Patents

Literature

39results about "Metal surface removal provision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

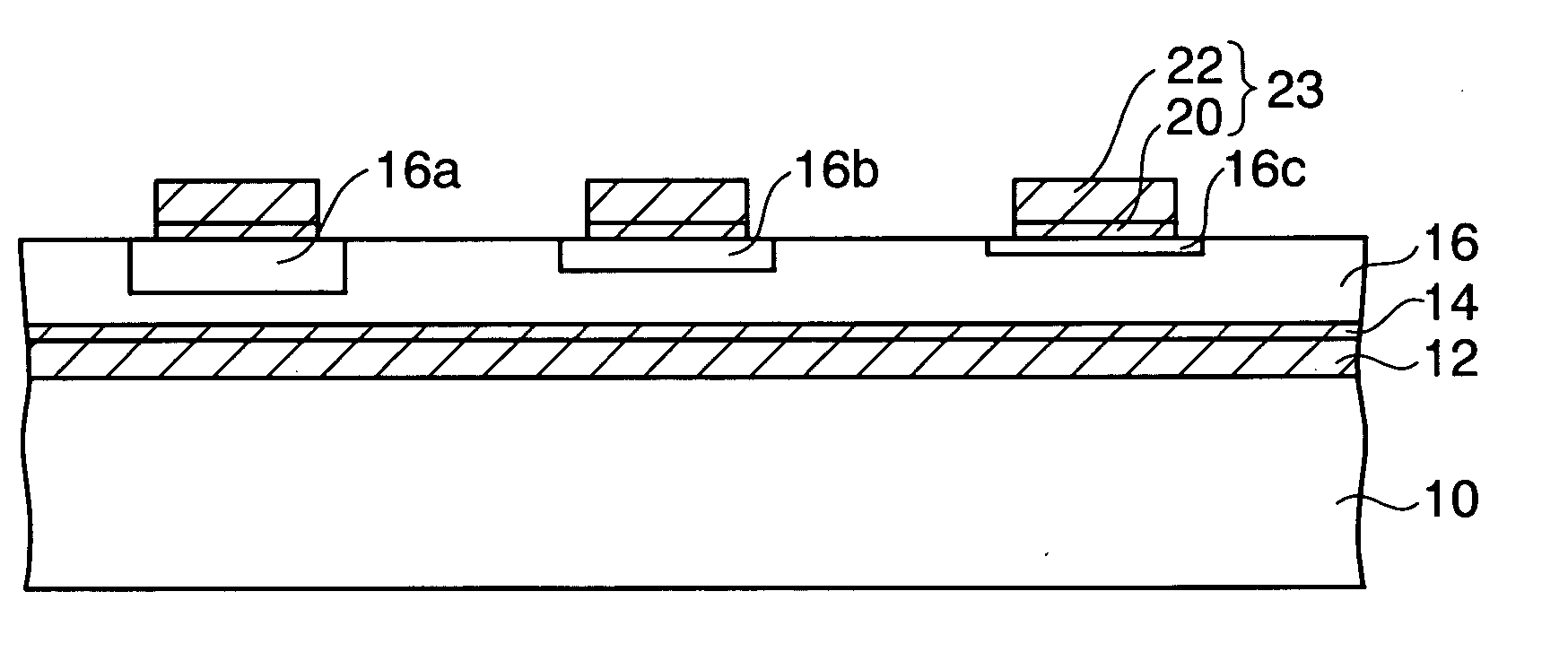

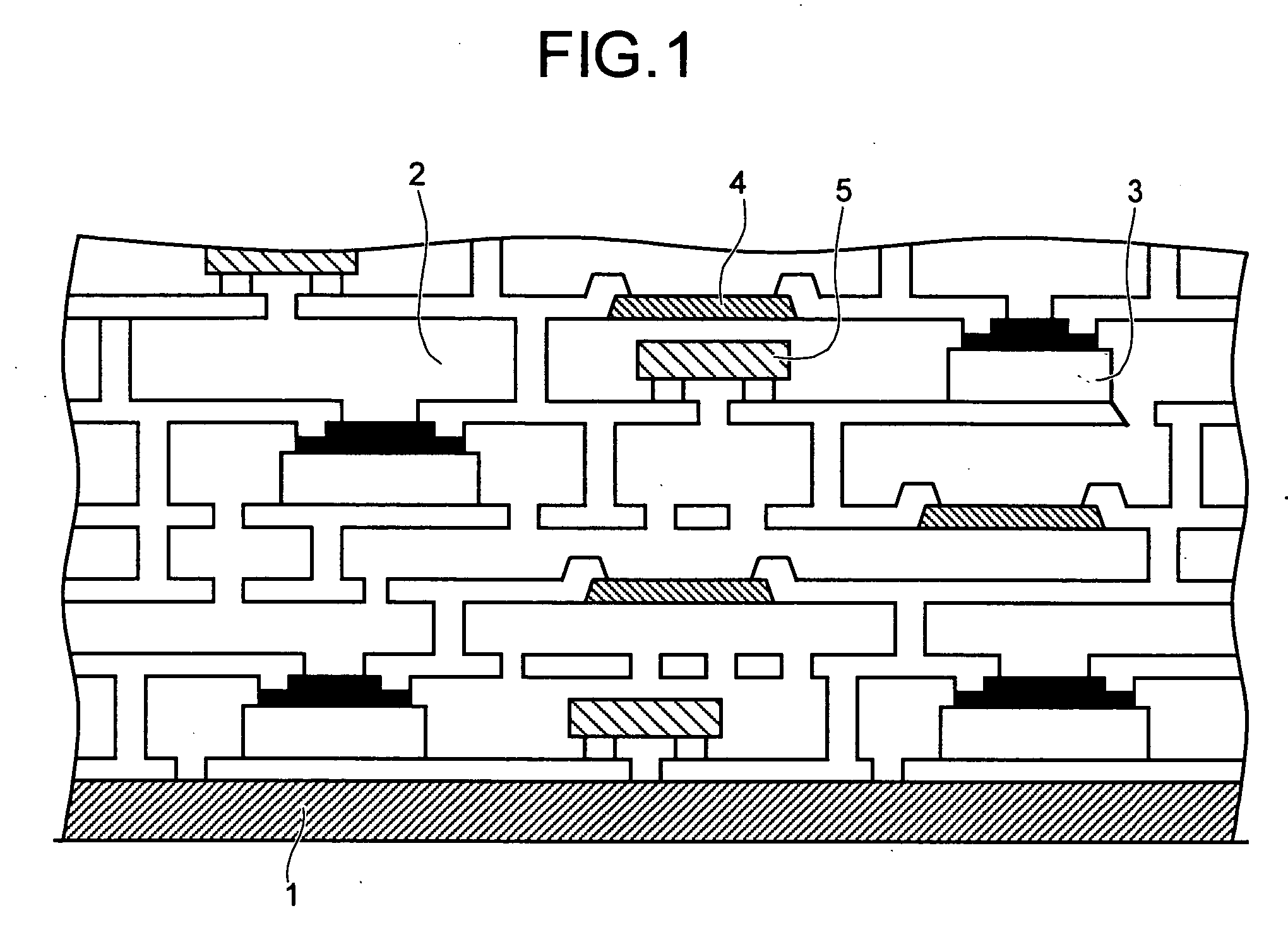

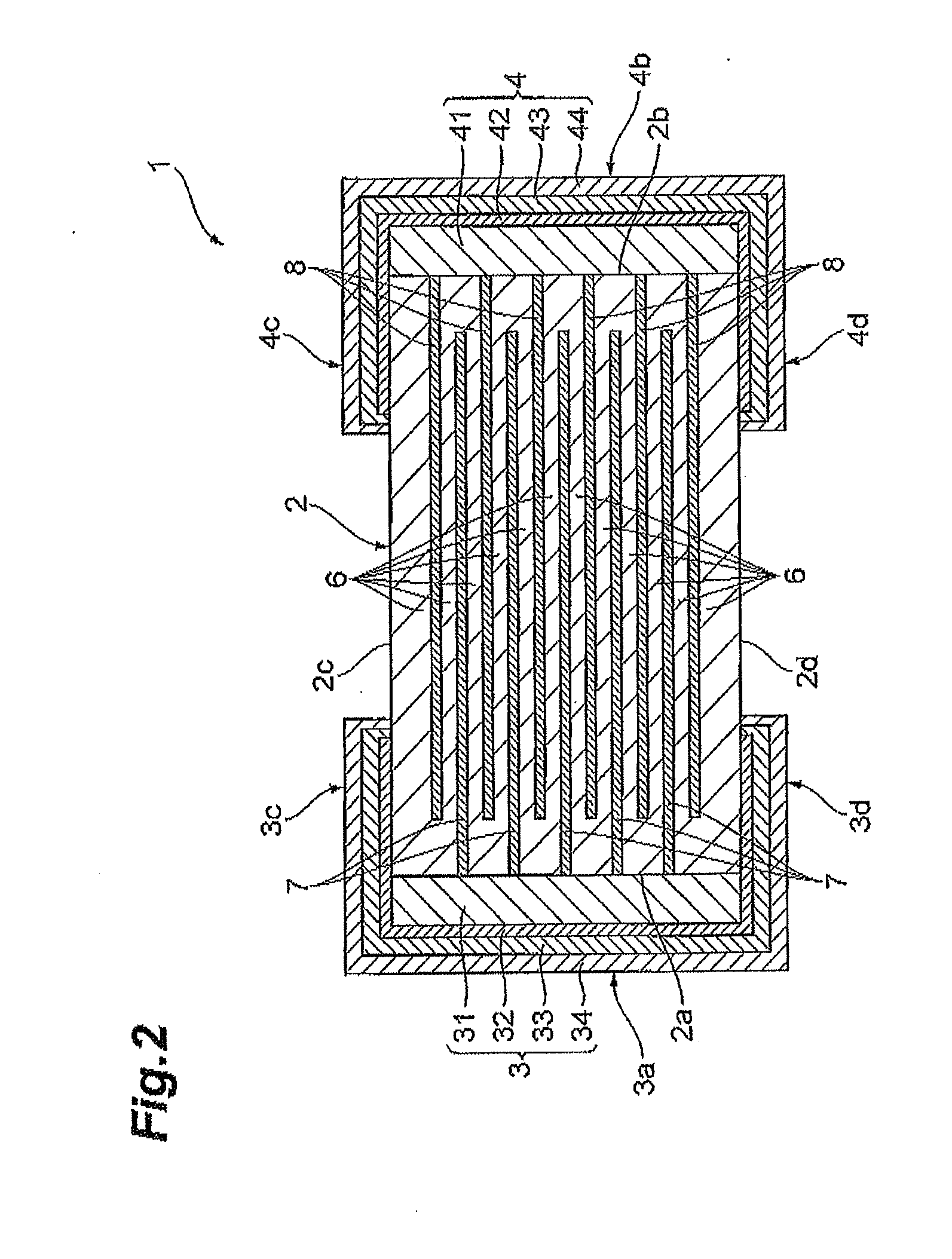

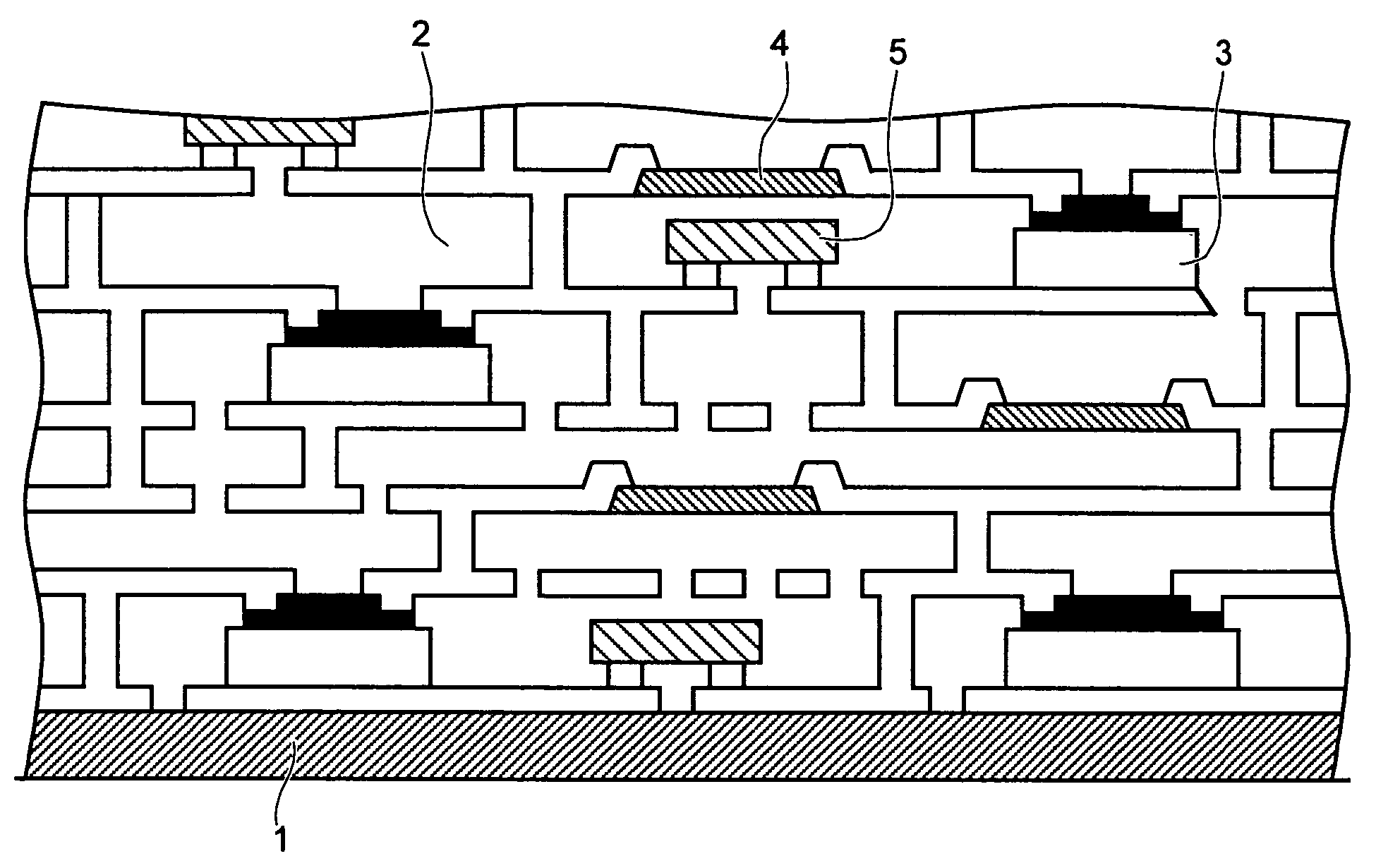

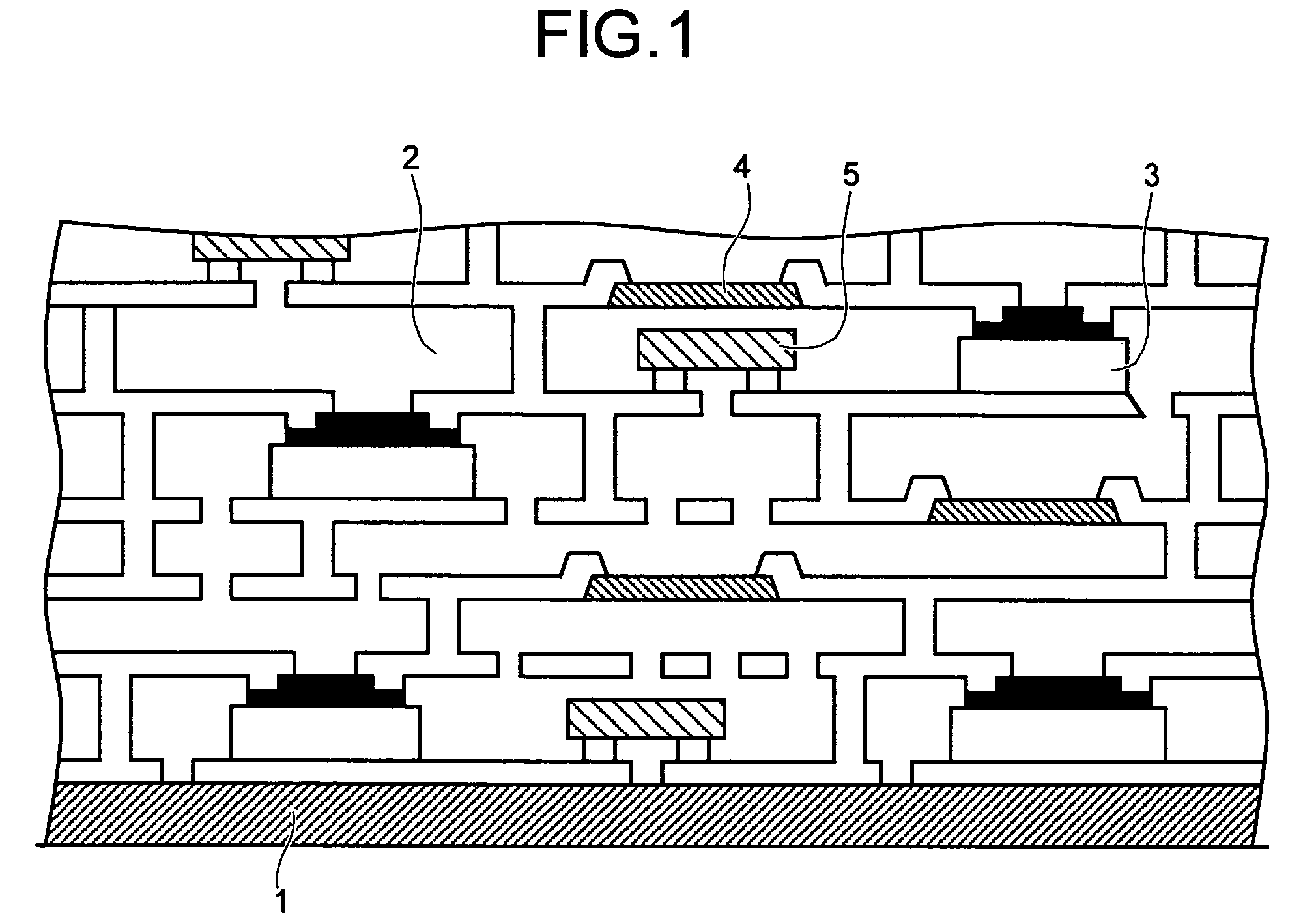

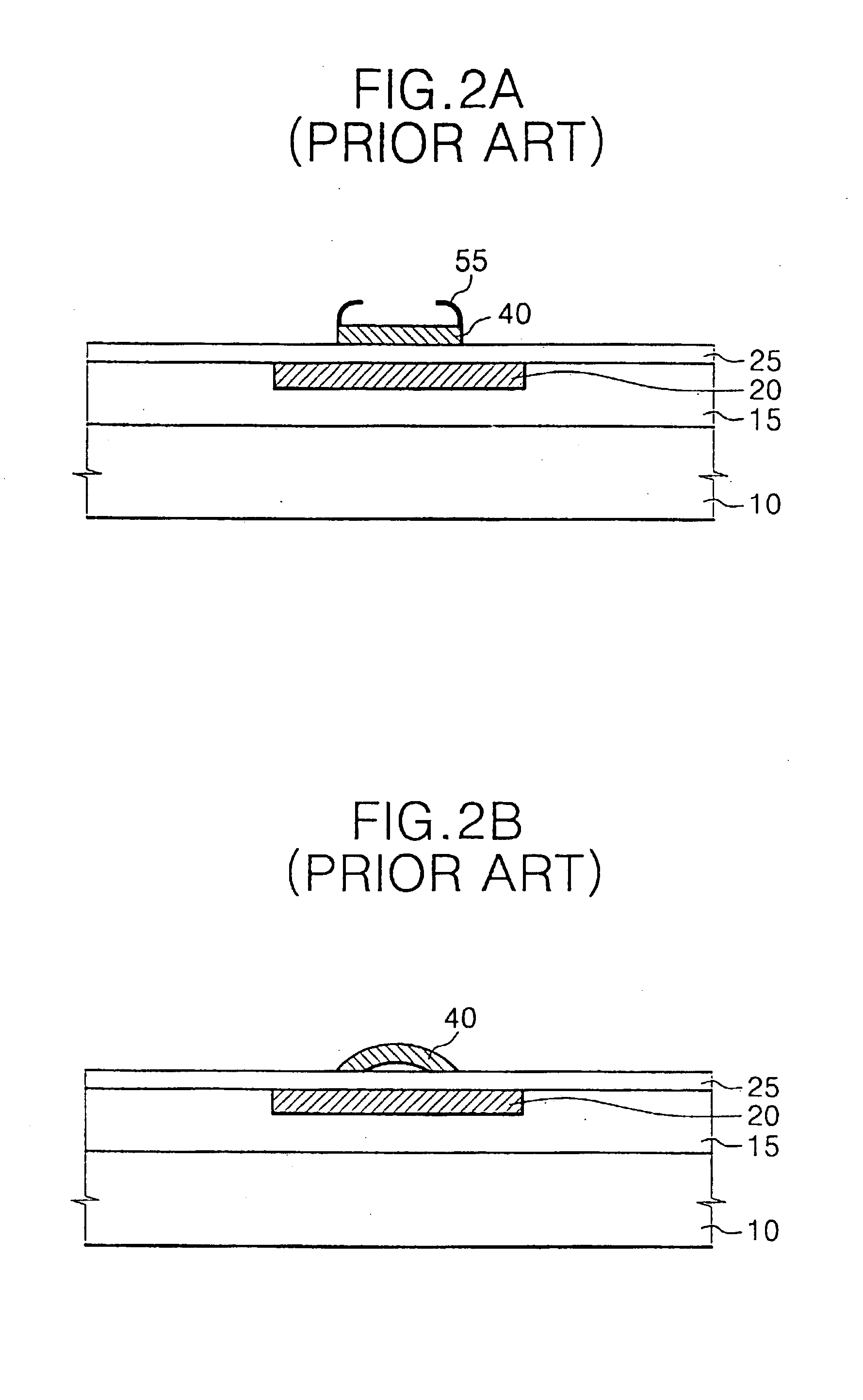

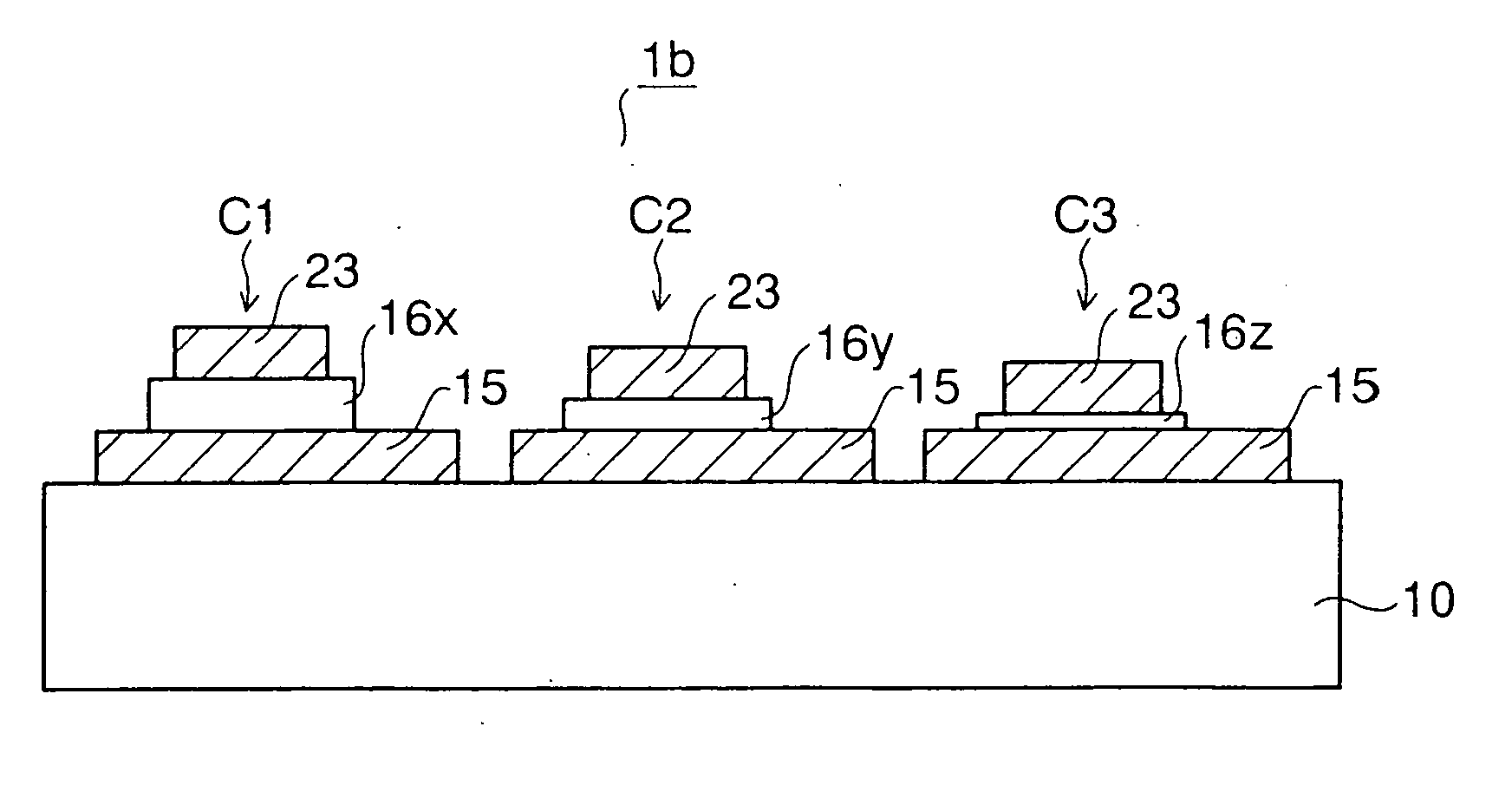

Capacitor device, electronic parts packaging structure, and method of manufacturing the capacitor device

ActiveUS20050141169A1Simple designReduce packaging costsSemiconductor/solid-state device detailsSolid-state devicesDielectric membraneCapacitor

In a capacitor device of the present invention includes a substrate, a plurality of lower electrodes formed on the substrate, a plurality of dielectric films formed on a plurality of lower electrodes respectively in a state that the dielectric films are separated mutually, and upper electrodes formed on a plurality of dielectric films respectively, a plurality of capacitors each composed of the lower electrode, the dielectric film, and the upper electrode are arranged on the substrate respectively, and each of the dielectric films in a plurality of capacitors has a different film thickness.

