Processing method for improving water resistance of low-voltage electrode foil, and application

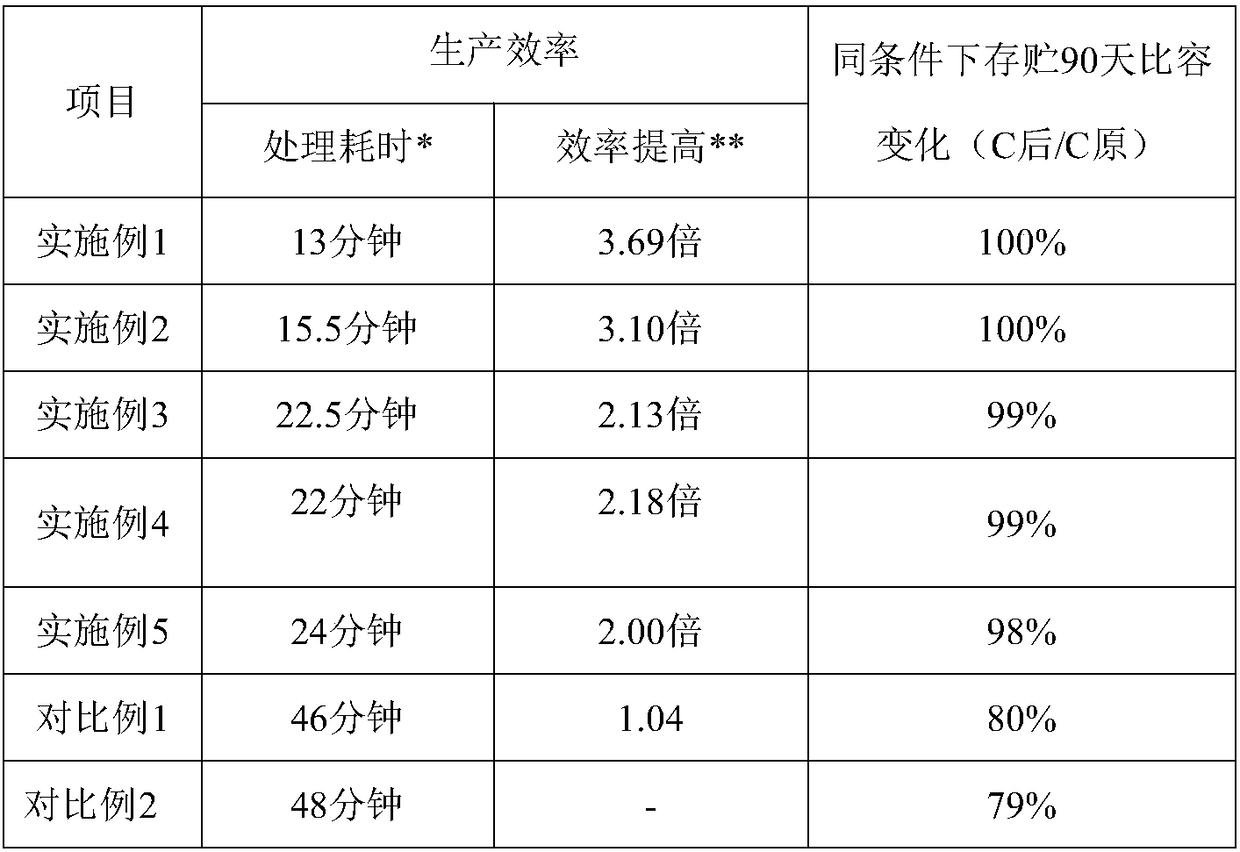

A low-voltage electrode and processing method technology, applied in circuits, capacitors, electrical components, etc., can solve the problems of low production efficiency of low-voltage electrode foils, and achieve the effects of improving water resistance, prolonging storage time and capacitor life, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Take corroded aluminum foil with a purity of 99.9%, place the aluminum foil in an aqueous solution of azelaic acid and sodium azelate with a mass ratio of 1%, at 55°C, and a current density of 50mA / cm 2 1. Under the condition of voltage of 45V, it is formed for 4 minutes, and then taken out for the first water washing;

[0029] 2. Put the aluminum foil after the first water washing into 0.3% propyl titanate aqueous solution by mass ratio, and take it out after immersing at room temperature for 1 minute; place the aluminum foil impregnated in the propyl titanate aqueous solution in In an aqueous solution of azelaic acid and azelaic acid salt with a mass ratio of 0.5%, at 70°C and a current density of 50mA / cm 2 1. Under the condition of voltage of 50V, it is formed for 2 minutes, then taken out and washed with water for the second time;

[0030] 3. Put the aluminum foil washed for the second time into 9% phosphoric acid aqueous solution at a temperature of 30°C for 2 ...

Embodiment 2

[0032] 1. Take the corroded aluminum foil with a purity of 99.9%, and place the aluminum foil in an aqueous solution of azelaic acid and sodium azelate with a mass ratio of 1.5%, at 58°C and a current density of 50mA / cm 2 1. Under the condition of voltage of 47V, it is formed for 7 minutes, and then taken out for the first water washing;

[0033] 2. Put the aluminum foil washed for the first time into 0.5% propyl titanate aqueous solution by mass ratio, soak it at room temperature for 1.5 minutes and then take it out; put the aluminum foil dipped in the propyl titanate aqueous solution in In an aqueous solution of azelaic acid and azelaic acid salt with a mass ratio of 0.8%, at 72°C and a current density of 50mA / cm 2 1. Under the condition of voltage of 51V, it is formed for 2 minutes, then taken out and washed with water for the second time;

[0034] 3. Put the aluminum foil washed for the second time into an aqueous phosphoric acid solution with a mass percentage of 9.2%, c...

Embodiment 3

[0036] 1. Take corroded aluminum foil with a purity of 99.9%, place the aluminum foil in an aqueous solution of azelaic acid and sodium azelate with a mass ratio of 2%, at 60°C, and a current density of 50mA / cm 2 1. Under the condition of voltage of 46V, it is formed for 10 minutes, and then taken out for the first water washing;

[0037] 2. Put the aluminum foil after the first water washing into 1% propyl titanate aqueous solution by mass ratio, and take it out after immersing at room temperature for 1.5 minutes; put the aluminum foil dipped in the propyl titanate aqueous solution in In an aqueous solution of azelaic acid and azelaic acid salt with a mass ratio of 1.0%, at 75°C and a current density of 50mA / cm 2 1. Under the condition of voltage of 52V, it is formed for 3 minutes, and then taken out for the second washing;

[0038] 3. Put the aluminum foil washed for the second time into a phosphoric acid aqueous solution with a mass percentage of 9.5%, passivate it at a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com