Patents

Literature

71 results about "Strontium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The chemical formula for strontium phosphate is Sr3(PO4)2. The formula indicates that a single molecule of strontium phosphate contains three atoms of strontium, symbolized by Sr, two atoms of phosphorus, represented by P, and eight atoms of oxygen, indicated by the elemental symbol O.

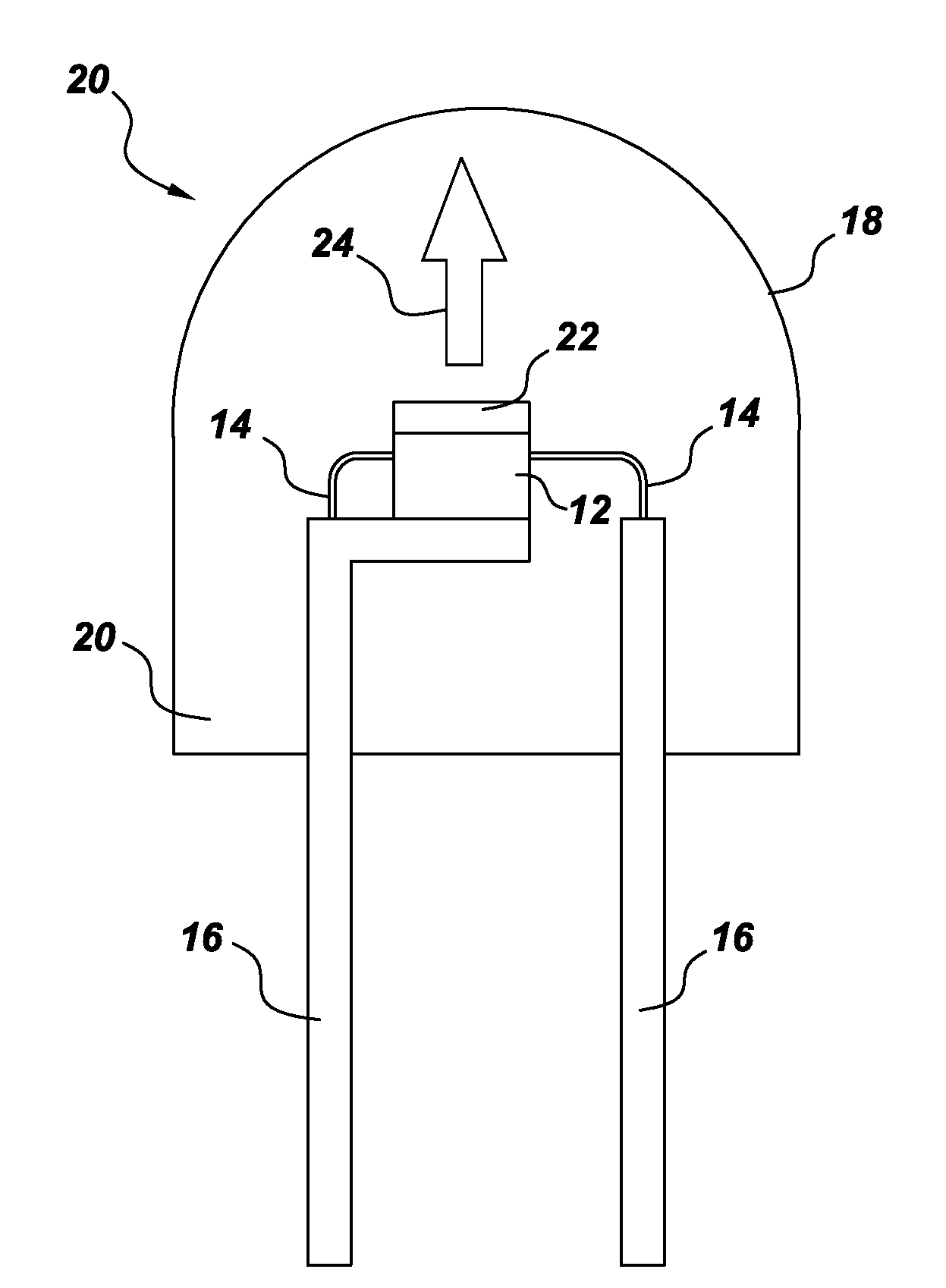

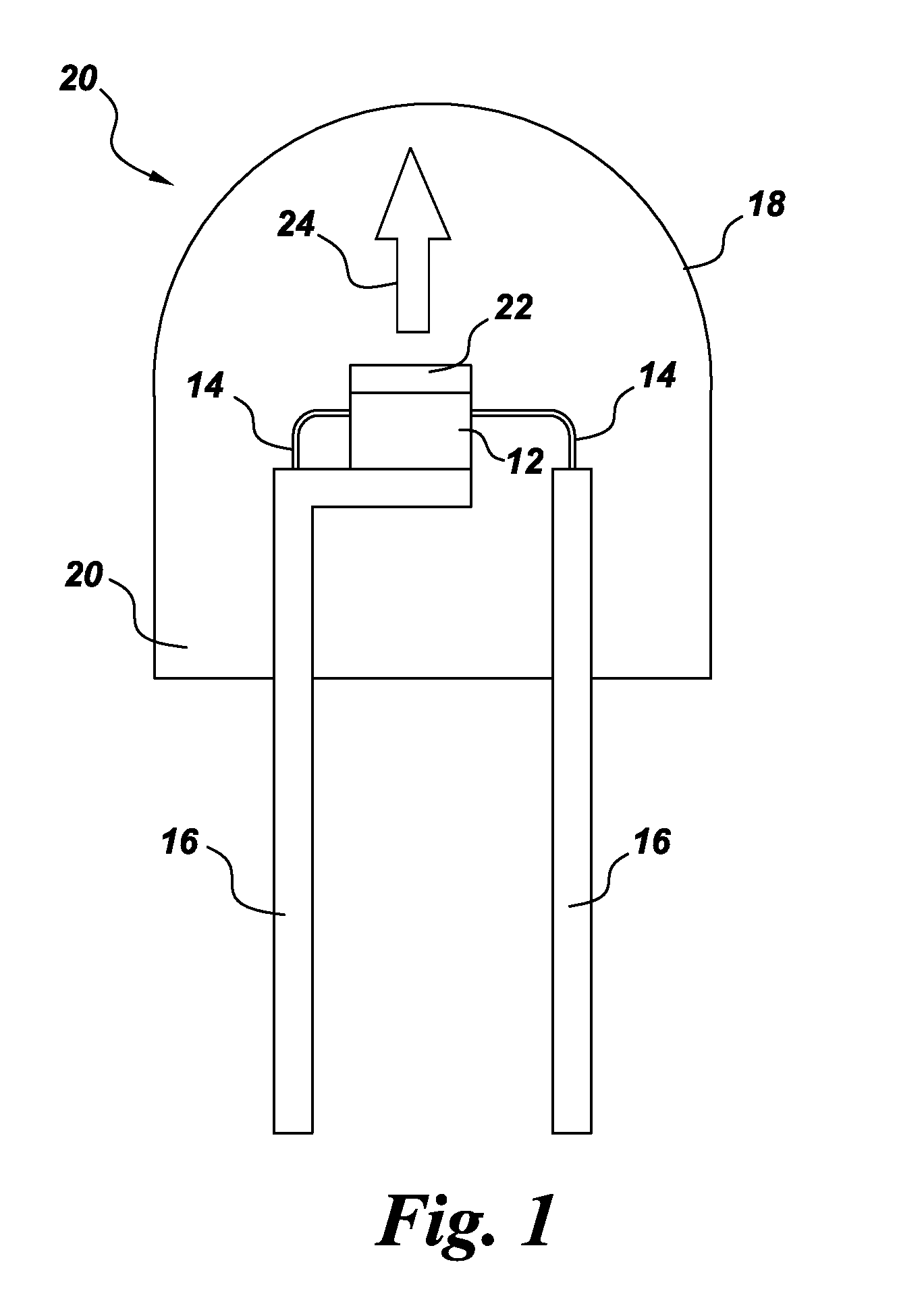

Color stable phosphors

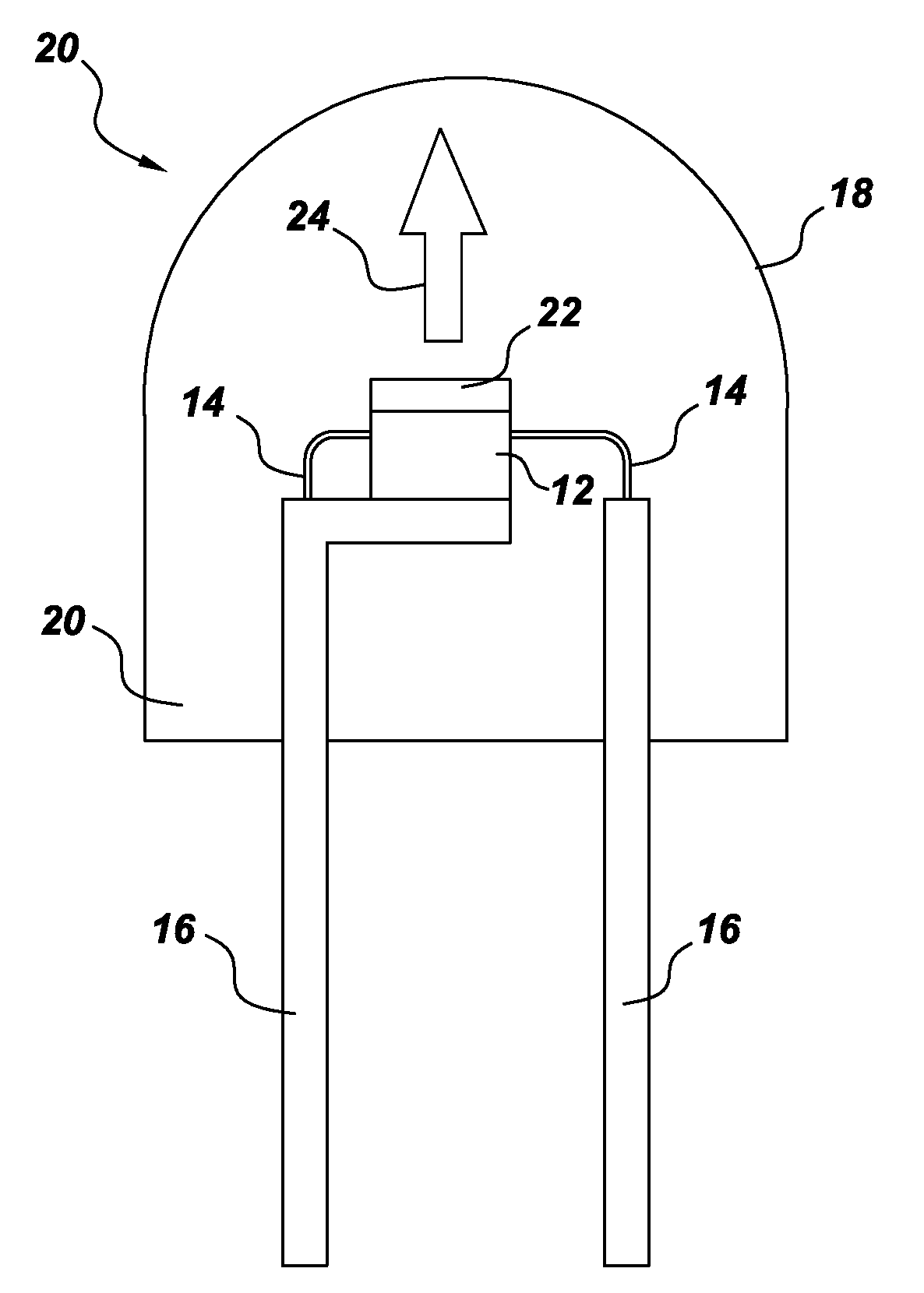

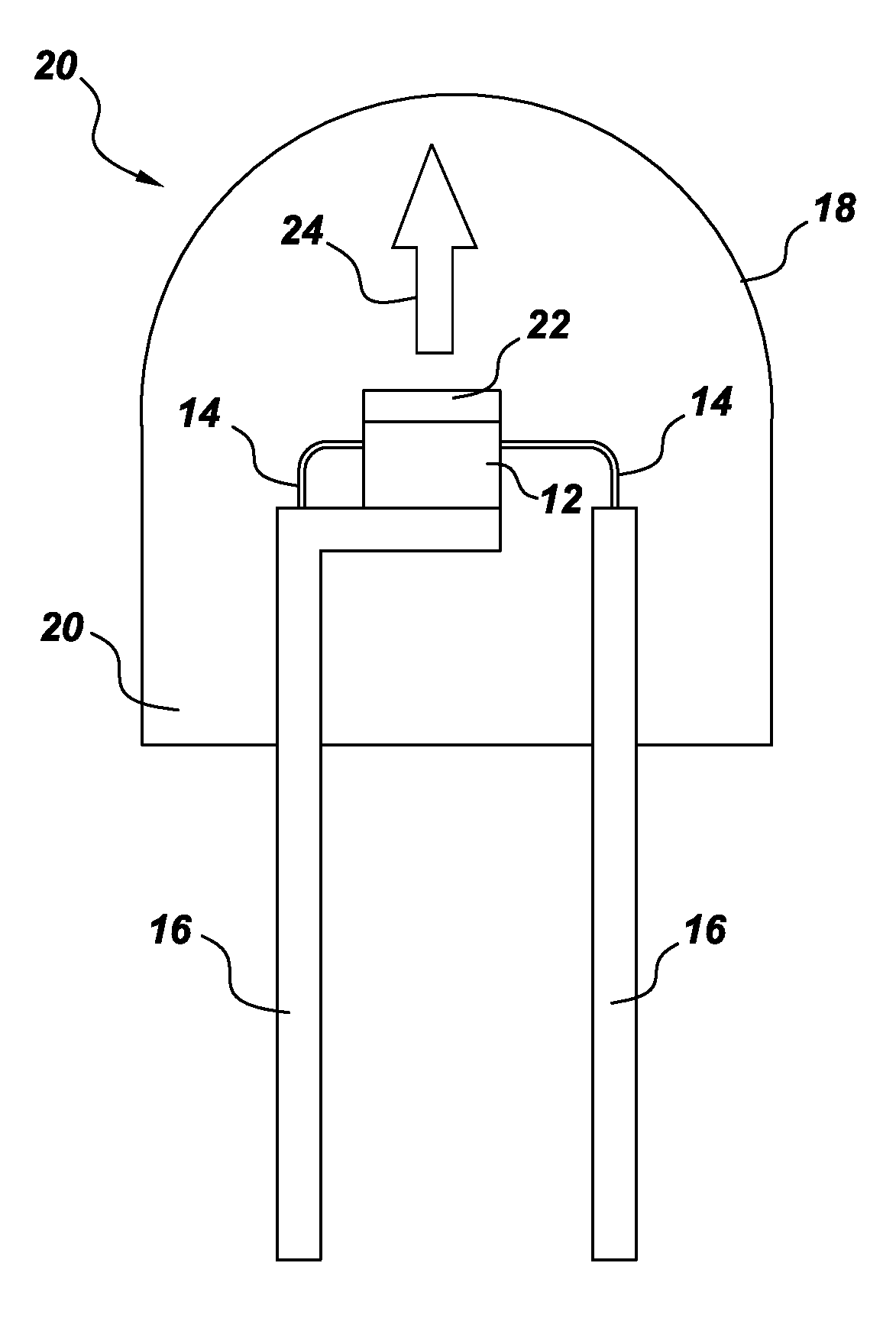

ActiveUS20110279011A1Discharge tube luminescnet screensLamp detailsZinc hydroxideMagnesium phosphate

An LED lamp includes a light source configured to emit radiation with a peak intensity at a wavelength between about 250 nm and about 550 nm; and a phosphor composition configured to be radiationally coupled to the light source. The phosphor composition includes particles of a phosphor of formula I, said particles having a coating composition disposed on surfaces thereof;((Sr1−zMz)1−(x+w)AwCex)3(Al1−ySiy)O4+y+3(x−w)F1−y−3(x−w) Iwherein the coating composition comprises a material selected from aluminum oxide, magnesium oxide, calcium oxide, barium oxide, strontium oxide, zinc oxide, aluminum hydroxide, magnesium hydroxide, calcium hydroxide, barium hydroxide, strontium hydroxide, zinc hydroxide, aluminum phosphate, magnesium phosphate, calcium phosphate, barium phosphate, strontium phosphate, and combinations thereof; andA is Li, Na, K, or Rb, or a combination thereof;M is Ca, Ba, Mg, Zn, or a combination thereof; and0<x≦0.10, 0≦y≦0.5, 0≦z≦0.5, 0≦x≦x.

Owner:GE LIGHTING SOLUTIONS LLC

Degradable biphase ceramics bone frame with high-strength and phosphate cement containing strontium and the preparing method

InactiveCN101041087AMeet the requirements for growthImprove pore structureBone implantSlurryCompressive strength

The invention discloses a high-strength degradable strontium phosphate dual-phase ceramic bone skeleton and relative preparation, wherein the initial material is calciprivia fermorite bone cement, whose solid phase powder is the mixture of Ca4(PO4)2O, SrHPO4, CaHPO4, and the liquid phase is 0.1mol / L-1mol / L H3PO4 water solution. The invention uses skeleton structure to controllably quickly print and shape RP optical sensitive resin as concave mold, to irrigate slurry, solidify, and thermally remove mold and following sinter to obtain the strontium phosphate dual-phase ceramic bone support with adjustable phases. The total porous rate of skeleton is 42.5-75%, the size of macro hole is 300mum-600mum, the volume of macro hole is 0-50%, the size of micro hole is 2-10mum, and the compression strength is 3.15MPa-21.53MPa, with wide application.

Owner:XI AN JIAOTONG UNIV

High strength and tenacity degradable strontium calcium superphosphate composite bone cement and its preparation method

The invention discloses a high tensile degradable strontium phosphate calcium composite bone cement for repairing or intensifying fixation of human body holding bone defect and preparation method thereof. The solid material of bone cement is mixed powder of Ca4(PO4)2O ceramic with high crystallinity, SrHPO4, CaHPO4, curing liquid is thin phosphoric acid water solution, additive plasticizing unit is biocompatibility degradable macomolecule fiber with high tensile strength, selecting from lactic acid - hydroxyacetic acid copolymer fibre, polylatic acid fiber or polyglycolic acid fiber or other absorbable surgical suture, the enhancing unit is Ca4(PO4)2O residual ceramic particles after curing reaction. The preparation method coalesces kinds of techniques of ceramic particles in-situ reinforcing, initial plasticizing and later stage degradation of degradable fiber, Sr modification to get a novel high tensile degradable strontium phosphate calcium composite bone cement in like physiologic environment. The material has good biocompatibility, bioactivity, bone conductivity and degradation property.

