Patents

Literature

106results about How to "Less likely to get stuck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

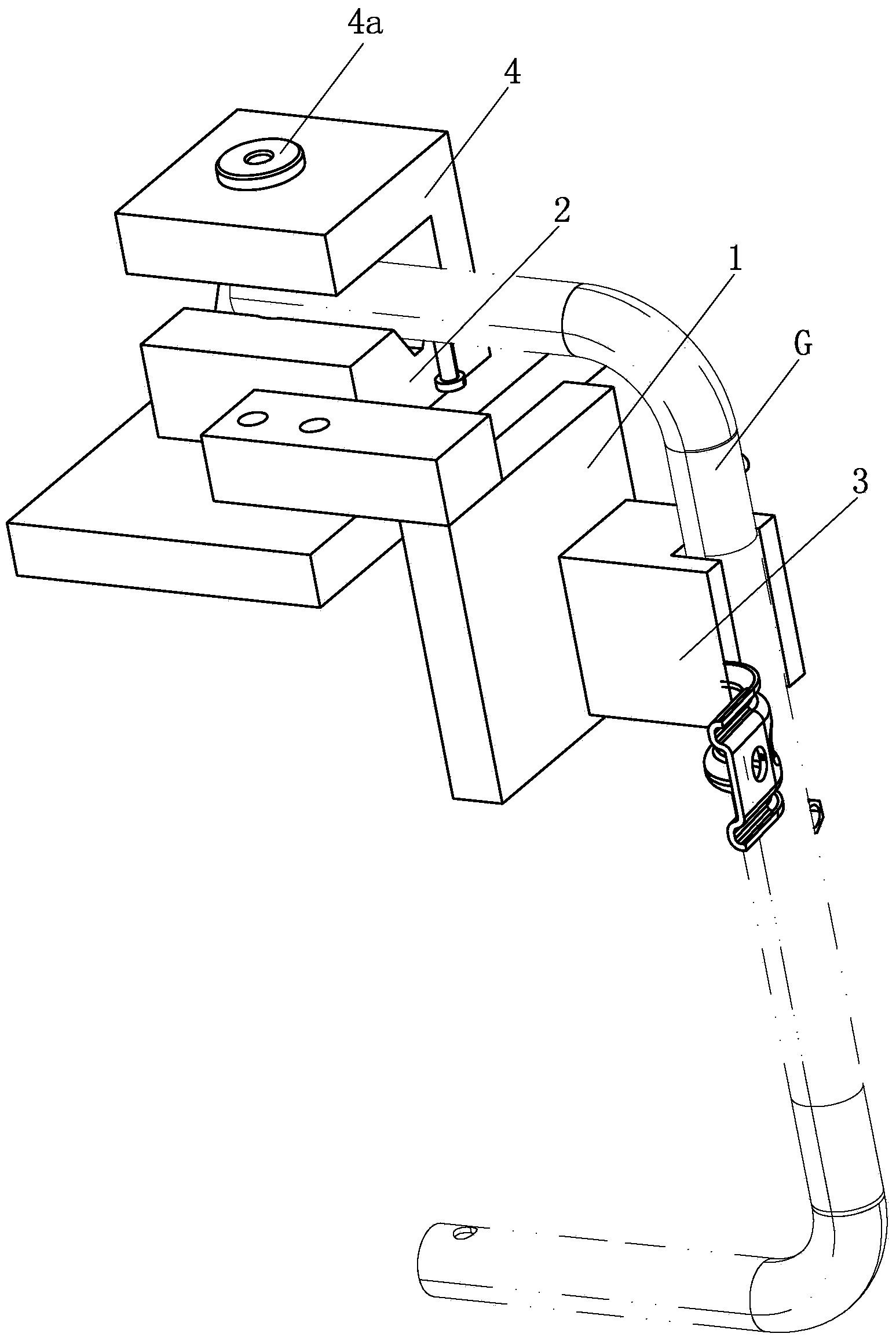

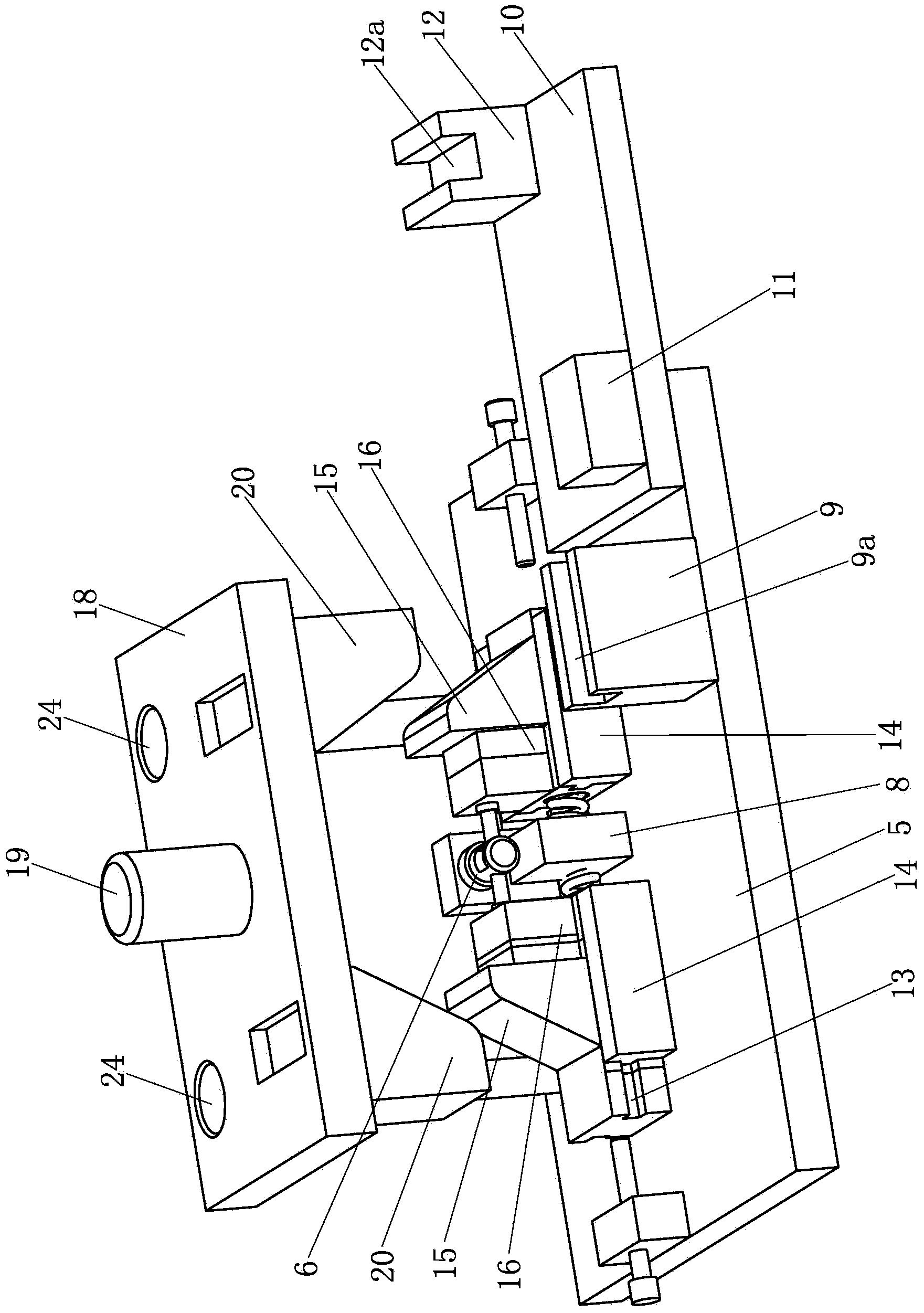

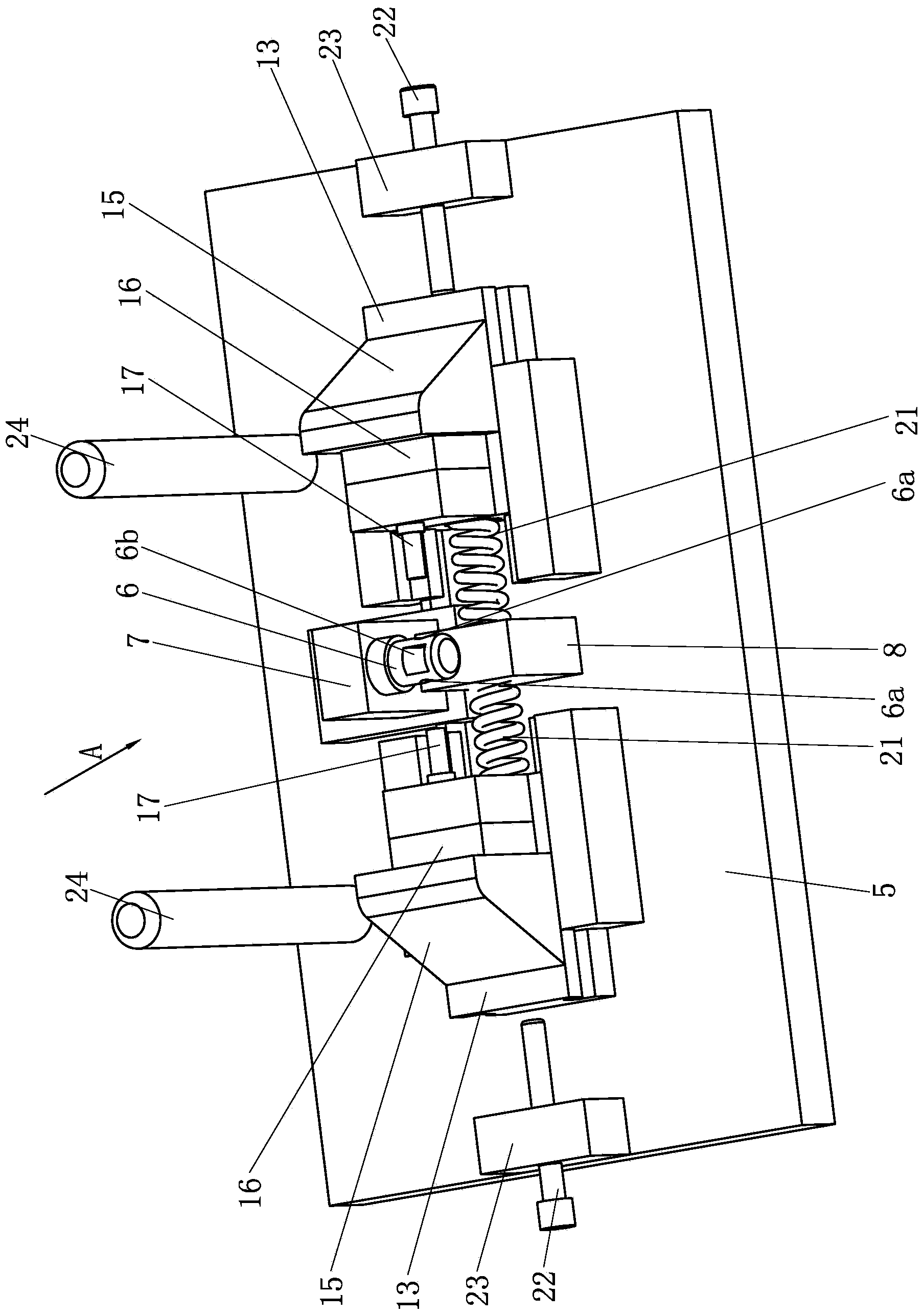

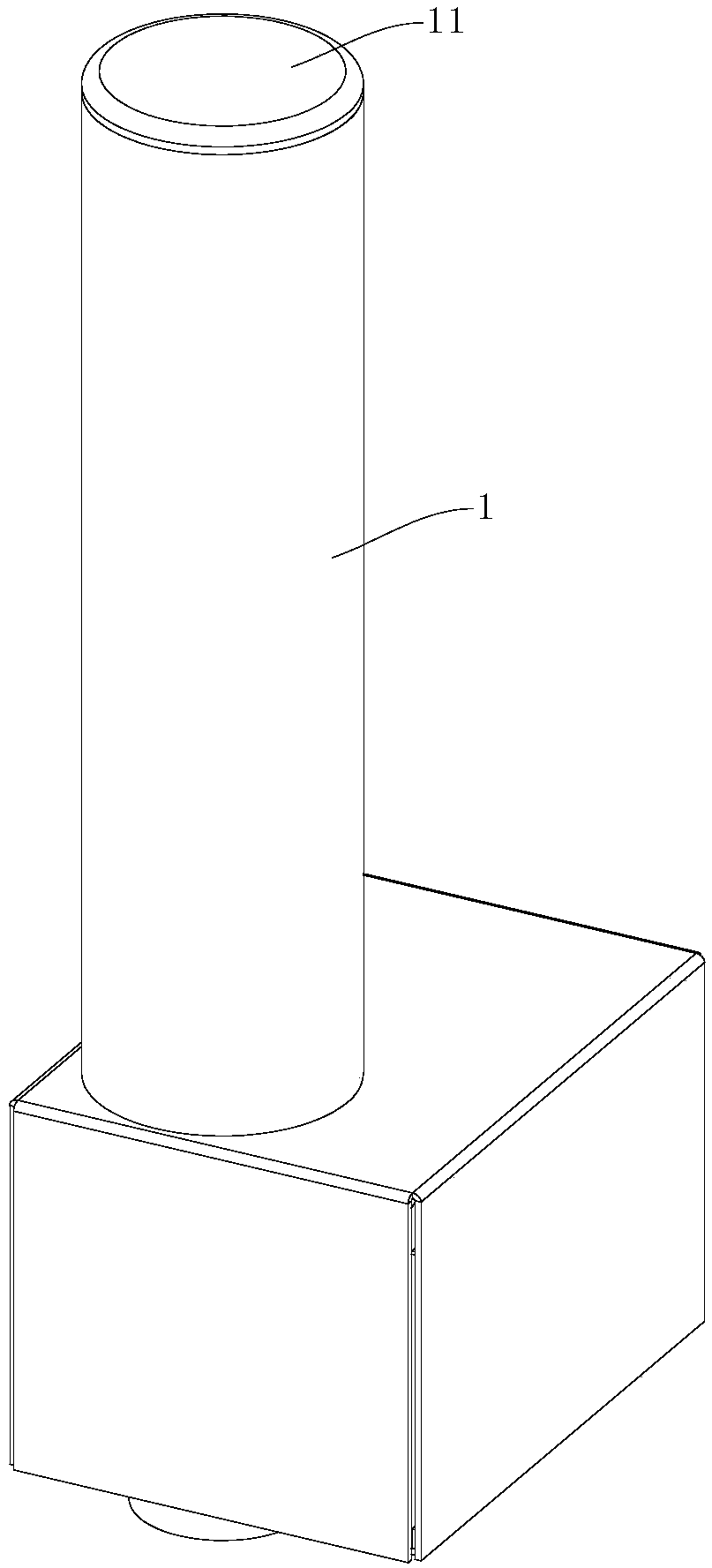

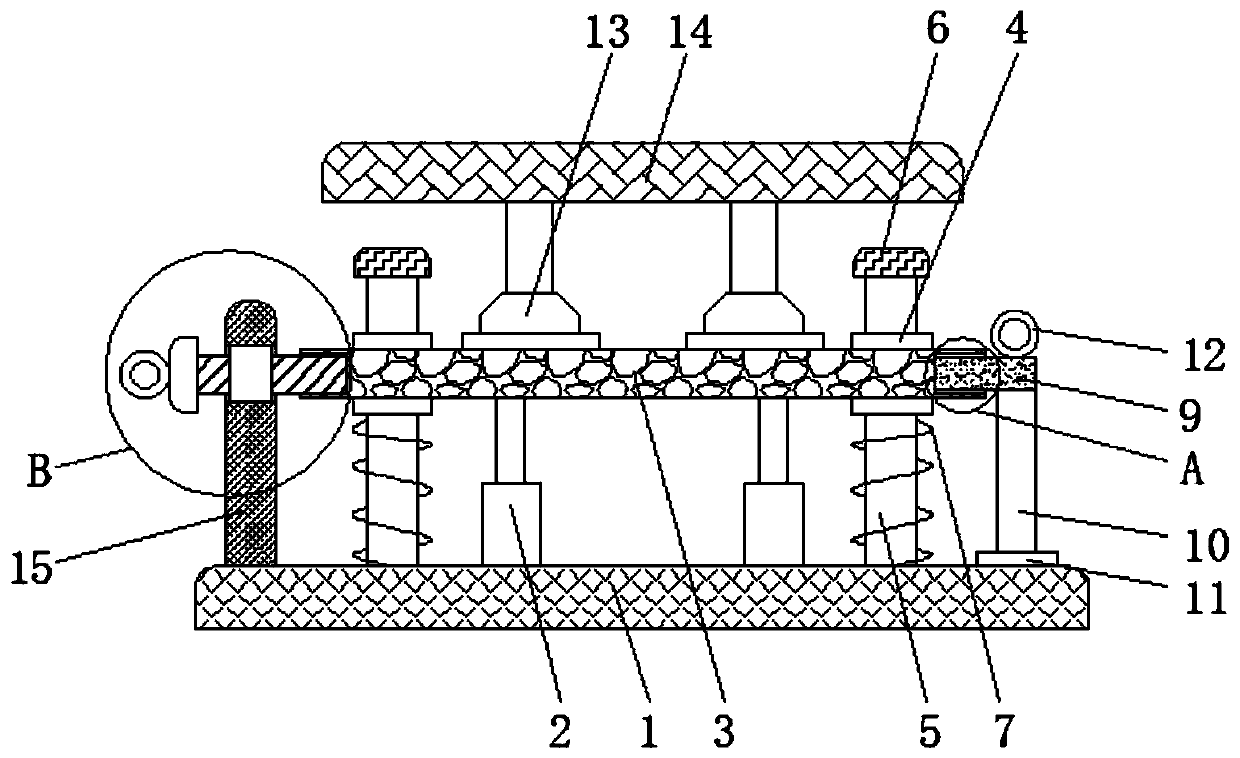

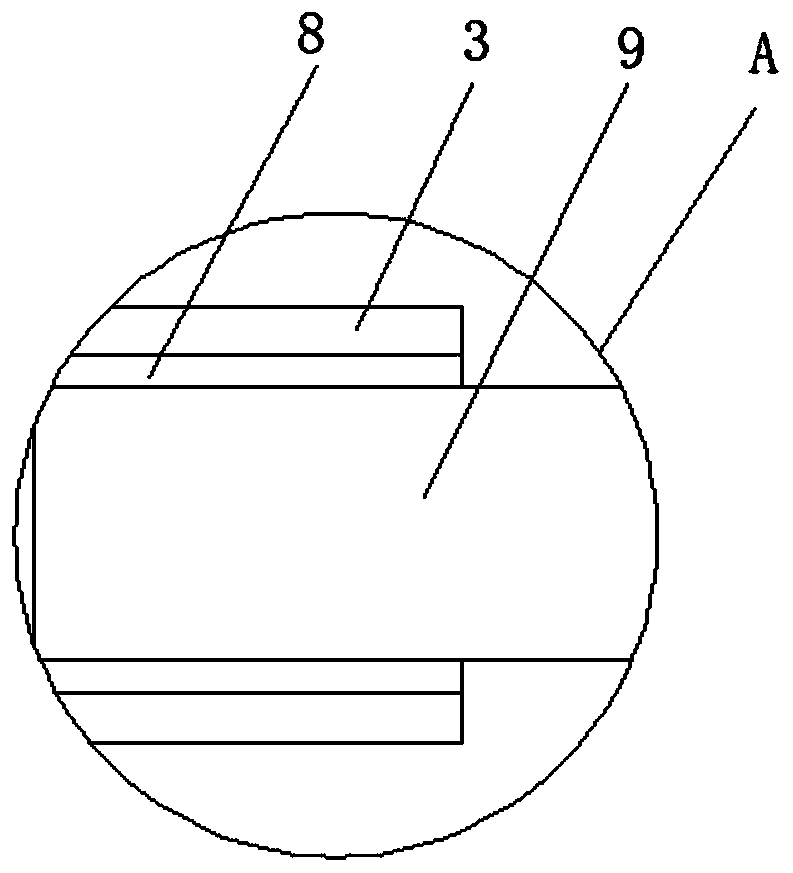

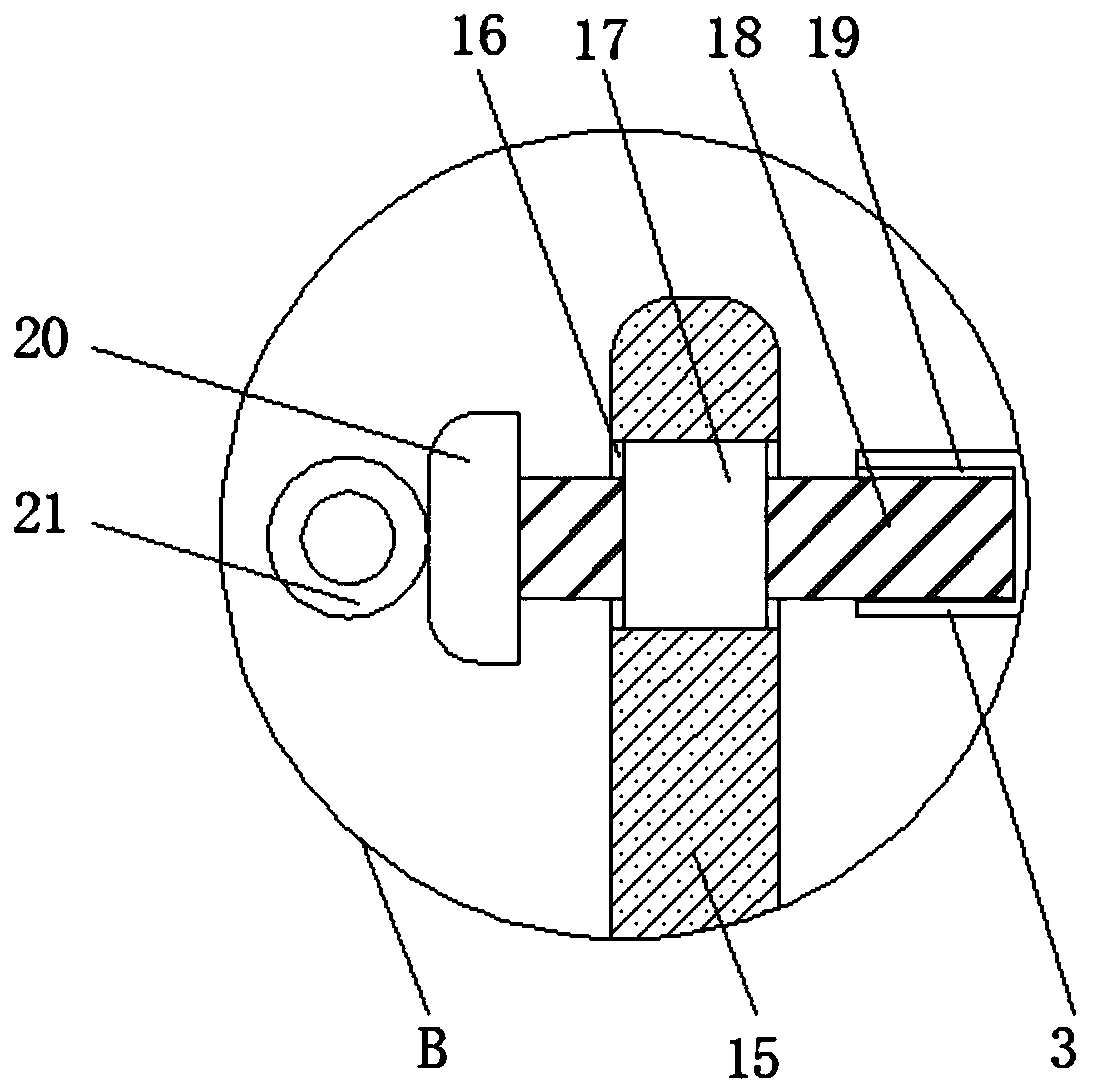

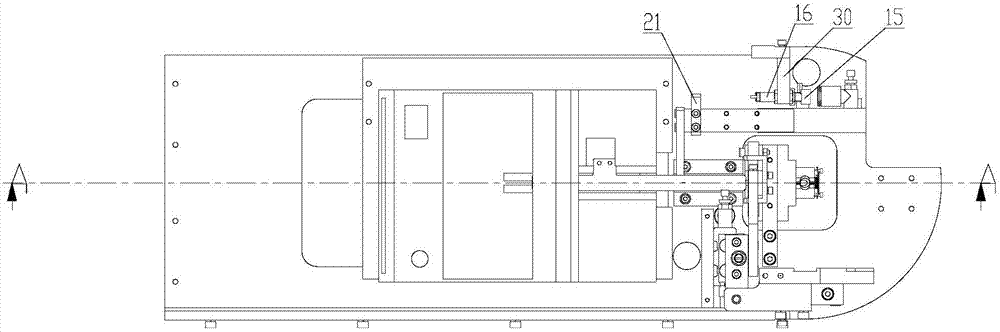

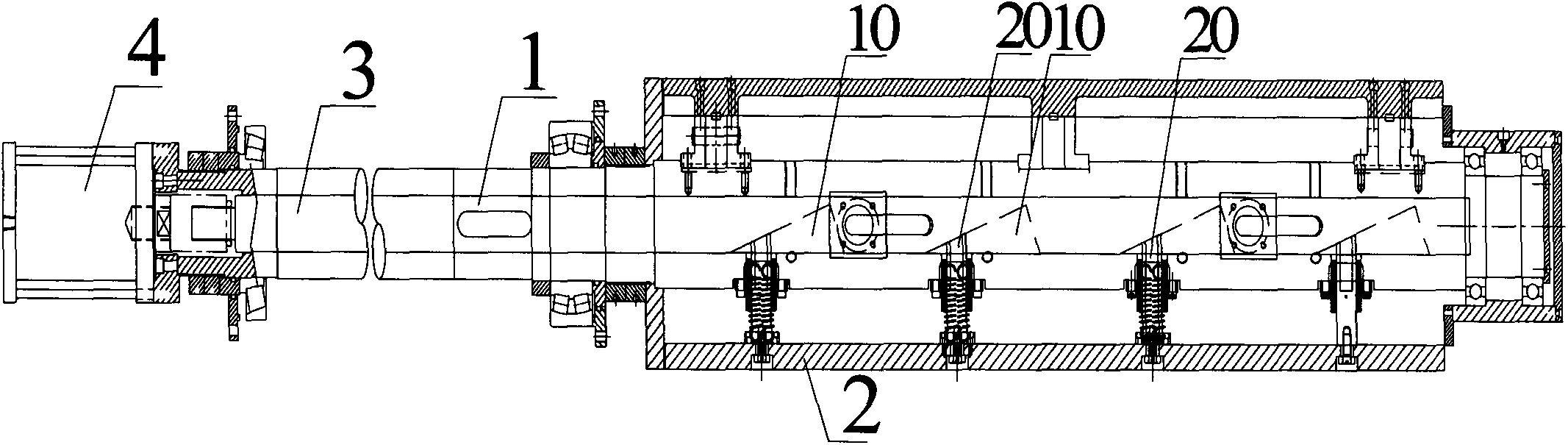

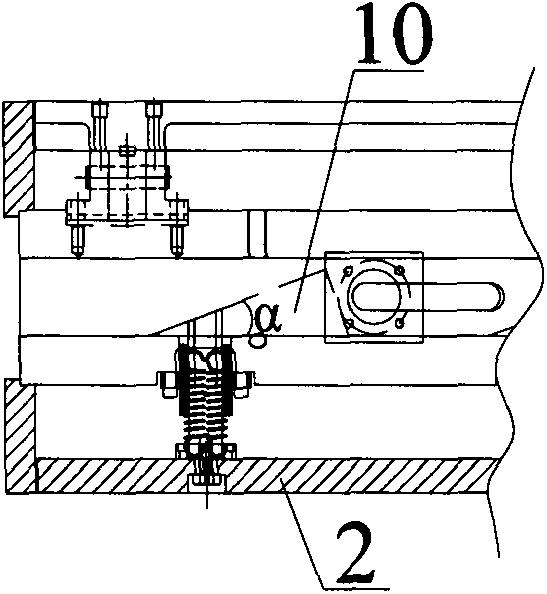

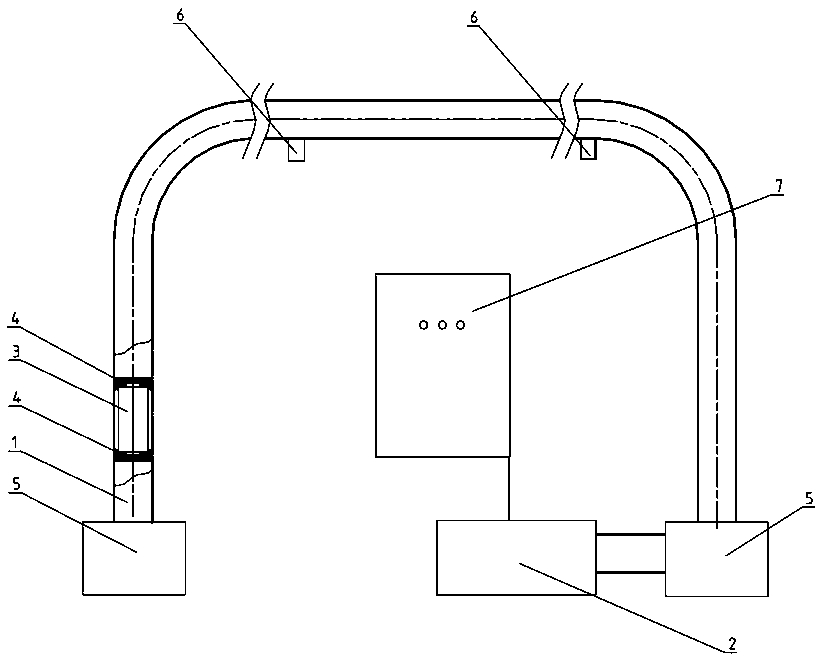

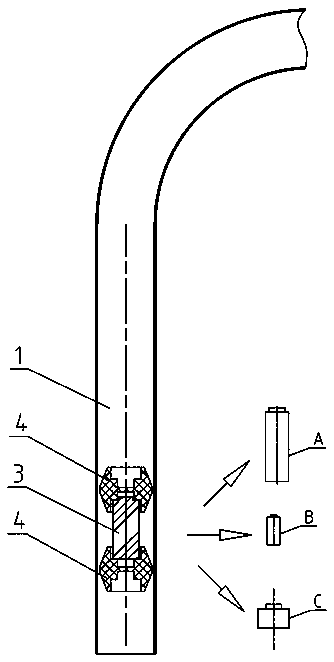

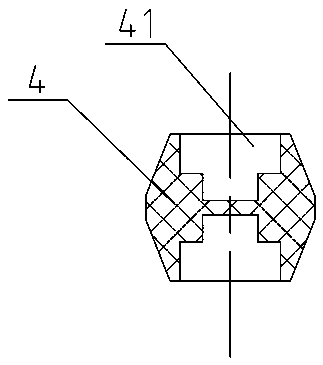

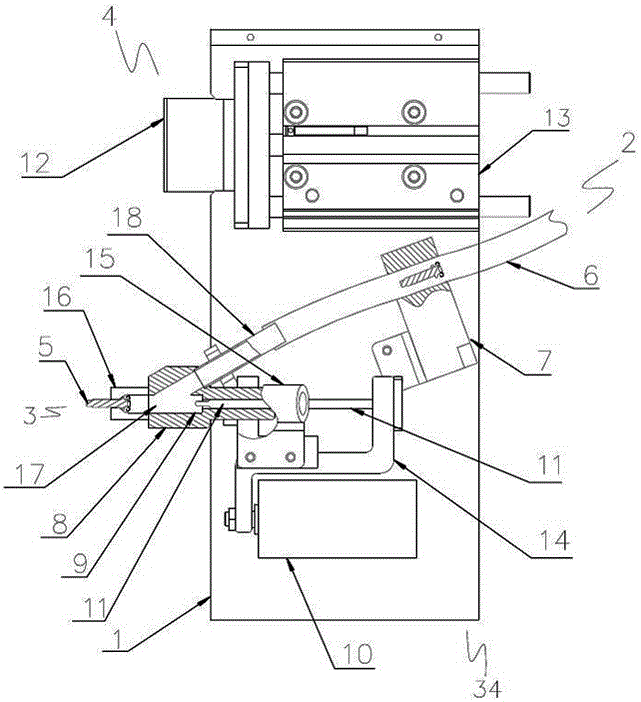

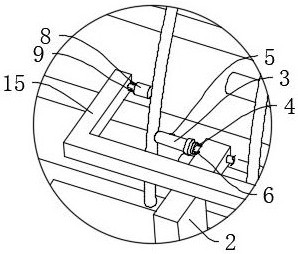

U-shaped pipe landing leg punching tool

InactiveCN103480721AEliminate height errorsImprove machining accuracyPerforating toolsMetal-working feeding devicesEngineeringPunching

