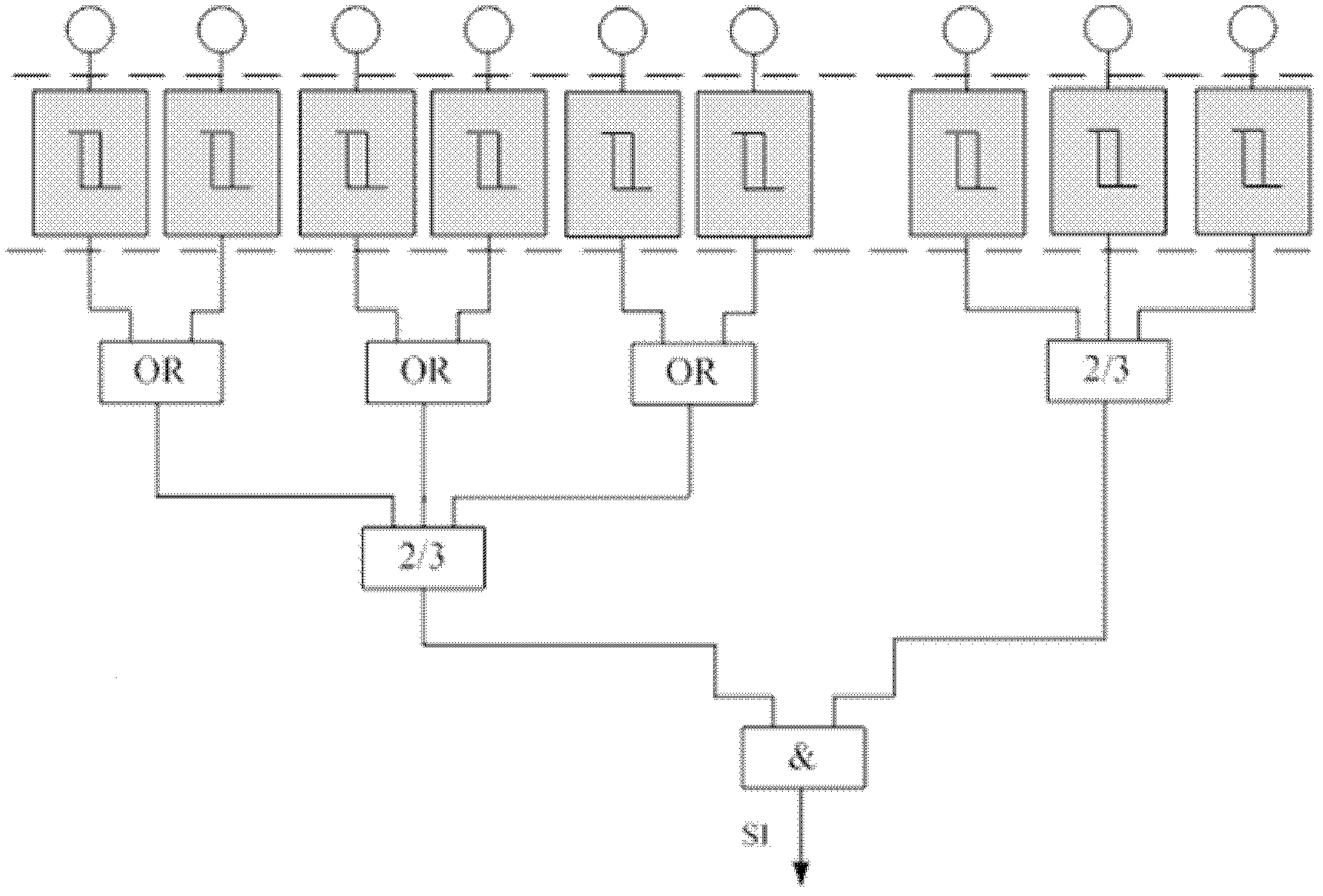

Method and system for handling faults of signal failures of DCS (Distributed Control System) safety injection system of nuclear power plant

ActiveCN102867556AReduce failure frequencyReduce frequencyPower plant safety arrangementNuclear energy generationNuclear powerStructure chart

The invention discloses a method and a system for handling faults of signal failures of a DCS safety injection system of a nuclear power plant, wherein the method comprises the following steps of: conforming a safety injection signal command for the failure of the safety injection system; according to the confirmed safety injection signal command, acquiring the topological structure chart of a digitalized instrument control system for implementing the safety injection signal; determining hardware equipment associated with the safety injection signal command according to the topological structure chart; and handling faults of the hardware equipment. According to the method disclosed by the invention, various different approaches and modes of the faults of the system equipment can be judged and then the proper prevention measures can be determined, so that the occurrence frequency of the faults is reduced and the consequences of the faults can be reduced; and the important upstream input is provided to the follow-up further establishment of models, the development of reliability analysis and the calculation of availability rate and the like.

Owner:中广核工程有限公司 +1

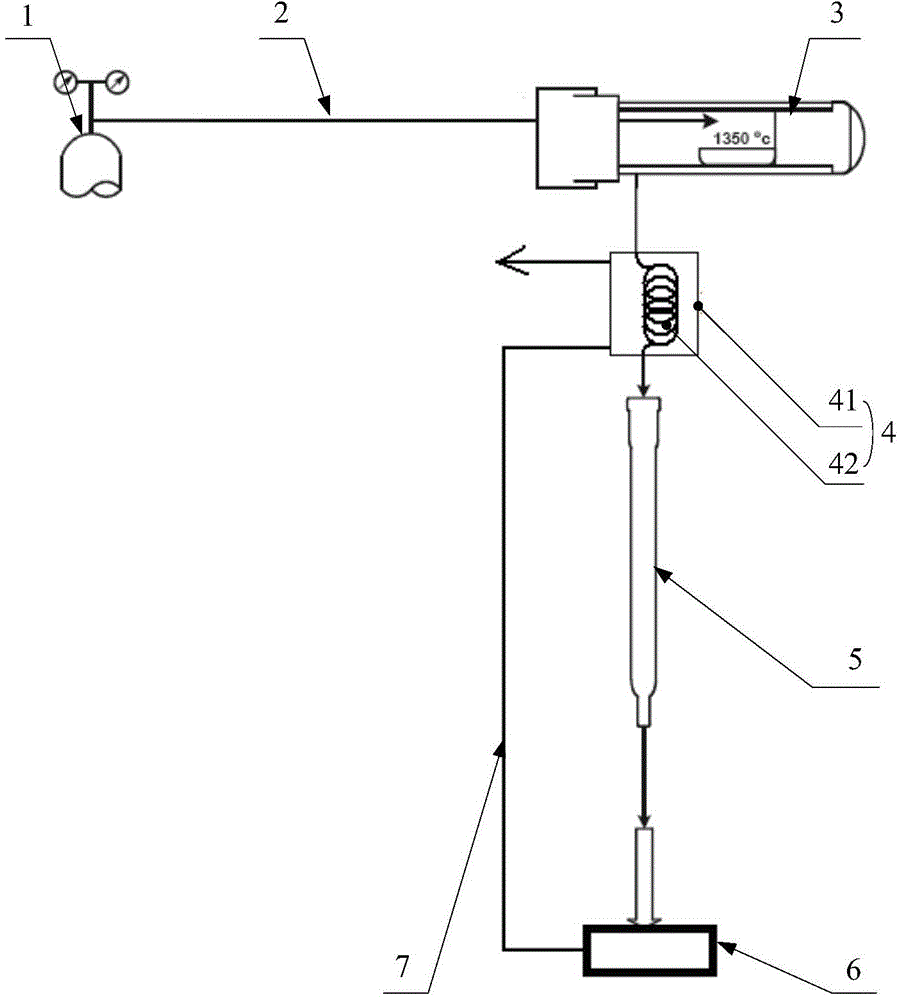

Sulfur measuring system

InactiveCN104089916AReduce failure frequencyReduce moisturePreparing sample for investigationColor/spectral properties measurementsCombustionSulfur

The invention discloses a sulfur measuring system, comprising a combustion tube (3), a drying tube assembly (5) filled with a magnesium perchlorate drying agent and a pre-dewatering device (4) arranged between the combustion tube (3) and the drying tube assembly (5), wherein the pre-dewatering device (4) comprises a nafion tube (41) and a shell (42) covering outside the nafion tube (41), the nafion tube (41) is connected between the outlet end of the combustion tube (3) and the air inlet end of the drying tube assembly (5), and the shell (42) is provided with an exhaust port and an air inlet for introducing dry gas. According to the sulfur measuring system, the nafion tube is used in the pre-dewatering device, and the nafion material is only used for bringing away internal moisture through external drying, so that the moisture flowing into the drying tube assembly is effectively reduced, the failure frequency of the magnesium perchlorate drying agent in the drying tube assembly is reduced, and the test cost is reduced.

Owner:CHANGSHA KAIYUAN INSTR

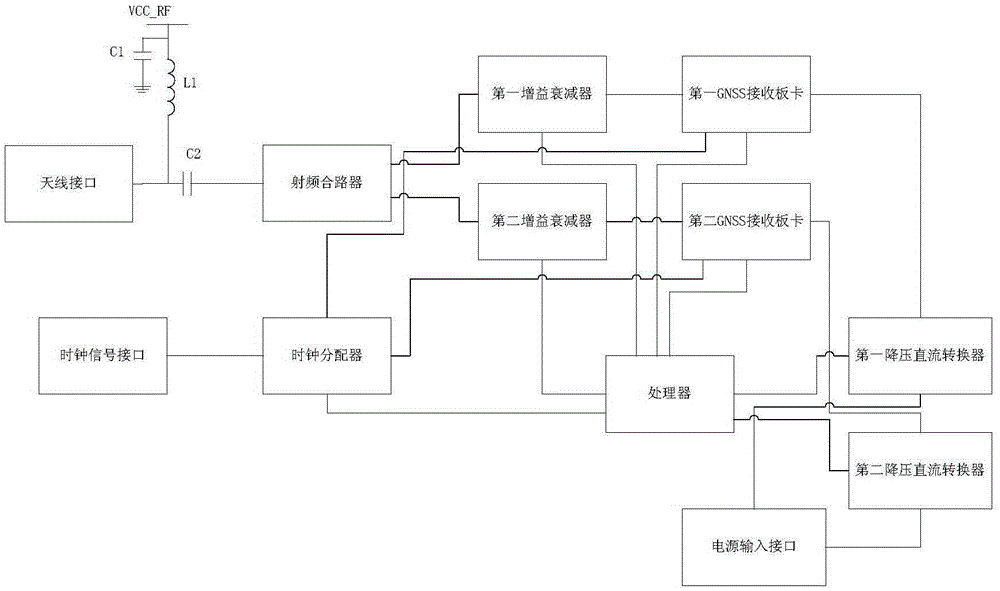

GNSS receiver

InactiveCN105301603AImprove the quality of text solutionImprove stabilitySatellite radio beaconingWork cycleFrequency band

A GNSS receiver comprises a first GNSS receiver board card, a second GNSS receiver board card, and a processor. The first GNSS receiver board card and the second GNSS receiver board card are electrically connected with the processor separately. The processor is used to switching the first GNSS receiver board card and the second GNSS receiver board card according to a preset work cycle, so that the first GNSS receiver board card and the second GNSS receiver board card work alternatively. As the first GNSS receiver board card and the second GNSS receiver board card work alternatively, better message solving frequency bands of different receiver board cards can be utilized to improve the overall message solving quality of a GNSS receiver, and the two receiver board cards do not need to work continuously in 24 hours, so that the service lives of the receiver board cards can be extended, the fault frequency can be reduced, and the stability of the receiver can be enhanced.