Owner:SHINKO ELECTRIC IND CO LTD

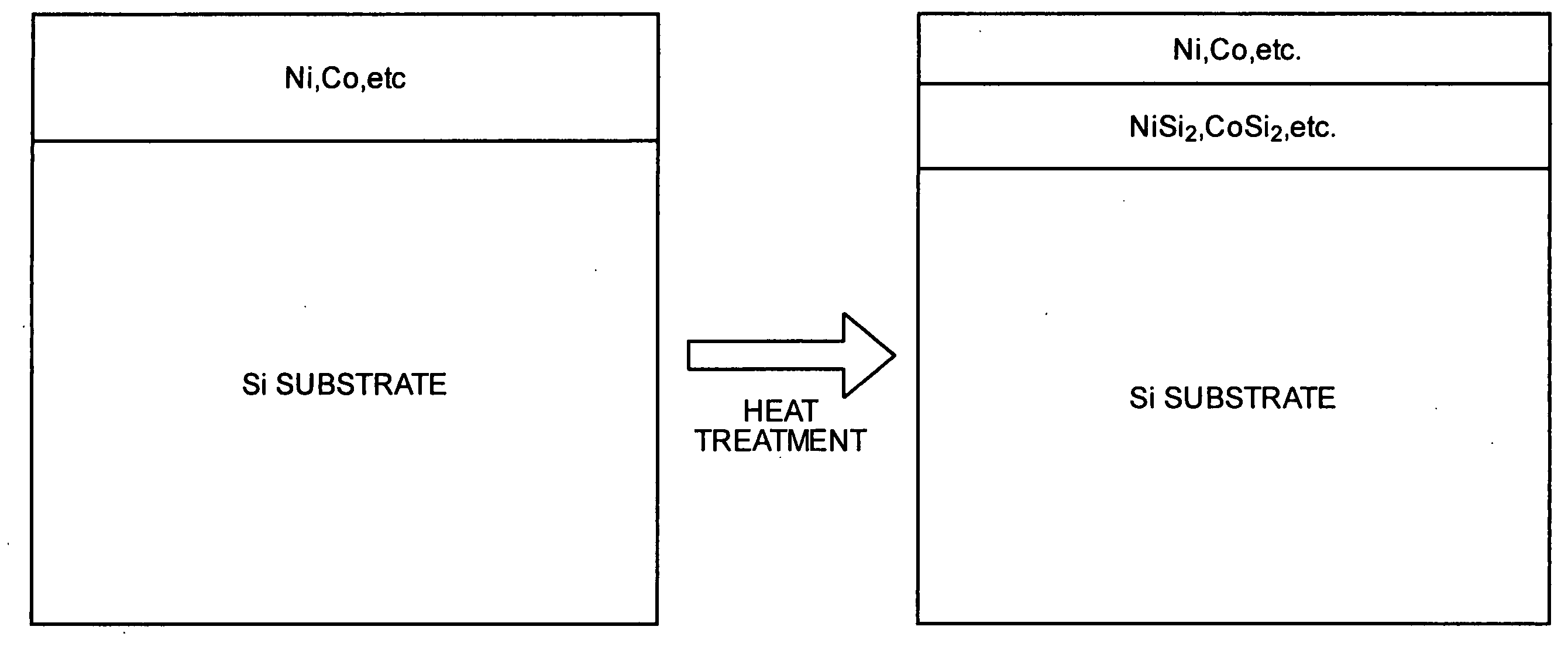

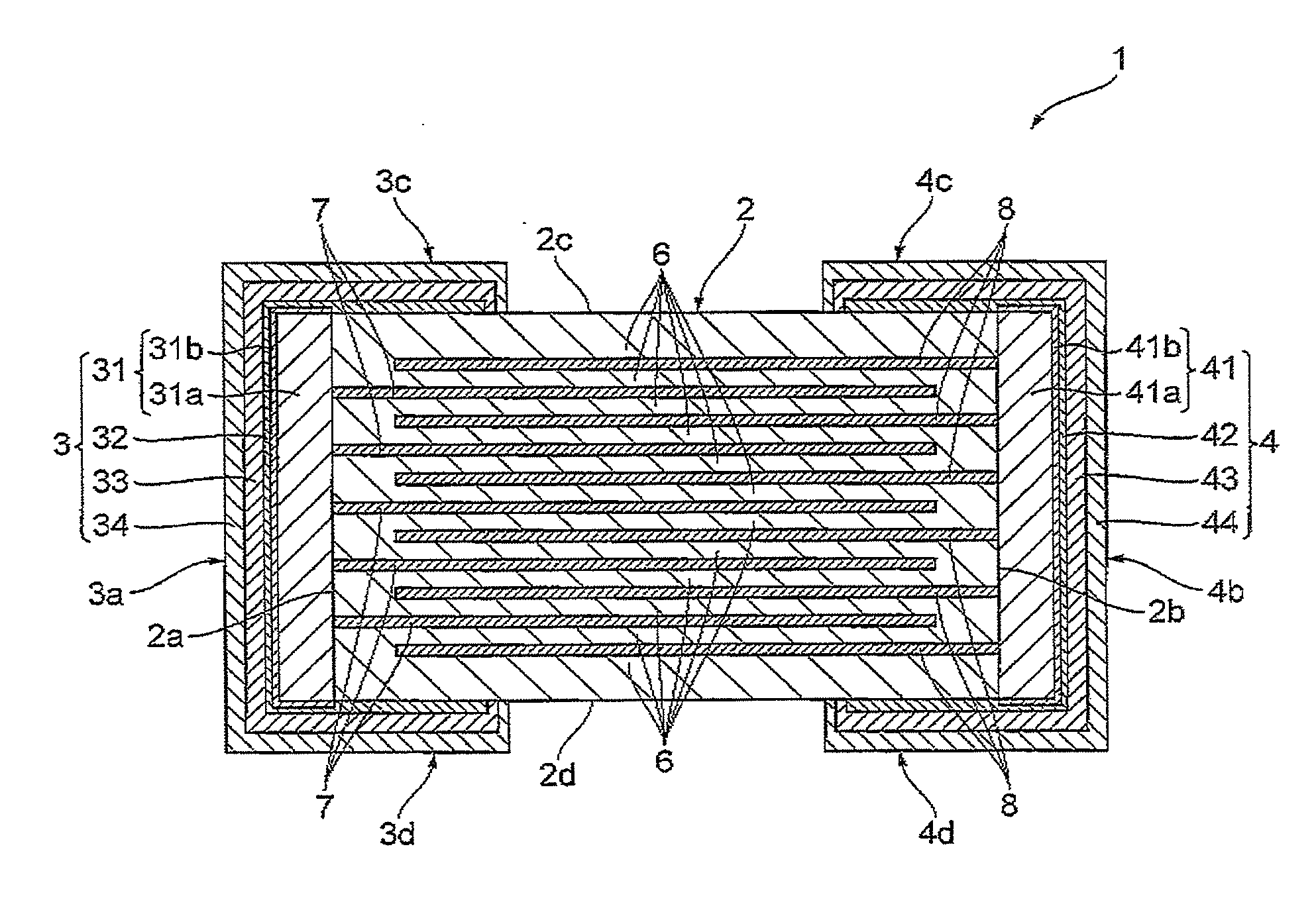

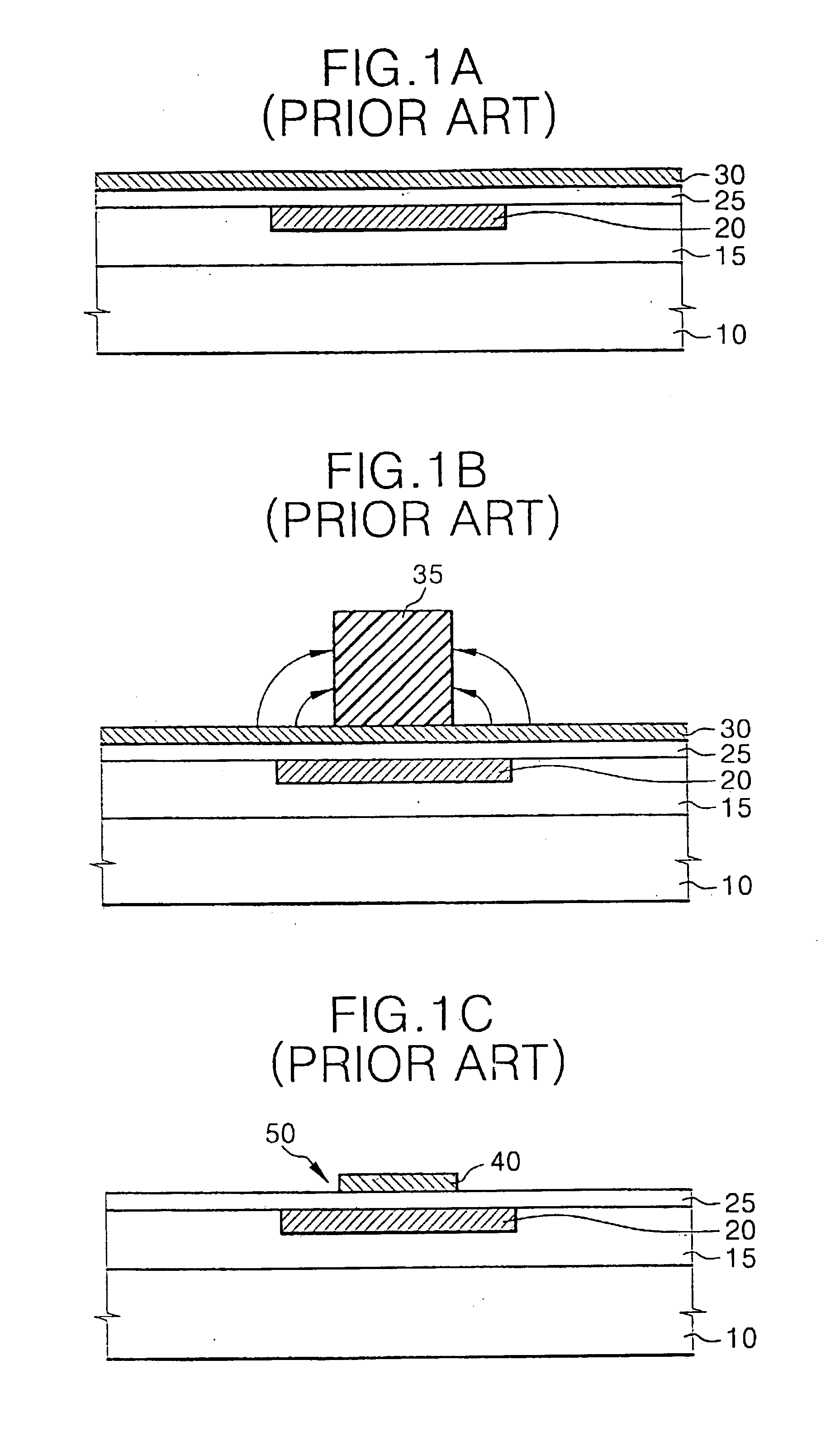

Thin film capacitor, high-density packaging substrate incorporating thin film capacitor, and method for manufacturing thin-film capacitor

InactiveUS20050111162A1Sufficient capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFilm capacitor

A capacitor capable of being incorporated into a packaging substrate, characterized in that the capacitor comprises a high-dielectric-constant layer, and an upper electrode layer and a lower electrode layer sandwiching the high-dielectric-constant layer from the upper side and the lower side. A packaging substrate containing the capacitor, and a method for producing the same are also provided.

Owner:WASEDA UNIV +2

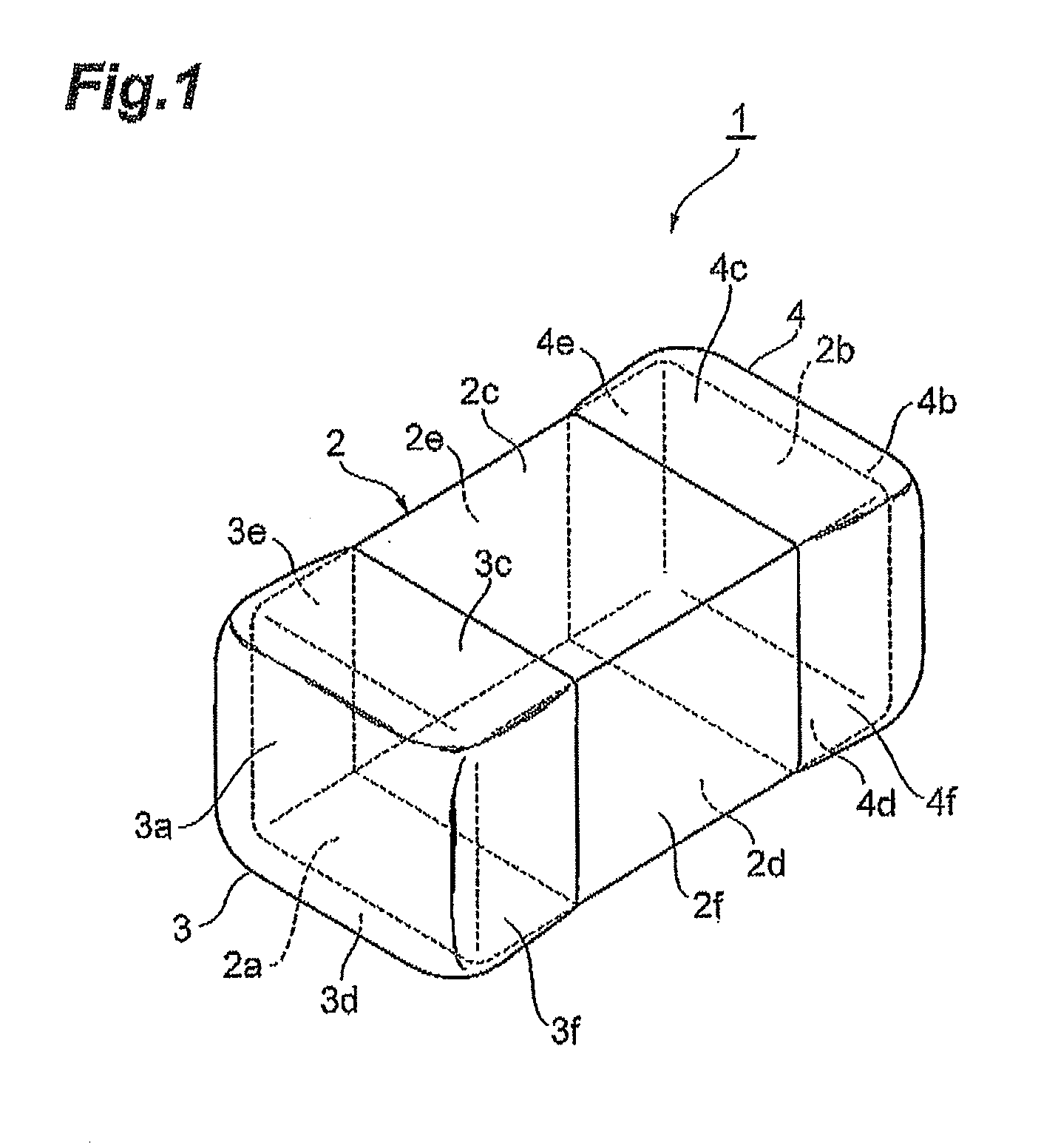

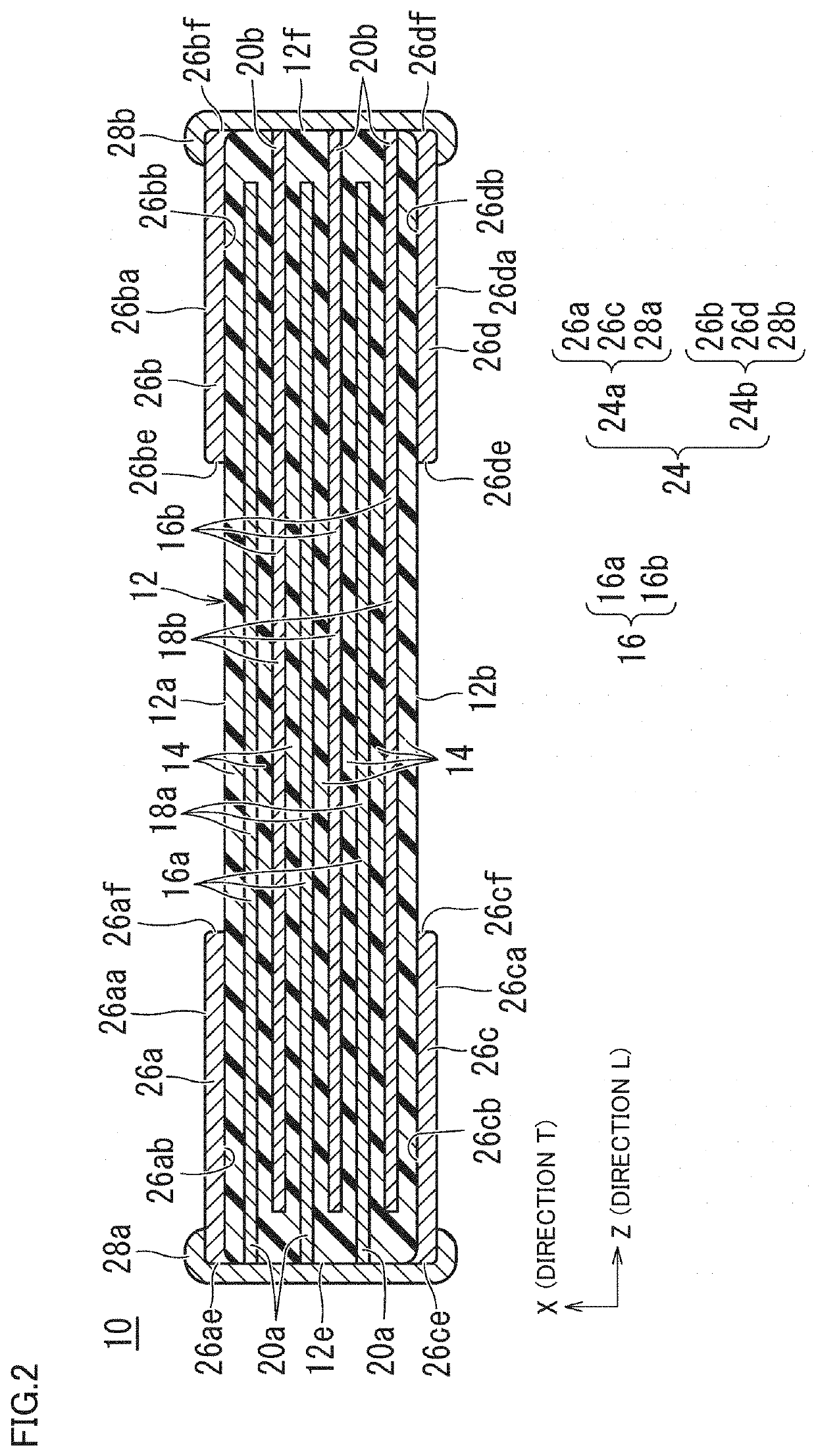

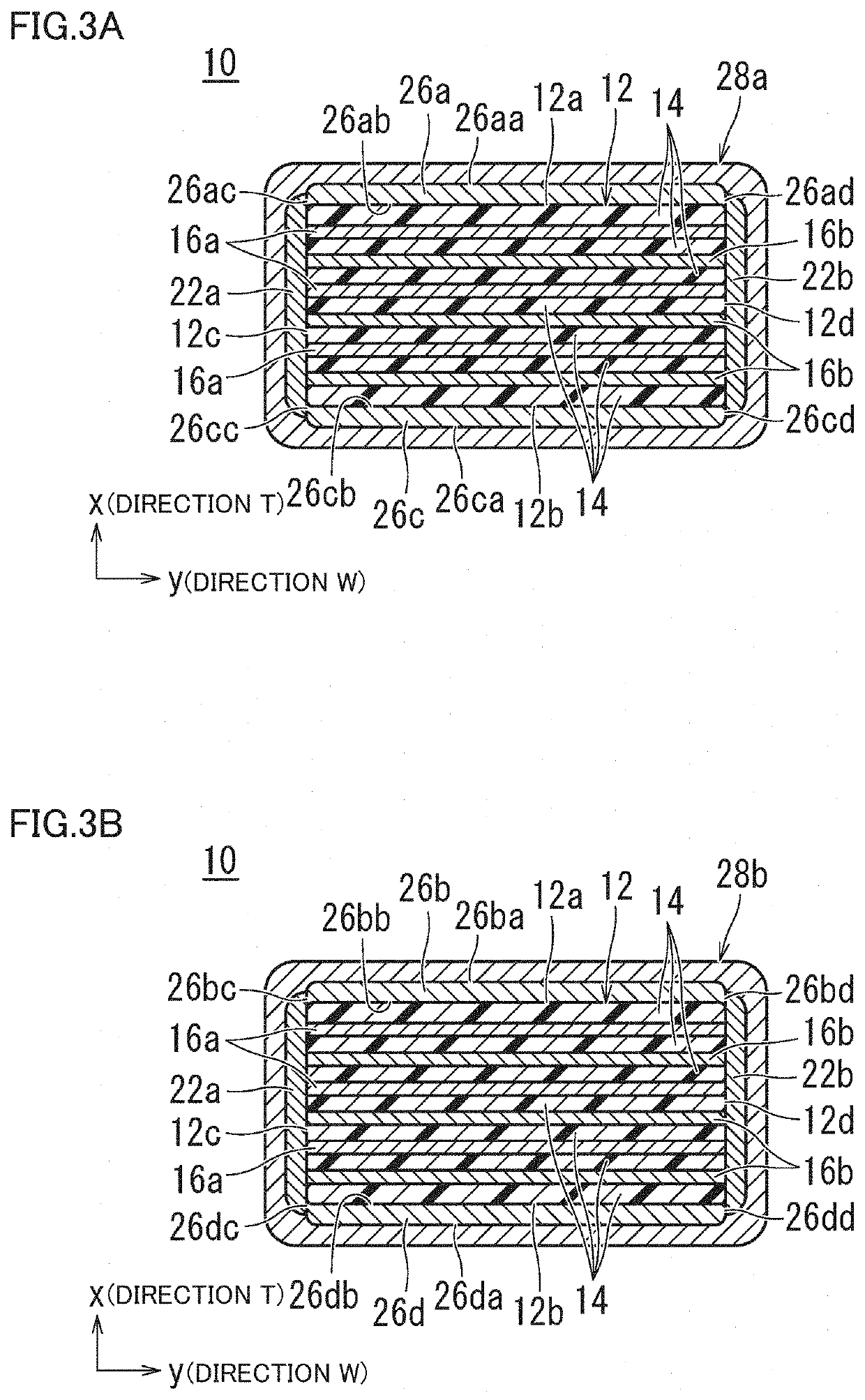

Electronic component and method for manufacturing electronic component

InactiveUS20130208401A1Small sizePrevent penetrationFixed capacitor electrodesFixed capacitor dielectricThin film electrodeAlloy

An electronic component has an element body and an external electrode arranged on the element body. The element body has a pair of end faces opposed to each other, a pair of principal faces opposed to each other, and a pair of side faces opposed to each other. The external electrode is formed so as to cover the end face and a partial region of the principal face and / or a partial region of the side face. The external electrode has a thick film electrode, a thin film electrode, and a plated layer. The thick film electrode is formed on the end face. The thin film electrode is formed so as to cover the thick film electrode and the partial region of the principal face and / or the partial region of the side face. The plated layer is formed outside the thin film electrode and contains Sn or an Sn alloy.