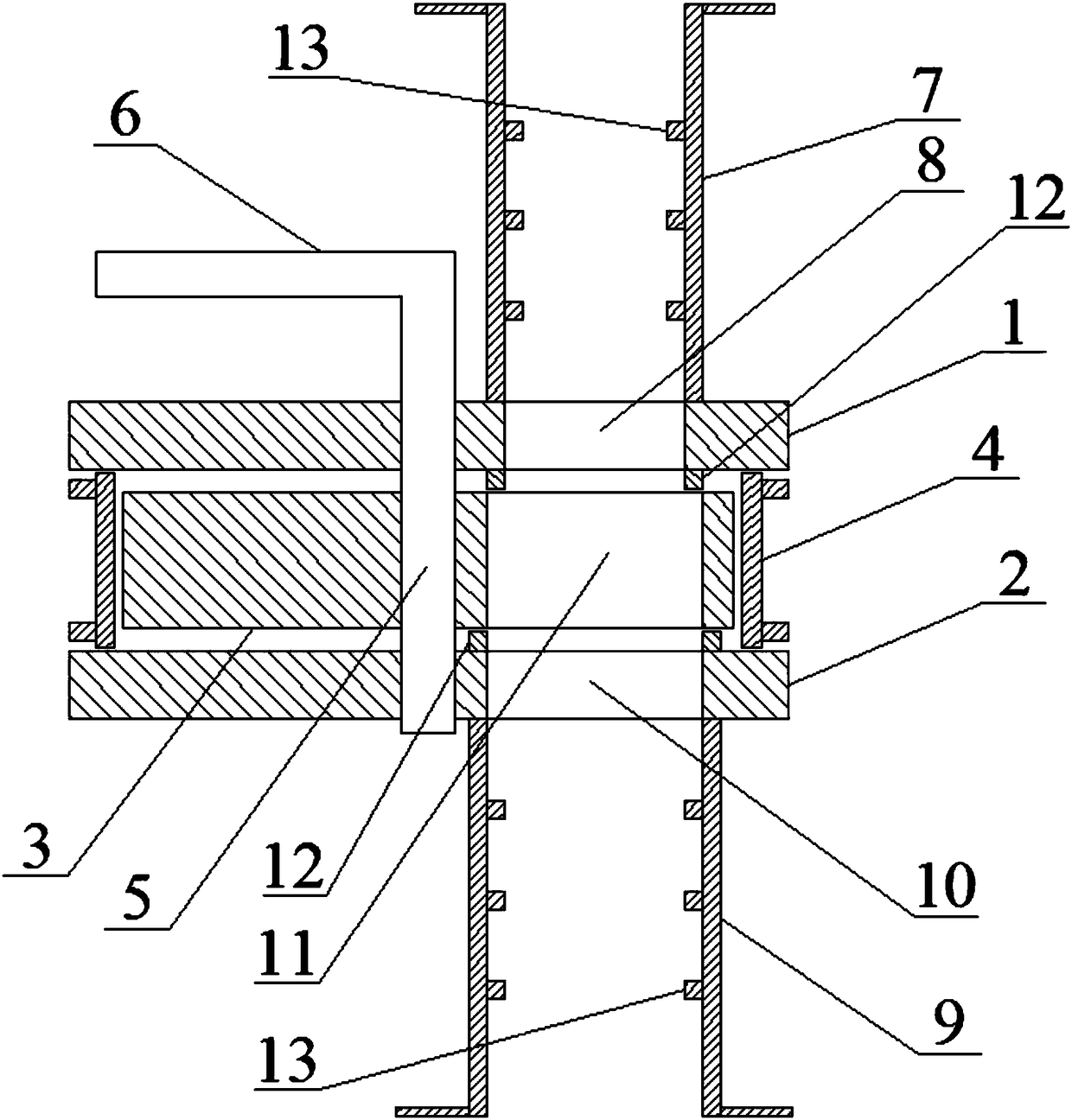

The invention discloses a U-shaped pipe landing leg punching tool, which is characterized in that a U-shaped pipe locating assembly and two side punching assemblies are arranged on the top surface of a horizontal bottom plate, wherein the side walls of a U-shaped pipe locating sleeve in the U-shaped pipe locating assembly are provided with punch via holes, the two side punching assemblies are symmetrical about the U-shaped pipe locating sleeve, a slider in each side punching assembly can slide left and right, the top surface of each slider is fixedly provided with a declivity wedge and a punch stopper, the end face, close to the U-shaped pipe locating sleeve, of each punch stopper is provided with a punch, a punching die is arranged right above the horizontal bottom plate, when the punching die downwards moves, two acclivity wedges push the two declivity wedges in the two side punching assemblies to simultaneously move towards the opposite direction, so that the two sliders can drive the two punches to simultaneously move towards the opposite direction. The U-shaped pipe landing leg punching tool can be used for well locating a U-shaped pipe and further machining holes in landing legs of the U-shaped pipe in a side punching manner, since the U-shaped pipe can be precisely located via the operation, the height error of machined holes in the two landing legs of the U-shaped pipe can be effectively eliminated.

Owner:重庆宏华唯实达汽车部件有限公司

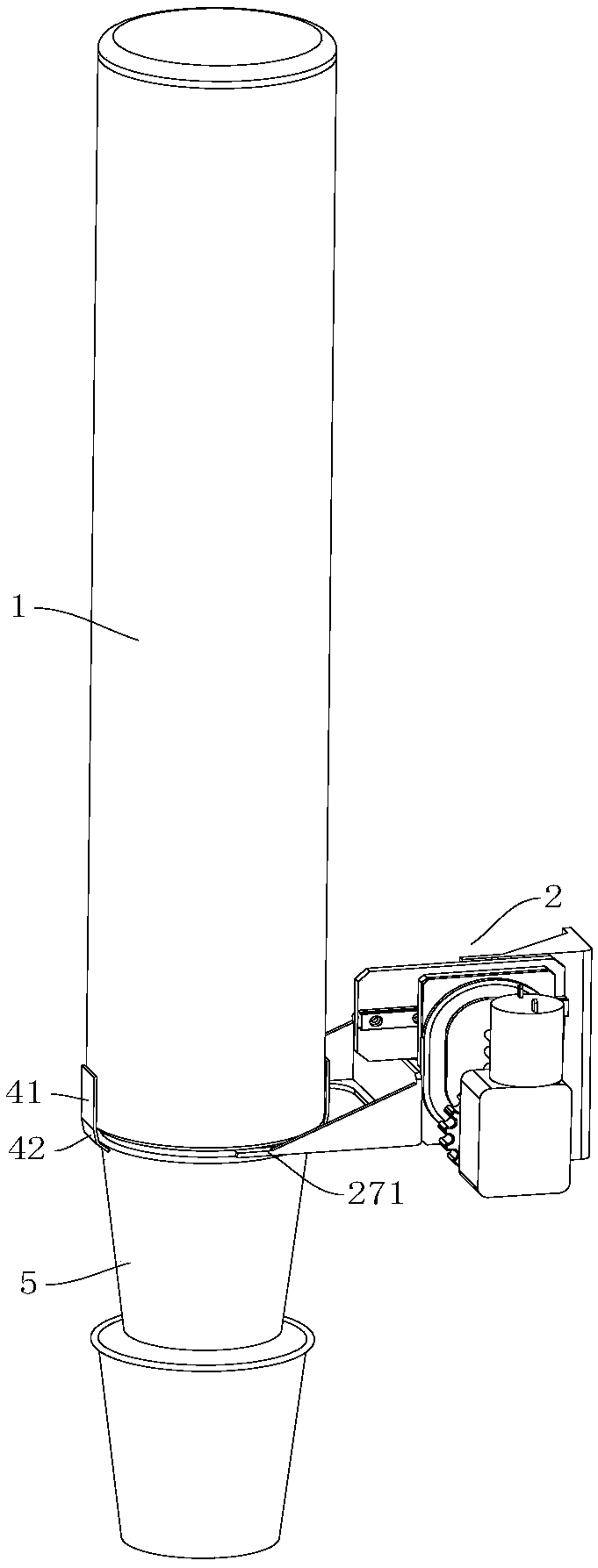

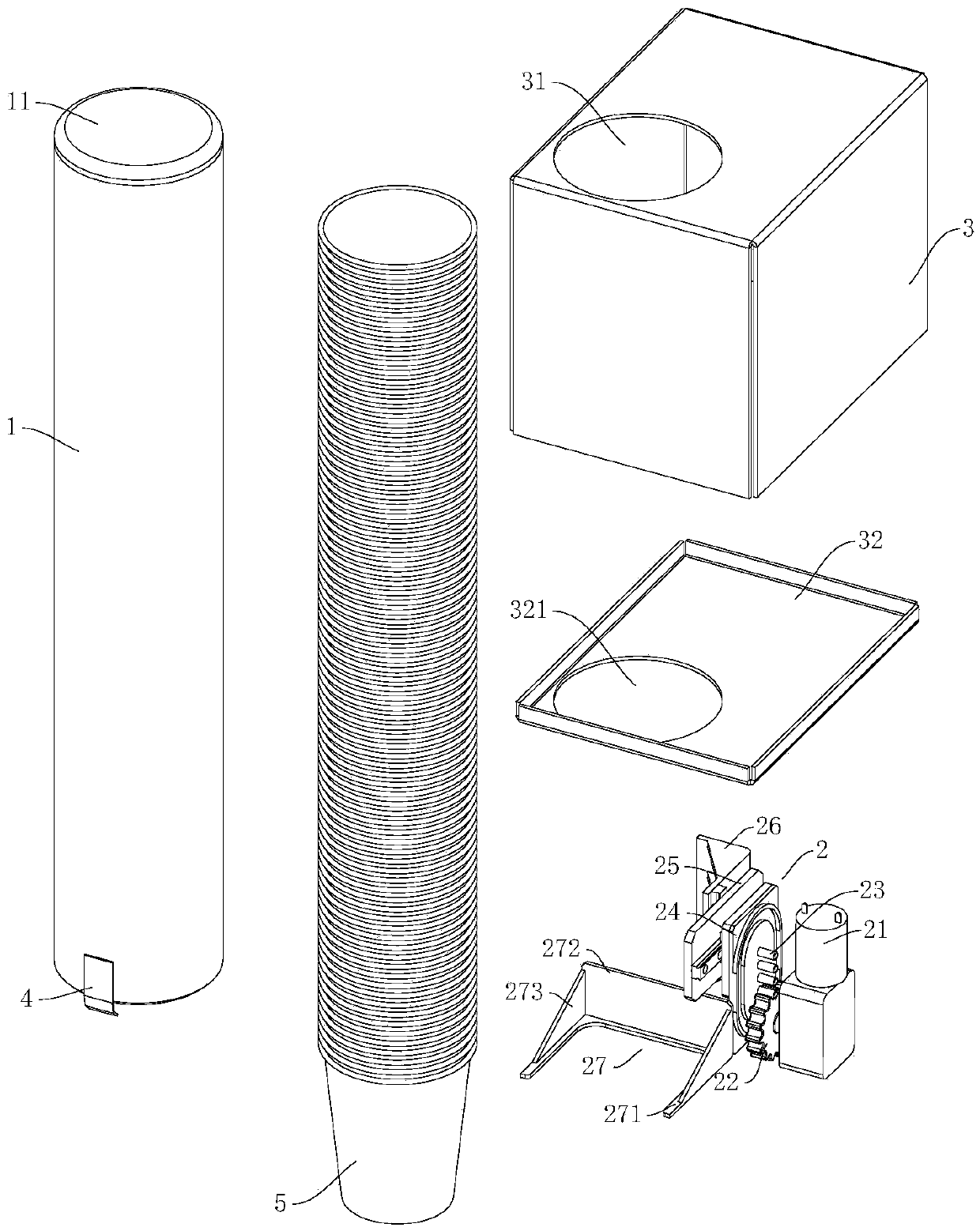

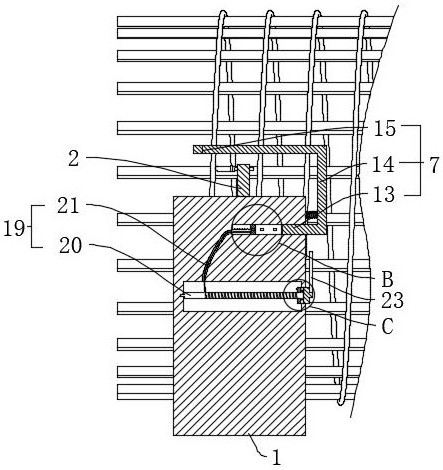

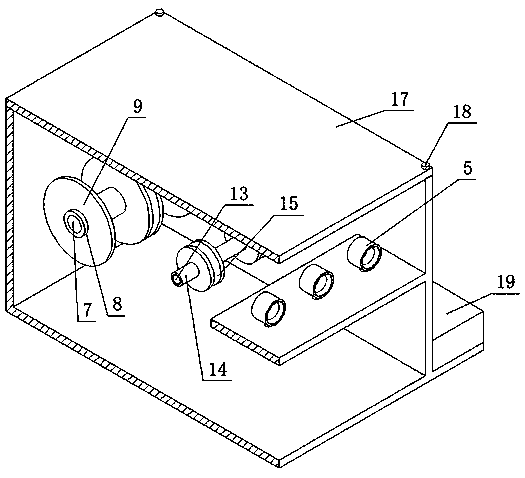

Automatic unloading machine for appliances

The invention discloses an automatic unloading machine for appliances. The automatic unloading machine comprises a storage cylinder, a baffle and a driving mechanism, wherein the storage cylinder comprises a blanking hole and a feeding hole; the baffle is used for bearing an appliance on the bottommost layer; the driving assembly comprises a pushing assembly, a groove wheel mechanism, an X-direction sliding plate, a Y-direction sliding plate, a driving component and a pedestal, the Y-direction sliding plate is connected with the pedestal in a sliding manner and can slide in a Y direction, andthe X-direction sliding plate is connected with the Y-direction sliding plate in a sliding manner and can slide in an X direction; the groove wheel mechanism comprises a groove wheel mechanism and a plurality of transmission columns distributed in a row along the Y direction, and the transmission columns are arranged at the X-direction sliding plate and are meshed with the groove wheel; and the pushing assembly is arranged at the X direction and can be driven through the rotation of the driving component to drive the appliance on the bottom layer to be sequentially separated from the baffle and the appliance sleeved with the appliance on the bottommost layer. The automatic unloading machine has relatively good synchronicity, the appliances are relatively smoothly unloaded, and the unloading effect of the appliances is good.

Owner:GUANGZHOU FUGANG WANJIA INTELLIGENT TECH CO LTD

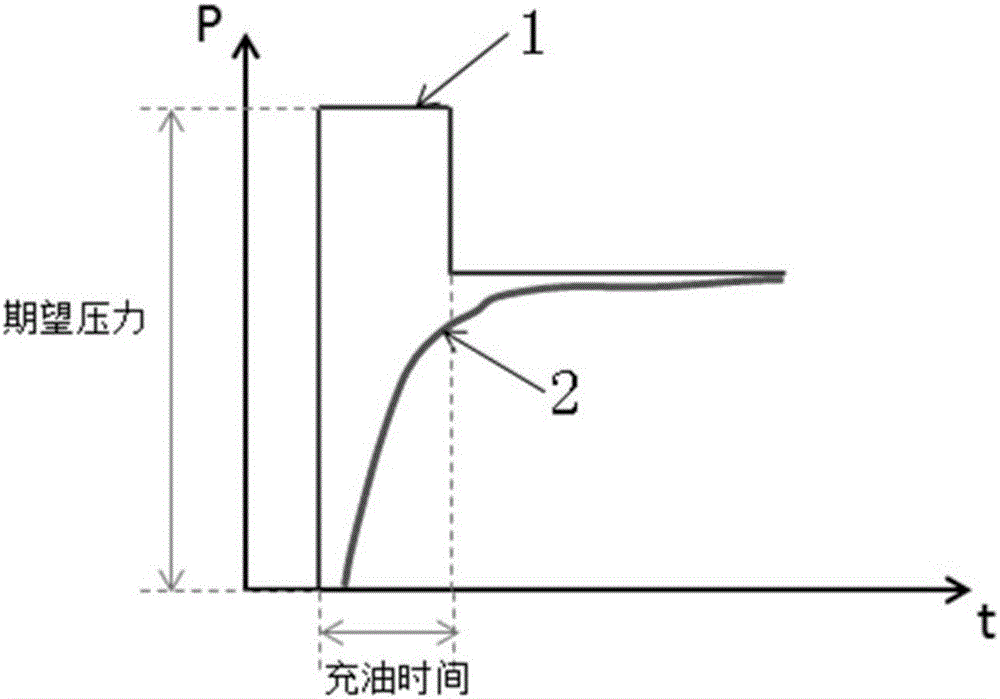

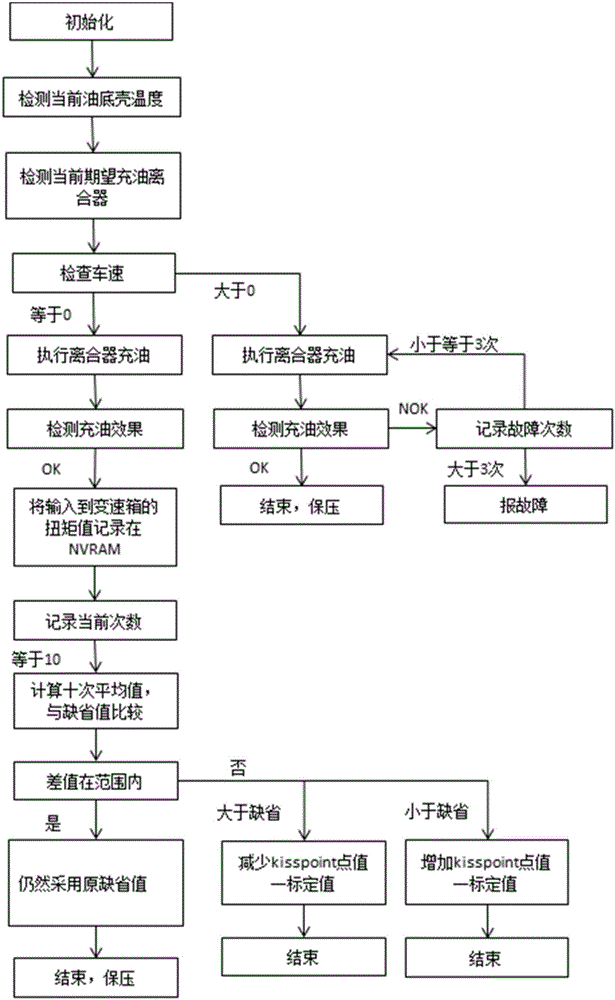

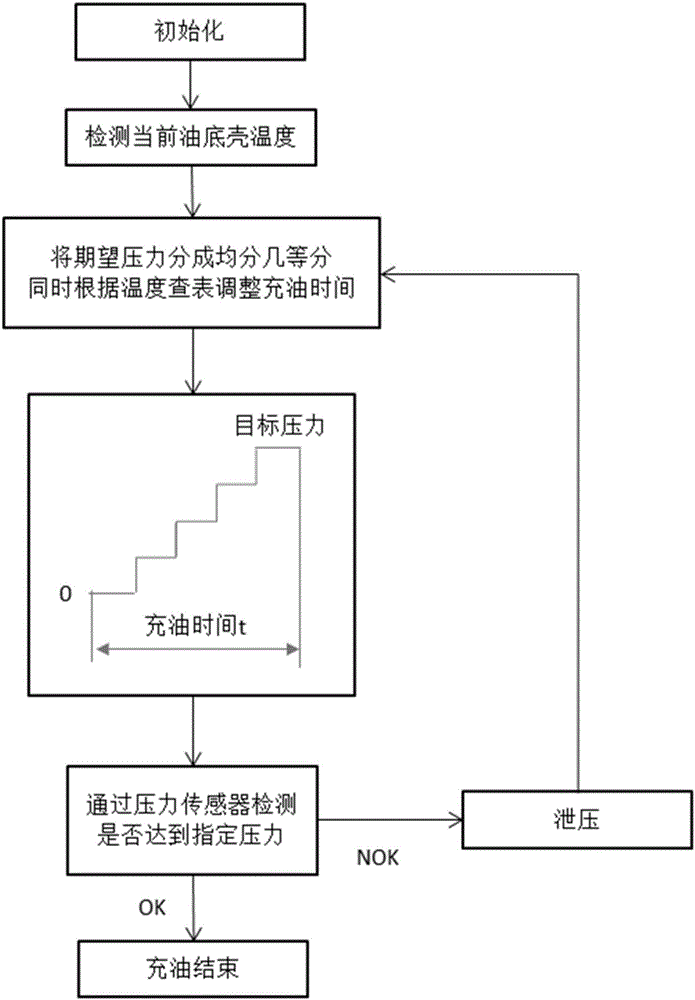

Oil charging and semi-linkage-point self-learning method of double-clutch automatic transmission

ActiveCN106224539AReduce biasImprove adaptabilityGearing controlFluid gearingsOil pressureElectromagnetic valve

The invention relates to an oil charging and semi-linkage-point self-learning method of a double-clutch automatic transmission. After an oil charging control module receives an oil charging command, the oil charging control module receives a present oil temperature detected by a sensor, and divides the oil charging pressure of a clutch into set phases according to the present oil temperature; and then, the oil charging control of the clutch is finished by an oil pressure step ascending mode. The method adopts an interpolation segmented ascending step oil charging method to reduce the clutch pressure impact problem and to prolong the service life of a hydraulic actuation unit; as the oil charging pressure is equally divided, the moving amplitude of an electromagnetic valve is relatively lower, the blockage is not easy to generate, the service life is prolonged, and the fault generation frequency is reduced; and meanwhile, the method is higher in response speed and precision.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

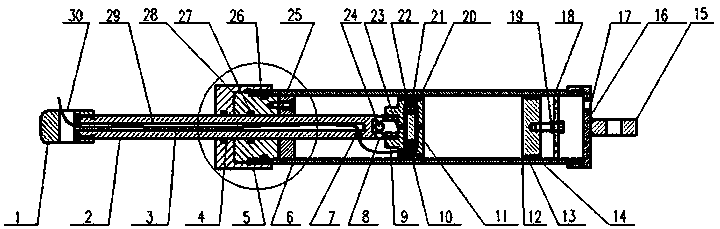

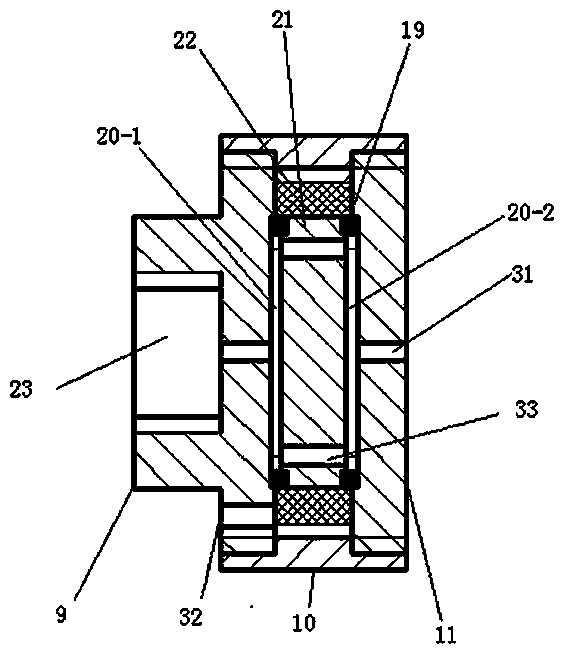

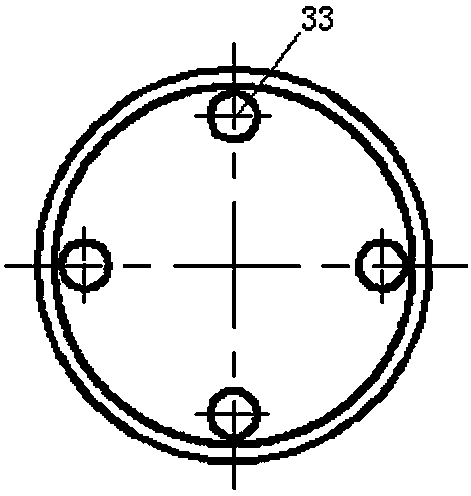

Inner-channel vehicle suspension system magnetorheological damper

InactiveCN103470674ASimple structureReduce manufacturing costSpringsNon-rotating vibration suppressionRoad surfaceMechanical engineering

The invention discloses an inner-channel vehicle suspension system magnetorheological damper, which comprises a cylinder barrel; a combined electromagnetic piston and a floating piston are arranged in the cylinder barrel in sequence from top to bottom; the combined electromagnetic piston divides the cavity chamber above the floating piston into an upper cavity chamber and a lower cavity chamber, which are filled with magnetorheological fluid; a bottom cover is arranged at the bottom end of the cylinder barrel; the bottom cover is respectively fixedly connected with an inflating and deflating valve and a lower lifting ring; a guide seat is arranged at the upper end of the cylinder barrel; the upper end of the guide seat tightly covers an upper end cover pressing the guide seat; the lower end of the guide seat is fixedly connected with a buffering block; the combined electromagnetic piston is fixedly connected with a piston rod penetrating through the guide seat and the upper end cover to extend outwards; the outer end of the piston rod is fixedly connected with an upper lifting ring of which the inside is provided with a wire outgoing groove. The inner-channel vehicle suspension system magnetorheological damper is simple in structure and low in manufacturing cost, can accurately adjust vehicle vibration generated by random excitation of a road face, and is high in work efficiency and work stability; the floating piston is enabled not to be clamped in the moving process up and down, and is stable when being used for pressure compensating; the liquid cannot easily leak in the work process.