Owner:GUANGZHOU HI TARGET NAVIGATION TECH

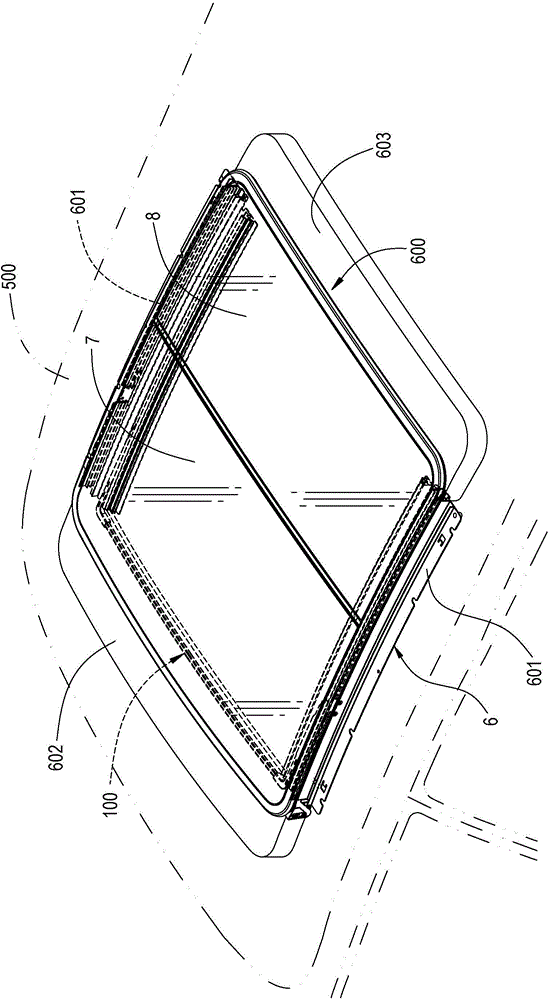

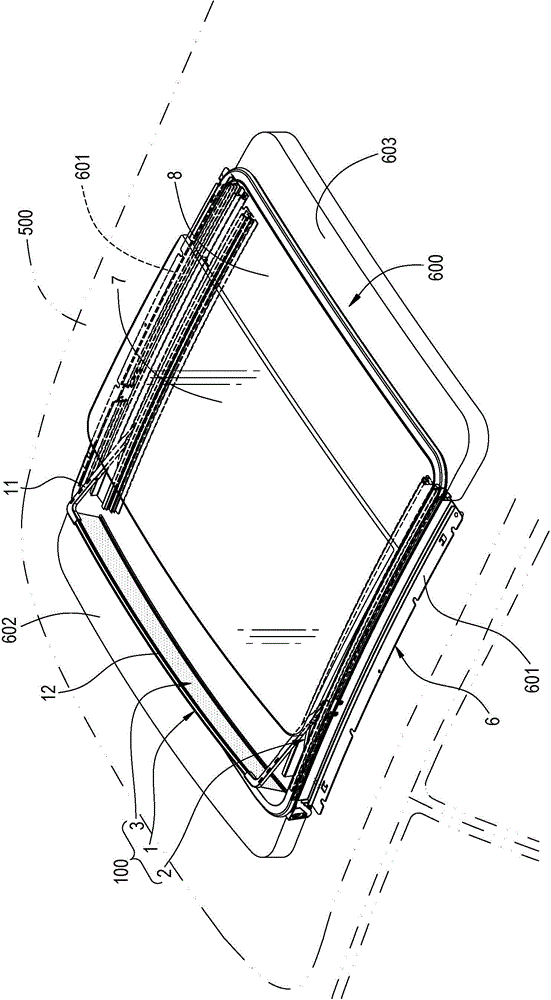

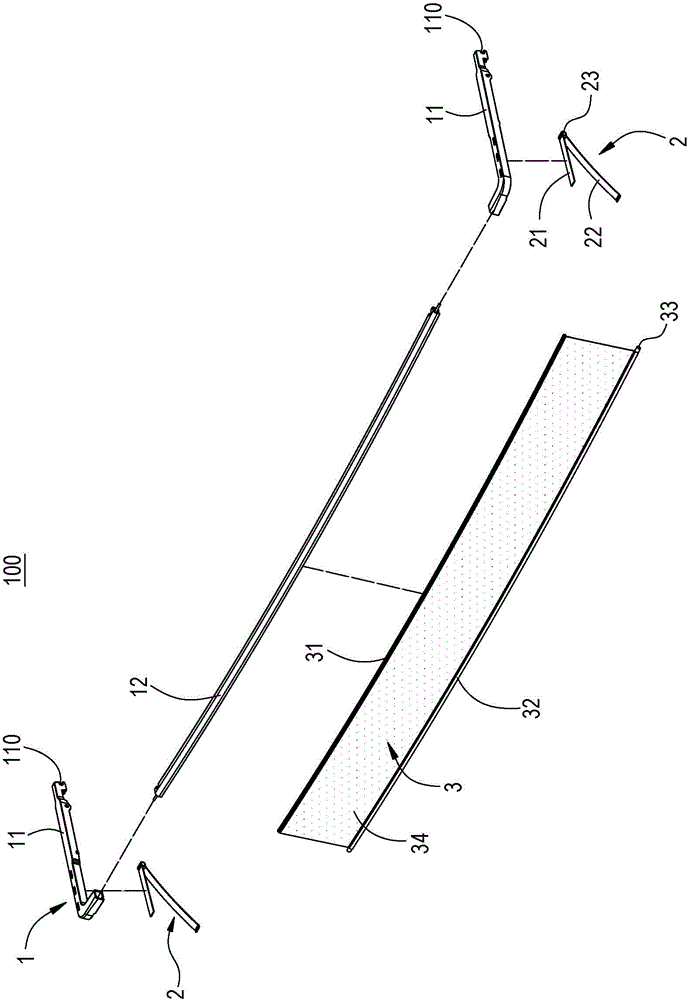

Wind structure of automobile skylight

The invention discloses a wind structure of an automobile skylight. The automobile skylight comprises a framework and mobile glass arranged in the framework; the wind structure comprises a support frame, an elastic support piece and soft sheet, wherein the support frame is arranged in the framework in a pivoting manner movably and positioned under the mobile glass when the mobile glass is closed; the elastic support piece is arranged on the support frame and is supported between the support frame and the framework elastically; a plurality of through holes are distributed in the soft sheet; the upper and lower edges of the soft sheet are connected between the support frame and the framework. When the mobile glass is closed, the support frame is pressed downwards in a linkage manner, and the elastic support piece is pressed downwards accordingly; when the mobile glass is opened, force used for pressing the support frame downwards is removed in a linkage manner, the support frame is supported elastically by the elastic support piece, and the soft sheet is spread accordingly. Erecting and lying of the wind structure can be realized without being driven by power, the failure frequency is lowered, the structure is simplified, maintenance is easy, and the overall cost is reduced.

Owner:HSIN CHONG MACHINERY WORKS

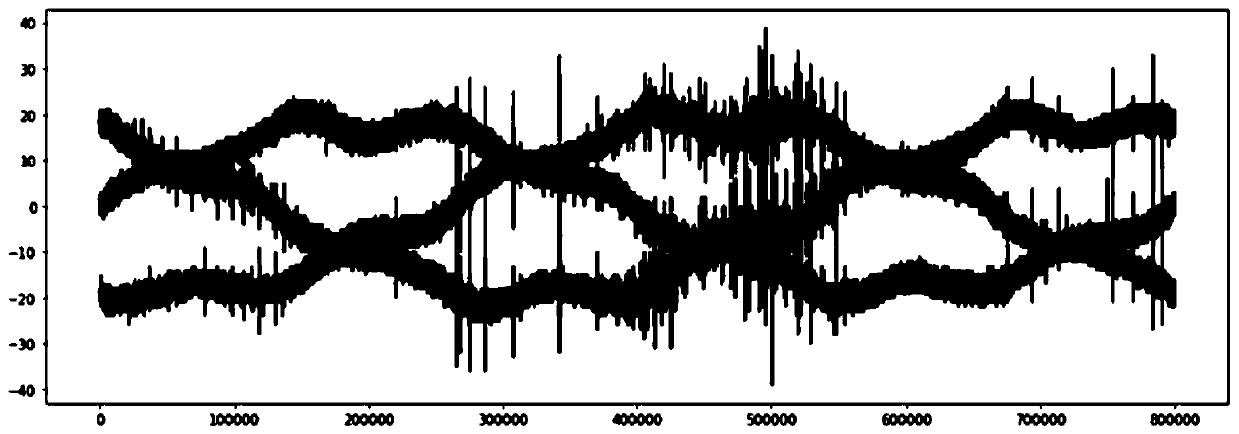

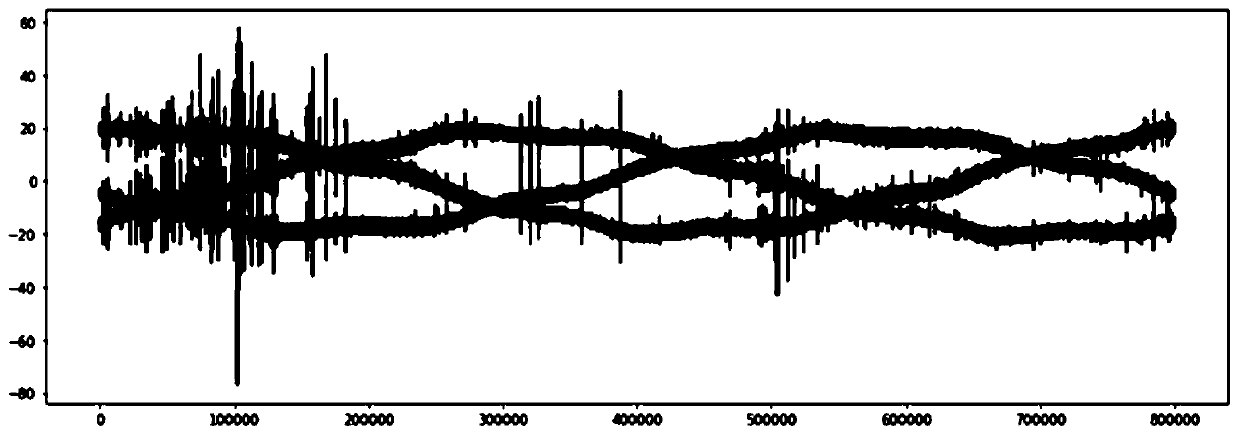

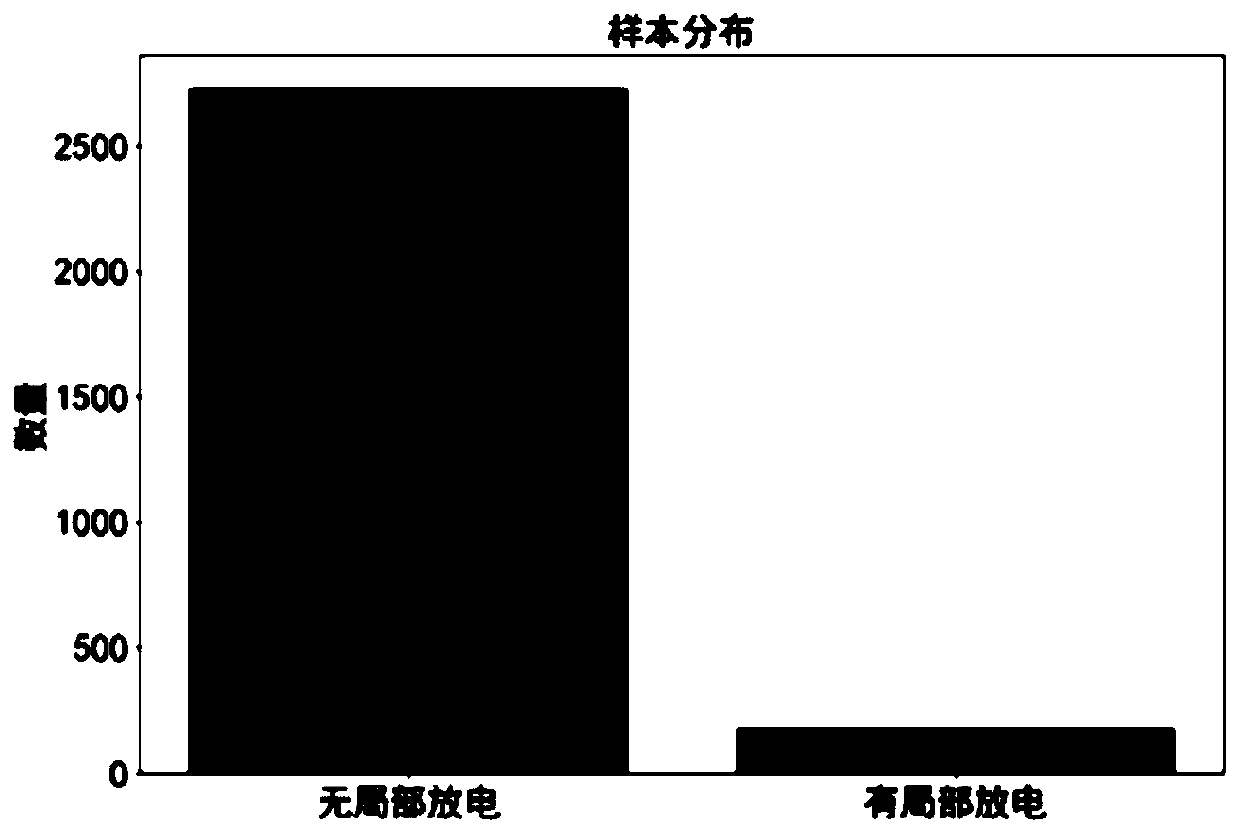

High-voltage power cable partial discharge phenomenon detection method based on deep learning

InactiveCN111579939ASimplify fault detectionReduce failure frequencyTesting dielectric strengthCharacter and pattern recognitionPower cableAlgorithm

The invention discloses a method for detecting the partial discharge phenomenon of a high-voltage power cable based on deep learning. The method comprises steps of carrying out preprocessing of the voltage time sequence signal data of an original high-voltage power cable, obtaining features of a high-voltage power line signal, and skipping the step if data preprocessing is not needed; converting the preprocessed high-voltage power cable voltage time sequence signal or the unprocessed signal into time sequence data inputted by a partial discharge phenomenon detection model; and obtaining a final partial discharge phenomenon detection model through training of the training set, judging performance of the detection model according to the evaluation indexes, and then improving the detection model till a model with a satisfactory effect is obtained. The method is advantaged in that whether a partial discharge phenomenon occurs in a monitored voltage time sequence signal of a certain sectionof high-voltage power line can be accurately judged.

