Oil charging and semi-linkage-point self-learning method of double-clutch automatic transmission

A technology of automatic transmission and double clutch, which is applied in the direction of transmission, fluid transmission, and components with teeth, etc., can solve problems such as impact, and achieve the effect of improving adaptability and reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

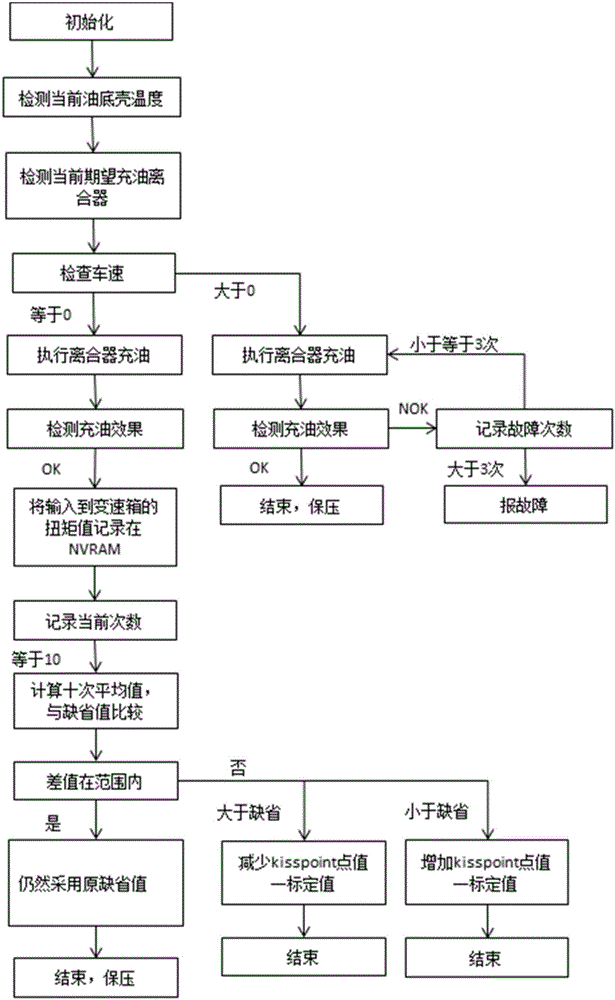

[0029] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

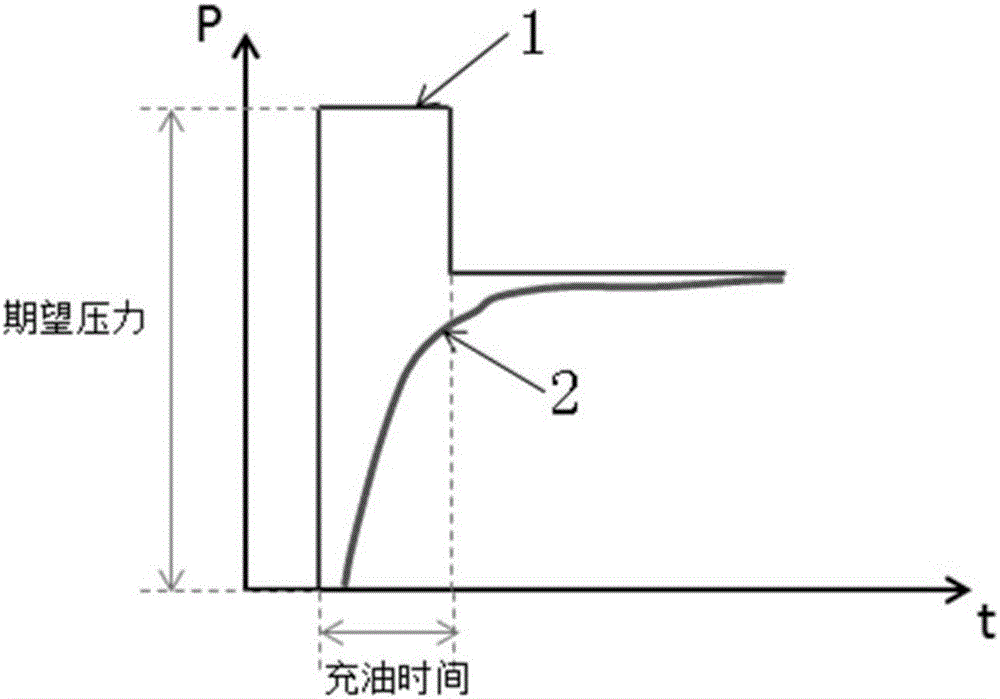

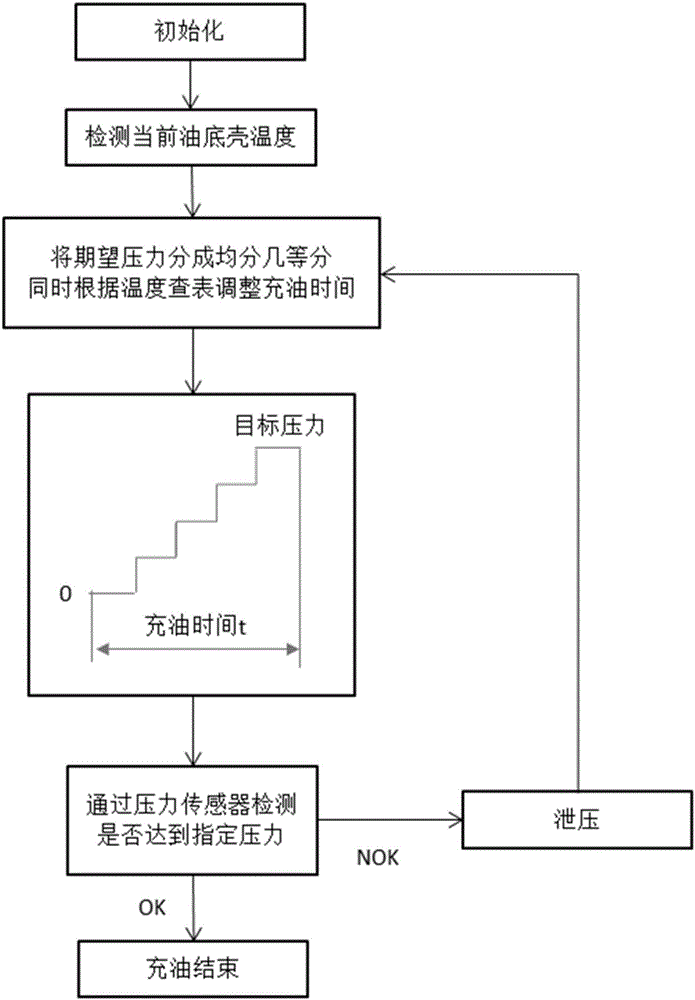

[0030] The invention provides a method for filling oil in a dual-clutch automatic transmission, comprising the following steps: image 3 and Figure 4 As shown, the oil filling method also includes the expected pressure 3 and the actual oil filling pressure 4 .

[0031] First of all, it is necessary to calibrate the dual-clutch automatic transmission at different oil temperatures, different oil filling pressures, and how many setting stages the corresponding oil filling pressure is divided into. , the difference in oil filling pressure at different gears is divided into different setting stages, and in this application, the difference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com