Owner:TDK CORPARATION

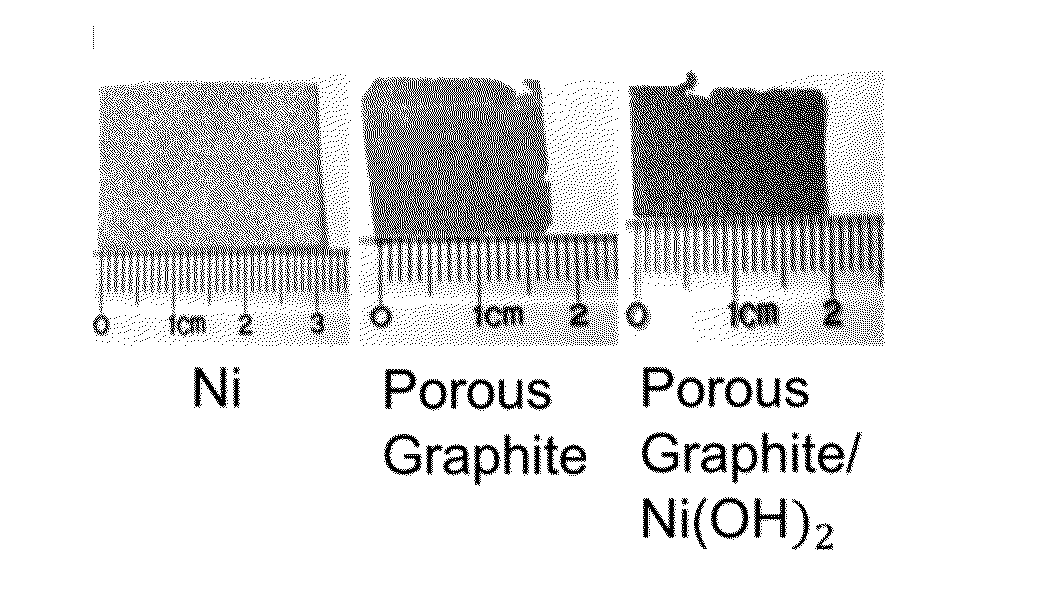

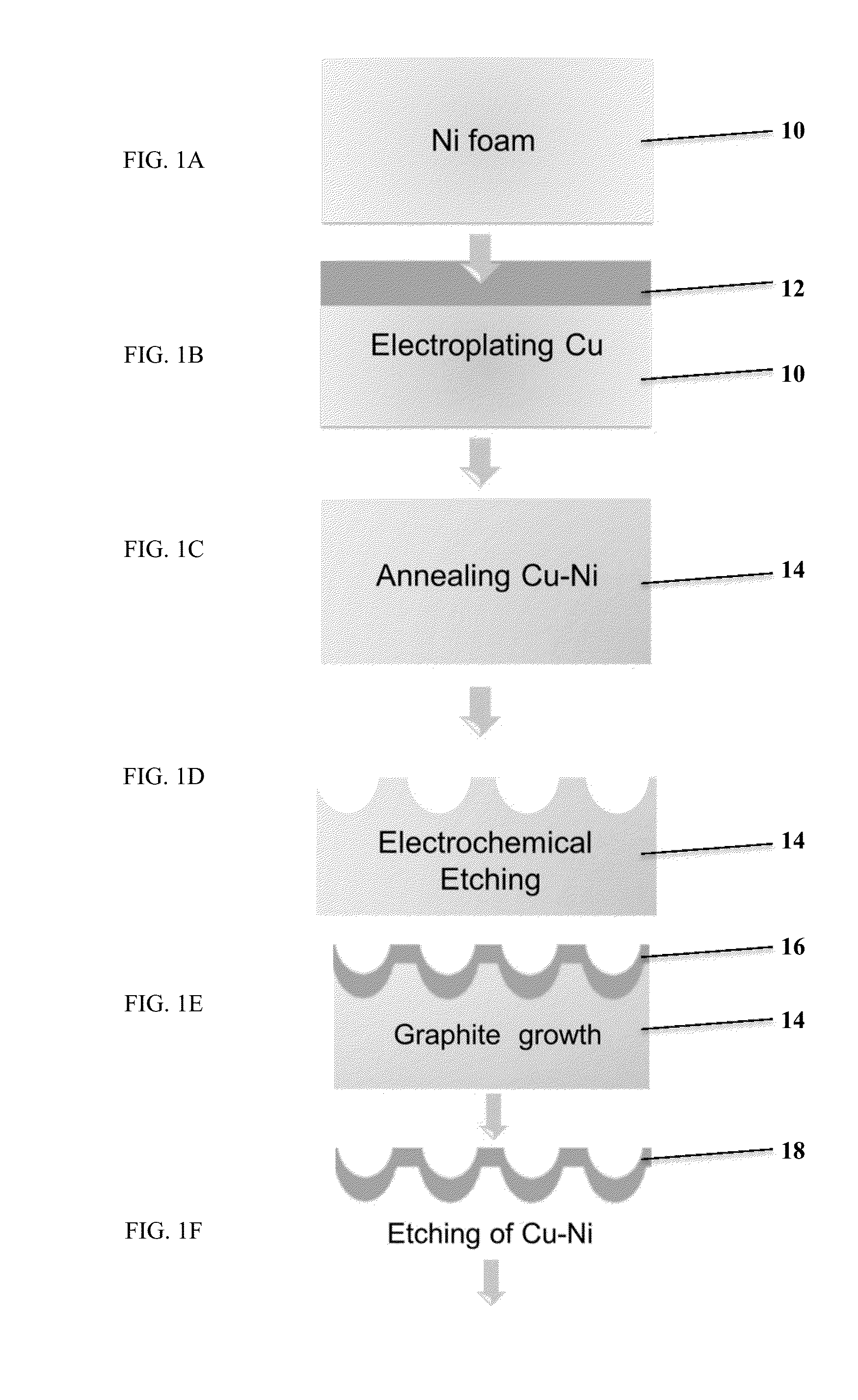

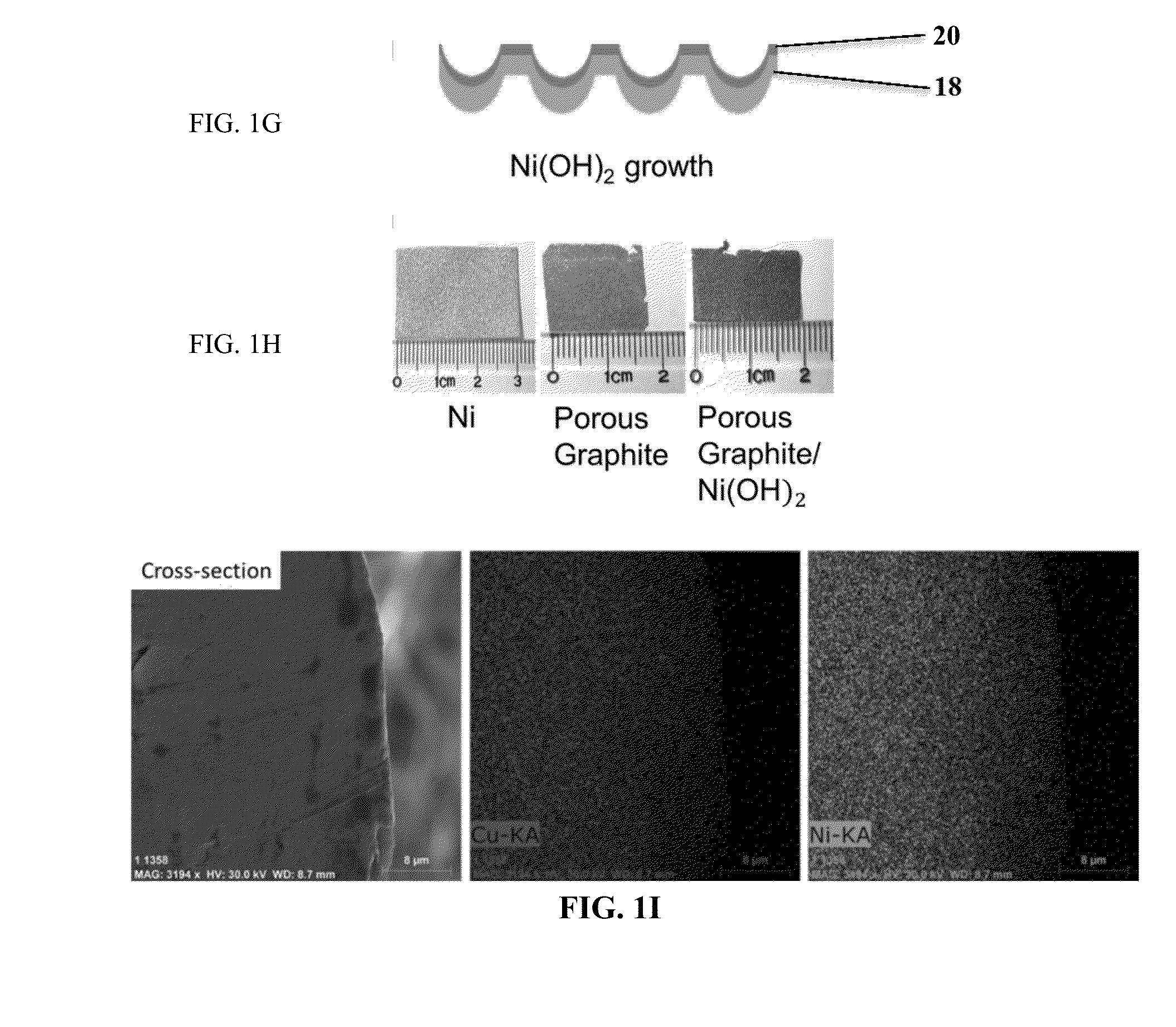

Method for manufacturing of three-dimensional freestanding porous thin-graphite with hierarchical porosity

The present invention includes an apparatus and a method of making a three dimensional graphite structure with a controlled porosity comprising: plating a metal layer on at least one of a nickel, an iron or a cobalt foam substrate; annealing the metal and the nickel, iron or cobalt foam into a porous metal-nickel, iron or cobalt catalyst, wherein the catalyst has a smooth and a porous surface; etching the smooth surface of the annealed porous metal-nickel, iron or cobalt catalyst; growing a carbonaceous layer on the porous surface of the annealed porous metal-nickel, iron or cobalt catalyst; and completely etching the porous metal-nickel, iron or cobalt catalyst to obtain the graphite layer.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

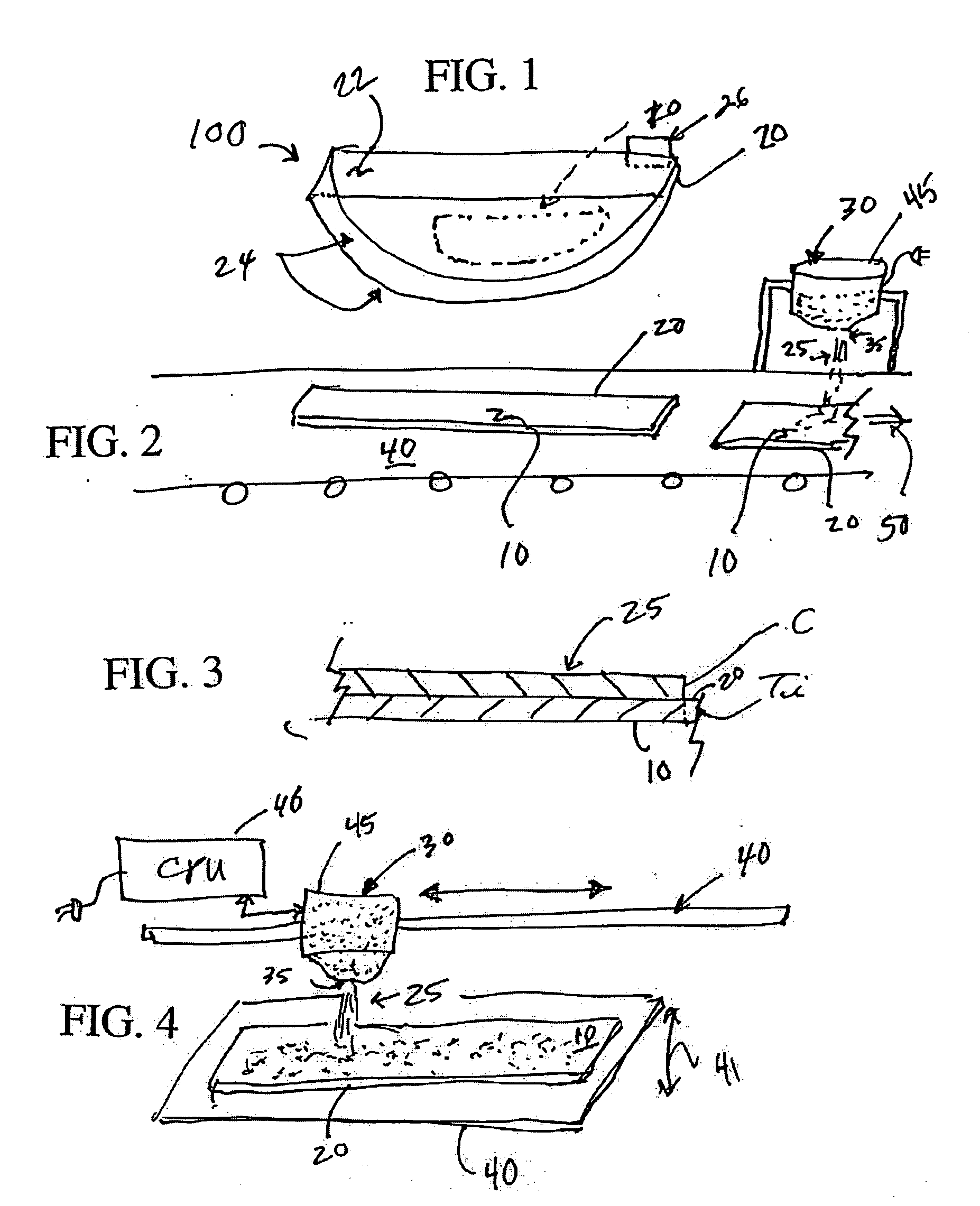

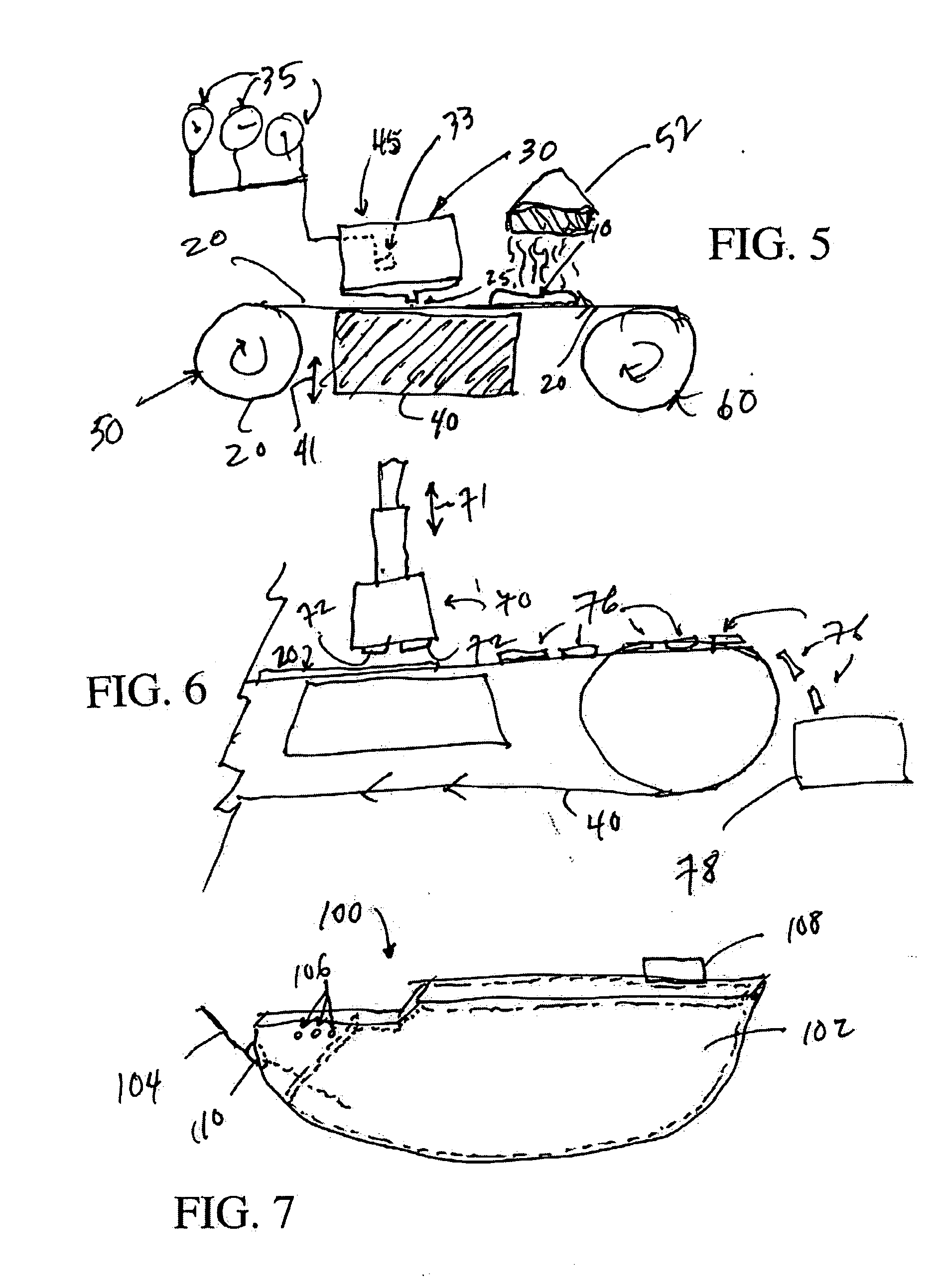

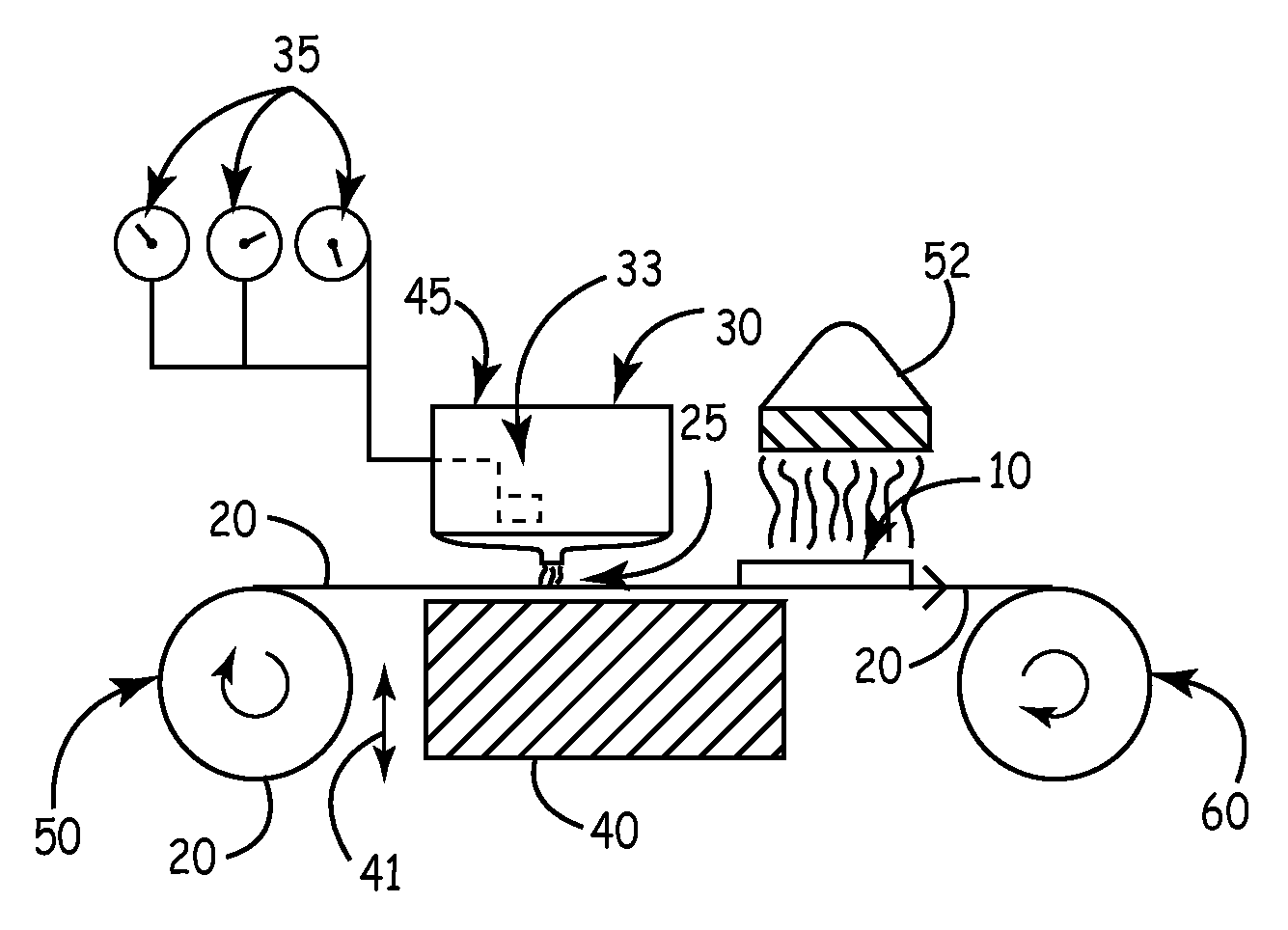

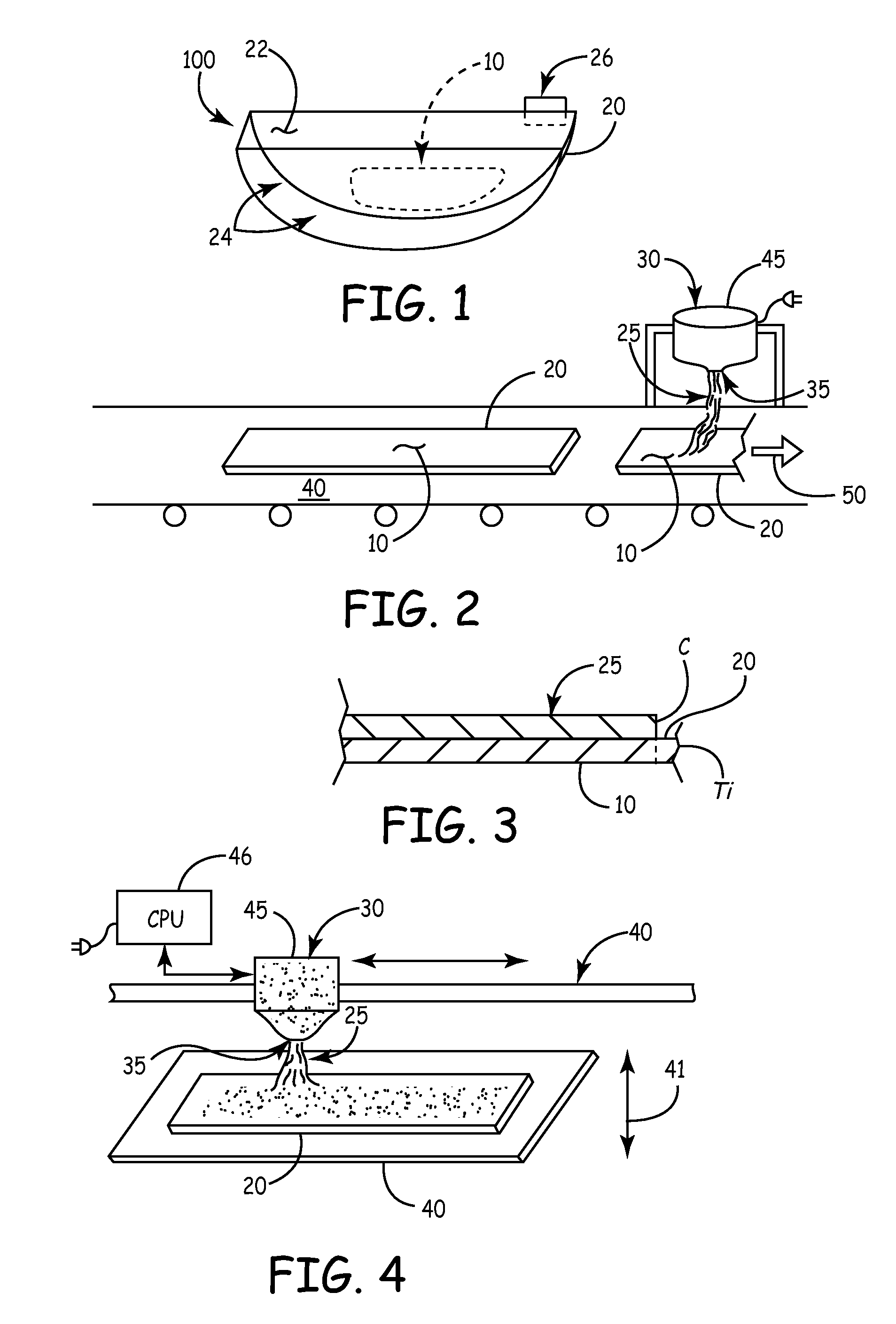

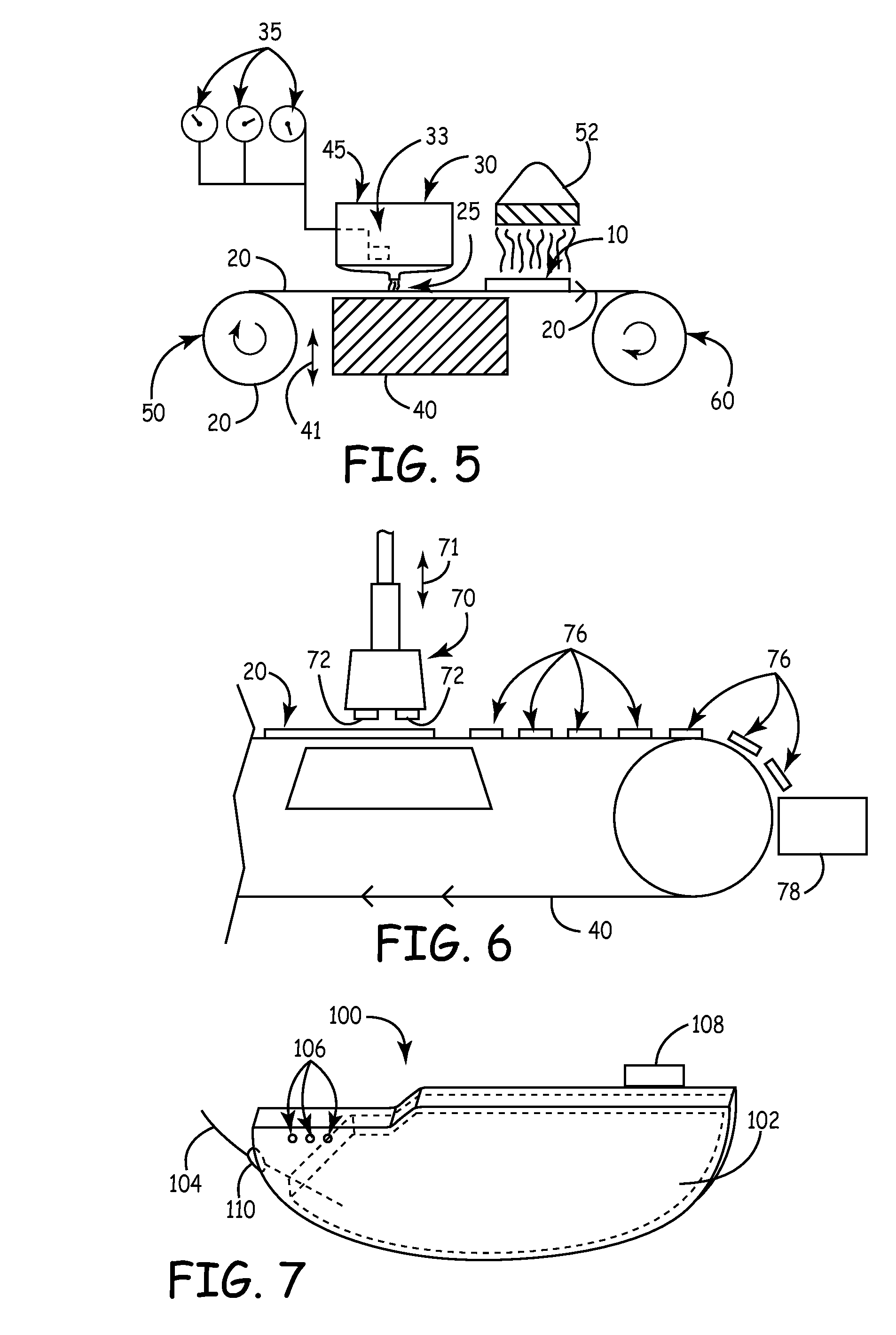

Methods and apparatus for producing carbon cathodes

ActiveUS20050098242A1Efficient mass productionImprove consistencyElectrode thermal treatmentDouble layer capacitorsTitaniumMetal powder

The present invention provides improved cathodes and industrialized methods for producing such cathodes using an industrial dosing valve-based electrode coating fluid emitting technique. The family of cathodes according to the present invention can be produced so that they inhabit a pre-existing metallic surface such as an inner surface of a titanium casing adjacent but insulated from direct electrical communication from an anode. Foil-type valve metal anodes as well as porous valve metal anodes formed from metallic powders may be used in conjunction with the cathodes of the present invention.

Owner:MEDTRONIC INC +1

Thin film capacitor, high-density packaging substrate incorporating thin film capacitor, and method for manufacturing thin-film capacitor

InactiveUS7196898B2Sufficient capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingHigh densityEngineering

A capacitor capable of being incorporated into a packaging substrate, which capacitor includes a high-dielectric-constant layer, and an upper electrode layer and a lower electrode layer sandwiching the high-dielectric-constant layer from the upper side and the lower side. A packaging substrate containing the capacitor, and a method for producing the same are also provided.