Owner:TIANJIN UNIV

Automatic pumping method for collecting well and pumping system based on automatic pumping method

ActiveCN106337802AReduce failure frequencyReduce frequencyPump controlPositive-displacement liquid enginesWater volumeEnvironmental engineering

The invention discloses an automatic pumping method for a collecting well and a pumping system based on the automatic pumping method. Different water level heights are set in the collecting well, the changes of water volumes between the different water level heights are matched with a first water pump and a second water pump, and the first water pump and the second water pump are used alternately to solve the problem that in the prior art, a collecting well water pump of a medium and small power plant works continuously and is prone to having failures frequently; and the purpose that the starting frequency and the working time of the single water pump are reduced to reduce the failure frequency of the water pump is achieved.

Owner:DAZHOU POWER BUREAU SICHUAN ELECTRIC POWER +1

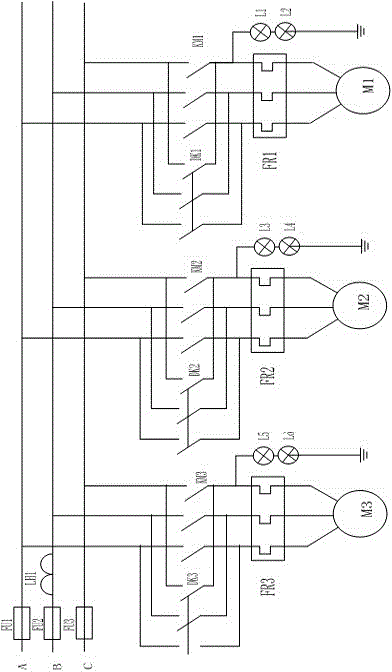

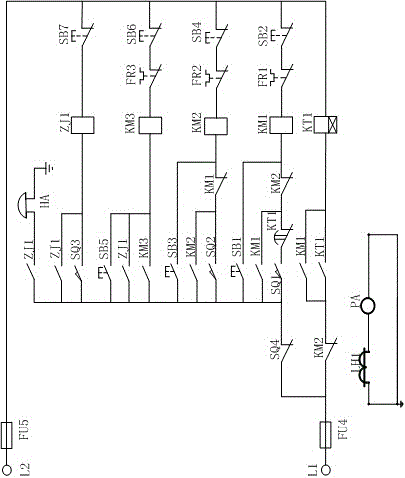

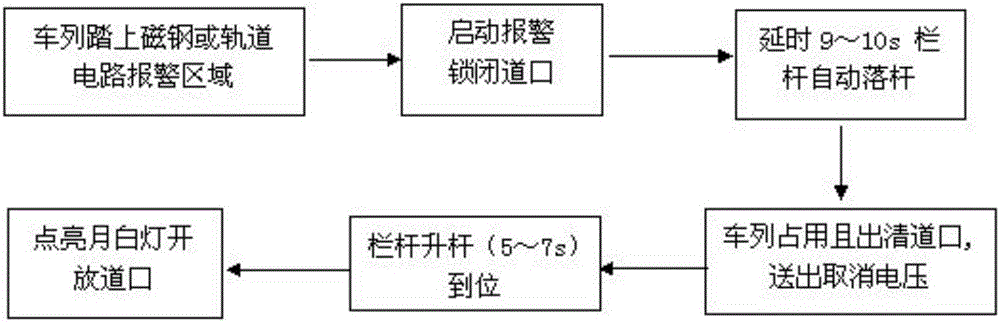

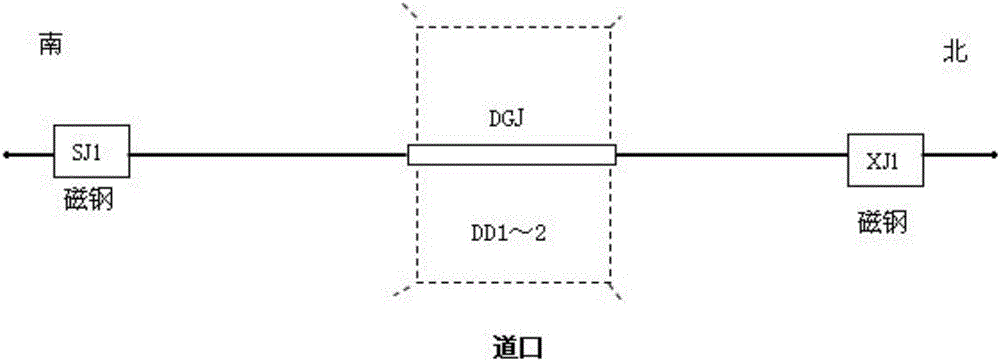

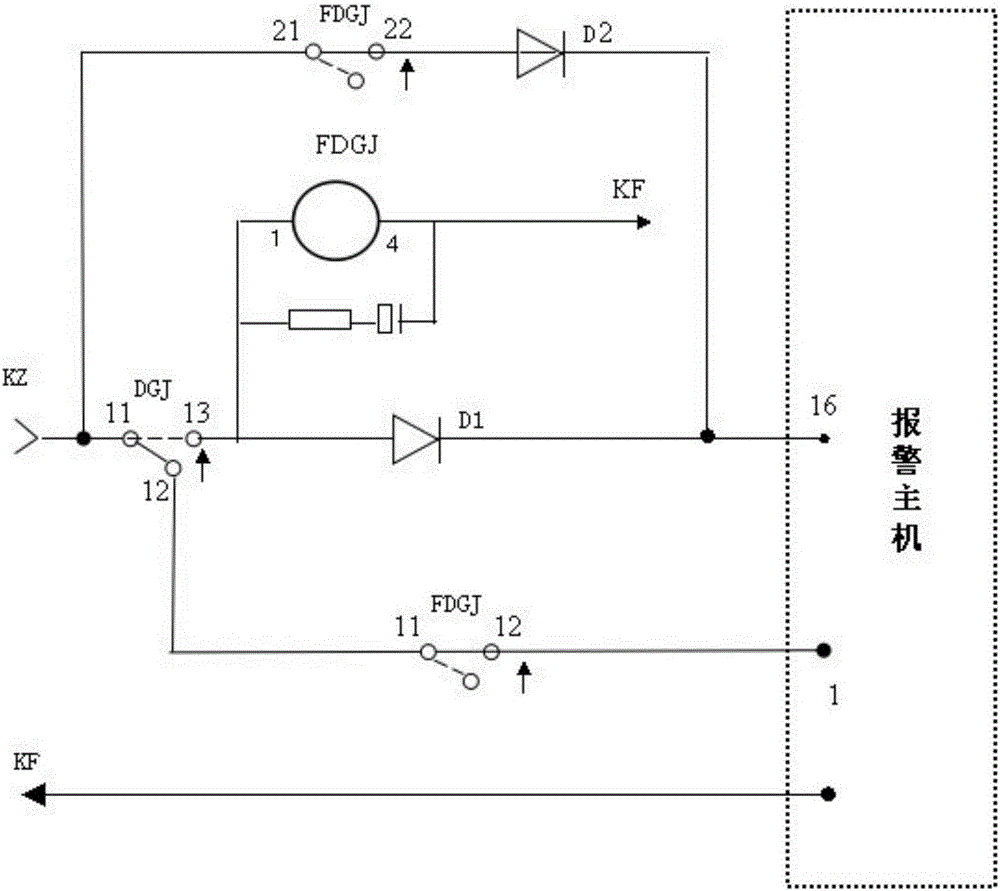

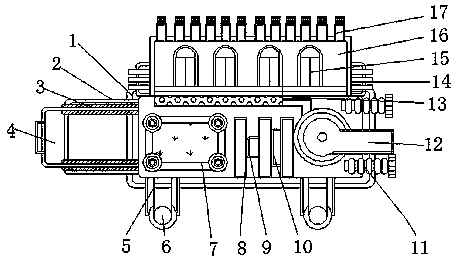

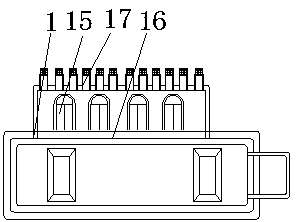

Alarm control method for crossing section

ActiveCN105799742ASafe and reliable actionSolve the problem of early interruption alarm-starting the boom of the log machineRoad traffic warning meansTraffic gates operationEngineeringControl circuit

The invention relates to an alarm control method for a crossing section. A device comprising a detection circuit and a control circuit is adopted. When a train gets close to magnetic steel, an alarm is given, the train occupies a crossing, a track relay is demagnetized, a continuous alarm circuit composed of the track relay, a first diode and a continuous alarm power terminal is switched on, and then the alarm is kept; meanwhile, an excitation power source of a reverse track relay is switched on to make the reverse track relay act to be attracted, and an RC circuit is charged at the same time; when the train travels out of the crossing, an alarm removing circuit composed of the track relay, the reverse track relay and an alarm removing terminal is switched on, an impulse voltage is sent out at a moment by means of immediate excitation of the track relay and slow release of the reverse track relay, and the alarm initiated by the corresponding magnetic steel is removed. Through the alarm control method, the problem that when the train runs in the occupied crossing section, an alarm is interrupted in advance and consequently a lifting rod of a keurboom machine is started can be solved.

Owner:NINGBO IRON & STEEL

Industrial dust treatment device

InactiveCN108677837AAvoid cloggingWon't clogDispersed particle filtrationRoad cleaningHydraulic cylinderEngineering

The invention discloses an industrial dust treatment device which comprises a main body and a dust extractor. A fixed board is connected to the left side of the main body. Sliding rods are installed on the upper side and the lower side of the fixed board. Supports are fixed to the left side and the right side of the bottom of the main body. Wheels are connected to the bottoms of the supports. A collection box is installed on the middle portions of the sliding rods. A hydraulic cylinder is connected to the middle portion at the bottom in the main body. A telescopic rod is installed on the leftside of the hydraulic cylinder. A push board is fixed to the left side of the telescopic rod. A magnet is installed on the left side of the push board. The dust extractor is arranged on the right sideof the hydraulic cylinder. Nuts are connected to the upper side and the lower side of the dust extractor. By the adoption of the industrial dust treatment device, the collection box slides among thefixed board and the sliding rods so that dust in the collection box can be removed, the inside of the main body can be prevented from being blocked through dust and dirt, the normal work of the main body is prevented from being affected, and the collection box is cleaned so that the dust treatment device can have enough space to remove other industrial dust.

