Patents

Literature

64results about How to "Calcination temperature is high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

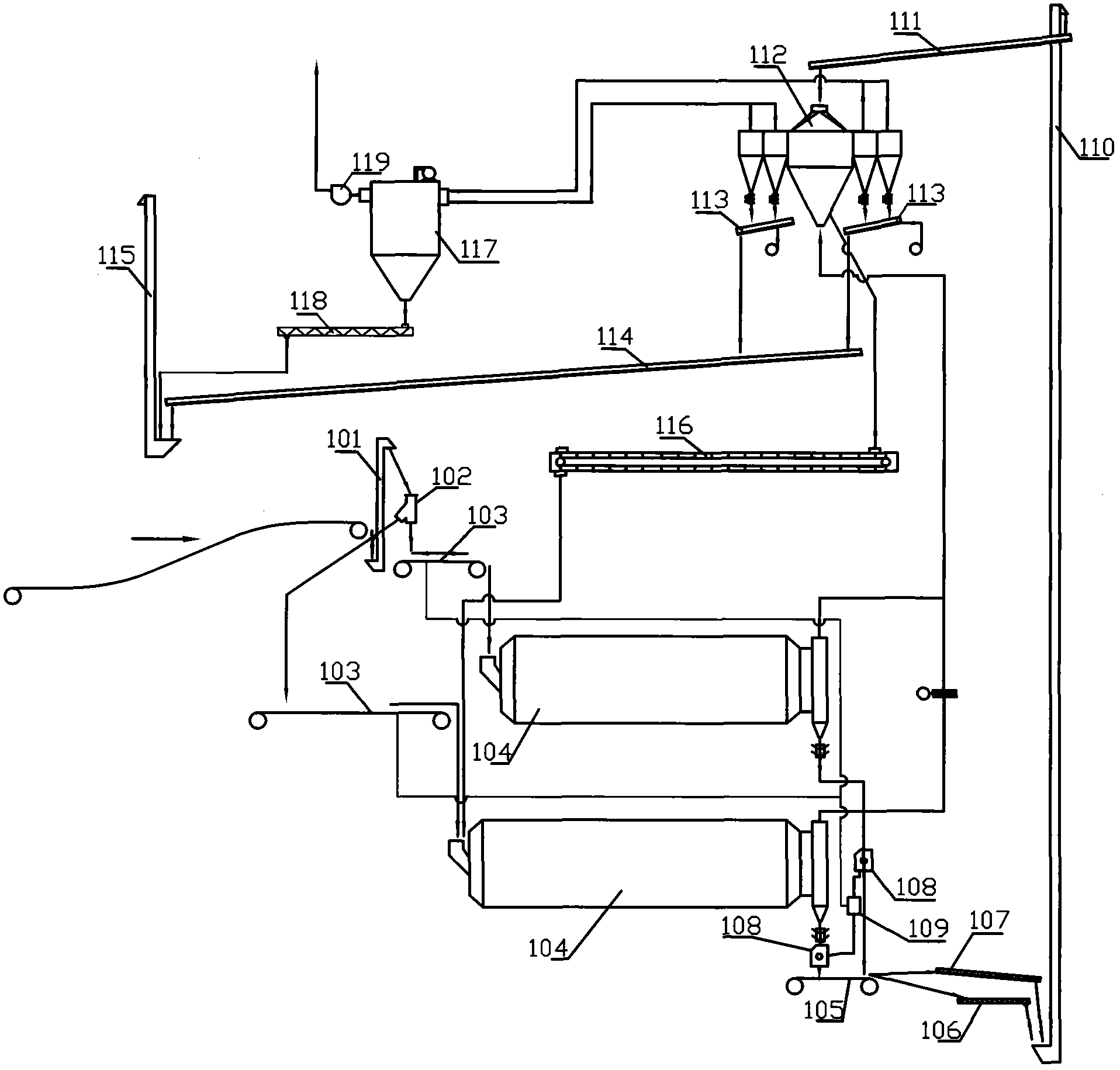

Heat accumulating type double-hearth lime kiln

InactiveCN102557492AShort stayCalcination temperature is highLime productionProcess engineeringSulfur content