Owner:WASEDA UNIV +2

Method for manufacturing a metal-insulator-metal capacitor

A method of manufacturing a MIM capacitor having a bottom electrode is provided by forming a metal wire including copper on a substrate. After the metal wire is formed on the substrate, a dielectric film is formed on the metal wire. A top electrode film is formed on the dielectric film, and then the top electrode film is etched to form a top electrode. A hard metallic polymer formed during the etching of the top electrode film is removed using a mixture of an oxygen gas and a fluorocarbon based gas. The lifting of the thin films is effectively prevented, and the yield of the manufacturing process for manufacturing a MIM capacitor is increased. Additionally, the MIM capacitor has a uniform capacitance because the damage to the dielectric film is prevented, and the oxidation of the bottom electrode is also prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

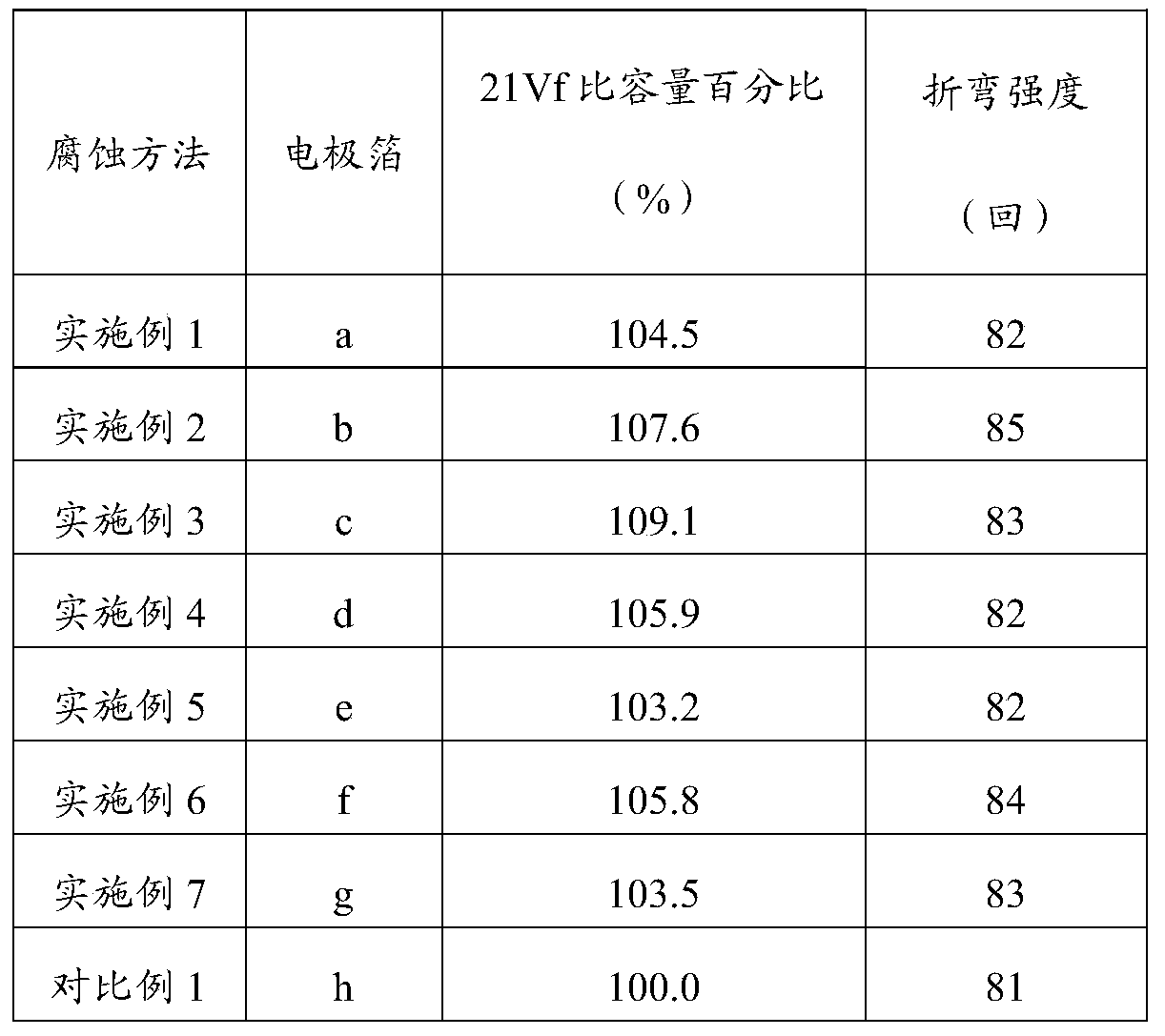

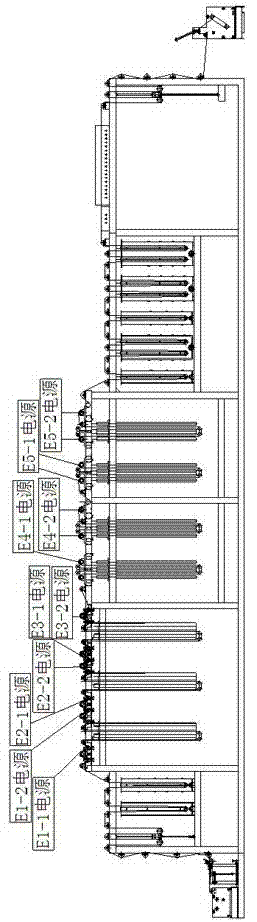

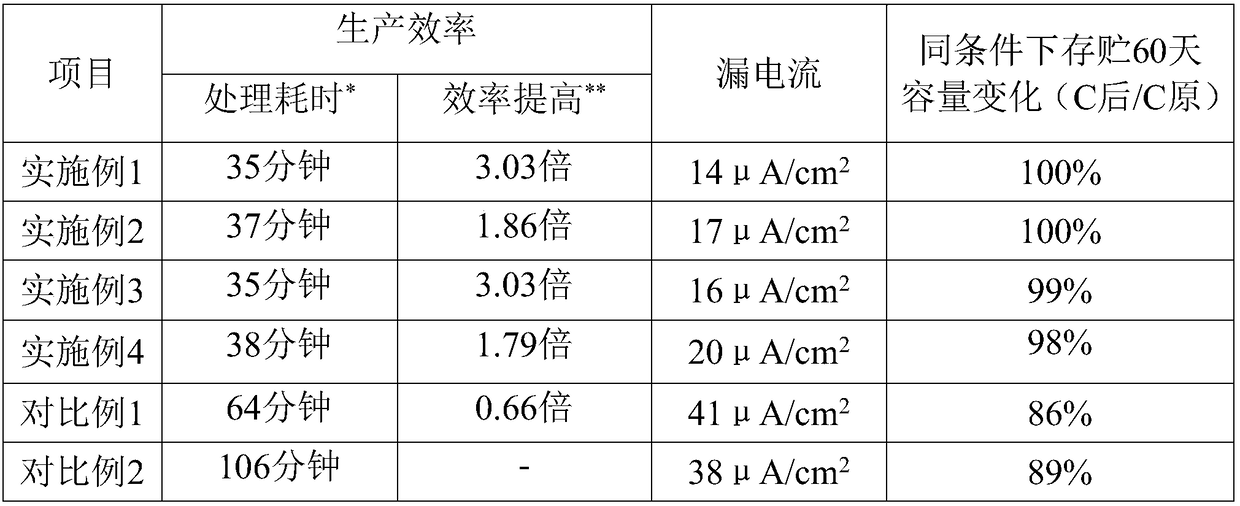

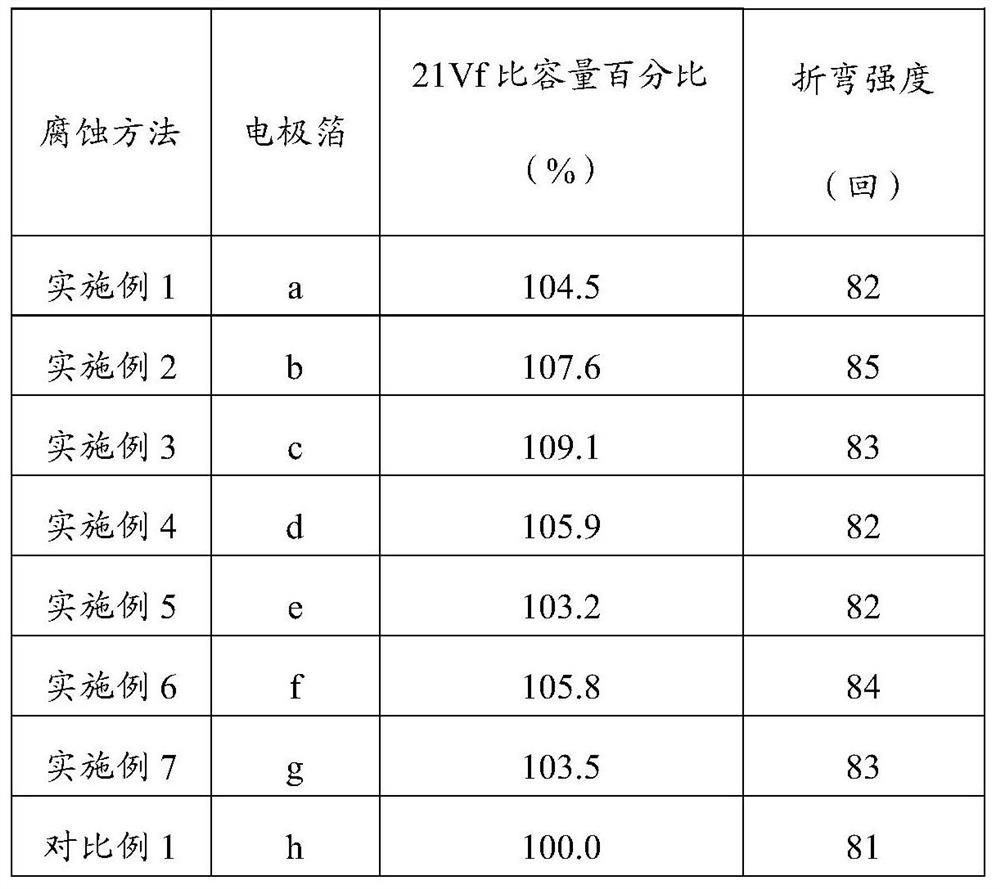

Six-level forming method of medium and high voltage aluminum electrolytic capacitor anode foil

InactiveCN103187181AIncrease capacityMeet the volumeMetal surface removal provisionCapacitor electrodesElectrolysisMetallurgy

The invention discloses a six-level forming method of a medium and high voltage aluminum electrolytic capacitor anode foil. The six-level forming method comprises the main steps of carrying out high-temperature water treatment on an aluminum foil after electrolytic corrosion treatment after the aluminum foil passes through an aluminum feeder roller, carrying out first-level, second-level and third-level forming, and sequentially carrying out four-level, five-level and six-level forming after liquid feeding, wherein only one forming groove is used in the previous five levels of forming process, five forming grooves are used in the six-th level of forming process, and the three forming grooves in the middle are connected in series. The anode foil prepared by the method is high in capacity and high in bending strength. Compared with the film formed in the prior art, the film formed by using the six-level forming method has the advantages that quality is greatly improved; and the demands of the existing electrolytic capacitor on small size, high capacity and long service life are completely met.

Owner:YINGJING XUGUANG ELECTRONICS

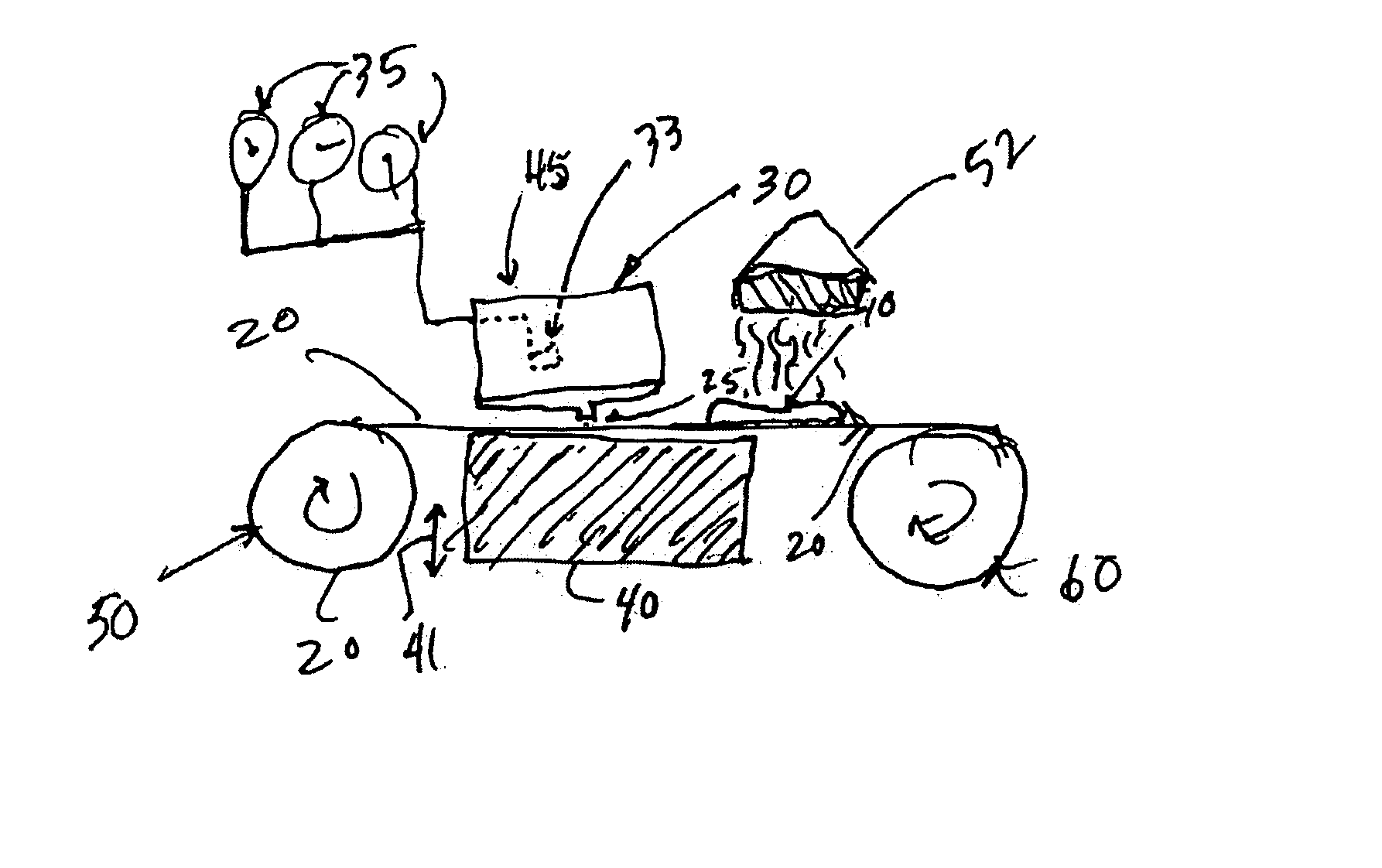

Methods and apparatus for producing carbon cathodes

ActiveUS7687102B2Efficient mass productionImprove consistencyElectrode thermal treatmentElectrolytic capacitorsElectricityTitanium

The present invention provides improved cathodes and industrialized methods for producing such cathodes using an industrial dosing valve-based electrode coating fluid emitting technique. The family of cathodes according to the present invention can be produced so that they inhabit a pre-existing metallic surface such as an inner surface of a titanium casing adjacent but insulated from direct electrical communication from an anode. Foil-type valve metal anodes as well as porous valve metal anodes formed from metallic powders may be used in conjunction with the cathodes of the present invention.

Owner:MEDTRONIC INC +1

Novel etched foil chambering technology

InactiveCN107502948AExtended service lifeEasy to handleElectrolytic capacitorsMetal surface removal provisionCopperMaterials science

The invention relates to a novel etched foil chambering technology. The novel etched foil chambering technology comprises the following steps that (1) pretreatment is carried out; (2) first-stage etching hole forming is carried out; (3) medium treatment is carried out; (4) second-stage pure chemistry chambering etching is carried out; and (5) aftertreatment is carried out. The novel etched foil chambering technology is mainly used for solving the problem that in the existing chambering technology, electrocorrosion is adopted, and therefore the factors like high cost, large heat generating amount, short copper bar using service life and the like exist.

Owner:江苏国瑞科技有限公司

Production method and device of electronic components

InactiveCN101677034ALower resistanceForm easily and preciselyHybrid capacitor electrodesCapacitor terminalsOptoelectronicsElectrolytic capacitor

The present invention relates to a production method and device of electronic components. The invention provides a production method of electronic components and a device thereof, in particular provide a production method and devices for winding type electronic components (particularly electrolytic capacitors), wherein the traditional tools are replaced and a laser radiation device is used to radiate the laser to an electrode foil, in order to isolate and remove an etching layer or a coating layer from the electrode foil, and holes are formed in the electrode foil, then a groove is formed in ahorizontal side facing to the electrode foil. According to the invention, it is possible to optionally set the shape of the electrode foil from which the etching layer or the coating layer is removed, and to optionally set the shapes of the holes and the groove. As a result, it is possible to expand a contacting area between a joint of the lead wire terminal and metal of the electrode foil.

Owner:JCC ENG

Formation processing method for improving low-voltage formed foil water resistance

ActiveCN103258649AExtend your lifeImprove water resistanceElectrolytic capacitorsMetal surface removal provisionO-Phosphoric AcidPhosphate

The invention discloses a formation processing method for improving low-voltage formed foil water resistance. The formation processing method comprises the steps that an aluminum foil is placed in an adipic acid saline solution for dipping, the aluminum foil is taken out and then placed in an ammonium adipate and adipate water solution, the aluminum foil is taken out for washing after first-level formation, and then high-temperature treatment is carried out; then the aluminum foil is placed in an ammonium adipate and dihydric phosphate mixed water solution for second-level formation, after being taken out and washed, the aluminum foil is placed in a phosphoric acid solution for heat treatment, then high-temperature treatment and washing are carried out, finally, the aluminum foil is placed in a dihydric phosphate water solution, and the aluminum foil is taken out after third-level formation and washed and dried. The formation processing method has the advantages that product water resistance is obviously improved, storage time is prolonged, and capacitor performance is improved.

Owner:NANTONG HAIXING ELECTRONICS

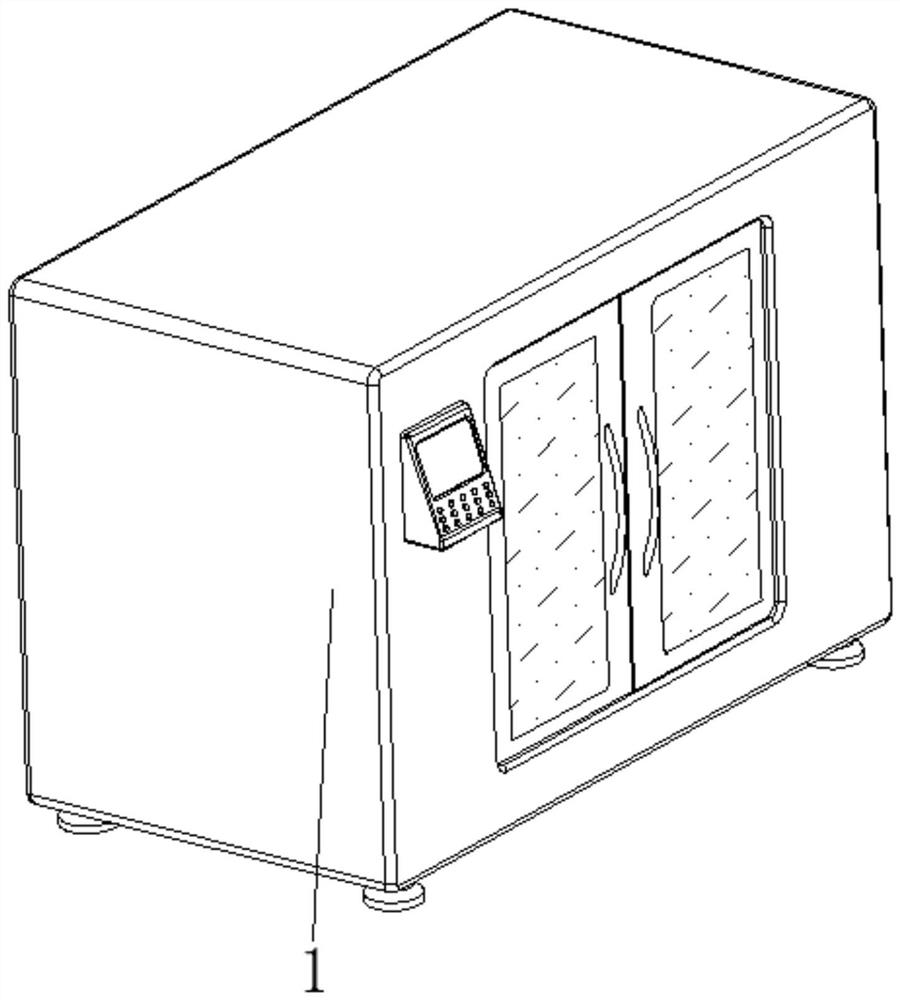

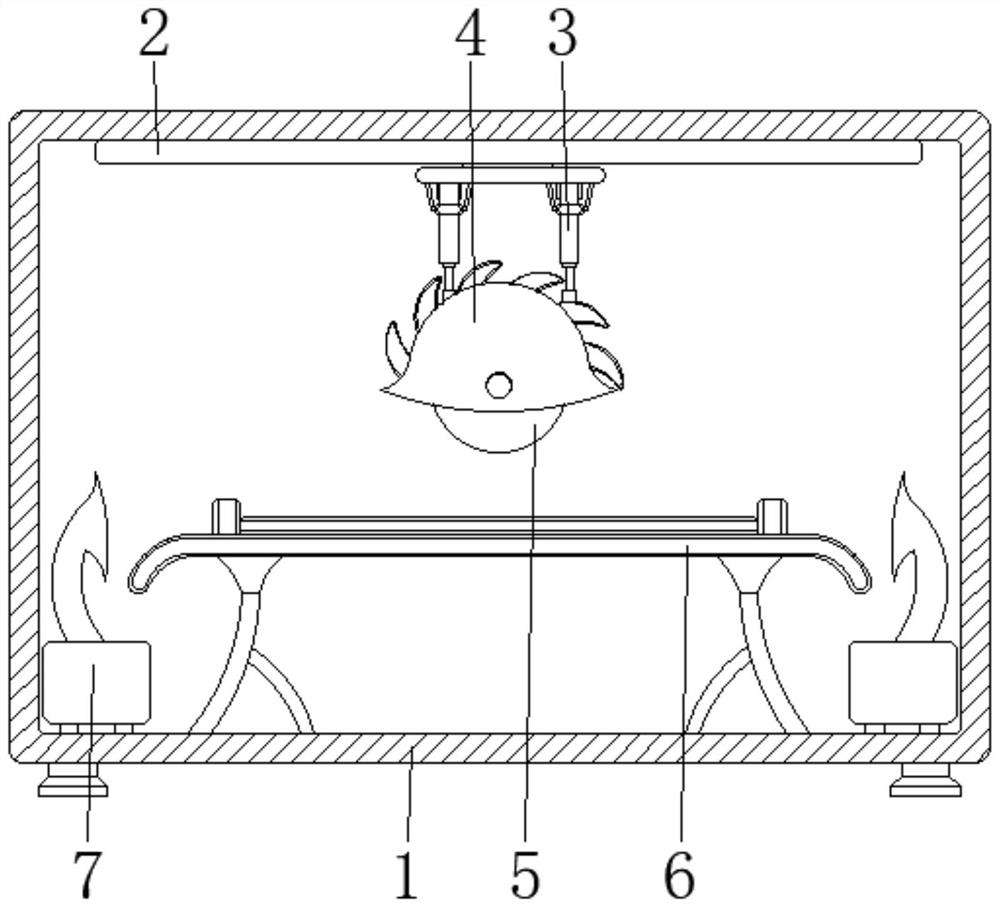

Surface treatment equipment and treatment method for chip capacitor

ActiveCN114400154ATimely processingLess likely to depositGrinding drivesMetal surface removal provisionDust controlStructural engineering

The surface treatment equipment comprises a machine body, a linear driving mechanism, a lifting mechanism, a housing device and a polishing device, the housing device is arranged at the bottom of the lifting mechanism, and the polishing device is arranged in the housing device and is close to the bottom. The dust removal device is arranged at the top of the arc-shaped housing body and is close to the conical opening, the cambered surface flow guide assembly is fixed to the inner wall of the ox horn shell and is close to the conical opening, the filter screen is fixed to the inner wall of the ox horn shell, and the cleaning device is arranged in the ox horn shell and is close to the filter screen. The invention relates to the technical field of capacitor processing equipment. According to the surface treatment equipment for the chip capacitor, the effect of removing impurities is achieved, the impurities can be removed in time, impurity deposition, polishing scratches and abrasion are not prone to occurring, the polishing quality is high, meanwhile, dust diffusion is reduced, human health is facilitated, safety and reliability are achieved, and the working efficiency and the use performance are improved.