Owner:XIANGTAN UNIV

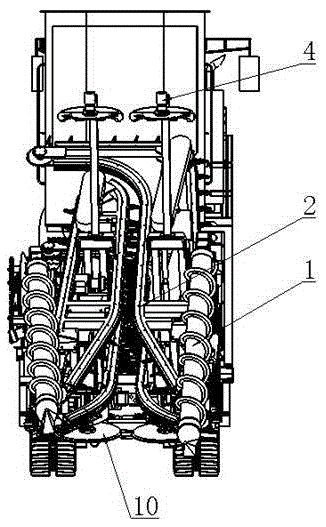

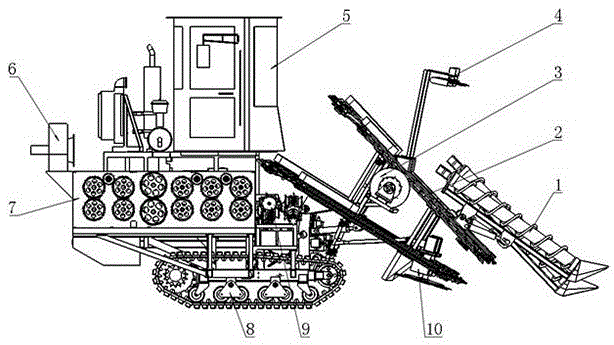

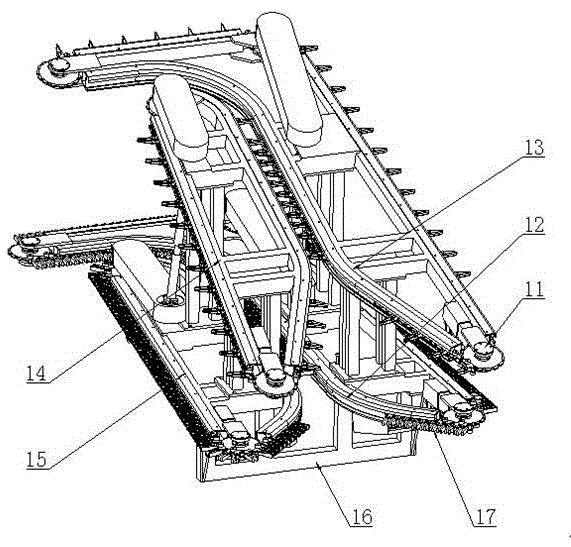

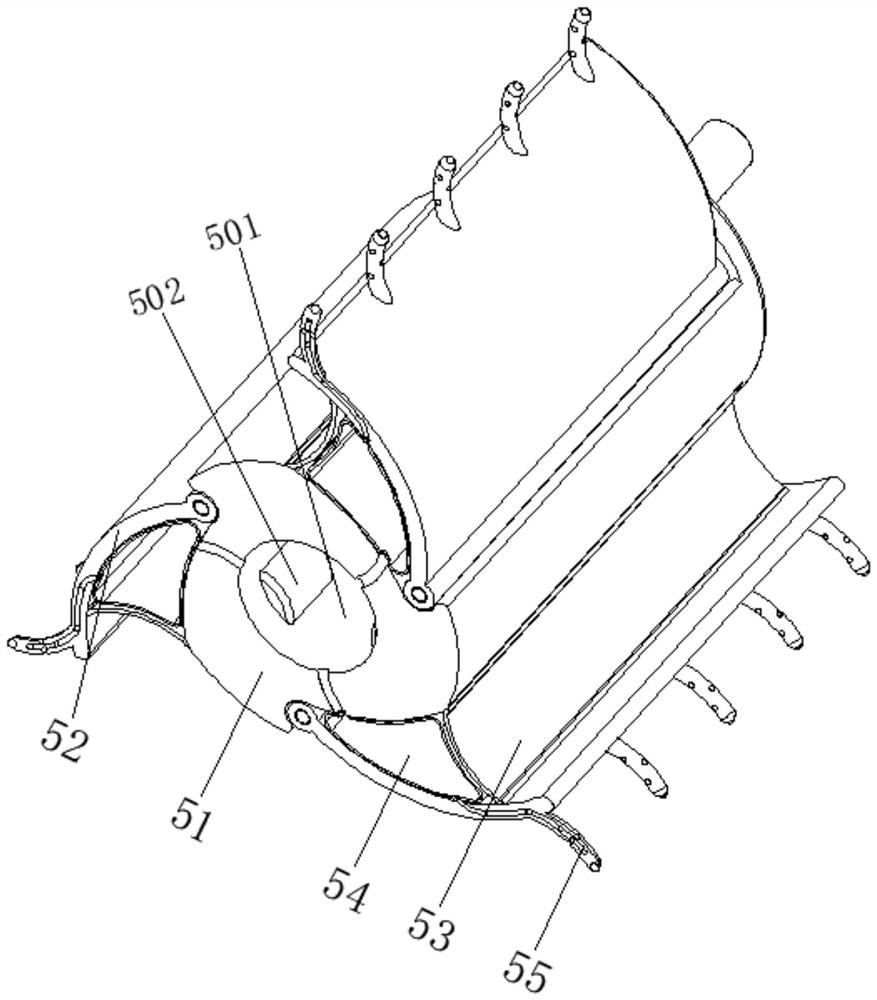

Crawler-travelling whole-stalk clamping type sugarcane harvester

InactiveCN105612924AImprove passabilityUniform and smooth logisticsHarvestersEngineeringMechanical engineering

The invention discloses a crawler-travelling whole-stalk clamping type sugarcane harvester comprising a harvester body and a harvesting mechanism. The harvesting mechanism comprises sugarcane lifters, a clamping device, a cutter device, a sugarcane tip cutting device, a primary feeder, a secondary feeder, a passage device and a fan device, wherein the clamping device comprises a left rail assembly and a right rail assembly, the cutter device is mounted at the front ends of lower rails, the sugarcane lifters are mounted at the front ends of upper rails, the sugarcane tip cutting device is positioned at the tail ends of the upper rails, the primary feeder is positioned between the upper rails and the lower rails, the secondary feeder is positioned at an inlet of the passage device, and the fan device is arranged above an outlet of the passage device. The crawler-travelling whole-stalk clamping type sugarcane harvester is capable of clamping sugarcanes sequentially to avoid clamping stagnation and enhancing detrashing and tailing effects to enable the sugarcanes to be harvested more completely.

Owner:HUBEI SHENYU HEAVY IND CO LTD

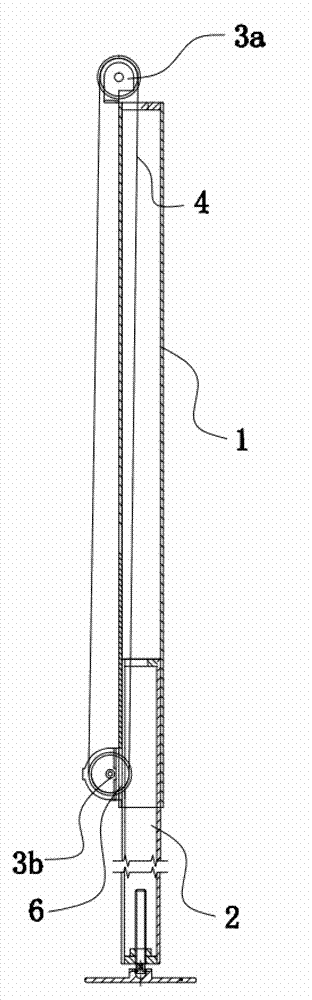

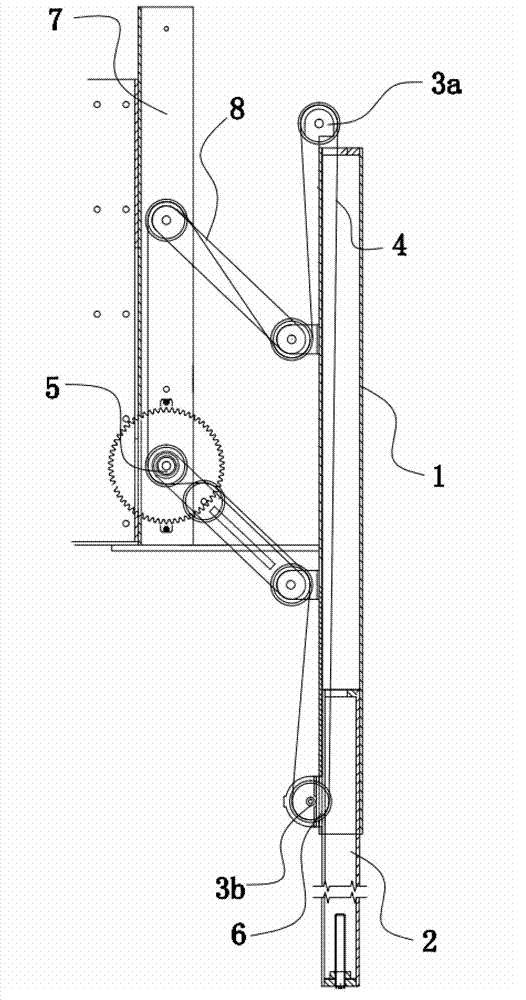

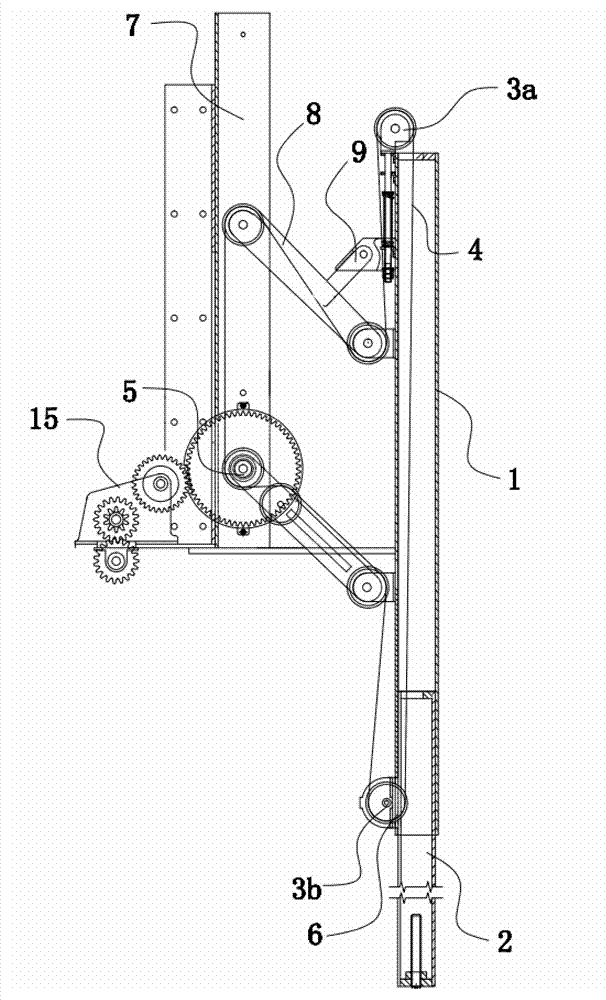

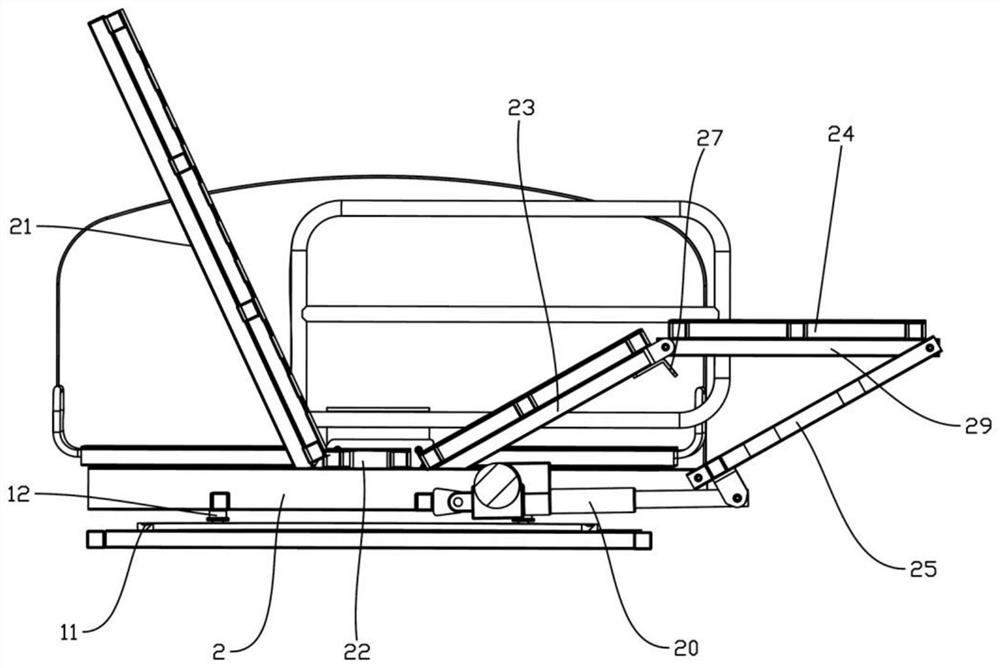

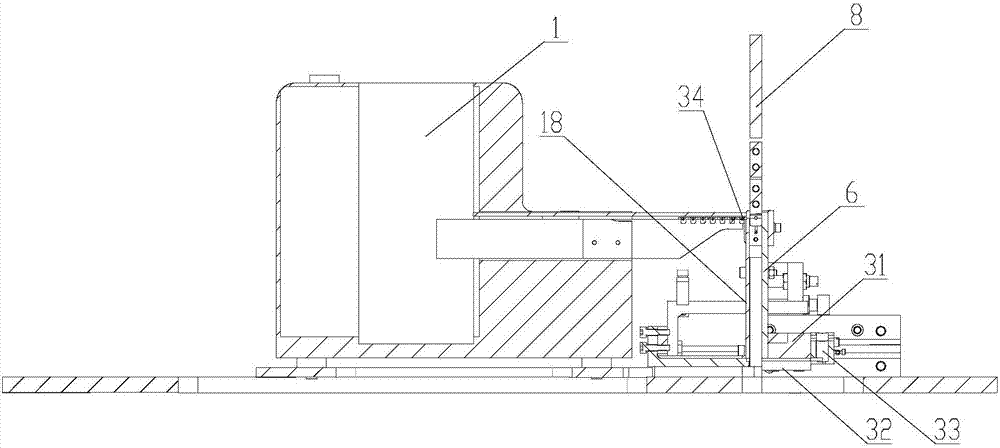

Shelter lifting mechanism

ActiveCN102862928AShort operating timeImprove lifting efficiencyLifting framesBuilding constructionsSprocketControl theory

Owner:SICHUAN JOINER MACHINERY & AUTOMATIC EQUIP

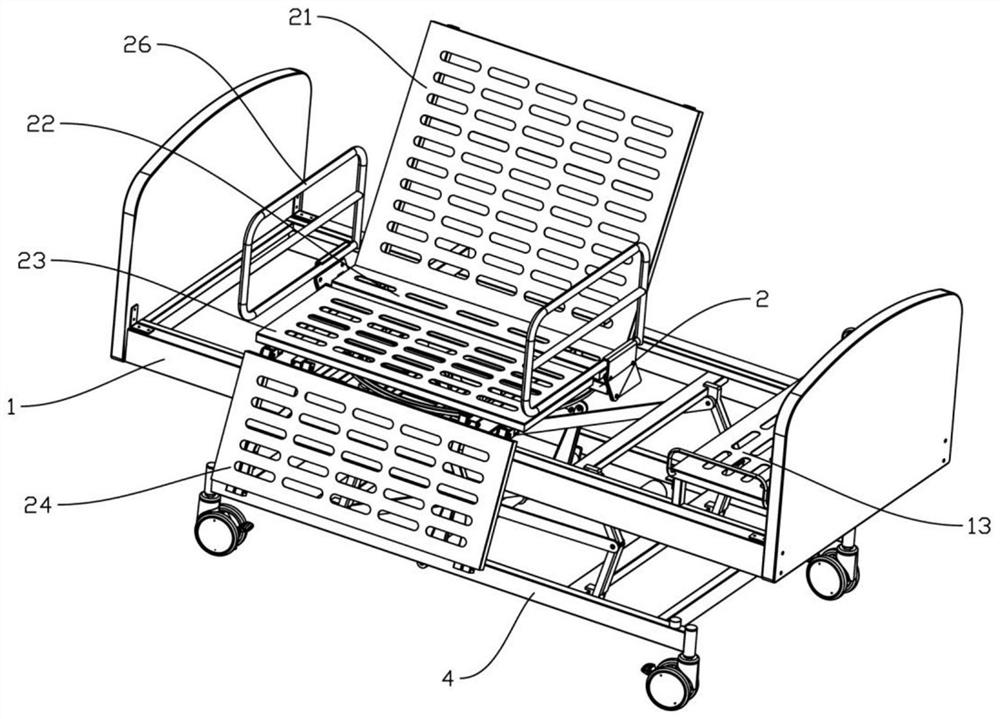

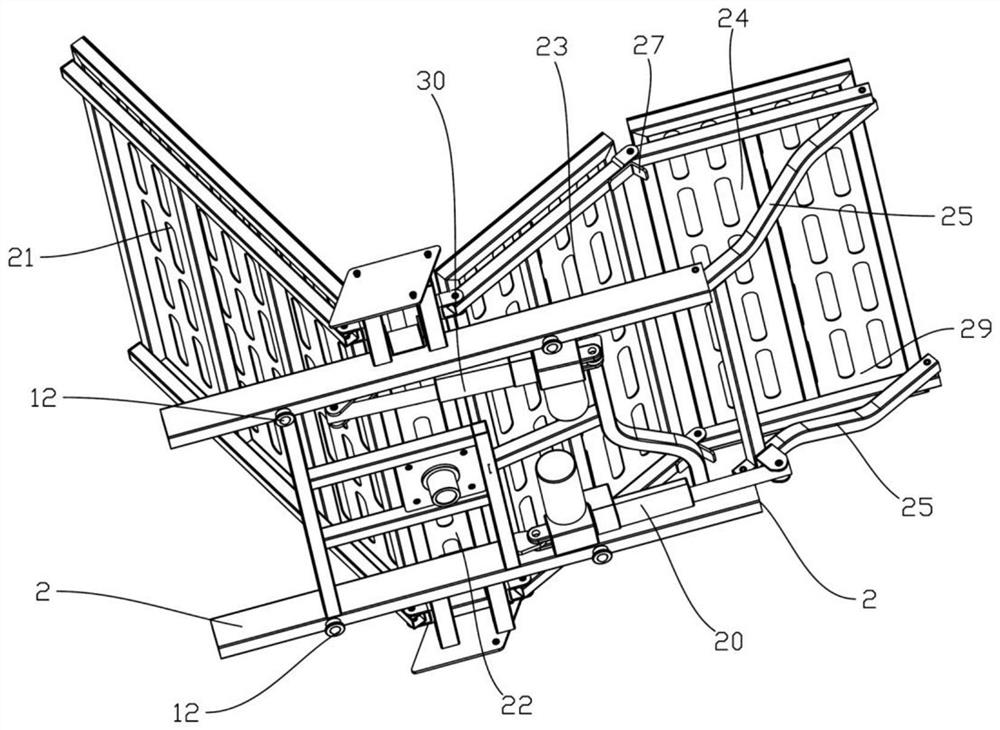

Nursing bed

PendingCN112076035AEasy to moveImprove comfortNursing bedsPhysical medicine and rehabilitationNursing care

The invention relates to a nursing bed. The nursing bed comprises a bed frame, wherein a mattress is arranged on the upper side of the bed frame and comprises a backrest cushion, a fixed cushion, a thigh supporting cushion and a shank supporting cushion, one end of the backrest cushion is rotationally fixed with the fixed cushion, one end of the thigh supporting cushion is rotationally fixed withthe fixed cushion, the shank supporting cushion is rotationally fixed with the other end of the thigh supporting cushion, the fixed cushion is fixed with a mattress frame, the mattress frame is supported and connected onto the bed frame in a manner of horizontally rotating around the vertical axis, and the shank supporting cushion is connected with a leg support driving mechanism for overturning the shank supporting cushion. The nursing bed has the advantages that the use and operation steps are fewer, the use comfort is higher, and the mattress is more stable and not prone to inclination during use.

Owner:ZHEJIANG INNUOVO REHABILITATION DEVICES CO LTD

Brewer and capsule coffee machine

The invention discloses a brewing device and a capsule coffee machine. The brewing device comprises a fixed brewing base and a brewing head moving relative to the brewing base. The brewing head is provided with a clamping mechanism. The clamping mechanism is used for clamping coffee capsules so that the coffee capsules can move synchronously along with the brewing head when the brewing head moves towards the brewing base. The brewing device is novel in structure and simple in construction.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

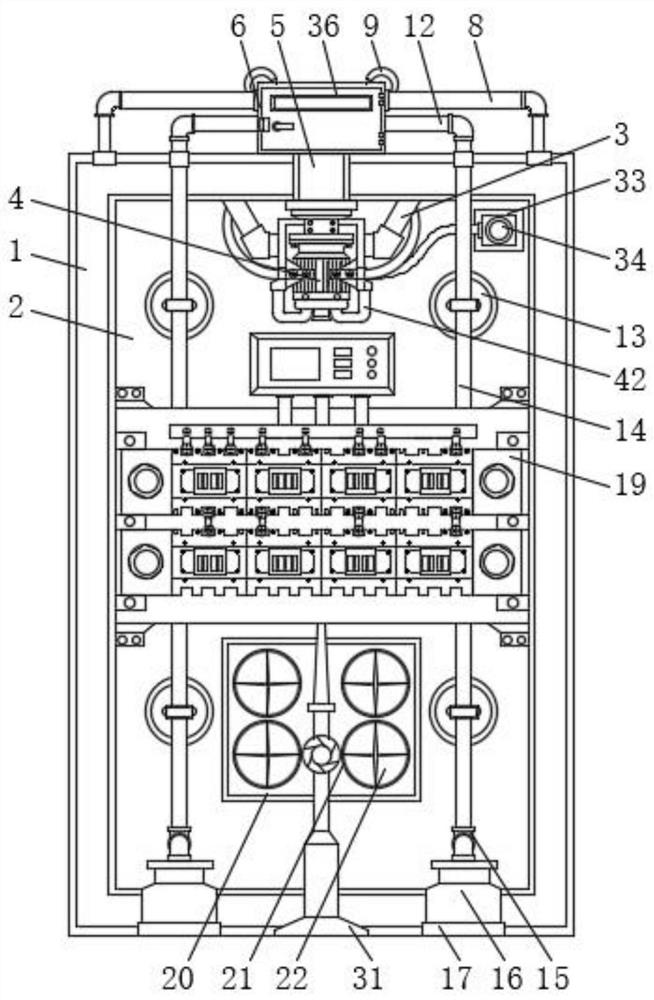

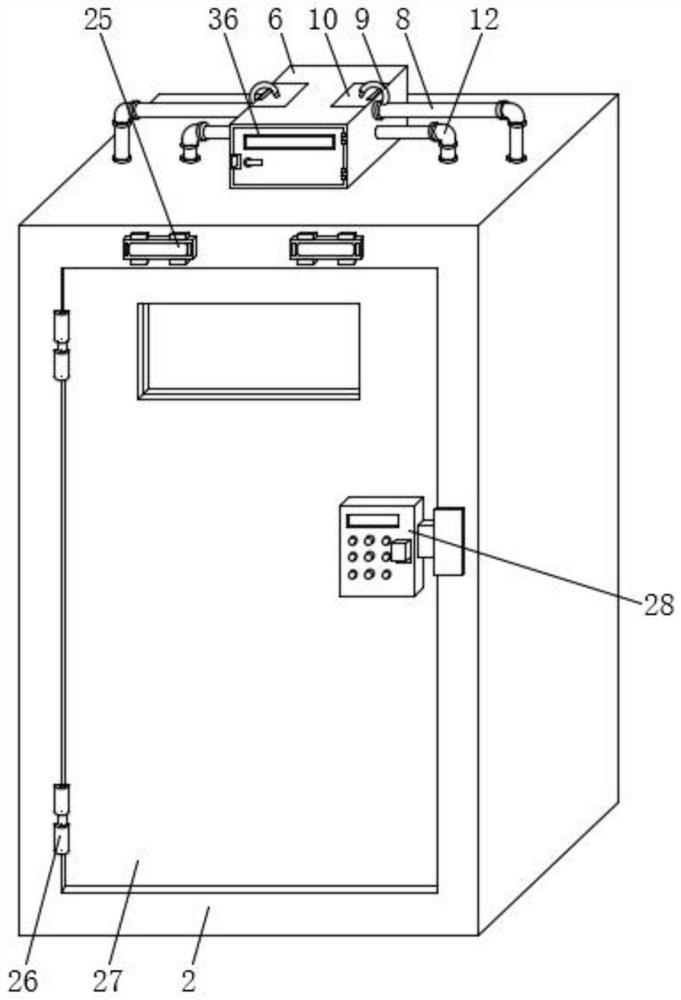

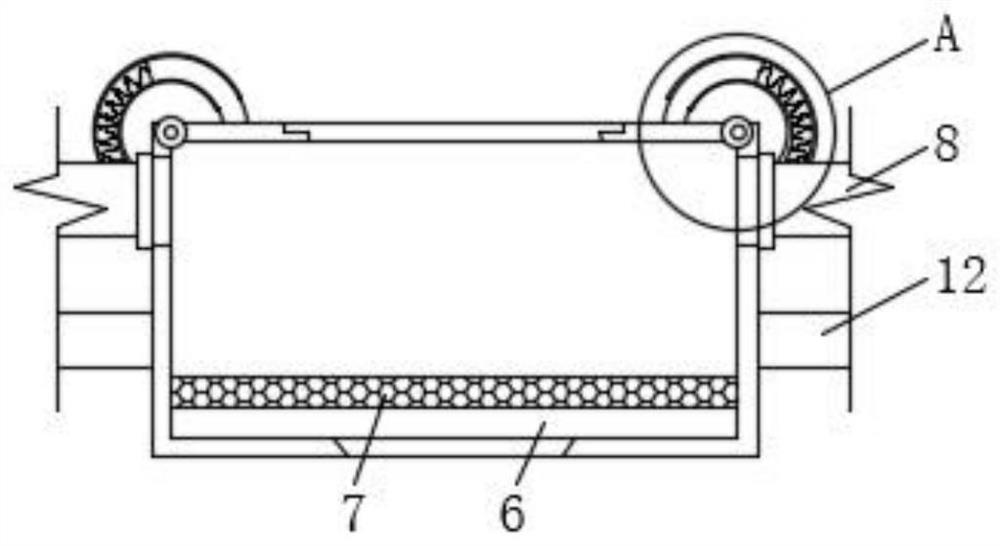

Alternating-current low-voltage power distribution cabinet

InactiveCN112909770AGuaranteed stabilityReduced stabilityEarthing arrangementsSubstation/switching arrangement cooling/ventilationAir pumpNoise

The invention discloses an alternating-current low-voltage power distribution cabinet, and particularly relates to the technical field of power distribution cabinets, the alternating-current low-voltage power distribution cabinet comprises a first protective shell, the inner wall of the first protective shell is fixedly connected with the outer surface of a second protective shell, the upper surface of the inner wall of the second protective shell is fixedly connected with the top end of a supporting frame, and an air pump is arranged in the supporting frame. According to the power distribution cabinet, by arranging the air pump, the back plate suction cup and the bottom plate suction cup, after the cabinet door plate of the power distribution cabinet is closed, the space of the first protection shell and the space of the second protection shell can form a space similar to vacuum due to air shortage, and therefore it is guaranteed that sound generated in the operation process of the power distribution cabinet is not likely to be transmitted to the outside, the noise processing effect of the power distribution cabinet is improved, and when the air pump operates, the back plate suction cups and the bottom plate suction cups can also play a role in fixing the power distribution cabinet, so that the stability of the power distribution cabinet during operation is guaranteed, and the situation that equipment in the power distribution cabinet shakes or topples over due to operation is reduced.