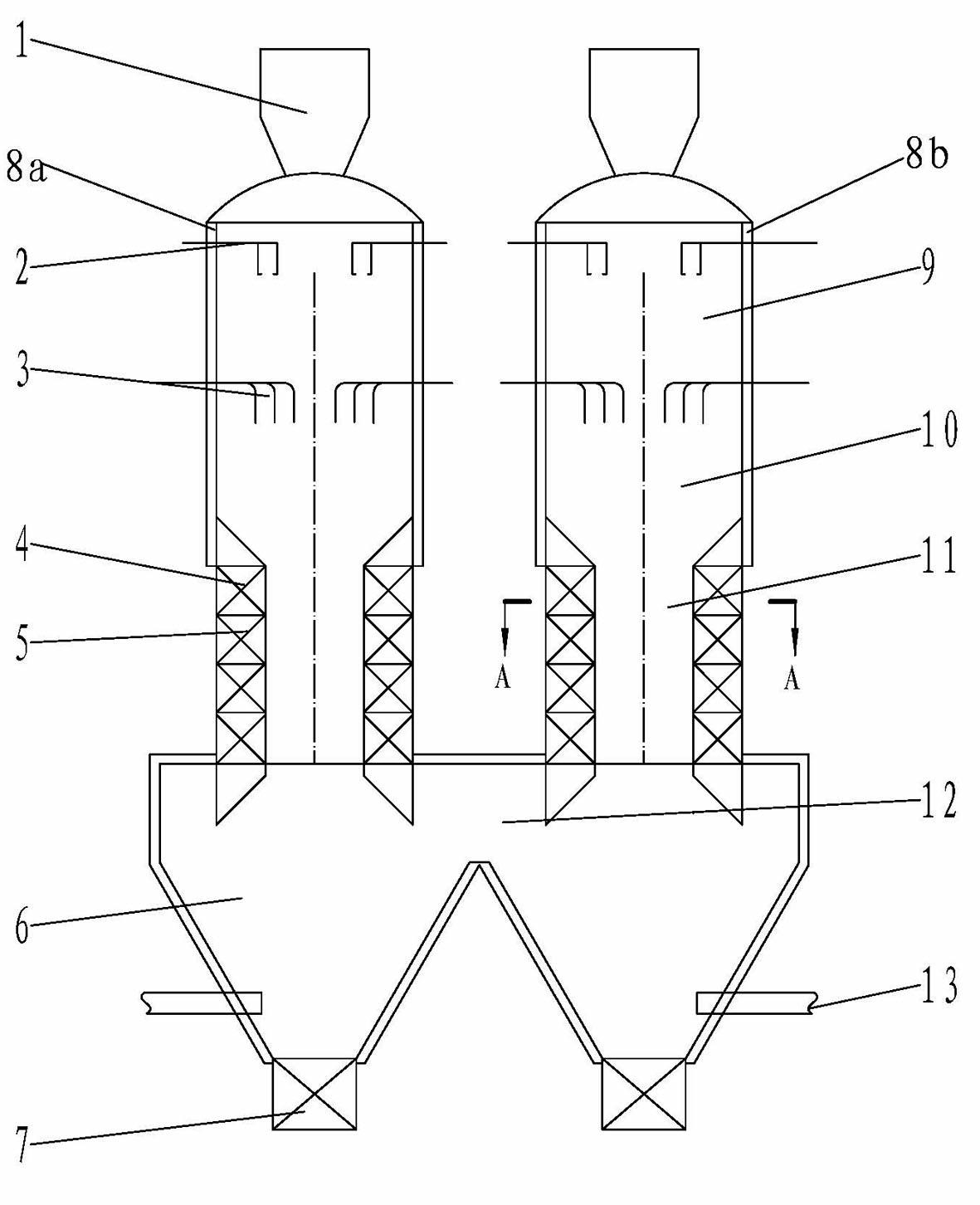

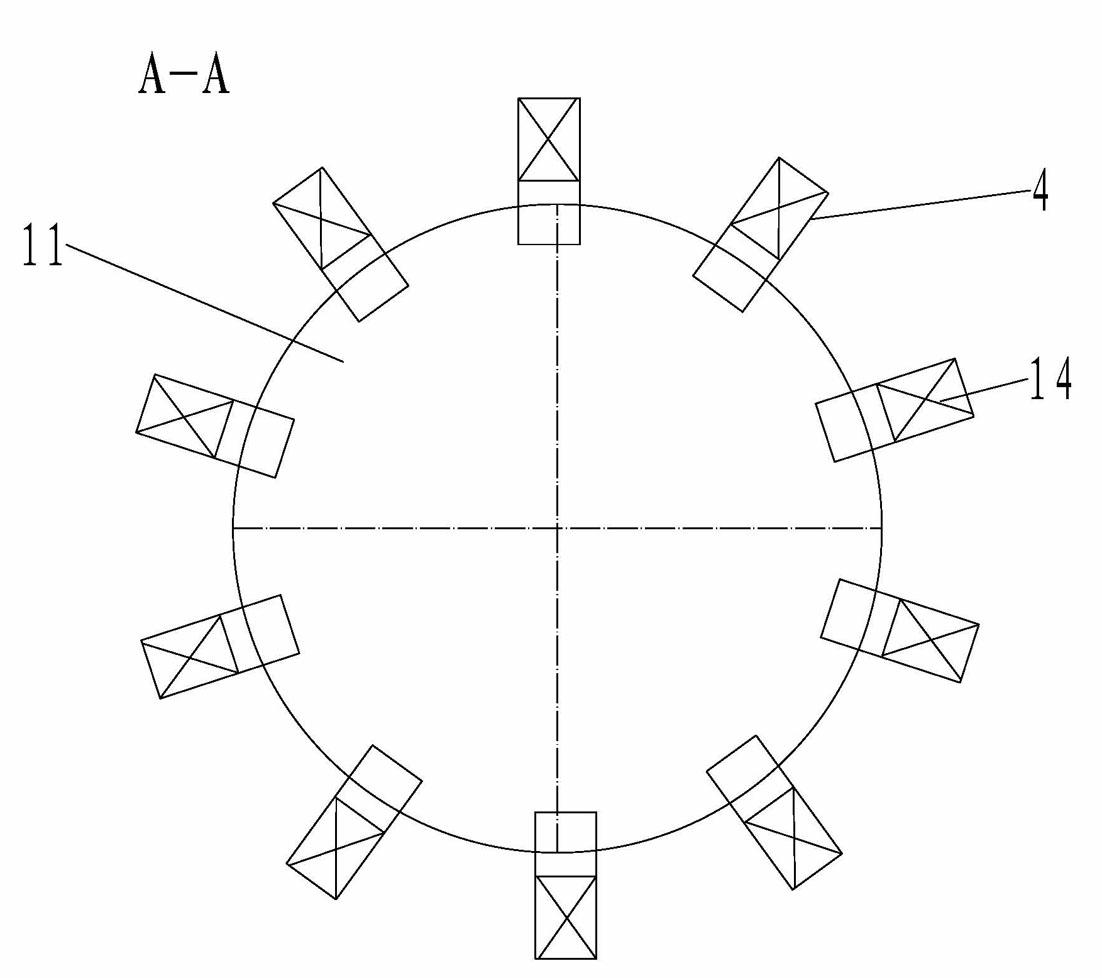

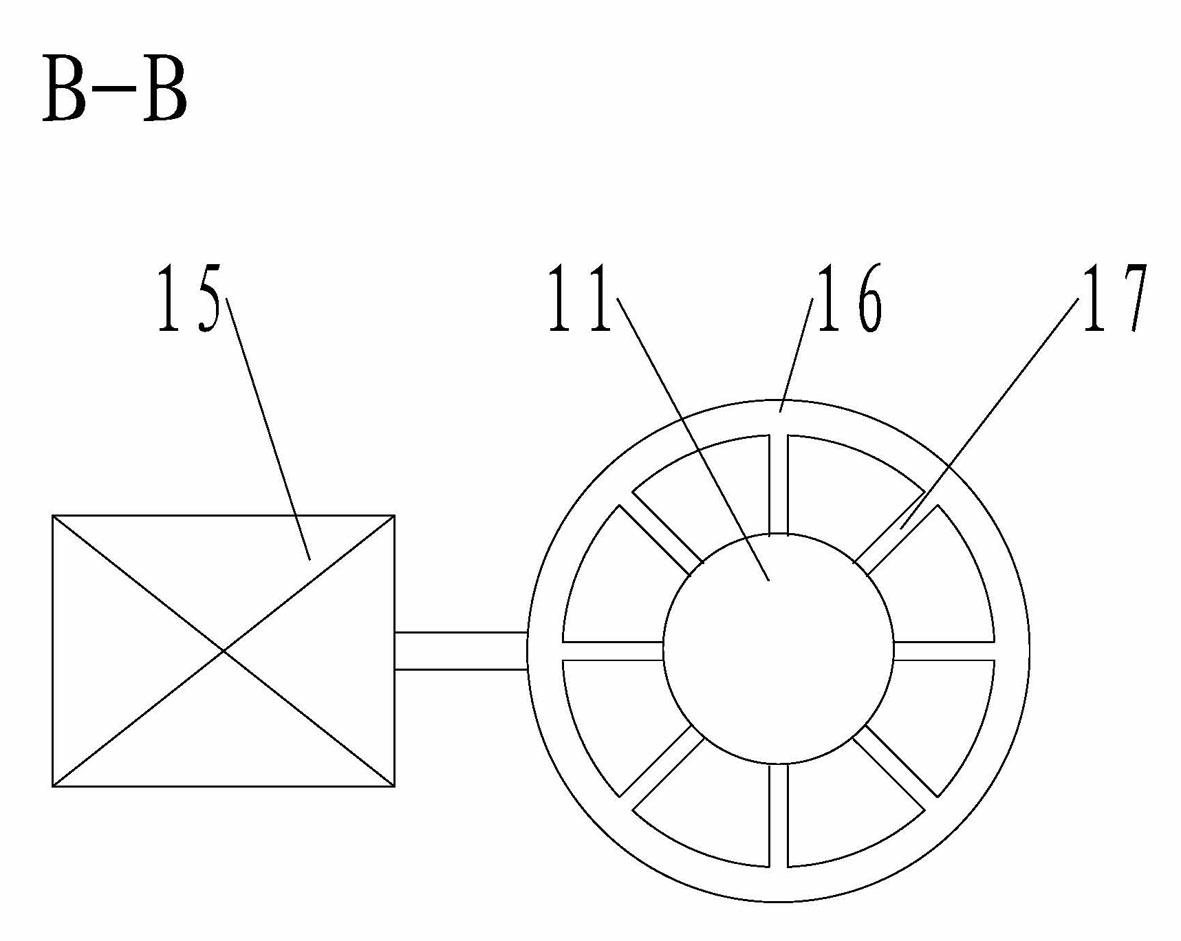

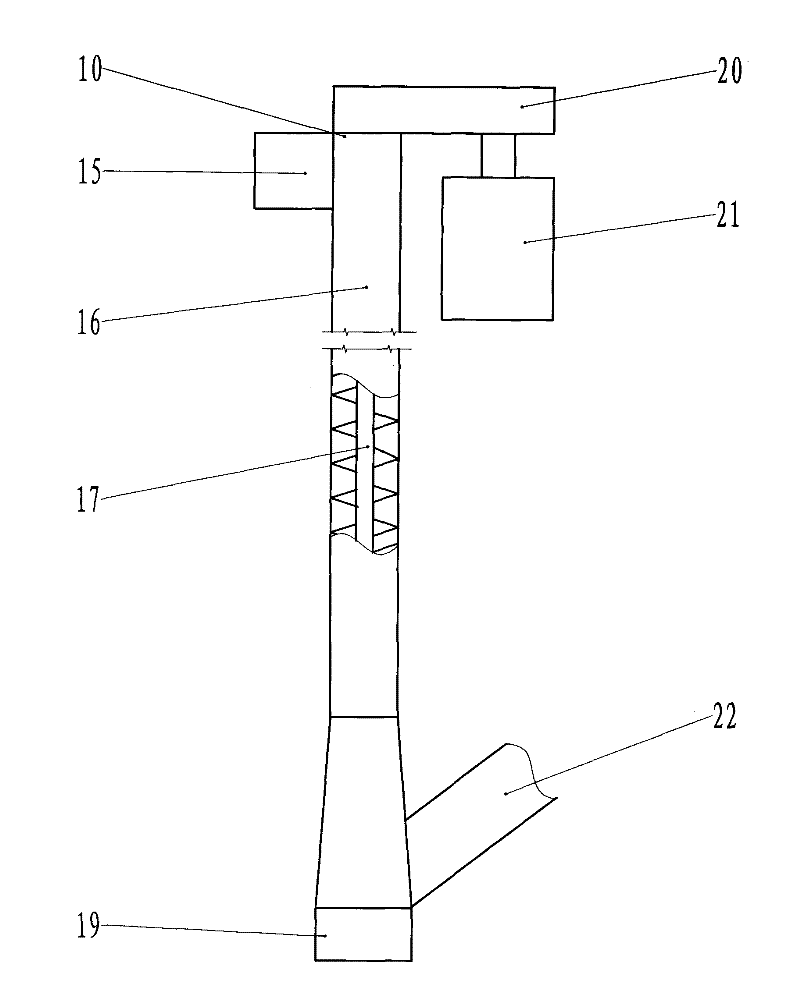

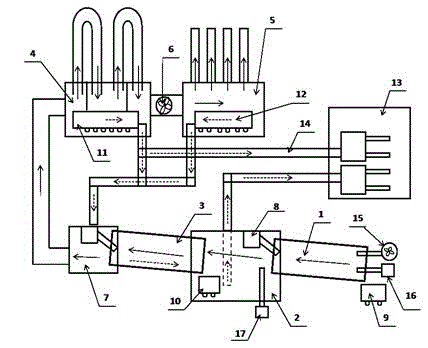

The invention relates to a heat accumulating type double-hearth lime kiln. The heat accumulating type double-hearth lime kiln comprises a feeding system, a discharging system, a combustion system, an air supply system, an exhaust emission system and two kiln bodies arranged in parallel, wherein each kiln body is respectively provided with a feeding port, a preheating zone, a calcining zone, a cooling zone and a discharging port; the two kiln bodies are communicated with each other through an annular channel on the upper parts of the cooling zones; a gas collecting device is arranged on the upper part of the preheating zone; an inserting type burner is arranged on the calcining zone; a cooled air inlet is formed in the cooling zone; a high-temperature calcining zone is arranged between the calcining zone and the cooling zone; the high-temperature calcining zone is provided with a fuel gas heat accumulator or 1 to 5 rows of fuel gas heat accumulating burners and 1 to 5 rows of combustion-supporting gas heat accumulating burners; and the fuel gas heat accumulating burners and the combustion-supporting gas heat accumulating burners are arranged at intervals and annularly arranged at the periphery of the kiln wall. The high-temperature calcining zone performs calcination in a secondary combustion manner, so that sulfur content of the calcined product is reduced and the quality of the calcined product is improved. The high-temperature calcining zone adopts the heat accumulating burners and utilizes oxygen for supporting combustion, thereby facilitating the improvement on intensity of combustion and reducing the energy consumption.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Calcining method for preparing aluminum-electrolytic pre-baked carbon anode petroleum coke