Owner:淮安永捷电子科技有限公司

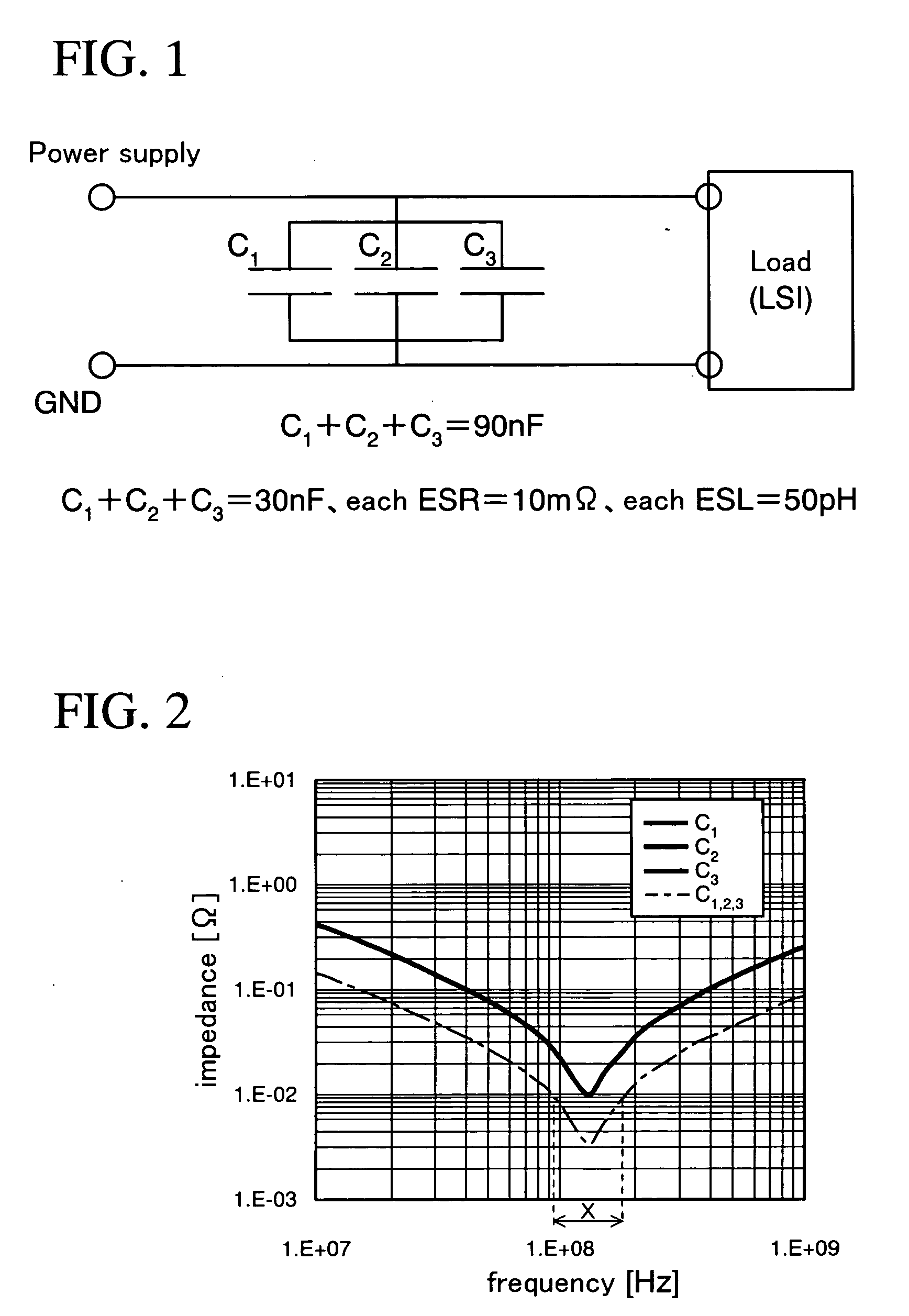

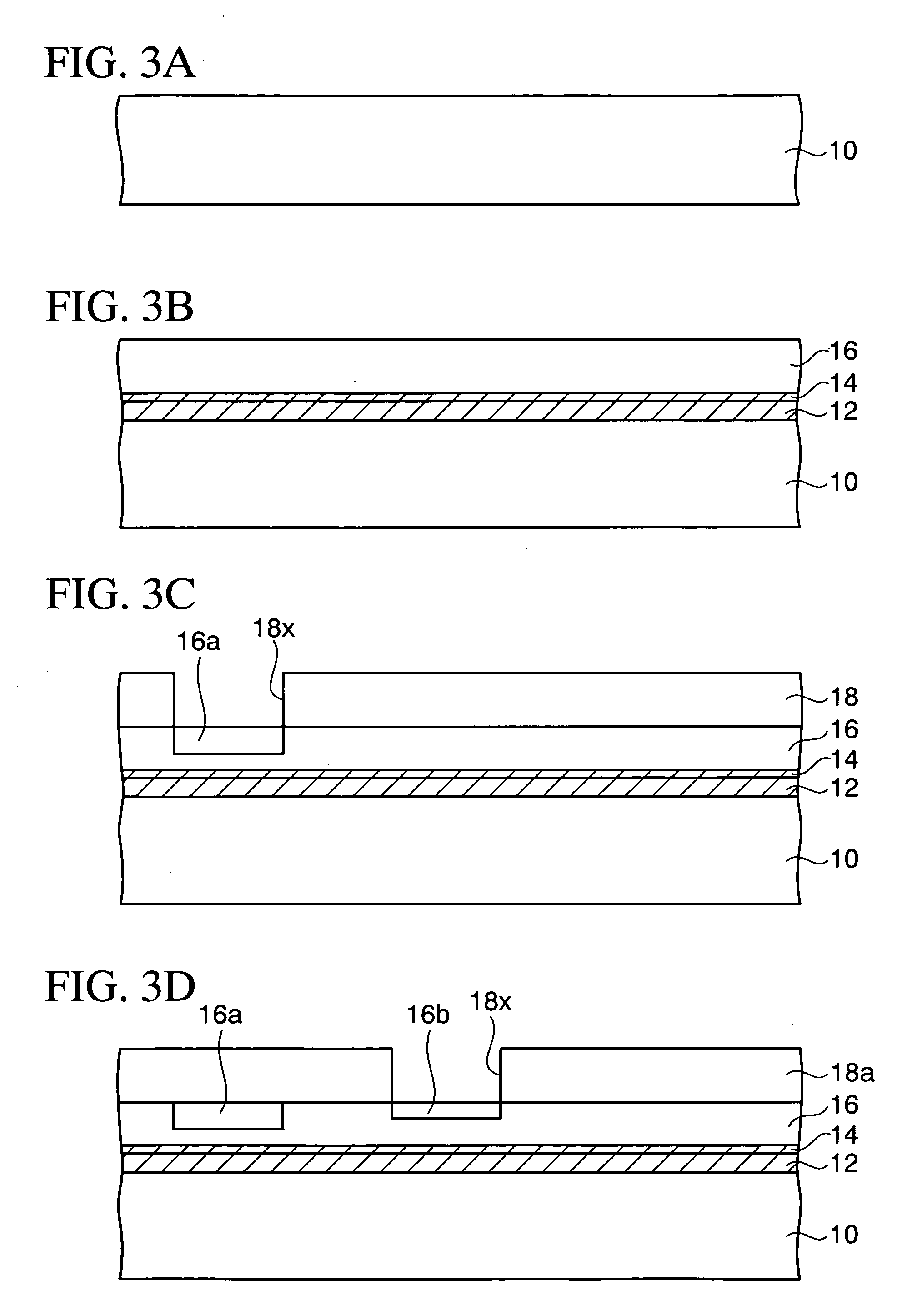

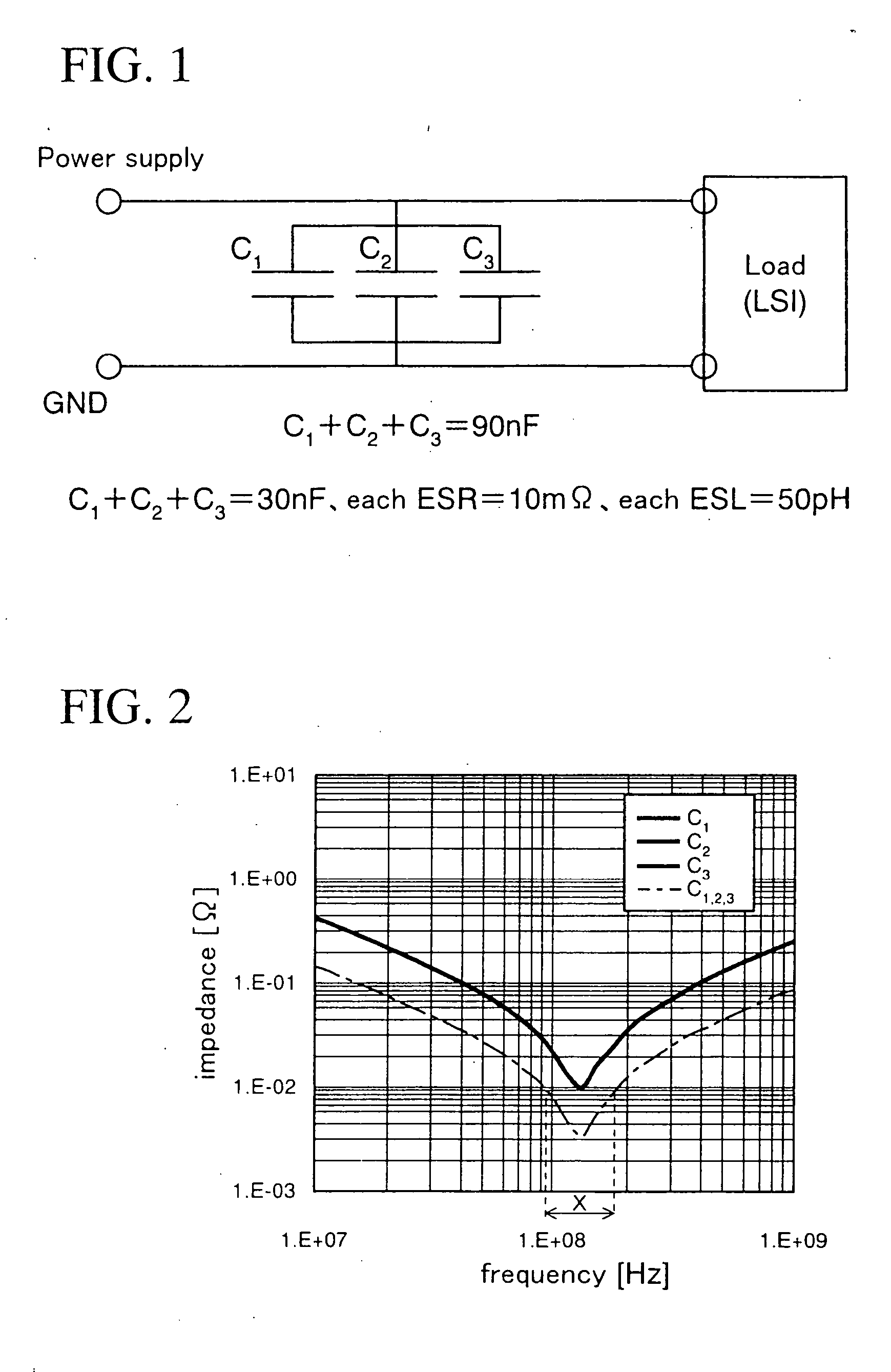

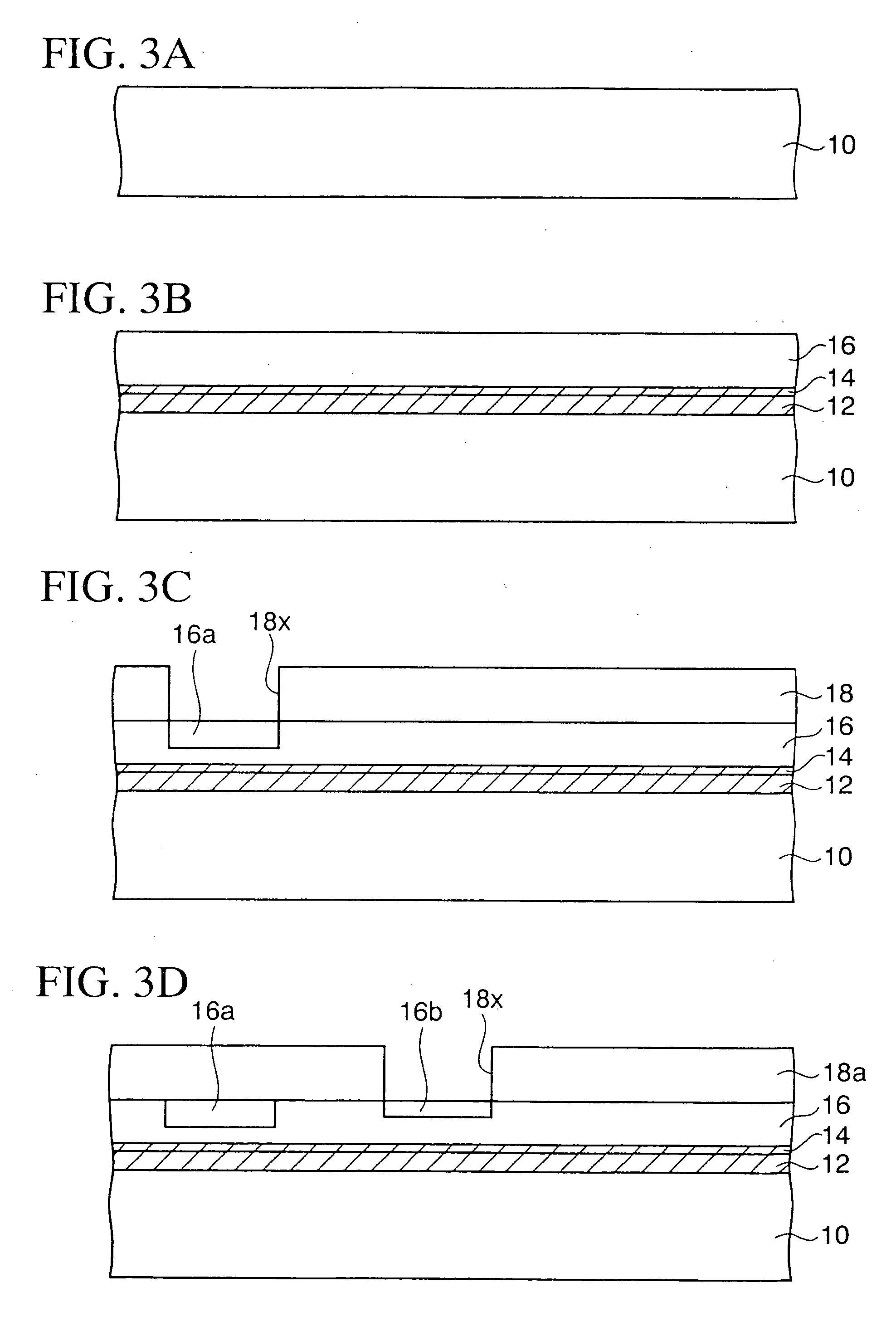

Capacitor device, electronic parts packaging structure, and method of manufacturing the capacitor device

ActiveUS20060061936A1Lower impedanceHigh frequencySemiconductor/solid-state device detailsSolid-state devicesDielectric membraneEngineering

In a capacitor device of the present invention includes a substrate, a plurality of lower electrodes formed on the substrate, a plurality of dielectric films formed on a plurality of lower electrodes respectively in a state that the dielectric films are separated mutually, and upper electrodes formed on a plurality of dielectric films respectively, a plurality of capacitors each composed of the lower electrode, the dielectric film, and the upper electrode are arranged on the substrate respectively, and each of the dielectric films in a plurality of capacitors has a different film thickness.

Owner:SHINKO ELECTRIC IND CO LTD

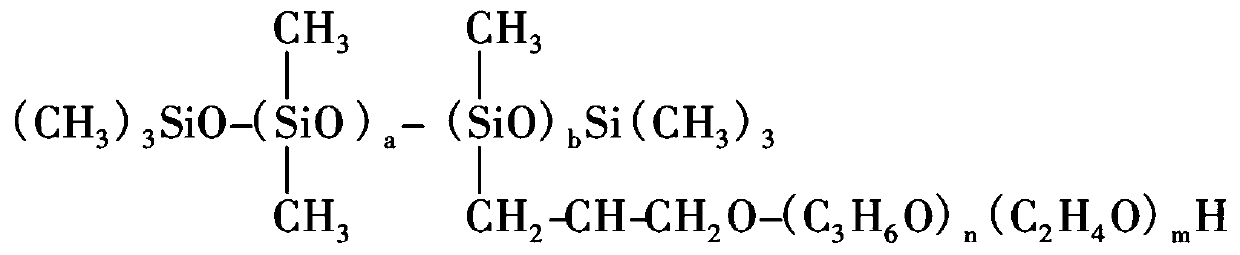

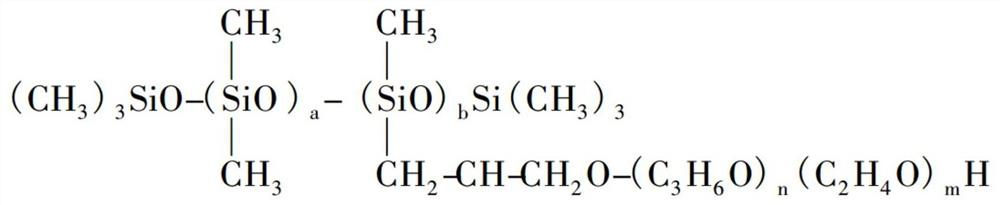

Method for improving specific volume of low pressure corrosion aluminum foil

ActiveCN110085455AImproved current distributionEasy and uniform growthMetal surface removal provisionPhosphatePhosphoric acid

The invention discloses a method for improving specific volume of a low pressure corrosion aluminum foil. The method comprises steps that (1), the aluminum foil is immersed in aqueous phosphoric acidsolution and washed with the water; (2), the treated aluminum foil is subjected to cloth hole etching in the aqueous solution containing hydrochloric acid, sulfuric acid, aluminum trichloride and an emulsion type polyether-siloxane copolymer silicone foam breaker and washed with the water; (3), the treated aluminum foil is subjected to medium treatment in the aqueous solution of hydrogen phosphateor dihydrogen phosphate and washed with the water; (4), the treated aluminum foil is then subjected to deep growth etching in the aqueous solution containing hydrochloric acid, sulfuric acid, aluminum trichloride and an emulsion type polyether-siloxane copolymer silicone foam breaker and washed with the water; (5), the steps (3) and step (4) are repeated for 3-6 times; (6), the treated aluminum foil is then immersed in the aqueous solution of sulfuric acid and washed with the water, the washed aluminum foil is then immersed in the triethanolamine solution and washed with the water; and (7), the aluminum foil is dried. The method is advantaged in that the specific volume of the low pressure corrosion aluminum foil can be improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD +1

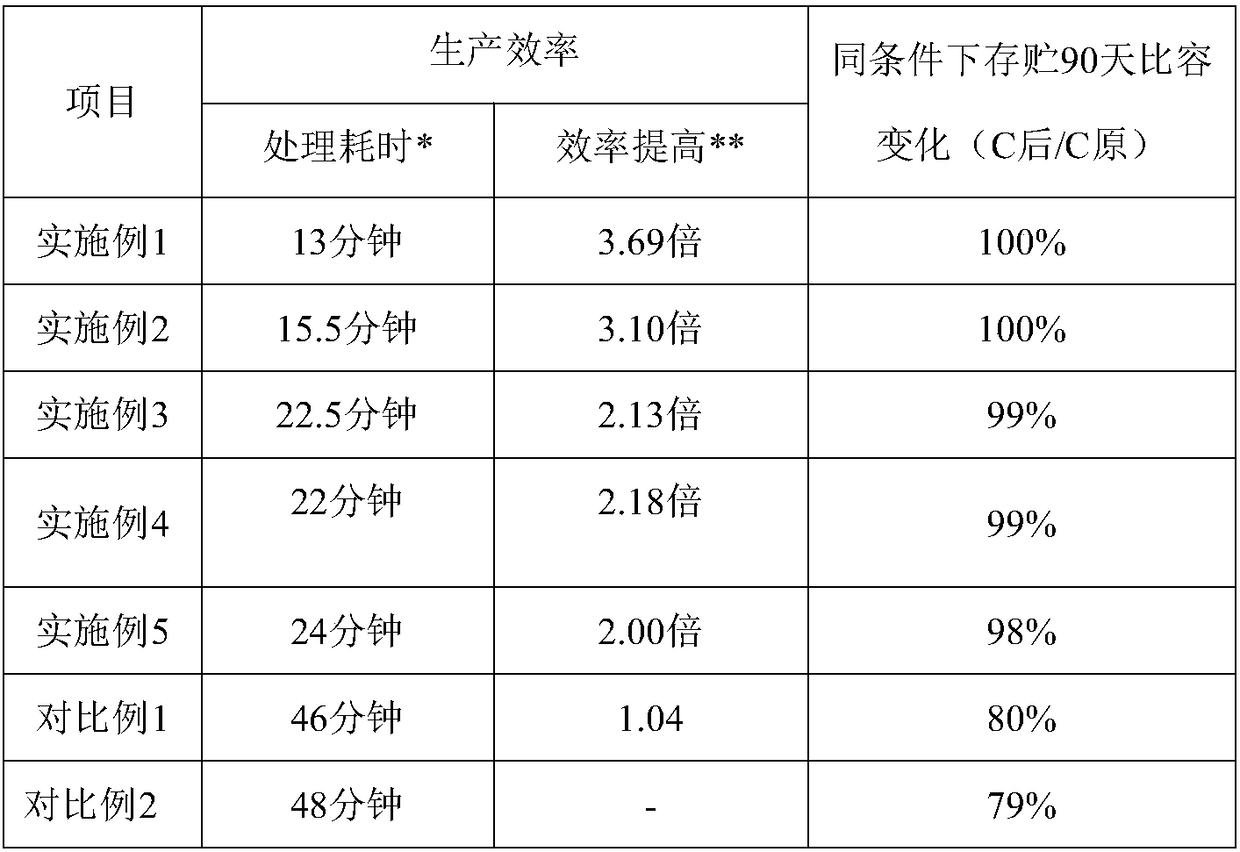

Processing method for improving water resistance of low-voltage electrode foil, and application

InactiveCN108109845AImprove water resistanceIncrease productivityElectrolytic capacitorsMetal surface removal provisionPhosphateLow voltage

The invention belongs to the technical field of manufacturing of aluminum electrolytic capacitors, and discloses a processing method for improving water resistance of low-voltage electrode foil, and an application. The processing method comprises the steps of placing corroded aluminum foil in an aqueous solution of azelaic acid and azelate, performing formation and water washing on the aluminum foil and then placing the aluminum foil into a titanium n-propoxide aqueous solution for soaking, placing the aluminum foil into an aqueous solution of azelaic acid and azelate, performing formation andwater washing on the aluminum foil and then placing the aluminum foil into a phosphoric acid aqueous solution, performing passivation treatment on the aluminum foil at a temperature of 30-45 DEG C, then performing heat treatment on the aluminum foil at a temperature of 400-600 DEG C, performing water washing on the aluminum foil and then placing the washed aluminum foil in a titanium phosphate aqueous solution, and performing formation and water washing on the aluminum foil and drying the aluminum foil to obtain the low-voltage electrode foil. The electrode foil prepared by adopting the processing method has the advantages of significantly increased water resistance, prolonged storage time, shortened formation time and high production efficiency, and the low-voltage electrode foil is mainly used in the manufacturing field of aluminum electrolytic capacitors.

