Roller washing machine

A technology of a drum washing machine and a clamping part, which is applied in the field of washing machines, can solve the problems of large moving displacement of the inner drum system, long time required for tightening bolts, difficulty in disassembly and maintenance, etc., so as to shorten the installation time, improve the installation efficiency, Easy to remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

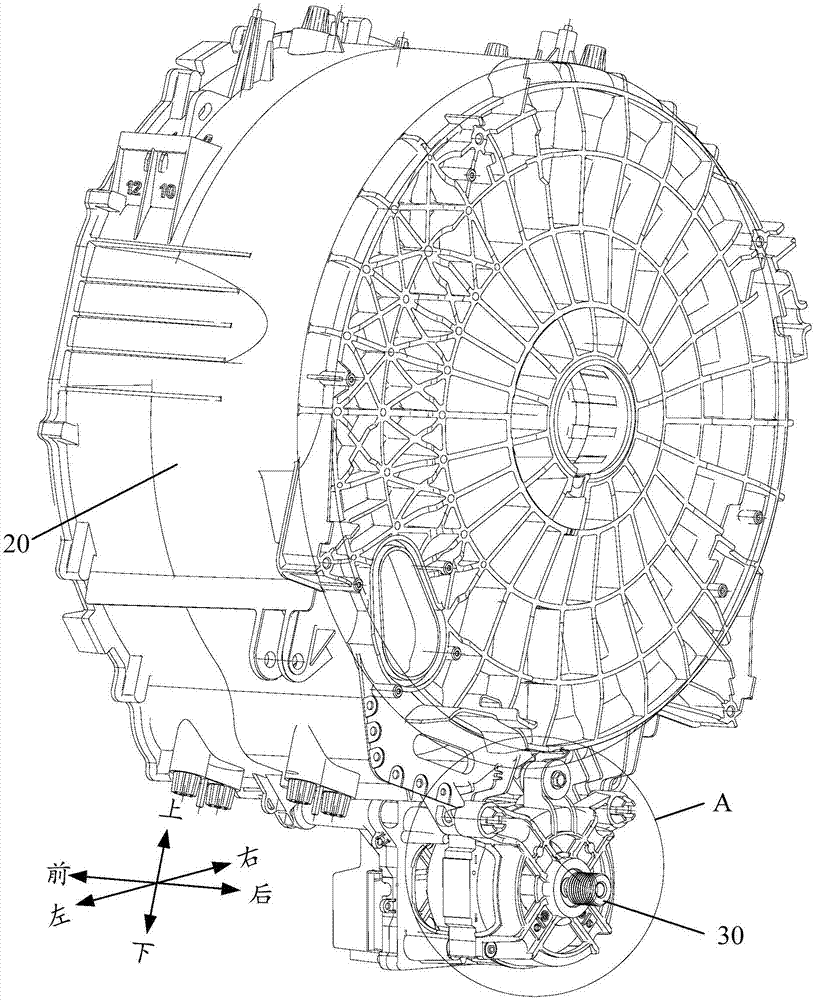

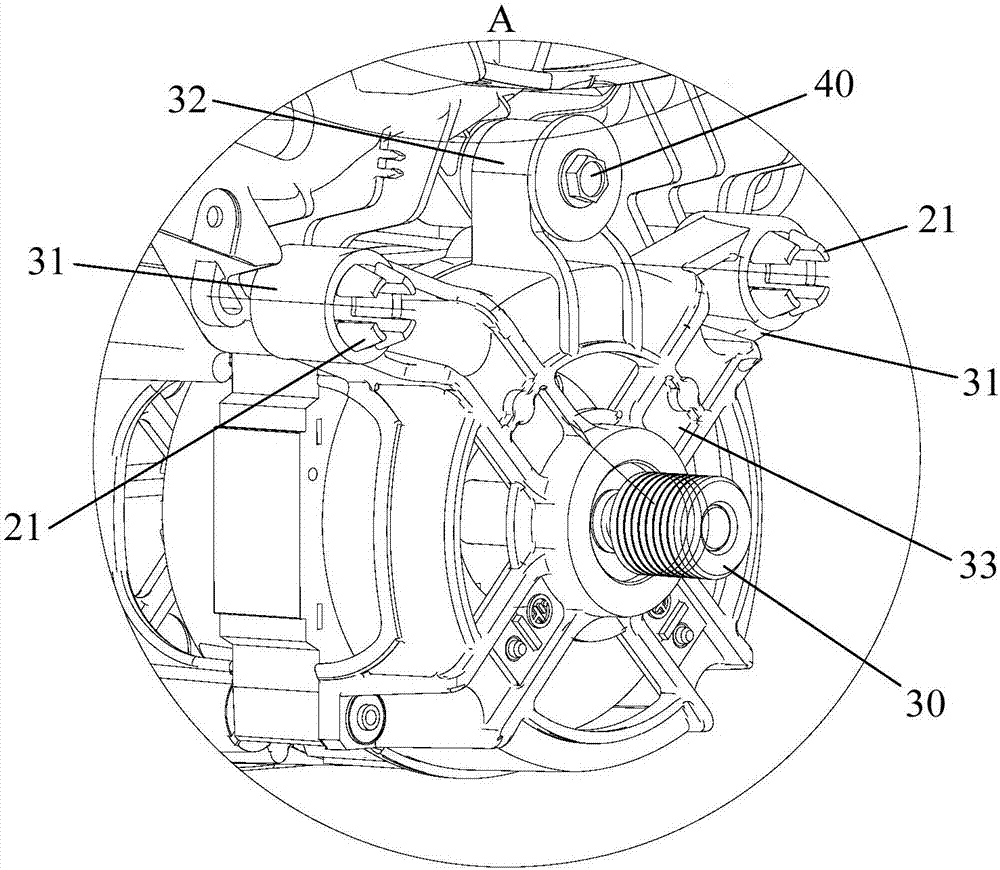

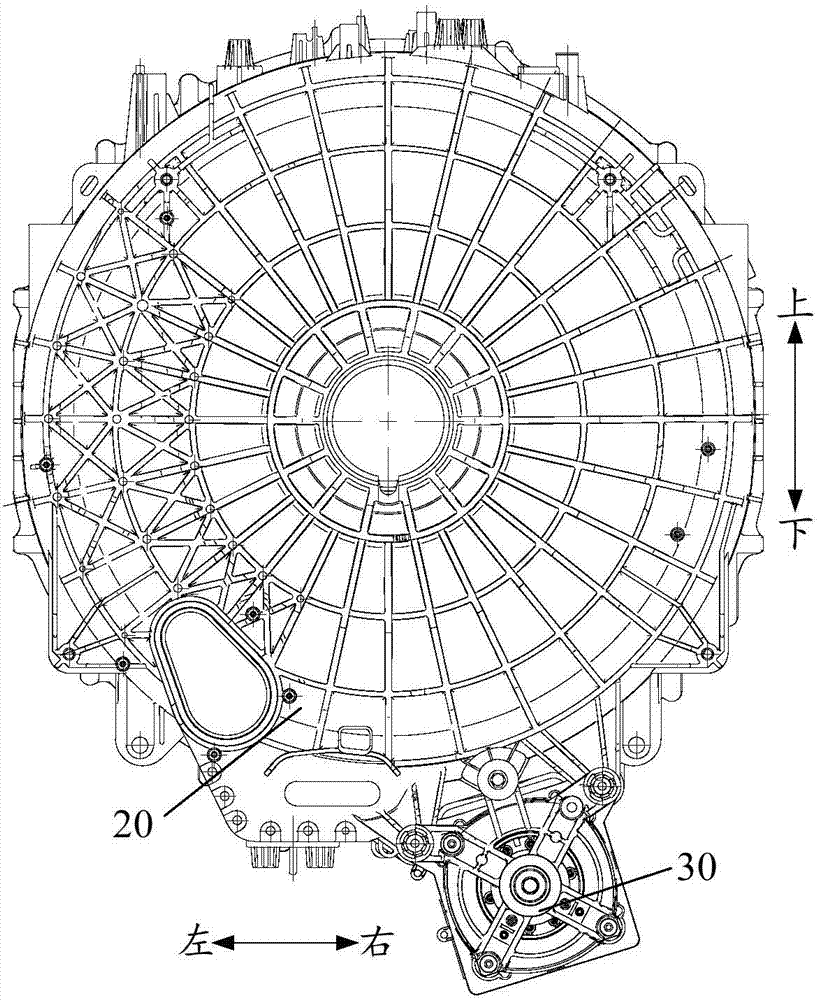

[0072] Embodiment one (as Figure 1 to Figure 12 shown)

[0073] The first engaging portion is the claw 21 , the second engaging portion is the insertion hole 311 , the claw 21 can pass through the insertion hole 311 and be hooked on the opening end of the insertion hole 311 , so that the motor 30 is engaged with the tub 20 .

[0074] The first clamping part is the claw 21, and the second clamping part is the socket 311. Then the claw 21 is inserted into the socket 311, and the top of the claw 21 can be automatically hooked on the opening end of the socket 311. Due to the structural limitation of the claw 21, the motor 30 cannot slide out no matter how it shakes under the action of an external force, and it has sufficient reliability, thereby realizing the clamping and fixing of the motor 30 and the outer barrel 20; and when assembling, only need to execute The insertion action is enough, and the claw 21 and the socket 311 will be automatically locked in place, which is very ...

Embodiment 2

[0116] Embodiment 2 (not shown in the figure)

[0117] The difference from the first embodiment is that the first engaging part is an insertion hole, and the second engaging part is a claw.

Embodiment 3

[0118] Embodiment three (not shown in the figure)

[0119] The difference from Embodiment 1 is that both the first clamping part and the second clamping part include claws and sockets, that is, claws and sockets are set on the outer barrel and the motor at the same time, and the claws on the outer barrel and the motor The jack on the outer barrel is compatible with the jack on the outer barrel and the claw on the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com