The invention relates to a calcining method for preparing aluminum-electrolytic pre-baked carbon anode petroleum coke, which is characterized in that calcination temperature is controlled at 1300-1350 DEG C; the fluctuation range of temperature is not larger than 30 DEG C; discharging amount is controlled by the volatile matter content in the petroleum coke, and the volatile matter is controlled in 10-15%; the secondary ventilation quantity of a rotary kiln is 2000-2600 m3 / h, and the third ventilation quantity is 1600-2200m3 / h; and negative pressure is controlled in 20- 40Pa. the invention causes a calcining process to obtain system optimization, the coke performance after calcination is greatly improved, the oxidation resistance and the electrical conductivity after calcination are significantly increased, and the true density is more than 2.05g / cm3. The produced anode quality is more uniform and stable, the ratio of first-grade products is significantly increased, and the electrolytic carbon consumption is greatly reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

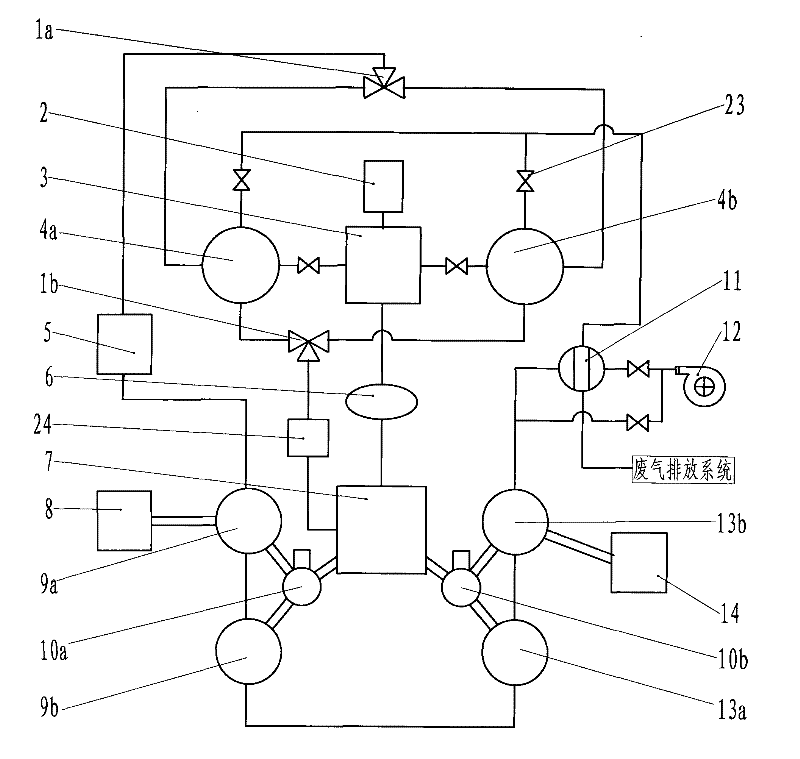

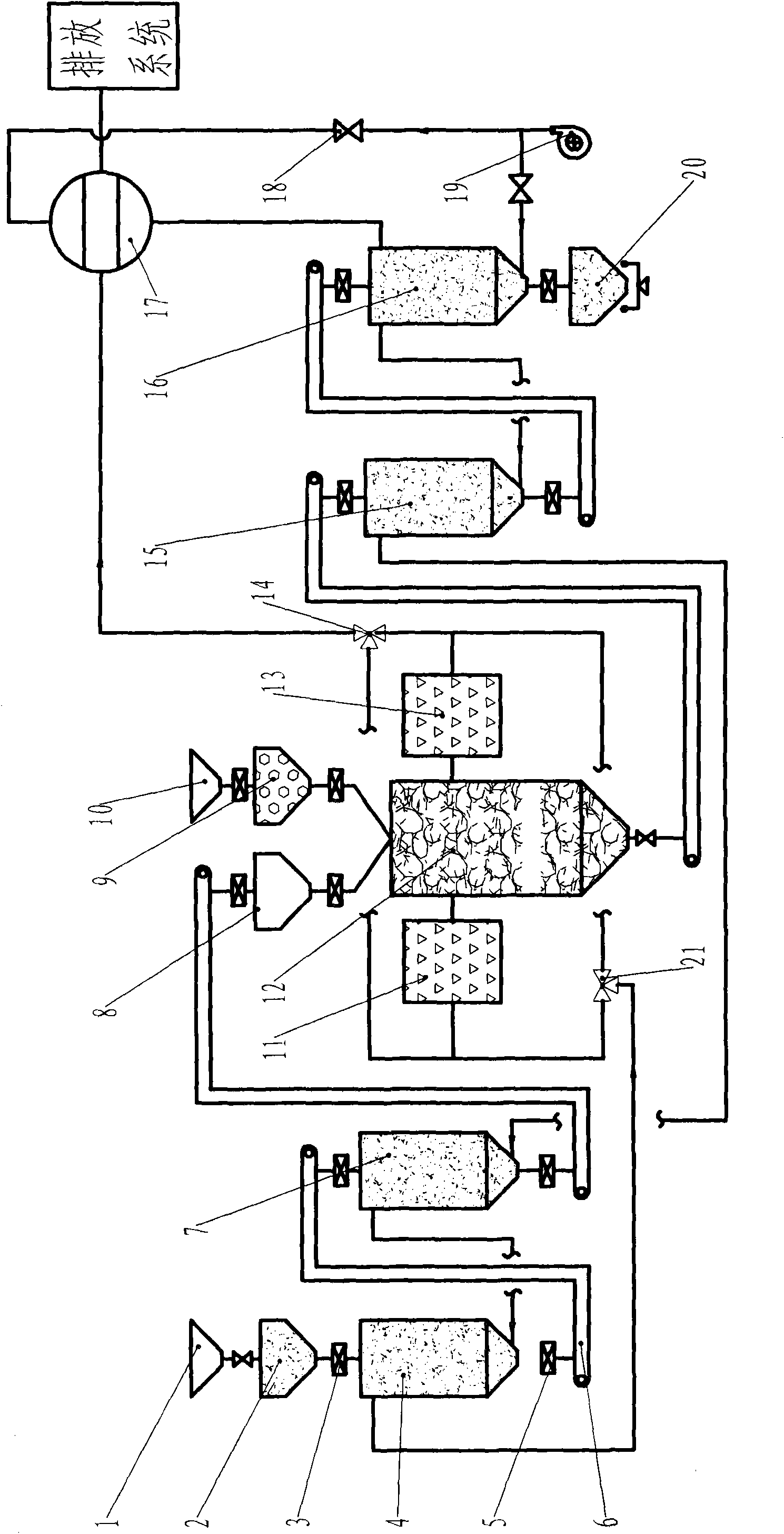

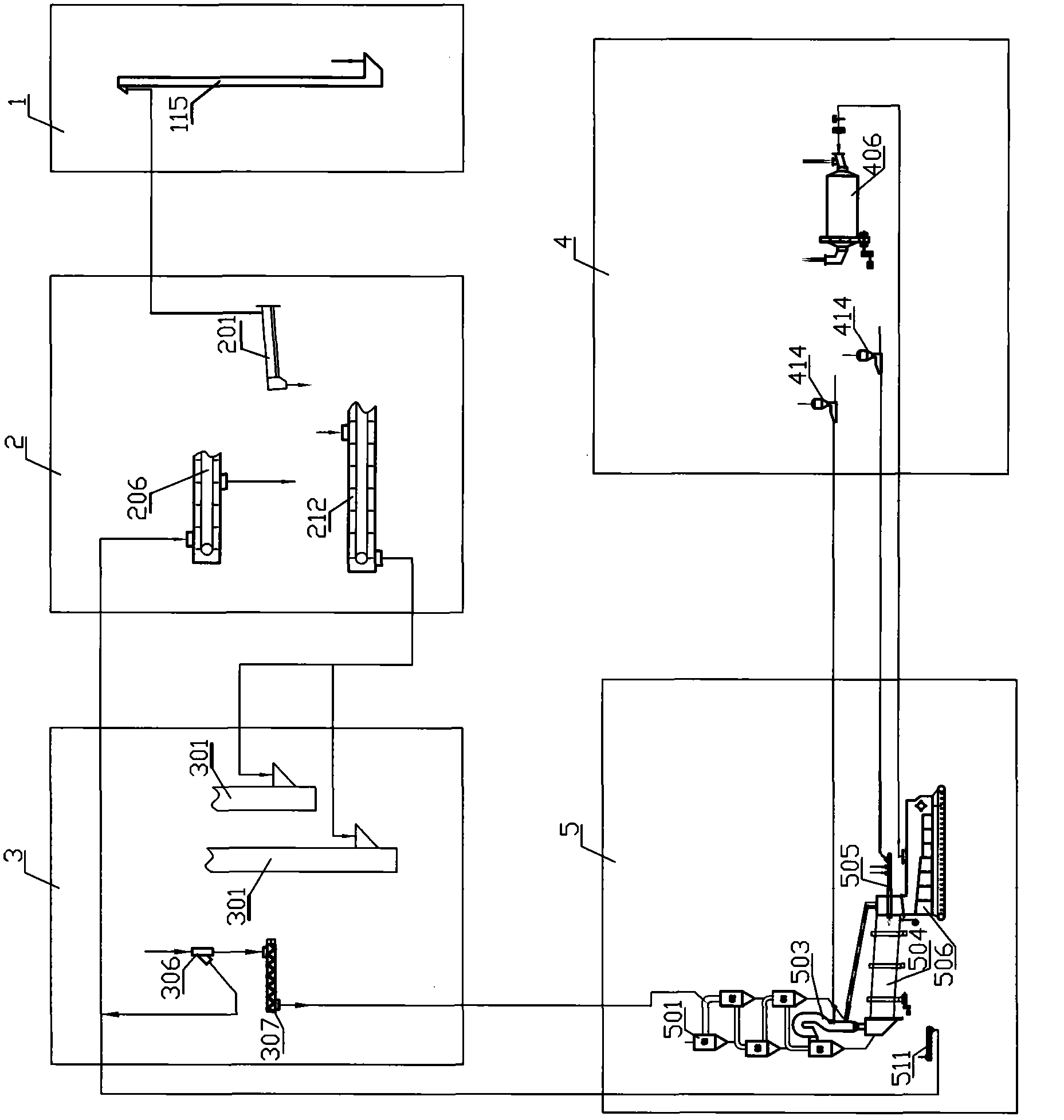

Method and device for calcining materials

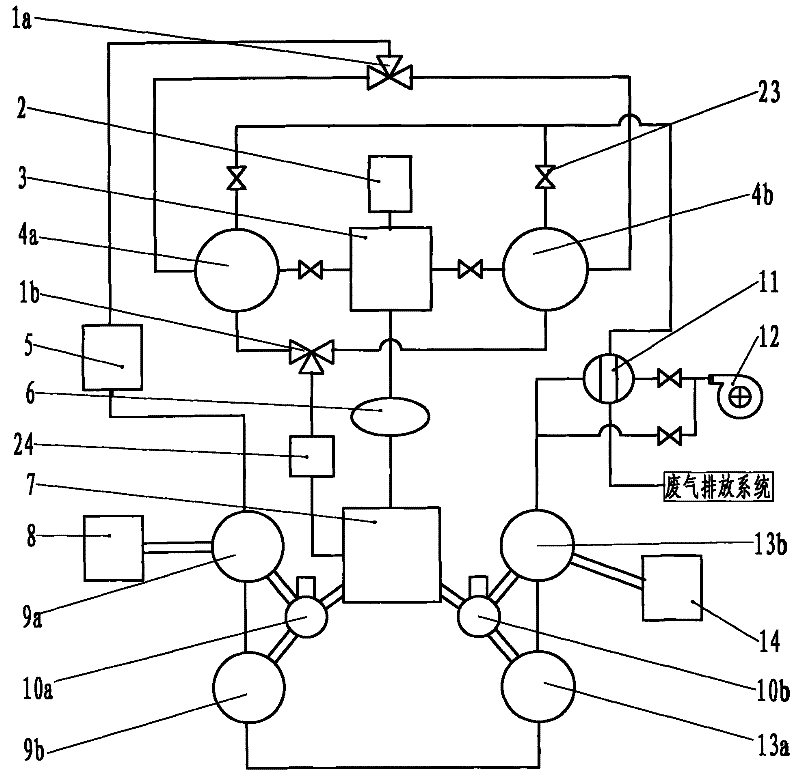

The invention provides a method and a device for calcining materials. The device has a splitting type structure comprises a burning chamber, preheating chambers, a calcining chamber, cooling chambers, a heat accumulator, a gas processing unit, a material conveying machine, a feed device, a discharge device and an exhaust gas discharging system. Material to be calcined is conveyed by the material conveying machine between the preheating chambers, between the preheating chambers and the calcining chamber, between the calcining chamber and the cooling chamber and between the cooling chambers. Smoke generated by the burning in the external burning chamber is processed by the gas processing unit, and then enters the burning chamber for calcining the material. Air for cooling lime and preheating limestone material is subject to