Owner:汪知义

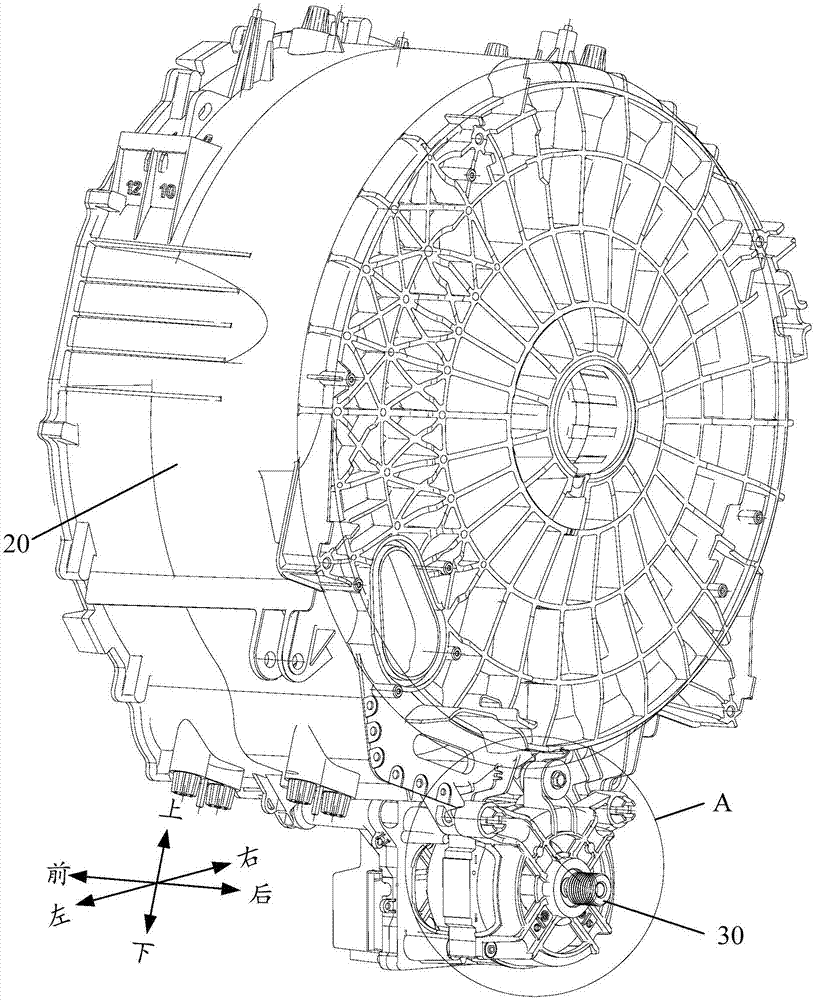

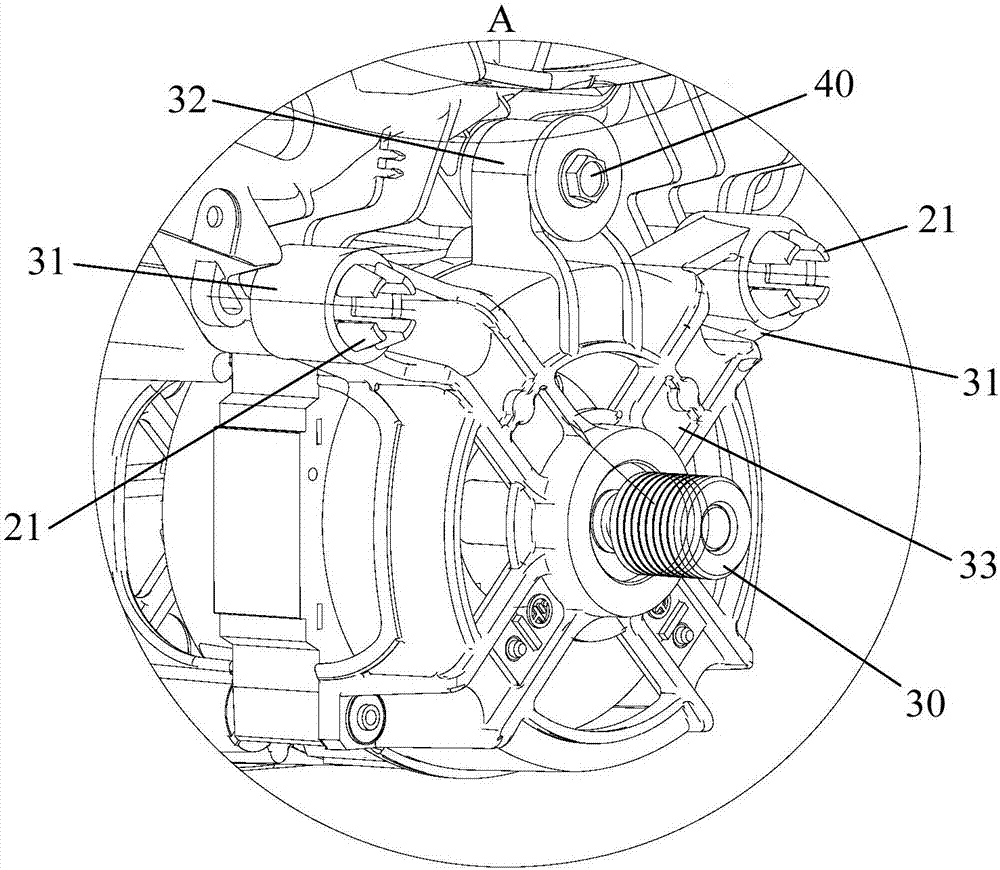

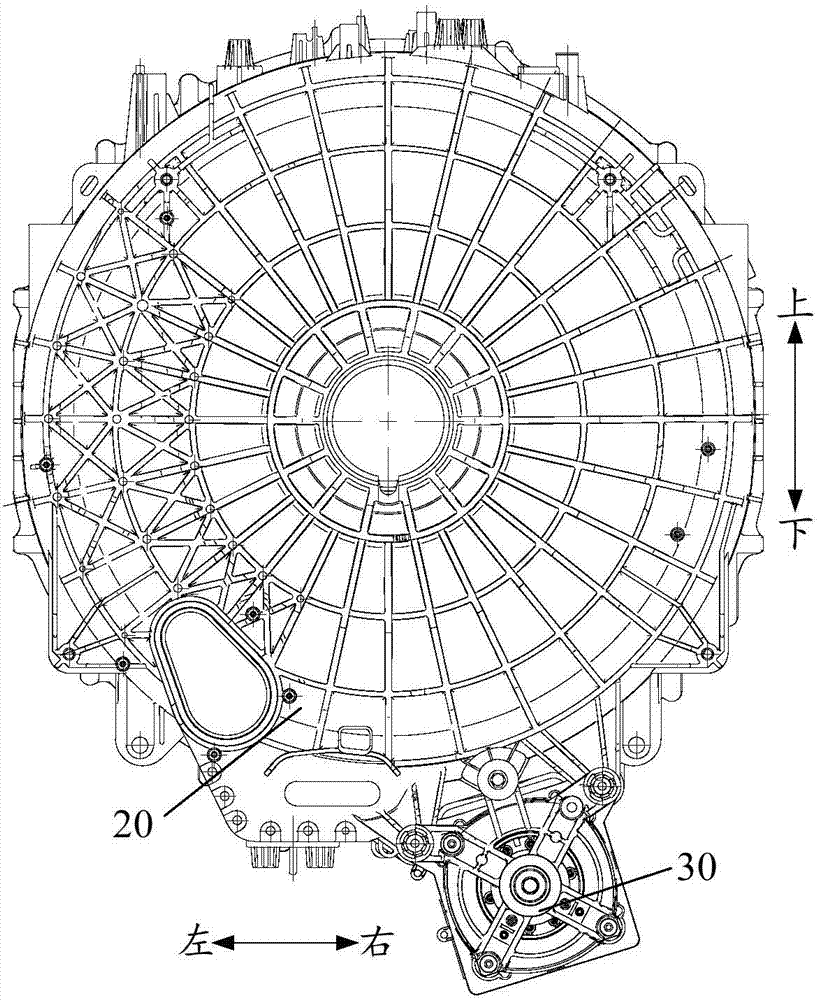

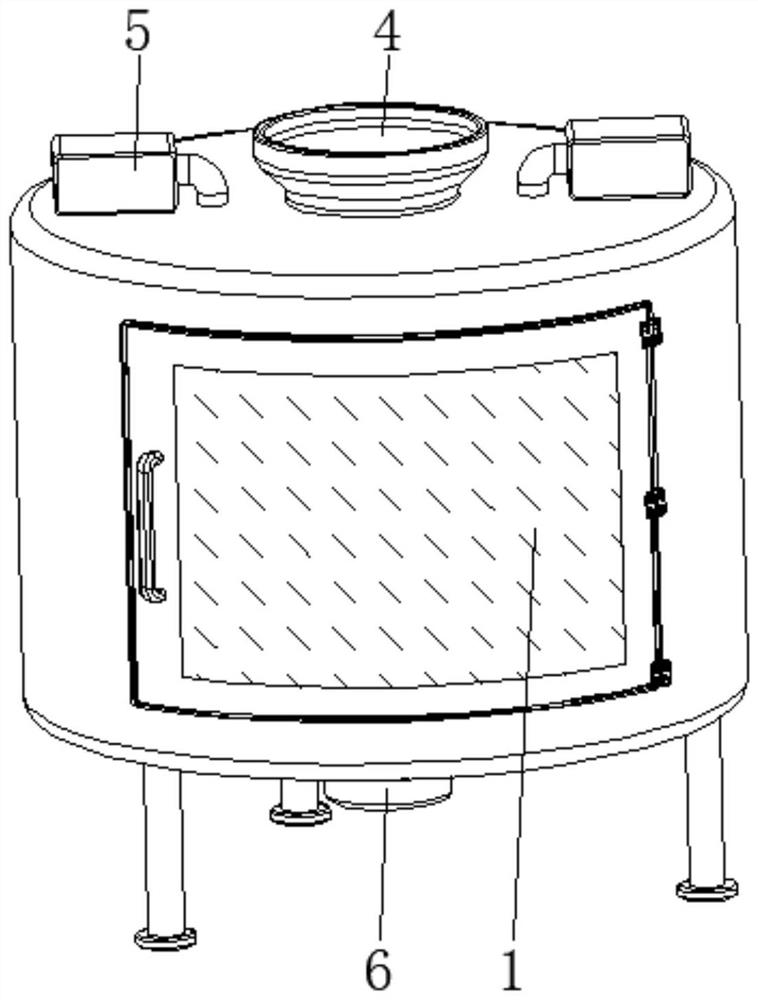

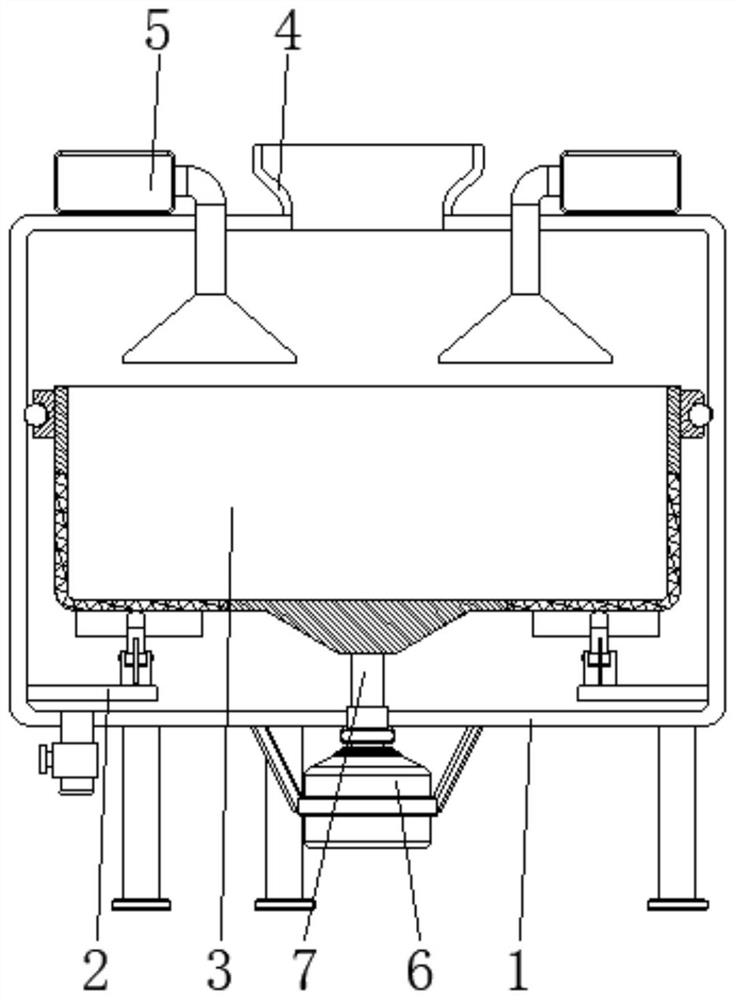

Roller washing machine

ActiveCN107503082AIncrease productivitySo as not to damageOther washing machinesTextiles and paperState of artEngineering

The invention provides a roller washing machine, which comprises a box body, an outer barrel and a motor; the outer barrel is installed in the box body, and a first buckling part is arranged on the outer barrel; a second buckling part matched with the first buckling part is arranged on the motor, and buckled with the first buckling part, thus the motor is buckled with the outer barrel. Theroller washing machine applies the buckling cooperation of the first buckling part and the second buckling part to realize the buckling and fixing of the motor and the outer barrel, and replace the method of fixing the motor by two bolts in the prior art, thus the installing difficulty of the motor is significantly reduced, the motor installing time is shortened, and the production efficiency of the roller washing machine is improved; meanwhile, the buckling method is convenient to dismount, and can be operated manually without tools; therefore, an inner cylinder system is not required to move, the labor force and materials are saved; moreover, damage of the washing machine cannot be caused by drawing internal leads and colliding to the spare parts at the inner part, the dismounting and repairing in the late period are facilitated.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

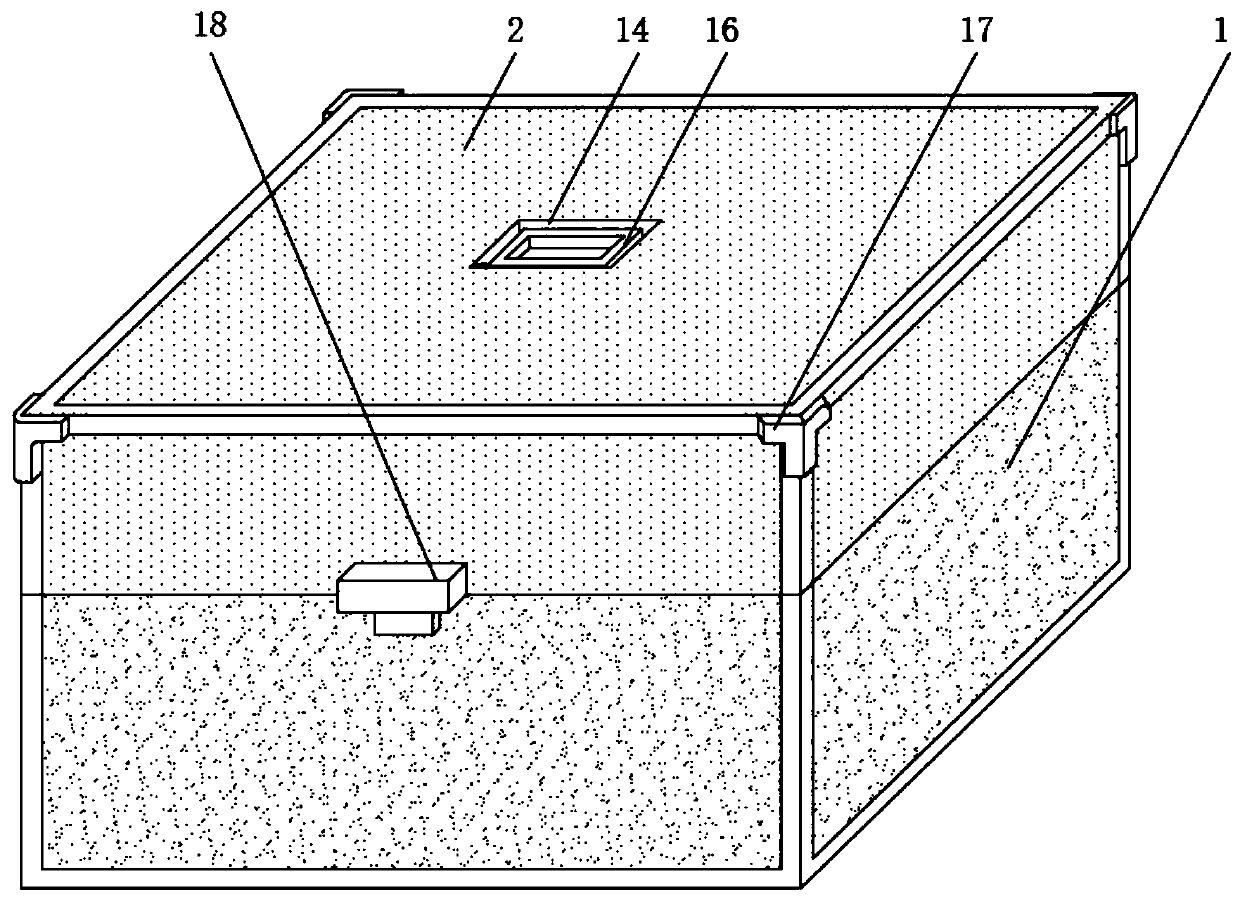

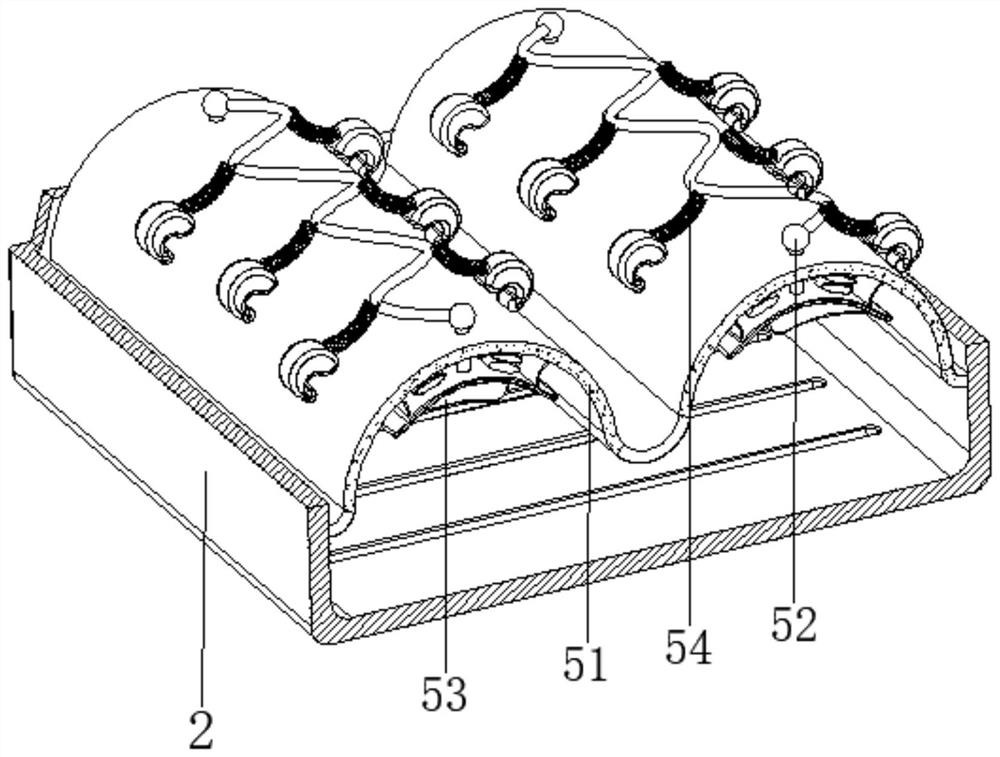

Electronic component processing equipment and method

ActiveCN114322465AFacilitate water removalAdaptableDrying solid materials without heatDrying gas arrangementsMaterial storageElectronic component

The electronic component processing equipment comprises a machine body, a knocking device and a material storage device, the knocking device is arranged on the inner wall of the machine body and close to the bottom, the material storage device is arranged in the machine body and close to the knocking device, and a curved surface supporting column is fixed to the end, away from the inner wall of the machine body, of the top of a base. The striking device is arranged at the top of the curved-surface supporting column, the arc-shaped elastic piece is arranged between the two sides, corresponding to the surface of the curved-surface supporting column, of the surface of the striking device, the bottom end of the supporting and jacking piece is hinged to the top of the curved-surface supporting column, and the arc-surface striking head is fixed to the top end of the supporting and jacking piece. According to the electronic component processing equipment and method, the rapid drying effect is achieved, sheet parts are not prone to adhesion and accumulation, rapid and thorough drying can be conducted, follow-up use is facilitated, safety and reliability are achieved, and the working efficiency and the use performance are improved.