Owner:XI AN JIAOTONG UNIV

Preparation method of bionic mineralized collagen scaffold

The invention provides a preparation method of a bionic mineralized collagen scaffold. The preparation method comprises the following steps: 1), preparing a bionic mineralized liquid: adjusting the pHvalue of carboxymethyl chitosan-amorphous calcium phosphate (or amorphous strontium phosphate or amorphous strontium carbonate) nanocomposite liquid to be lower than an isoelectric point of CMC; 2),preparing the bionic mineralized collagen scaffold: mixing the bionic mineralized liquid and acid-dissolved type-I collagen, then putting into a dialysis bag, sealing, then putting into a PBS buffer liquid, self-assembling and mineralizing for 2-5 days, then adding an alkaline CMC / ACP (ASP or ASC) liquid into the dialysis bag, and changing the PBS buffer liquid; 1-3 days later, putting the dialysis bag into deionized water for dialyzing for 10-72h, changing the deionized water for several times, centrifuging the liquid in the bag to obtain collagen gel, and performing freeze drying to obtain the bionic mineralized collagen scaffold. By the preparation method, collagen self-assembly and mineralization are cooperatively performed, intra-collagen fiber mineralization is achieved at relativelyhigh efficiency, and osteogenic ability-promoting strontium is integrated into the collagen scaffold, so that the preparation method has a wide clinical application prospect.

Owner:博纳格科技(天津)有限公司

Preparation process of degradable foam-like strontium-doped calcium phosphate ceramic bone holder material

The present invention discloses the preparation process of bone tissue engineering rack material of degradable foamed Sr-doped calcium phosphate ceramic. It is prepared through bone cement copying foam structure process, and the Sr-doped apatite bone cement slurry as material includes solid phase particles of Ca4(PO4)2, CaPO4 and SrPO4 in certain molar ratio and liquid phase of 0.5-1.0 mol / L H3PO4 aqua in the solid / liquid ratio of 1.5-3.0. Polyurethane foam template is adopted. The final product is mixture of Sr-doped apatite and tricalcium strontium phosphate or the mixture of tricalcium strontium phosphate and calcium strontium pyrophosphate, and its component phase contents may be controlled through regulating the molar ratio of materials, solid / liquid ratio and phosphoric acid concentration so as to control the material degrading rate.

Owner:XI AN JIAOTONG UNIV

Color stable phosphors for LED lamps and methods for preparing them

ActiveUS8593062B2Discharge tube luminescnet screensElectroluminescent light sourcesZinc hydroxideMagnesium phosphate

An LED lamp includes a light source configured to emit radiation with a peak intensity at a wavelength between about 250 nm and about 550 nm; and a phosphor composition configured to be radiationally coupled to the light source. The phosphor composition includes particles of a phosphor of formula I, said particles having a coating composition disposed on surfaces thereof;((Sr1-zMz)1-(x+w)AwCex)3(Al1-ySiy)O4+y+3(x−w)F1-y-3(x−w) Iwherein the coating composition comprises a material selected from aluminum oxide, magnesium oxide, calcium oxide, barium oxide, strontium oxide, zinc oxide, aluminum hydroxide, magnesium hydroxide, calcium hydroxide, barium hydroxide, strontium hydroxide, zinc hydroxide, aluminum phosphate, magnesium phosphate, calcium phosphate, barium phosphate, strontium phosphate, and combinations thereof; andA is Li, Na, K, or Rb, or a combination thereof;M is Ca, Ba, Mg, Zn, or a combination thereof; and0<x≦0.10, 0≦y≦0.5, 0≦z≦0.5, 0≦x≦x.

