Formation Method for Reducing Leakage Current of Medium and High Voltage Formation Foil

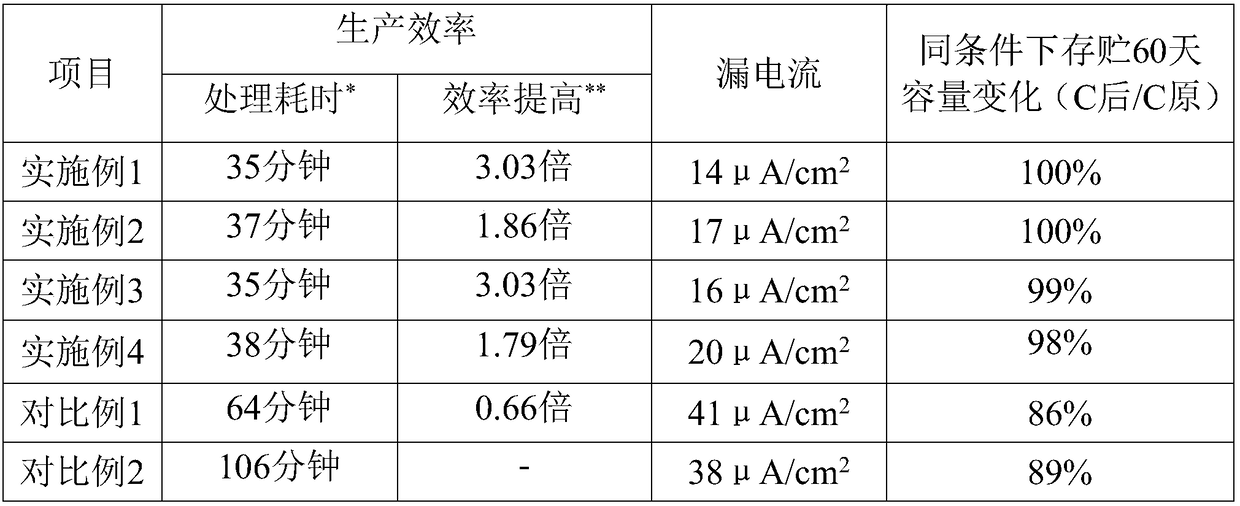

A chemical formation method and foil formation technology, which are applied to circuits, capacitors, electrical components, etc., can solve the problems of large leakage current, low production efficiency, and long time consumption of electrode foils, and achieve reduced leakage current rate, improved production efficiency, and short formation time. The effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take the corroded aluminum foil with a purity of 99.99%, immerse the aluminum foil in water at 85°C for 5 minutes, and then place it in 0.4% sodium azelate aqueous solution with a mass percentage of 0.4%, at 78°C, the current density is 40mA / cm 2 1. Under the condition of a voltage of 150V, the first stage is formed for 5 minutes, and the first water washing is taken out. Place the aluminum foil after washing once in a 1.5% aqueous solution of sodium azelate at 82°C with a current density of 40mA / cm 2 1. Under the condition of the voltage of 310V, the second stage is formed for 4 minutes, and then taken out and washed with water for the second time. Place the aluminum foil after the secondary water washing in 0.8% by mass percent sodium azelate aqueous solution, at 80°C, the current density is 40mA / cm 2 1. Under the condition of 450V voltage, the three-stage formation takes 5 minutes. The aluminum foil after the tertiary chemical synthesis was placed in 0.7% 3,5-dihyd...

Embodiment 2

[0029] Take corroded aluminum foil with a purity of 99.99%, immerse the aluminum foil in water at 88°C for 5 minutes, then place it in 1.5% aqueous solution of sodium azelate by mass, at 77°C, the current density is 40mA / cm 2 , Under the condition of a voltage of 150V, the first stage was formed for 4 minutes, and the first water washing was taken out; the aluminum foil after the first water washing was placed in an aqueous solution of sodium azelate with a mass percentage of 1.8%, at 83°C, and the current density was 40mA / cm 2 , Under the condition of a voltage of 310V, the secondary formation was carried out for 6 minutes, and the second water washing was taken out; the aluminum foil after the second water washing was placed in an aqueous solution of 0.8% by mass of sodium azelate, at 77°C, the current density was 40mA / cm 2 , Under the condition of voltage of 450V, the three-stage chemical conversion was carried out for 6 minutes; the aluminum foil after the three-stage che...

Embodiment 3

[0031] Take the corroded aluminum foil with a purity of 99.99%, immerse the aluminum foil in 82°C water for 6 minutes, then place it in a 2% sodium azelate aqueous solution by mass, at 80°C, the current density is 40mA / cm 2 , Under the condition of a voltage of 150V, the first stage is formed for 4 minutes, and the first washing is taken out; the aluminum foil after the first washing is placed in a 1.2% aqueous solution of sodium azelate at 81°C, and the current density is 40mA / cm 2 , Under the condition of a voltage of 310V, the secondary formation was carried out for 4 minutes, and the second water washing was taken out; the aluminum foil after the second water washing was placed in an aqueous solution of sodium azelate with a mass percentage of 1.3%, at 80°C, the current density was 40mA / cm 2 , Under the condition of a voltage of 450V, the three-stage chemical reaction was performed for 4 minutes; the aluminum foil after the three-stage chemical reaction was placed in 0.7%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com