dust removing by a cyclone separator and is preheated by the heat accumulator, and then enters the burning chamber for supporting combustion. In the invention, the fuel burning and the material calcining are separated, so that the pollution of lime products caused by harmful substances can be avoided, and the quality of the lime product can be improved. The gas is subject to dust removing and then enters the heat accumulator, thus avoiding blocking a gas channel in the heat accumulator. The material conveying machine is used for conveying the material, so that the conveying efficiency is high, and the occupied space is small.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

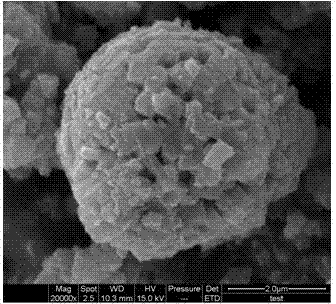

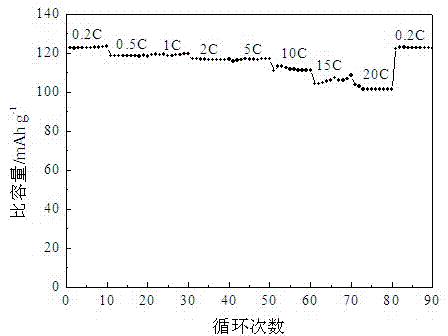

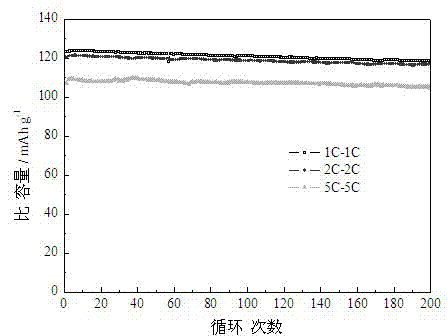

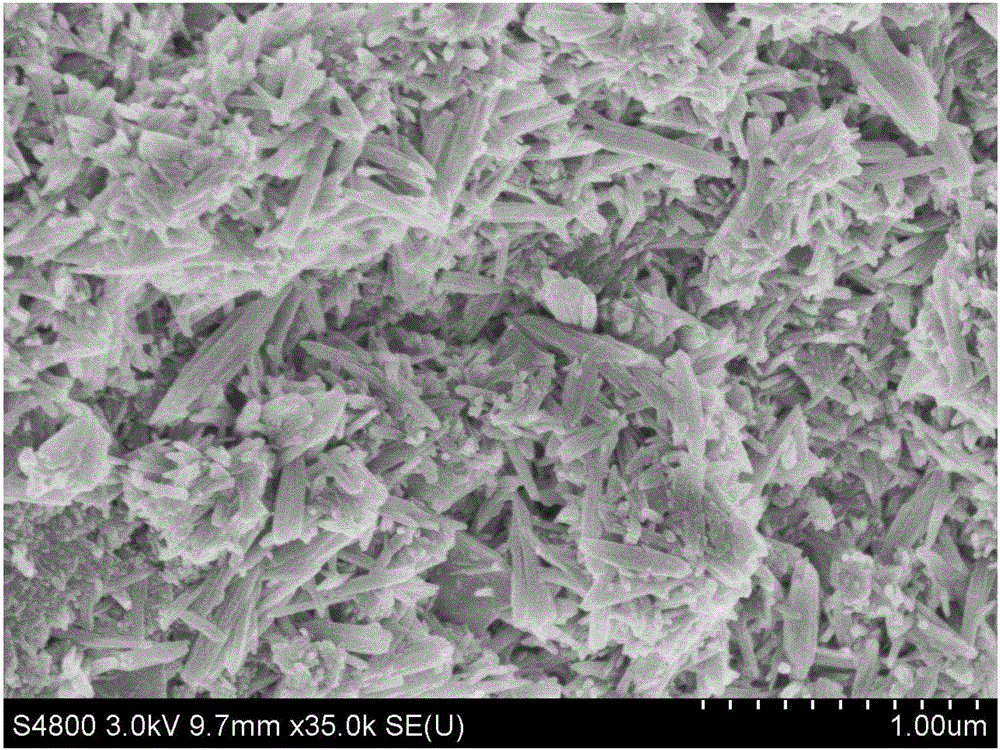

Preparation method of high-voltage nickel lithium manganate cathode material with porous morphology

A preparation method of a high-voltage nickel lithium manganate cathode material with porous morphology belongs to the field of material synthesis technology. The method is as below: calcining manganese salt at 200-800 DEG C for 3-10 h to obtain a porous manganese oxide A; weighing a lithium source, a nickel source and the manganese oxide A according to a molar ratio of Li:Ni:Mn=1-1.1:0.5:1.5, and mixing the three to obtain a precursor; putting the precursor in a muffle furnace air atmosphere, pre-sintering at 300-500 DEG C for 3-8 h, heating to 700-1000 DEG C and calcining for 8-20 h to obtain the nickel lithium manganate material. The particles of the nickel lithium manganate cathode material prepared by the invention have a porous structure and controllable morphology. The apertures in the porous nickel lithium manganate can buffer changes in structural stress and volume caused by lithium de-intercalation, enhance cycle performance, shorten transmission distance of lithium ions, increase the contact area of the electrode and an electrolyte and improve multiplying power performance, thereby gaining excellent multiplying power performance and cycle performance.