Owner:GE LIGHTING SOLUTIONS LLC

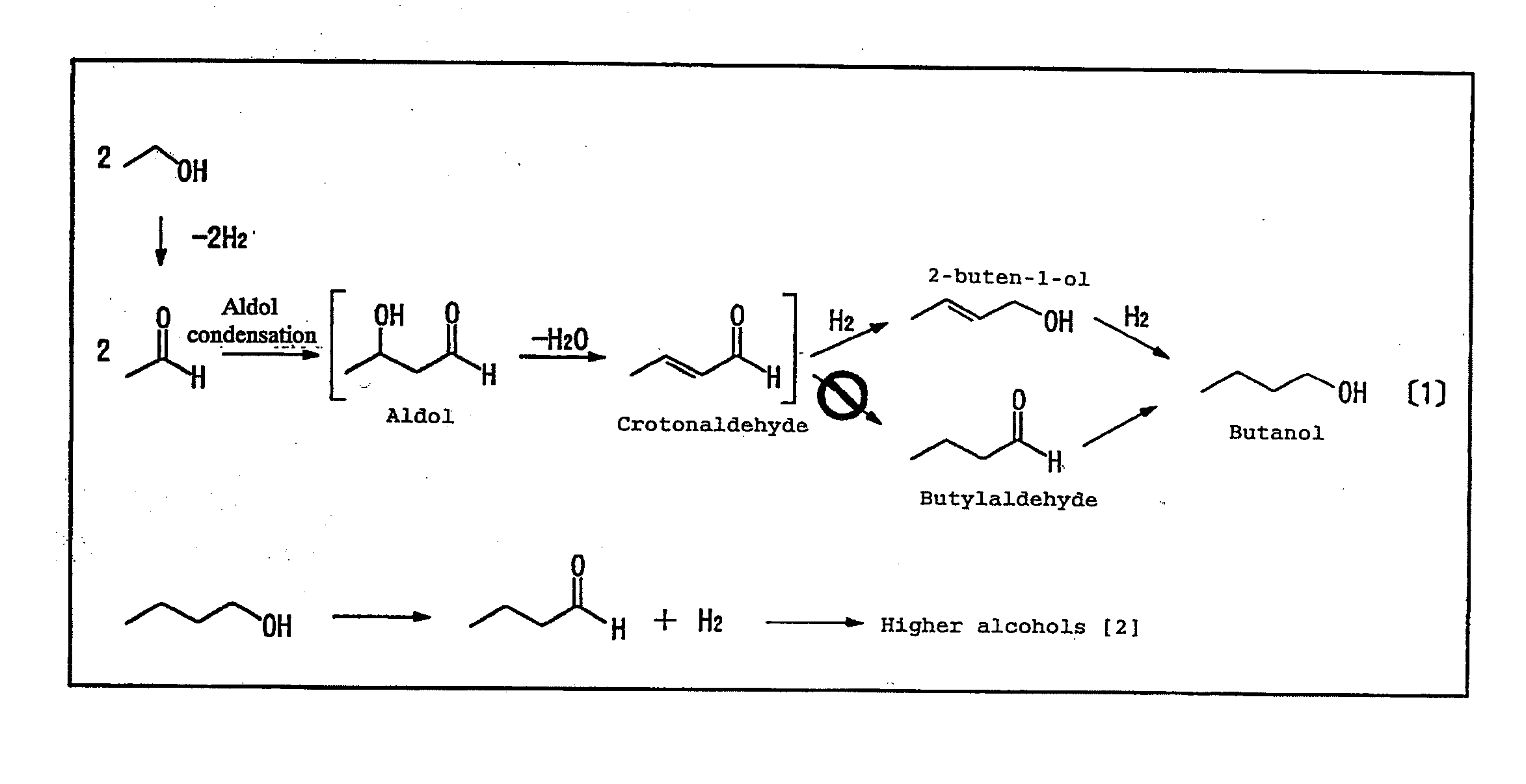

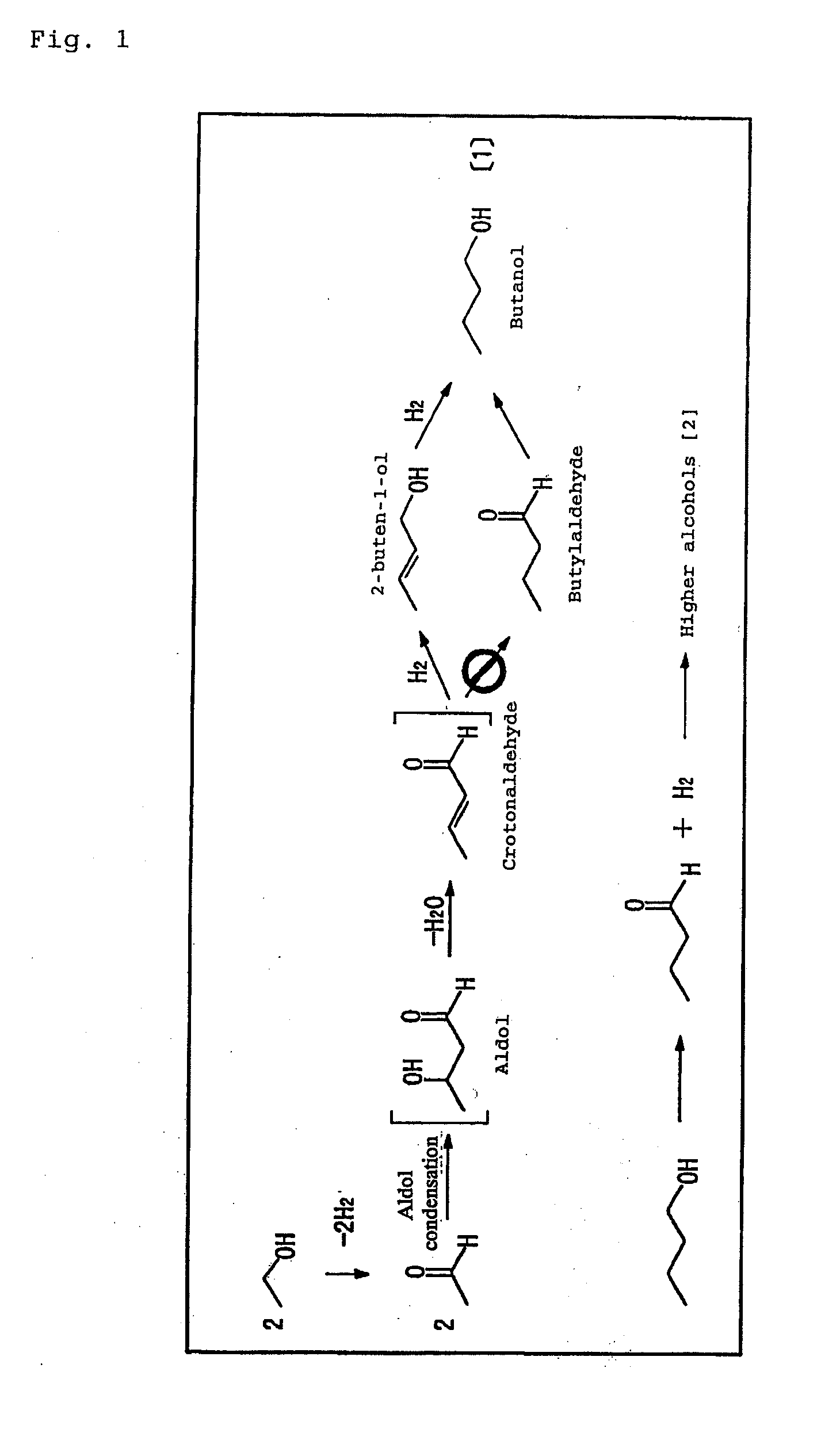

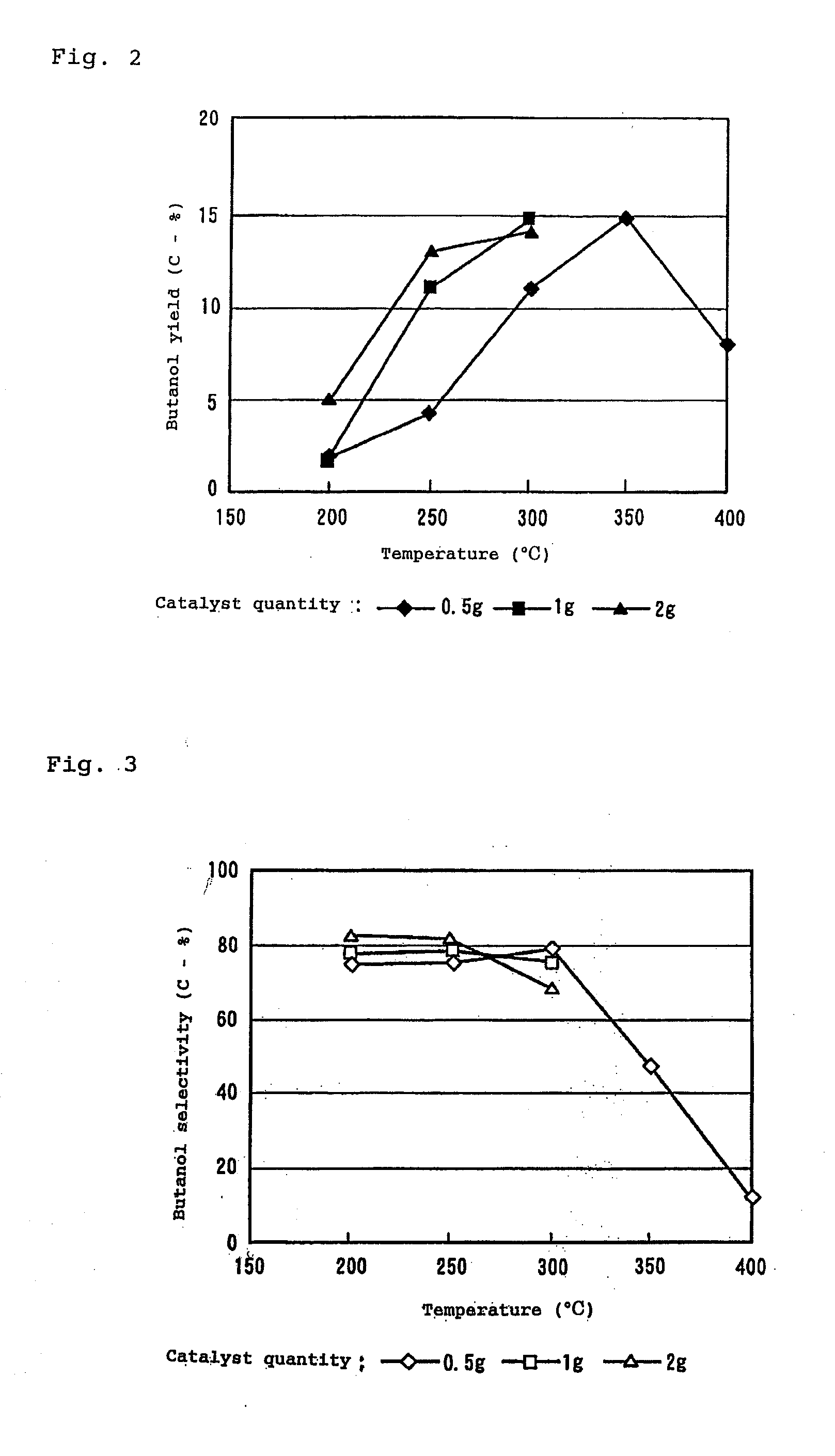

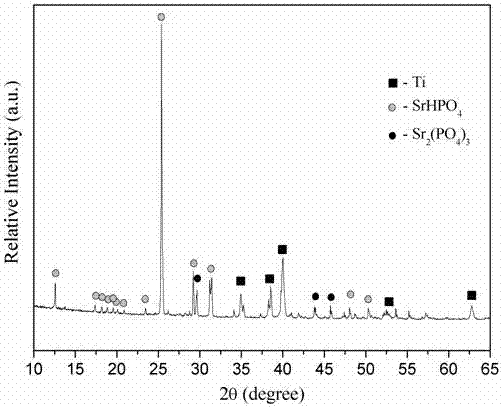

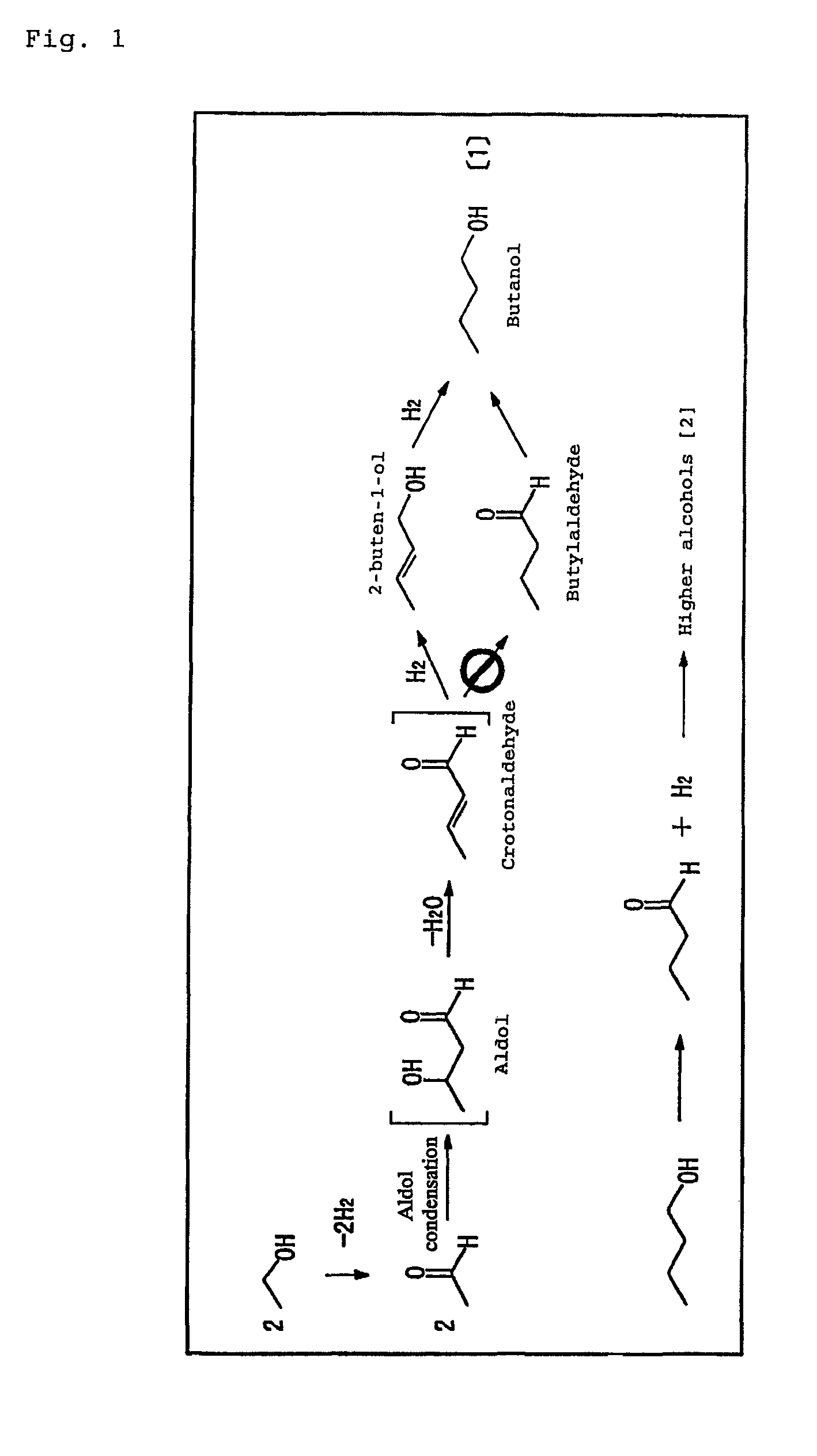

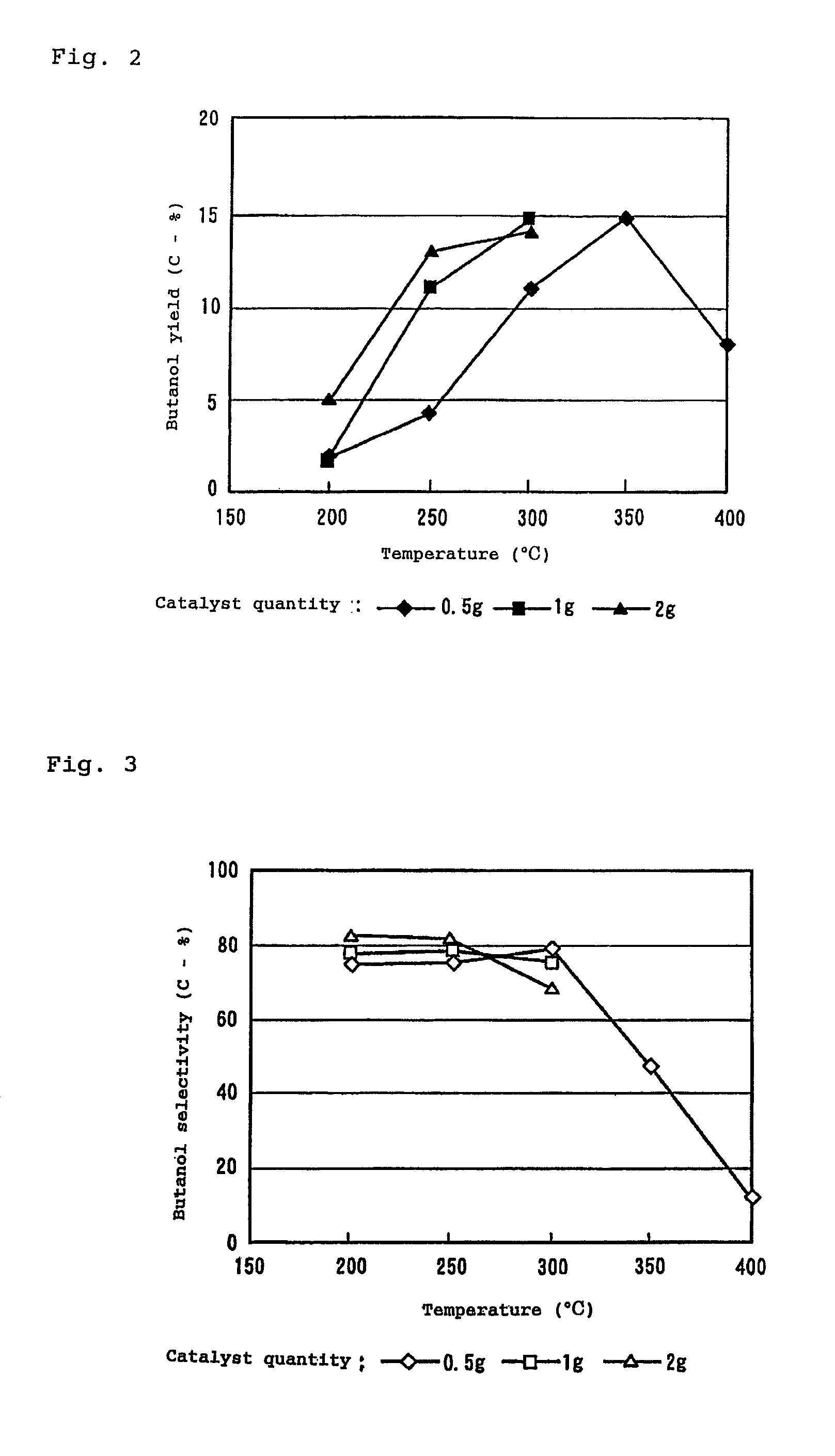

Catalyst And Alcohol Synthesis Method

ActiveUS20110190553A1High selectivityOxygen-containing compound preparationPhosphatesAlcoholSynthesis methods

The present invention is intended to provide a catalyst which is for synthesizing butanol from ethanol at a high selectivity and which comprises strontium phosphate apatite having the Sr / P atomic ratio of 1.5-2.0, and the synthesis method.

Owner:NAT UNIV CORP KOCHI UNIV +1

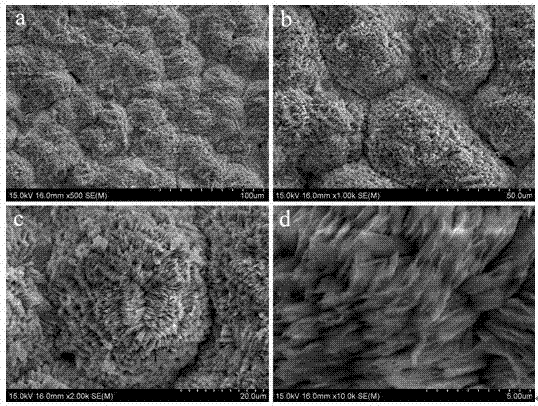

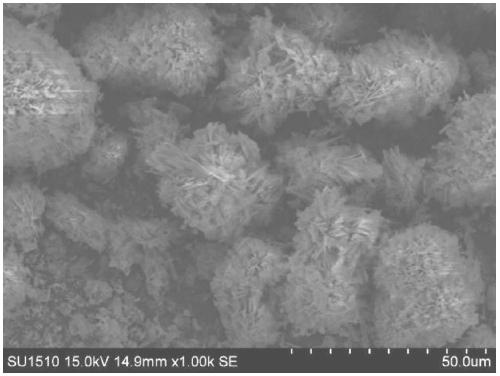

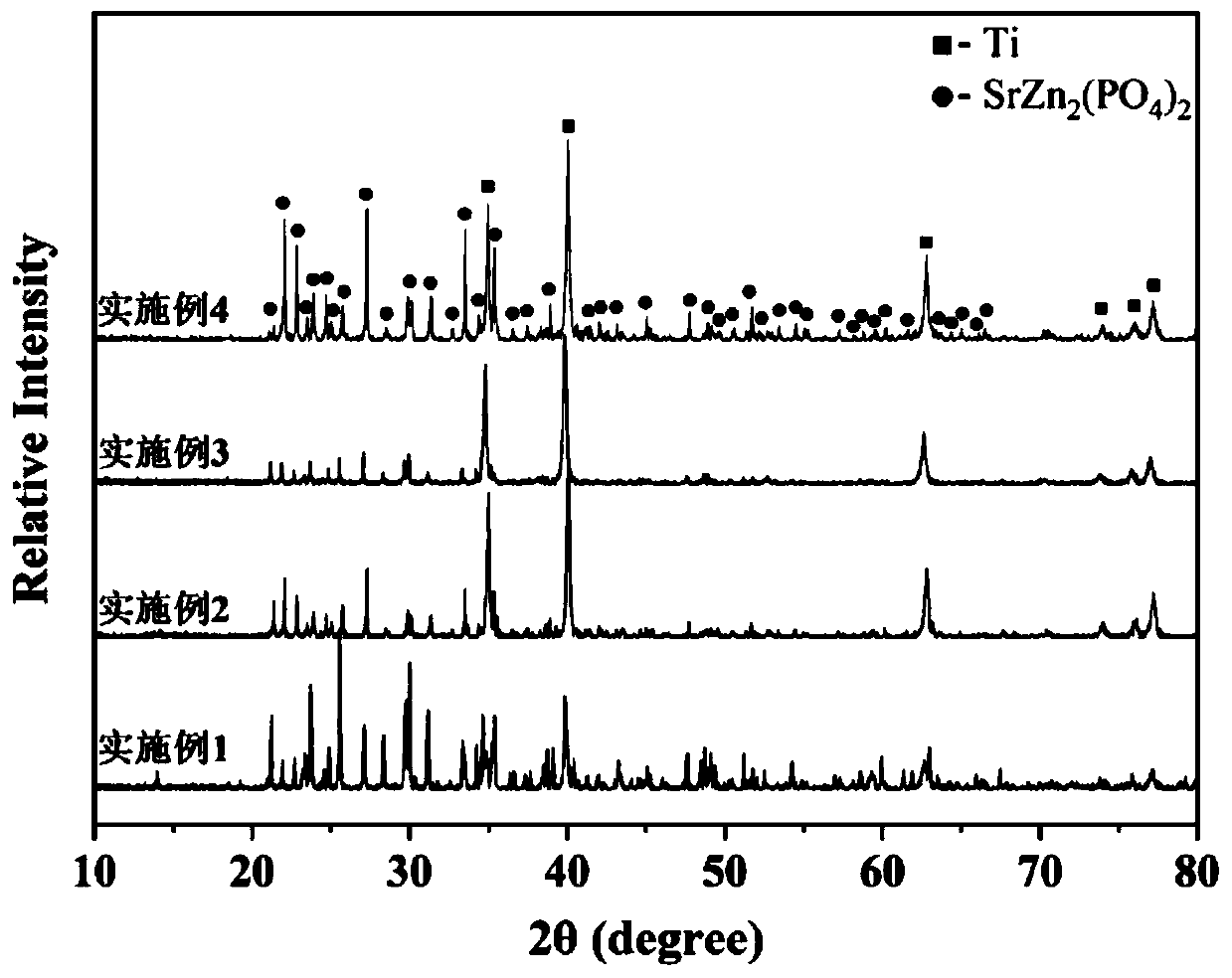

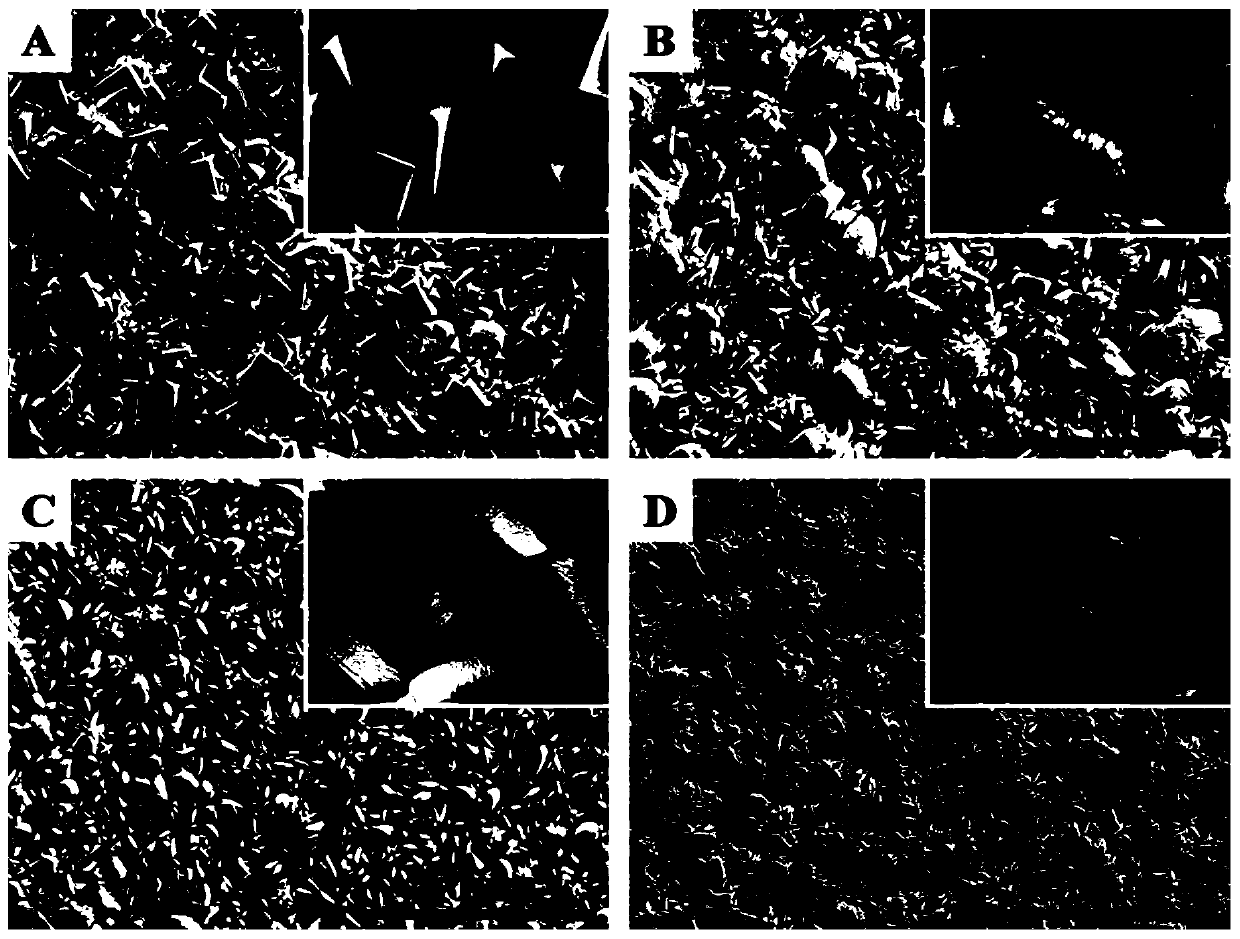

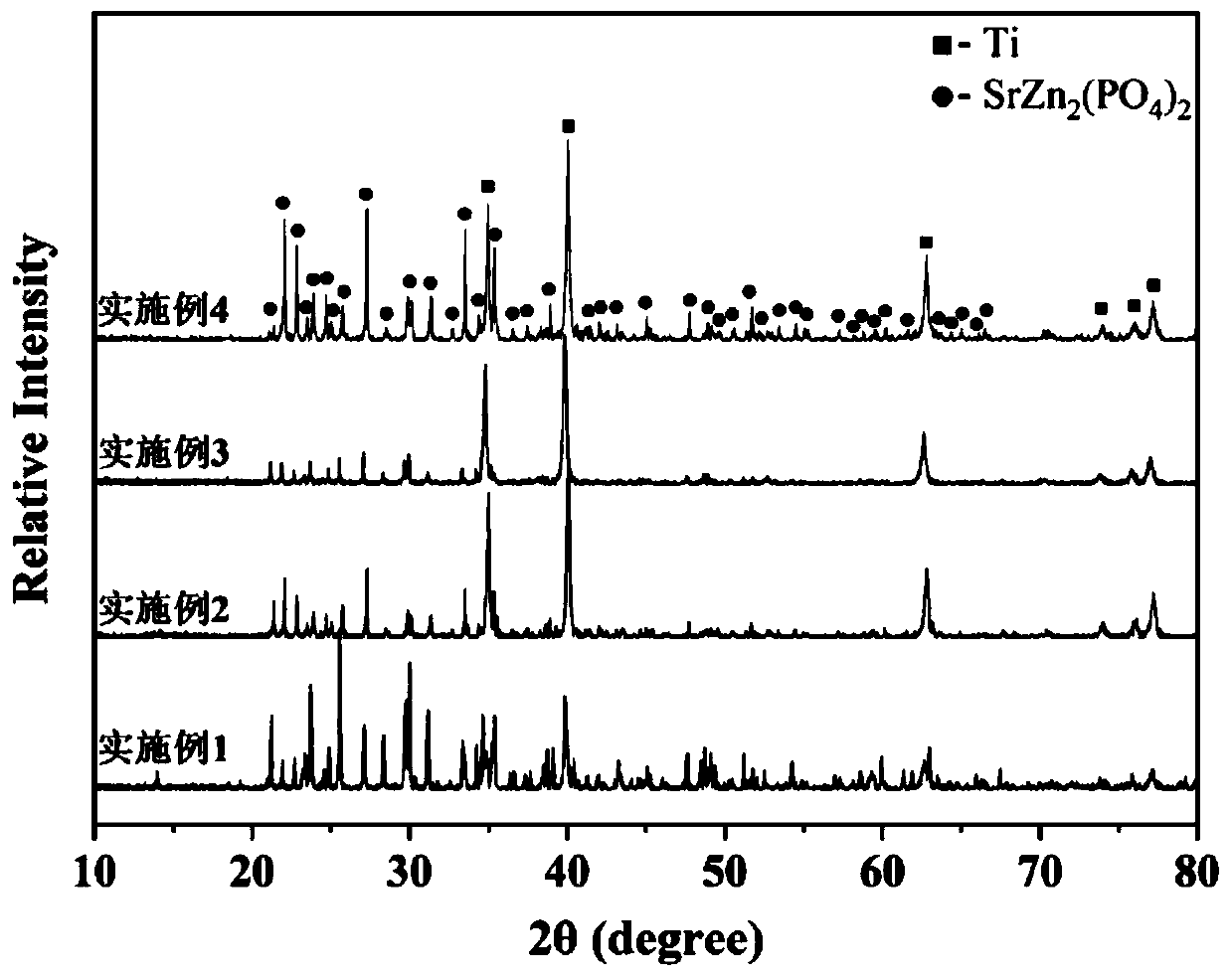

Preparation method of strontium-containing phosphate bioactivity conversion coating on titanium surface

InactiveCN107338425ASimple preparation processNo pollution in the processLiquid/solution decomposition chemical coatingProsthesisPhosphate ionTitanium alloy

The invention relates to a preparation method of a strontium-containing phosphate bioactivity conversion coating on a titanium surface. According to the method, the strontium-containing phosphate bioactivity conversion coating with micron and nanoscale crystal structures grows on titanium and titanium alloy surfaces in situ directly by means of a phosphate chemical conversion technology. The method comprises the following steps: preparing a chemical conversion basic liquid containing phosphate ions, strontium ions and an accelerant; successively performing pickling, washing and surface activating on the surface of a titanium matrix; and immersing the treated titanium matrix in the chemical conversion basic liquid for chemical conversion treatment, wherein the conversion temperature is 55-75 DEG C and the conversion time is 20-50min. The strontium-containing phosphate bioactivity conversion coating on the titanium surface prepared by the method is in a porous multilayered micron and nanoscale crystal structure shape. The coating is primarily composed of strontium monophosphate strontium phosphate phases. The coating can effectively accelerate deposition of a hydroxyapatite phase in immersion in an in vitro simulation fluid.

