Blue-fluorescence luminescent material and method for making same

A luminescent material, blue fluorescent technology, applied in the field of fluorescent materials, can solve the problems of pollution and high cost, achieve the effect of cost reduction and large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh sodium carbonate Na 2 CO 3 :1.59g, strontium carbonate SrCO 3 :5.94g, barium carbonate BaCO 3 :7.89g, ammonia dihydrogen phosphate NH 4 H 2 (PO 4 ): 3.195g, after grinding and mixing uniformly, select air atmosphere for the first calcination, the temperature is 450℃, the calcination time is 1.5 hours, then cool to room temperature, and take out the sample.

[0035] Adding Europium Oxide (Eu) to the raw materials for the first calcination 2 O 3 :0.0528g, again mix and grind the mixture well, and sinter it for the second time at 700℃ in a reducing atmosphere such as hydrogen or nitrogen-hydrogen mixture. The sintering time is 5 hours, and it is cooled to room temperature to obtain a powder. A blue fluorescent luminescent material doped with rare earth ion europium strontium barium sodium phosphate.

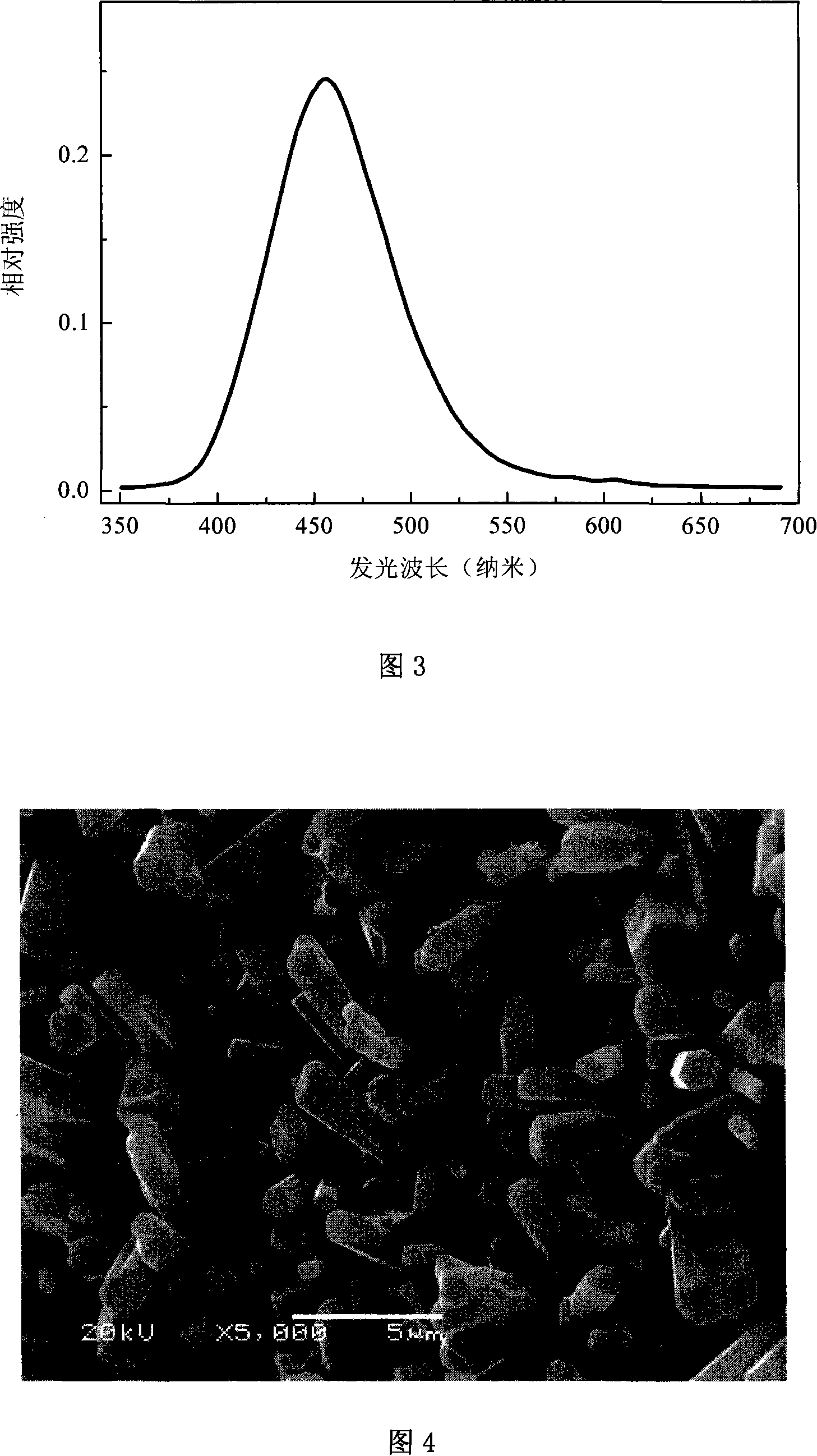

[0036] The sample obtained in this embodiment is excited under vacuum ultraviolet light to obtain blue fluorescence.