Owner:南京时拓能源科技有限公司

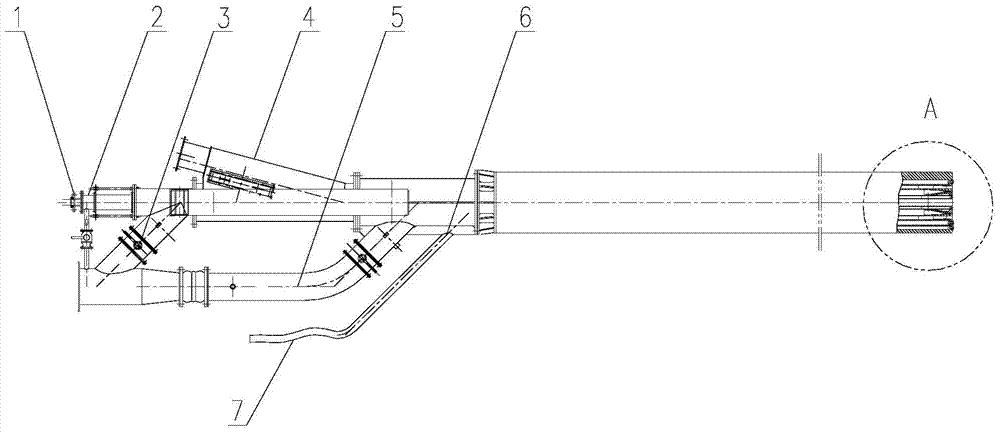

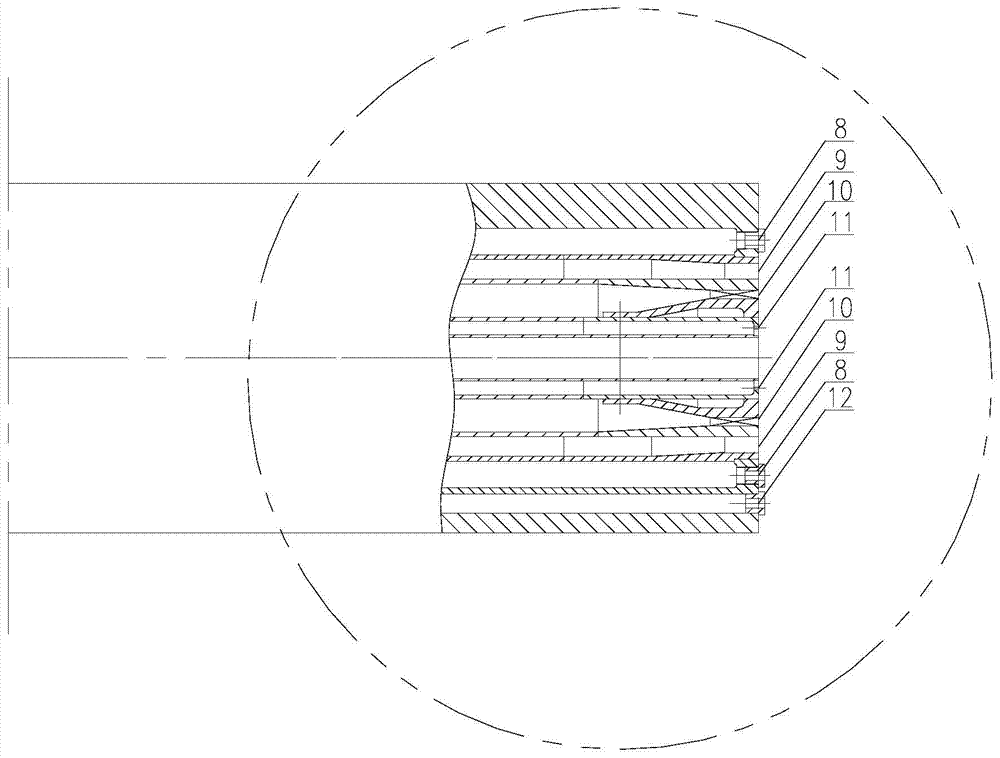

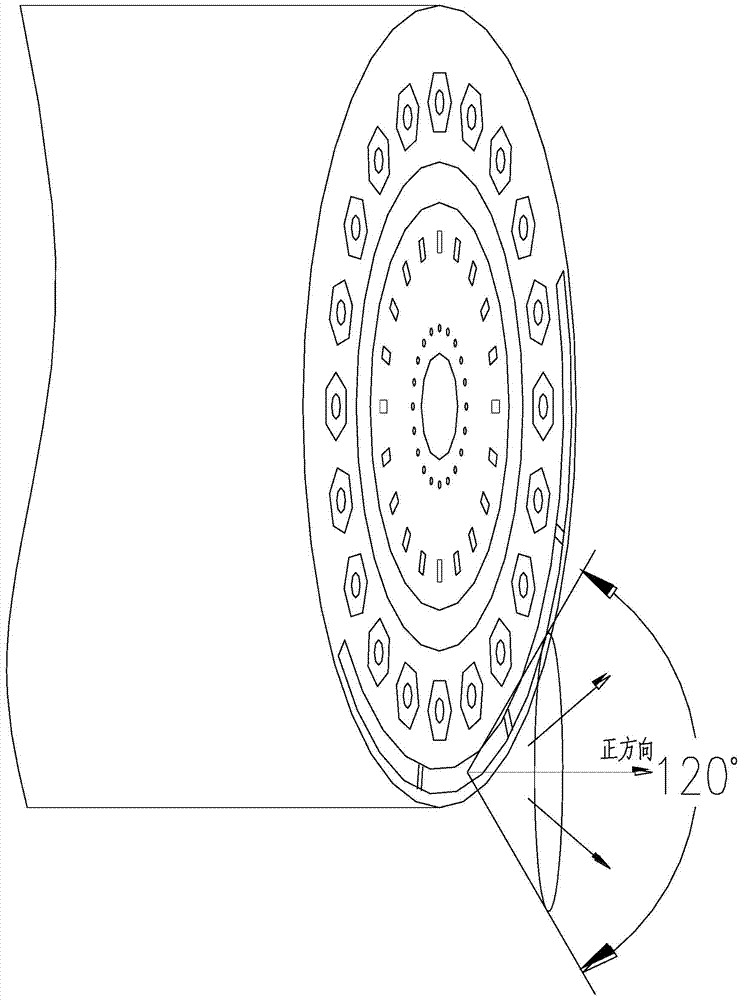

Local oxygen-enriched combustor for cement kiln furnace

InactiveCN103672886AImprove thermal energy utilization efficiencyStandard coal consumption decreasedPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCement kilnRotary kiln

The invention relates to a local oxygen-enriched combustor for a cement kiln furnace. Through the arrangement of an oxygen-enriched air passage outside an axial flow air passage of the combustor and the arrangement of a spray nozzle at an outlet of the oxygen-enriched air passage, the spray nozzle is arranged at the lower part of the outer side circumference of the air flow air spray nozzle and is near the clinker or analogue side, so the local concentration of the oxygen gas at the contact side of the lower part of the combustor and the oxygen-enriched air passage is raised, the combustion speed of the fuel can be accelerated, the local heat accumulation is directly caused, the adjacent fuel also begins to combust along with the proceeding of the diffusion, heat transfer and heat radiation processes, the temperature of the direct contact side of the clinker or analogue of a rotary kiln with the oxygen-enriched air passage is obviously raised, and the response to the raw material mass fluctuation caused by proportioning can be realized. In addition, a center angle corresponding to a distribution region in the circumferential direction is set to be smaller than or equal to 270 degrees, the angle range can completely cover the region of the fuel and the cement clinker or analogue rotating along with the rotary kiln, and the use precision and the economization of oxygen-enriched air can be ensured.