Owner:淮安市宝鼎科技有限公司

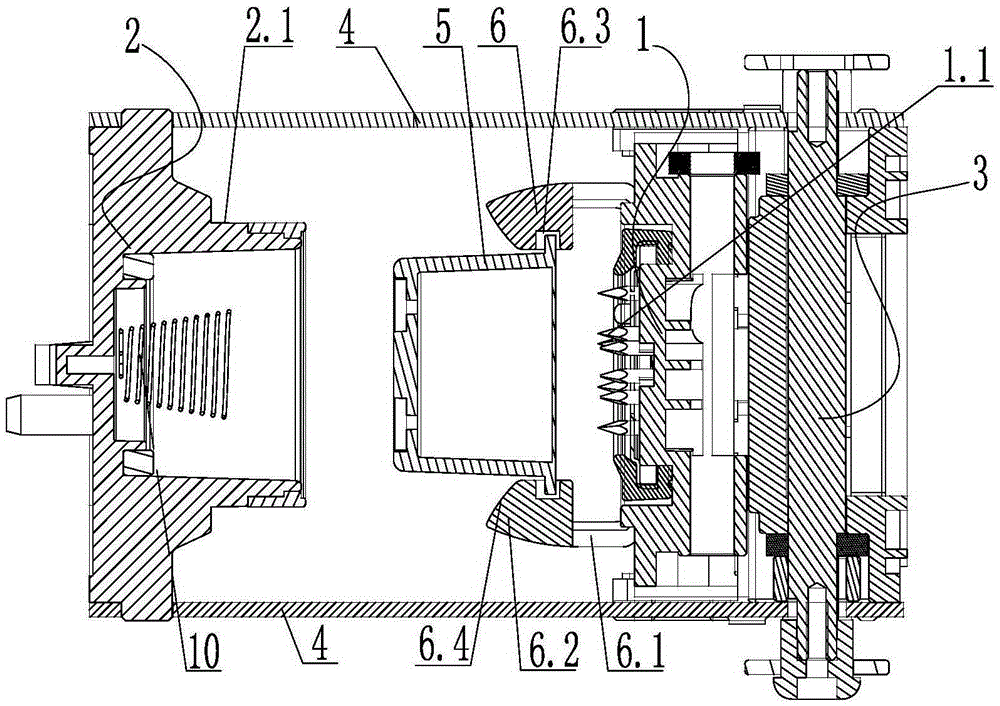

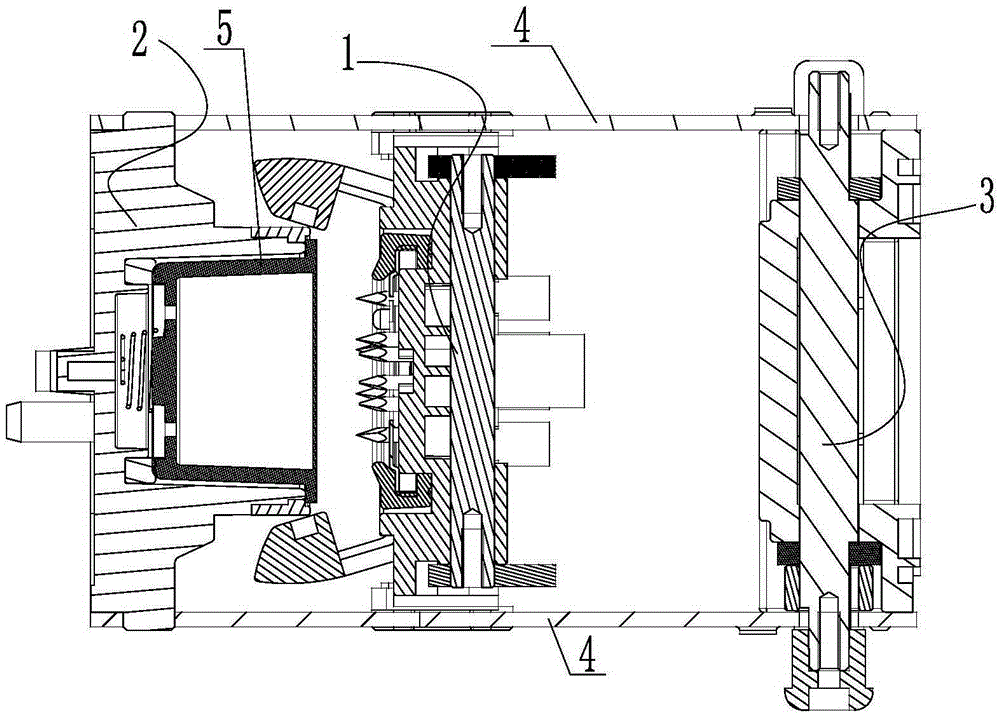

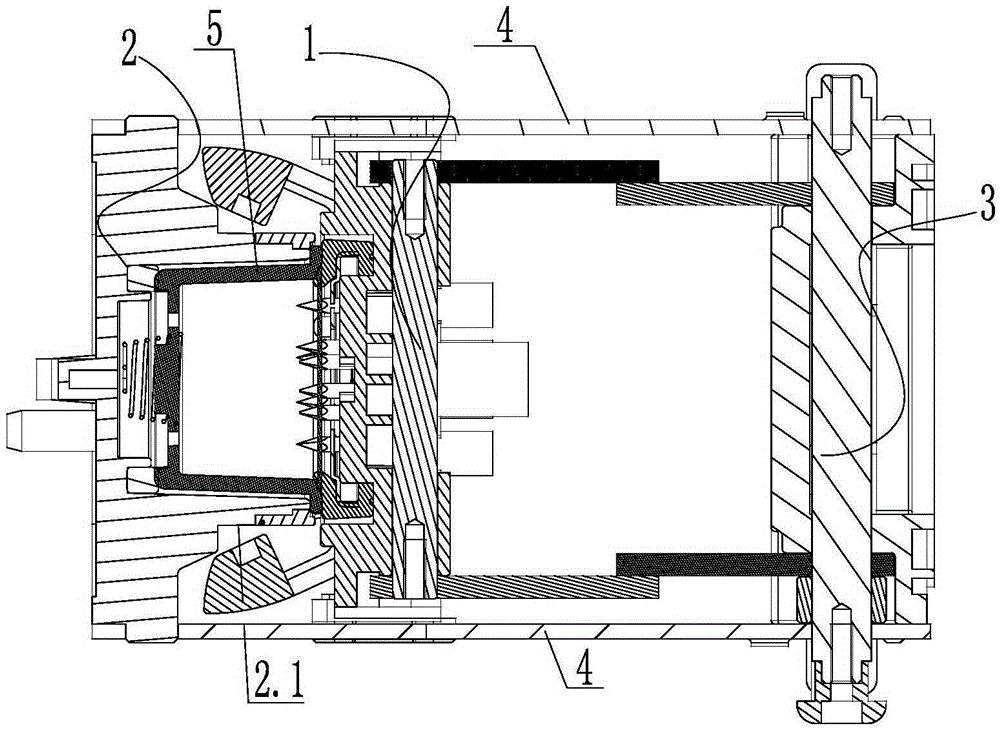

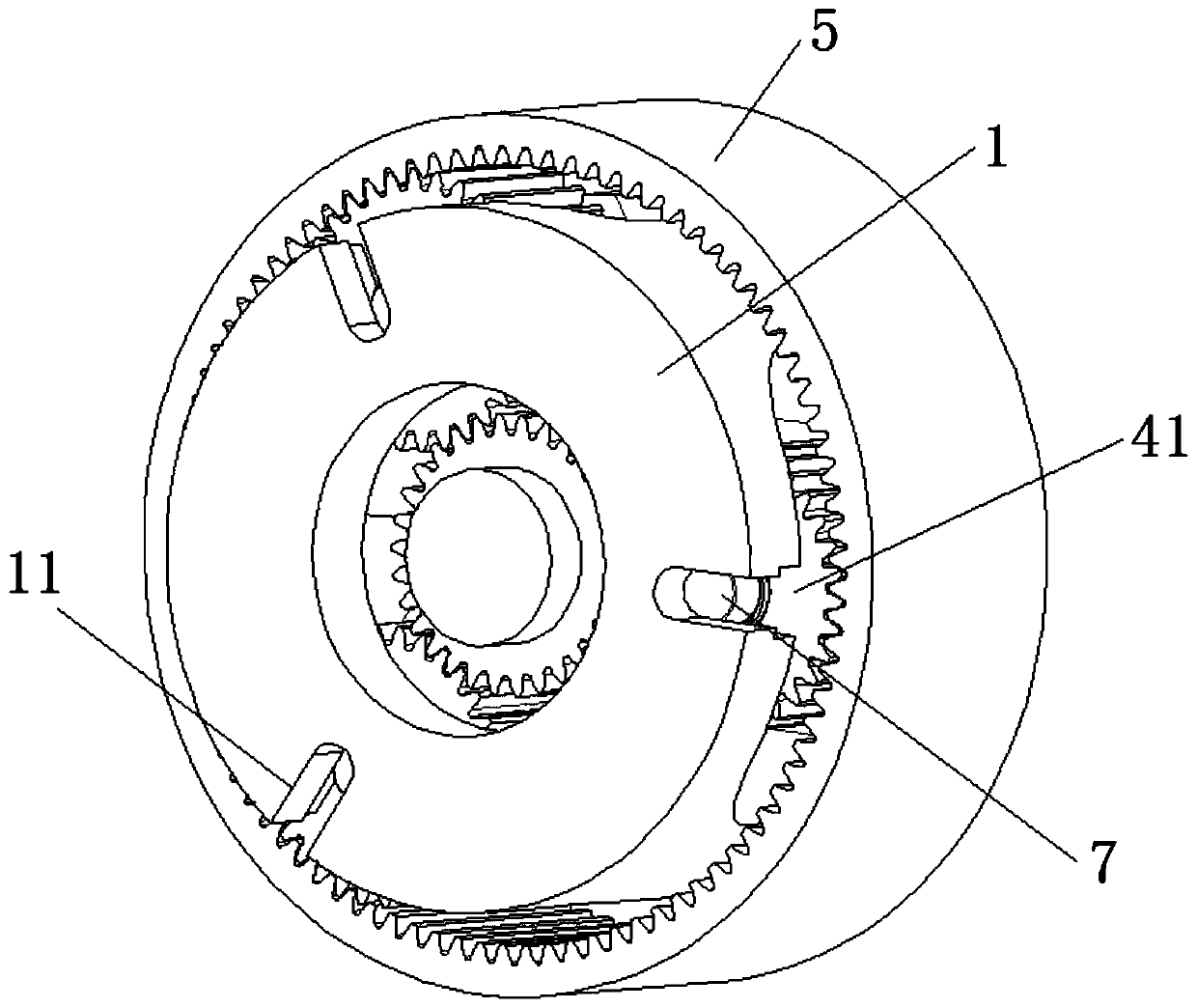

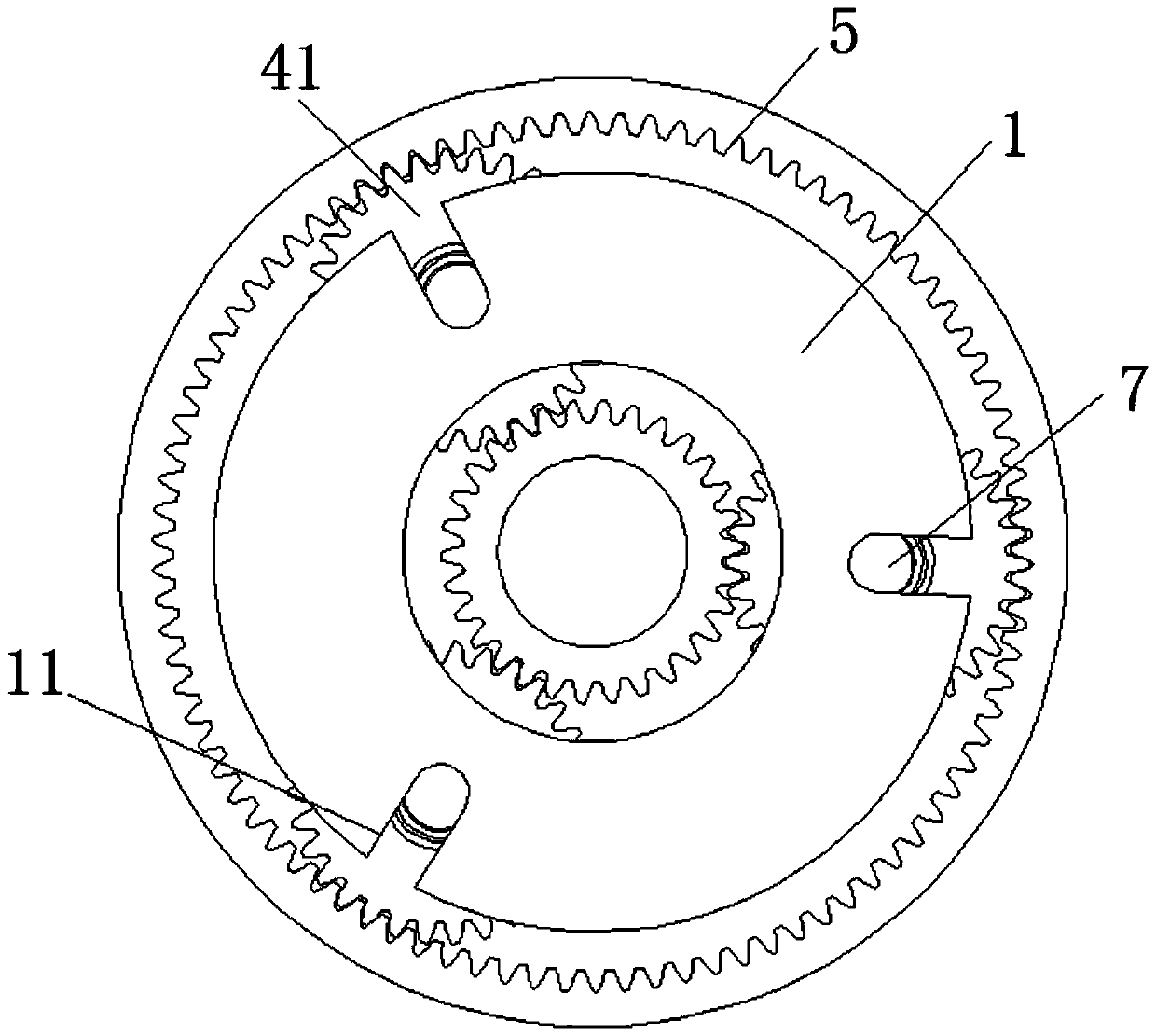

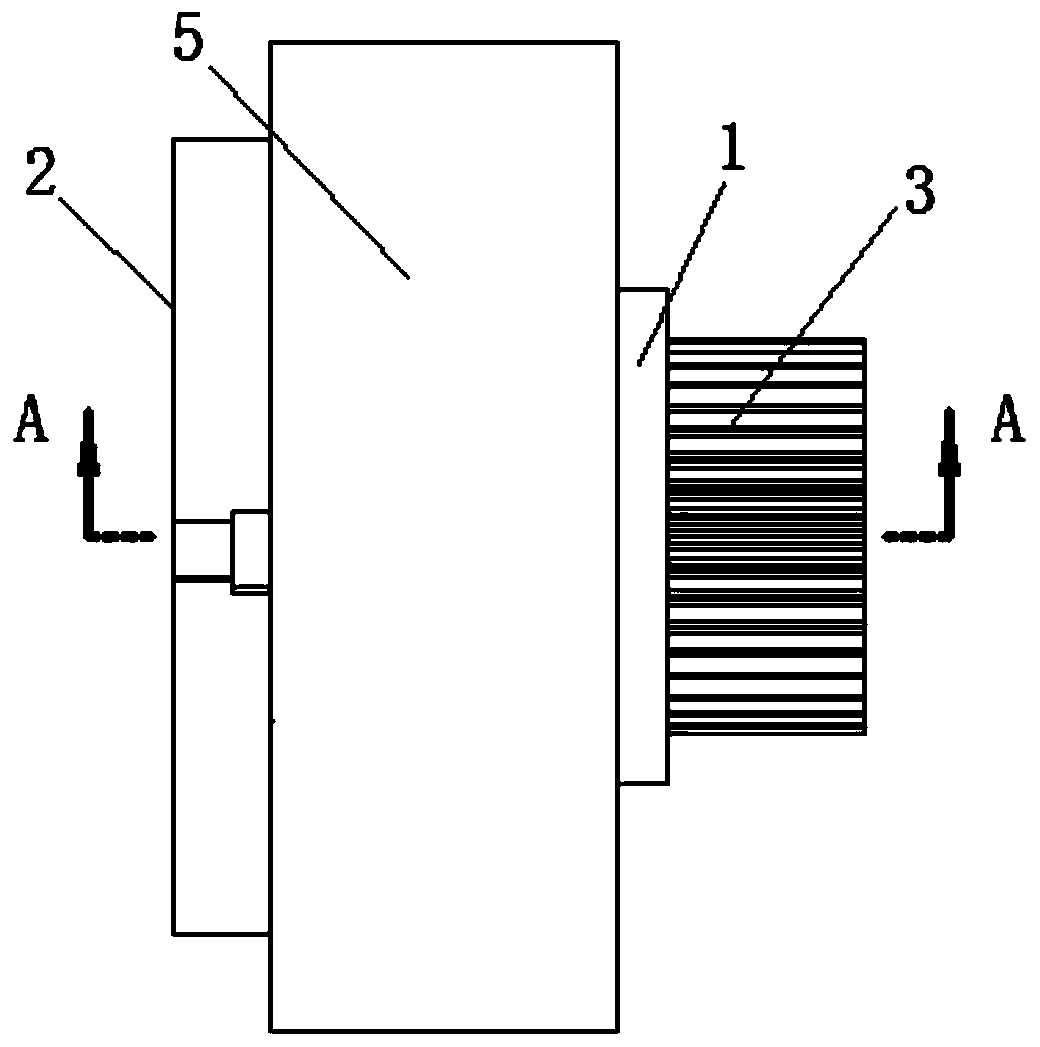

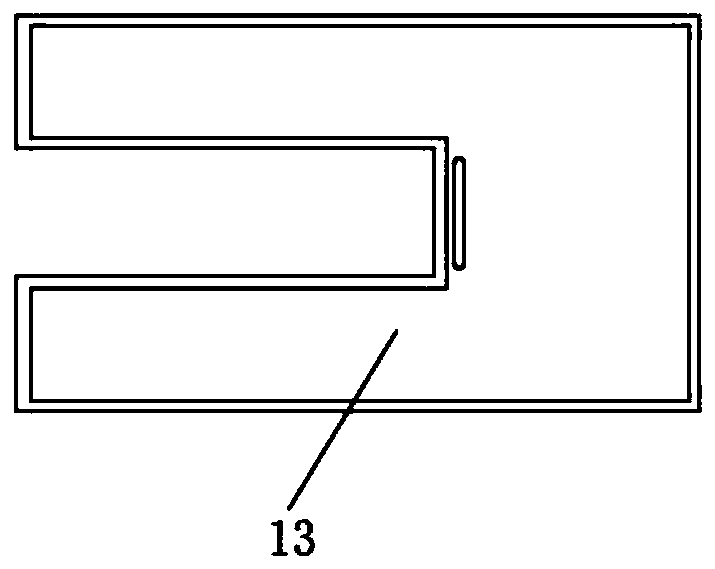

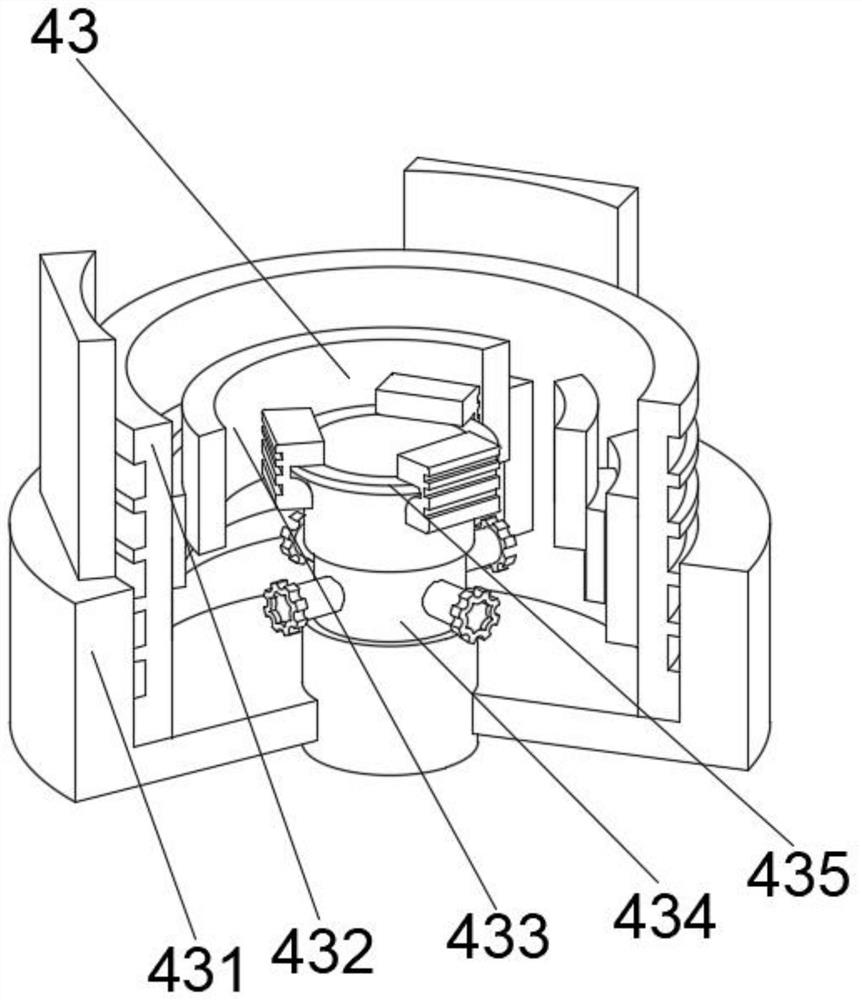

Floating planetary gear train structure for miniature precise planetary reducer

PendingCN110159710AUniform loadLimited axial movementGear vibration/noise dampingToothed gearingsLow speedReducer

The invention discloses a floating planetary gear train structure for a miniature precise planetary reducer. The floating planetary gear train structure comprises a planetary carrier, a high-speed sungear, a low-speed sun gear, a planetary gear set and an inner gear ring, wherein the high-speed sun gear is meshed with the planetary gear set, the inner gear ring is meshed with the planetary gear set, the planetary carrier is in a cage type structure, and the planetary gear set is arranged on the cage type planetary carrier in a floating mode to automatically adapt to the central distance and the matching clearance; the floating planetary gear train structure further comprises a gasket, and the two ends of the planetary gear set are correspondingly limited by the cage type planetary carrierand the gasket to limit the axial movement of the planetary gear set. The floating planetary gear train structure for the miniature precise planetary reducer is exquisite and compact in structure, aU-shaped stepped slot and an annular open slot are designed on the cage type planetary carrier, planetary gears are mounted on the U-shaped stepped slot in a rotating floating mode through pin shaftsand needle bearings so as to automatically adapt to the central distance and the matching clearance, so that the loads of all the planetary gears are uniform, the meshing transmission of the sun gear,the planetary gear and the inner gear ring is ensured, the operation is smooth, the noise and the temperature rise are reduced, the problems of blockage or unbalance are solved, and the reliability is high.

Owner:ZHEJIANG UNIV KUNSHAN INNOVATION INST

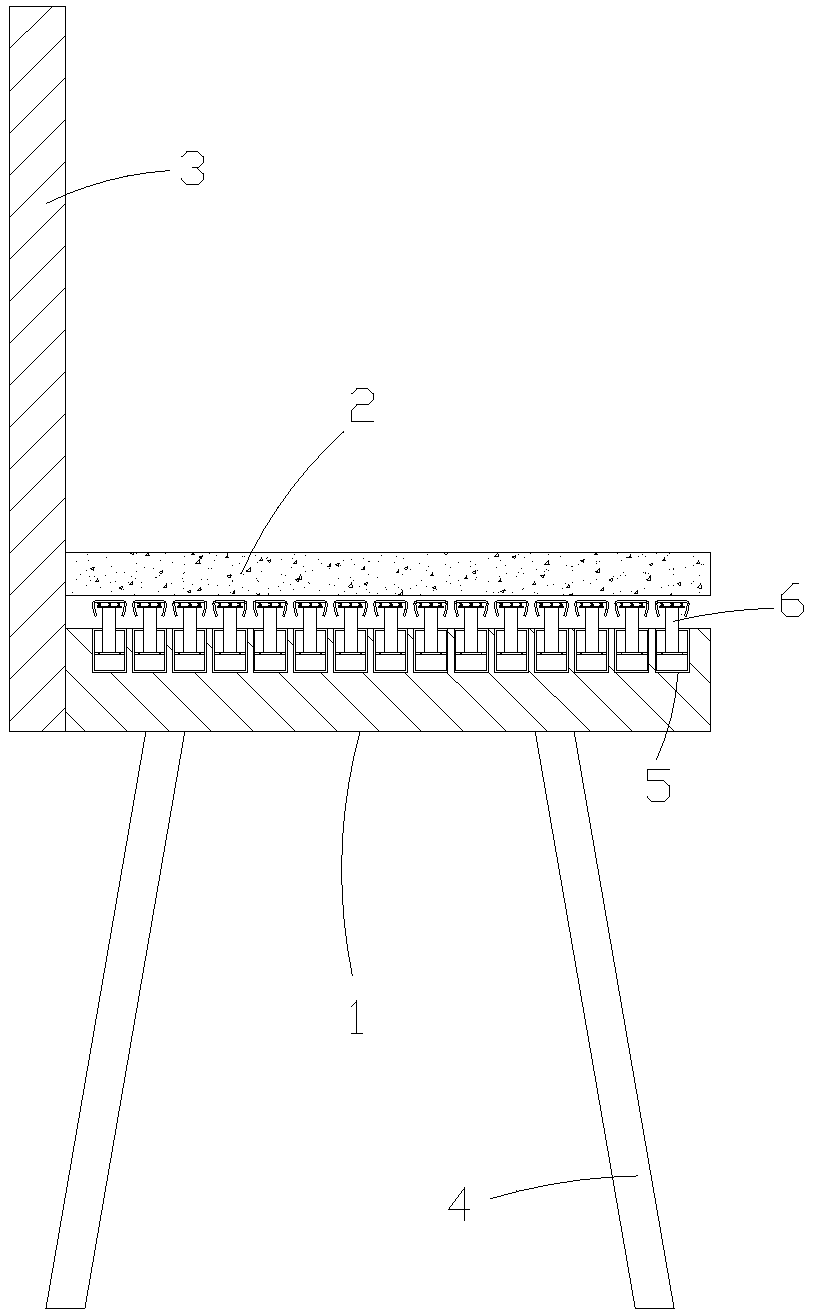

Hydraulic buffer base for lathe

InactiveCN109848719ADamage reliefExtended service lifeLarge fixed membersMaintainance and safety accessoriesEngineeringWorking environment

The invention discloses a hydraulic buffer base for a lathe, and relates to the technical field of lathes. The hydraulic buffer base for the lathe comprises a base; the upper surface of the base is fixedly connected with hydraulic rods; two hydraulic rods are provided; the top ends of the two hydraulic rods are fixedly connected with the lower surface of a fixed plate; two slide sleeves are clamped on the lower surface of the fixed plate; slide rods sleeve the inner surfaces of the slide sleeves; the bottom ends of the slide rods are fixedly connected with the upper surface of the base; and the top ends of the slide rods are fixedly connected with lower surfaces of limiting blocks. In the hydraulic buffer base for the lathe, through cooperation of the hydraulic rods, the slide rods, the slide sleeves, springs, the limiting blocks, rotating shafts, bearings, a first handle, a second handle, thread columns and thread caps, the service life of a lathe main body is prolonged, the noise generated during working of the lathe main body is lowered, the working environment of workers becomes more comfortable, and the working efficiency of the workers is improved.

Owner:孙蓉

Screw conveying device and screw turning mechanical hand system with screw conveying device

ActiveCN107538192AReduce extrusion friction and wearNot prone to overlapping nailsMetal working apparatusEngineeringManipulator system

The embodiment of the invention provides a screw conveying device. The screw conveying device comprises a screw supplying structure, a first movement mechanism used for conveying screws provided by the screw supplying structure to the first position, a second movement mechanism used for conveying the screws conveyed to the first position to the second position, a screwdriver nozzle arranged at thesecond position and an installation frame used for bearing all the above parts. By the adoption of the screw conveying device, the manner that a pneumatic element is used for conveying the screws isadopted, one screw is conveyed each time, the phenomena of screw stacking and screw clamping are not likely to happen, the structure is simple and compact, the performance is stable, reliability is high, and due to the fact that the extruding frictional wear among the screws is reduced, the beneficial effects of energy conservation and environment friendliness can also be achieved.

Owner:天津新松机器人自动化有限公司

Apparatus for preventing blood coagulation of blood transfusion bag or blood transfusion bottle

InactiveCN111495249AEasy to useLess susceptible to necrotic damageShaking/oscillating/vibrating mixersShock-sensitive articlesDrive wheelEngineering

The invention discloses an apparatus for preventing blood coagulation of a blood transfusion bag or a blood transfusion bottle, and belongs to the technical field of medical instruments. The apparatuscomprises a shell, a driving device is fixedly connected to the lower surface of the inner wall of the shell, and a driving wheel is arranged at the top end of the driving device. According to the apparatus for preventing blood coagulation of the blood transfusion bag or the blood transfusion bottle, a motor, a driving pulley, a reaction box, a supporting rod, a sliding groove and a spring are matched with one another, when a medical worker places a blood bag in the reaction box, the medical personnel only need to start the motor, the motor drives the driving wheel to rotate, the pulley tightly clings to the surface of the driving wheel to slide, and at the moment, the reaction box can repeatedly move left and right under the action of the motor and the spring, so that the apparatus can fully mix the blood and an anticoagulant in the blood bag, and under the state that cooling equipment is started, hemoglobin in the blood is not prone to necrosis and damage, and a patient is not proneto using the damaged blood.

