State monitoring and failure diagnosis system for thick plate mill AGC servo valve

A fault diagnosis system and servo valve technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the lack of performance degradation prediction, single semaphore, and no current operating status of the servo valve, etc. problems, to achieve the effect of reducing maintenance workload and maintenance costs, reducing the frequency of occurrence, and improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

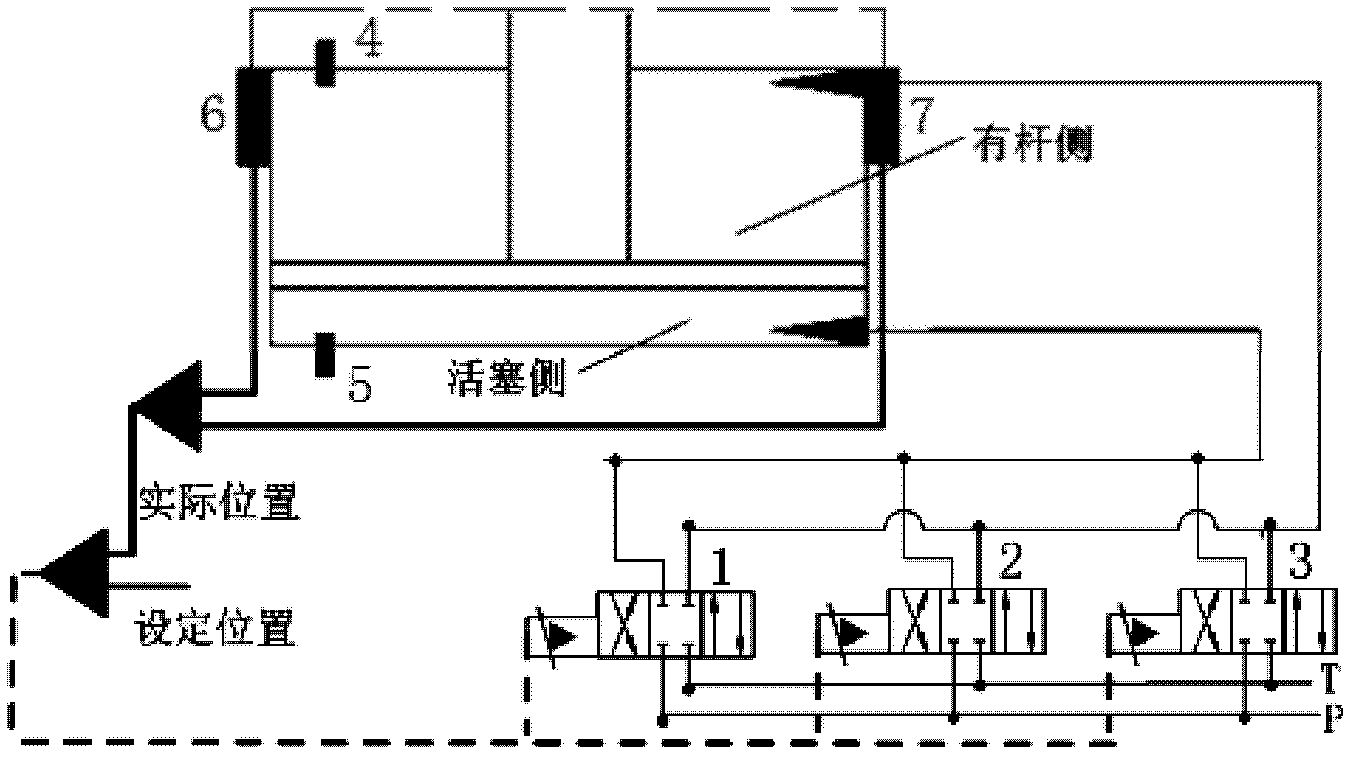

[0023] as attached figure 1 Shown is the schematic diagram of the position control of the AGC system of a general thick plate rolling mill. The system compares the deviation between the measured plate thickness and the required rolled plate thickness, and adjusts the pressing cylinder through the control of the servo valve system to achieve the required exit plate. thick.

[0024] The electro-hydraulic servo valves 1, 2 and 3 are connected in parallel in the hydraulic oil circuit. During normal operation, only two of the three valves are used. If 1 and 2 are used, there is one mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com