Owner:NANJING KISEN INT ENG

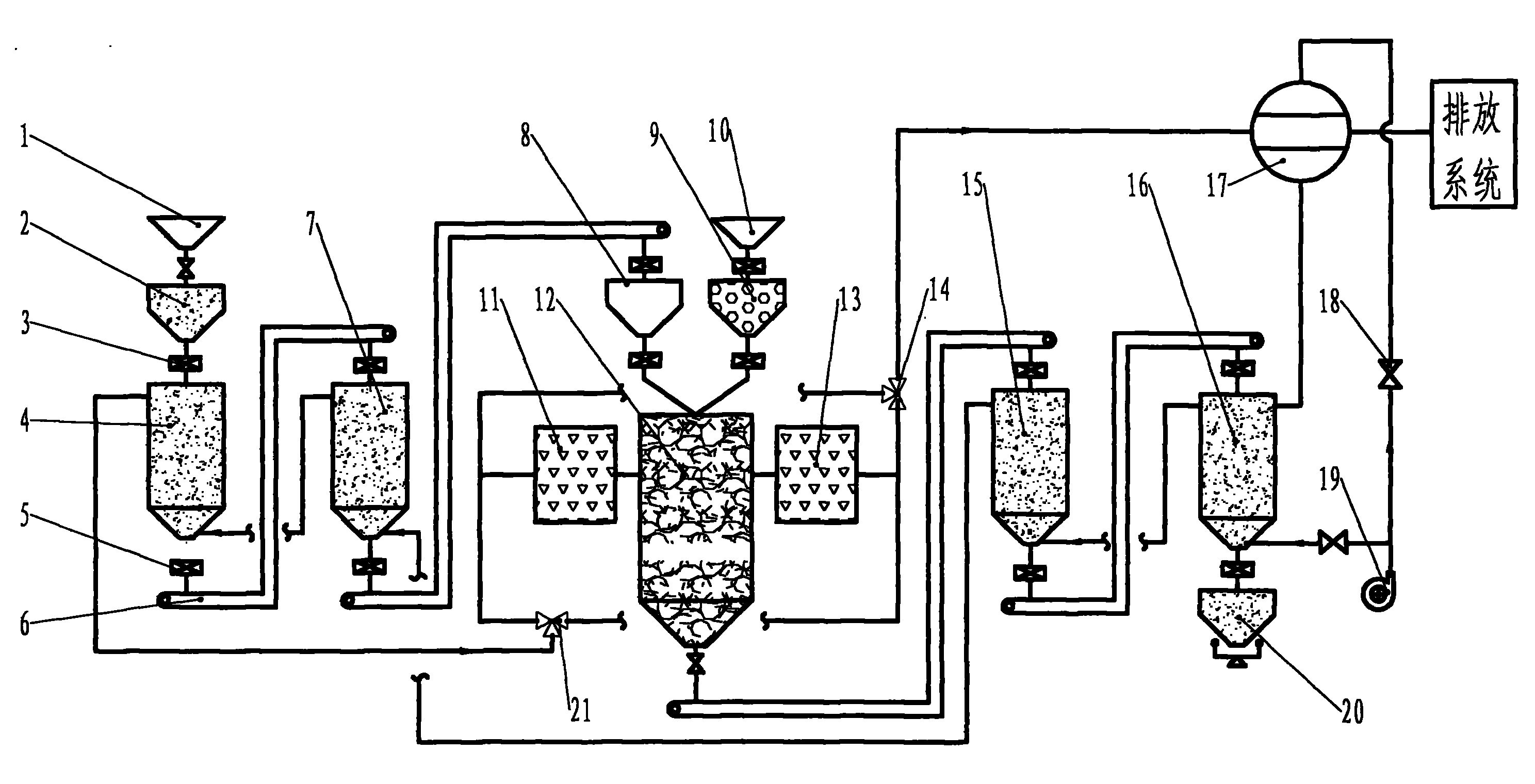

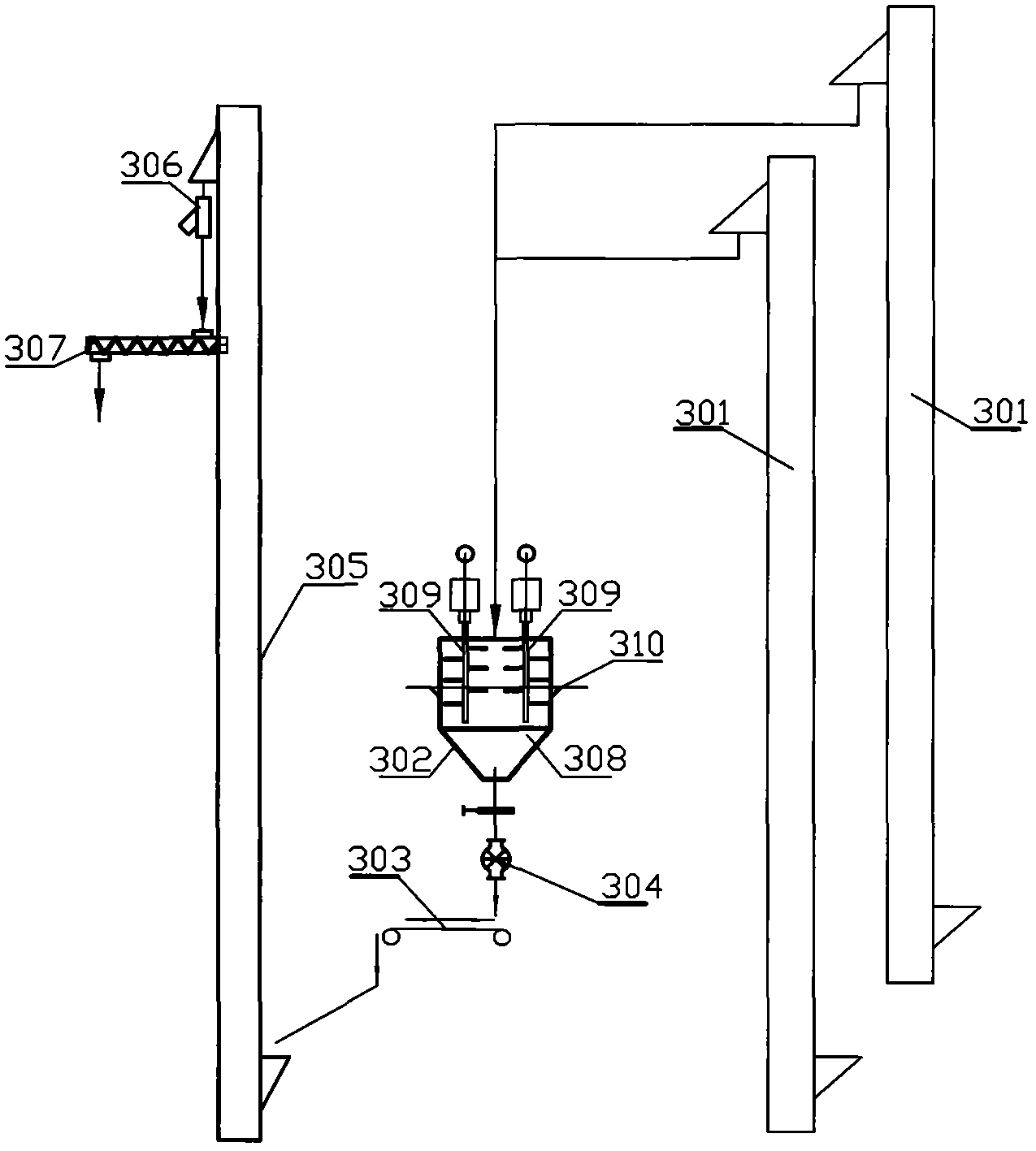

Method and equipment for calculating materials

ActiveCN101817649AImprove product qualityIncrease profitLime productionCombustionNuclear engineering

The invention provides a method and equipment for calculating materials. A preheating chamber, a calculating chamber and a cooling chamber of the equipment are in split structures; and the calculated materials are delivered by a bucket-type hoister among feeding equipment, the preheating chamber, the calculating chamber and the cooling chamber. The calculated materials are preheated, calculated and cooled in the split preheating chamber, calculating chamber and cooling chamber to obtain calculating products. High-temperature gas generated during cooling products in the cooling chamber is delivered to the preheating chamber by a gas pipeline for preheating the calculated materials and enters the calculating chamber to be used as combustion-supporting air after being preheated by a heat accumulator. The invention fully utilizes heat energy, reduces the consumption of fresh air and the emission of room temperature gas and is beneficial to environmental protection. Various units of the equipment are independent assemblies, can be separately produced and assembled on site and are beneficial to serially producing and calculating the equipment. The materials are delivered among various chambers by using the bucket-type hoister, so that the invention realizes split operations and improves the flexibility of operations.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

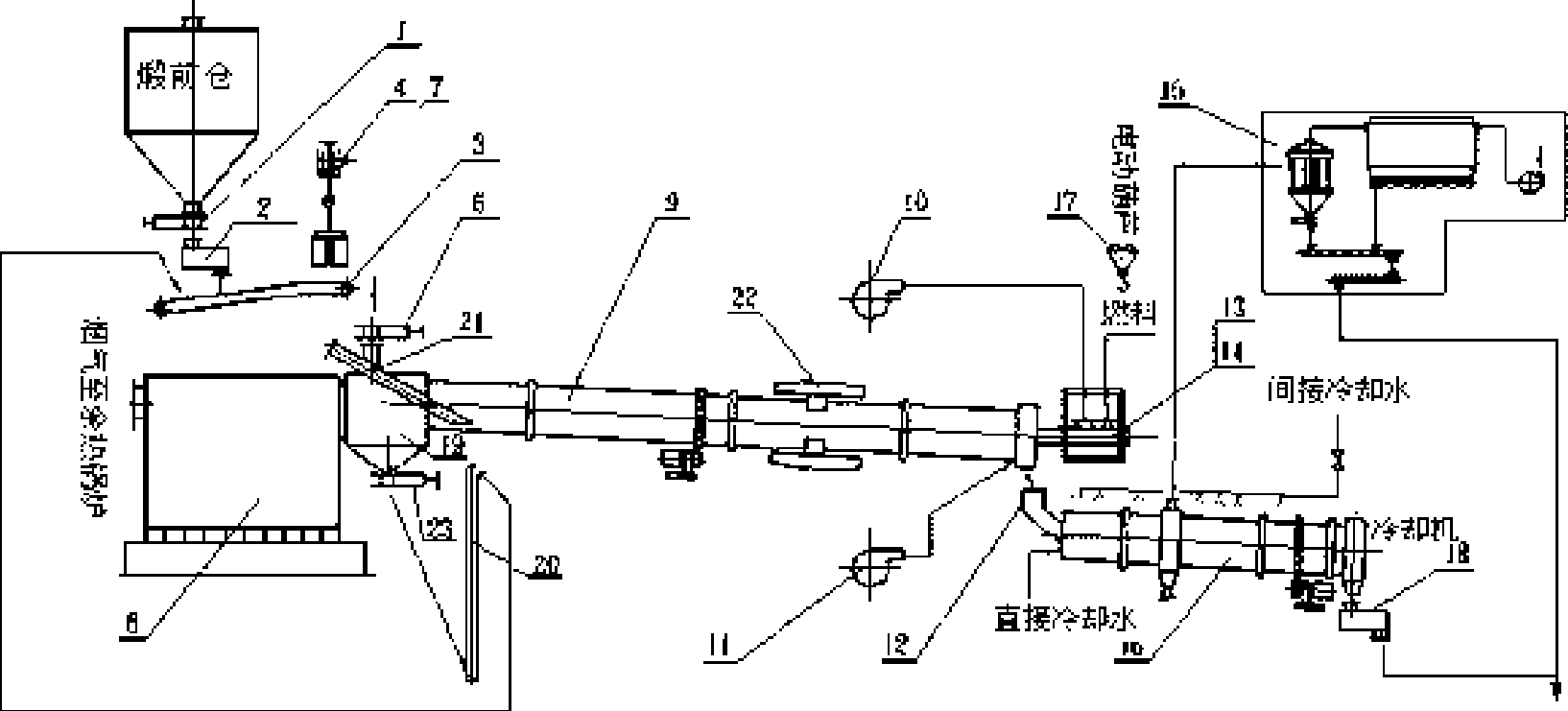

Rotary kiln for calcining refinery coke

The invention discloses a petroleum coke calcining rotary kiln, which comprises a rotary kiln(9); an insert plate valve(1) is arranged below a calcining front chamber; an adhesive tape constant feeder(2) is arranged below the insert plate valve, and an adhesive tape conveyer(3) is arranged behind the adhesive tape constant feeder (2) and connected with the rotary kiln(9) by an oblique cutting feed tipping tube of an electric insert plate valve(6); the tail part of the rotary kiln(9) is connected with a dust deposition chamber(8), and the head part of the rotary kiln(9) is connected with a cooling machine(16) and provided with a burner nozzle(13) and a burner nozzle hanger(14); the petroleum coke calcining rotary kiln is also provided with a one-time combustion fan(10) matched with the burner nozzle; and a dust-containing waste gas processing system(15) is arranged beside the cooling machine(16). The petroleum coke calcining rotary kiln has the advantages of improving the unit volume capacity, greatly enhancing comprehensive utilization of waste heat and adaptability of other calcining materials such as needle coke, anthracite and the like, reducing burning loss of charcoal, saving raw materials and energy, improving automatization level and reducing labor intensity of a worker.