Owner:SUZHOU RES INST SHANDONG UNIV

Catalyst and alcohol synthesis method

ActiveUS8232433B2High selectivityOxygen-containing compound preparationOrganic compound preparationSynthesis methodsApatite

The present invention is intended to provide a catalyst which is for synthesizing butanol from ethanol at a high selectivity and which comprises strontium phosphate apatite having the Sr / P atomic ratio of 1.5-2.0, and the synthesis method.

Owner:NAT UNIV CORP KOCHI UNIV +1

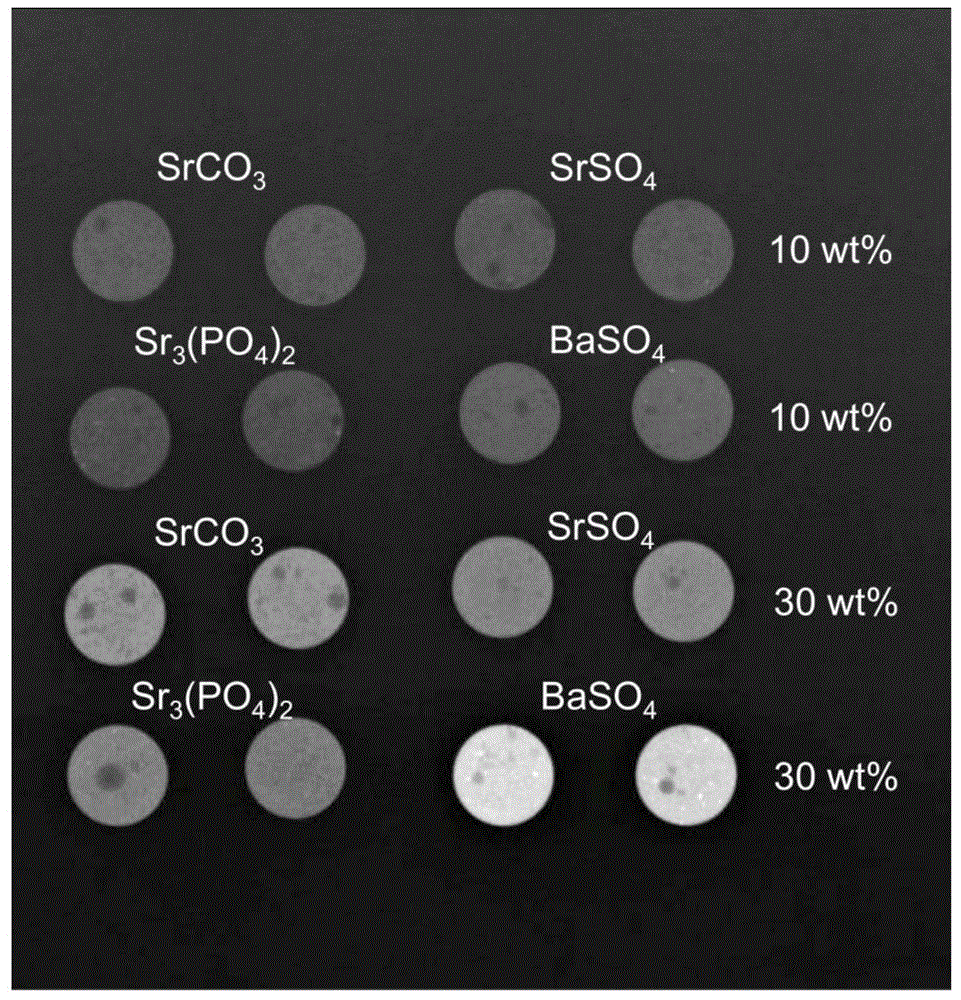

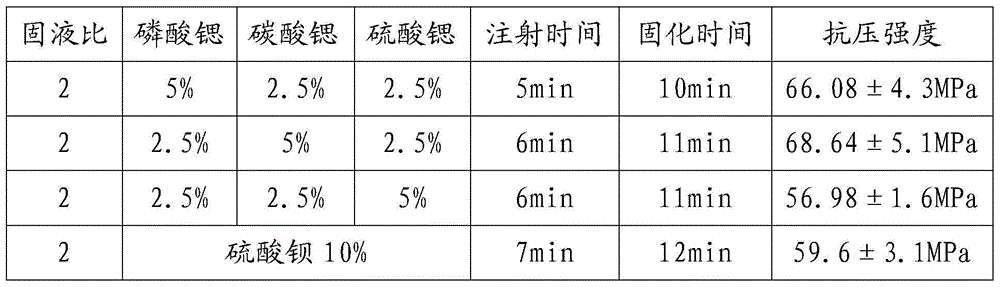

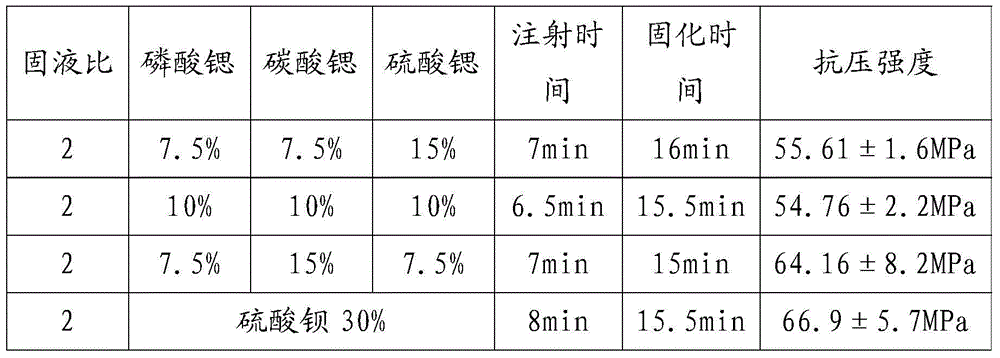

Development bone cement and its preparation method and use

The invention discloses development bone cement and its preparation method and use. The development bone cement comprises powder and a liquid. The powder comprises polymethyl methacrylate (PMMA), a developer and benzoyl peroxide. The liquid comprises a methyl methacrylate (MMA) monomer as a main component. The developer is a strontium salt. The strontium salt is one of strontium phosphate, strontium sulfate and strontium carbonate. A mass ratio of the developer to the bone cement powder is in a range of 10%-30%. The development bone cement can be used for fixing of fracture caused by osteoporosis and bone defect filling.

Owner:山东明德生物医学工程有限公司

Photothermographic materials containing phosphors and methods of using same

InactiveUS20050233269A1Low costHigh sensitivityX-ray/infra-red processesRadiation applicationsOrganic solventPhosphor

Photothermographic materials contain an X-radiation-sensitive phosphor that emits in the range of from about 100 to about 410 nm. The X-radiation-sensitive phosphor is a rare earth phosphate, a yttrium phosphate, a strontium phosphate or a strontium fluoroborate. These photothermographic materials can be provides out of organic solvent or aqueous solvent coating formulations.

Owner:CARESTREAM HEALTH INC

Heat insulated environmental protection glass

An environment protection type thermal insulating glass contains SiO2, barium phosphate, strontium phosphate, calcium phosphate, magnesium phosphate, beryllium phosphate, lead phosphate and iron phosphate. Its advantages are low water-soluble loss, high resistance to acetic acid, high stability and good effect to adsorb infrared ray and isolate harmful ray and heat.

Owner:CENTURY ZHONGBANG SCI TECH TRADE BEIJING

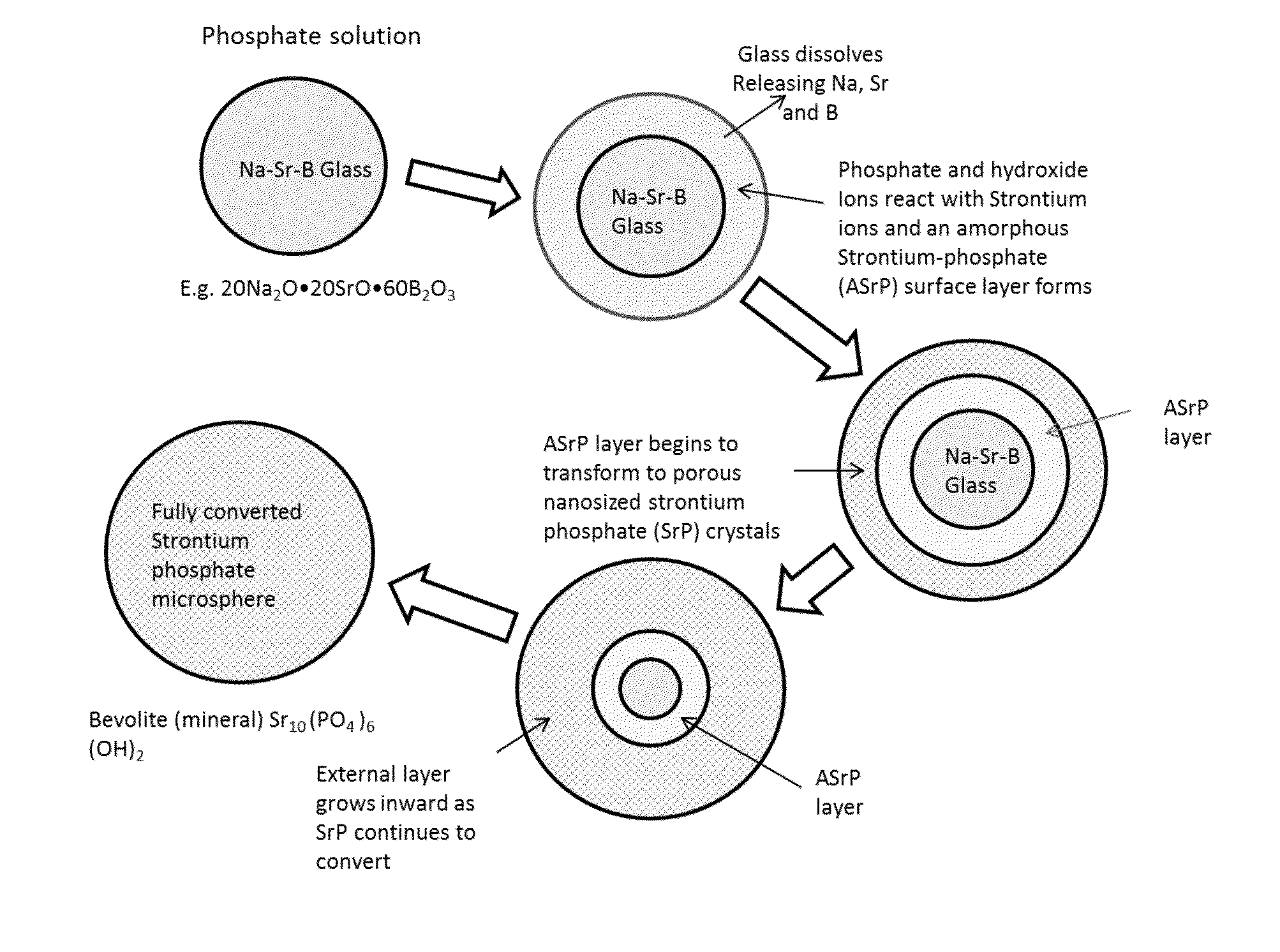

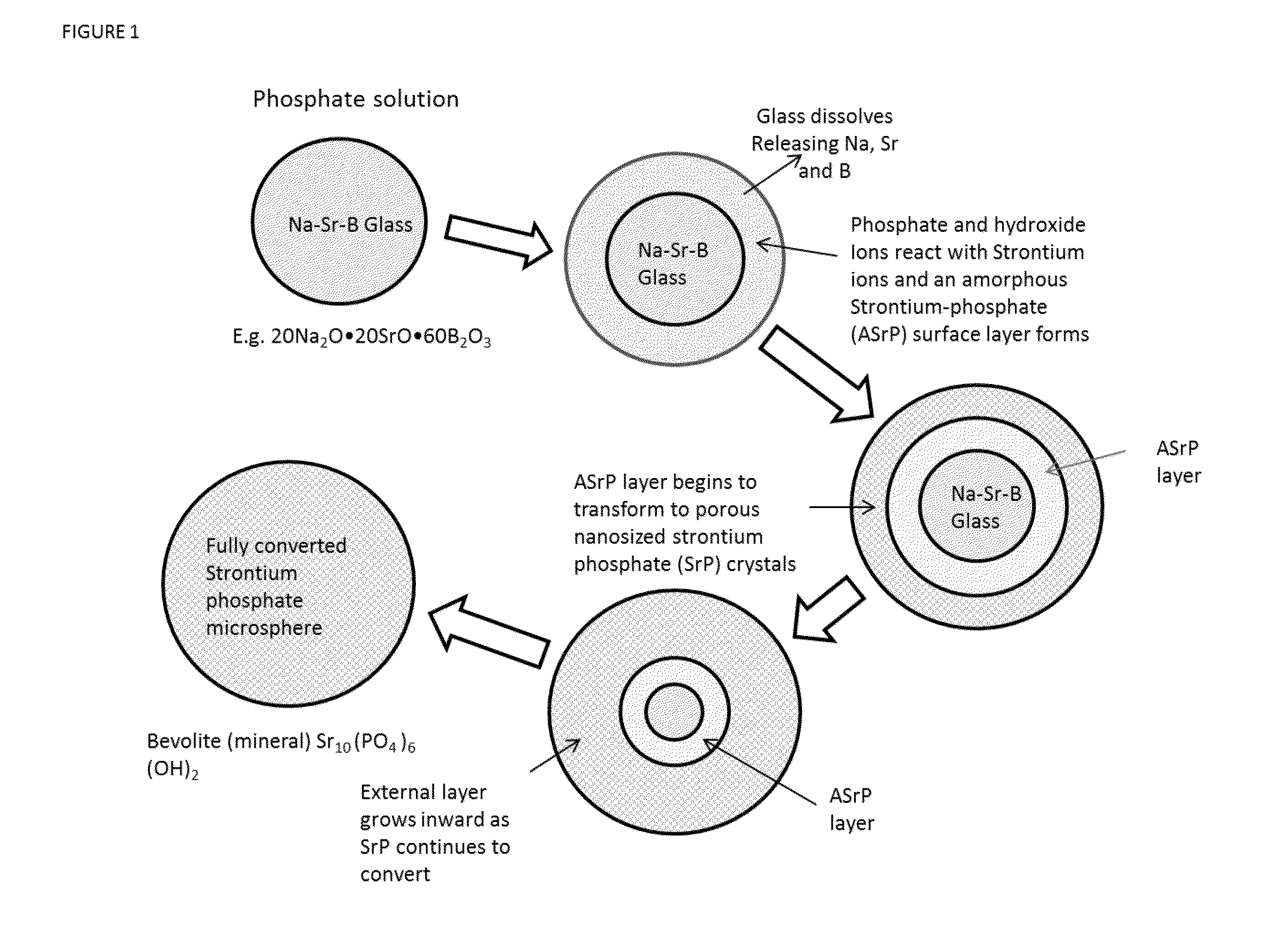

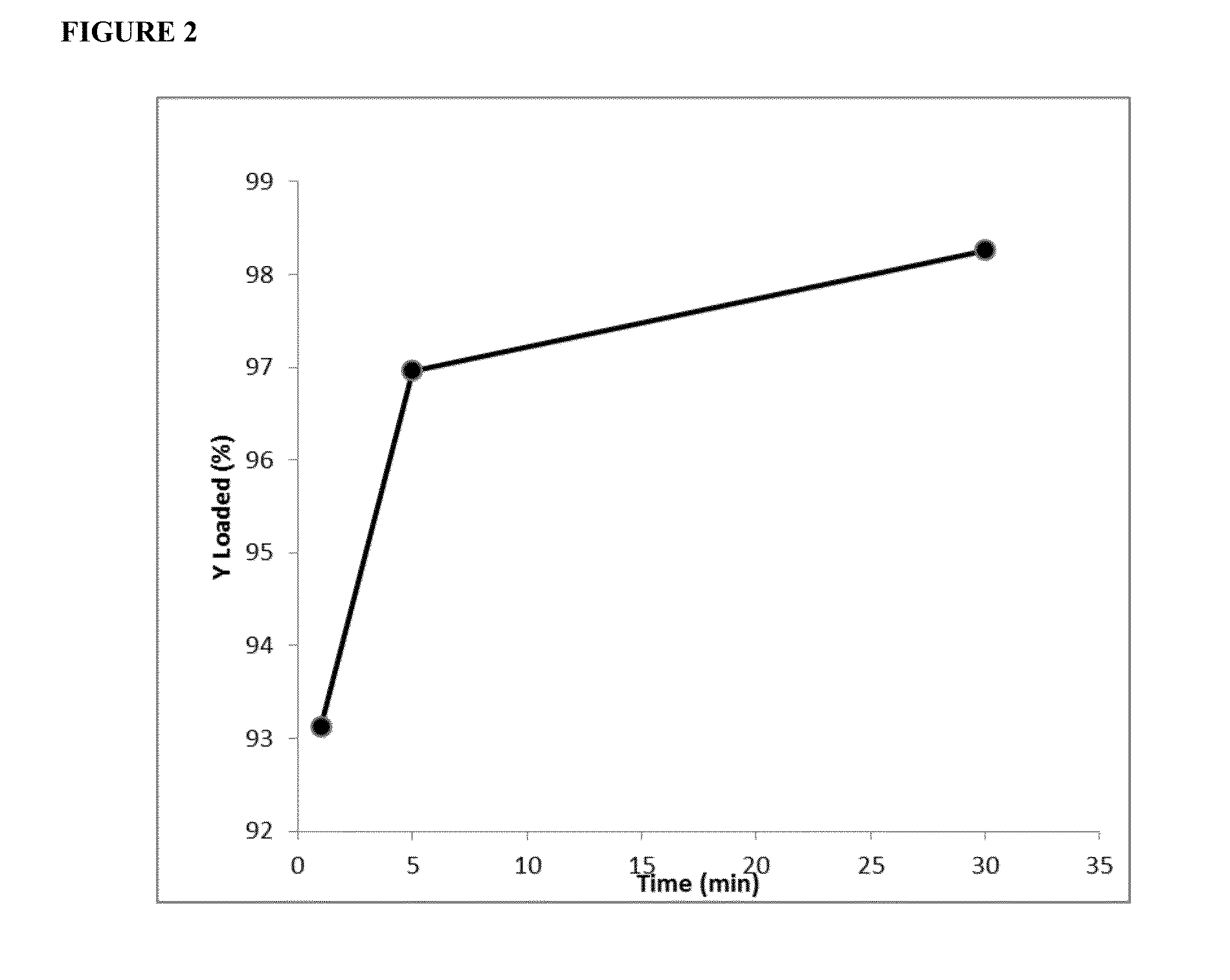

Strontium phosphate microparticle for radiological imaging and therapy

ActiveUS20150118495A1Short half-lifeRapid quenchingPowder deliveryTransuranic element compoundsRadio isotopesMicroparticle

Owner:MO SCI

Photothermographic materials containing phosphors and methods of using same

InactiveUS7074549B2High sensitivityLower levelX-ray/infra-red processesRadiation applicationsOrganic solventPhysical chemistry

Photothermographic materials contain an X-radiation-sensitive phosphor that emits in the range of from about 100 to about 410 nm. The X-radiation-sensitive phosphor is a rare earth phosphate, a yttrium phosphate, a strontium phosphate or a strontium fluoroborate. These photothermographic materials can be provides out of organic solvent or aqueous solvent coating formulations.