Owner:FOSHAN UNIVERSITY

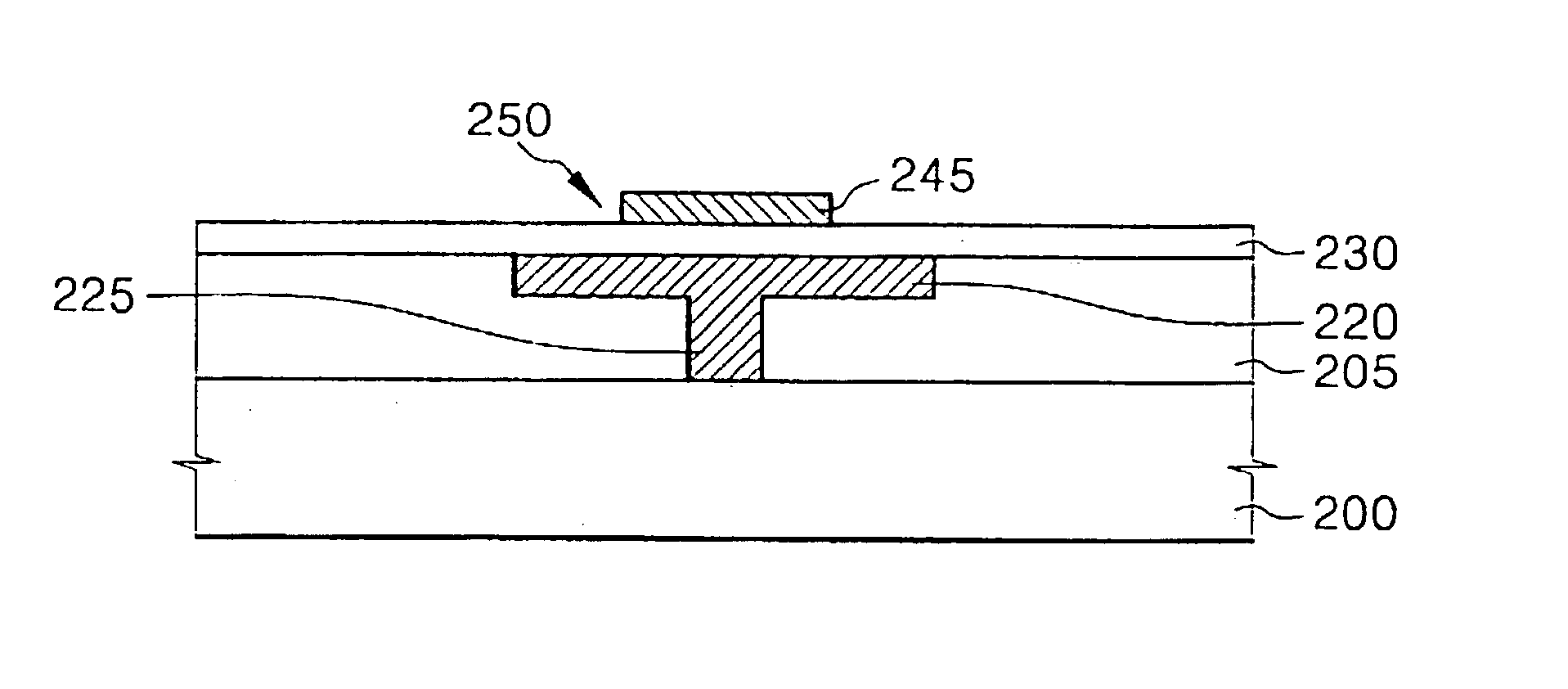

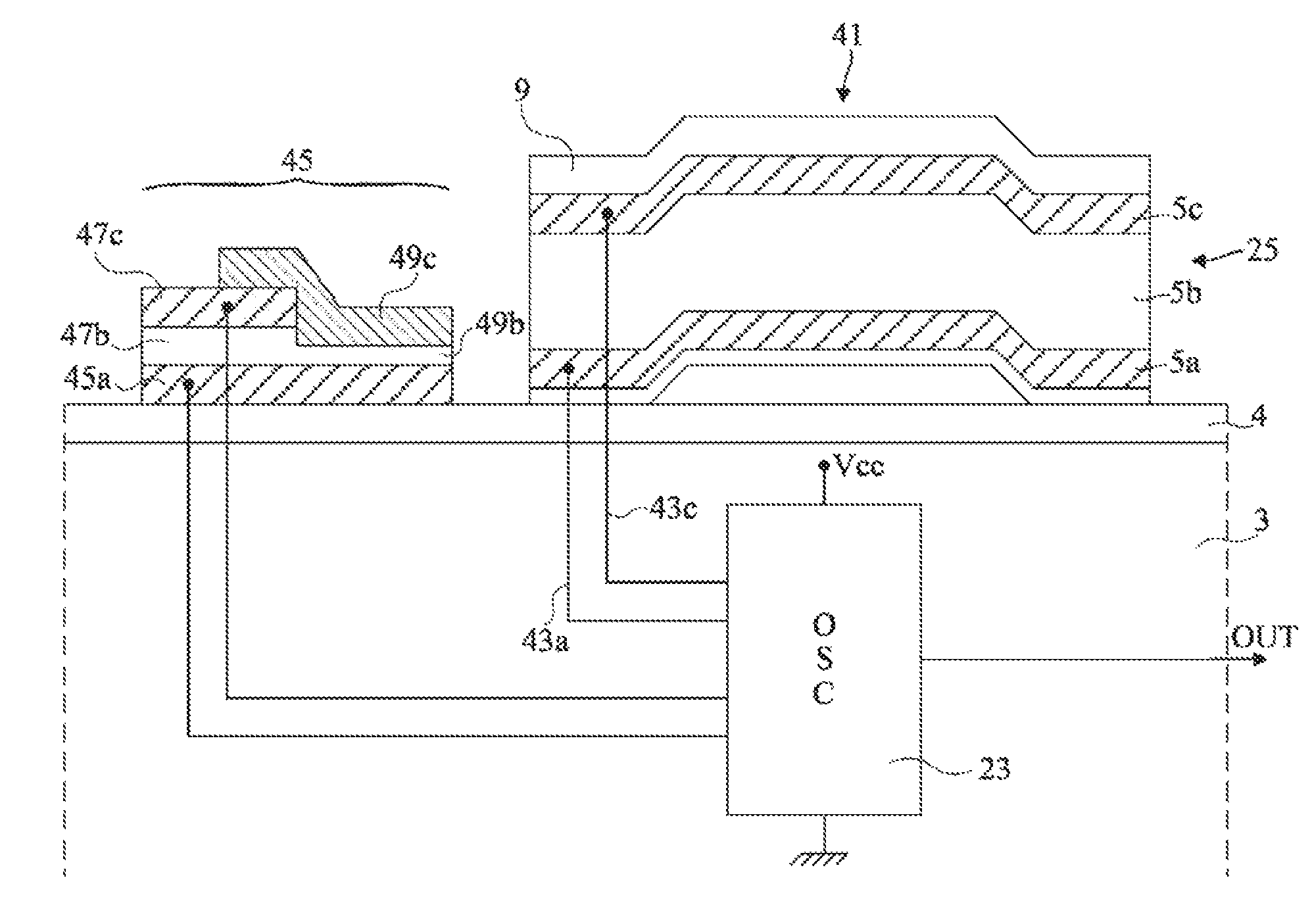

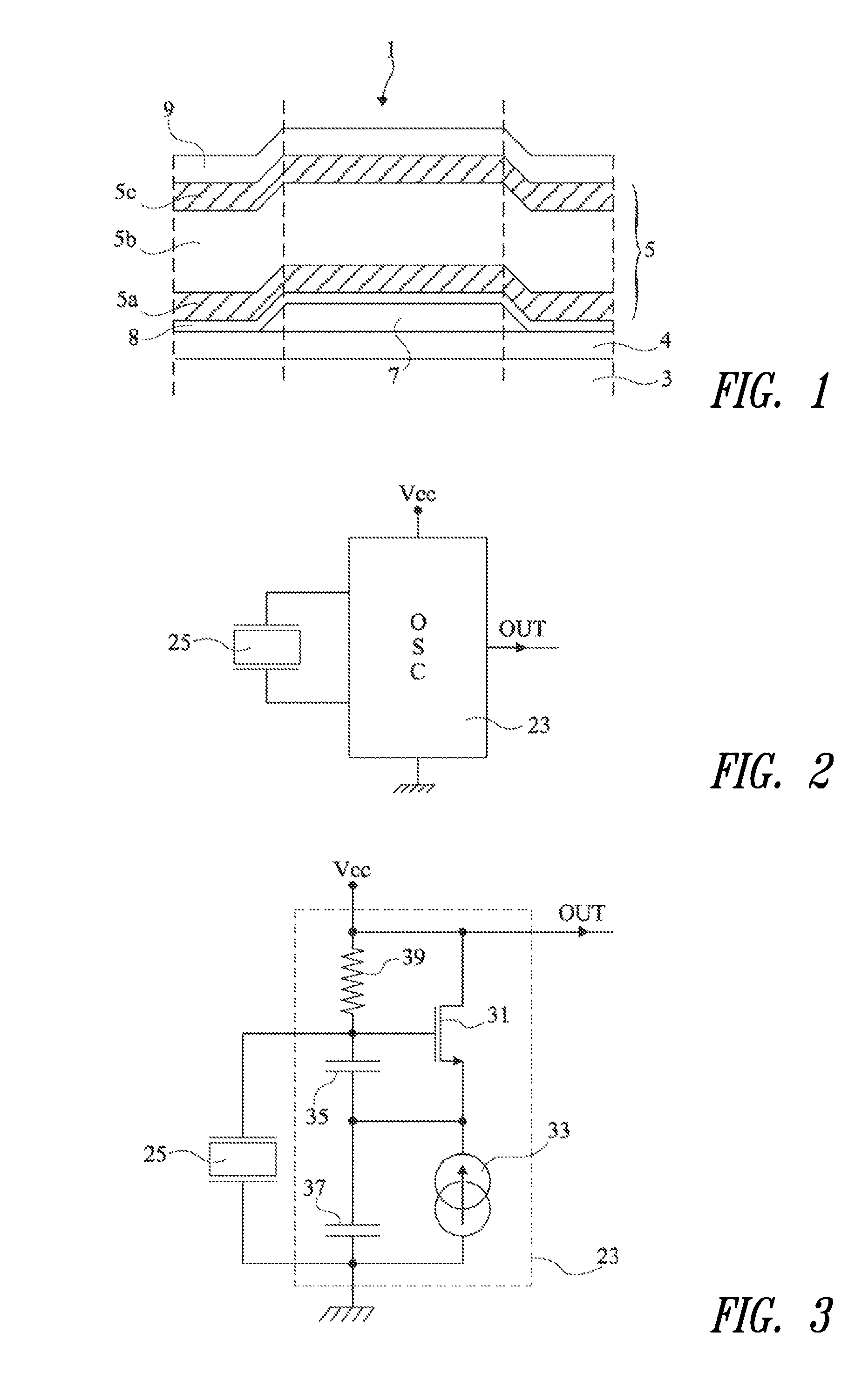

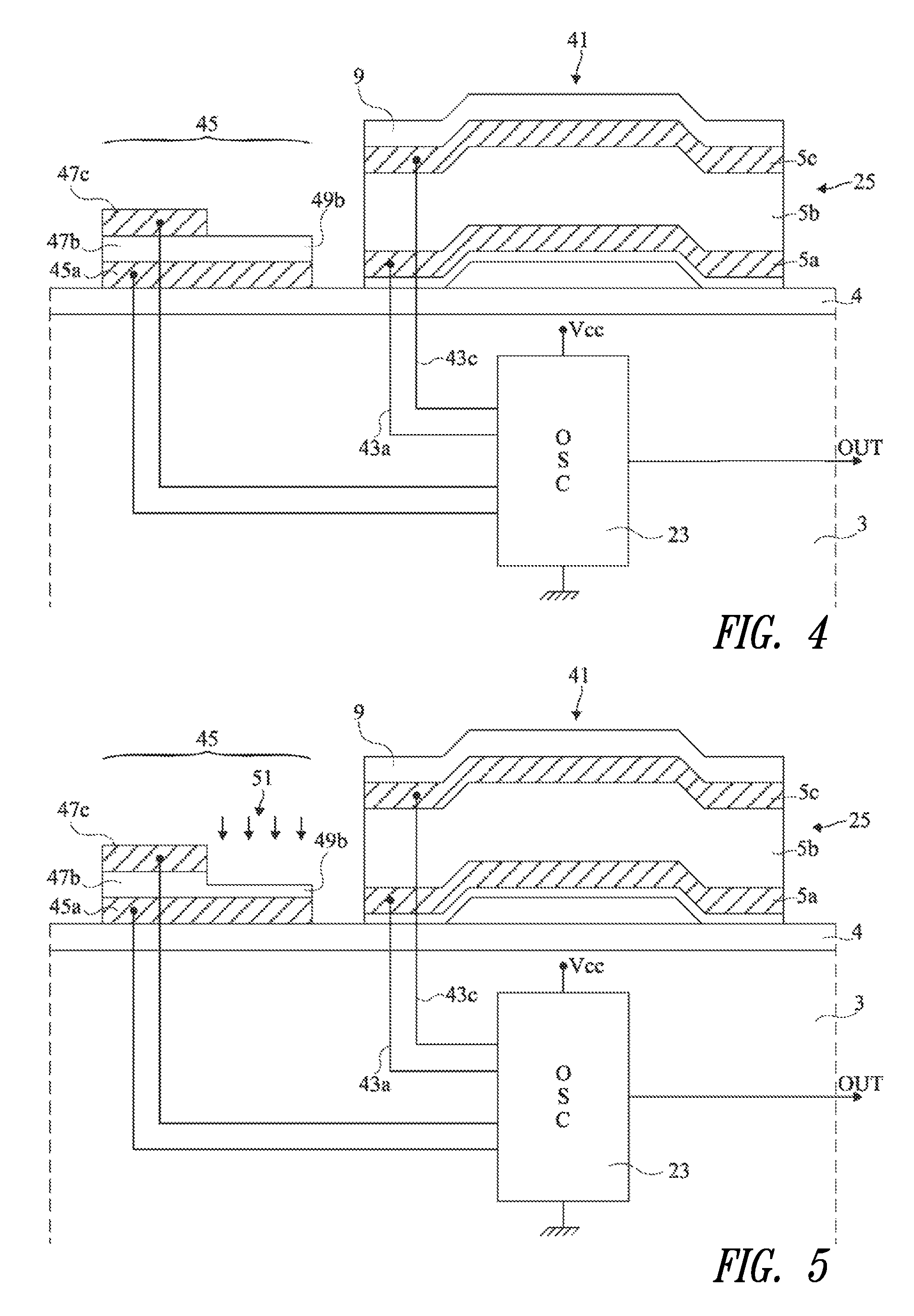

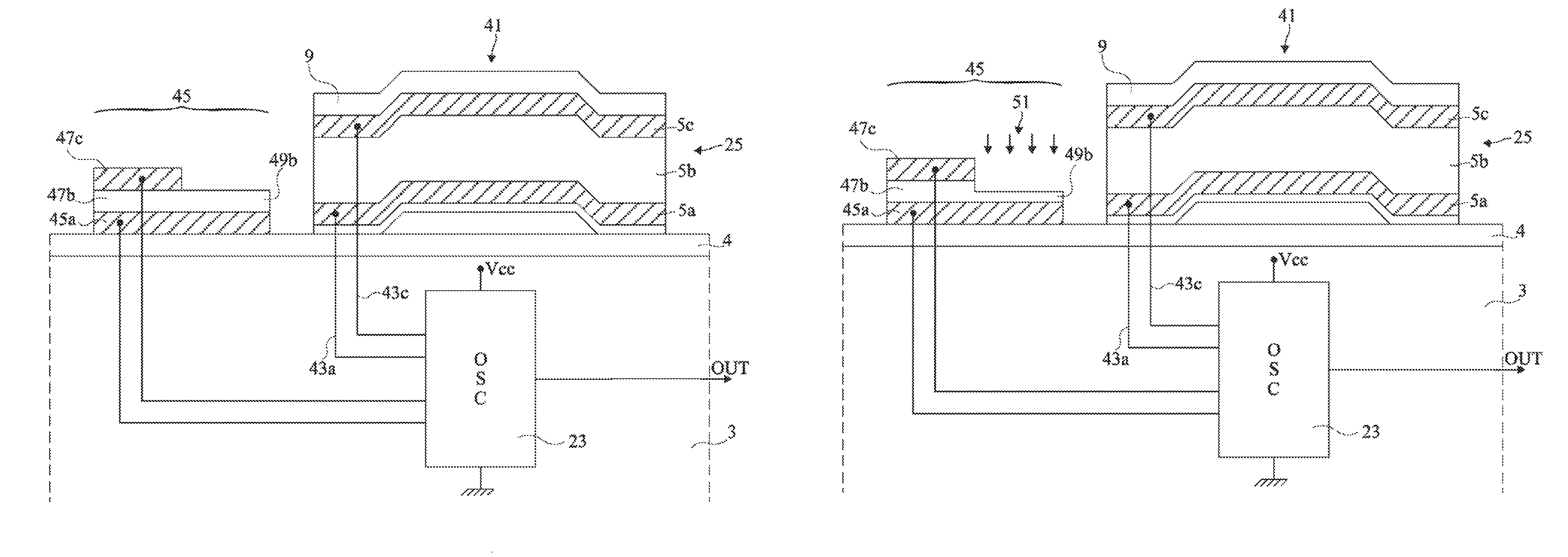

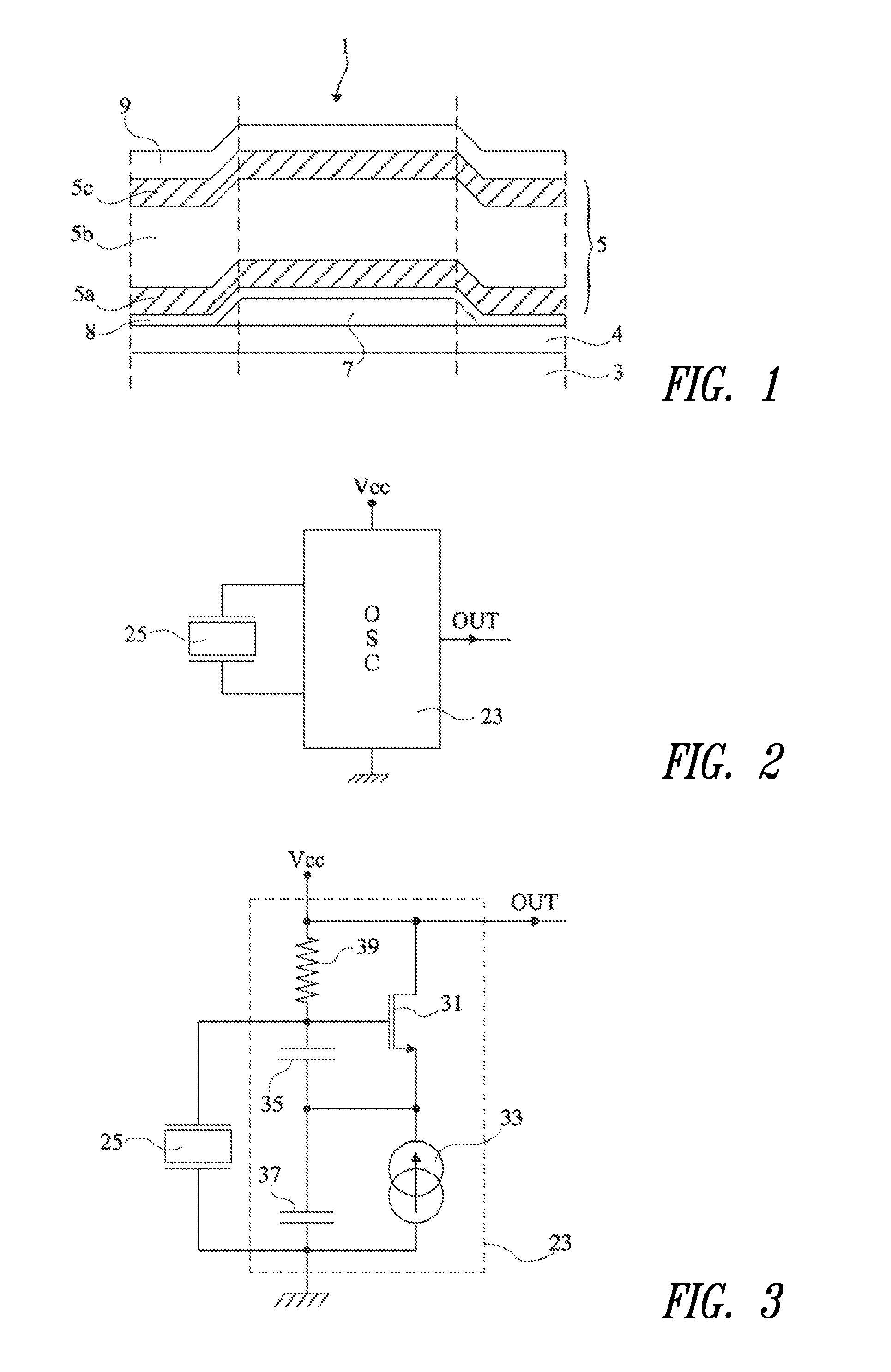

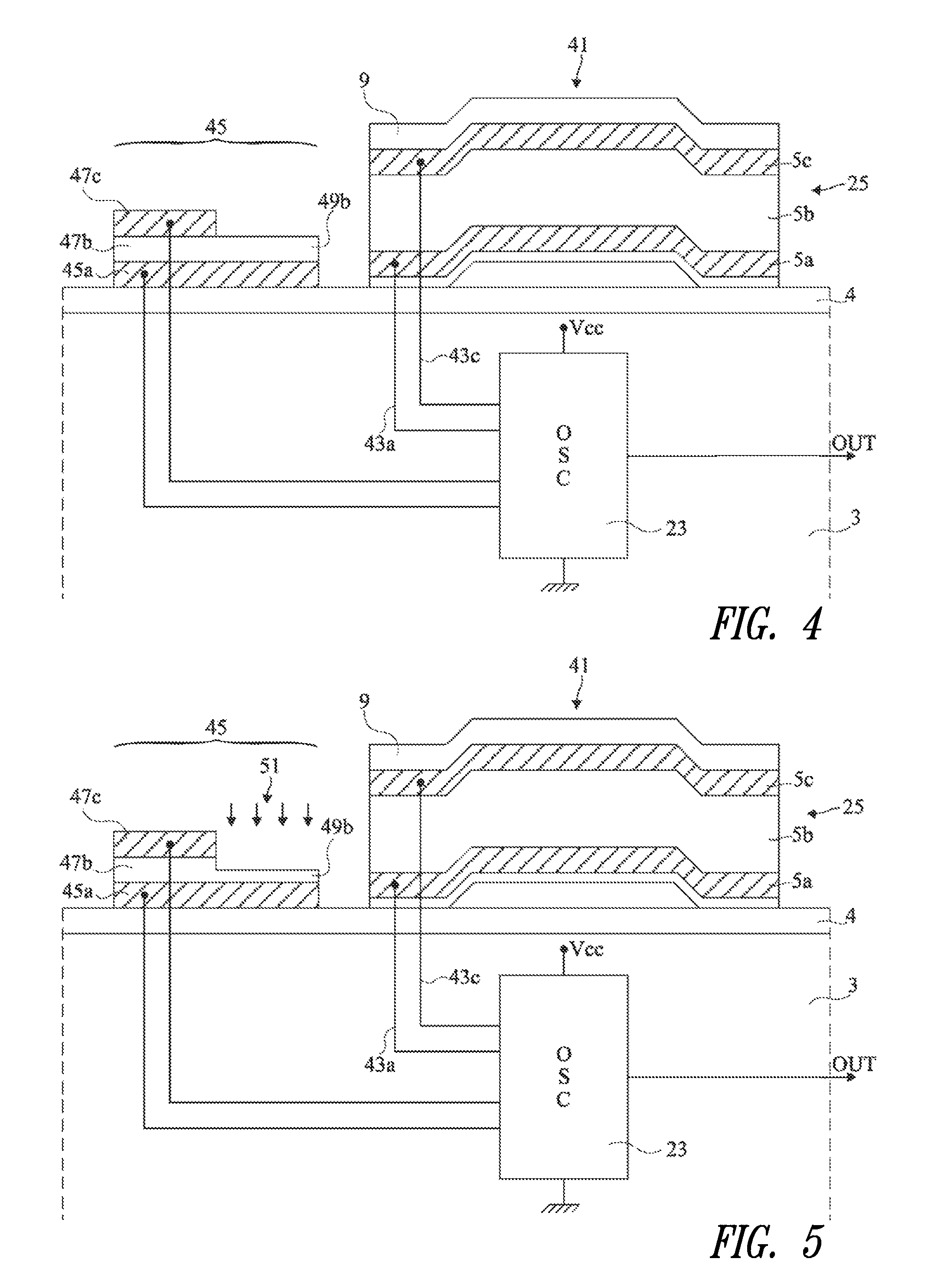

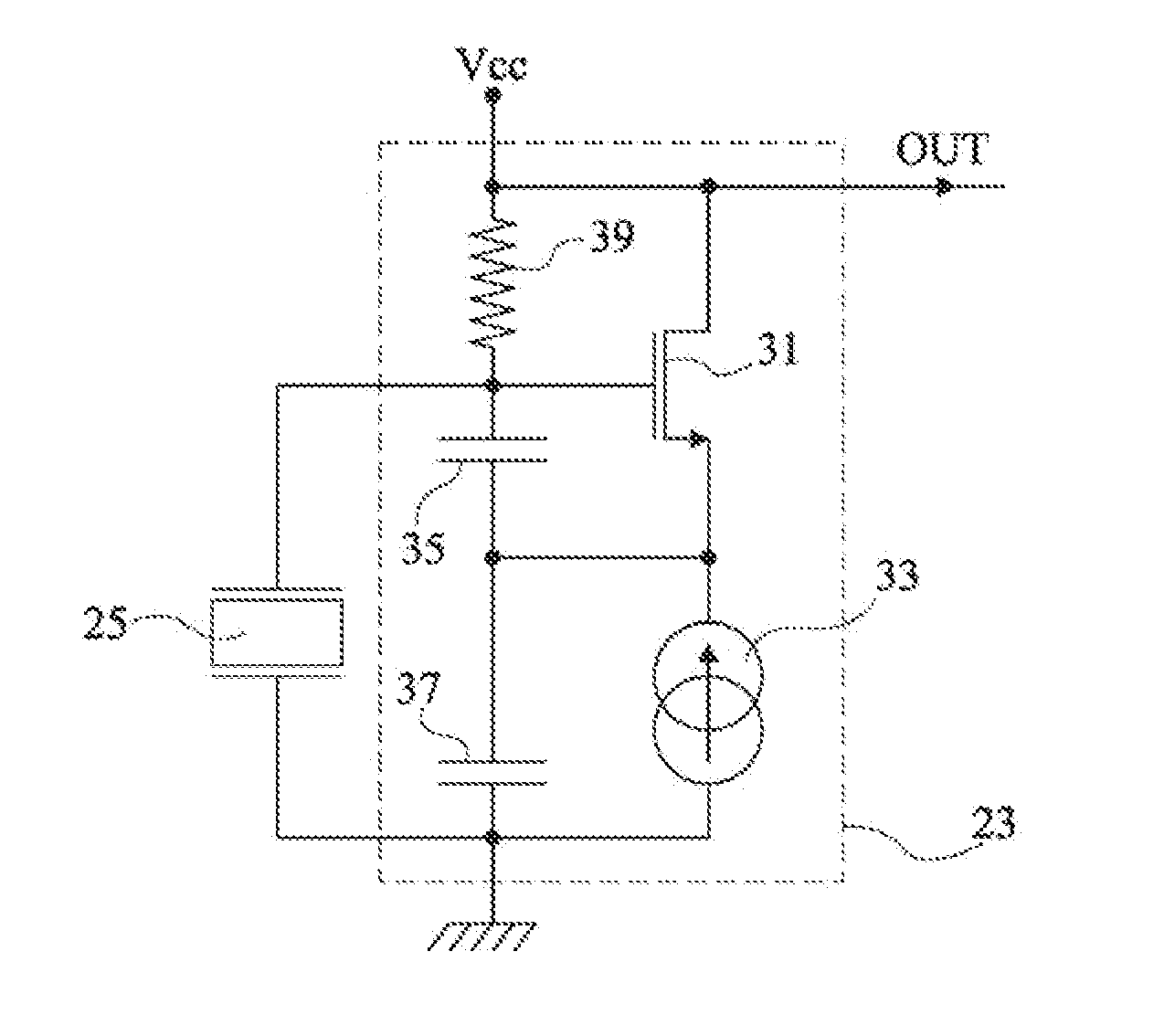

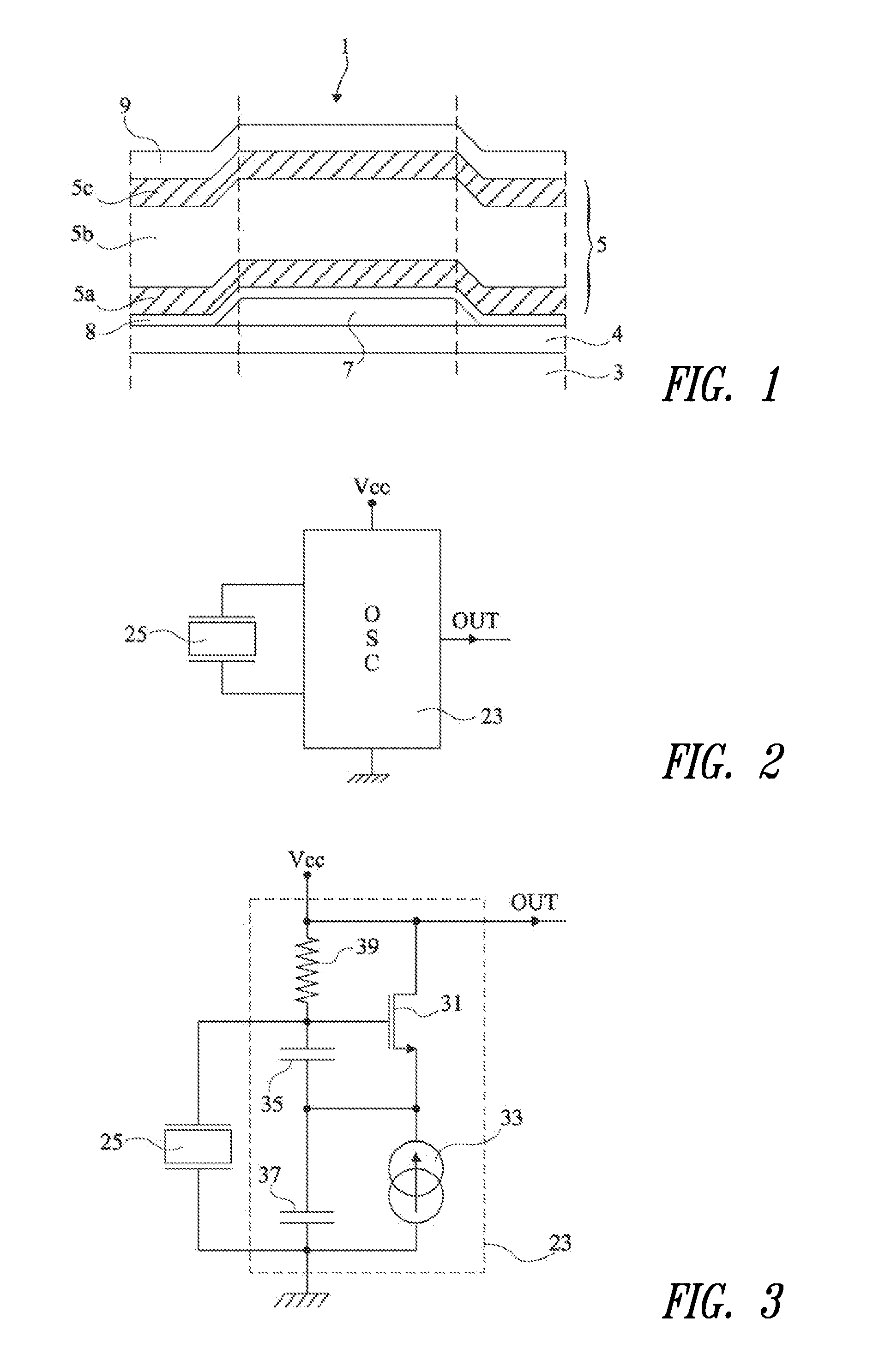

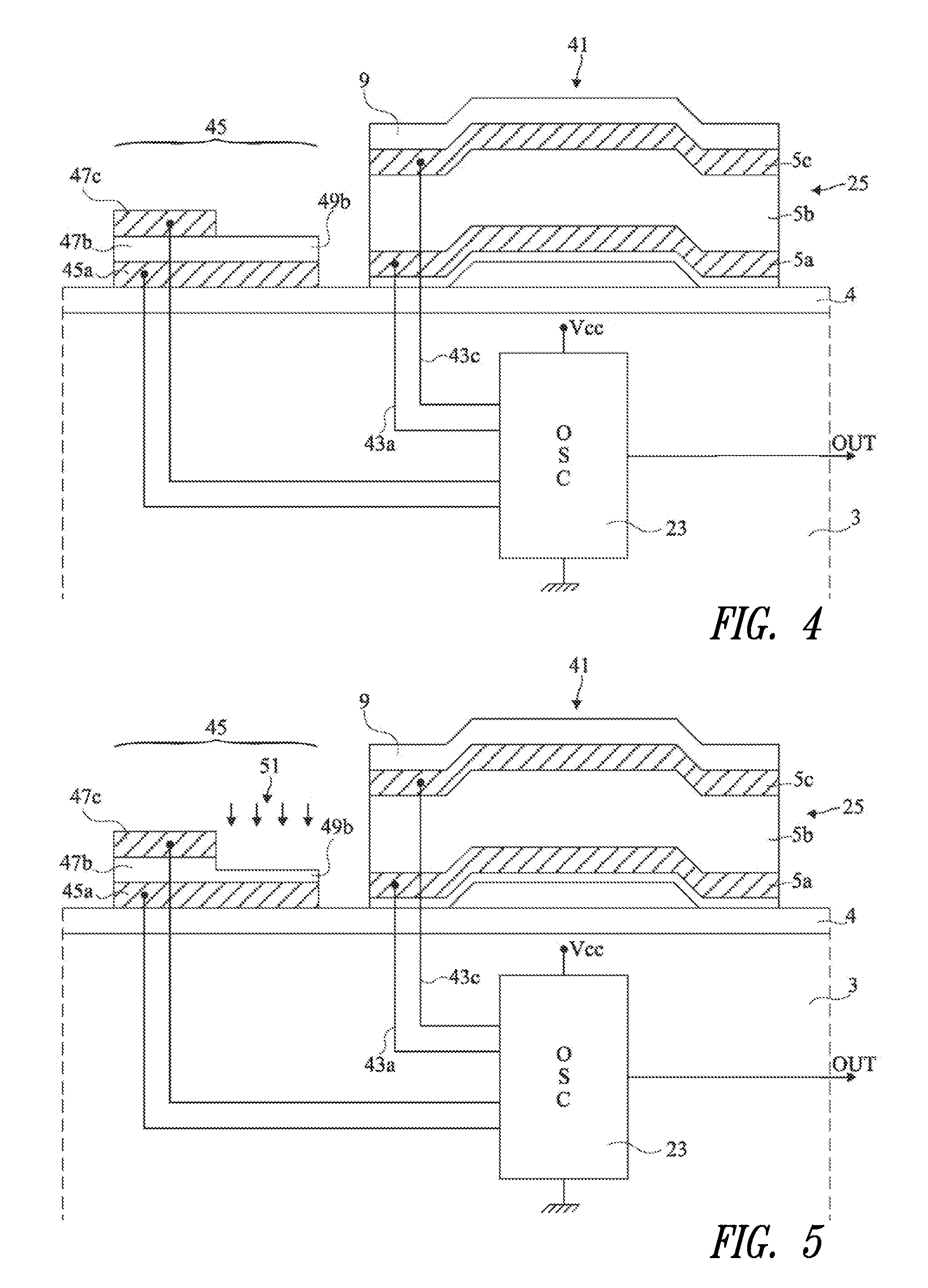

Method of adjustment on manufacturing of a circuit having a resonant element

ActiveUS8587921B2Minimize inaccuracyMinimizing or suppressing the calibration switched capacitor networkImpedence networksSemiconductor/solid-state device testing/measurementCapacitanceEngineering

A method of adjustment in the manufacture of a capacitance of a capacitor supported by a substrate, the method including the steps of: a) forming a first electrode parallel to the surface of the substrate and covering it with a dielectric layer; b) forming, on a first portion of the dielectric layer, a second electrode; c) measuring the capacitance between the first electrode and the second electrode, and deducing therefrom the capacitance to be added to obtain the desired capacitance; d) thinning down a second portion of the dielectric layer, which is not covered by the second electrode, so that the thickness of this second portion is adapted to the forming of the deduced capacitance; and e) forming a third electrode on the thinned-down portion and connecting it to the second electrode.