Owner:GUIYANG AL-MG DESIGN & RES INST

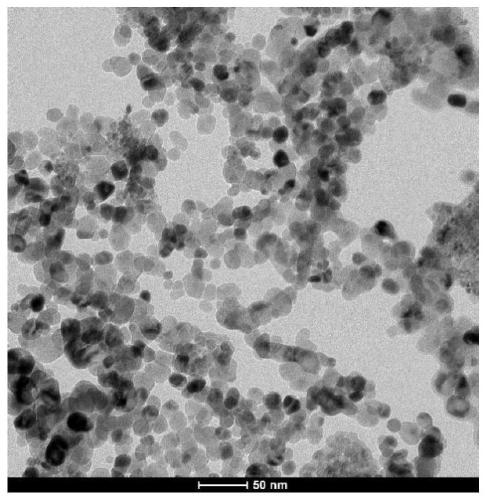

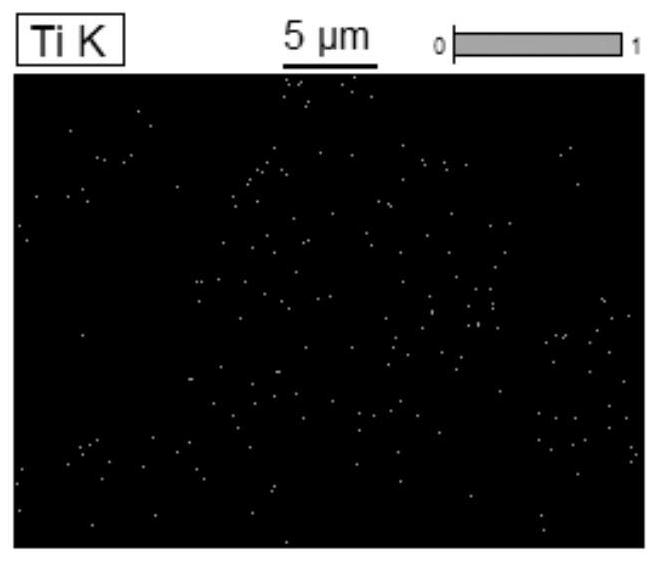

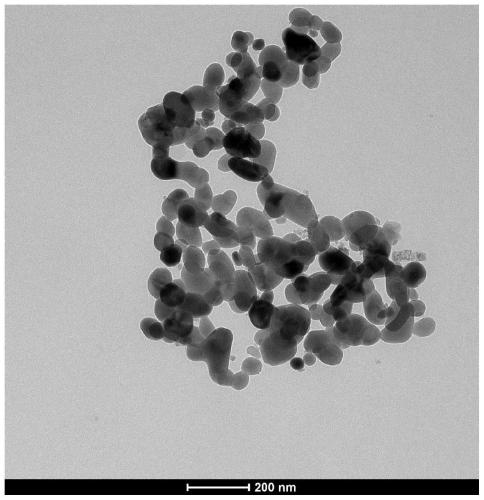

Metal oxide nanoparticles and preparation method of metal oxide nanoparticles

PendingCN111320193AGood dispersionHigh crystallinityMaterial nanotechnologyAluminium oxide/hydroxide preparationMetal oxide nanoparticlesPhysical chemistry

The invention discloses a metal oxide nanoparticle and a preparation method of the metal oxide nanoparticle, which comprises the following steps: preparing an organosol containing the metal element, mixing the organosol with a water-soluble salt, performing standing or centrifuging to precipitate the water-soluble salt, removing the superfluous organosol at the upper part, and keeping the temperature to convert the organosol into gel; along with evaporation of the solvent, shrinking the gel, and coating the surfaces of the water-soluble salt particles with a layer of xerogel film; and calcining the sample at a high temperature between 400 DEG C and a salt melting point, converting the dry gel film into metal oxide nanoparticles, dispersing and attaching the nanoparticles to the surfaces ofwater-soluble salt particles, cooling, and washing with water to remove the salt, thereby obtaining the high-dispersion metal oxide nanoparticles; if the calcined product is reduced in a reducing atmosphere, converting the metal oxide nanoparticles attached to the surfaces of the water-soluble salt particles into corresponding metal nanoparticles, cooling, and washing with water to obtain the high-dispersion metal nanoparticles. According to the method, the high-crystallinity and high-dispersion metal oxide and metal nanoparticles can be rapidly prepared in batches.