Owner:林再颐

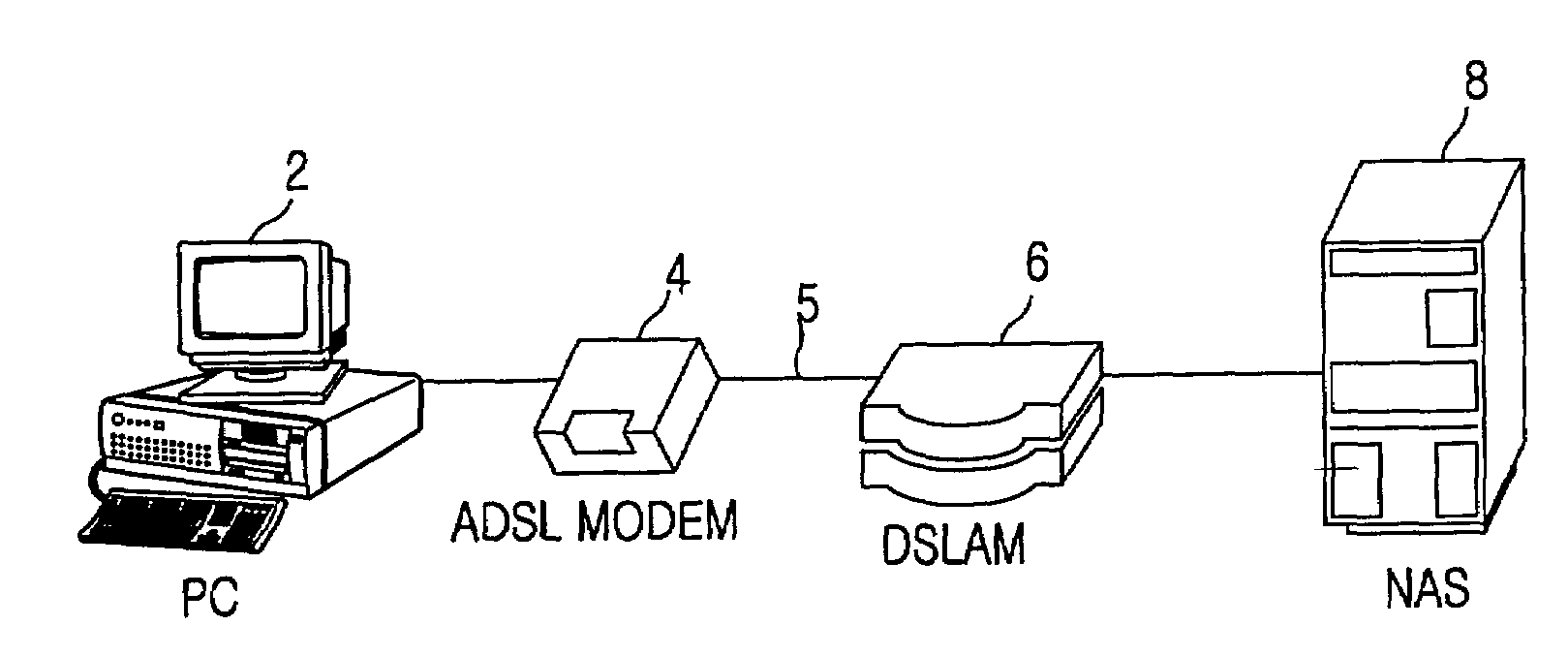

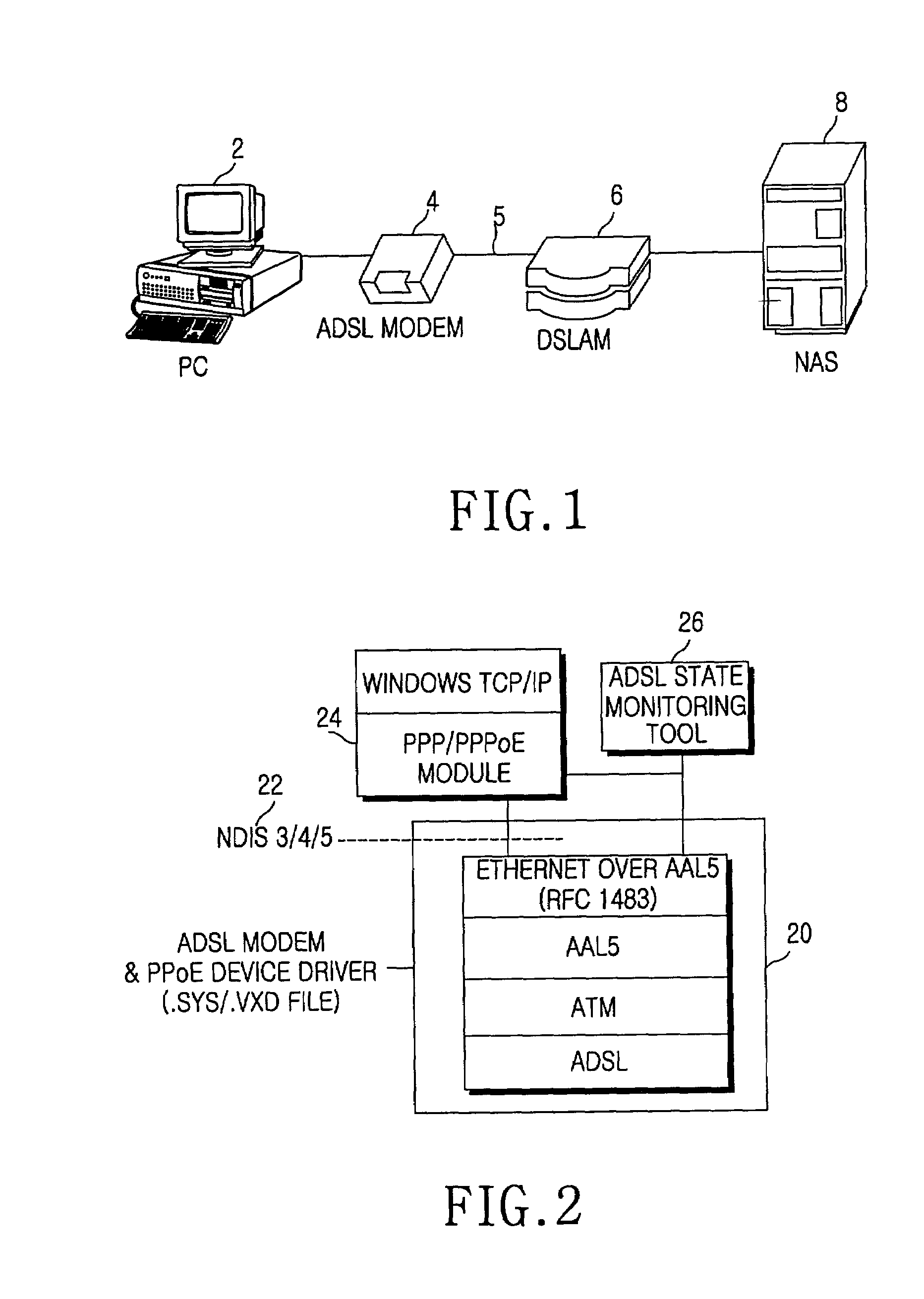

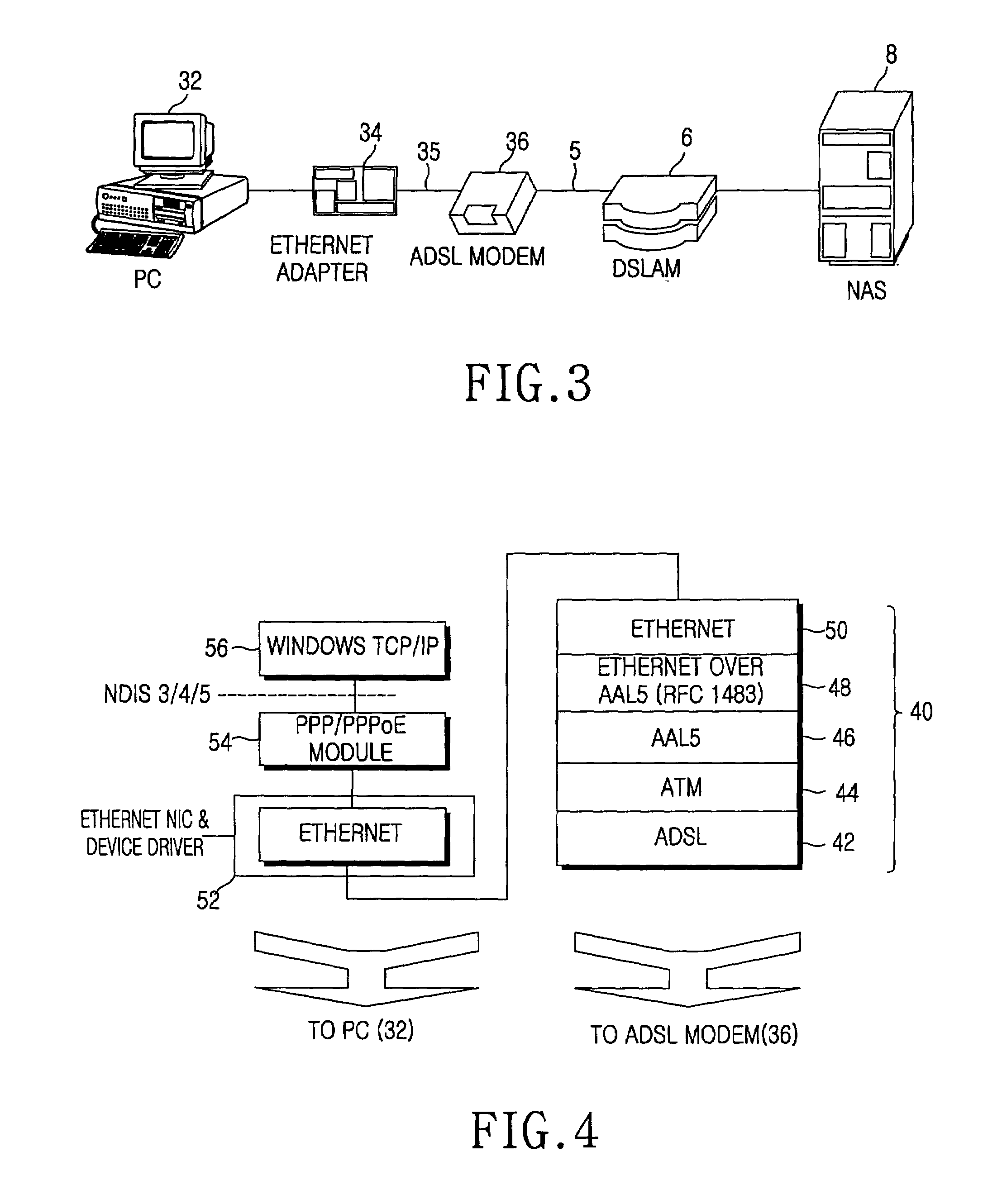

Automatic internet access method using digital subscriber line

InactiveUS7647390B2Reduce the number of stepsReduce failure frequencyMultiple digital computer combinationsTransmissionUser authenticationVia device

An automatic Internet access method using a digital subscriber line includes: upon receiving an automatic Internet access program install request from a user, installing a PPPoE device driver including a PPPoE adapter and an NDISWAN (Network Driver Interface Specification Wide Area Network) miniport driver, and an ADSL monitoring tool which is an application program for informing the user whether ADSL (Asynchronous Digital Subscriber Line) is connected, in a user PC; upon power on of the user PC, attempting automatic Internet access by the PPPoE device driver on WINDOWS™ over a device driver, and interposing between TCP / IP and the PPPoE device driver a PPP / PPPoE module for informing the user of a current connection state through the ADSL monitoring tool under the control of the device driver; receiving a user ID and a password input by the user through a user interface while installing the PPPoE device driver in the user PC, and storing the received user ID and password in a registry; and upon power on of the user PC, attaining by the device driver user authentication from a NAS server on the Internet using the user ID and the password stored in the registry, and performing Internet access.