Owner:STMICROELECTRONICS SRL

Method of adjustment during manufacture of a circuit having a capacitor

InactiveUS8756778B2Minimize inaccuracyMinimizing or suppressing the calibration switched capacitor networkElectrical transducersWave amplification devicesCapacitanceEngineering

A method of adjustment during manufacture of a capacitance of a capacitor supported by a substrate, the method including the steps of: a) forming a first electrode parallel to the surface of the substrate and covering it with a dielectric layer; b) forming, on a first portion of the dielectric layer, a second electrode; c) measuring the electrical signal between the first electrode and the second electrode, and deducing therefrom the capacitance to be added to obtain the desired capacitance; d) thinning down a second portion of the dielectric layer, which is not covered by the second electrode, so that the thickness of this second portion is adapted to the forming of the deduced capacitance; and e) forming a third electrode on the thinned-down portion and connecting it to the second electrode.

Owner:STMICROELECTRONICS SRL

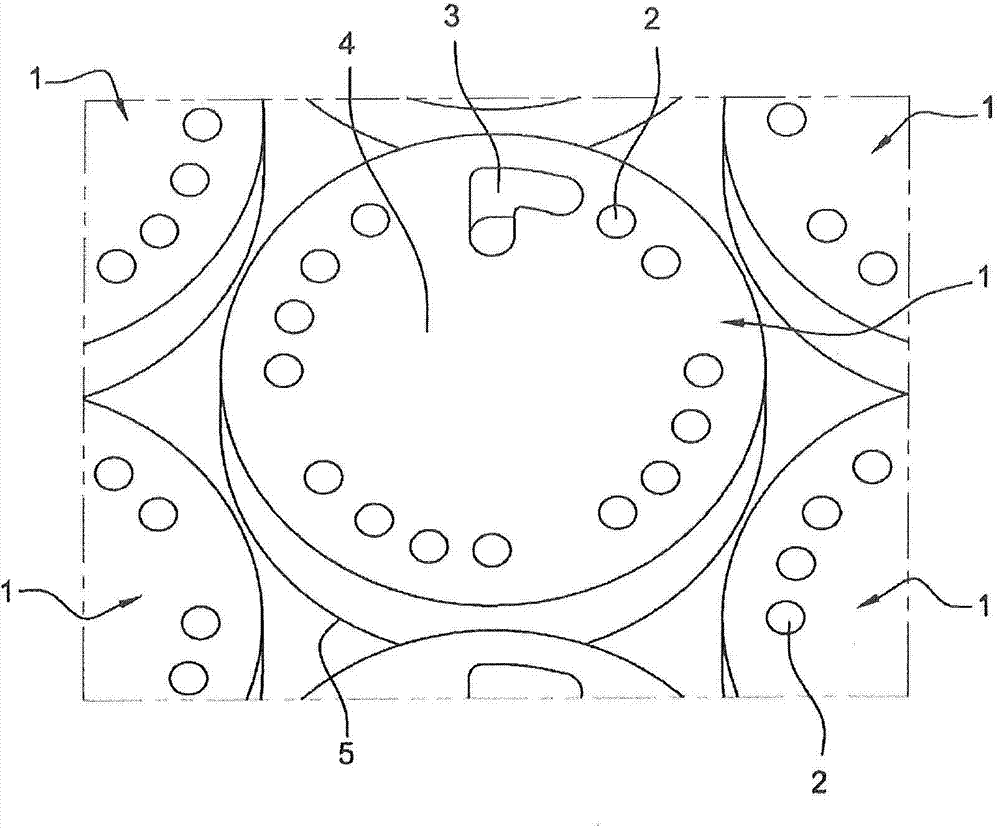

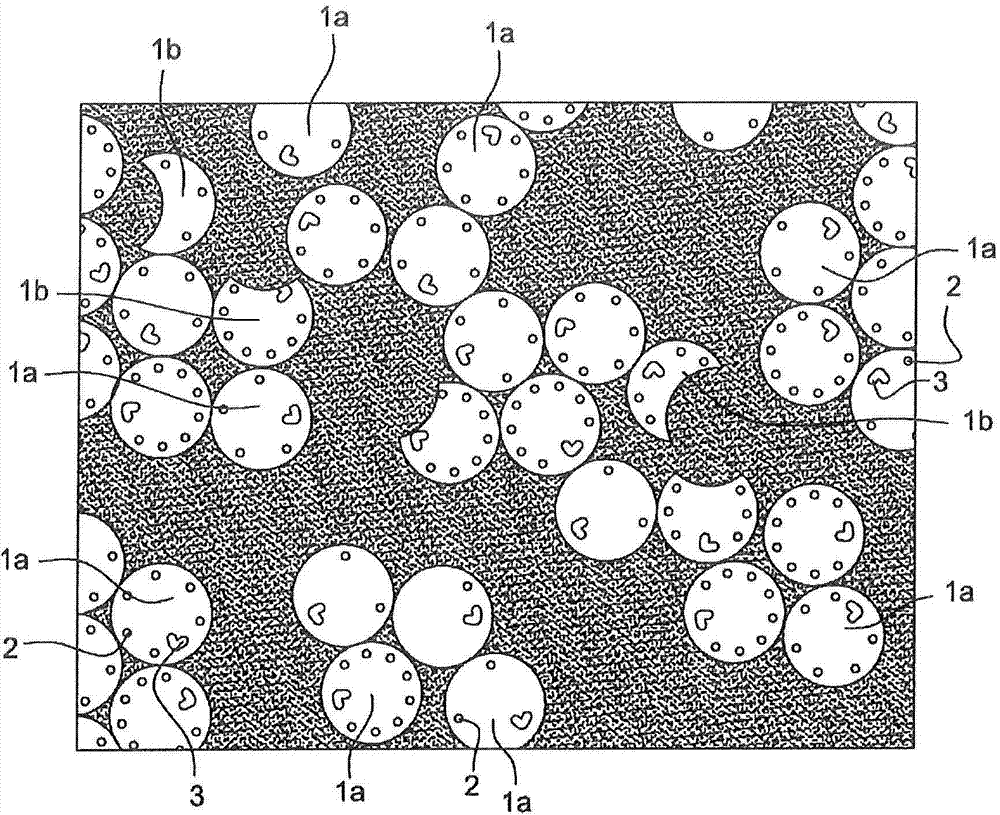

Method for producing microcarriers

The present invention relates to a method for producing microcarriers comprising the following steps: (a) providing a wafer (6) having a sandwich structure comprising a bottom layer (7), a top layer (8) and a insulating layer (9) located between said bottom and top layers (7, 8), (b) etching away the top layer (8) to delineate lateral walls (12) of bodies (11) of the microcarriers, (c) depositing a first active layer (13) at least on a top surface (14) of the bodies (11), (d) applying a continuous polymer layer (16) over the first active layer (13), (e) etching away the bottom layer (7) and the insulating layer (9), (f) removing the polymer layer (16) to release the microcarriers.

Owner:麦卡提斯有限责任公司

Method of adjustment during manufacture of a circuit having a capacitor

InactiveUS20110298554A1Overcome disadvantagesMinimize inaccuracyImpedence networksSemiconductor/solid-state device testing/measurementCapacitanceEngineering

A method of adjustment during manufacture of a capacitance of a capacitor supported by a substrate, the method including the steps of: a) forming a first electrode parallel to the surface of the substrate and covering it with a dielectric layer; b) forming, on a first portion of the dielectric layer, a second electrode; c) measuring the electrical signal between the first electrode and the second electrode, and deducing therefrom the capacitance to be added to obtain the desired capacitance; d) thinning down a second portion of the dielectric layer, which is not covered by the second electrode, so that the thickness of this second portion is adapted to the forming of the deduced capacitance; and e) forming a third electrode on the thinned-down portion and connecting it to the second electrode.

Owner:STMICROELECTRONICS SRL

Production process of high-voltage super farad capacitor

InactiveCN107275125AIncrease capacityMetal surface removal provisionWinding capacitor machinesThermal sprayingNew energy

The invention discloses a production process of a high-voltage super Farad capacitor, comprising (1), material selection; (2), thermal spraying; (3), electrochemical treatment; (4), capacitor preparation. The present invention realizes a supercapacitor with a capacitor capacity of 0.47-100F under the condition of 100-800V. Since the above-mentioned requirements can be realized, its application will be extremely wide, especially for wind power, photoelectric energy storage, new energy vehicle power and laser weapons, It is of great significance for high-power military equipment such as particle beam weapons, submarines, and aerospace.

Owner:四川华保新能源科技有限公司

Method for enlarging surface area of ultrahigh voltage electrode foil by corrosion

InactiveCN102877066AIncrease specific volumeHigh strengthMetal surface removal provisionUltra high pressureSpecific volume

The invention relates to a method for enlarging the surface area of ultrahigh voltage electrode foil by corrosion. The method at least comprises the following steps of: selecting raw materials, performing pretreatment, washing, performing primary corrosive surface area enlarging treatment, washing, performing secondary corrosive surface area enlarging treatment, washing, performing third-time corrosive surface area enlarging treatment, washing, performing fourth-time corrosive surface area enlarging treatment, washing, performing fifth-time corrosive surface area enlarging treatment, washing, performing chemical washing, washing by pure water, and drying a finished product. By the method, the ultrahigh voltage electrode foil with high specific volume and high strength can be produced.

Owner:ZHEJIANG FENGCHUAN ELECTRONICS TECH

Formation Method for Reducing Leakage Current of Medium and High Voltage Formation Foil

ActiveCN107452518BIncrease productivityReduced leakage current rateElectrolytic capacitorsMetal surface removal provisionBenzoic acidPhosphoric acid

The invention discloses a formation method capable of reducing the leak current in medium and high voltage formed foils. The method herein includes the following steps: immersing an aluminum foil in water, then immersing the aluminum foil in an azelate solution, performing first level formation, then performing first level rinsing, then placing the aluminum foil in the azelate solution, perform second level formation, and second level formation, placing the aluminum foil in the azelate solution, performing third level formation, immersing the aluminum foil which undergoes formation through the third level formation to a 3, 5 dihydroxy-benzoic acid solution, performing high-temperature heat treatment, placing the aluminum foil which undergoes the high temperature treatment in a boric acid and strontium phosphate solution, performing fourth level formation, performing high temperature heat treatment, finally placing the aluminum foil in a boric acid and strontium phosphate solution and performing fifth level formation, then immersing the aluminum foil in a phosphoric acid solution, taking out the aluminum foil, rinsing the aluminum foil, and drying the aluminum foil. According to the invention, the method herein allows products to have explicit reduction of leak current, and since the intensity of the formed current has doubled, the time for formation reduced by half, and seven formation steps has reduced to five, production efficiency has doubled.

Owner:FOSHAN UNIVERSITY

Aluminum Gel Reverse Analysis Method for Improving the Specific Volume of Formed Foil

ActiveCN103021683BIncrease surface areaIncrease specific volumeMetal surface removal provisionReverse analysisThree stage

An aluminum gel reverse analysis method for increasing the specific volume of formed foil includes the steps: roasting etched foil at the high temperature of 460-580 DEG C for 10-30min, taking out the foil and repeatedly forming the foil in a forming agent for 1-3 times by 0.05-0.10A / cm<2> for 10-30min to obtain a forming agent containing aluminum gel; and placing the etched foil in the forming agent containing the aluminum gel, forming the foil according to a conventional three-stage forming method and increasing the specific volume of the formed foil by 1-15%.