Owner:CARESTREAM HEALTH INC

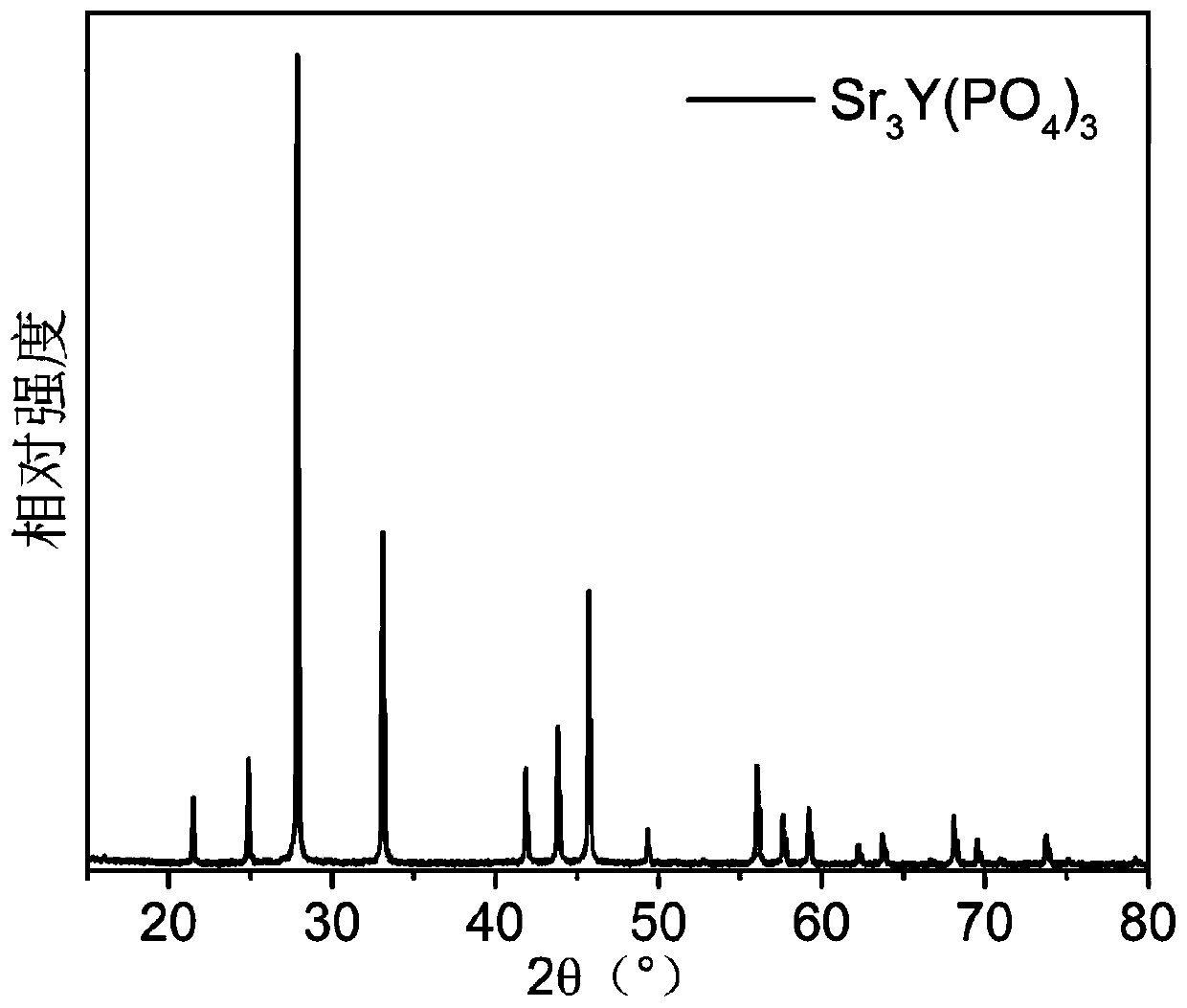

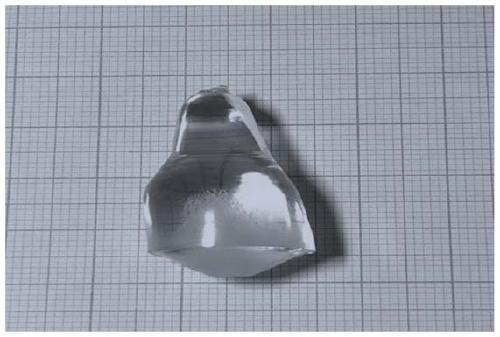

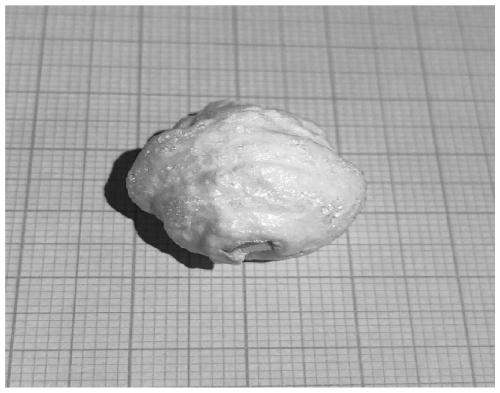

Yttrium strontium phosphate crystal as well as preparation method and application thereof

ActiveCN110079861AMeet the requirements of high optical qualityGuaranteed growth qualityPolycrystalline material growthBy pulling from meltSingle crystal growthStrontium phosphate

The invention relates to an yttrium strontium phosphate crystal as well as a preparation method and an application thereof. The chemical formula of the yttrium strontium phosphate crystal is Sr3Y(PO4)3, and the crystal is of an asymmetric structure and belongs to a cubic crystal system-43 m point group. The preparation method of the yttrium strontium phosphate crystal comprises the following steps: strontium yttrium phosphate polycrystalline materials are synthesized, and a homogeneously melted solution of yttrium strontium phosphate is obtained after heating and melting; an iridium bar or anyttrium strontium phosphate crystal is used as a seed crystal, so that the bottom end of the seed crystal is in close contact with the homogeneously melted solution of yttrium strontium phosphate; anda czochralski method is used for single crystal growth, and the temperature of the single crystal growth is 1700-1850 DEG C. The melting point of the yttrium strontium phosphate crystal is higher than 1800 DEG C, no phase transition from room temperature to the melting point exists, the chemical properties are stable, and no deliquescence exists, so that the yttrium strontium phosphate has significant application advantages in the high temperature piezoelectric and wide temperature nonlinear optical fields.

Owner:SHANDONG UNIV

Functionalized nano biological ceramic coating and preparation process thereof

InactiveCN106581769AHigh bonding strengthGood biocompatibilityTissue regenerationCoatingsFiberOsteoblast

The invention discloses a functionalized nano biological ceramic coating and a preparation process thereof. The functionalized nano biological ceramic coating is prepared from the following components: tricalcium phosphate, chromium sulfate, strontium fluorapatite, aluminum chloride, sodium metatitantate, ammonium molybdate, silica gel, chitosan fibers, carbon molecular sieve-220, carboxymethyl chitin, polyhydroxybutyric acid, acetylglutamic acid, tartaric acid, cellulose acetate, 3-acrylamide dopamine, methyl salicylate, eucalyptol, urea, span-80 and distilled water. The biological ceramic coating provided by the invention is significantly high in bonding intensity with an implant, and the maximum bearing load of the biological ceramic coating reaches 105-127N or above, so that a demand on the mechanical performance of the coating of the implant is satisfied; and in addition, the coating is excellent in biocompatibility, and the coating is capable of promoting the adhesion and growth of osteoblast, accelerating repair and healing rates and shortening a healing cycle.

Owner:苏州纳贝通环境科技有限公司

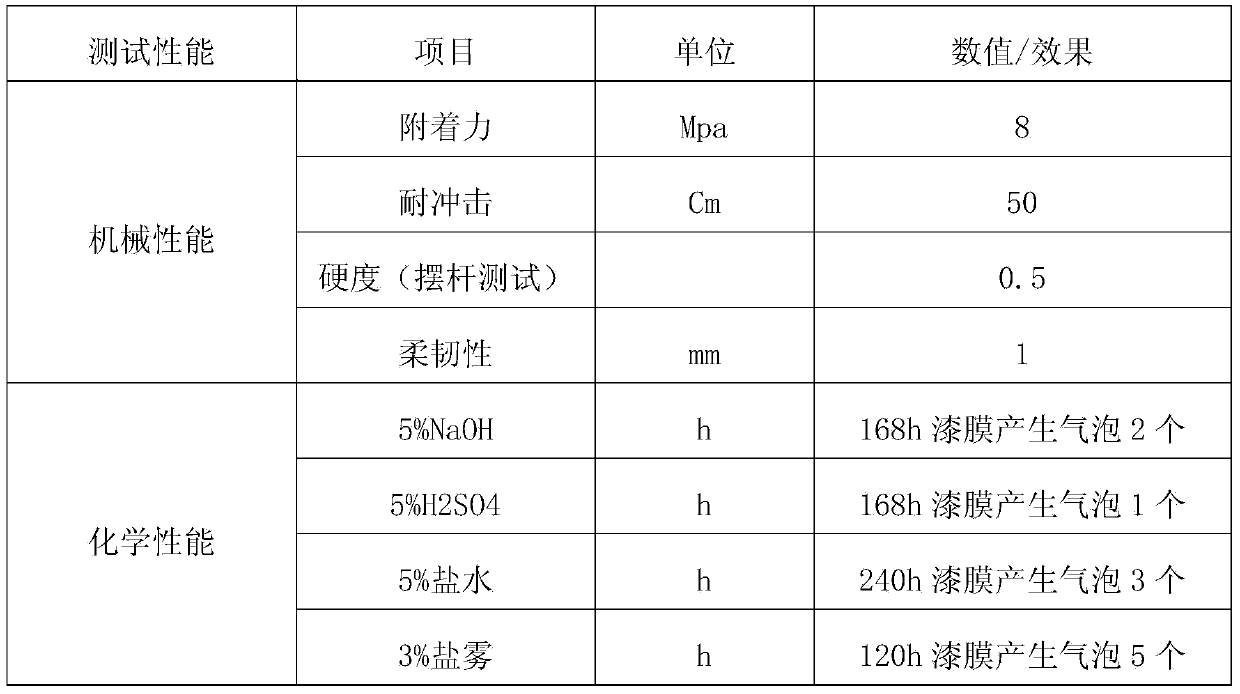

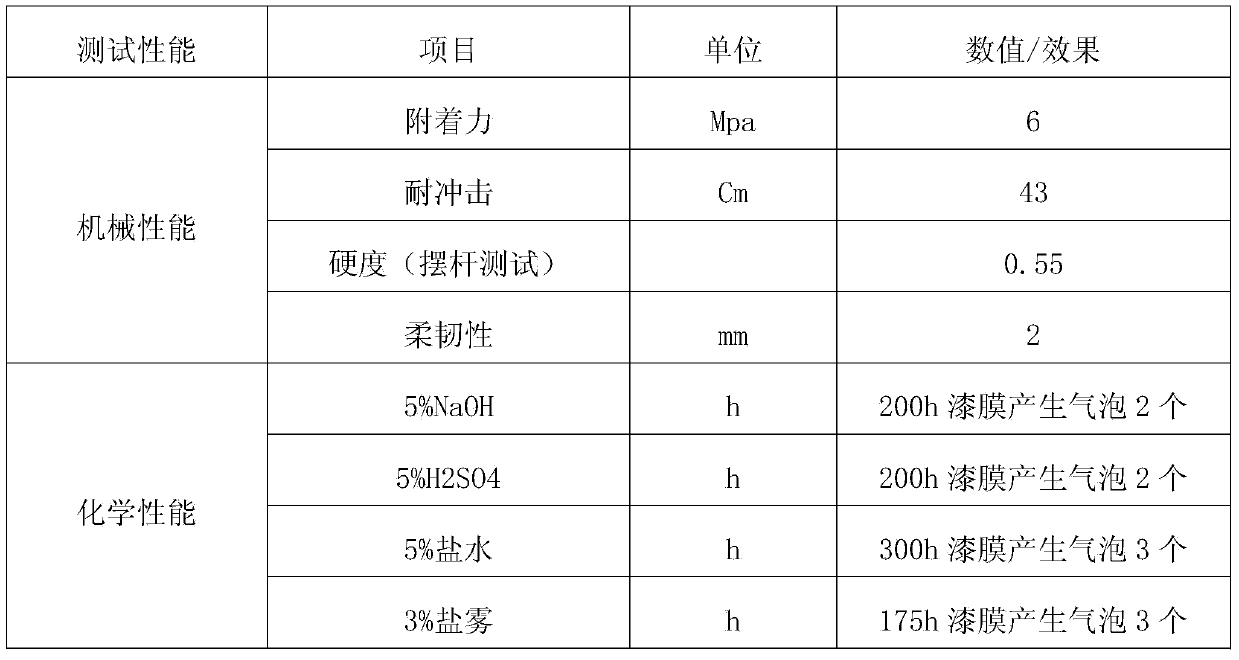

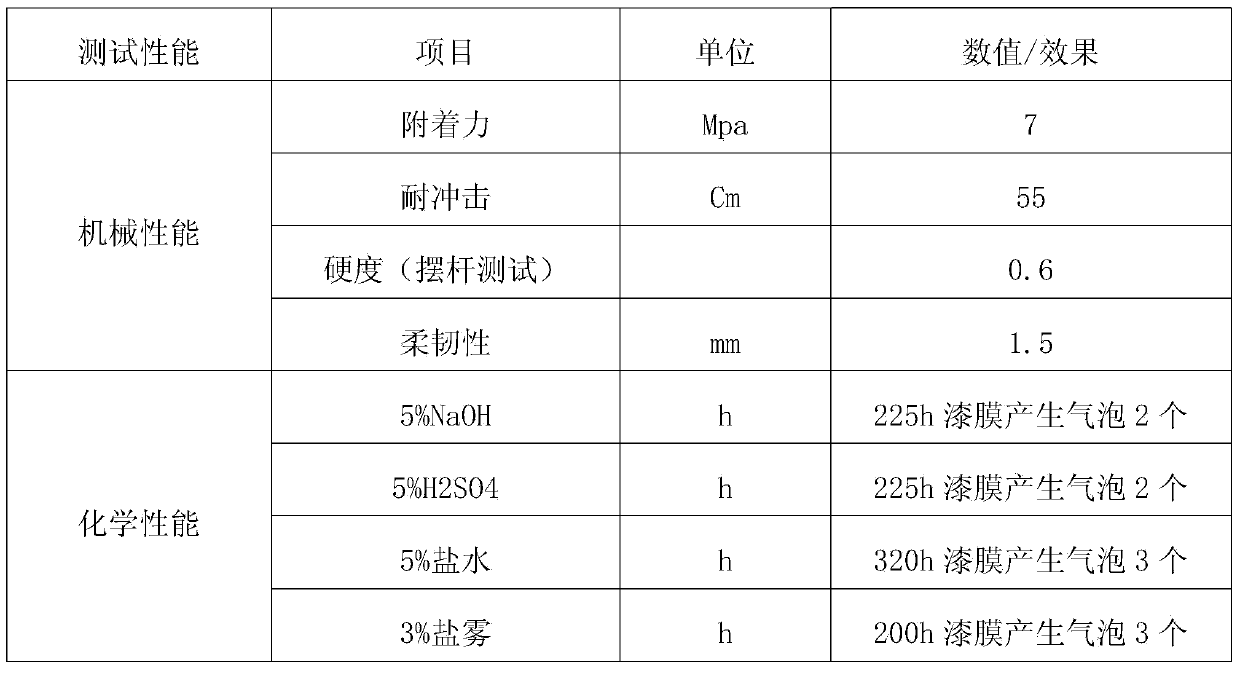

Anticorrosion coating for buried pipeline and preparation method of anticorrosion coating

InactiveCN104212352AImprove adhesionGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention discloses an anticorrosion coating for a buried pipeline. The anticorrosion coating is prepared from the following components in percentage by weight: 25-40 percent of epoxy resin, 35-45 percent of modified liquid asphalt, 5-10 percent of a flame retardant, 10 percent of talc, 1-5 percent of an auxiliary, 5-15 percent of a curing agent, 1-3 percent of zinc phosphate, 2-4 percent of strontium phosphate, 3-5 percent of sodium hexametaphosphate and 5-8 percent of sodium pyrophosphate. The invention also discloses a preparation method of the anticorrosion coating for the buried pipeline. The anticorrosion coating can be constructed by adopting a spraying process, a brushing coating process and a roll coating process and has the advantages of excellent gumminess, chemical corrosion, abrasion and permeability resistance, fast dry and flame retardancy. With the application of the anticorrosion coating, the original functions can be greatly strengthened, unnecessary anticorrosion materials are prevented from being applied again, the comprehensive cost of the anticorrosion engineering is lowered, and the use is convenient.