Owner:刘红玲

Steel plate coiling device

Owner:KUNSHAN GUOZHI PRECISION MACHINERY

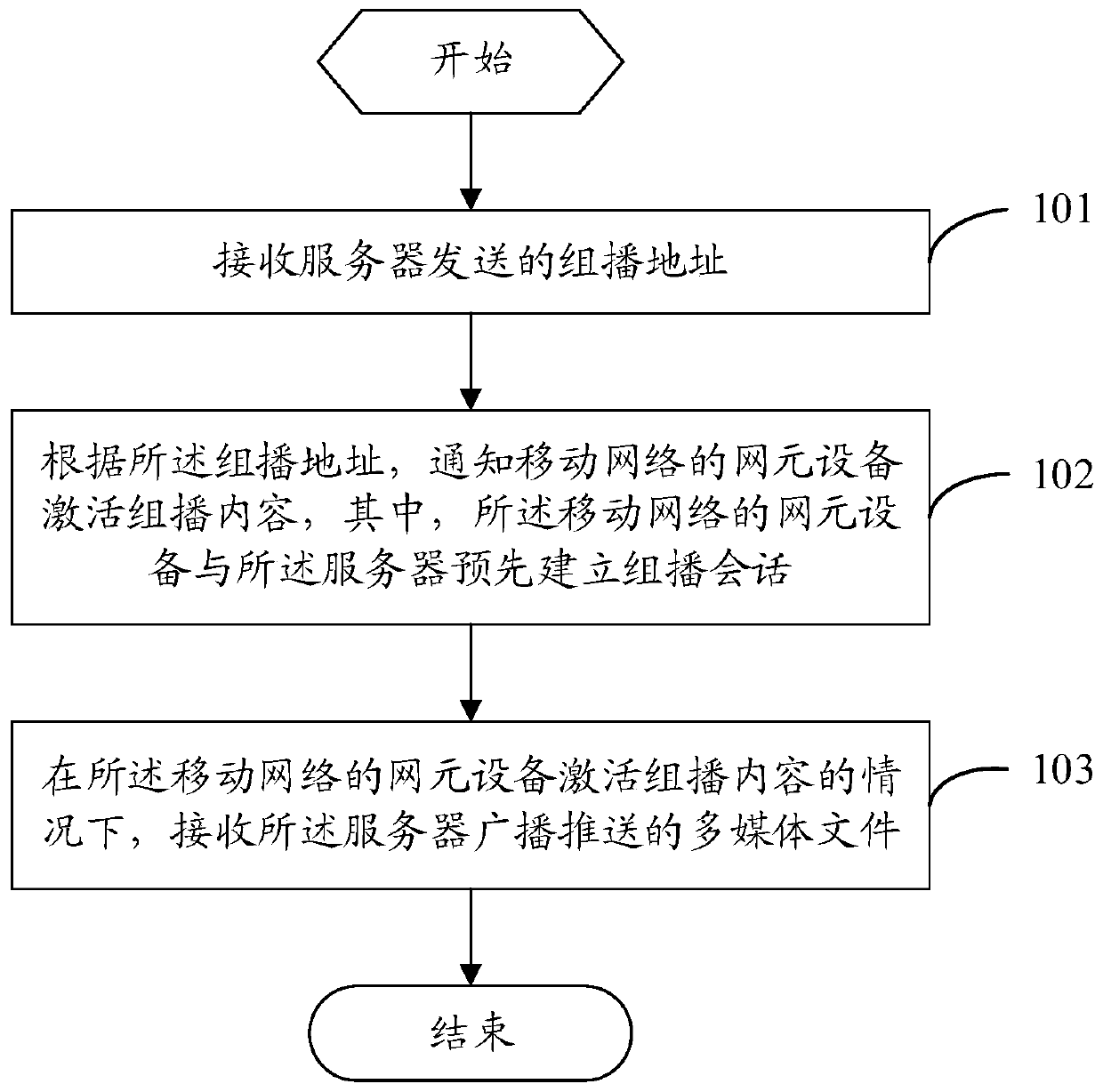

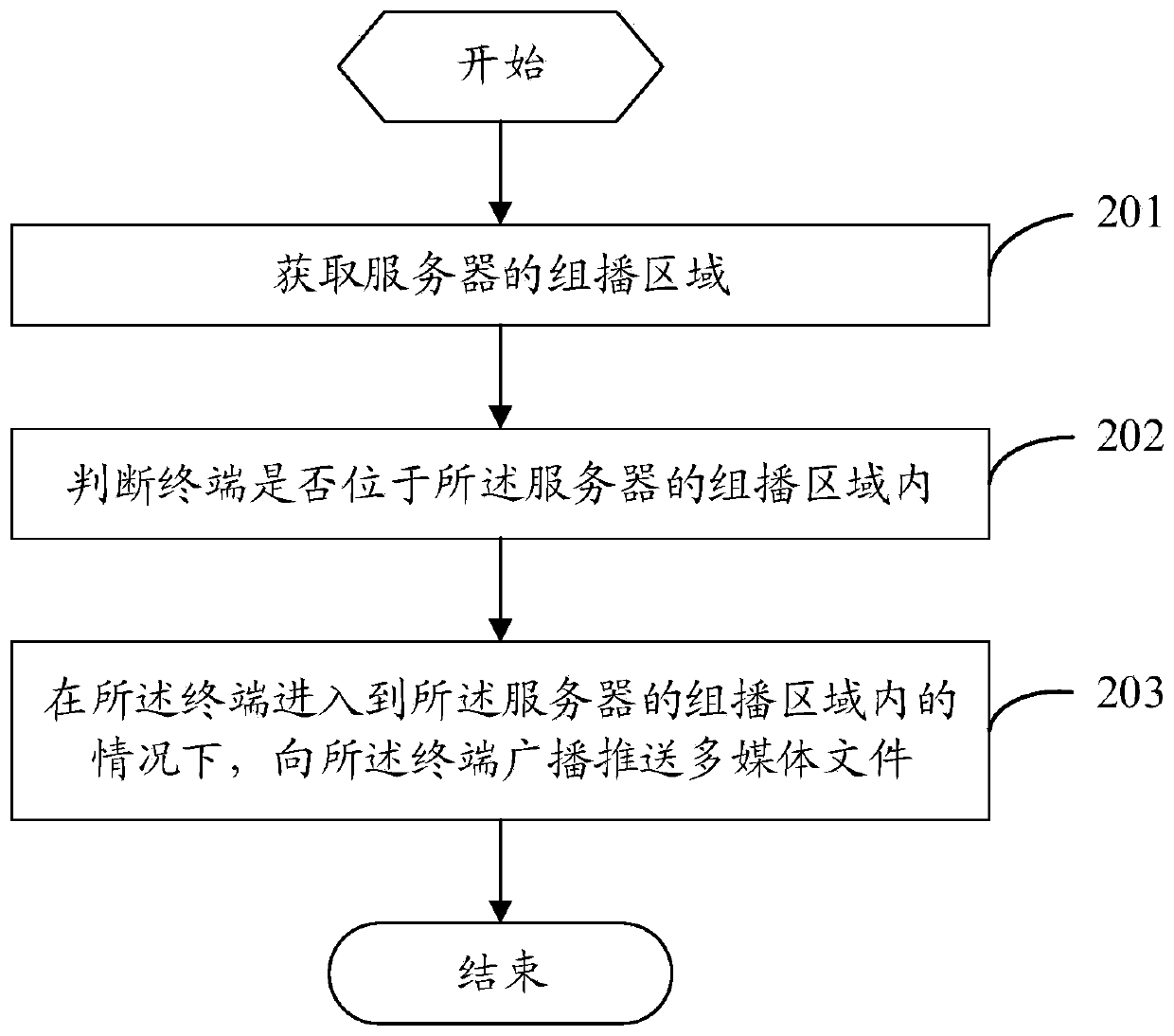

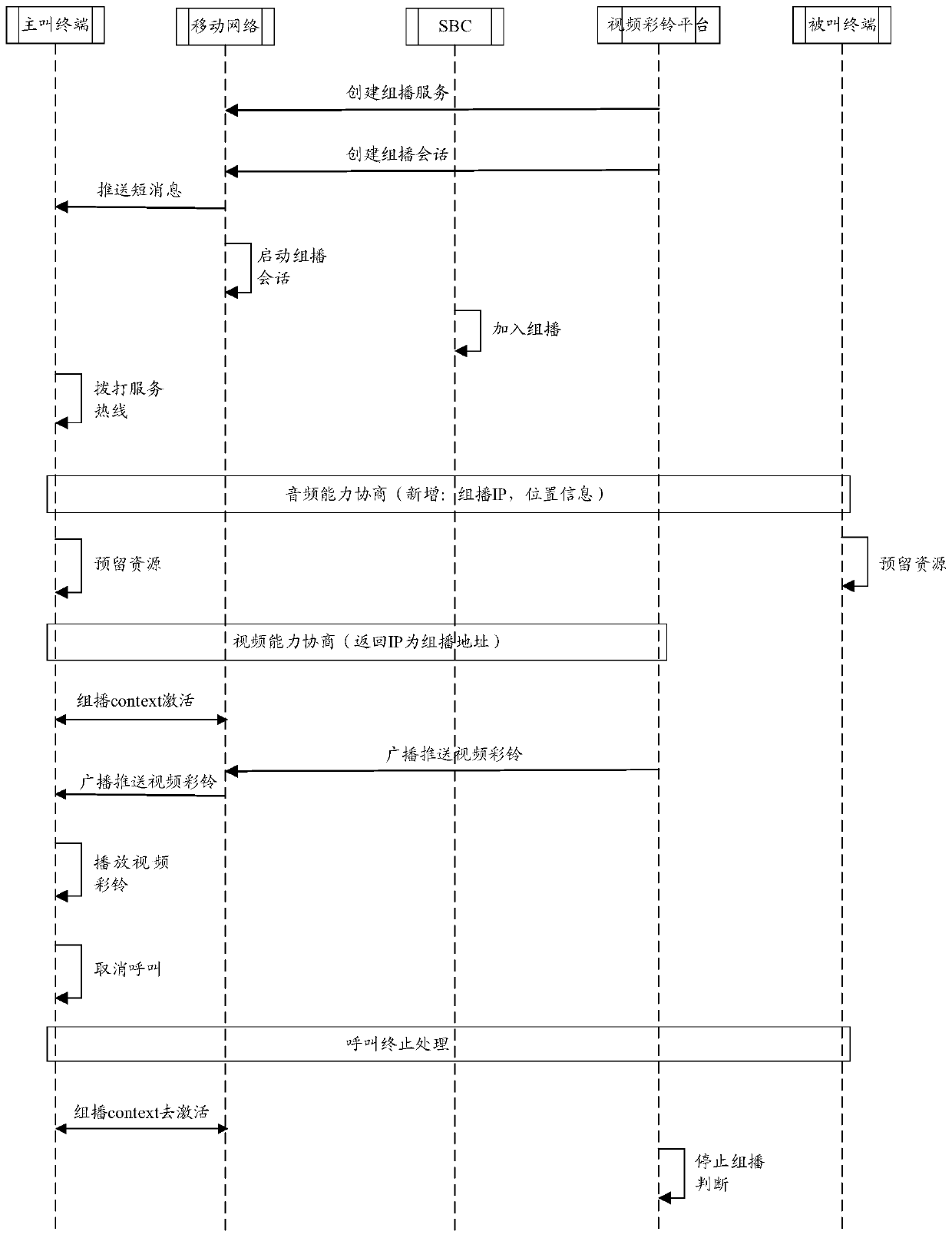

Multimedia file transmission method, terminal, server, system and storage medium

The invention discloses a multimedia file transmission method, a terminal, a server, a system and a storage medium, relates to the technical field of communication, and aims to solve the problem thatmultimedia file playing is blocked due to the fact that an existing multimedia file transmission mode is easily limited by bandwidth in a multi-user pushing scene. The method comprises the following steps: receiving a multicast address sent by a server; notifying network element equipment of a mobile network to activate multicast content according to the multicast address, the network element equipment of the mobile network establishing a multicast session with the server in advance; and under the condition that the network element equipment of the mobile network activates the multicast content, receiving the multimedia file broadcasted and pushed by the server. The multimedia file transmission method of the invention is not limited by bandwidth resources of a mobile network, so that the terminal is not easy to be jammed when playing the received multimedia file.

Owner:MIGU CO LTD

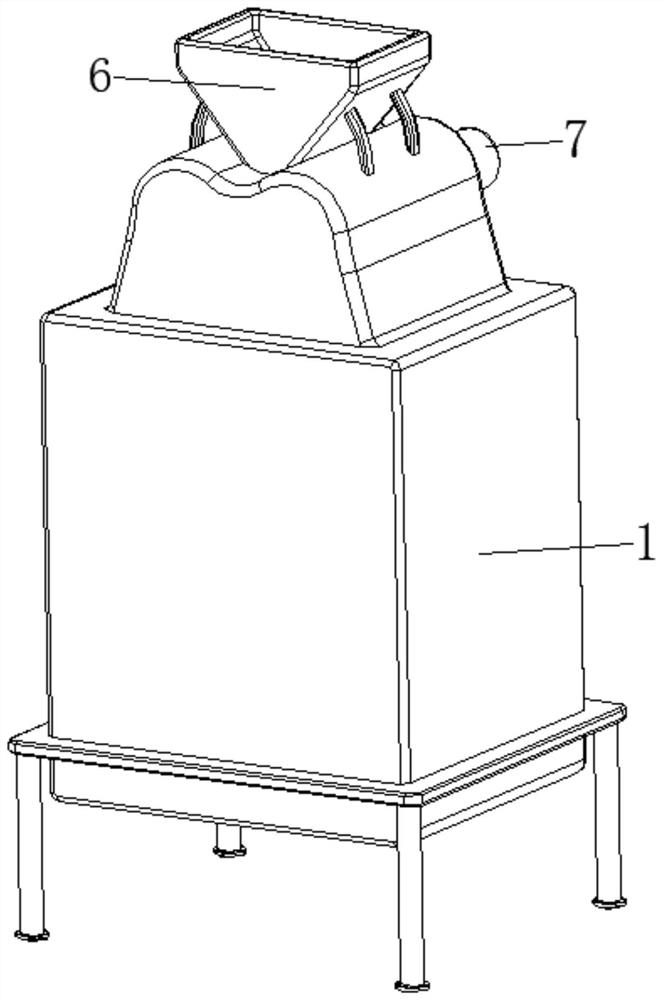

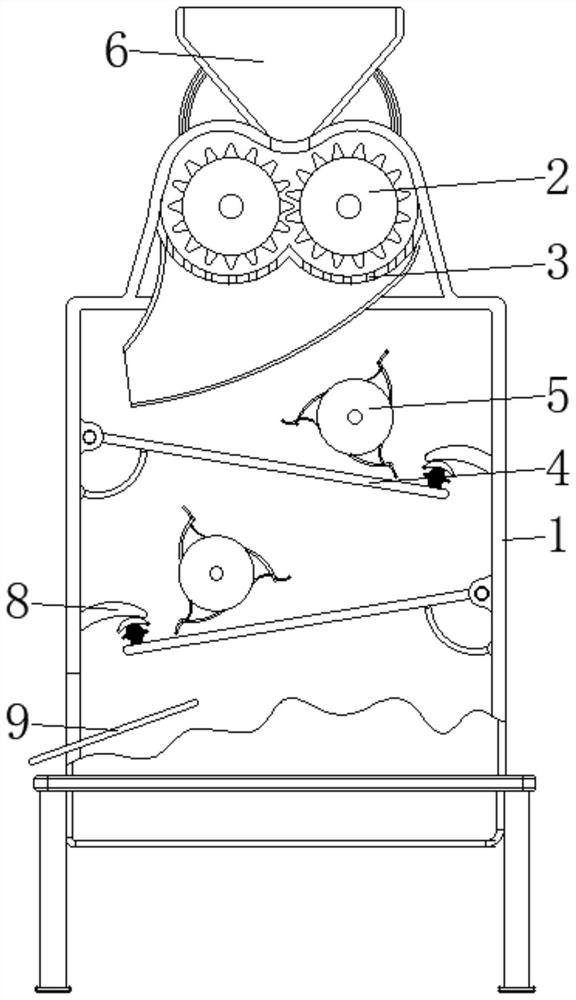

Ceramsite particle forming device and forming method

ActiveCN114471828AReduce the impactNot easy to stick to each otherSievingScreeningEngineeringMechanical engineering

The ceramsite particle forming device comprises a machine body, a profiling roller, a sorting device, a screening device and a poking device, the poking device is arranged in the machine body and close to the top of the screening device, and an arc-shaped elastic plate is arranged between the surface of a driving roller and the two corresponding sides of the surface of the driving roller. The comb tooth device is arranged on the surface of the cambered surface connecting plate and is away from one end of the driving roller, the top end of the comb tooth body is fixedly connected with the surface of the cambered surface connecting plate, the air injection hole is formed in the comb tooth body and is located in the surface position, and the air injection hole communicates with the air outlet end of the bag body; the invention relates to the technical field of ceramsite particle production. According to the ceramsite particle forming device, the rapid drying effect is achieved, rapid drying can be achieved, particle forming, sorting and drying are integrated, meanwhile, the situation that particles adhere to one another is not prone to occurring, blocking is effectively prevented, safety and reliability are achieved, and the working efficiency and the use performance are improved.

Owner:江苏睿新世越环保新材料科技有限公司

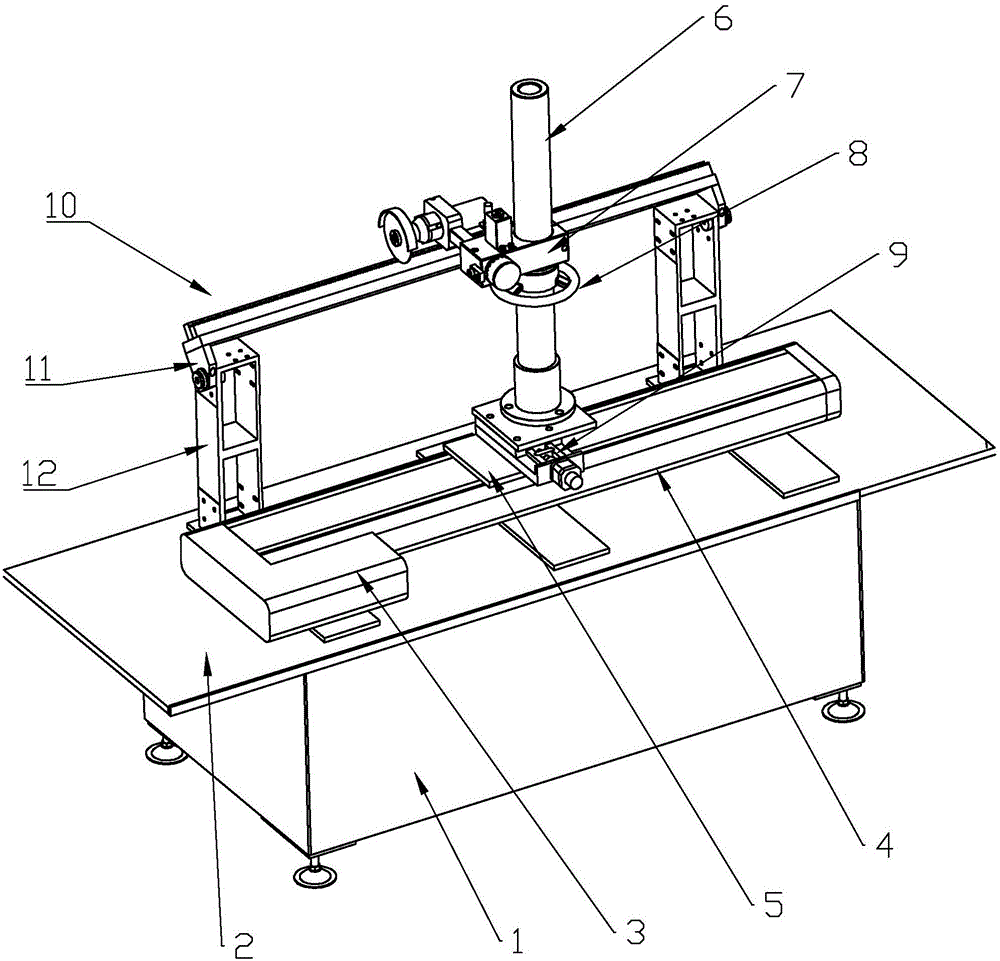

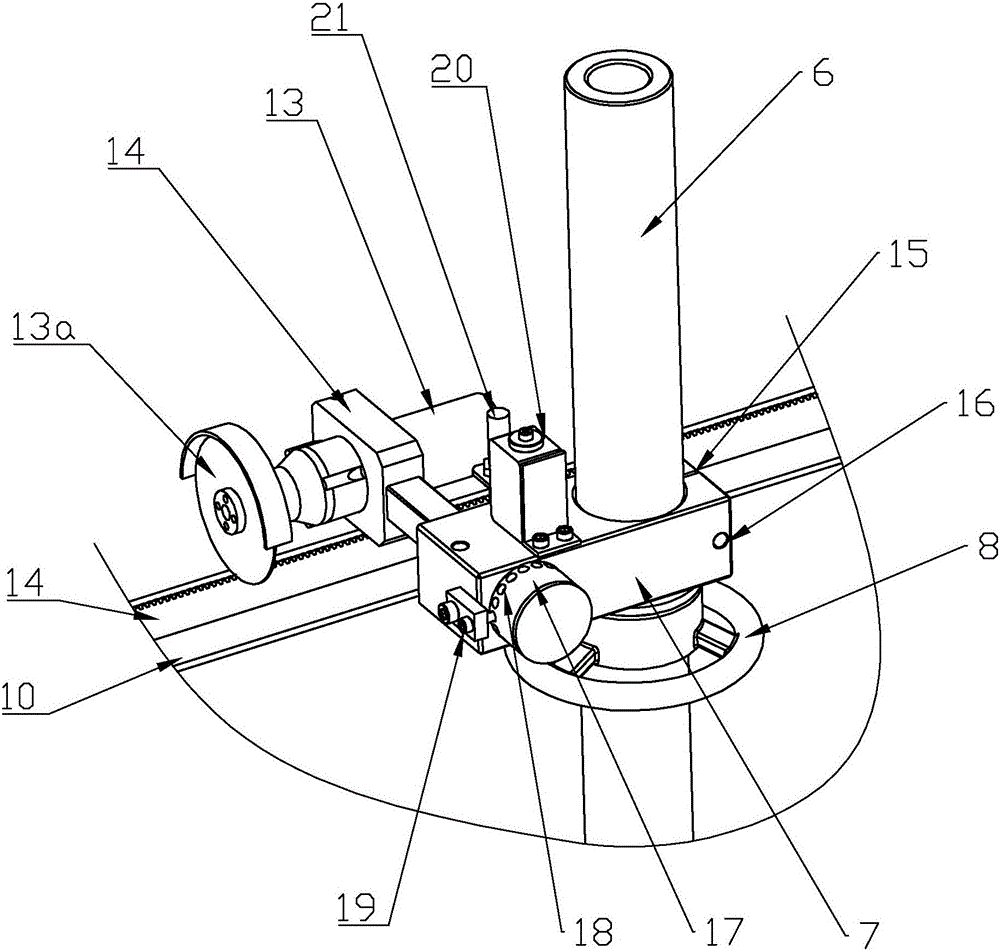

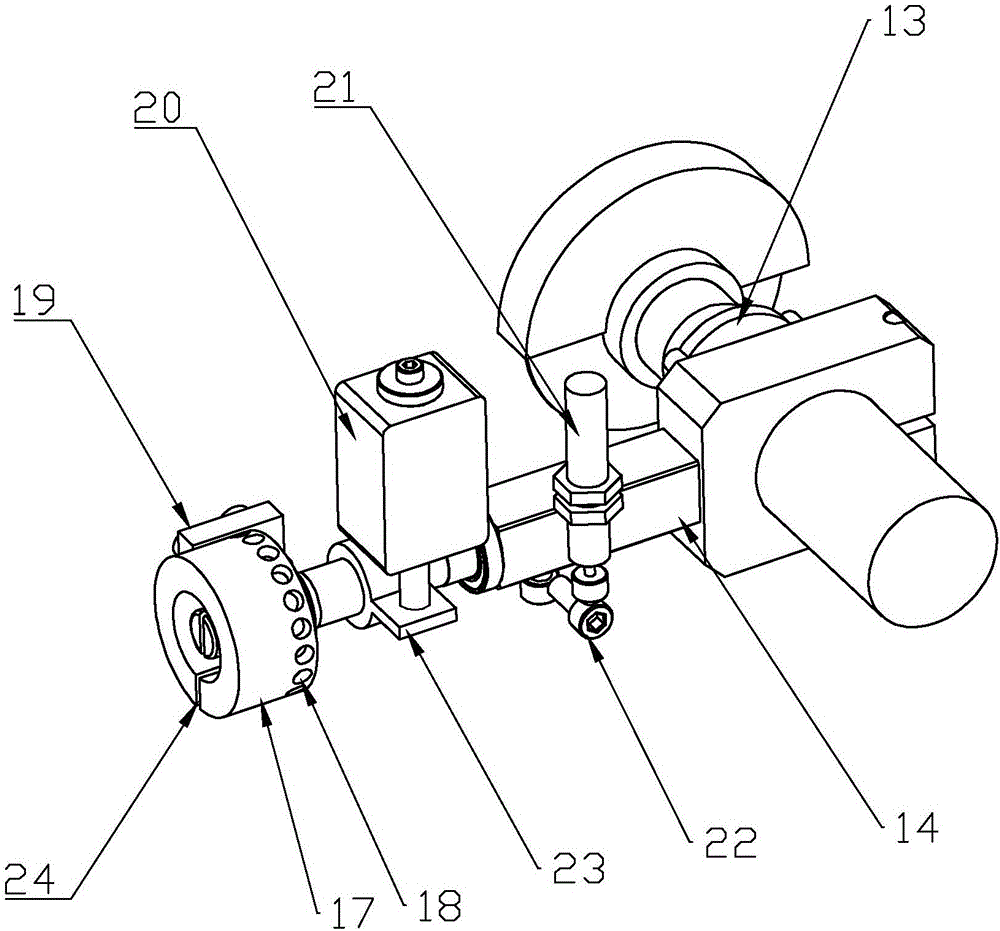

Toothed rack angle lapping machine

InactiveCN106216776AOutstanding and Beneficial Technical EffectsGrinding to achieveGear-cutting machinesGear teethEngineeringBench grinder

A toothed rack angle lapping machine comprises a transverse traveling mechanism. A rack placement frame is arranged on one side of the transverse traveling mechanism and provided with a rack placement station parallel with the traveling direction of the transverse traveling mechanism. A grinding wheel machine is arranged above the rack placement station. The transverse traveling mechanism drives the grinding wheel machine to travel transversely. The grinding wheel machine is connected with a swinging shaft and controlled by elastic force. Under the action of the elastic force, the grinding wheel machine has the trend of rotating around the swinging shaft and enabling a grinding wheel piece to get close to the rack placement station. According to the toothed rack angle lapping machine provided in the scheme, a rack subjected to heat treatment is subjected to finish angle lapping by adopting a copying following principle, the machining accuracy is high, the consistency is high, and time and labor are saved.

Owner:TAIZHOU TAIPUNC EQUIP CO LTD

Material pneumatic conveying system driven by multiple piston sheaths

The invention discloses a material pneumatic conveying system driven by multiple piston sheaths, comprise a conveying line unit and a driving air source unit. A material to be conveyed is disposed inside the conveying line unit. The driving air source unit is communicated with the conveying line unit so as to produce positive / negative pressure in the conveying line unit, more than two piston sheaths fitting a conveying line are also disposed inside the conveying line unit, the material to be conveyed is disposed between adjacent two of the piston sheaths and lies in contact with the axial ends of both piston sheaths, and the piston sheaths move in the conveying line unit under the action of the driving air source unit so as to drive the material to be conveyed, for pneumatic conveying. This system has the advantages of good compatibility, low cost of use, conveying convenience and quickness, high safety and the ability to ensure physical features of a sample and precision.

Owner:HUNAN SUNDY SCI & TECH DEV

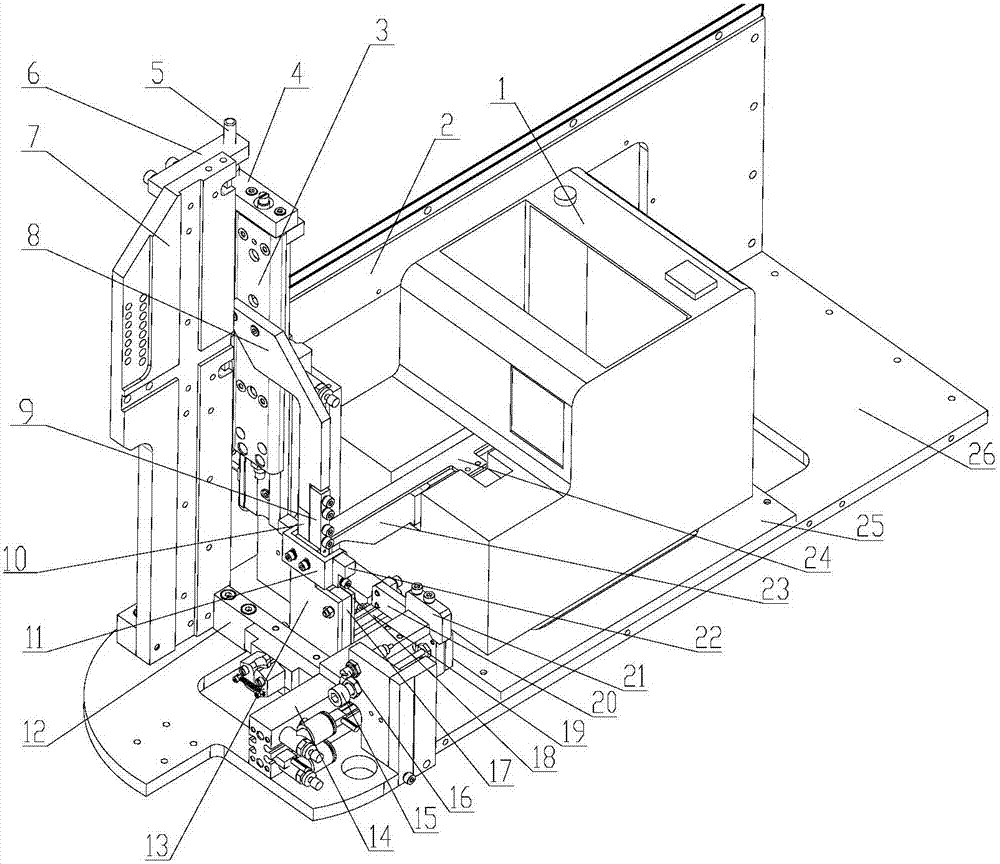

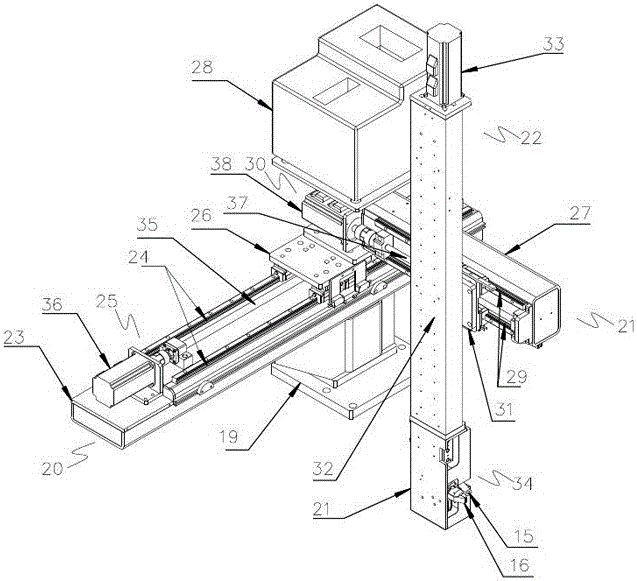

Horizontal loading and taking robot and operating method thereof

InactiveCN106182578AImprove coordinationEasy to operateDomestic articlesEngineeringMechanical engineering

The invention discloses a horizontal loading and taking robot and an operating method thereof. The robot comprises a base, an X-axis mechanism mounted on the base, a Y-axis mechanism slidably connected to the X-axis mechanism and a Z-axis mechanism slidably connected to the Y-axis mechanism, wherein the X-axis mechanism comprises an X-axis main body mounted on the base, an X-axis slide rail arranged on the X-axis main body and an X-axis driving device which drives the Y-axis mechanism to slide on the X-axis slide rail; the Y-axis mechanism comprises a Y-axis slide seat slidably connected to the X-axis slide rail, a Y-axis main body fixedly connected to the Y-axis slide seat, a stud sorter mounted on the X-axis main body, a Y-axis slide rail arranged on the Y-axis main body and a Y-axis driving device which drives the Z-axis mechanism to slide on the Y-axis slide rail; the Z-axis mechanism comprises a Z-axis slide seat slidably connected to the Y-axis slide rail, a Z-axis main body fixedly connected to the Z-axis slide seat, a Z-axis motor which is mounted in the top of the Z-axis main body and drives the Z-axis main body to lift perpendicularity and an emptying mechanism mounted in the bottom of the Z-axis main body. Therefore, manual work is replaced.

Owner:江门市蓬江区联诚达科技发展有限公司

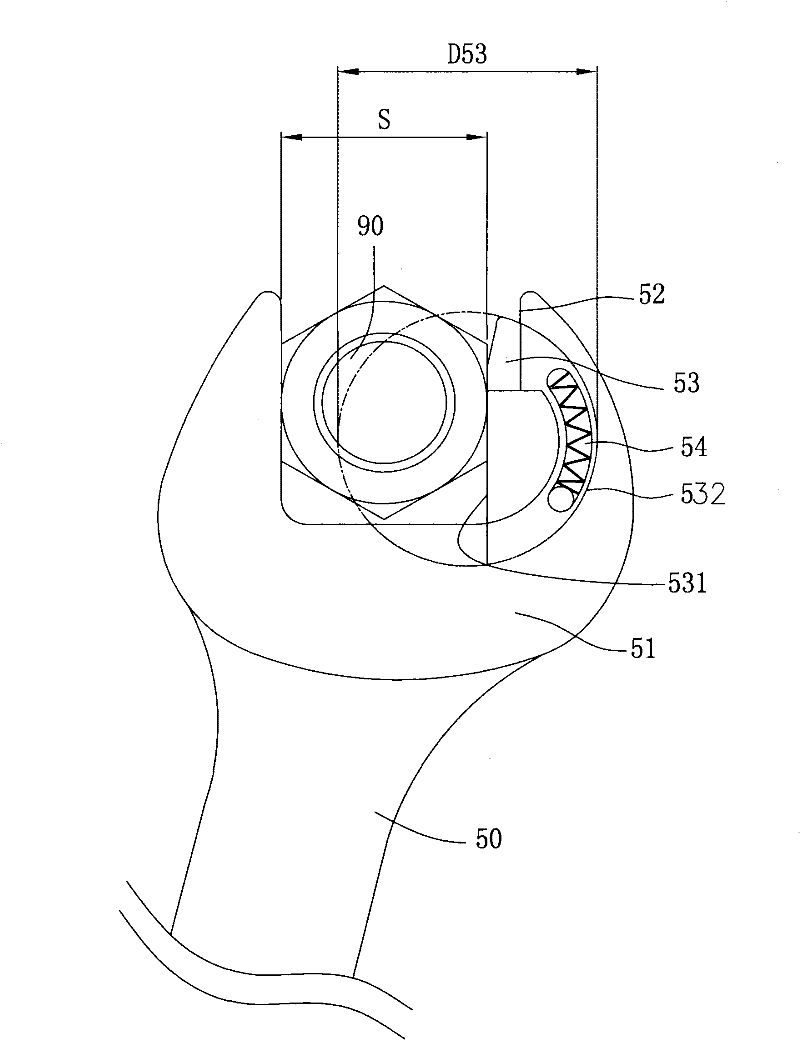

Open end wrench capable of being wrenched to and fro

The invention discloses an open end wrench capable of being wrenched to and fro. The open end wrench comprises a body which is provided with a grip jaw; a sliding chute is formed in the grip jaw; a chute body of the sliding chute can be processed at one time; a sliding block can slide along an arc in the sliding chute and is provided with a guide slot through which a guide column can pass to ensure a structure is reinforced and does not fall off easily; two sides of a first wrenching plane of the sliding block are provided with a first expanding surface respectively; a first jaw and a second jaw of the clamping jaw, the first wrenching plane of the sliding block and an inner circle diameter formed between two expansion surfaces can rotate relative to an axis position of a working substance and do not generate clamping interference; and the areas of the expansion surfaces of the two sides of the sliding block are expanded outward from the first wrenching plane to two side walls of a first support wall and a second support wall of the body, so the contact area of the first wrenching surface and a fourth forward-direction stress surface of the contacted working substance is increased.

