Inner-channel vehicle suspension system magnetorheological damper

A magnetorheological shock absorber, automobile suspension technology, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problem of unequal gap width, piston axial damping force stuck, valve The opening cannot be accurately controlled, etc., to achieve the effect of increased working stroke, high magnetic field utilization, and high working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

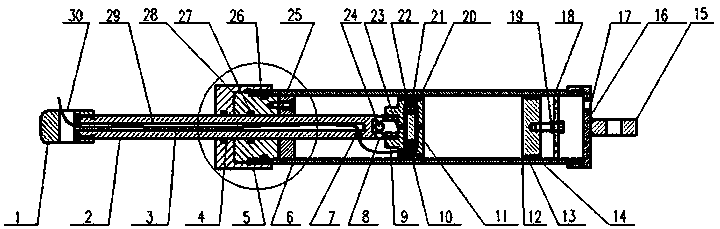

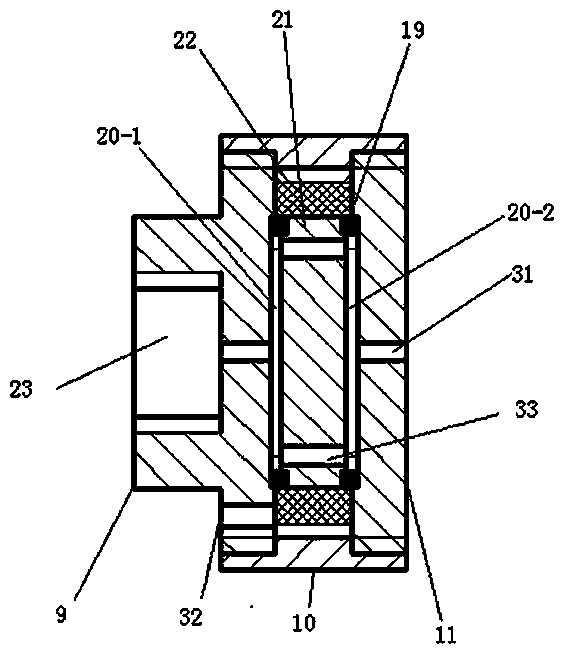

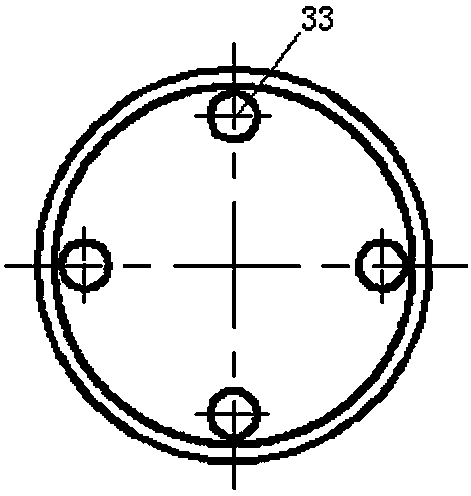

[0030] refer to figure 1 , the present embodiment includes a cylinder 6, a combined electromagnetic piston and a floating piston are arranged in the cylinder 6, and the combined electromagnetic piston divides the chamber above the floating piston into an upper chamber and a lower chamber filled with magnetorheological fluid, The bottom end of the cylinder 6 is provided with a bottom cover 16, the bottom cover 16 is fixedly connected with the filling and deflation valve 17 and the lower suspension ring 15 respectively, and the upper end of the cylinder 6 is provided with a guide seat 28, and the upper end of the guide seat 28 is fastened to the upper end The cover 5 presses the guide seat 28 through the upper end cover 5, and the lower end of the guide seat 28 is fixedly connected with a buffer block 25; the combined electromagnetic piston is fixedly connected to the piston rod 2, and the piston rod 2 extends outward through the guide seat 28 and the upper end cover 5 , the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com