Owner:JIANGSU MARINE VICTORY COATING

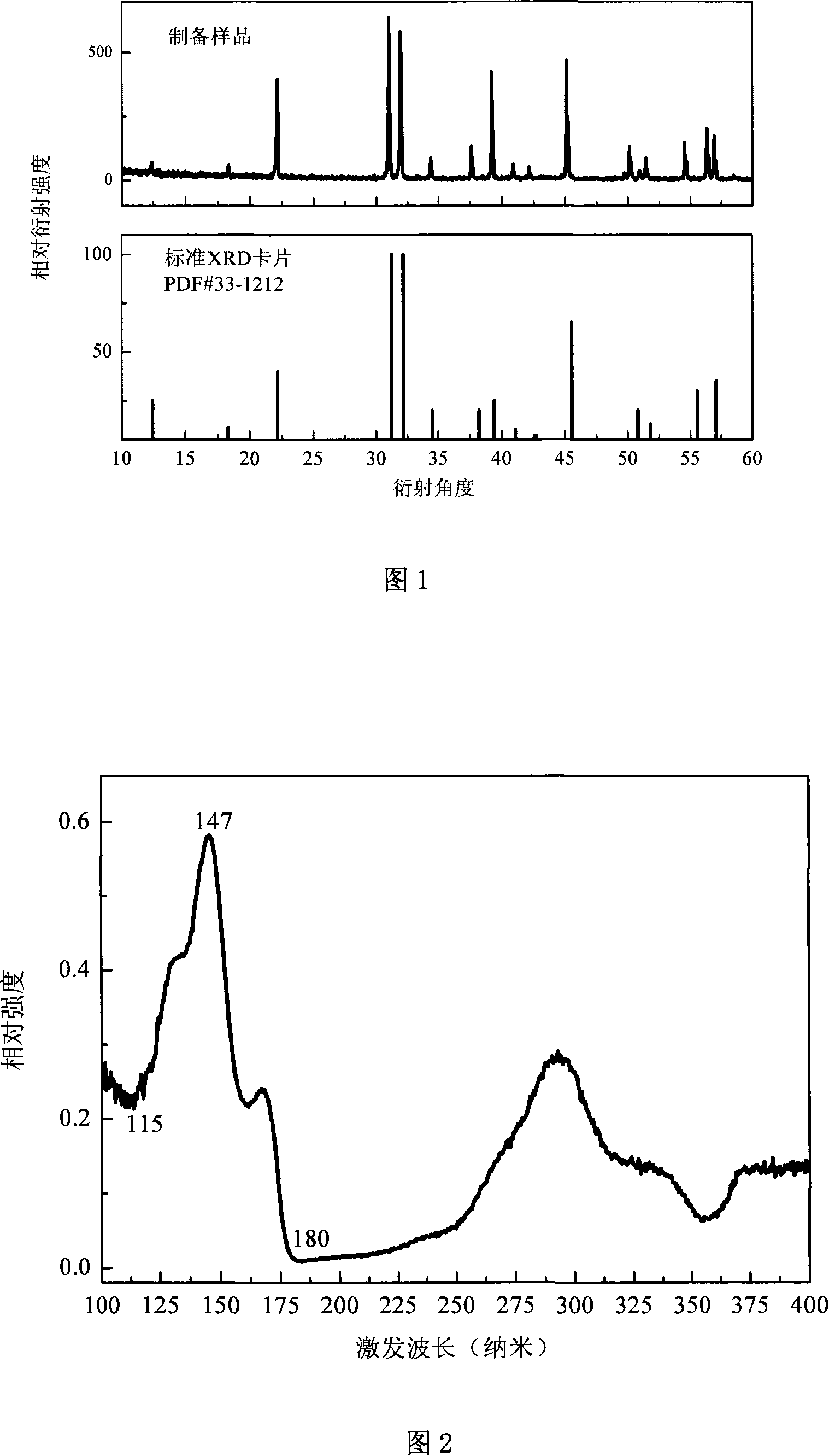

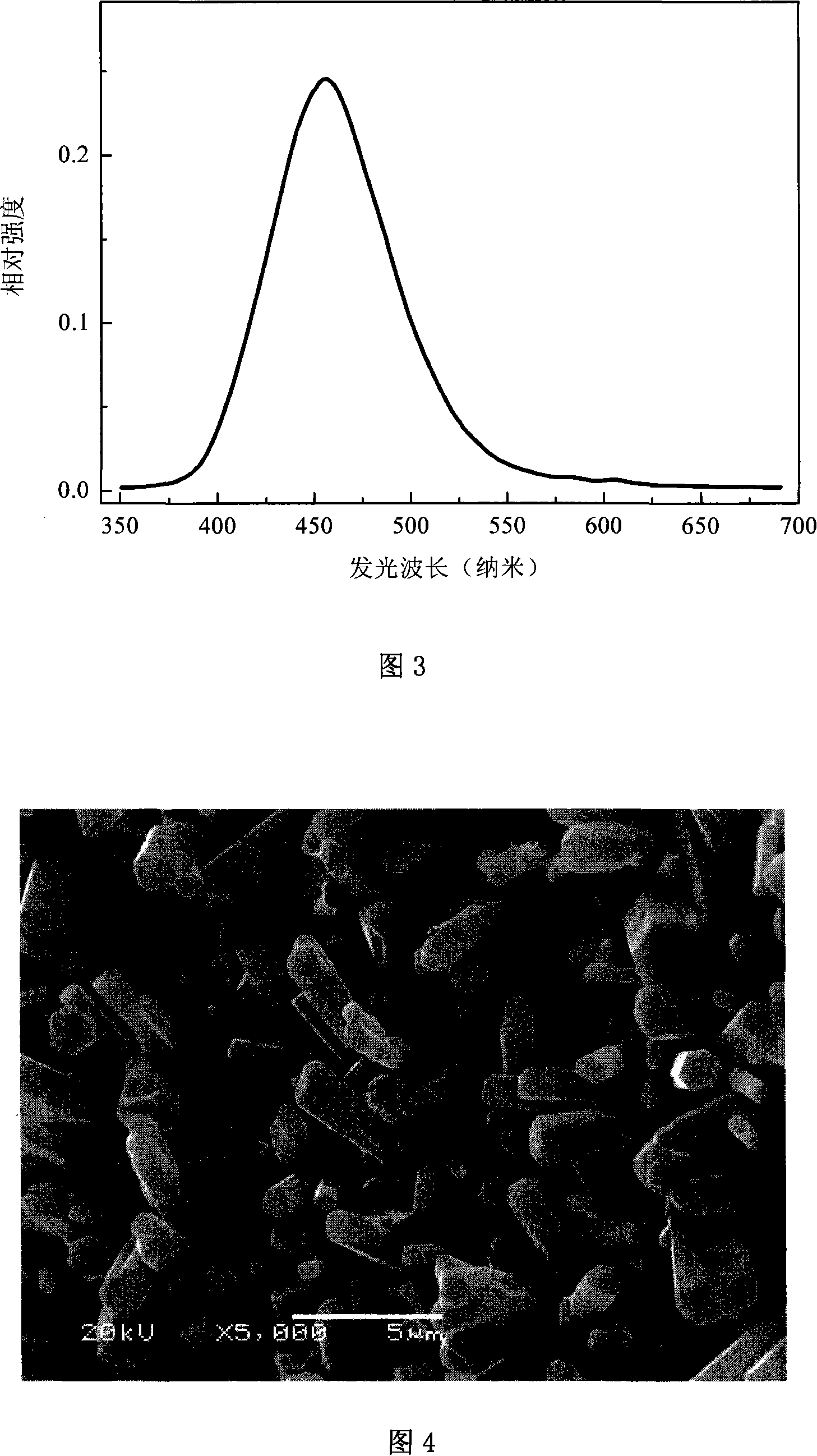

Blue-fluorescence luminescent material and method for making same

InactiveCN101113334APromote reductionSave raw materialsLuminescent compositionsRare-earth elementNoble gas

The invention relates to a blue fluorescence luminescent material and a preparation method thereof, pertaining to the technical field of luminescent material. The technic proposal adopted by the invention is to prepare strontium phosphate barium stone, of which a chemical formula is M(Srx, Ba1-x)PO4:Eu, wherein, M is equal to Li+, Na+, K+, Rb+, x is equal to 0-1, doping content of rare earth element europium (Eu2+) is 0.0005-10 percent mol of the total amount of strontium and barium. An excitation field of the invention tallies closely with vacuum uv (VUV) generated by ionomer such as mixed gas of xenon and ne (Xe plus Ne) which is applied presently. Excited by vacuum uv less than 200nm, the invention emits blue fluorescence; the invention has high crystallinity, good luminescent quality, low cost, simple preparation technique and no pollution and is especially applicable to ionomer plate displaying technology and luminescent and displaying devices with vacuum uv as an excitation source, such as a noble gas discharge lamp, etc.

Owner:SUZHOU UNIV

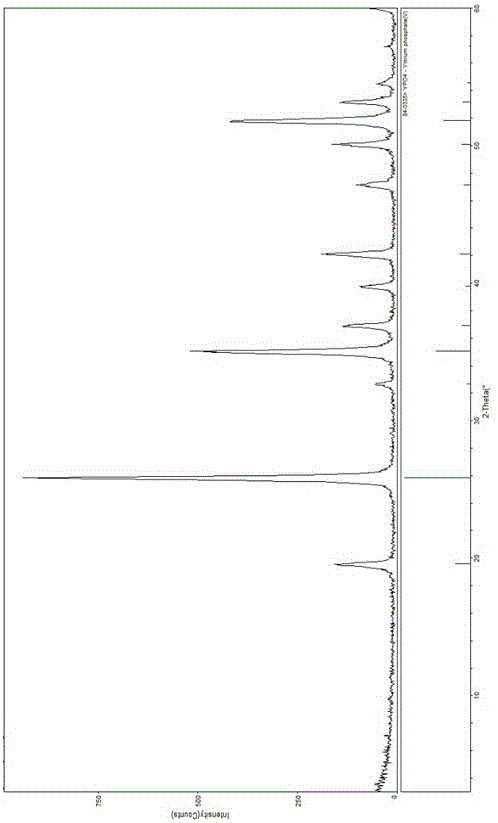

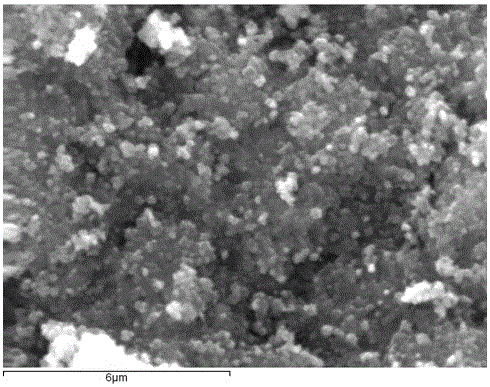

Strontium phosphate-based nano-assembling spherical anticorrosive pigment

The invention belongs to the technical field of material chemistry and particularly relates to a preparation method of strontium phosphate-based nano-assembling spherical anticorrosive pigment. The strontium phosphate-based nano-assembling spherical anticorrosive pigment is of an ordered structure assembled by nanobelts, and the surface of the pigment can be firmly composited with benzotriazole and a surfactant. The strontium phosphate-based nano-assembling spherical anticorrosive pigment 2-3 micrometers in overall diameter and prepared from the nanobelts 20-30 nm thick has the advantages of good dispersity, excellent compatibility and excellent corrosion resistant performance.

Owner:EAST CHINA UNIV OF SCI & TECH

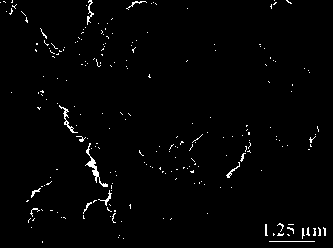

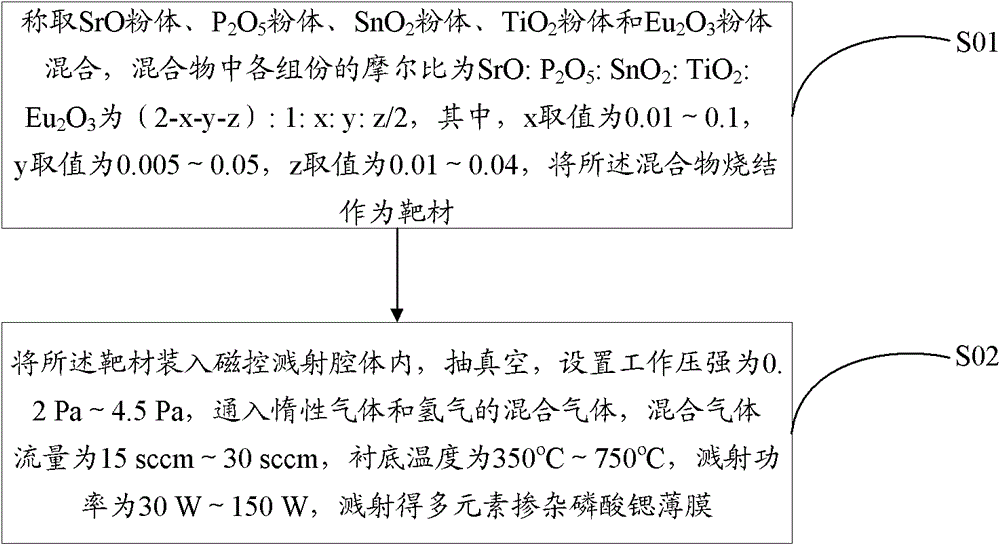

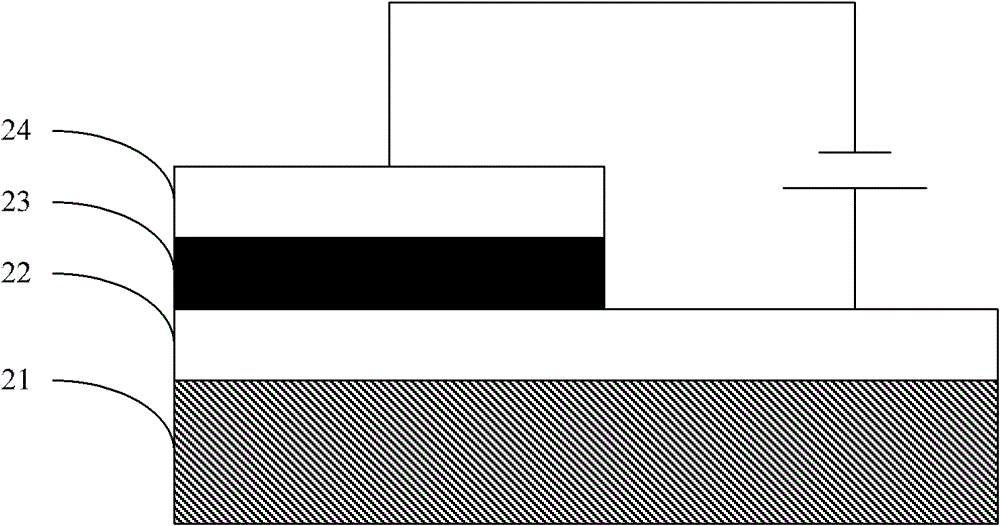

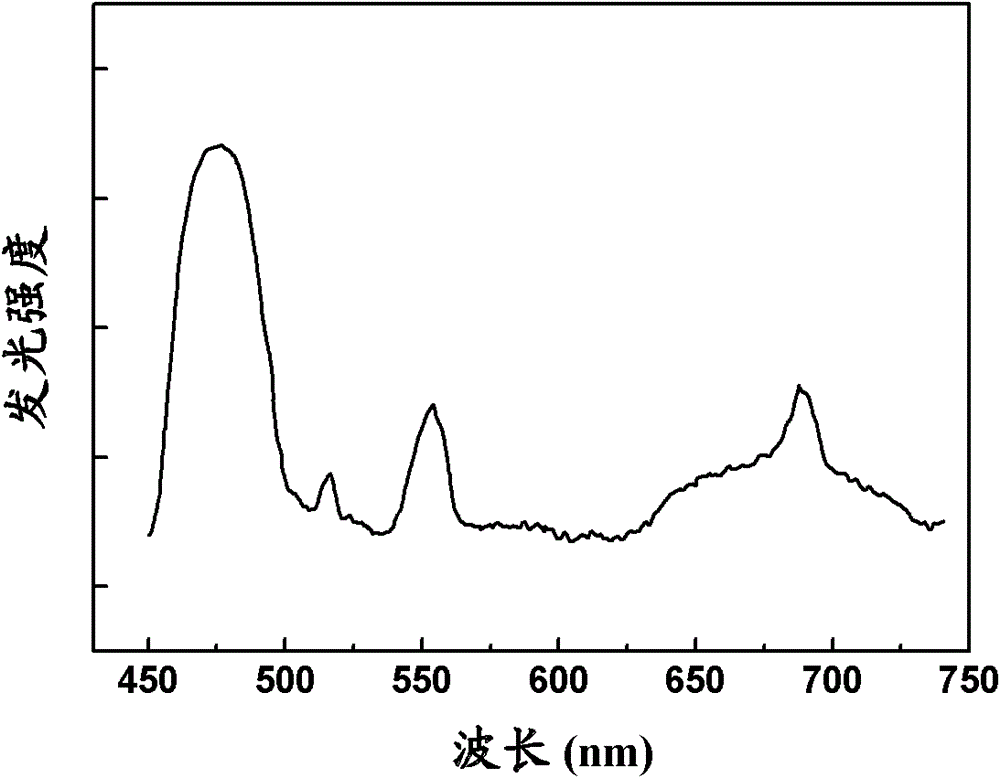

Multielement-doped strontium phosphate luminescent film, and preparation method and applications thereof

InactiveCN102796984AWide luminous rangeImprove thermal stabilityVacuum evaporation coatingSputtering coatingField emission deviceStrontium phosphate

The invention relates to the field of semiconductor photoelectric materials, and provides a multielement-doped strontium phosphate luminescent film which has a general formula of Sr[2-x-y-z]P2O7 : xSn<4+>, yTi<4+>, zEu<3+>, wherein x value is 0.01-0.1; y value is 0.005-0.05; and z value is 0.01-0.04. The invention also provides a preparation method for the multielement-doped strontium phosphate luminescent film and applications of the multielement-doped strontium phosphate luminescent film obtained by the method in field emission devices, cathode-ray tubes or electroluminescent devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

High strength and tenacity degradable strontium calcium superphosphate composite bone cement and its preparation method

InactiveCN101053673BHas the effect of slow-release strontium ionsPromote degradationProsthesisFiberPolymer science

The invention discloses a high tensile degradable strontium phosphate calcium composite bone cement for repairing or intensifying fixation of human body holding bone defect and preparation method thereof. The solid material of bone cement is mixed powder of Ca4(PO4)2O ceramic with high crystallinity, SrHPO4, CaHPO4, curing liquid is thin phosphoric acid water solution, additive plasticizing unit is biocompatibility degradable macomolecule fiber with high tensile strength, selecting from lactic acid - hydroxyacetic acid copolymer fibre, polylatic acid fiber or polyglycolic acid fiber or other absorbable surgical suture, the enhancing unit is Ca4(PO4)2O residual ceramic particles after curing reaction. The preparation method coalesces kinds of techniques of ceramic particles in-situ reinforcing, initial plasticizing and later stage degradation of degradable fiber, Sr modification to get a novel high tensile degradable strontium phosphate calcium composite bone cement in like physiologicenvironment. The material has good biocompatibility, bioactivity, bone conductivity and degradation property.

