Method for controlling head-to-tail width of high broadening ratio steel plate

A control method and width ratio technology, applied in the direction of metal rolling stands, metal rolling mill stands, etc., can solve the problems of increasing equipment investment and increasing vertical roll mills, so as to improve the yield of finished products, reduce the amount of trimming, Improved follow-through effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 steel type AH36

[0032] Continuous casting slab size: 200×1800×3040mm

[0033] Finished steel plate size: 8.25×4150×31000mm

[0034] PVPC (Plate Plane Shape Control) Mode in Roughing Mill: Manual Mode

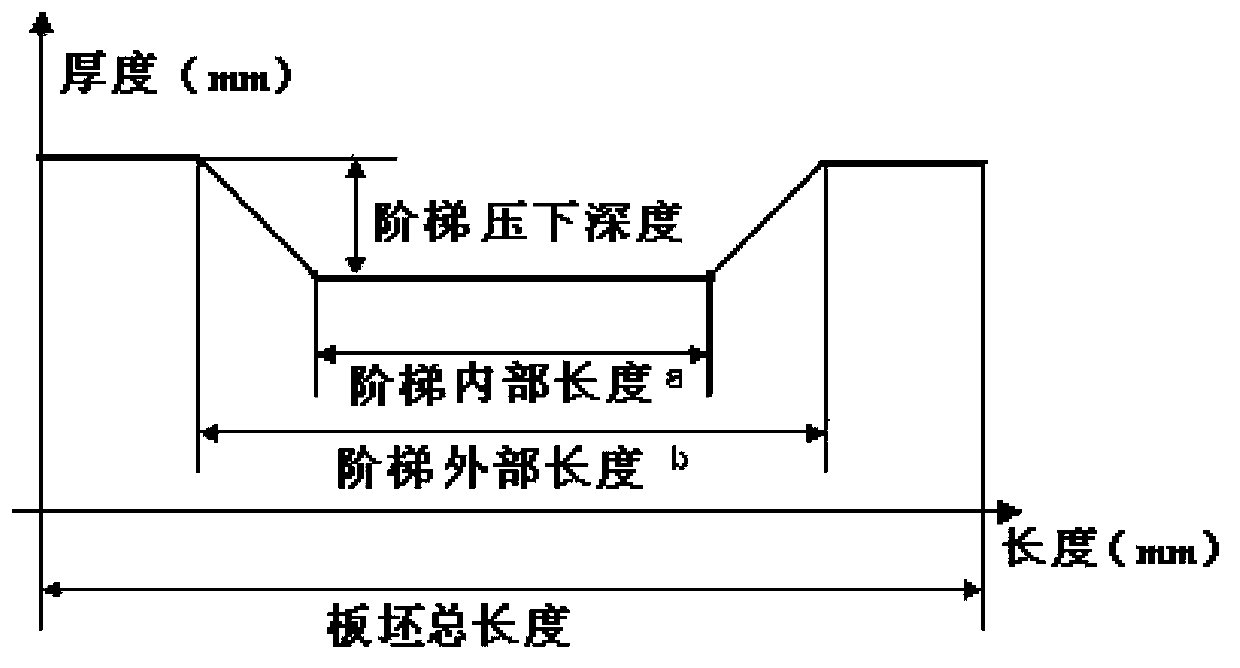

[0035] Artificial mode PVPC internal length a: 70% of the total length of the slab

[0036] Manual mode PVPC external length b: 85% of the total length of the slab

[0037] Step depression depth h=2.3×(B / B′);

[0038] Forming pass rolling speed V=(b-a)×(V HGC / h) / 2

[0039] The specific rolling is as follows:

[0040] A total of 6 passes for rough rolling;

[0041] One pass in the forming stage, the reduction in the forming pass is 35mm, the step reduction depth in the forming pass is 5.3mm, and the rolling speed in the forming pass is 0.8m / s;

[0042] There are 4 rolling passes in the widening stage, and the rolling speed of each pass is 2.1m / s, 2.3m / s, 2.4m / s, 2.6m / s;

[0043] In the longitudinal rolling stage, one pass is rolled, and the rolling...

Embodiment 2

[0053] Embodiment 2 steel type Q345E

[0054] Continuous casting slab size: 200×1500×3580mm

[0055] Finished steel plate size: 16×3200×21000mm

[0056] PVPC Mode in Roughing Mill: Manual Mode

[0057] Artificial mode PVPC internal length a: 70% of the total length of the slab

[0058] Manual mode PVPC external length b: 85% of the total length of the slab

[0059] Step depression depth h=2.3×(B / B′);

[0060] Forming pass rolling speed V=(b-a)×(V HGC / h) / 2

[0061] The specific rolling is as follows:

[0062] A total of 6 passes for rough rolling;

[0063] One pass in the forming stage, the reduction in the forming pass is 15mm, the step reduction depth in the forming pass is 4.9mm, and the rolling speed in the forming pass is 1.0m / s;

[0064] In the widening stage, there are 3 rolling passes, and the rolling speed of each pass is 2.4m / s, 2.6m / s, and 2.8m / s;

[0065] In the longitudinal rolling stage, there are 2 passes, and the rolling speed of each pass is 3.1m / s an...

Embodiment 3

[0075] Embodiment 3 steel type Q345qD

[0076] Continuous casting slab size: 300×1800×3200mm

[0077] Finished steel plate size: 25×3600×19200mm

[0078] PVPC Mode in Roughing Mill: Manual Mode

[0079] Artificial mode PVPC internal length a: 70% of the total length of the slab

[0080] Artificial mode PVPC external length b: 85%

[0081] The step reduction depth of the total length of the slab h=2.3×(B / B′);

[0082] Forming pass rolling speed V=(b-a)×(V HGC / h) / 2

[0083] The specific rolling is as follows:

[0084] A total of 7 passes for rough rolling;

[0085] One pass in the forming stage, the reduction in the forming pass is 25mm, the step reduction depth in the forming pass is 4.6mm, and the rolling speed in the forming pass is 0.9m / s;

[0086] There are 4 rolling passes in the widening stage, and the rolling speed of each pass is 1.9m / s, 2.1m / s, 2.3m / s, 2.6m / s;

[0087] In the longitudinal rolling stage, there are 2 passes, and the rolling speed of each pass i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com