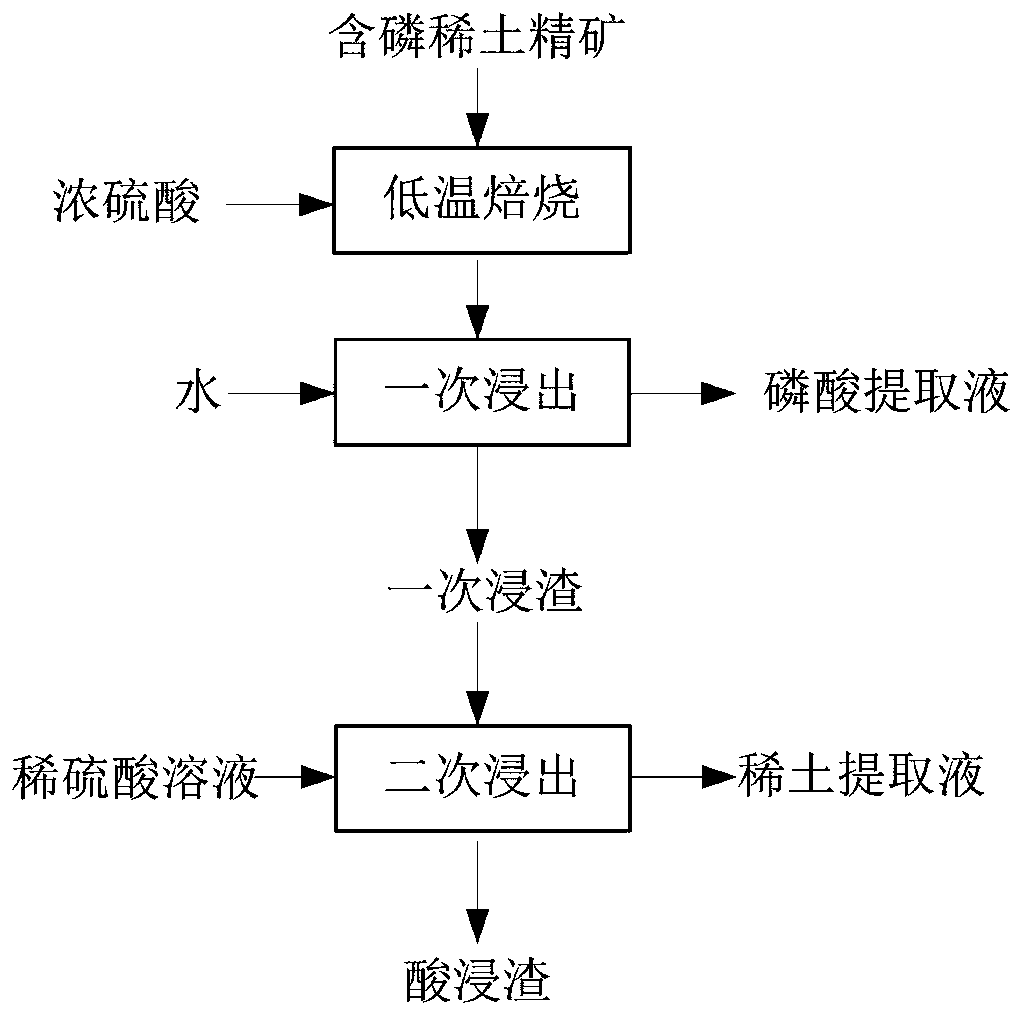

Method for step-by-step extraction of phosphorus and rare earth from concentrated sulfuric acid low-temperature roasting phosphorus-containing rare earth concentrate

A rare earth concentrate, low-temperature roasting technology, applied in chemical instruments and methods, phosphorus compounds, process efficiency improvement and other directions, can solve the problems of low phosphoric acid concentration and increasing difficulty in recovery, and achieve the goal of reducing iron resources and reducing slag amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The mixed rare earth concentrate with a rare earth grade of 60% is mixed with concentrated sulfuric acid at a weight ratio of 1:1.8, and roasted and decomposed at 350°C to obtain roasted ore. The roasted ore is mixed with water for one leaching, the solid-to-liquid weight ratio is 1:1, the leaching time is 10 minutes, and the leaching temperature is 30°C. After filtering and washing, P 2 o 5 Phosphoric acid extraction solution and primary leaching residue with a content of 40g / L have a phosphorus extraction rate of 92%. The primary leaching residue was leached again with the dilute sulfuric acid solution with a pH value of 0.5 according to the solid-to-liquid weight ratio of 1:6. The leaching time was 3 hours and the leaching temperature was 40°C. After filtration, REO was 38g / L and the pH value was 0.4. Rare earth extract and acid leaching residue.

Embodiment 2

[0038] The monazite rare earth concentrate with a rare earth grade of 60% is mixed with concentrated sulfuric acid at a weight ratio of 1:1.7, and roasted and decomposed at 350° C. for 1 hour to obtain roasted ore. The roasted ore is mixed with water for one leaching, the solid-to-liquid weight ratio is 1:2, the leaching time is 10 minutes, and the leaching temperature is 40°C. After filtering and washing, P 2 o 5 Phosphoric acid extraction solution and primary leaching residue with a content of 21g / L have a phosphorus extraction rate of 95%. The primary leaching residue was leached again with dilute sulfuric acid solution with a pH value of 1 according to the solid-to-liquid weight ratio of 1:6. The leaching time was 3 hours and the leaching temperature was 50°C. After filtration, REO was 35g / L and pH value was 0.8. Rare earth extract and acid leaching residue.

Embodiment 3

[0040] The mixed rare earth concentrate with a rare earth grade of 60% is mixed with concentrated sulfuric acid at a weight ratio of 1:1.6, and roasted and decomposed at 300°C for 1 hour to obtain roasted ore. The roasted ore is mixed with water for one leaching, the solid-to-liquid weight ratio is 1:0.4, the leaching time is 30 minutes, the leaching temperature is 20°C, and P is obtained after filtration and washing. 2 o 5Phosphoric acid extraction solution and primary leaching residue with a content of 91g / L have a phosphorus extraction rate of 85%. The primary leaching residue was leached again with dilute sulfuric acid solution with a pH value of 2 according to the solid-to-liquid weight ratio of 1:10. The leaching time was 1 hour, and the leaching temperature was 60°C. After filtration, REO was 24g / L and pH value was 0.3 Rare earth extract and acid leaching residue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com