Owner:新疆广投桂东电子科技有限公司

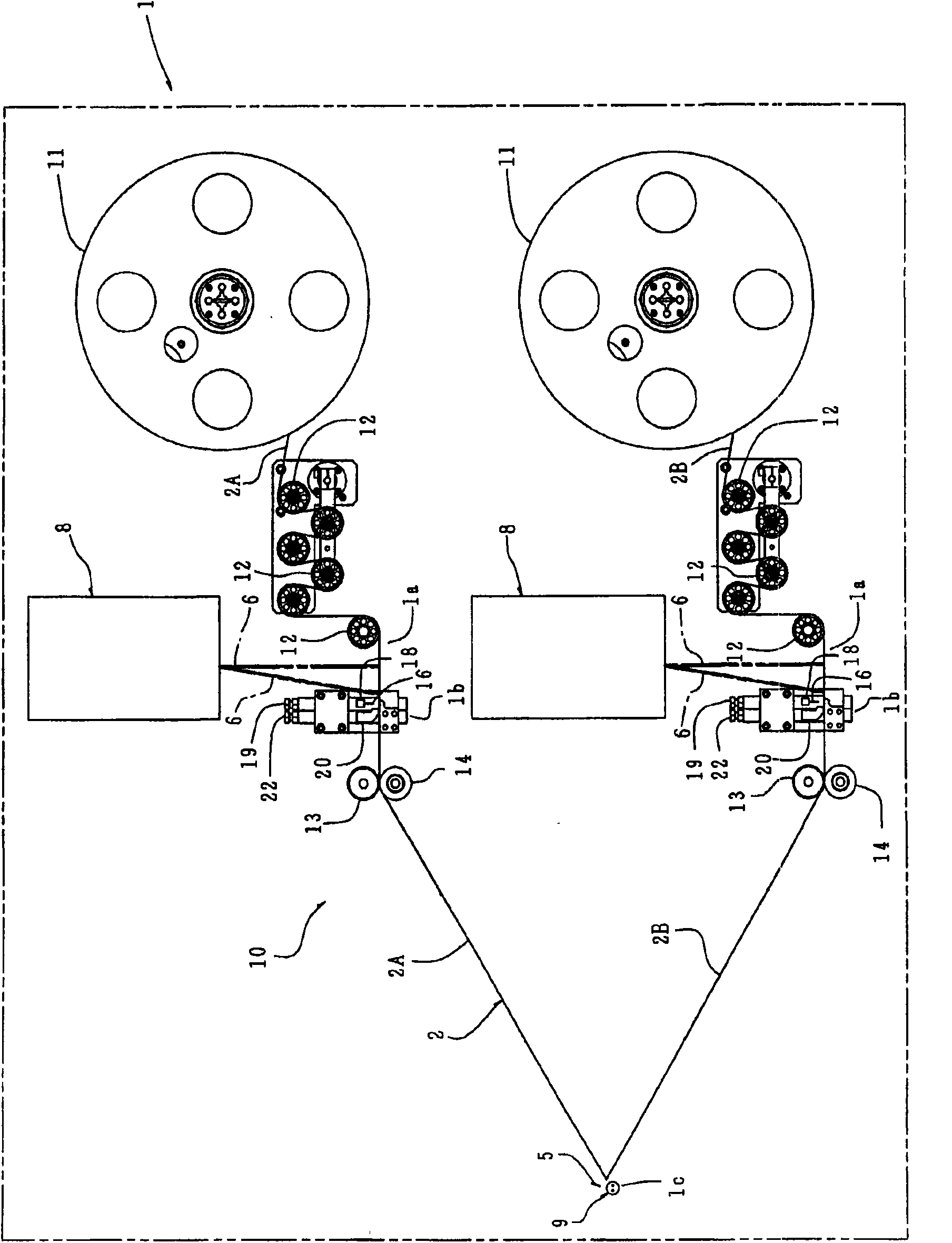

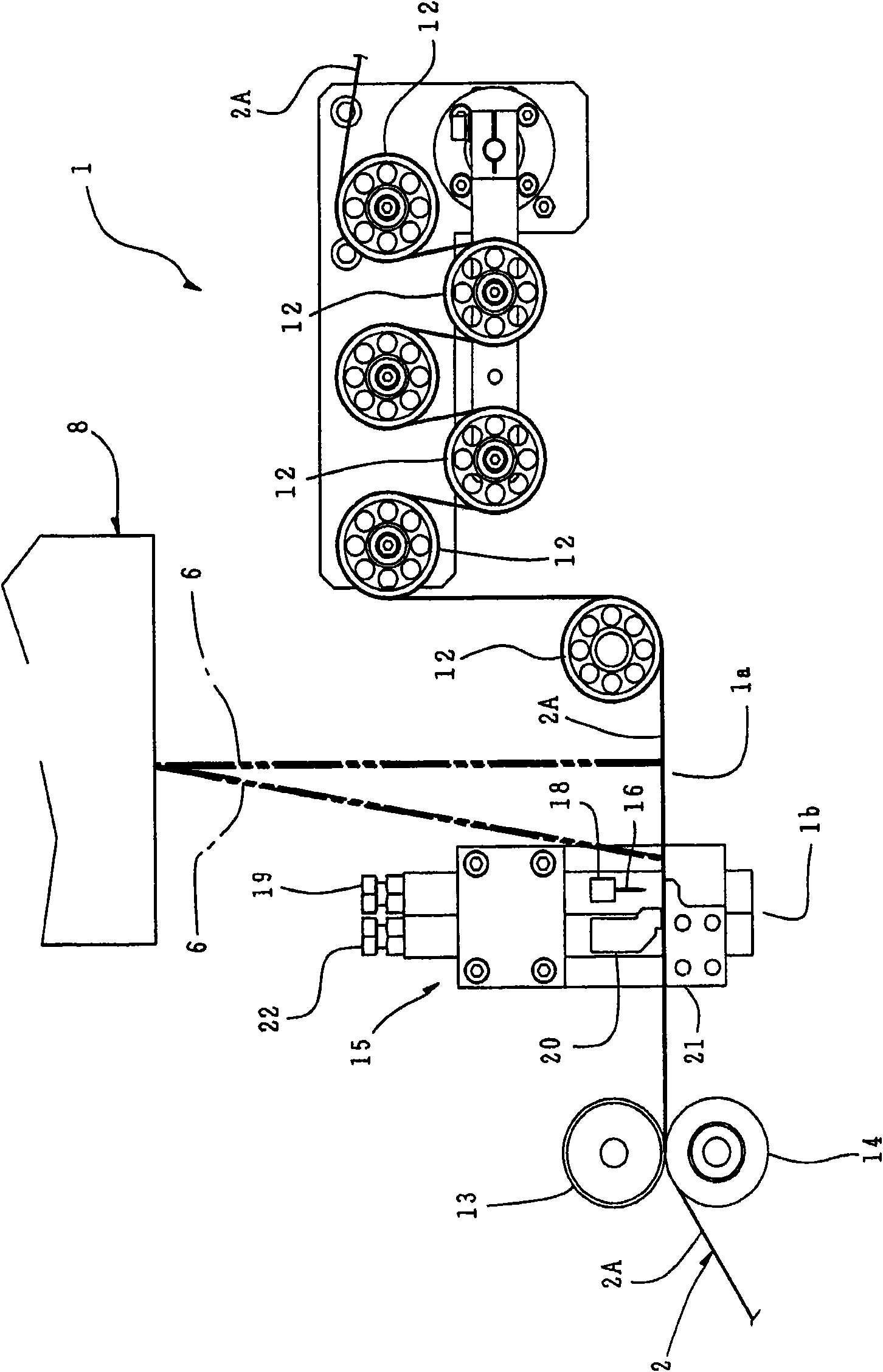

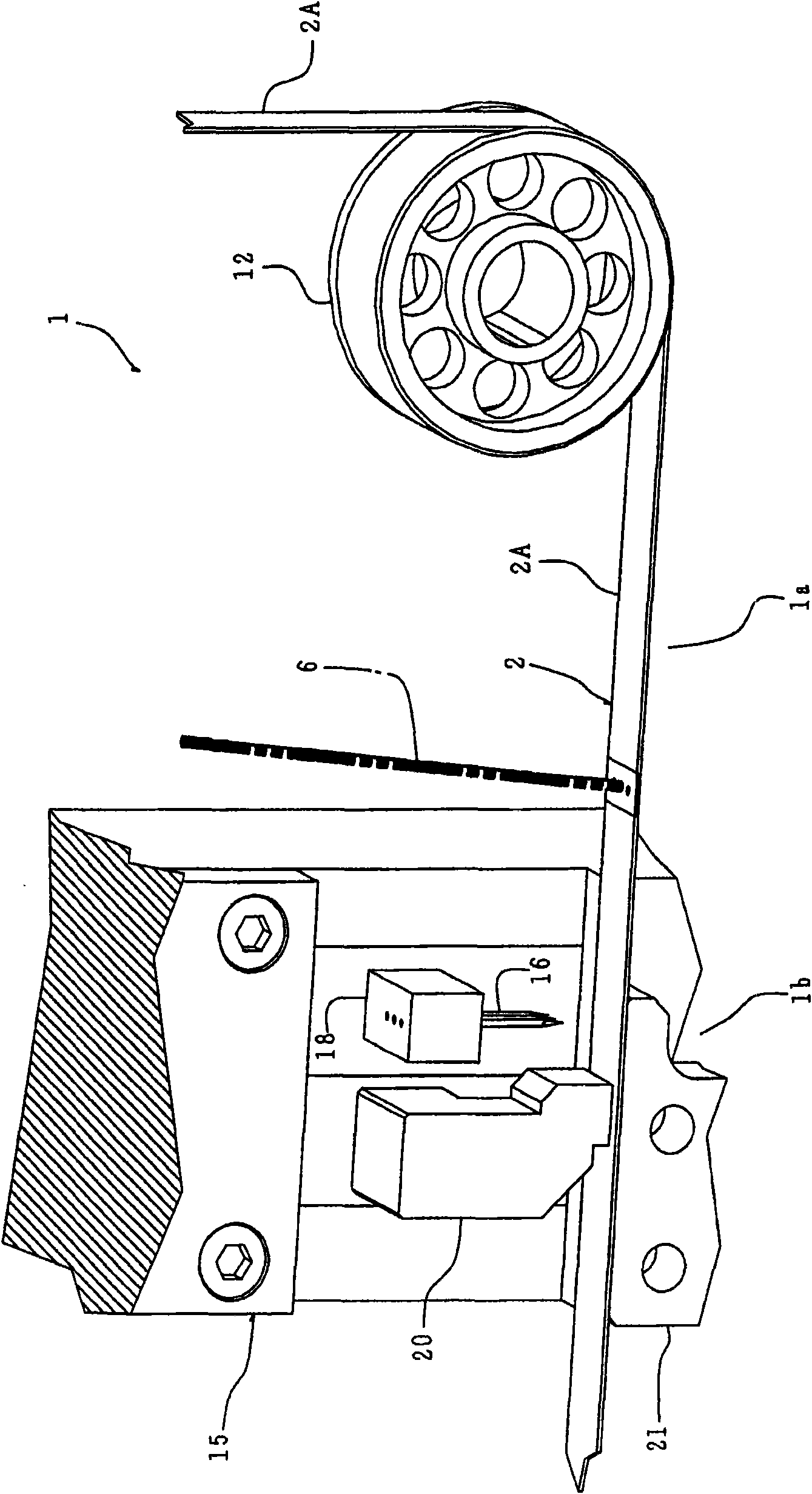

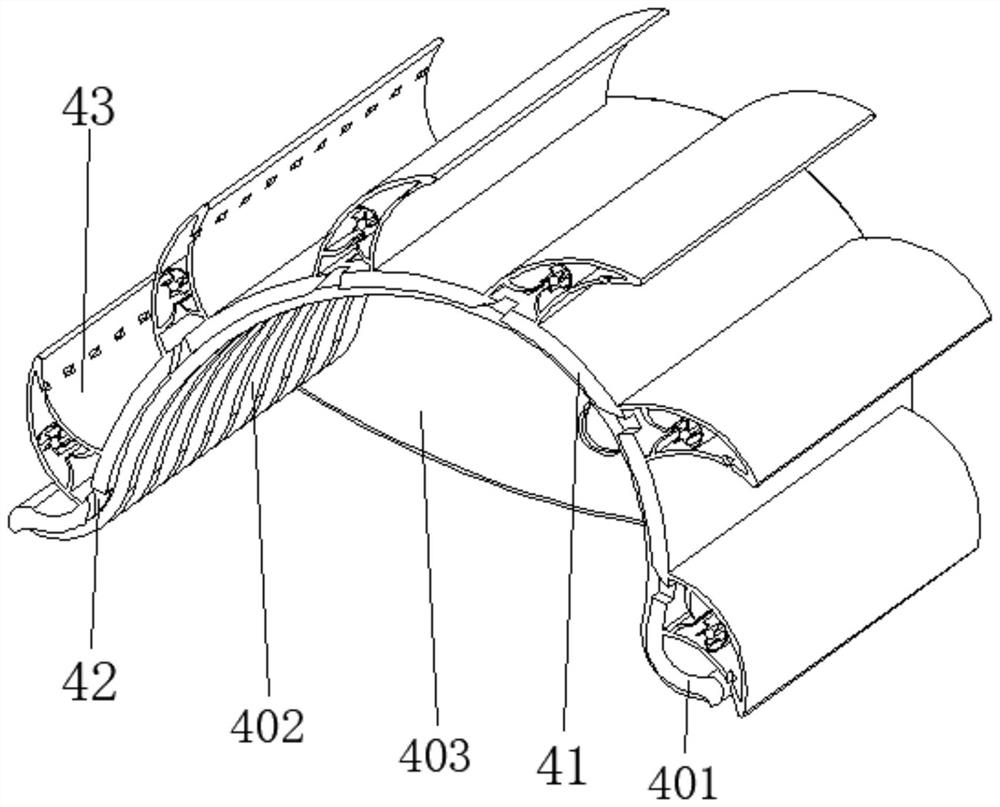

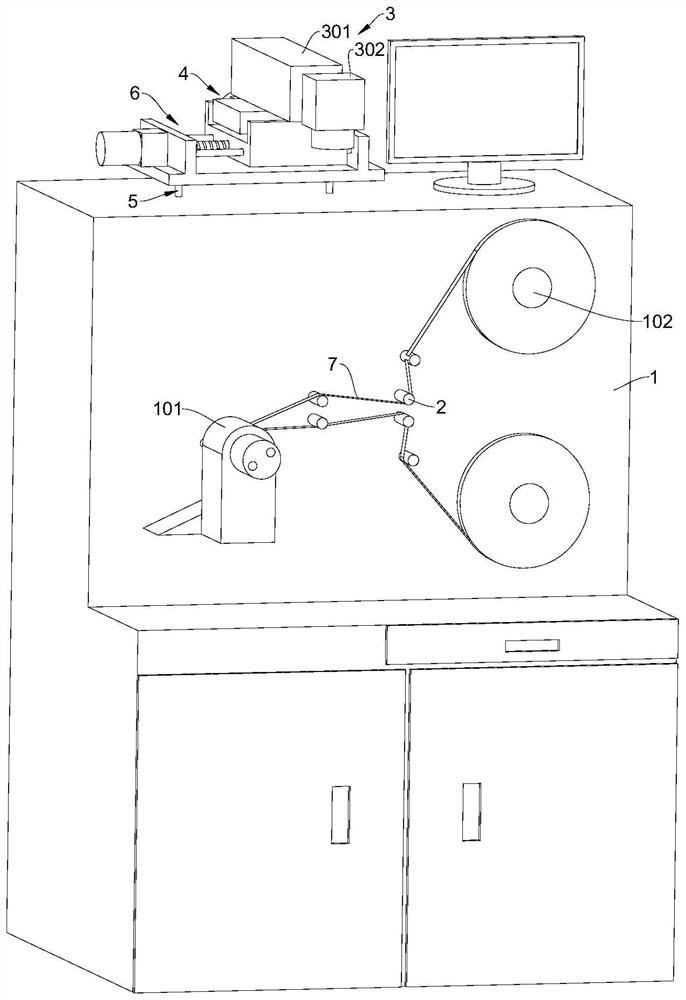

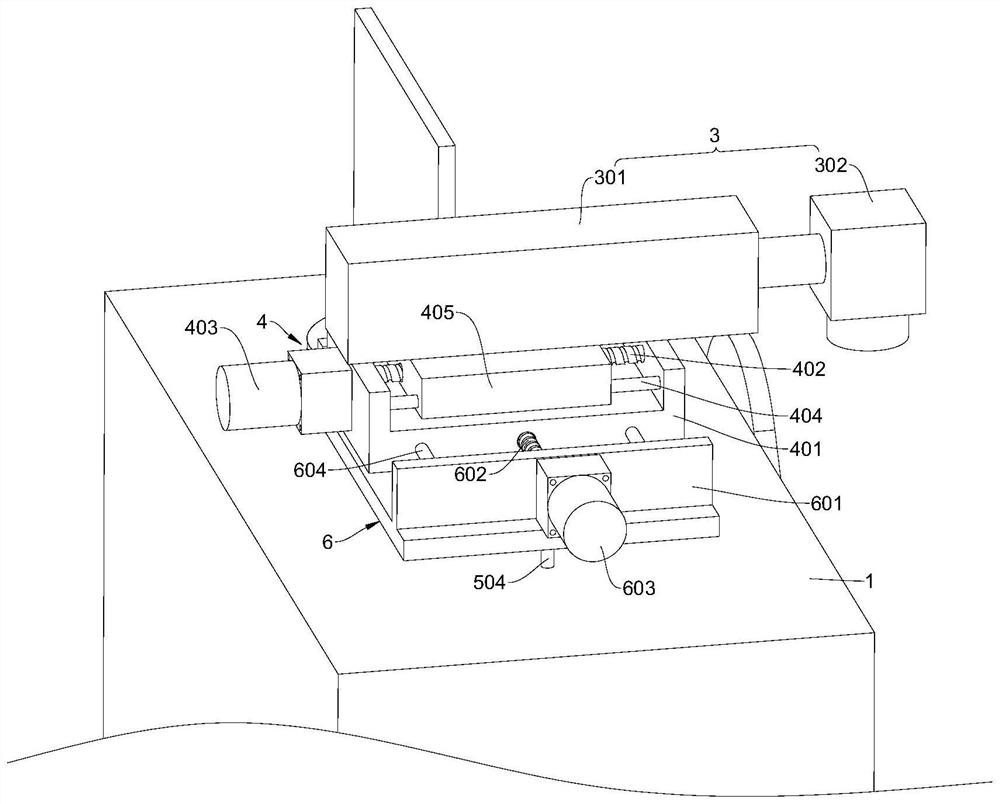

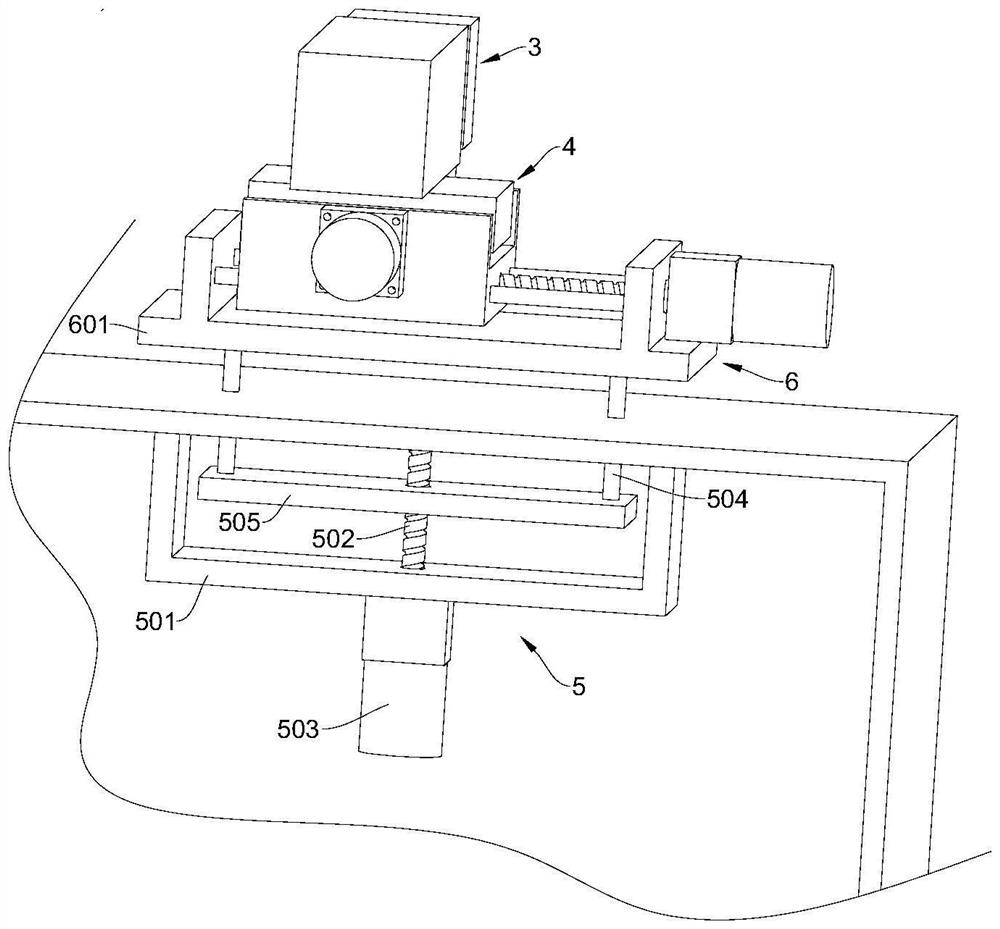

Laser metal layer removing device of metallized film capacitor winding machine

PendingCN114883120AImprove cleanlinessImprove applicabilityMetal surface removal provisionWinding capacitor machinesWinding machineEngineering

The invention relates to the technical field of capacitor manufacturing equipment, and provides a metallized film capacitor winding machine laser metal layer removing device which comprises a winding machine provided with a winding mechanism and at least one unwinding mechanism, and a laser removing device arranged between the winding mechanism and the unwinding mechanism. The device is used for removing a metal layer on the surface of a film in the film winding and unwinding process and comprises a Y-direction adjusting mechanism used for adjusting the position of the laser removing device in the film width direction. And the Z-direction adjusting mechanism is used for adjusting the position of the laser removing device in the film thickness direction. The device can adapt to metalized films with different widths and different thicknesses, and the applicability is improved.

Owner:SICHUAN ZHONGXING ELECTRONICS

Method to increase the specific volume of low-pressure corroded aluminum foil

ActiveCN110085455BImprove the efficiency of surface expansionLarge capacityMetal surface removal provisionPhosphatePhosphoric acid

The invention discloses a method for improving specific volume of a low pressure corrosion aluminum foil. The method comprises steps that (1), the aluminum foil is immersed in aqueous phosphoric acidsolution and washed with the water; (2), the treated aluminum foil is subjected to cloth hole etching in the aqueous solution containing hydrochloric acid, sulfuric acid, aluminum trichloride and an emulsion type polyether-siloxane copolymer silicone foam breaker and washed with the water; (3), the treated aluminum foil is subjected to medium treatment in the aqueous solution of hydrogen phosphateor dihydrogen phosphate and washed with the water; (4), the treated aluminum foil is then subjected to deep growth etching in the aqueous solution containing hydrochloric acid, sulfuric acid, aluminum trichloride and an emulsion type polyether-siloxane copolymer silicone foam breaker and washed with the water; (5), the steps (3) and step (4) are repeated for 3-6 times; (6), the treated aluminum foil is then immersed in the aqueous solution of sulfuric acid and washed with the water, the washed aluminum foil is then immersed in the triethanolamine solution and washed with the water; and (7), the aluminum foil is dried. The method is advantaged in that the specific volume of the low pressure corrosion aluminum foil can be improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD +1

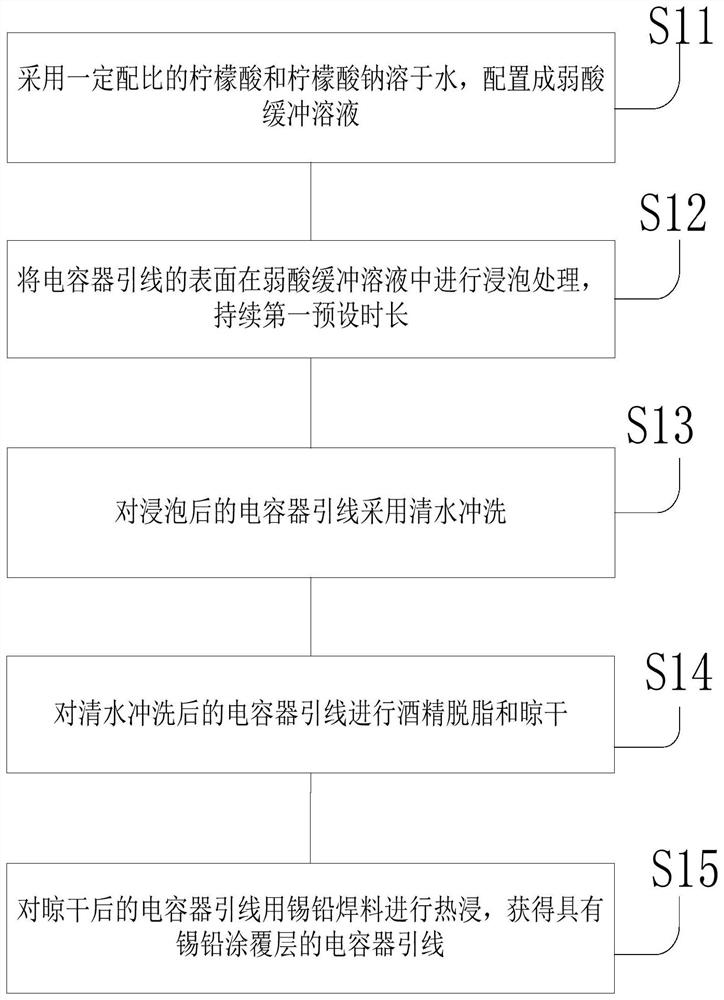

Capacitor lead processing method

PendingCN114156099AEnvironmentally friendlyModerate and effectiveLiquid surface applicatorsFixed capacitor dielectricEngineeringBuffer solution

The invention discloses a capacitor lead processing method which comprises the following steps: dissolving citric acid and sodium citrate in water according to a certain ratio to prepare a weak acid buffer solution; soaking the surface of the capacitor lead in a weak acid buffer solution for a first preset duration; the soaked capacitor lead is washed with clear water; carrying out alcohol degreasing and airing on the capacitor lead washed by the clear water; and carrying out hot dipping on the dried capacitor lead by using the tin-lead solder to obtain the capacitor lead with the tin-lead coating layer. Sodium citrate and citric acid in a certain proportion are dissolved in water, and the prepared weak acid buffer solution can properly and effectively treat an oxide layer on the surface of the lead, so that a new tin-lead coating layer can be coated, good weldability and electric connectivity during use are ensured, and the service life of the lead is prolonged. Meanwhile, compared with inorganic acid, the weak acid buffer solution is more environment-friendly and convenient to treat and recycle.

Owner:北京七星飞行电子有限公司

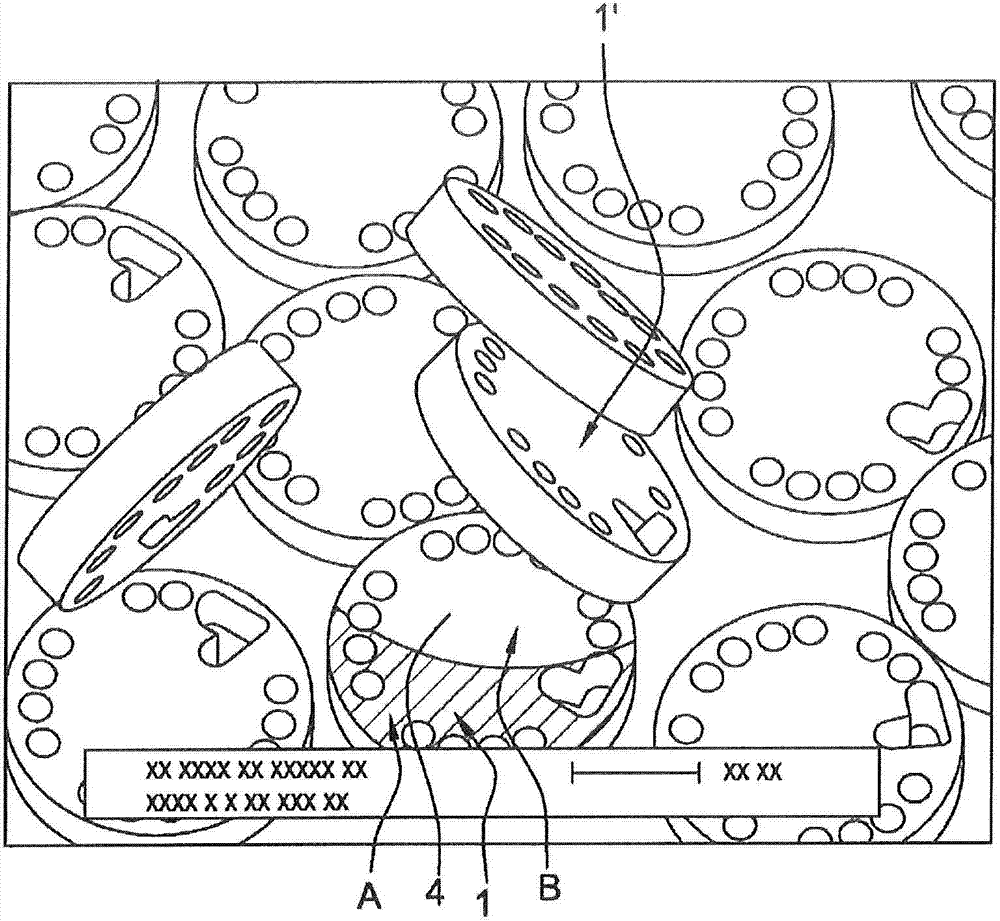

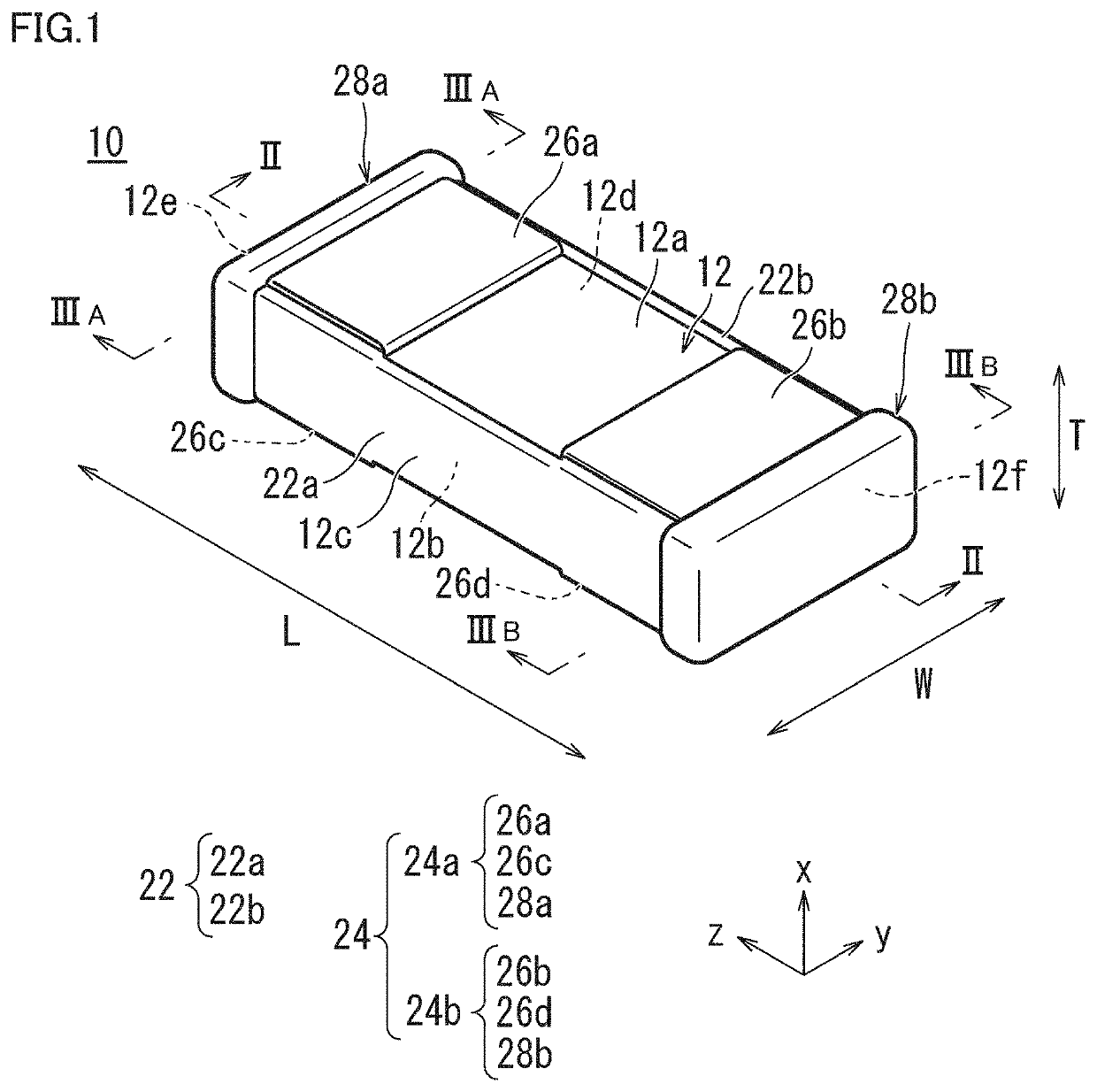

Multilayer ceramic electronic component and method for manufacturing the same

ActiveUS20210090811A1Less likely be damagedLess likely be destroyedFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorElectronic component

A multilayer ceramic electronic component includes a multilayer body including two major surfaces opposite to each other in a layer stacking direction, two side surfaces opposite to each other in a widthwise direction orthogonal or substantially orthogonal to the layer stacking direction, and two end surfaces opposite to each other in a lengthwise direction orthogonal or substantially orthogonal to the layer stacking direction and the widthwise direction, and external electrodes provided on the two end surfaces. A method for manufacturing the multilayer ceramic capacitor component includes preparing a plurality of multilayer bodies, stacking the plurality of multilayer bodies via a binder, rotating the plurality of multilayer bodies by about 90° with the lengthwise direction defining and functioning as an axis of rotation, and providing a side gap portion; and removing the binder from the multilayer body provided with the side gap portion.

Owner:MURATA MFG CO LTD

Chemical formation treatment method for improving water resistance of low pressure chemical formation foil

ActiveCN103258649BExtend your lifeImprove water resistanceElectrolytic capacitorsMetal surface removal provisionO-Phosphoric AcidPhosphate

The invention discloses a chemical conversion treatment method for improving the water resistance of low-pressure chemical formed foil, which comprises dipping the aluminum foil in an aqueous solution of adipate, taking it out and placing it in an aqueous solution of ammonium adipate and adipate, and then Formation, take out and wash with water, then conduct high-temperature heat treatment, then place in the mixed aqueous solution of ammonium adipate and dihydrogen phosphate, perform secondary formation, take out and wash with water, and then treat in phosphoric acid solution at high temperature, then perform high-temperature heat treatment and water washing, Finally, put it in the dihydrogen phosphate aqueous solution, take it out after the tertiary formation, wash it with water, and dry it. The invention has the advantages of obviously improving the water resistance of the product, prolonging the storage time and improving the performance of the capacitor.

Owner:NANTONG HAIXING ELECTRONICS

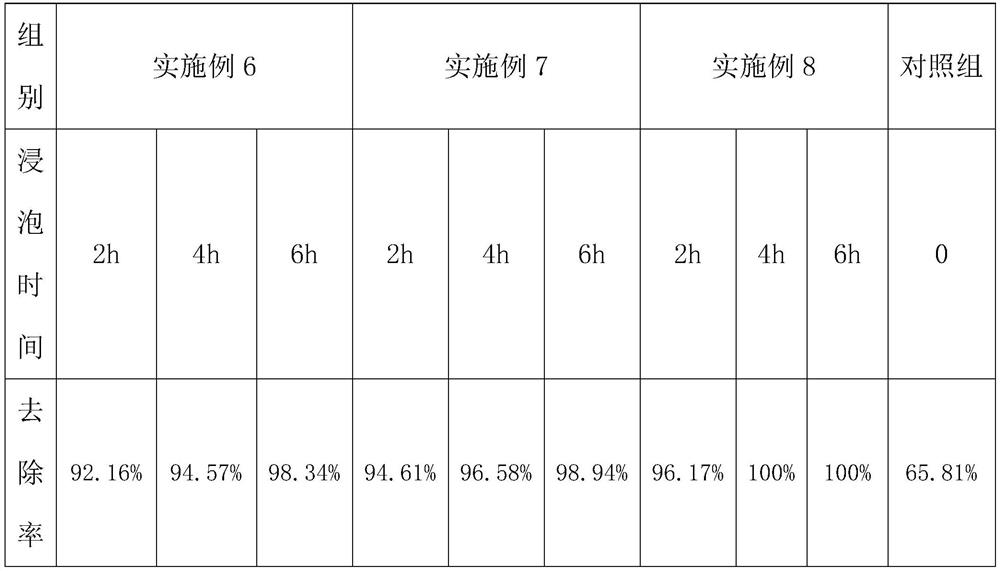

Surface polymer remover of electrode needle for tantalum capacitor and method for removing surface polymer of electrode needle for tantalum capacitor

ActiveCN113990678AQuick peelImprove processing efficiencyElectrolytic capacitorsMetal surface removal provisionTantalum capacitorActive agent

The invention belongs to the technical field of tantalum capacitors, and particularly relates to a method for removing a polymer on the surface of an electrode needle for a tantalum capacitor, which comprises the following steps of: placing the electrode needle of which the surface polymer is to be removed in a soaking tank, adding enough remover into the soaking tank, soaking for 2-6 hours, and naturally airing after soaking; and fixing the naturally air-dried electrode needle on a stepping platform, and demolding the surface of the electrode needle by adopting a laser spot scanning method. The remover comprises the following components in parts by weight: 20-50 parts of a softening agent, 12-26 parts of a surfactant, 24-48 parts of inorganic acid, 2-6 parts of a coupling agent and 4-12 parts of an emulsifier. The defects in the prior art are overcome, the polymer on the surface of the electrode needle is softened through the remover, and then the polymer is removed in a laser spot mode.

Owner:江苏振华新云电子有限公司

Popular searches

Printed circuit manufacture Printed capacitor incorporation Semiconductor devices Multiple fixed capacitors Stacked capacitors Printed circuit aspects Fixed capacitor terminals Printed circuit non-printed electric components association Printed circuit secondary treatment Terminal applying apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com