Owner:胡厚飞

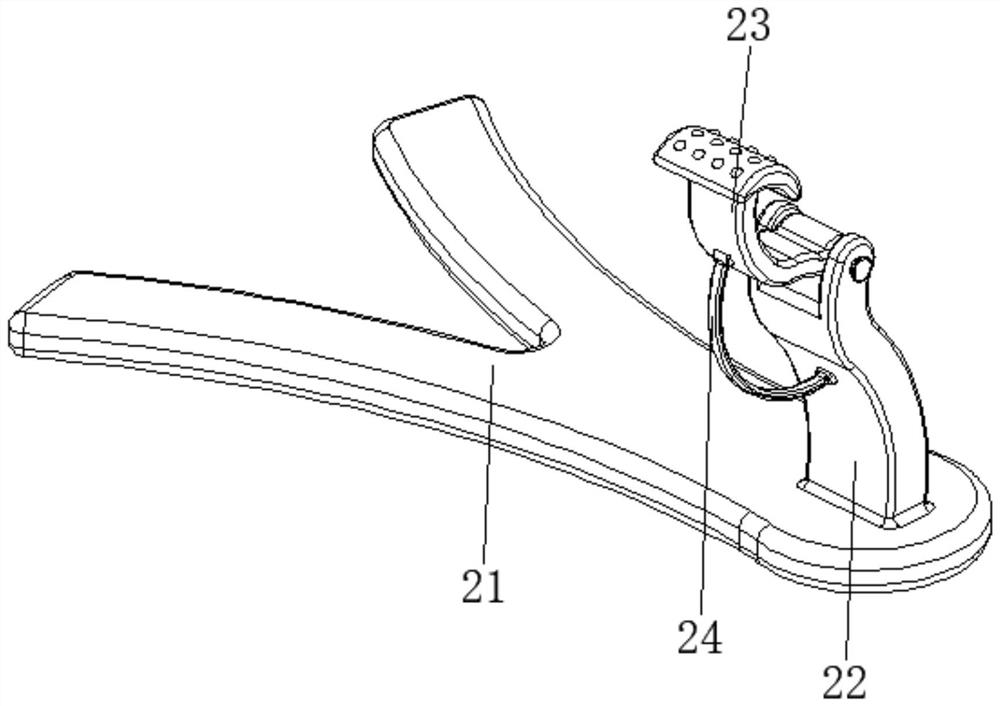

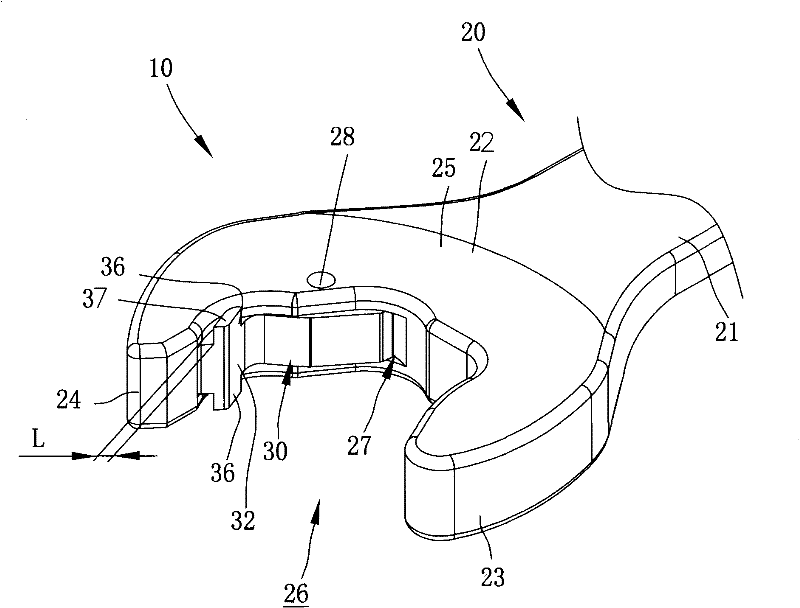

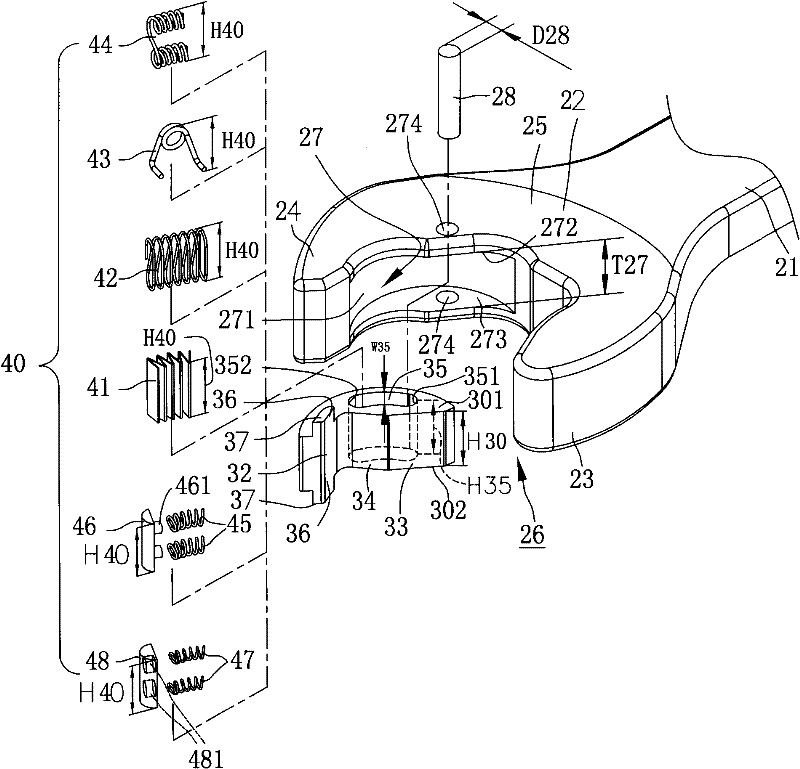

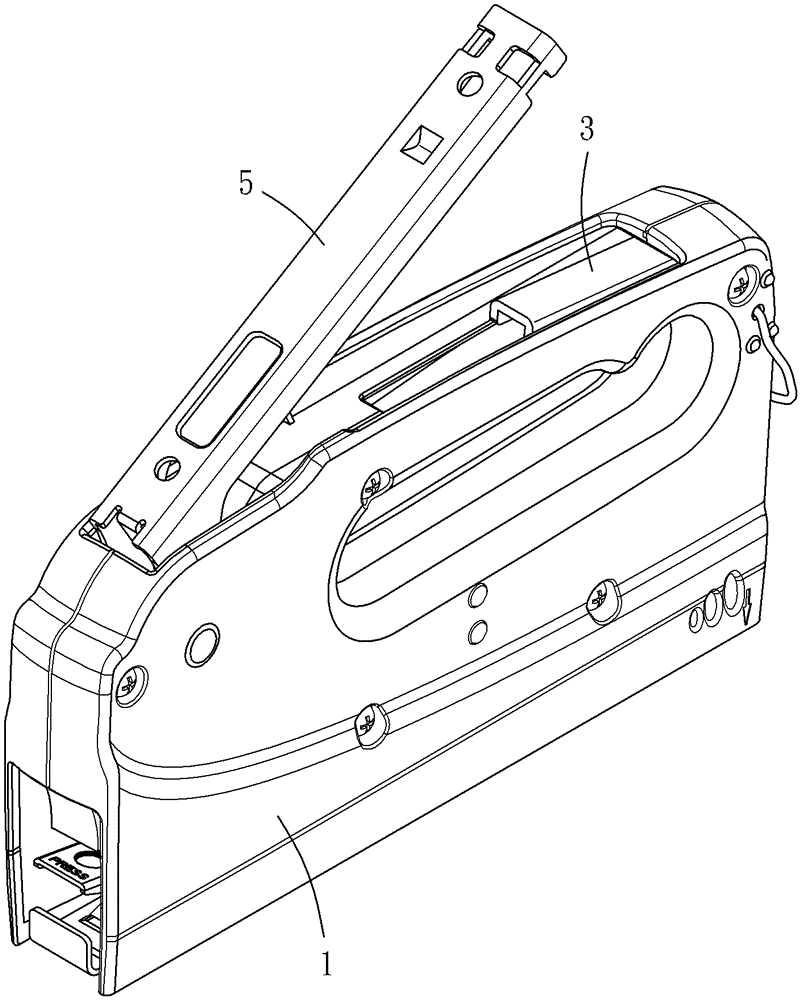

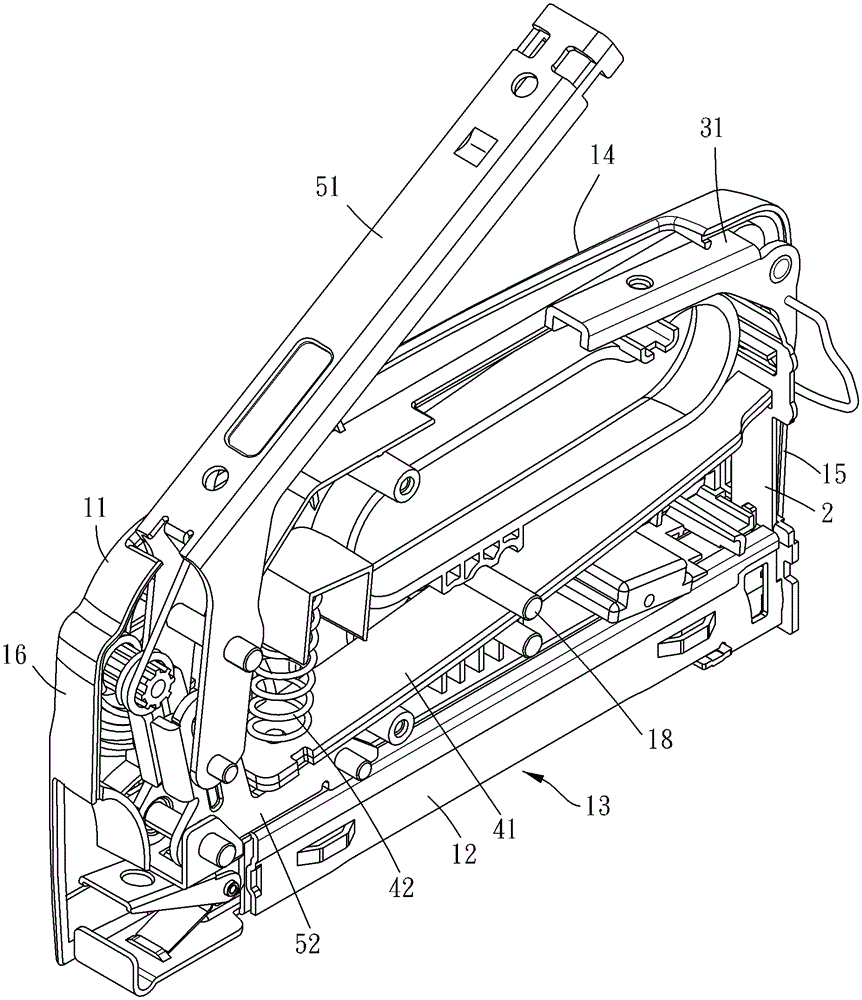

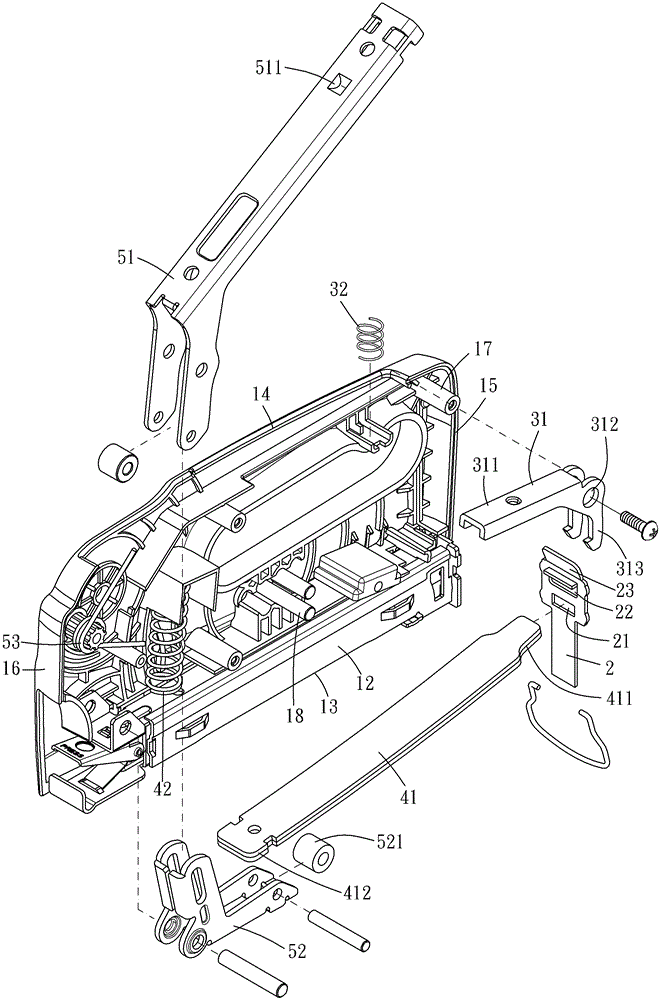

The nailing gun with the striker separated from the nail in advance

The invention provides a nailing gun having a hitting board separated from a nail needle in advance. The nailing gun has a hitting board used for cocking a nail needle, a limiting mechanism, a force accumulation mechanism and an actuating mechanism, the limiting mechanism can maintain the hitting board in the initial position, the actuating mechanism can realize actuation and allows the force accumulation mechanism to accumulate elastic force potential energy, and the hitting board bears the elastic force of the force accumulation mechanism after the limiting mechanism is triggered in order to cock the nail needle, so the maintenance of the hitting board in the initial position in advance in the elastic force potential energy accumulation process of the force accumulation mechanism is realized, and the hitting board is separated from the nail needle, thereby the nail needle can move to a fixed position, and the false nailing possibility during continuous nail needle cocking can be reduced.

Owner:APEX MFG

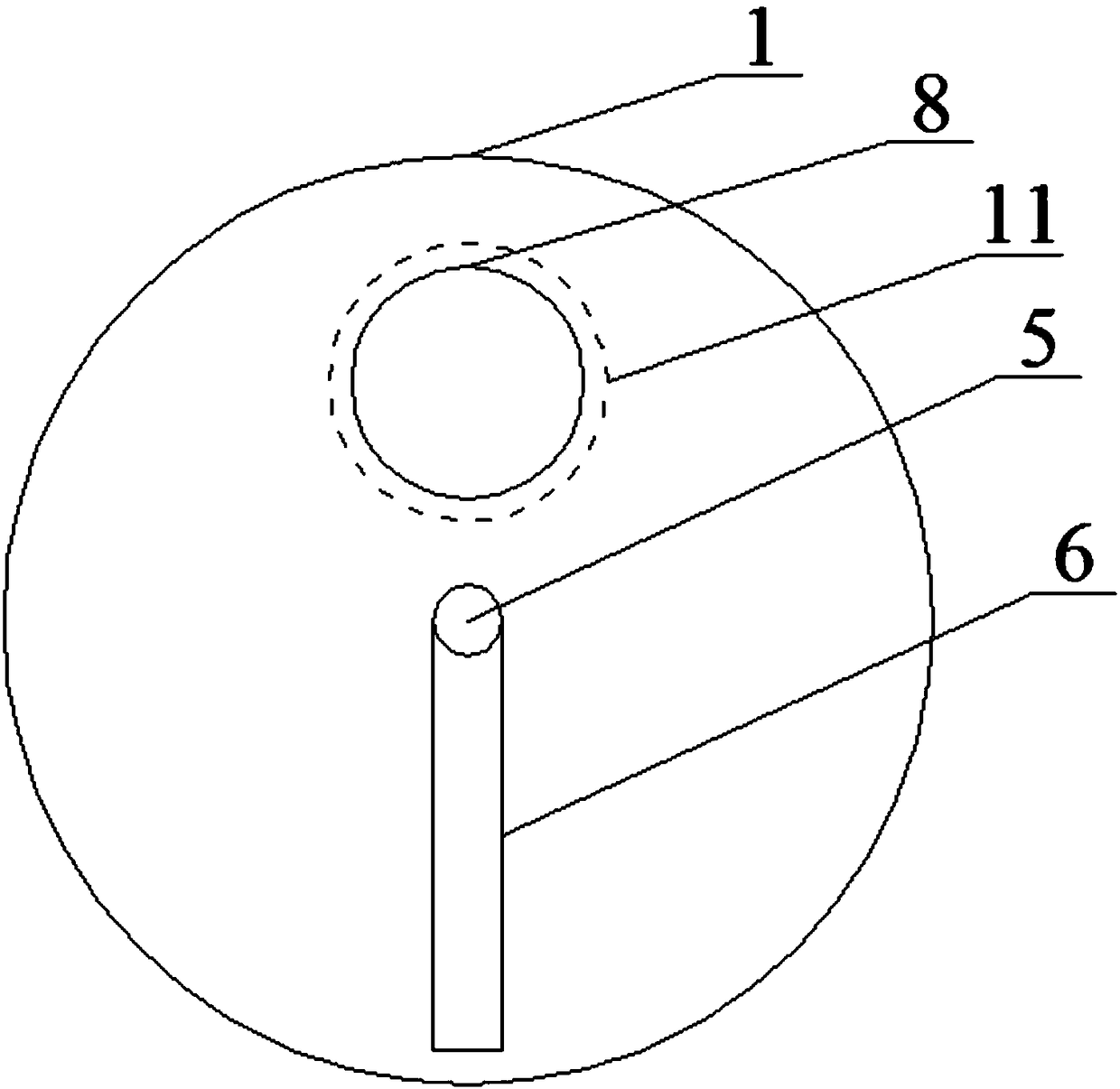

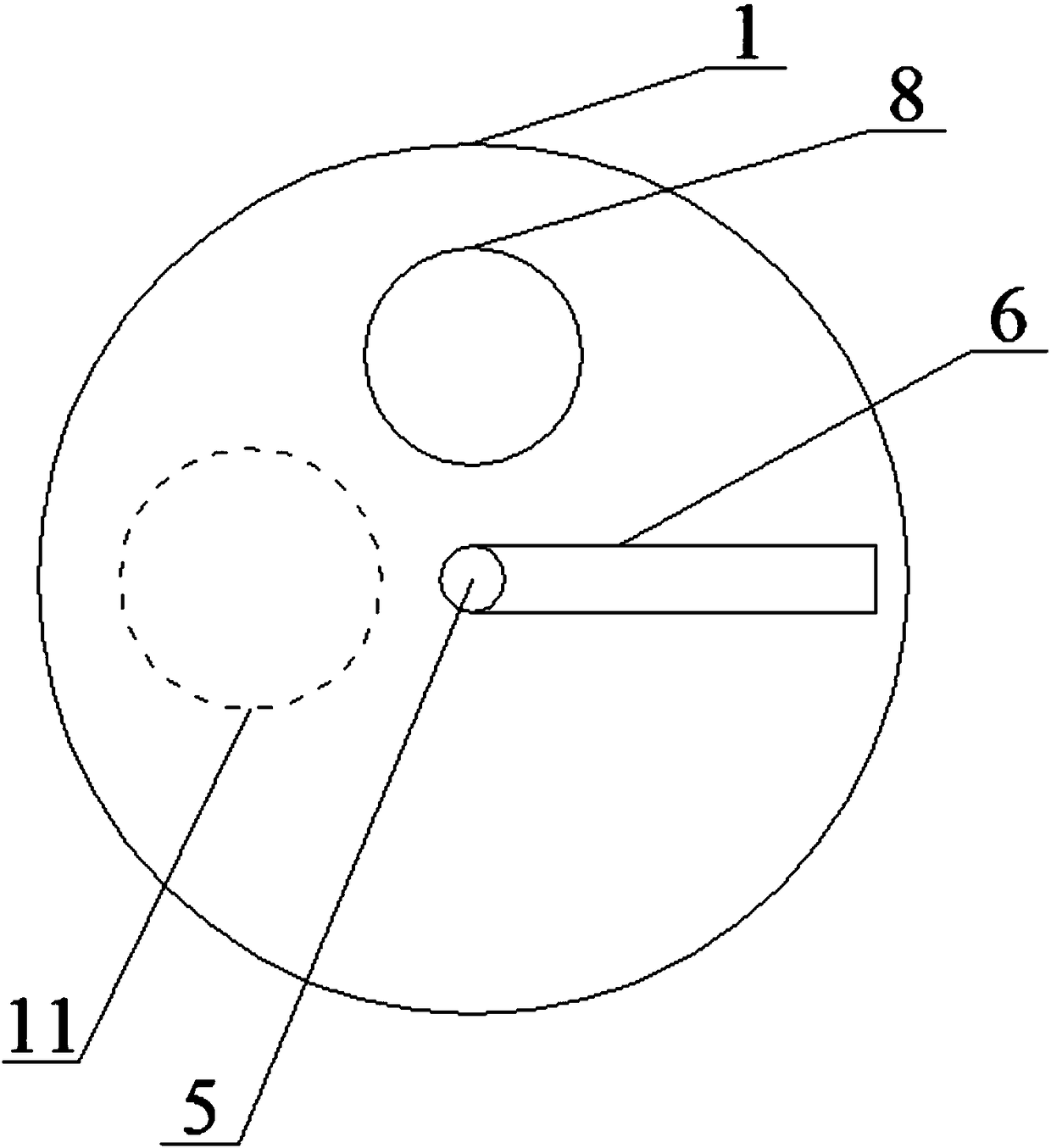

Anti-clamping flushing-resistance material door and use method thereof

InactiveCN108468823ALow rotational driveReduced rotational drivePlug valvesOperating means/releasing devices for valvesEngineeringMechanical engineering

The invention discloses an anti-clamping flushing-resistance material door. The anti-clamping flushing-resistance material door includes an upper fixed valve plate, a lower fixed valve plate and a rotating valve plate which can circumferentially rotate in a reciprocating mode. Through-flow holes are formed in the upper fixed valve plate, the lower fixed valve plate and the rotating valve plate, and the through-flow holes on the upper fixed valve plate and the lower fixed valve plate correspond to each other in the flowing direction and are separately used as a feeding inlet and a discharging outlet. Opening and closing of the material door are realized by rotating the rotating valve plate, specifically, when the rotating valve plate is rotated, the through-flow hole on the rotating valve plate shears the through-flow holes on the upper fixed valve plate and the lower fixed valve plate and gradually blocks and closes the material door; and when the rotating valve plate is rotated, the through-flow hole on the rotating valve plate gradually communicates with the through-flow holes on the upper fixed valve plate and the lower fixed valve plate to open the material door. A buffer partis arranged on the inner wall of a feeding pipe connected with the through-flow hole of the upper fixed valve plate. The invention further provides a use method of the anti-clamping flushing-resistance material door. Opening and closing of a material pipeline are realized through shearing action, the phenomenon of material clamping and clamping of the material door is avoided, and flushing of thematerial to the material door and the pipeline is further reduced through the buffer part.

Owner:潘健

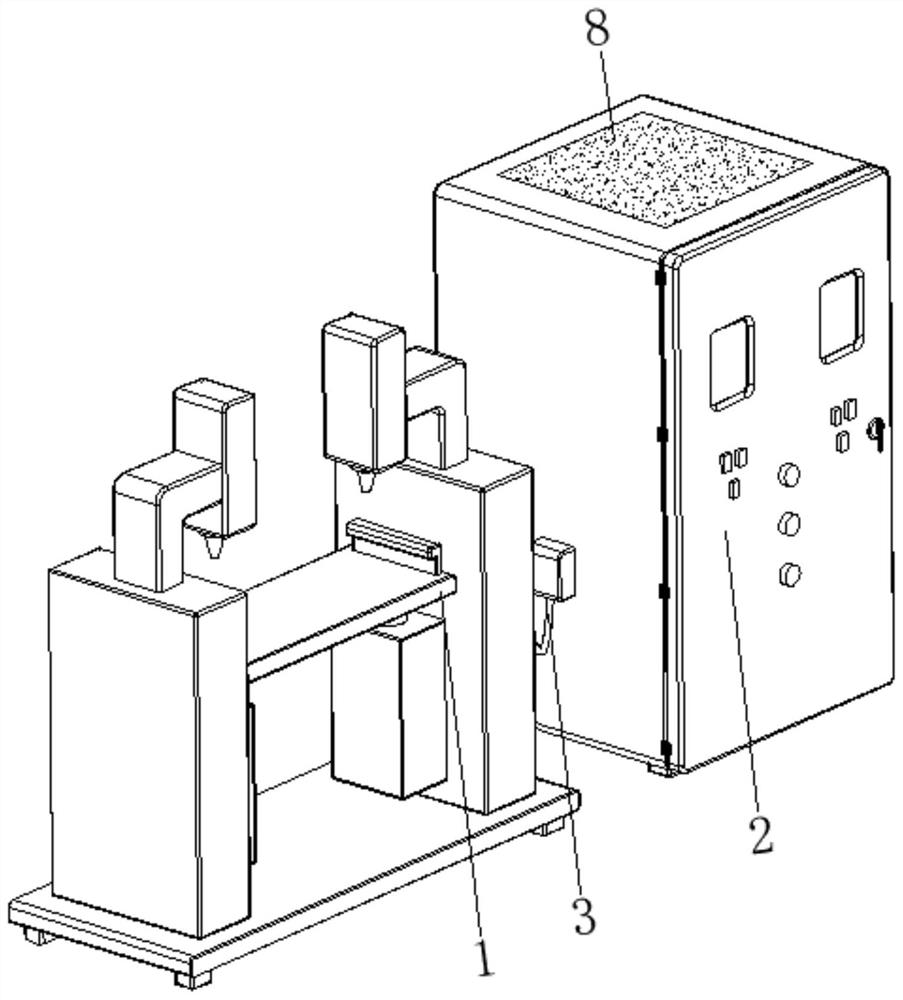

Novel motor shell welding equipment

InactiveCN113478079AImprove stabilityAvoid injuryWelding/cutting auxillary devicesManufacturing dynamo-electric machinesElectric machineryStructural engineering

The invention discloses novel motor shell welding equipment. The equipment comprises a welding main body, wherein box doors are arranged at the two sides of the bottom of the front face of the welding main body; a welding device is fixedly connected to the top of the welding main body; blocking frames are fixedly connected to the two sides of the top of the welding device; a cover plate is fixedly connected to the tops of the blocking frames; and the right side of the front surface of the cover plate is fixedly connected with a control panel. The invention relates to the technical field of motor shells. According to the novel motor shell welding equipment, a laser welding device has good stability during welding, the situation of blocking is not prone to occurring in the moving process, so that the accuracy during welding is improved, and the situation of repeated welding or welding missing is avoided; and clamping blocks are arranged on the welding platform, the connecting position of the device can be fixed, sparks generated during welding are conveniently intercepted, workers are effectively prevented from being injured, the cover plate can prevent the sparks from splashing upwards, and the use safety of the device is further improved.