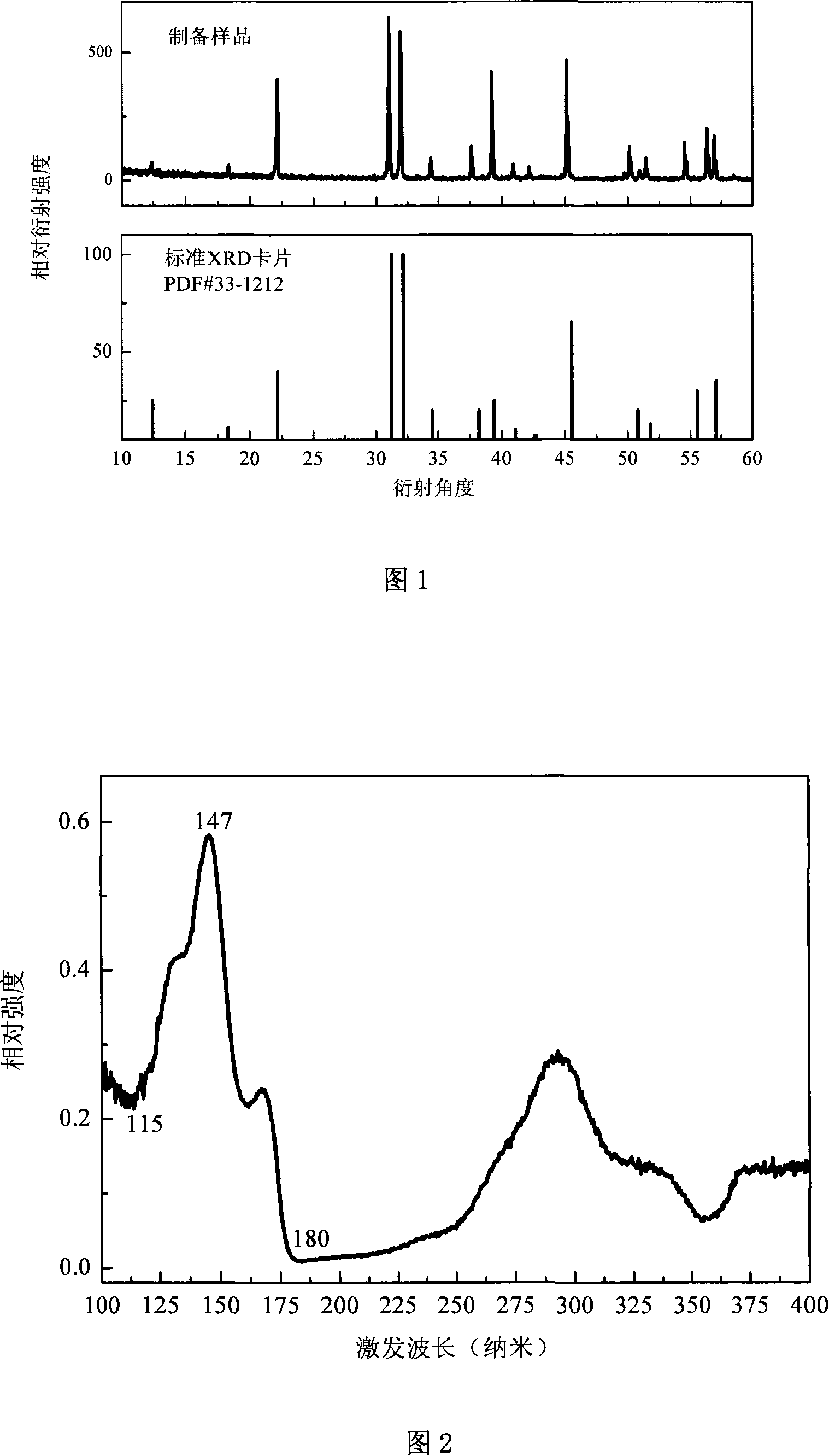

[0037] Refer to Figure 1, which is a comparison betwe...

Embodiment 2

[0042] Weighing out sodium carbonate Na 2 CO 3 :1.590 grams, strontium carbonate SrCO 3 :3.100g, barium carbonate BaCO 3 :1.776 g, ammonia dihydrogen phosphate NH 4 H 2 (PO 4 ): 3.195g, after grinding and mixing uniformly, select the first calcination in air atmosphere, the temperature is 500℃, the pre-sintering time is 2 hours, and it is cooled to room temperature. Take out the sample and add Europium Oxide Eu at this time 2 O 3 :0.108g, again fully ground and mixed uniformly, the second calcination, in the reducing atmosphere of carbon monoxide gas, sintering at 720 ℃ for 6 hours, then the divalent rare earth Eu 2+ The activated blue luminescent powder, the main structural properties, excitation spectrum and luminescence spectrum are similar to those in Example 1.

Embodiment 3

[0044] According to the ratio of the elements in the expression, weigh the sodium carbonate Na 2 CO 3 :1.0812g, barium carbonate BaCO 3 :3.947g, ammonia dihydrogen phosphate NH 4 H 2 (PO 4 ): 2.3466 g, after grinding and mixing uniformly, calcination in air atmosphere, first pre-sintering at 480°C for 1 hour, cool to room temperature, take out the sample, add europium oxide at this time 2 O 3 :0.018g, fully grind again and mix evenly, in a reducing atmosphere such as nitrogen (add activated carbon), carbon monoxide gas, hydrogen or nitrogen-hydrogen mixture, sinter for the second time at 750℃, and the sintering time is 5 hours, you can get Rare Earth Eu 2+ Activated blue glowing luminescent powder. The main structural properties, excitation spectrum and luminescence spectrum are similar to those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com