a rich co 2 Method for hydrothermally synthesizing yttrium phosphate nanospheres

A technology of hydrothermal synthesis and yttrium phosphate, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of not very high degree of crystallization, uneven size, lack of crystal shape and appearance, etc., to achieve uniform size, Good crystallization degree, environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

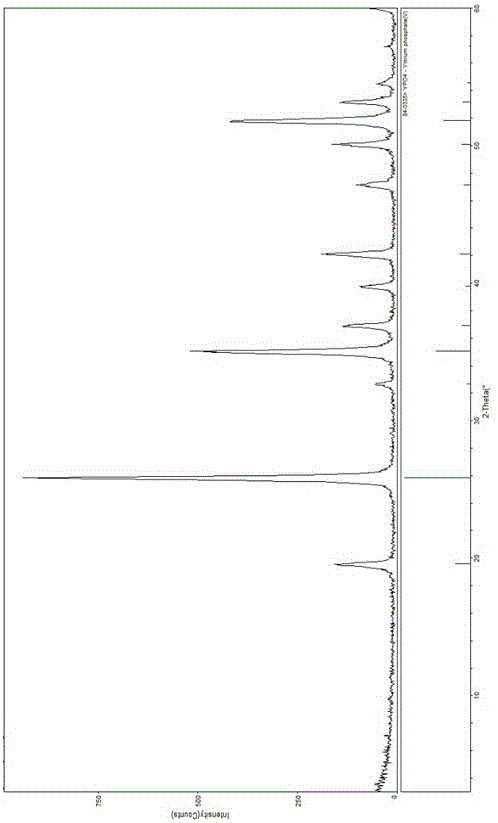

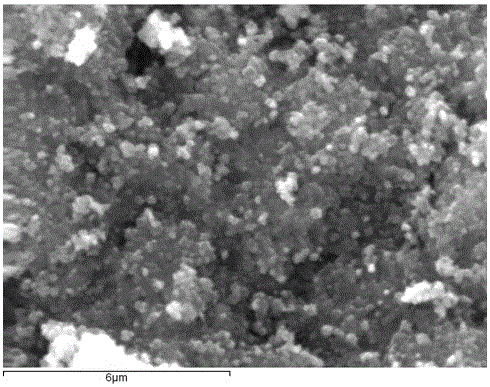

Embodiment 1

[0014] Weigh a certain mass of yttrium nitrate [Y(NO 3 ) 3 ·6H 2 O] and diammonium hydrogen phosphate [(NH 4 ) 2 HPO 4 ], be made into the aqueous solution of the yttrium nitrate of 0.36mol / L and the aqueous solution of diammonium hydrogen phosphate respectively with deionized water. Add the yttrium nitrate solution and the diammonium hydrogen phosphate solution into the reactor according to the volume ratio of 1:1, stir while adding, control the initial filling degree of the reactor to 70%, and keep stirring for 30min to 1h. Fill the autoclave with 1MPa carbon dioxide gas and close the autoclave. The autoclave was heated to control the reaction temperature at 180° C. for 2 days, and then the autoclave was naturally cooled to room temperature. After the reaction kettle was depressurized, the product was filtered, centrifuged, and washed twice with deionized water and absolute ethanol alternately, and finally the product was dried at 70°C for 12 hours.

Embodiment 2

[0016] Weigh a certain mass of yttrium nitrate [Y(NO 3 ) 3 ·6H 2 O] and diammonium hydrogen phosphate [(NH 4 ) 2 HPO 4 ], be made into the aqueous solution of the yttrium nitrate of 0.36mol / L and the aqueous solution of diammonium hydrogen phosphate respectively with deionized water. Add the yttrium nitrate solution and the diammonium hydrogen phosphate solution into the reactor according to the volume ratio of 1:1, stir while adding, control the initial filling degree of the reactor to 70%, and keep stirring for 30min to 1h. Fill the autoclave with 5MPa carbon dioxide gas and close the autoclave. The autoclave was heated to control the reaction temperature at 180° C. for 2 days, and then the autoclave was naturally cooled to room temperature. After the reaction kettle was depressurized, the product was filtered, centrifuged, and washed twice with deionized water and absolute ethanol alternately, and finally the product was dried at 70°C for 12 hours.

Embodiment 3

[0018] Weigh a certain mass of yttrium nitrate [Y(NO 3 ) 3 ·6H 2 O] and diammonium hydrogen phosphate [(NH 4 ) 2 HPO 4 ], be made into the aqueous solution of the yttrium nitrate of 0.36mol / L and the aqueous solution of diammonium hydrogen phosphate respectively with deionized water. Add the yttrium nitrate solution and the diammonium hydrogen phosphate solution into the reactor according to the volume ratio of 1:1, stir while adding, control the initial filling degree of the reactor to 70%, and keep stirring for 30min to 1h. Add dry ice (solid carbon dioxide) to the autoclave, control the internal pressure of the autoclave to be 10Mpa, and close the autoclave. The autoclave was heated to control the reaction temperature at 180° C. for 2 days, and then the autoclave was naturally cooled to room temperature. After the reaction kettle was depressurized, the product was filtered, centrifuged, and washed twice with deionized water and absolute ethanol alternately, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com