Owner:SAMSUNG ELECTRONICS CO LTD

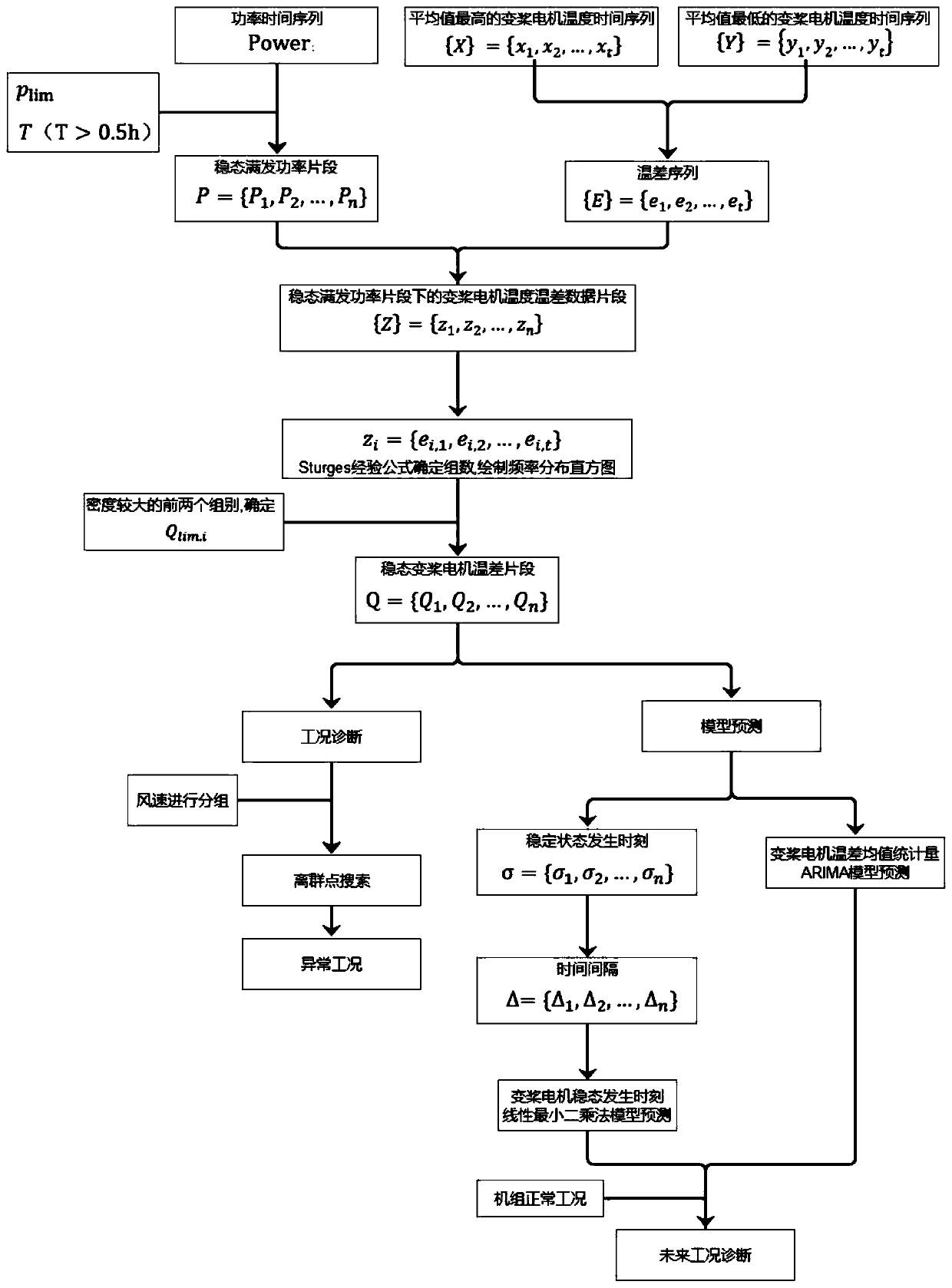

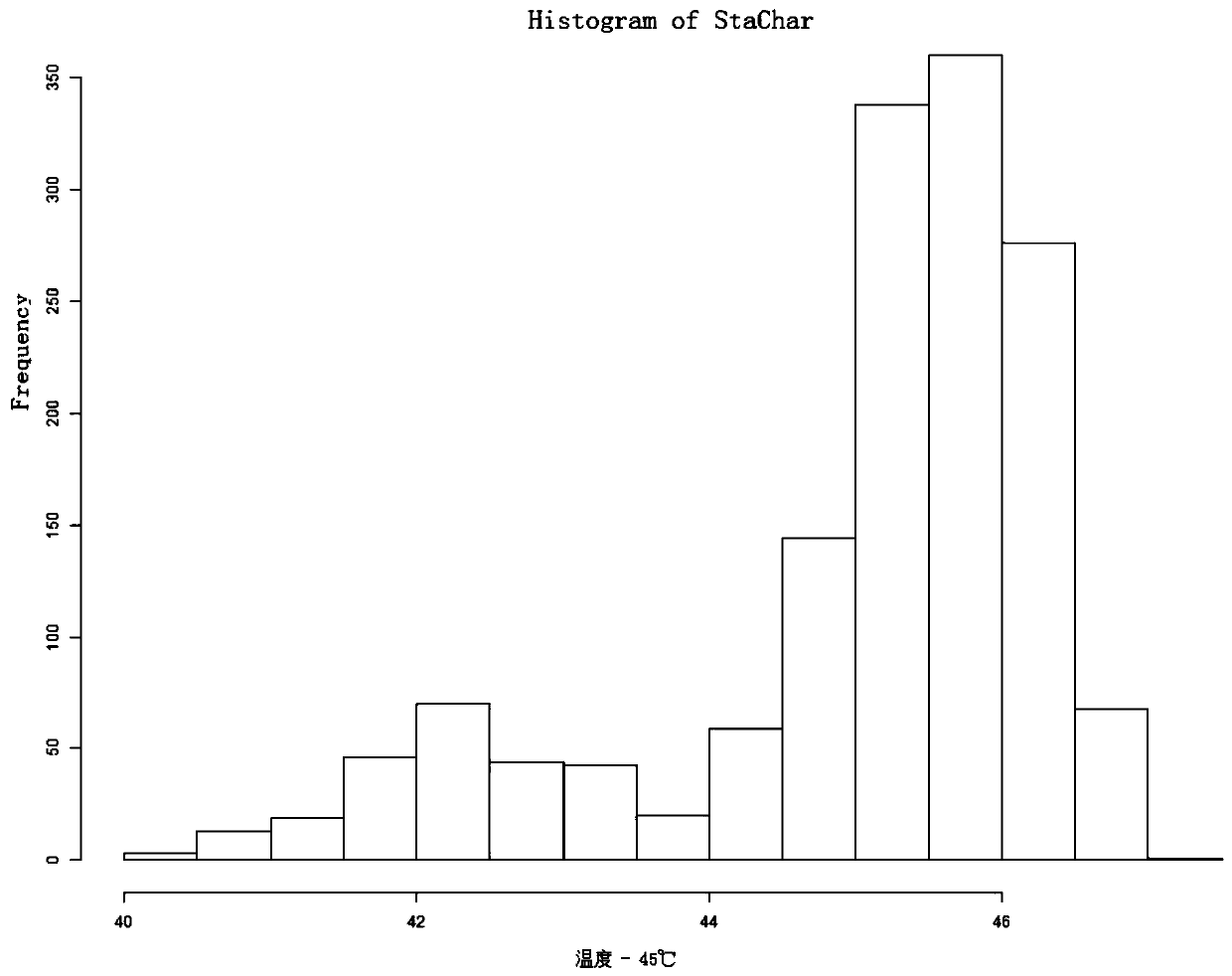

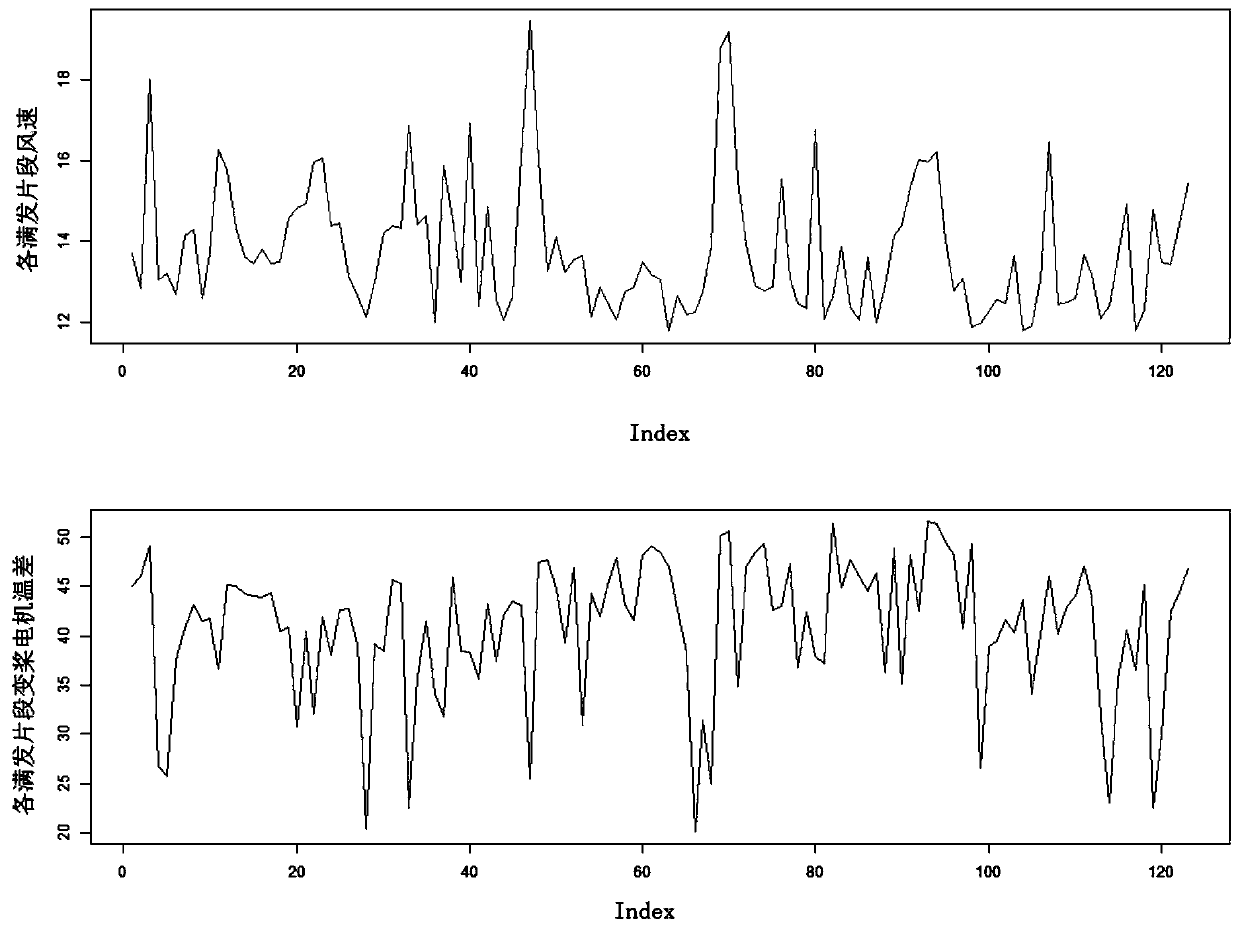

Variable-pitch motor temperature anomaly monitoring method and early warning method

ActiveCN110939550AReduce failure frequencyImprove operational efficiencyMachines/enginesEngine controlReal-time computingTemperature difference

The invention relates to a variable-pitch motor temperature anomaly monitoring method and an early warning method. According to the monitoring method, a temperature difference time sequence between avariable-pitch motor with maximum average temperature and a variable-pitch motor with minimum average temperature in a wind turbine generator under each steady-state full-load power segment in a certain time period is calculated, an average temperature difference value of the temperature difference time sequence corresponding to each steady-state full-load power segment is calculated, and a temperature difference average point beyond a temperature difference average value fluctuation interval of the variable-pitch motor is searched according to the distribution condition of the temperature difference average value. The methods aim to diagnose the abnormal working condition of the generator, discover hidden dangers as soon as possible, reduce the fault frequency of the generator and improvethe operation efficiency of the generator.