Owner:彭鹏飞

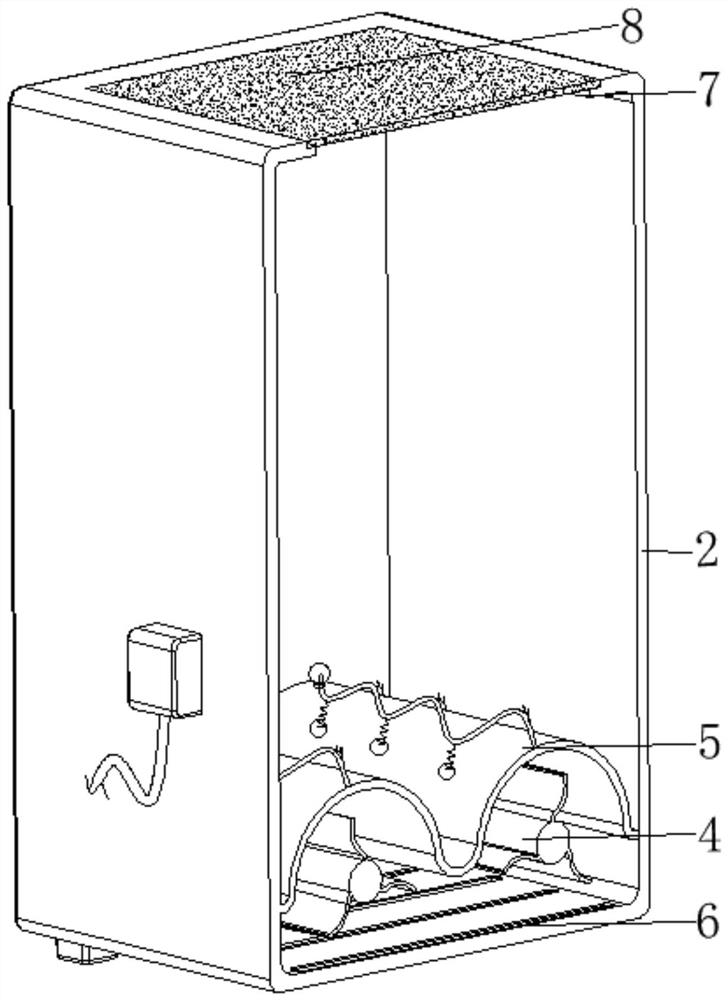

Transformer cooling fin spot welding machine

ActiveCN114669919ALess likely to depositExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesTransformerEngineering

The transformer cooling fin spot welding machine comprises a machine body, a control cabinet, a connecting wire, a cooling device and an impurity removing device, the cooling device is arranged at the bottom of the inner wall of the control cabinet, the impurity removing device is arranged in the control cabinet and is close to the cooling device, and the surface edge of a butterfly-shaped filter screen is fixedly connected with the inner wall of the control cabinet; the pressed driving device is arranged at the bottom of the butterfly-shaped filter screen and close to the ball head sliding rod, the cleaning device is arranged at the top end of the ball head sliding rod and close to the top of the butterfly-shaped filter screen, the top end of the supporting spring is fixedly connected with the surface of the connecting piece, and the surface end of the knocking head is fixedly connected with the bottom end of the supporting spring. The invention relates to the technical field of spot welding equipment. According to the transformer cooling fin spot welding machine, the self-cleaning effect is achieved, components can be cooled in time, sundries can be treated in time, self-cleaning is conducted, sundries are not prone to deposition, the service life of equipment is prolonged, safety and reliability are achieved, and the use performance is improved.

Owner:江苏长川科技有限公司

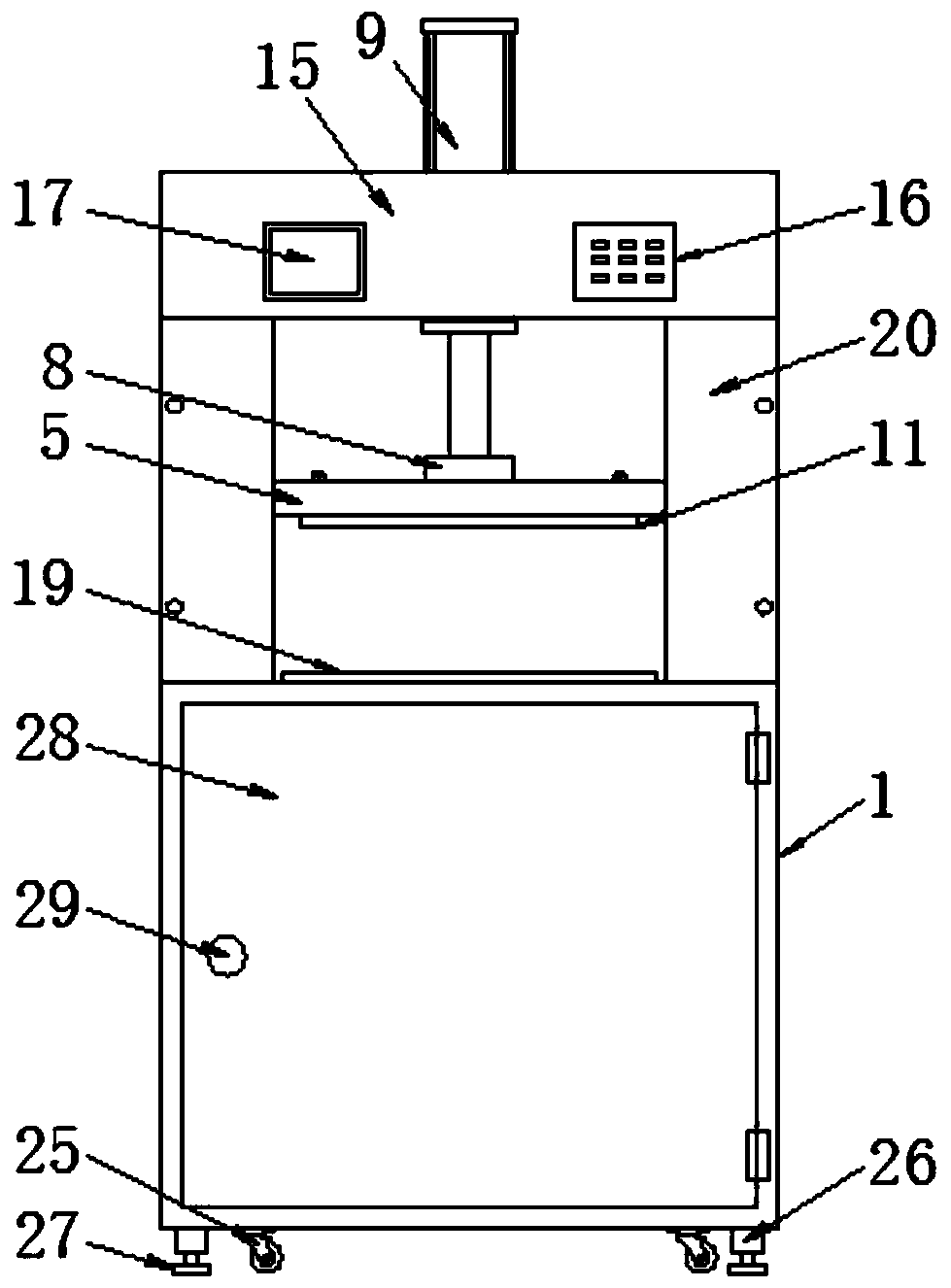

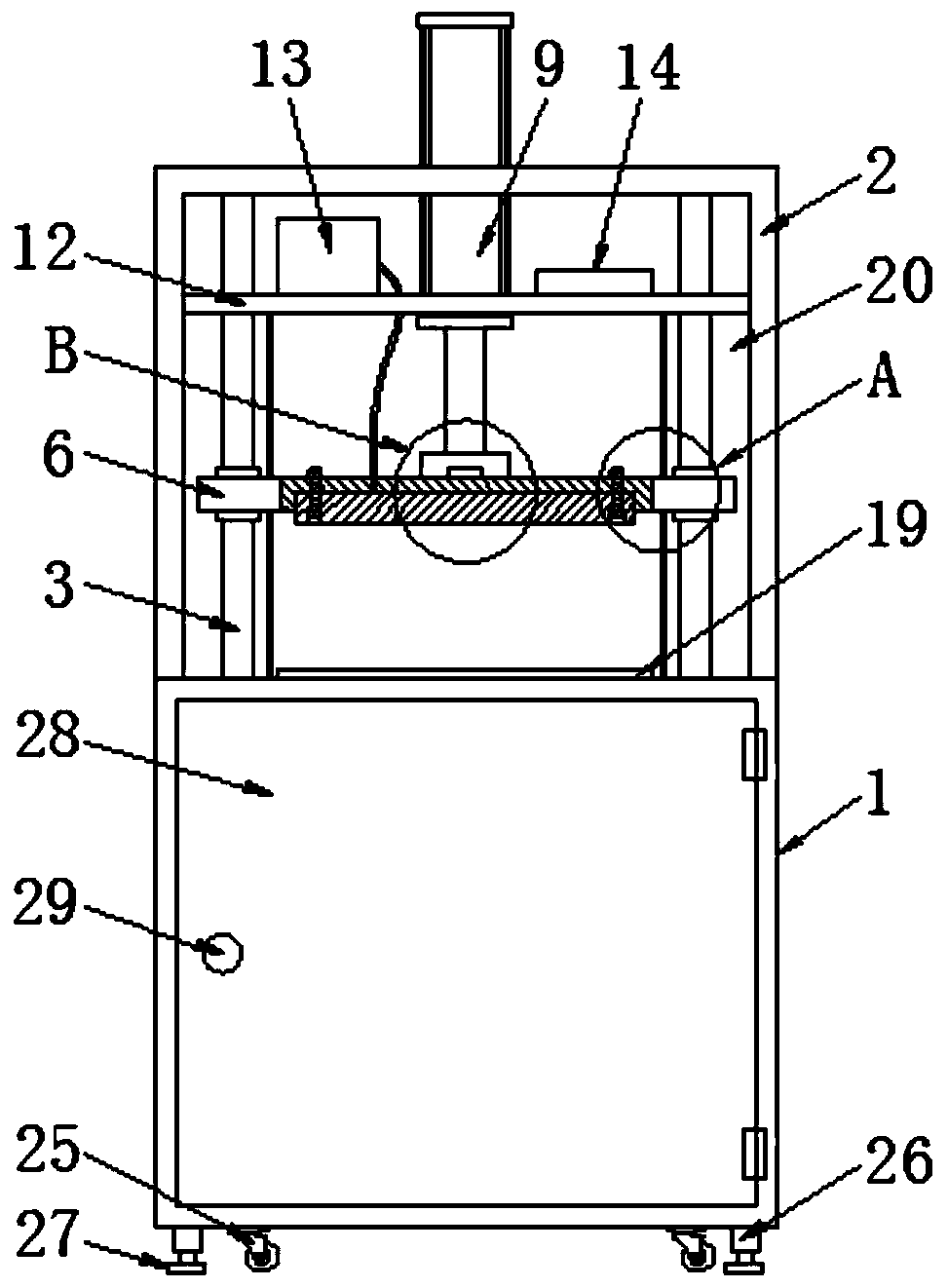

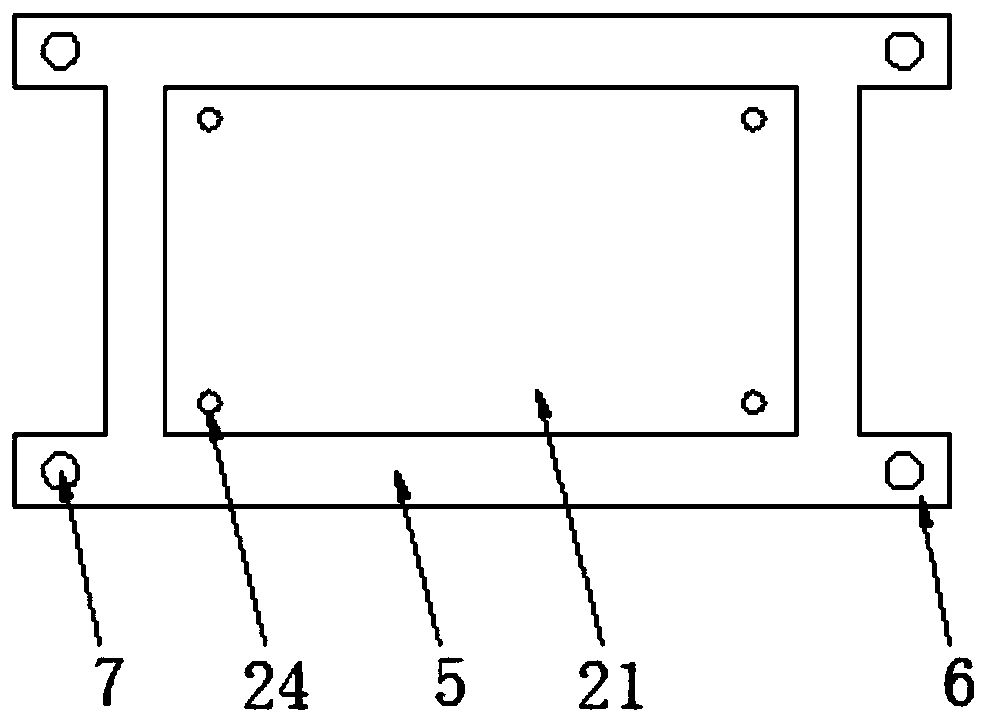

5G high-frequency high-speed hot press

InactiveCN110667171AImplementation orientationIntelligent Pressure ControlLaminationLamination apparatusForeign matterPressure stabilization

The invention relates to the technical field of hot presses, and discloses a 5G high-frequency high-speed hot press which comprises a bottom box. A top frame is fixedly connected to the top of the bottom box, four guide shafts are fixedly arranged between the bottom of the top frame and the top of the bottom box in a connected mode, linear bearings are movably connected to the surfaces of the fourguide shafts, a movable pressing plate is arranged among the four guide shafts, and extension parts are arranged on the front surfaces and the back surfaces of two sides of the movable pressing plate. According to the 5G high-frequency high-speed hot press, the guide shafts are fixedly arranged between the bottom of the top frame and the top of the bottom box in the connected mode, the linear bearings and the guide shafts are matched to realize the guide of the movable pressing plate, the intelligent pressure control is realized, the parallelism and the pressure stability of the movable pressing plate mechanism after long-time operation are realized, the product quality is guaranteed, the linear bearings are easier to install and implement compared with a ball screw structure, the guide shafts are less prone to blocking caused by foreign matters compared with a screw rod, and operation is more stable and reliable.

Owner:四川豪威尔信息科技有限公司

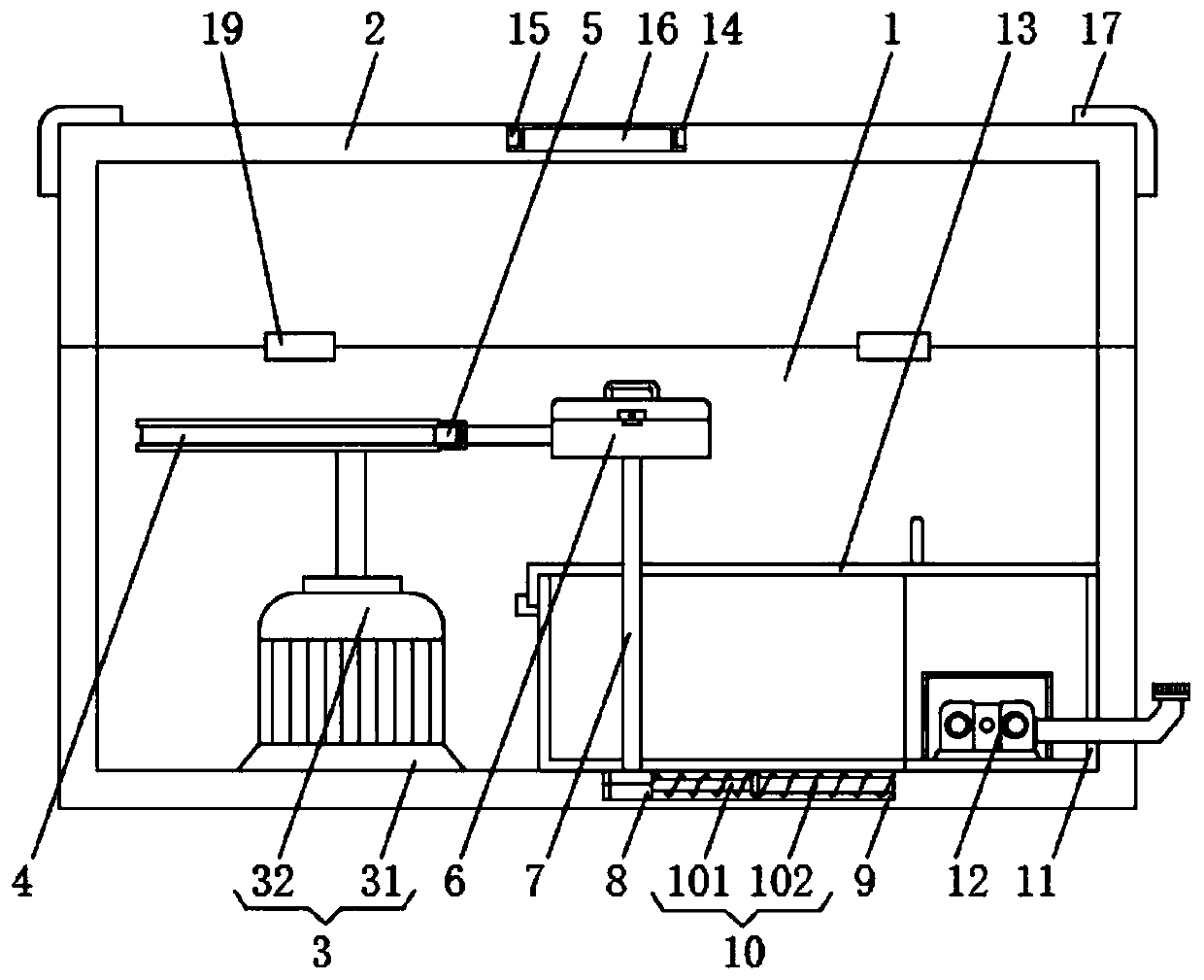

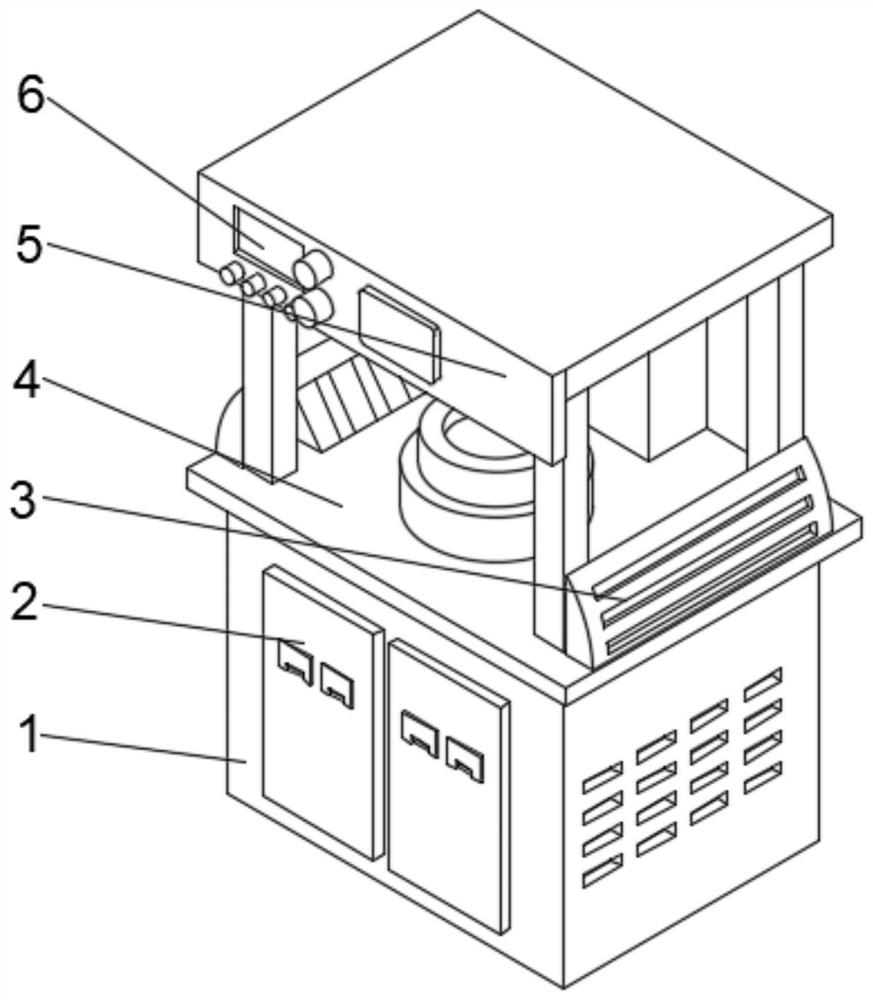

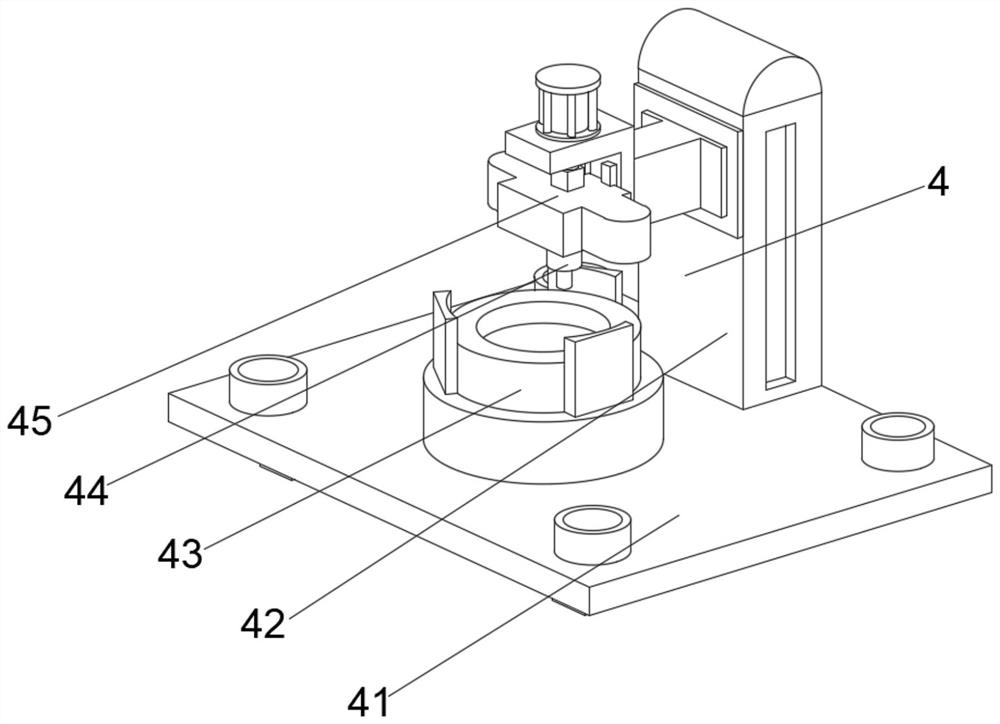

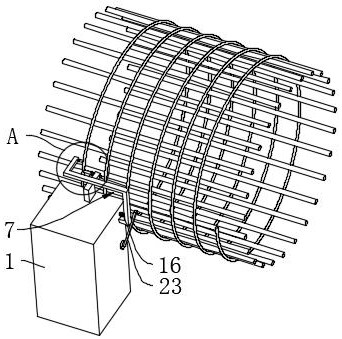

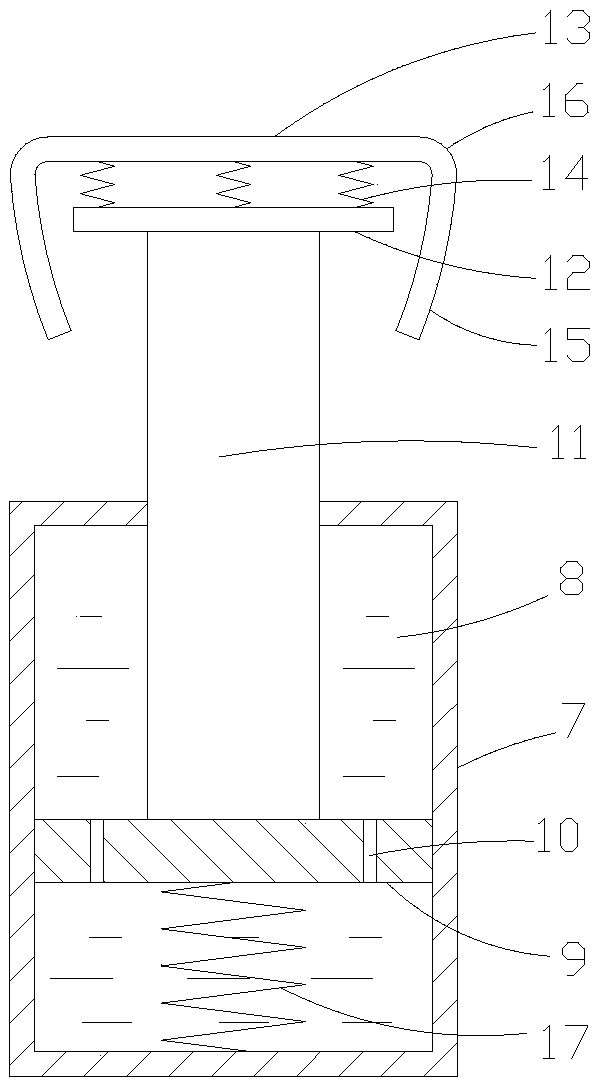

Reinforcement cage stirrup spot welding device without welding spot omission

PendingCN114769470ALess likely to get stuckImprove use reliabilityWire networkMetal working apparatusClassical mechanicsEngineering

The reinforcement cage stirrup spot welding device comprises a machine body, a mounting plate is arranged on the top face of the machine body, a welding gun is slidably connected to the side wall of the mounting plate, a first spring is arranged between the welding gun and the mounting plate and used for pushing the welding gun away from the mounting plate and abutting against a stirrup, and a first contact switch is arranged on the side wall of the welding gun. And when the main reinforcement extrudes the contact switch I, the welding gun is used for welding the joint point of the stirrup and the main reinforcement. During use, the welding gun is attached to the side wall of the stirrup all the time under the elastic force of the first spring, when the main rib extrudes the first contact switch on the side wall of the welding gun, the welding gun right faces the joint point of the stirrup and the main rib, and therefore the welding gun can weld the joint point of the stirrup and the main rib. The welding gun can abut against the side wall of the stirrup and weld the joint point of the stirrup and the main reinforcement, the situation of solder skips or insufficient solder is not prone to occurring, and the spot welding device is high in use reliability.

Owner:四川高速公路建设开发集团有限公司

Hip self-adaptive office chair

The invention discloses a hip self-adaptive office chair. The hip self-adaptive office chair comprises a seat; a sponge cushion is arranged on the seat; a backrest is arranged on the back side of theseat; supporting legs are arranged at the bottom of the seat; a plurality of counterbores are formed in the upper end face of the seat; seat adjusting modules are arranged in the counterbores; each seat adjusting module comprises a cylinder body fixedly arranged in each counterbores; hydrolytic oil and a piston are arranged in the cylinder body; a through hole is formed in the piston; a pressure spring connected with the cylinder body is arranged below the piston; the piston is fixed with a supporting plate positioned above the cylinder body through a piston rod; a universal rotating plate isarranged above the supporting plate; the supporting plate and the universal rotating plates are connected through a plurality of springs; the sponge cushion is arranged on the universal rotating plate. The hip self-adaptive office chair can fit and support the hip in different sitting postures well and has the advantage of delaying fatigue of office staff.

Owner:ANJI DAZHI FURNITURE MFG CO LTD

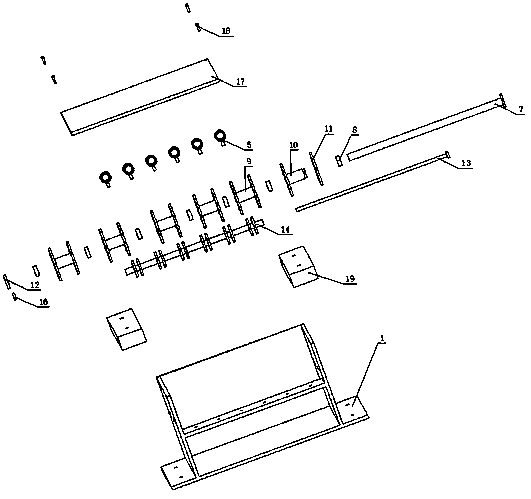

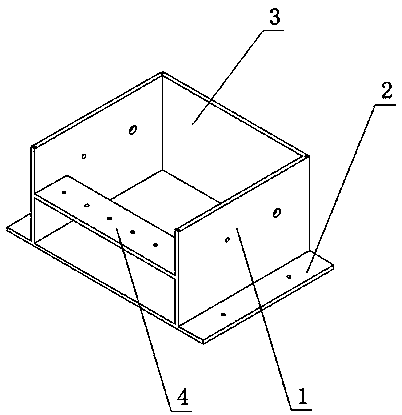

A wiring device for hydropower construction

PendingCN109244989ALess likely to get stuckLess likely to get tangledElectrical apparatusTruss connector plateEngineering

The invention discloses a wiring device for hydropower construction, which includes a mounting bracket for wiring fixing; the mounting frame is composed of a bottom plate and three vertical plates, the vertical plates are vertically welded to each other to form an integral body, the vertical plate is integrally arranged in the middle of the end face of the bottom plate, and the vertical plate andthe bottom plate are integrally welded, the three vertical plates and the bottom plate form a hollow cuboid with both opened ends, A connector plate is welded in the rectangular body cavity, the sideof the connector plate coincides with the open end face of the rectangular body, a conductor ring is arranged above the end face of the connector plate far away from the bottom plate, and the wire coil rotates along the axis during wiring through the use of the wire coil assembly, so that the wire wire is not easy to be stuck; Through the combination of the spacer sleeve, the wire coil assembly and the wire clamp loop, the wires are separated, the situation of wire winding is not easy to occur, and many wires can be distributed at the same time; The use of counterweight blocks makes the entirewiring device of the more stable and less prone to dumping.

Owner:贵州富邦水电工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com