Transformer cooling fin spot welding machine

A heat sink and spot welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reduced performance, debris entry, unfavorable heat dissipation of components, etc., to accelerate heat dissipation , prolong the service life and improve the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

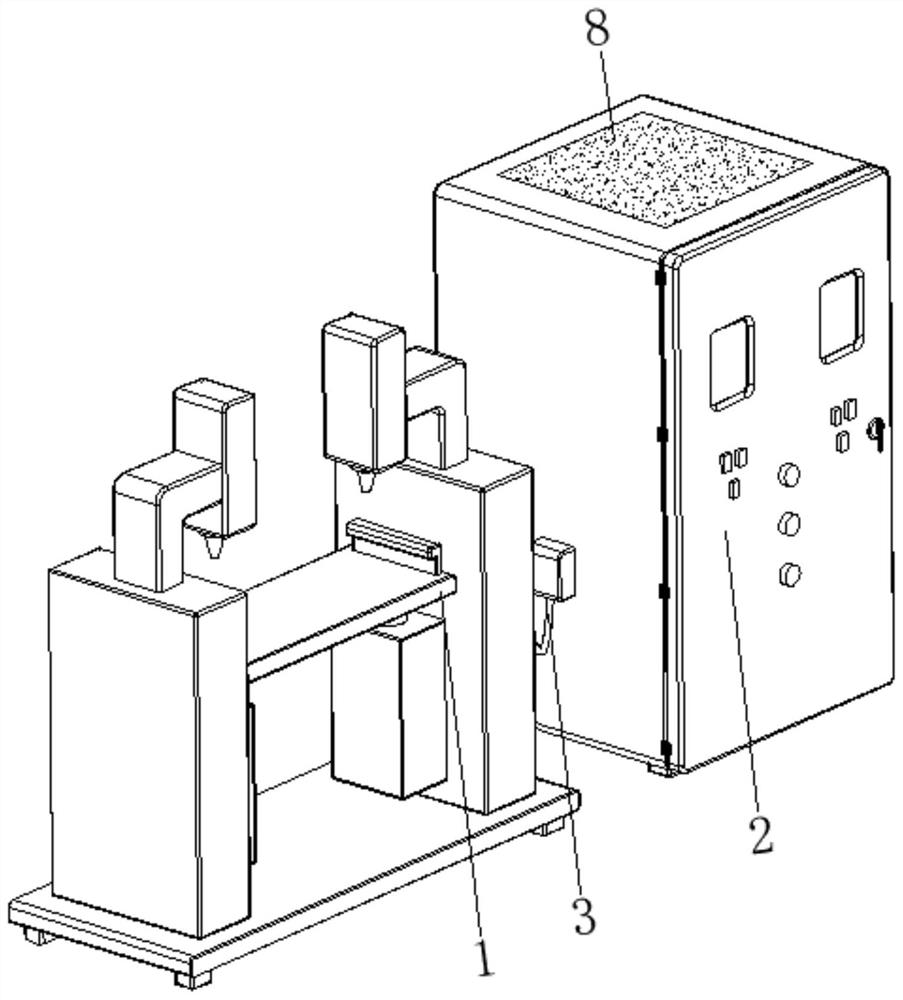

[0033] see Figure 1-Figure 8 , The present invention provides a technical solution: a transformer heat sink spot welding machine, comprising a body 1, a control cabinet 2, a connecting wire 3, a heat dissipation device 4, and an impurity removal device 5. The control cabinet 2 is arranged on one side of the body 1, The body 1 and the control cabinet 2 are connected by a connecting wire 3, the heat sink 4 is arranged at the bottom of the inner wall of the control cabinet 2, and the impurity removal device 5 is arranged inside the control cabinet 2 and close to the position of the heat sink 4;