Owner:风脉能源(武汉)股份有限公司

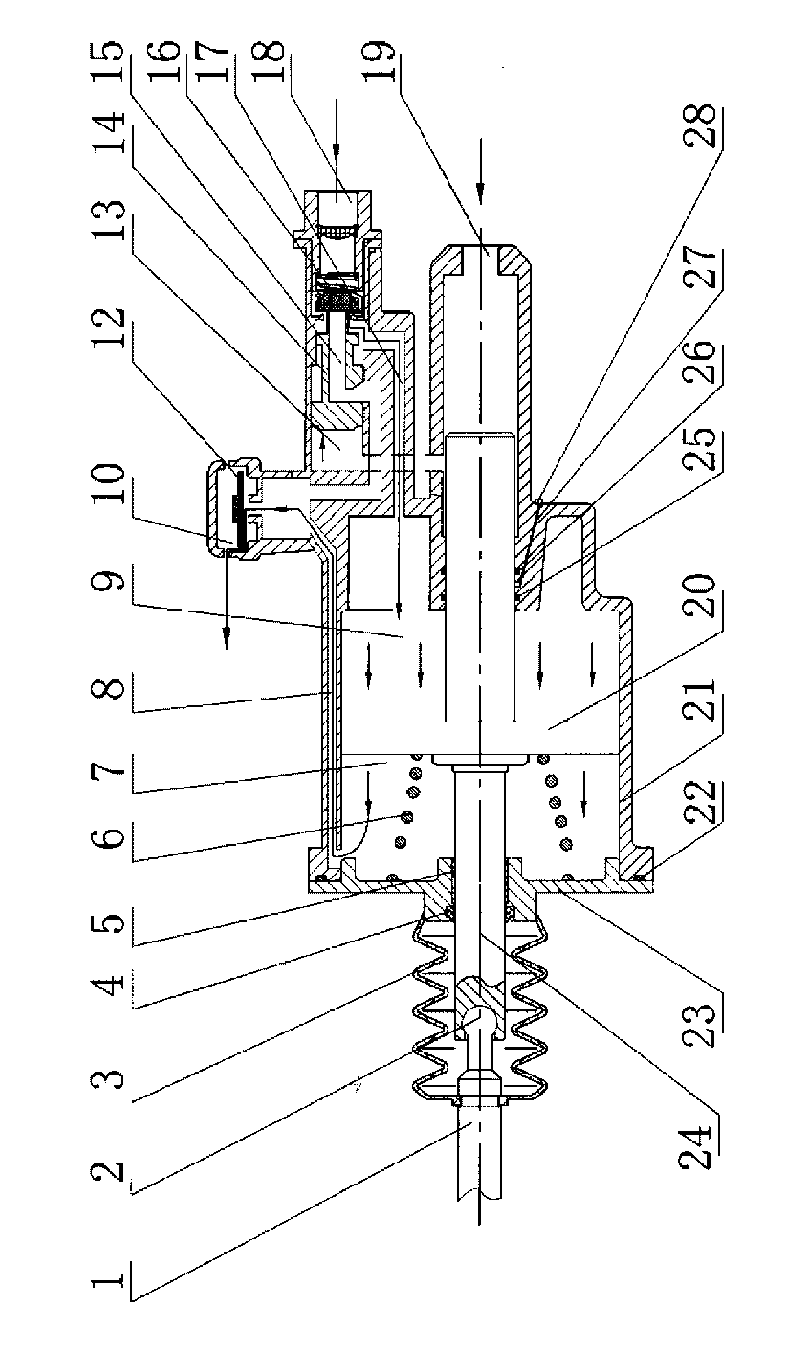

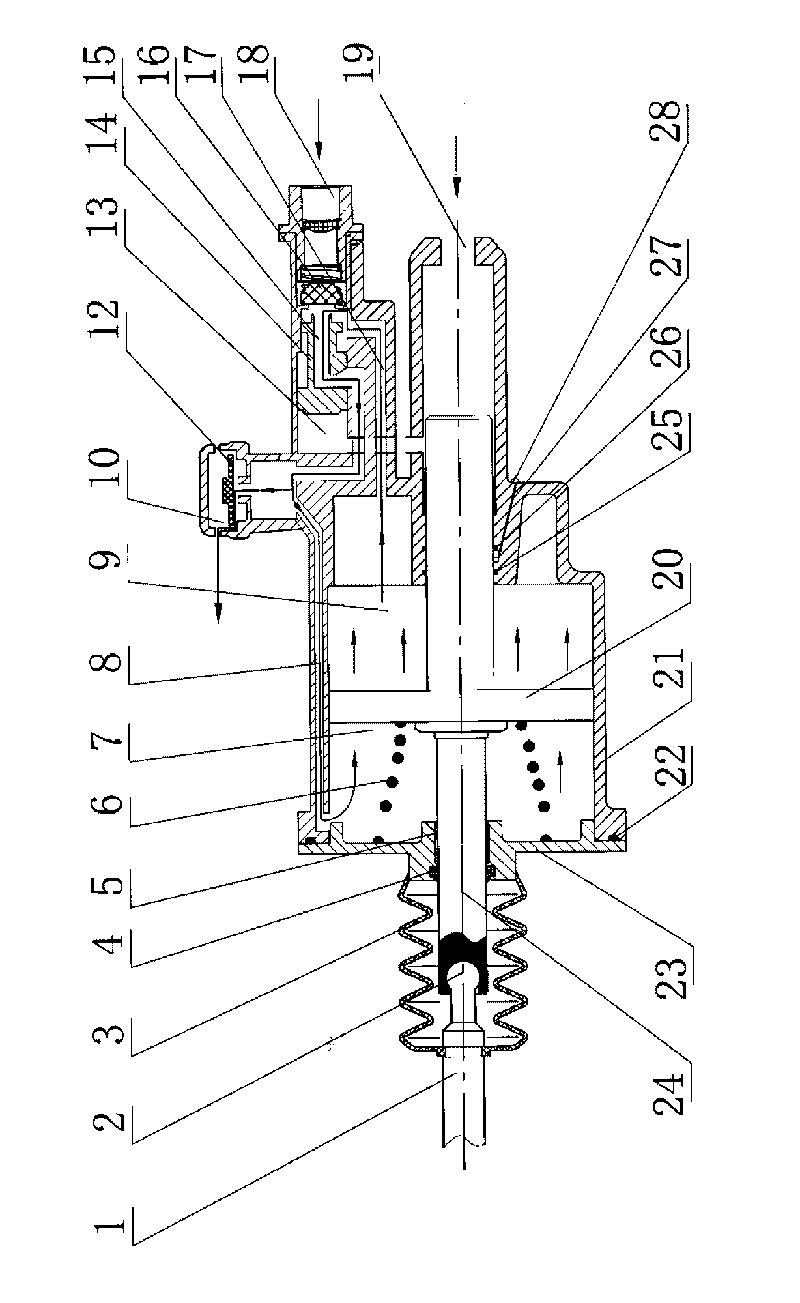

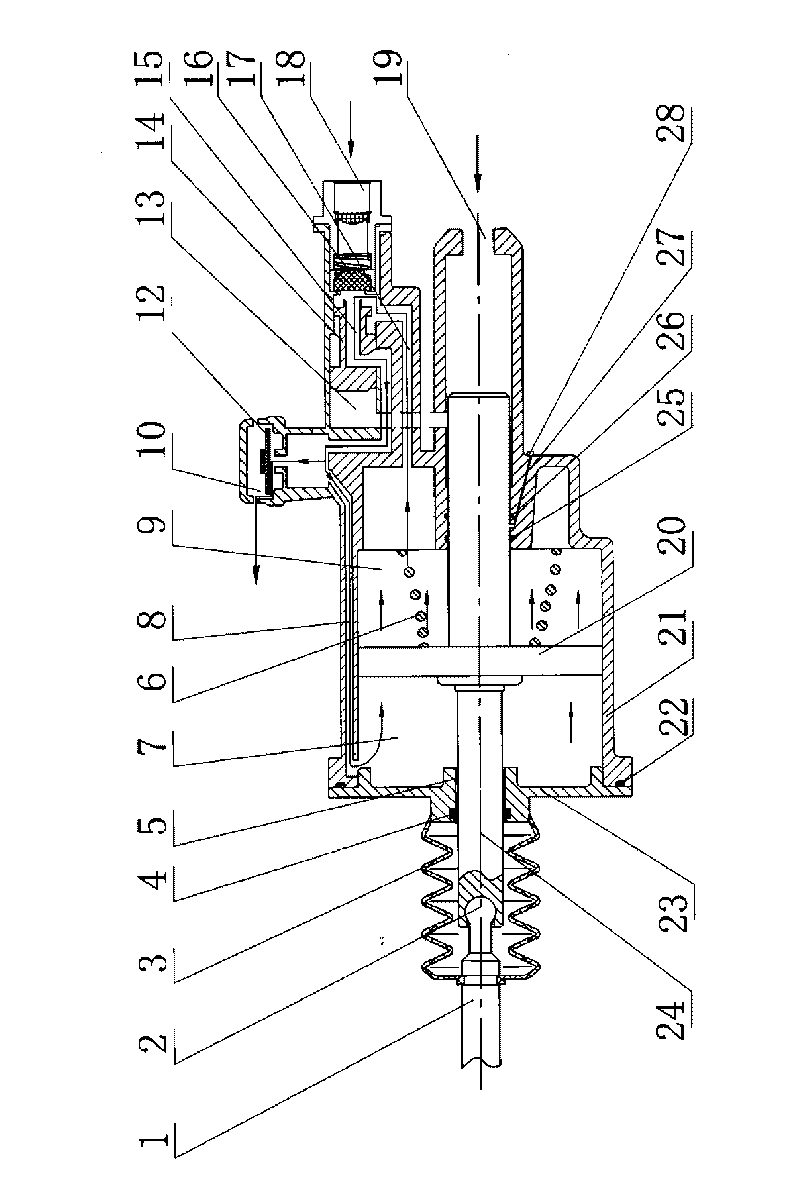

Internal recycle booster

The invention discloses an internal recycle booster comprising a case (21), an end cover (23), a boosting piston (20), an offsetting spring (6) and a piston rod (24), wherein the boosting piston (20) is arranged in the case (21); the boosting piston (20) divides the cylinder body into a front cavity (7) and a rear cavity (9); the offsetting spring (6) is installed in the case (21) and is in contact with the boosting piston (20); the case (21) is provided with an air inlet (18), an air outlet (10) and an oil inlet (19), wherein the air inlet (18) is respectively communicated with the air outlet (10) and the rear cavity (9). The internal recycle booster is characterized in that the end cover (23) and the front cavity (7) form a totally-enclosed cavity body which is communicated with the air outlet (10). After the front cavity of the internal recycle booster becomes a sealed cavity, the front cavity is not directly communicated with outside, thus preventing outside impurities from entering the front cavity, lowering booster invalidation efficiency, prolonging the service life of the booster, and improving the performance of the booster assembly.

Owner:蒋伟荣

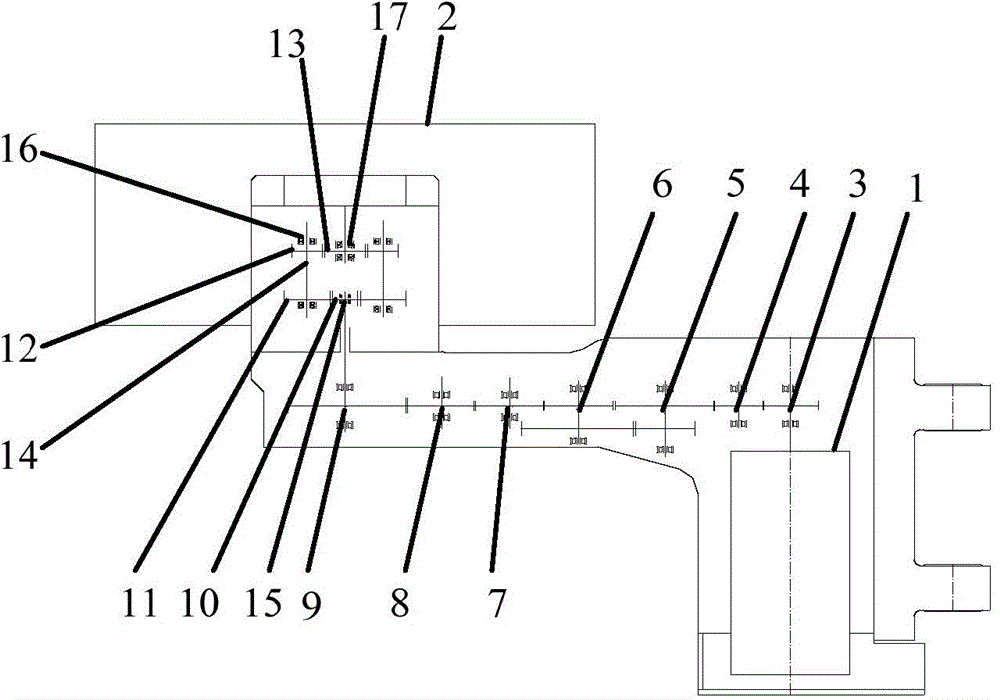

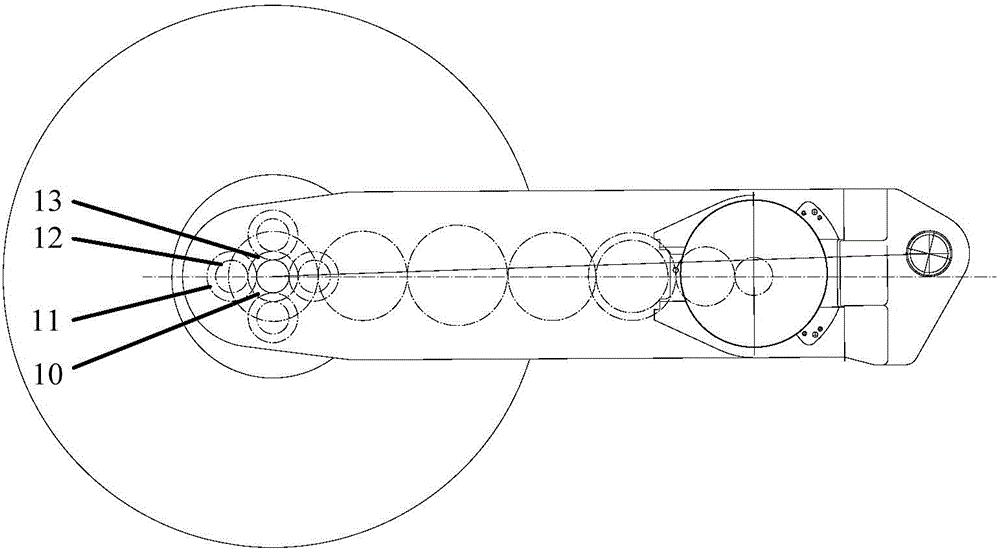

Rocker arm structure and coal mining machine

ActiveCN104806240AGuaranteed stabilityReduce failure frequencyDriving meansCutting machinesFailure rateControl theory

The invention provides a rocker arm structure applying to a coal mining machine. The rocker arm structure comprises a motor, a straight tooth driving part and a torque splitting part, wherein the motor supplies power to the rocker arm structure; the straight tooth driving part comprises shaft assemblies connected with the motor; the torque splitting part comprises input channels, output channels and a connecting part; first gear assemblies of the input channels are connected with the shaft assemblies of the straight tooth driving part, second gear assemblies of the output channels are connected with the first gear assemblies of the input channels and the connecting part, and the connecting part is connected onto a drum. Correspondingly, the invention provides the coal mining machine. According to the technical scheme, the driving efficiency of a rocker arm driving system is improved by means of combination of straight tooth driving and torque splitting driving, and the rocker arm structure has the advantages of low failure rate, light mass, small size and low cost.