Owner:XI AN JIAOTONG UNIV

a rich co 2 Method for hydrothermally synthesizing yttrium phosphate nanospheres

ActiveCN104692350BHigh purityUniform sizeMaterial nanotechnologyPhosphorus compoundsReaction temperatureHigh pressure

The invention discloses a method for hydrothermally synthesizing a yttrium phosphate nanosphere by using rich CO2. The method is characterized by comprising the following steps: respectively preparing a Y<3+> salt solution and a PO4<3+> salt solution at room temperature; adding the two solutions to a reaction kettle at a volume ratio of 1:1, stirring at the same time, and continuously stirring for 30 minutes to 1 hour; introducing CO2 gas or adding dry ice to the reaction kettle, controlling the pressure inside the reaction kettle to 1-10 Mpa, and sealing the high-pressure reaction kettle; heating the high-pressure reaction kettle, determining reaction temperature of 100-200 DEG C and duration time of 12 hours to 2 days, and then naturally cooling the high-pressure reaction kettle to room temperature; filtering a reacted product, and successively washing and centrifugalizing twice by using deionized water and absolute ethyl alcohol; and drying the washed and centrifugalized product at 50-100 DEG C for more than 6 hours to obtain a final pure product.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

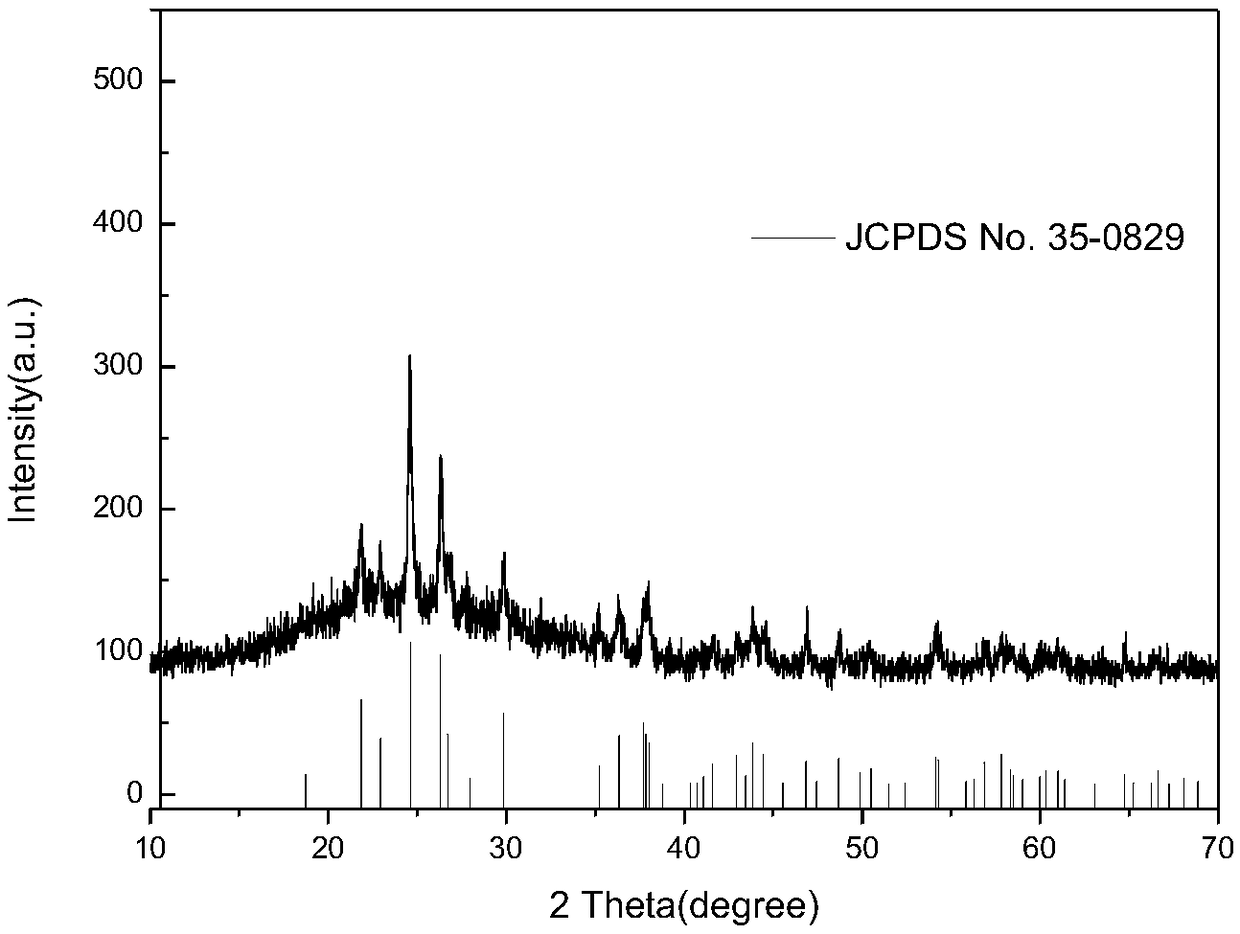

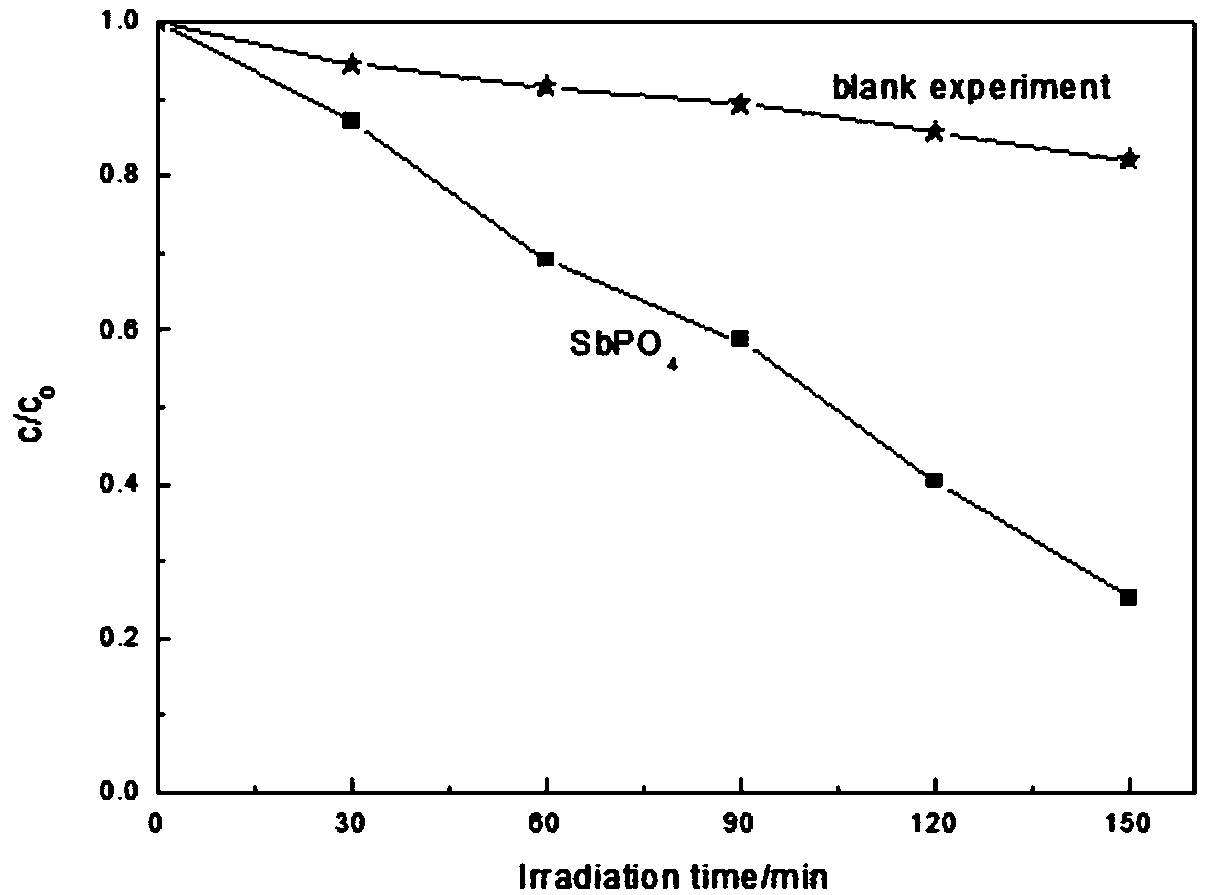

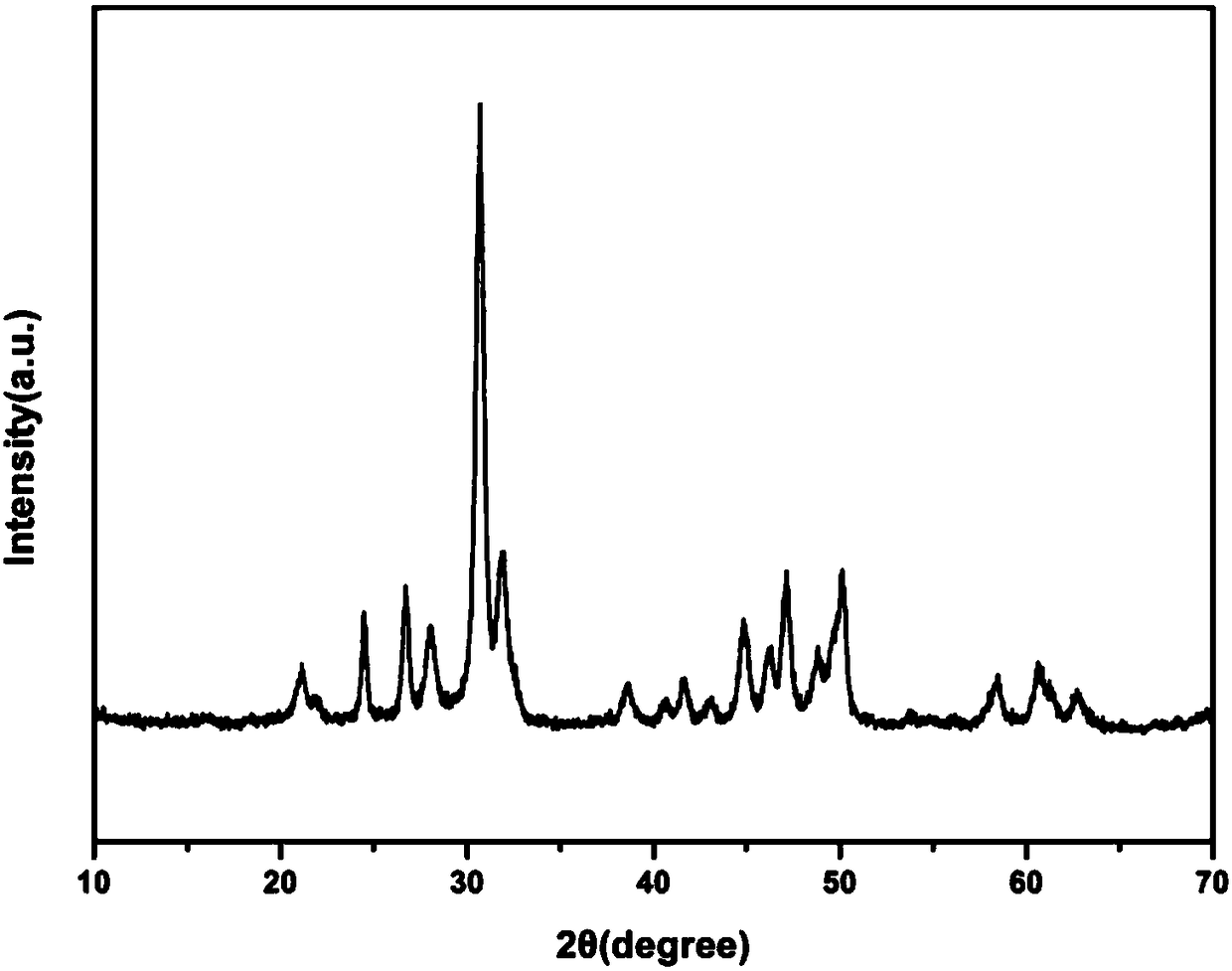

Preparation of a nano-superstructure of antimony phosphate and its new application in photocatalysis

ActiveCN106276839BImprove photocatalytic activityThe preparation method is simple and easyPhysical/chemical process catalystsPhosphorus compoundsWater bathsDiethylenetriamine

The invention relates to the preparation of an antimony phosphate nano superstructure and its new photocatalytic application. Diethylenetriaminepentacetic acid and antimony trichloride are sequentially dissolved in deionized water, and stirred fully under 60°C water bath conditions; then added Ammonium dihydrogen phosphate, stir thoroughly to form a precursor mixed solution, filter the precursor mixed solution to obtain a precursor solution and precursor precipitation; let the precursor solution stand in a 60°C water bath for 10 to 20 minutes to form a suspension system; take the suspension system The upper part of the suspended clarified liquid and all the precursor precipitates were poured into a polytetrafluoroethylene-lined stainless steel hydrothermal reactor, subjected to a constant temperature hydrothermal reaction at 160°C for 10 hours, centrifuged, washed and dried to obtain the product. The preparation method of the antimony phosphate nano superstructure of the present invention is simple, the prepared antimony phosphate has good photocatalytic activity, and expands the types of photocatalysts, morphology types and preparation methods of antimony phosphate.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Preparation method of medical composite glass fiber strontium containing enhanced bone cement product

Calcium nitrate, diammonium phosphate and urea are mixed and added with strontium phosphate to be mixed, stirred and heated, to prepare strontium containing hydroxyapatite; the hydroxyapatite is added into magnesium chloride and magnesium oxide, added with water to be dissolved, to prepare magnesium oxychloride adhesive; a hand lay-up bone pre-fabricated piece is paved with pulp and glass fiber cloth, flattened, paved uniformly and brushed with glue; and then the prefabricated outer skin is paved and compacted, the seam is sealed by plastic thin film, cured and stripped; the product is trimmed within one day after stripping, and a medical composite glass fiber strontium containing enhanced bone cement product is prepared. The composite material prepared by the invention has the advantages of uniform glass fiber dispersion and good combination of the strontium containing hydroxyapatite and a matrix interface, and biomedical composite material with very good application prospect.

Owner:李胜

Super-hydrophobic anticorrosive coating for magnesium alloy and preparation method of super-hydrophobic anticorrosive coating

PendingCN114213881AExtended service lifeImprove corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsMetallurgyStrontium phosphate

The invention discloses a preparation method of a super-hydrophobic anticorrosive coating for magnesium alloy. The preparation method comprises the following steps: preparing a strontium phosphate chemical conversion coating; treating a magnesium alloy matrix by using the strontium phosphate chemical conversion coating; preparing a super-hydrophobic coating; the magnesium alloy matrix is coated with the super-hydrophobic coating, and the super-hydrophobic anticorrosive coating is obtained after curing; the invention further discloses the super-hydrophobic anticorrosive coating for the magnesium alloy. By adopting the strontium phosphate chemical conversion coating and the super-hydrophobic coating which are properly coordinated in formula and proportion, the super-hydrophobic coating is added to the magnesium alloy matrix on the basis of the strontium phosphate anticorrosive coating, so that the surface hydrophobicity of the magnesium alloy matrix is optimized on the premise that the magnesium alloy matrix has good corrosion resistance, and the corrosion resistance of the magnesium alloy matrix is improved. And the self-cleaning performance, the super-hydrophobic performance and the corrosion resistance of the magnesium alloy are further improved.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN

Neodymium doped strontium fluorophosphate nano-microspheres and preparation method thereof

InactiveCN108147387AGood dispersionShort processMaterial nanotechnologyPhosphorus compoundsDispersityMicrosphere

The invention relates to neodymium doped strontium fluorophosphate nano-microspheres and a preparation method thereof. The average particle size of the neodymium doped strontium fluorophosphate nano-microspheres is 30-50 nanometers, and the neodymium doped strontium fluorophosphate nano-microspheres are even in particle size distribution. The preparation method includes the steps of firstly, dissolving Sr(NO3)2 and Nd(NO3)3 6H2O into deionized water to obtain a cation solution; secondly, dissolving NH4F and (NH4)2HPO4 into deionized water to obtain an anion solution; thirdly, adding the anionsolution into the cation solution, evenly stirring, standing, performing ultrasonic cleaning and centrifugal separation to obtain precipitates, drying the precipitates, and grinding to obtain the neodymium doped strontium fluorophosphate nano-microspheres. The preparation method has the advantages that the products are prepared through a precipitation method, nucleus growth rate is controlled by optimized process conditions such as reactant concentration and mixing rate, and the neodymium doped strontium fluorophosphate nano-microspheres which are good in dispersity and have near-spherical morphology.