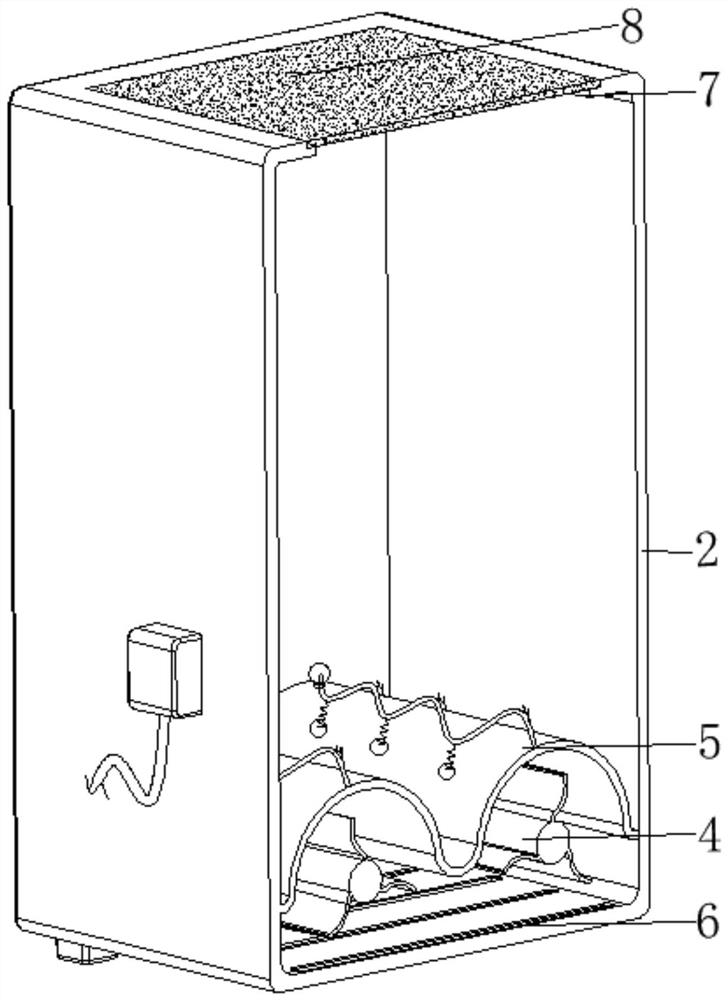

[0034] The bottom of the control cabinet 2 is provided with a rectangular hole 6, the central position of the top of the control cabinet 2 is provided with an air outlet 7, and the top of the control cabinet 2 is fixedly connected with a dust-proof cotton 8 at the position of the air outlet 7. After the roller body 42 is driven by the power mechanism, the heat dissipation device 4 can d...

Embodiment 2

[0036] The heat sink 4 is provided with a base 41 , a roller body 42 , a blade 43 , a brush 44 , and a pressing device 45 . The bottom of the base 41 is fixedly connected to the bottom of the inner wall of the control cabinet 2 , and the end of the roller body 42 is connected to the base 41 . The top of the place is rotated and connected, the surface edge side of the blade 43 is fixedly connected with the surface of the roller body 42, the brush 44 is arranged on the surface edge of the blade 43 and is away from the side of the roller body 42, and the pressing device 45 is arranged on the roller body 42. At the end of the surface and close to the position of the blade 43, when the roller body 42 is driven by the power mechanism to rotate, the blade 43 and the top pressing device 45 also rotate at this time, thereby blowing the air inside the control cabinet 2 and making the control The air inside the cabinet 2 is discharged from the air outlet 7. At this time, the outside air e...

Embodiment 3

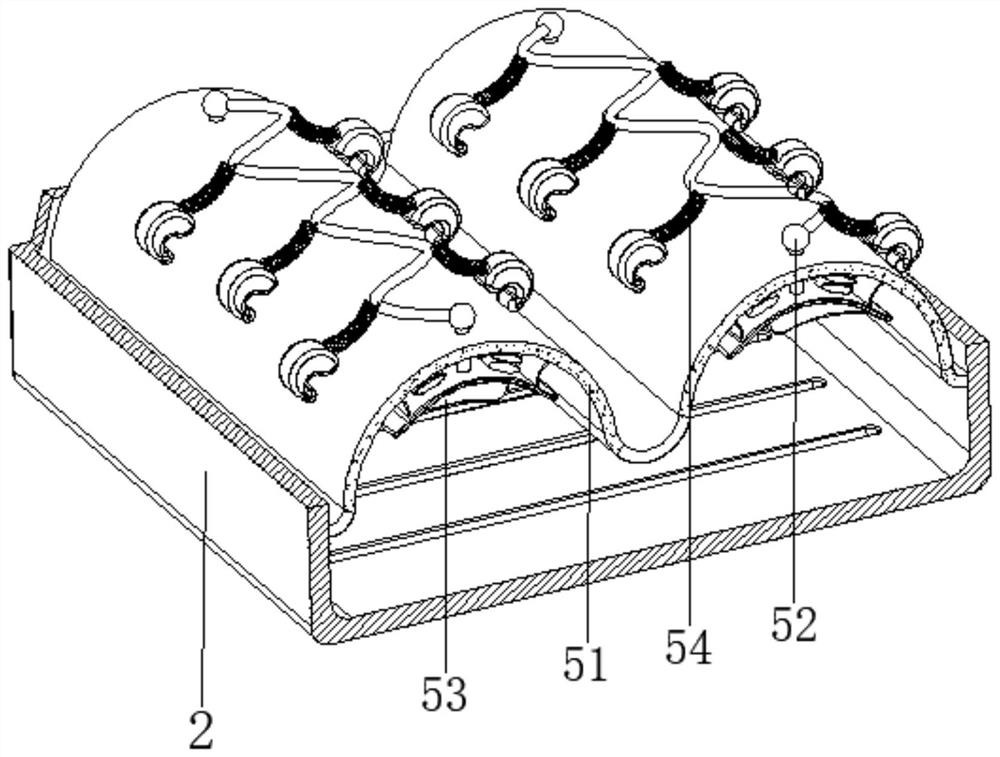

[0040] The pressure driving device 53 is provided with an arc-shaped elastic member 531, an arc-shaped base plate 532, a pressing block device 533, and a rubber elastic member 534. The top of the arc-shaped elastic member 531 is fixedly connected with the bottom of the butterfly filter screen 51. The arc-shaped base plate 532 The top of the base plate 532 is fixedly connected to the bottom end of the arc-shaped elastic member 531, and the top of the arc-shaped base plate 532 is fixedly connected to the bottom end of the ball head slider 52. The pressing block device 533 is arranged at the bottom center of the arc-shaped base plate 532, and the rubber elastic member 534 It is arranged between the two sides corresponding to the bottom of the butterfly filter 51 and the top of the arc-shaped base plate 532. When the rotating top pressing member 451 exerts top pressure on the pressing block body 5331 on the pressing block device 533, at this time, the ball Under the sliding and gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com