Owner:SANY HEAVY EQUIP

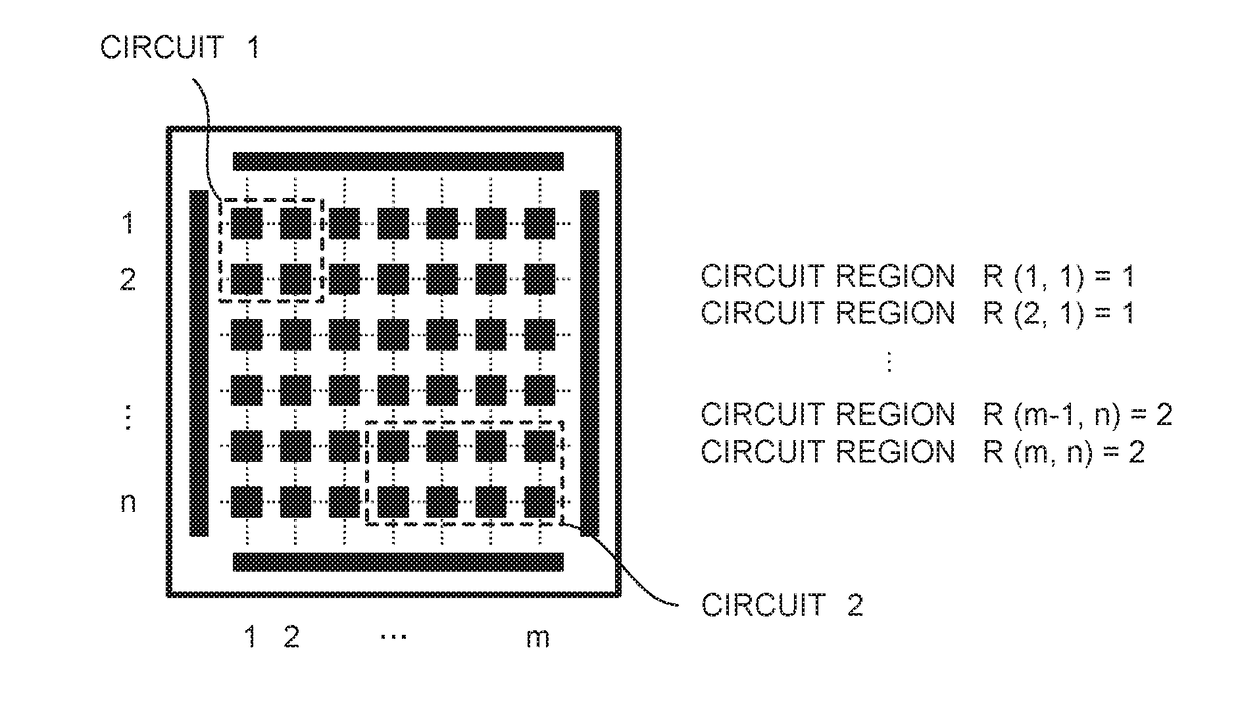

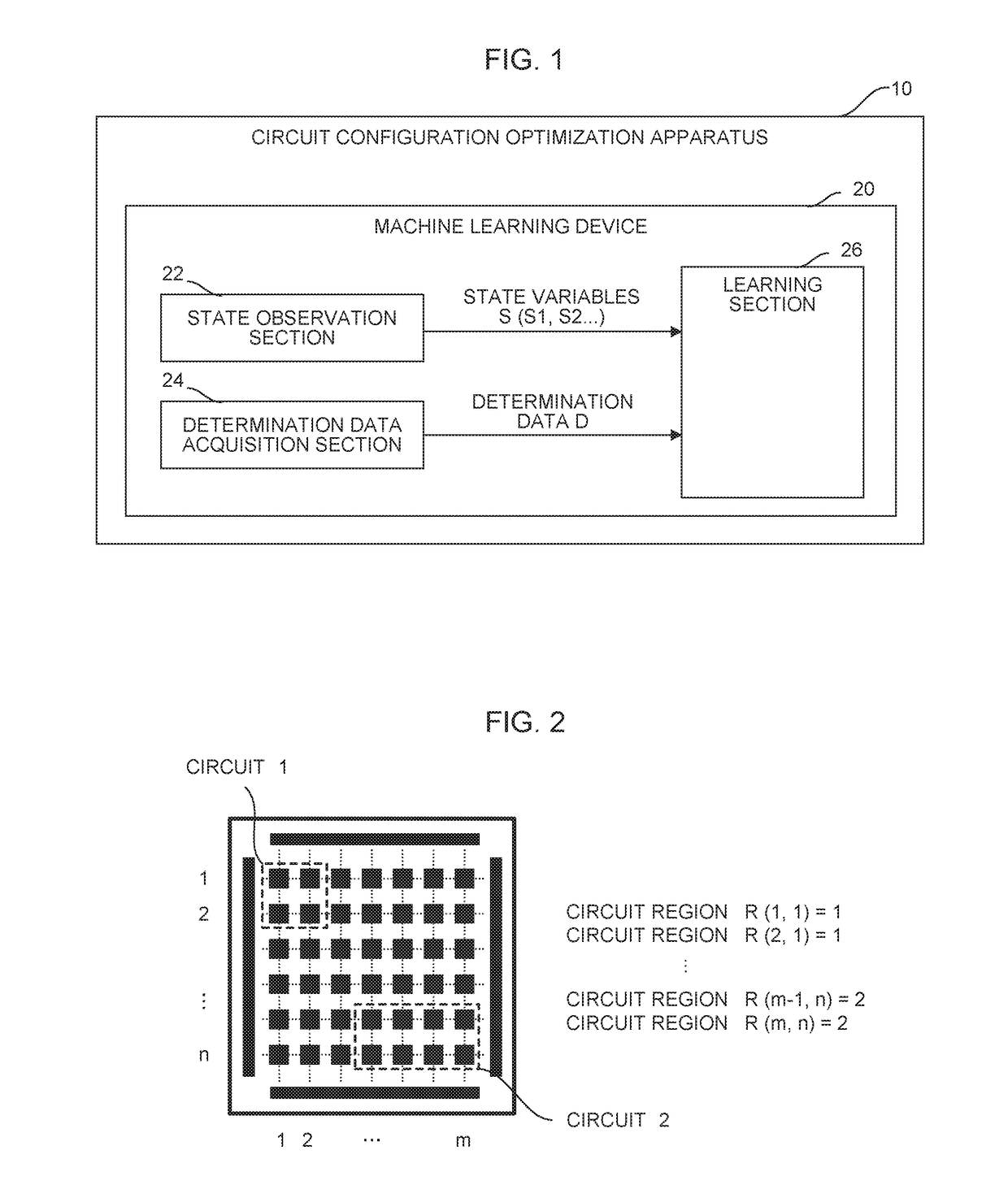

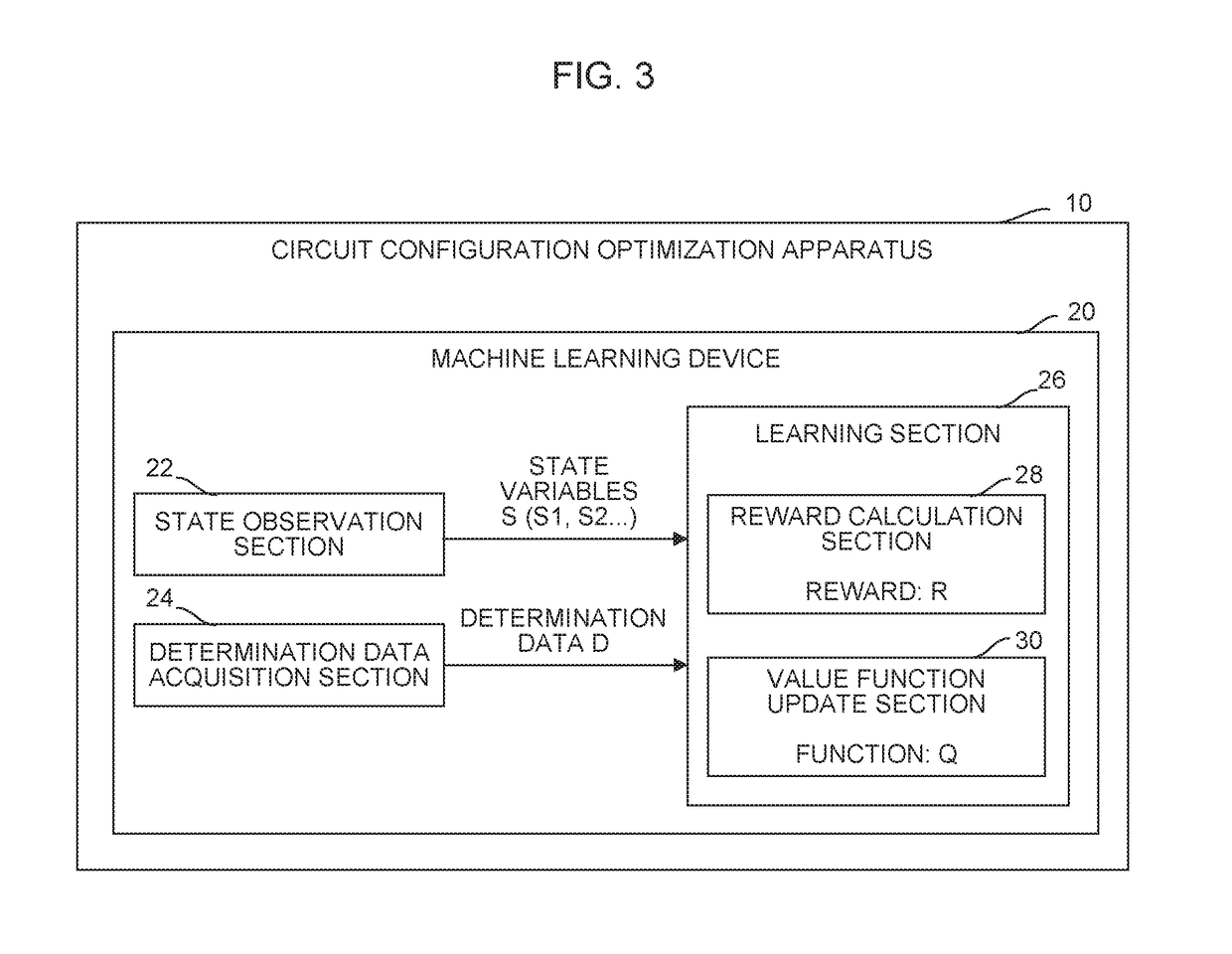

Circuit configuration optimization apparatus and machine learning device

ActiveUS20180300442A1Reduce frequencyReduce failure frequencyDigital computer detailsCAD circuit designConfiguration optimizationState variable

A circuit configuration optimization apparatus includes a machine learning device that learns a circuit configuration of a FPGA device. The machine learning device observes circuit configuration data of the FPGA device and FPGA error occurrence state data indicating an error occurrence state of the FPGA device as state variables that express a current state of an environment. In addition, the machine learning device acquires determination data indicating propriety determination results of an operating state of the FPGA device. Then, the machine learning device learns the circuit configuration of the FPGA device in association with the FPGA error occurrence state data, using the state variables and the determination data.