Owner:WUHAN UNIV OF TECH

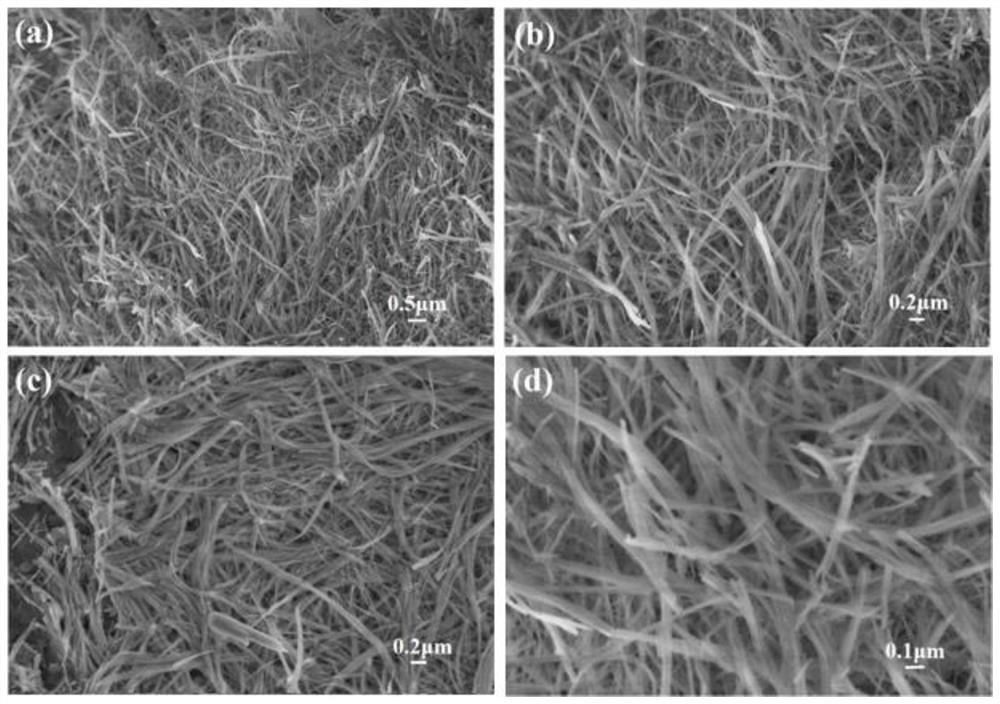

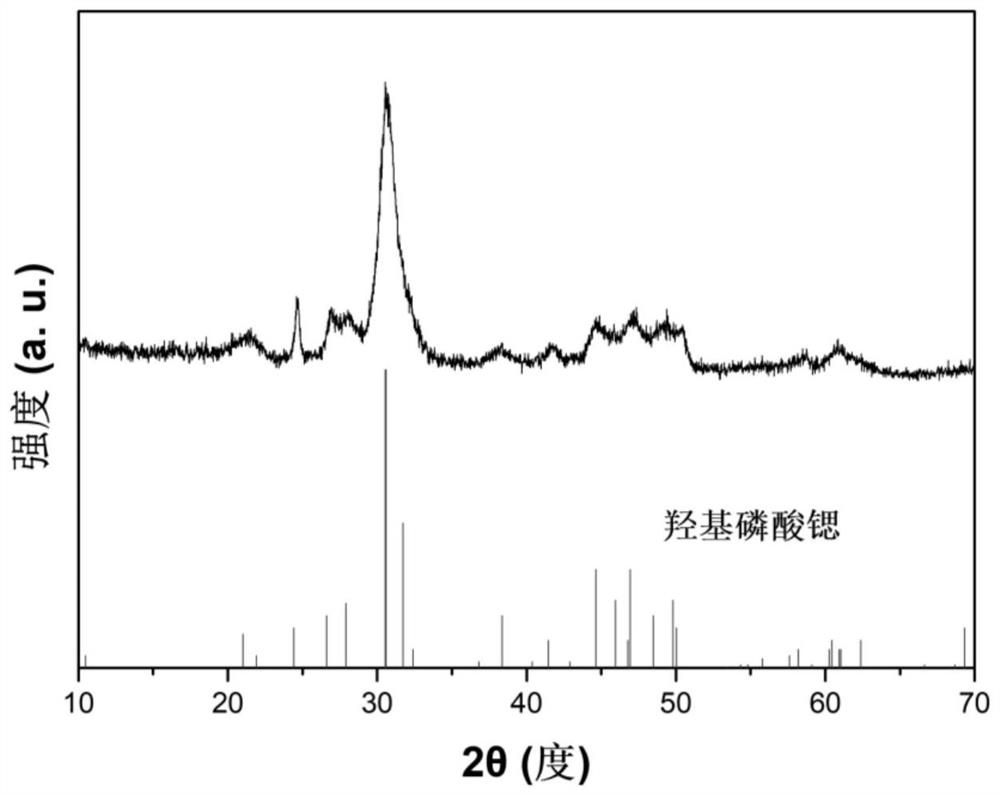

Hydroxyl strontium phosphate super-long nanowire as well as preparation method and application thereof

PendingCN114229813AHigh aspect ratioGood flexibilityNanotechnologyPhosphorus compoundsNanowireDrug carrier

The invention provides a hydroxyl strontium phosphate super-long nanowire and a preparation method thereof, and the preparation method comprises the following steps: step (1), uniformly stirring and mixing strontium salt as a strontium source, phosphate as a phosphorus source and oleate as a reactant and an emulsifier in a solvent to form a precursor suspension; (2) carrying out hydrothermal treatment on the precursor suspension liquid obtained in the step (1) in a closed container; and (3) separating and washing the product obtained in the step (2) to obtain the hydroxyl strontium phosphate super-long nanowire. The invention also provides application of the hydroxyl strontium phosphate super-long nanowire in the fields of bone defect repair, dental materials, drug carriers, energy and environmental protection. The invention also provides a macro-scale ordered structure material comprising the hydroxyl strontium phosphate super-long nanowire. The hydroxyl strontium phosphate super-long nanowire and the preparation method thereof have the advantages of simple process, low cost and the like, and are expected to be produced on a large scale.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

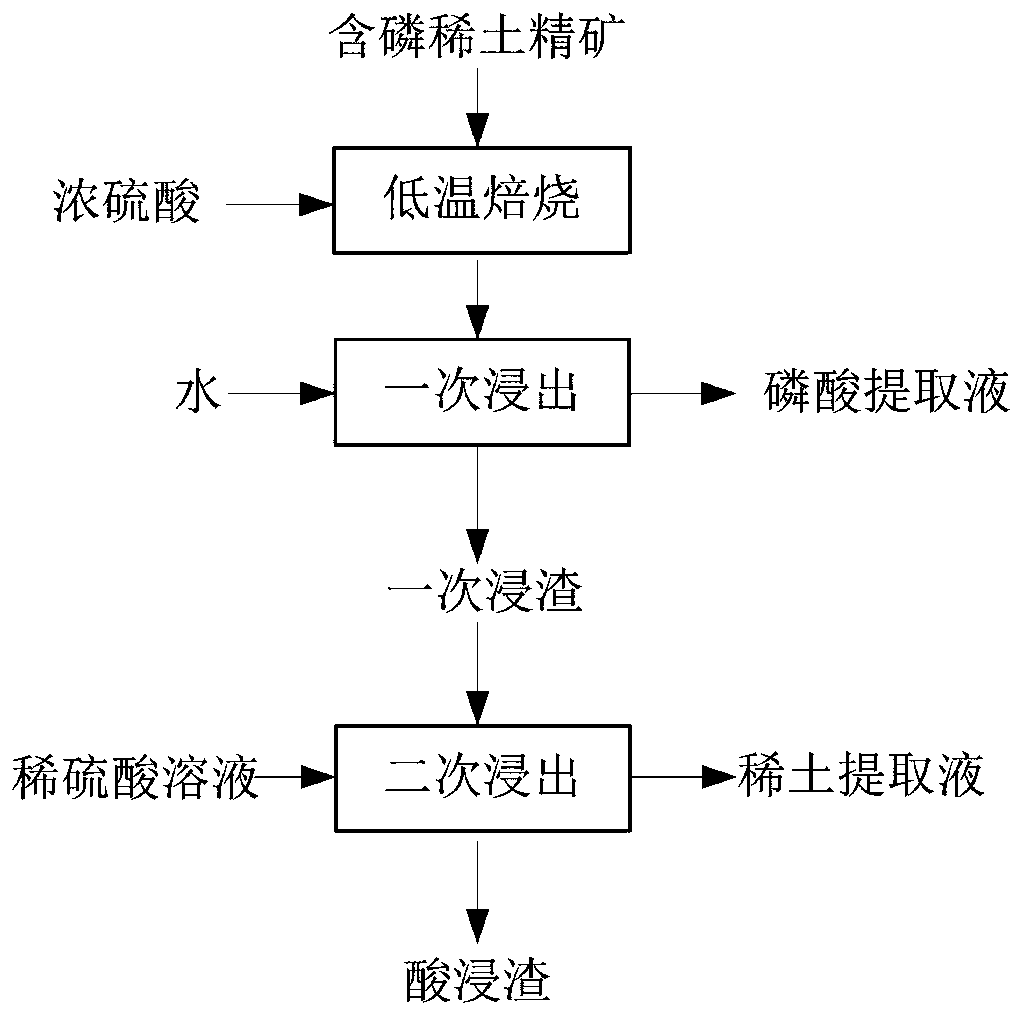

Method for step-by-step extraction of phosphorus and rare earth from concentrated sulfuric acid low-temperature roasting phosphorus-containing rare earth concentrate

ActiveCN108950188BReduce the frequency of low-temperature sintering ringsReduce trimmingProcess efficiency improvementPhosphorus compoundsO-Phosphoric AcidSulfate

The invention discloses a method for stepwise extraction of phosphorus and rare earth in phosphorus-containing rare earth concentrate through low-temperature roasting by concentrated sulfuric acid. The method comprises: uniformly mixing phosphorus-containing rare earth concentrate and concentrated sulfuric acid according to a ratio, carrying out calcining decomposition at 200-350 DEG C to obtain calcined ore, blending the calcined ore and water, carrying out primary leaching, carrying out filtration and washing to obtain phosphoric acid extract and primary residues, carrying out secondary leaching on the primary residues and a dilute sulfuric acid solution and carrying out filtration and washing to obtain rare earth extract and water leaching residues. The method utilizes the principle ofdifference in solubility of iron phosphate, rare earth phosphate and strontium phosphate and the diffusion rate of rare earth sulfate and phosphoric acid under acidic conditions to extract phosphoricacid step by step, realizes preliminary separation with rare earth and solves the problems in the prior art. .

Owner:BAOTOU RES INST OF RARE EARTHS +1

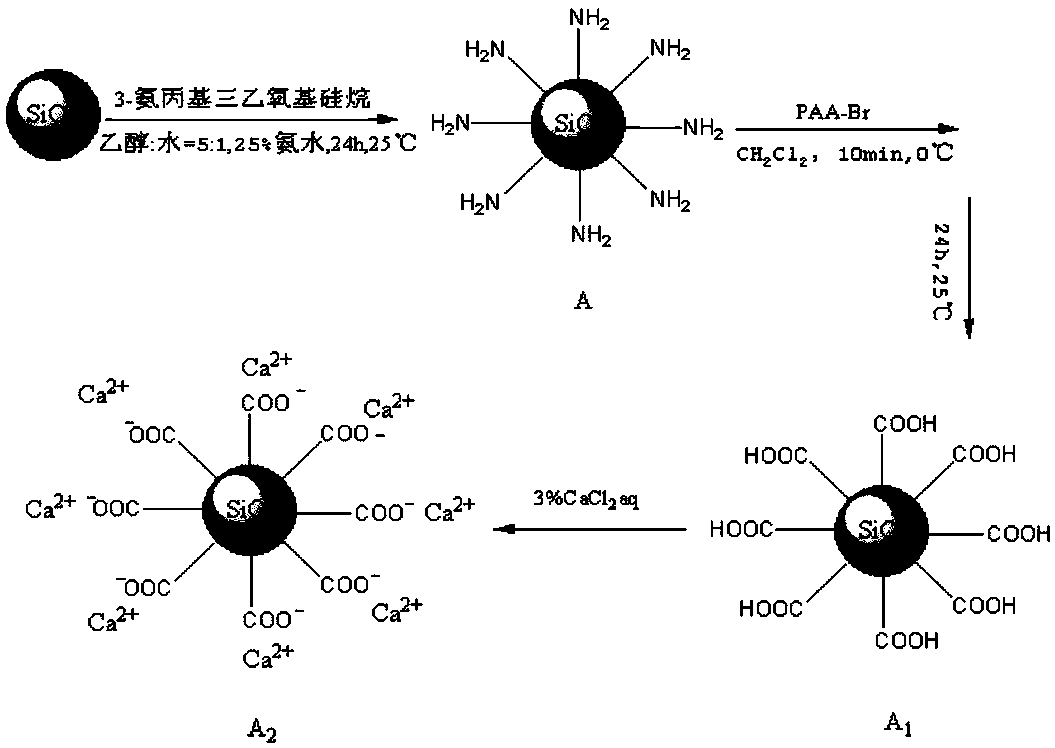

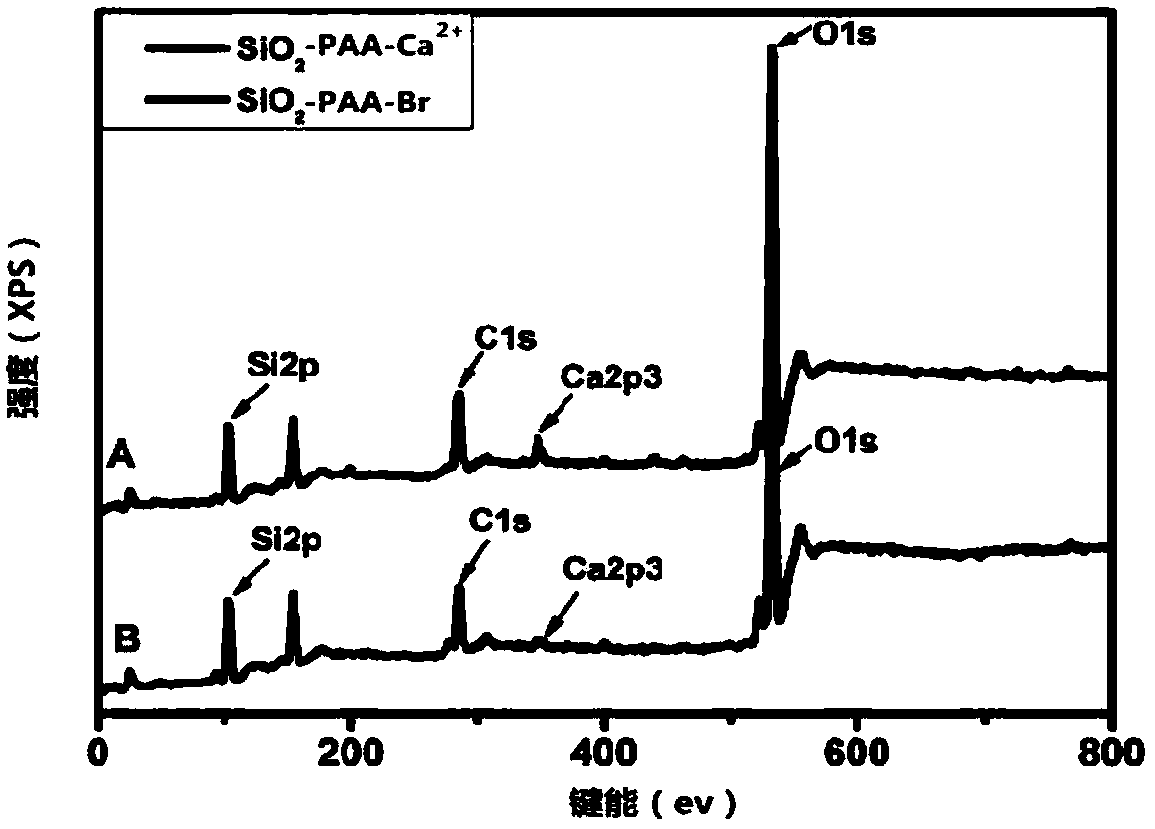

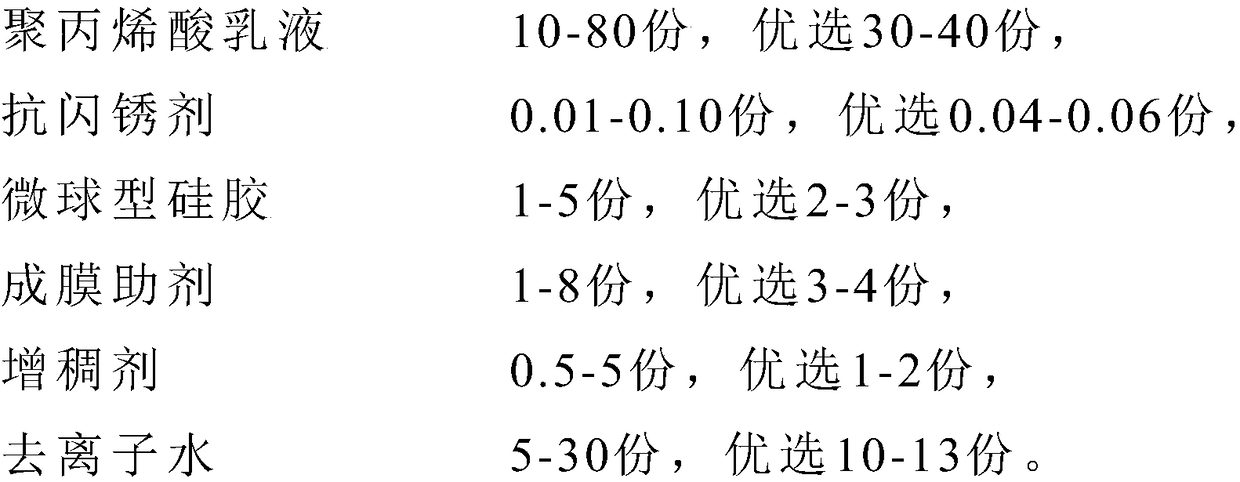

Microspheric ion exchange flash-rust-resistant anti-rust metal primer and preparation method thereof

The invention provides aqueous anti-rust metal primers, and in particular relates to microspheric ion exchange flash-rust-resistant anti-rust metal primer and a preparation method thereof. The primeris prepared from polyacrylic emulsion, polymer emulsion of a hollow structure, a coalescing agent, a thickening agent, a pH regulator, a flash-rust-resistant agent, a body filler, microspheric calcium-ion-containing silica gel, strontium phosphate, bentonite and water. The environmentally friendly anti-rust metal primer provided by the invention has excellent salt fog resistance and flash rust resistance; the film density is excellent, and the dry film of 0.5 mm can bear a water pressure of 0.3MPa for 30 minutes; the adhesive force is extremely high, and the national standard of automotive anti-rust primers can be reached; the content of prohibited substances is far lower than the content required in relevant laws and regulations.

Owner:哈尔滨雨阳佳泰环保新材料有限公司

Titanium surface micro-nano zinc phosphate strontium chemical conversion film and controllable preparation method thereof

ActiveCN109989054ASimple processLow costSurgeryPharmaceutical delivery mechanismMicro nanoZinc compounds

The invention discloses a titanium surface micro-nano zinc phosphate strontium chemical conversion film and controllable preparation method thereof. The method comprises the following steps of the chemical conversion solution is prepared, wherein the chemical conversion solution contains strontium ions, zinc ions, dihydrogen phosphate ions and an accelerant; carrying out iron powder curing treatment on the chemical conversion solution to obtain a curing solution; and coupling the cleaned and surface-activated titanium matrix with a pure iron clamp, and then soaking the titanium matrix and thepure iron clamp in a curing solution for chemical conversion treatment to obtain the chemical conversion film. The controllable preparation method of different micro-nano structures of the zinc-strontium-phosphate film layer is realized through the addition amount of the zinc-containing compound in the conversion solution and the regulation of the accelerator, the introduction of the biological functional element and the micro-nano structure regulation and control are combined, so that the early bone integration capability and the antibacterial property of the titanium-based implant are further improved, and the clinical application effect of the titanium-based implant is improved.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com