Owner:FANUC LTD

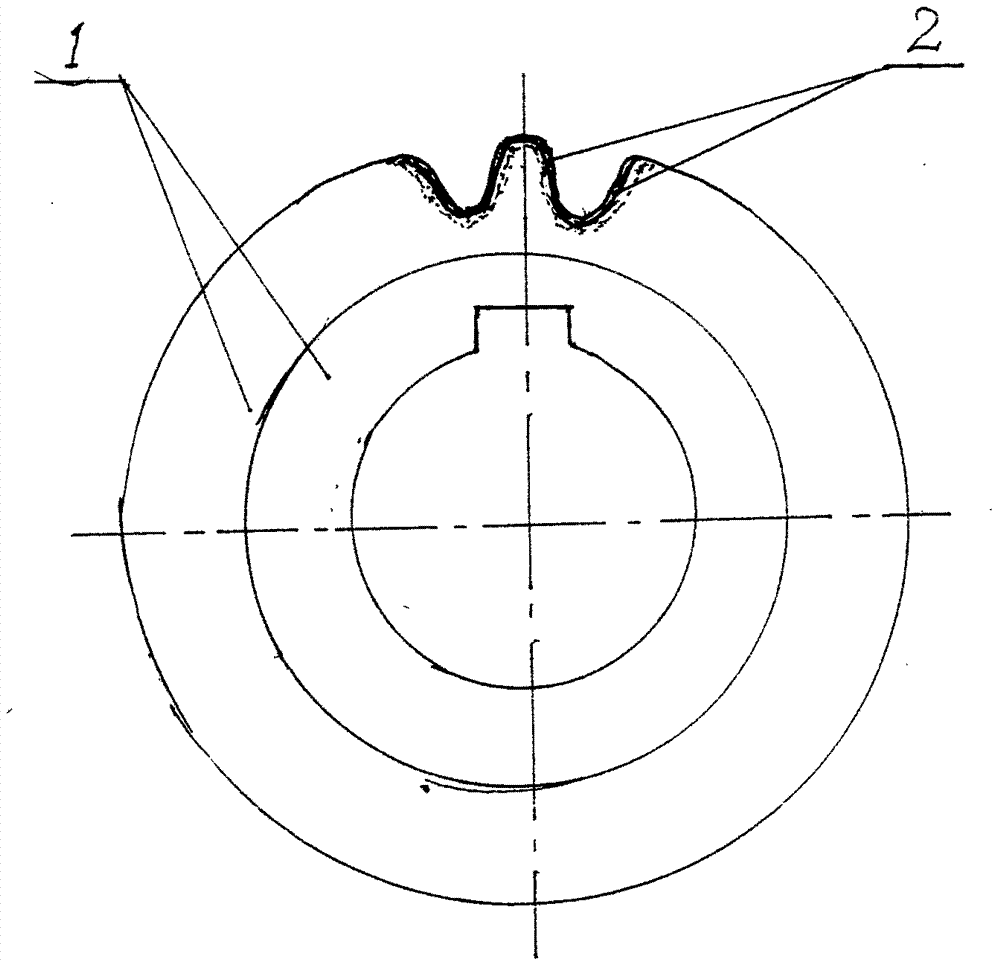

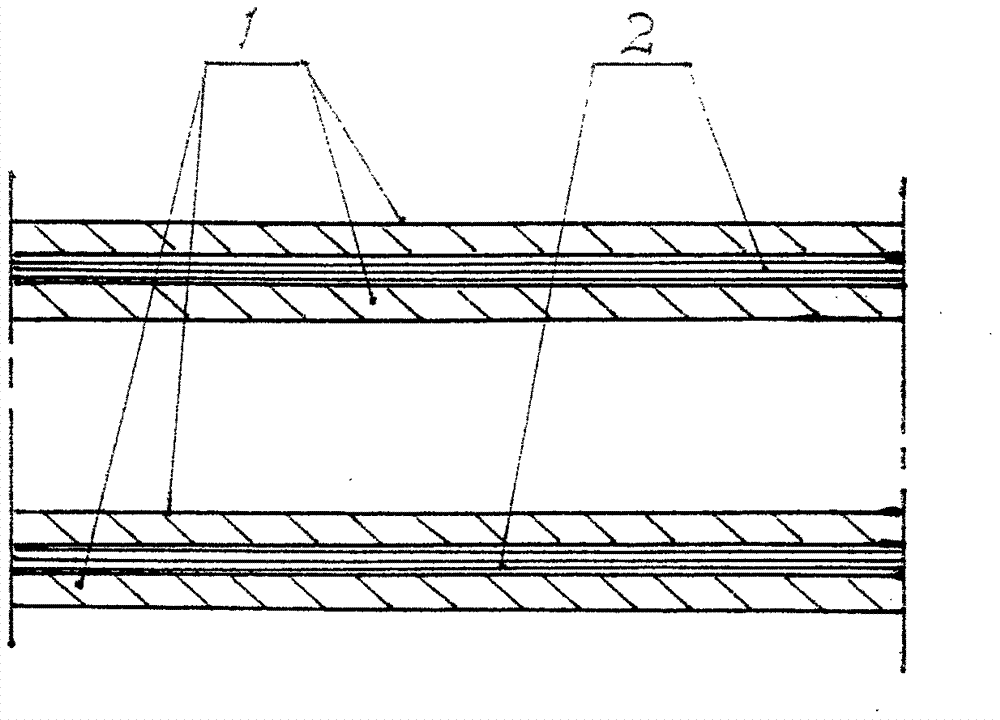

Graphene component

InactiveCN107364189AHigh breaking strengthHigh hardnessDrilling rodsPortable liftingBreaking strengthMechanical equipment

The invention relates to the technical field of components of mechanical equipment and structural systems, and concretely relates to a graphene component. The component is characterized in that the component (1) contains graphene (2). The graphene component has breaking strength resistance which reaches 130Gpa, high temperature resistance which reaches 2360 DEG C, density which is 1 / 8 to 1 / 5 of the density of steel, and elasticity modulus which is 118Gpa; the component has the advantages of electric conduction, heat conduction, water resistance, rust prevention, fatigue tolerance, corrosion resistance, wear resistance, resistance reduction, and scale prevention; and the surface has wide energy application fields.

Owner:马庆囝

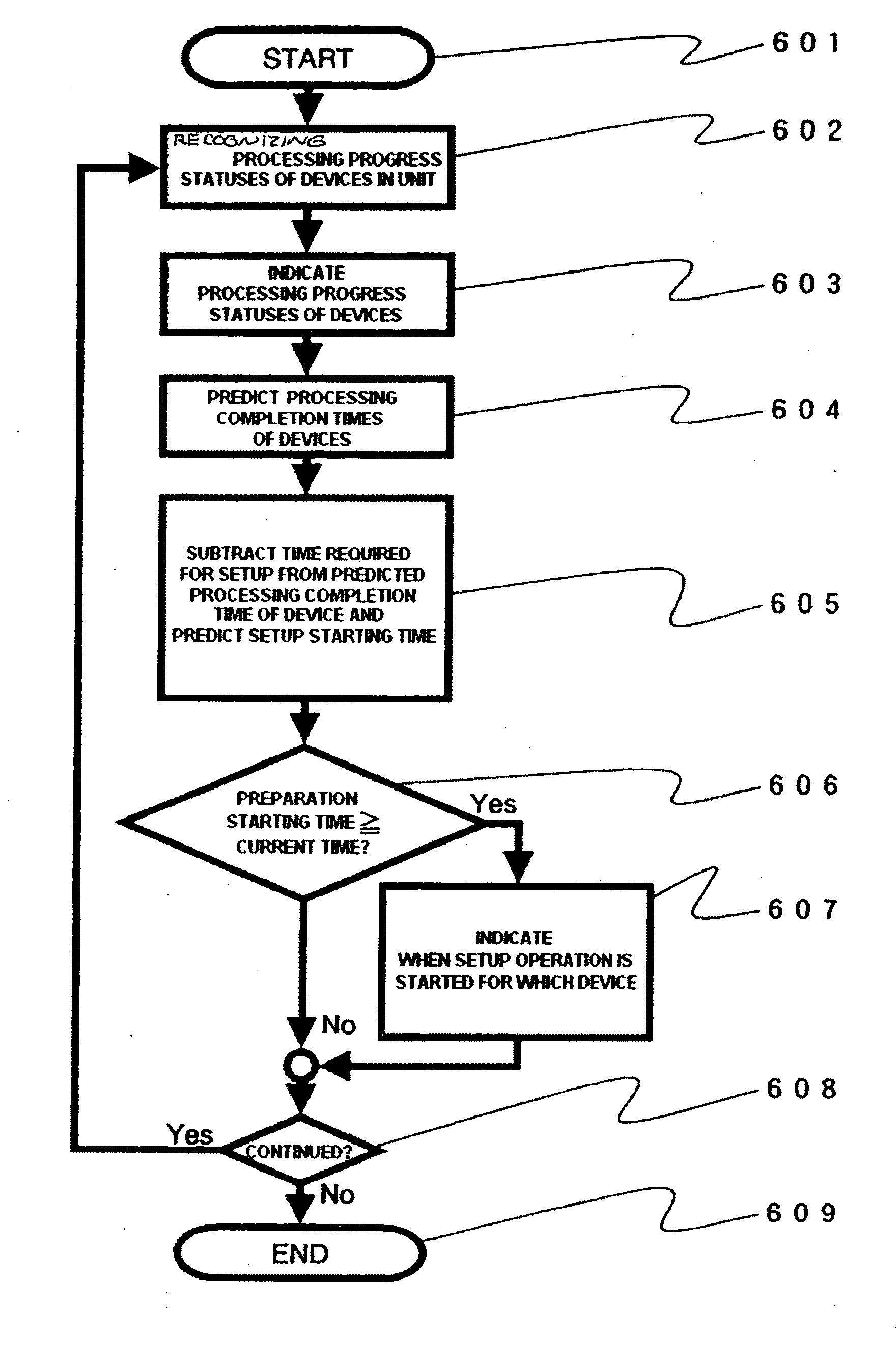

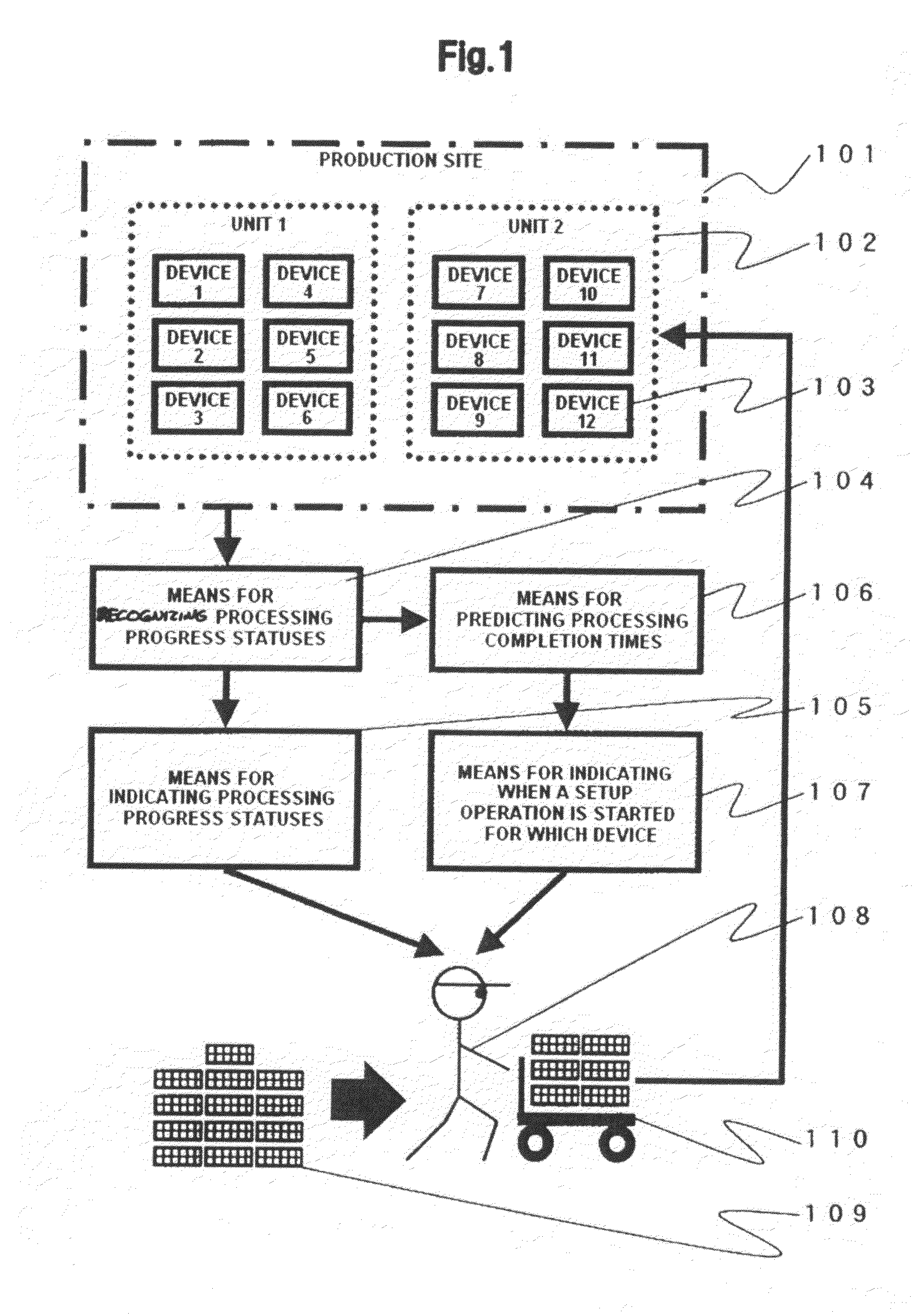

Status indication method and status indication system

InactiveUS20090118856A1Improve productivityShorten operation timeResourcesCommerceEmbedded systemStart time

Embodiments of the present invention provide a method and system for solving a location designation problem to give specific instructions to workers as to where the device that has completed processing is in the production site, and a setup starting time designation problem to give instructions to workers as to when the setup for operation after a test is completed is conducted. One embodiment includes a means for recognizing the processing progress statuses of the devices in the production site, means for indicating the processing progress statuses of the devices, means for predicting the processing completion times of the devices, and means for indicating when a preparation (setup operation) is started for a particular device. A worker receives the processing progress statuses of the respective devices of the respective units from the means for indicating the processing progress statuses of the devices, and records the time to carry in the works to be placed in the devices to the devices and start placement from the means for indicating when a setup operation is started for a particular device.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com