Owner:SOUTHEAST UNIV

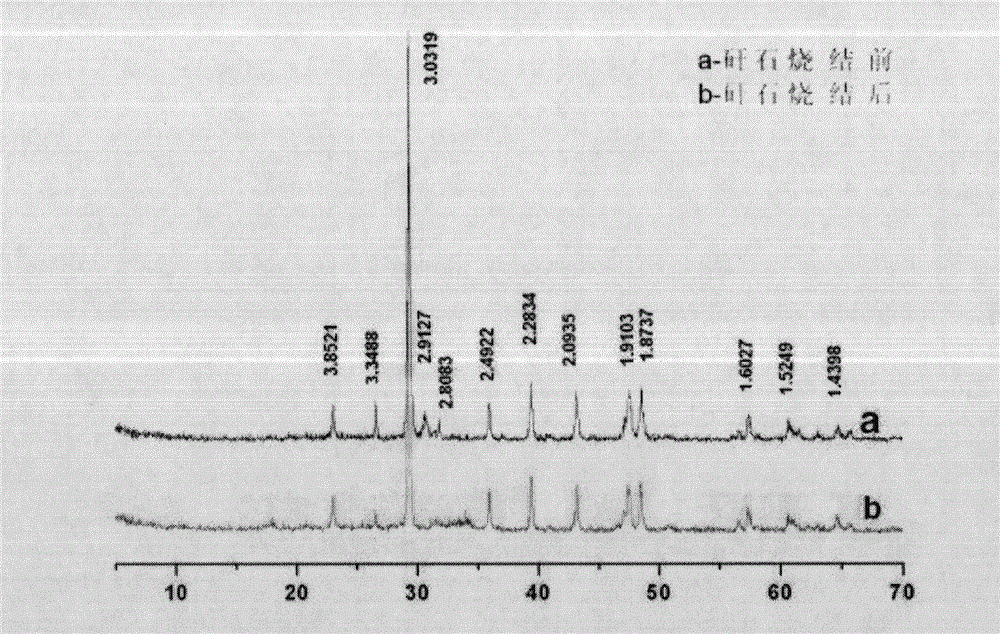

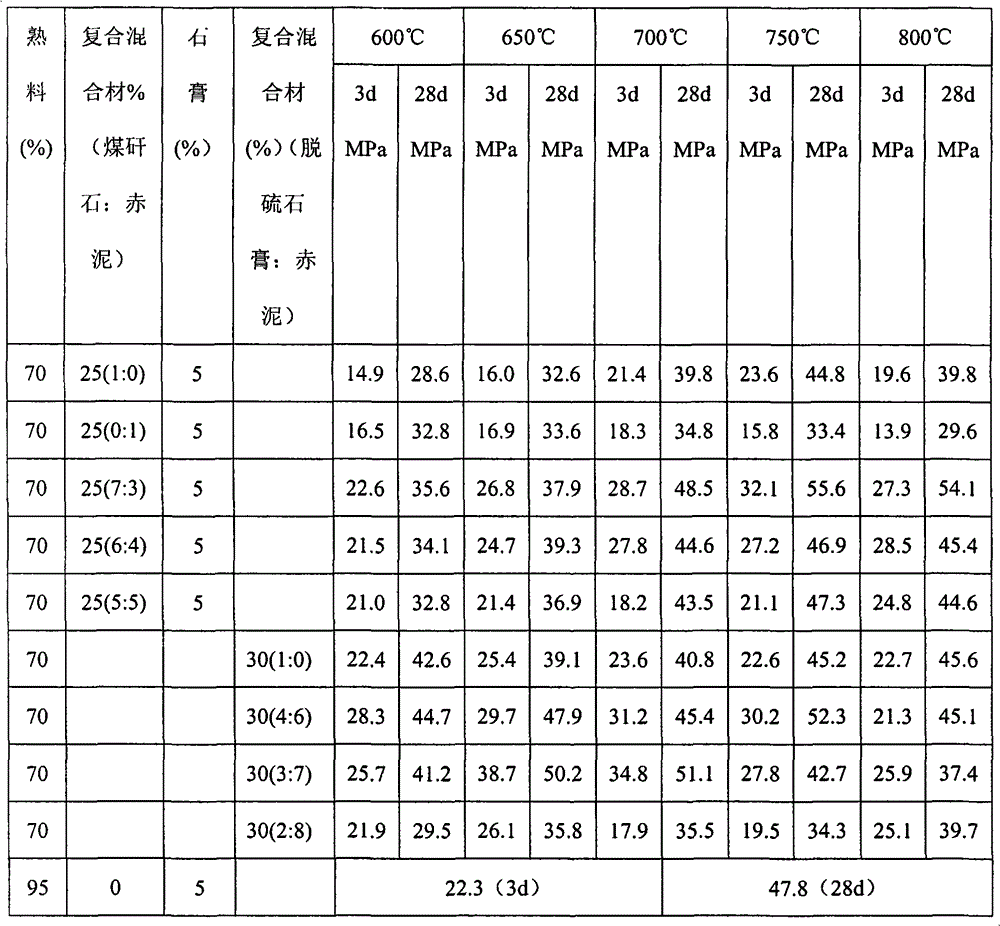

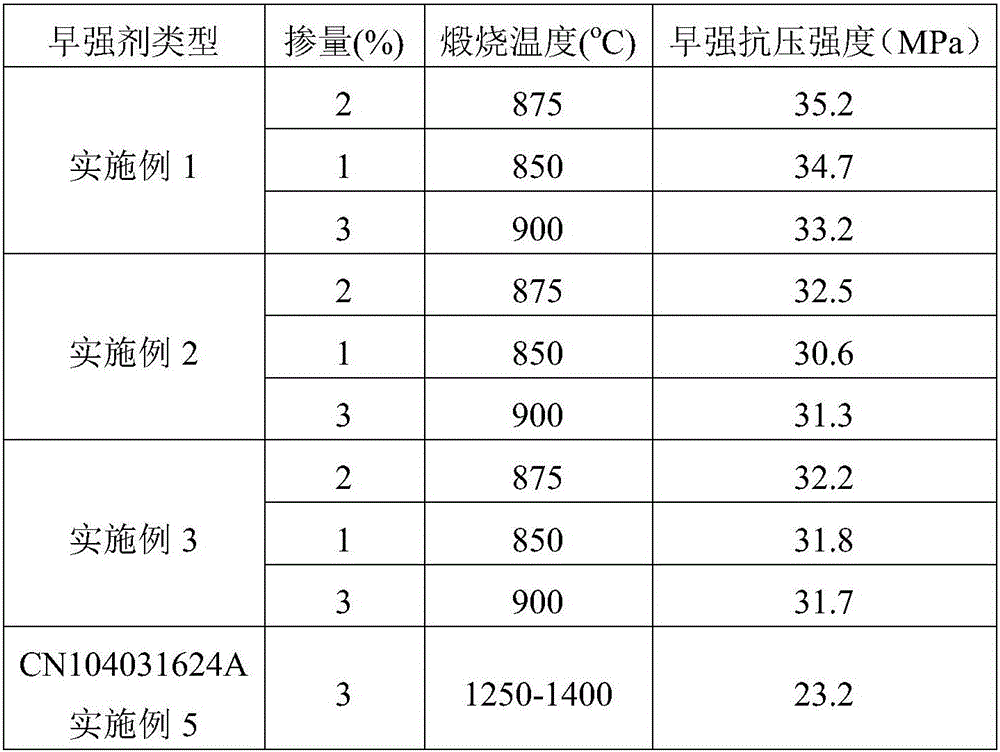

Preparation method for early strength cement admixture containing red mud or coal gangue

InactiveCN102718417ACalcination temperature is highReduced activityCement productionRed mudCement paste

The invention discloses a preparation method for an early strength cement admixture containing red mud or coal gangue. The method includes: respectively mixing the red mud and the coal gangue or flue gas desulfurization gypsum and the red mud according to following proportions, by weight, 8:2-6:4 for the red mud to the flue gas desulfurization gypsum and 3:7-5:5 for the red mud to the coal gangue, grinding, calcining at a temperature of 600 to 800 DEG C, composing the red mud and the coal gangue with cement clinker and gypsum, or composing the flue gas desulfurization gypsum and the red mud with the cement clinker to obtain the composite admixture capable of improving early strength of cement paste. The composite admixture obtained by industrial wastes such as the red mud, the coal gangue has good economic and environmental benefits, and the early strength cement admixture is low in firing temperature and economical in energy resources, meets national strategic guidelines on energy conservation and environment protection and has good development prospects.

Owner:HENAN POLYTECHNIC UNIV

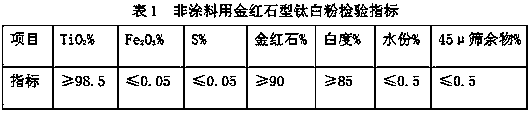

Production method of non-coating rutile type titanium dioxide

The invention relates to the field of titanium dioxide preparation, in particular to a production method of non-coating rutile type titanium dioxide. The method includes the steps of (1), selecting ofraw materials; (2), preparation of a titanium solution; (3), preheating of the titanium solution; (4), manufacturing of seed crystals; (5), adding of the seed crystals; (6), hydrolyzing; (7), flushing; (8), washing; (9), calcining. The acid-split titanium solution can be hydrolyzed without being concentrated, the energy consumption is low, a crystal form accelerant is added when the seed crystalsare prepared, the titanium dioxide can be converted into rutile in the production process, a high crystal form conversion accelerating effect is achieved, the calcining temperature is low, and damageto equipment is greatly relieved; by means of the two links that the crystal form accelerant is added when the seed crystals are prepared, and heat preservation is carried out for 3 hours after calcining is completed, it can be promoted that the produced titanium dioxide is converted into the rutile, the conversion rate of the rutile is high, and therefore the non-coating rutile type titanium dioxide with high rutile content is obtained.

Owner:ALFA FULL GUANGXI TENG COUNTY TITANIUM DIOXIDE

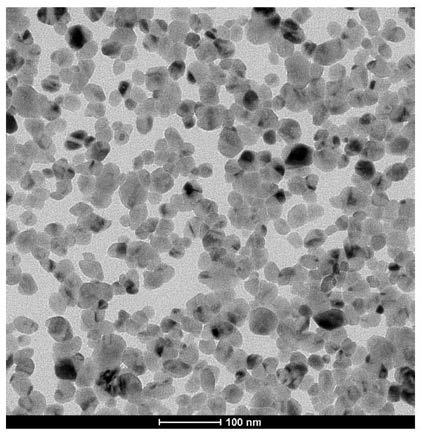

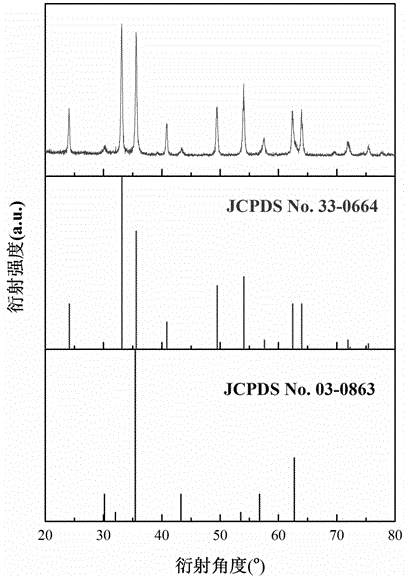

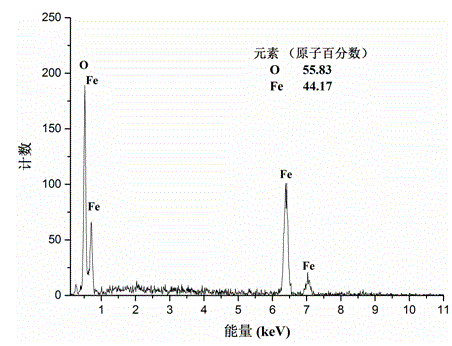

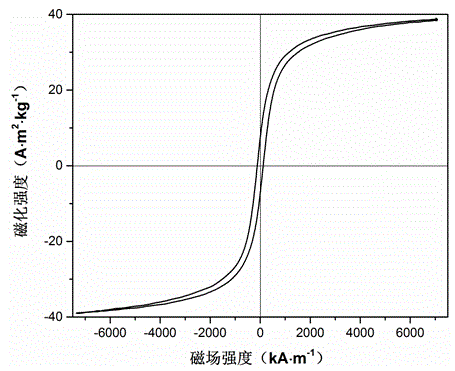

Preparation method of magnetic Fe2O3/Fe3O4 nano-heteroplasmon particles

ActiveCN104909412ALess types of raw materialsProcess is easy to controlMaterial nanotechnologyFerroso-ferric oxidesChemistryIron salts

The invention belongs to the technical field of preparation of inorganic nonmetal nanocomposite materials, and concretely relates to a preparation method of magnetic Fe2O3 / Fe3O4 nano-heteroplasmon particles. The method adopts metal iron salt, alcohol and an alcohol-soluble organic matter as raw materials, and comprises the following steps: adding the iron salt to alcohol or the alcohol-soluble organic matter according to a ratio of the iron salt to the alcohol of 1mol / 7mL or less, stirring for dissolving to prepare a sol solution, igniting and combusting the sol solution in air to prepare a gel, calcining the gel at 150-450DEG C under a heating rate of 0.5-15DEG C / min for 0.1-12h, and naturally cooling to prepare the magnetic Fe2O3 / Fe3O4 nano-heteroplasmon particles. The preparation method has the advantages of simple technology, convenient operation, easy process control, wide sources of the raw materials, low cost, environmental protection, low requirements on a required device, uniform diameter distribution of the particles, and convenience for large-scale industrial production. The microstructure and the morphology of the particles can be conveniently controlled by adjusting process factors and the chemical composition in order to control the performances of the particles.

Owner:江阴智产汇知识产权运营有限公司

Energy-saving and environment-friendly cement clinker preparation system

ActiveCN103351106AUniform and stable qualityQuality improvementClinker productionDecompositionScrew conveyor

The invention discloses an energy-saving and environment-friendly cement clinker preparation system, which includes a raw material preparation system, a raw material homogenization system, a fed raw material conveying system, a cement and pulverized coal preparation system and a cement clinker calcination system, wherein a material outlet of a loading bucket elevator is connected with a material inlet of a raw material homogenization air conveying chute; a material outlet of an unloading chain conveyer is connected with material inlets of two unloading bucket elevators respectively; a material outlet of a raw material feeding spiral conveyer is connected with a material inlet of a preheater; a material outlet of a spiral pneumatic conveying pump is connected with a material inlet of a decomposition furnace; a material outlet of another spiral pneumatic conveying pump is connected with a material inlet of a four-passage pulverized coal combustion device; a hot air outlet of an air-beam type grate cooler is connected with an air inlet of an air-swept coal mill; one material outlet of an electric tee scraper-trough conveyer and a material outlet of a kiln tail dust collection spiral conveyer are both connected with a material inlet of a re-homogenization loading chain conveyer. The system has the advantages as follows: the yield of the clinker is increased, the energy consumption is lowered, the emission is reduced, the quality of the clinker is improved, and the quality of the cement is stable.

Owner:INNER MONGOLIA MENGXI CEMENT CO LTD

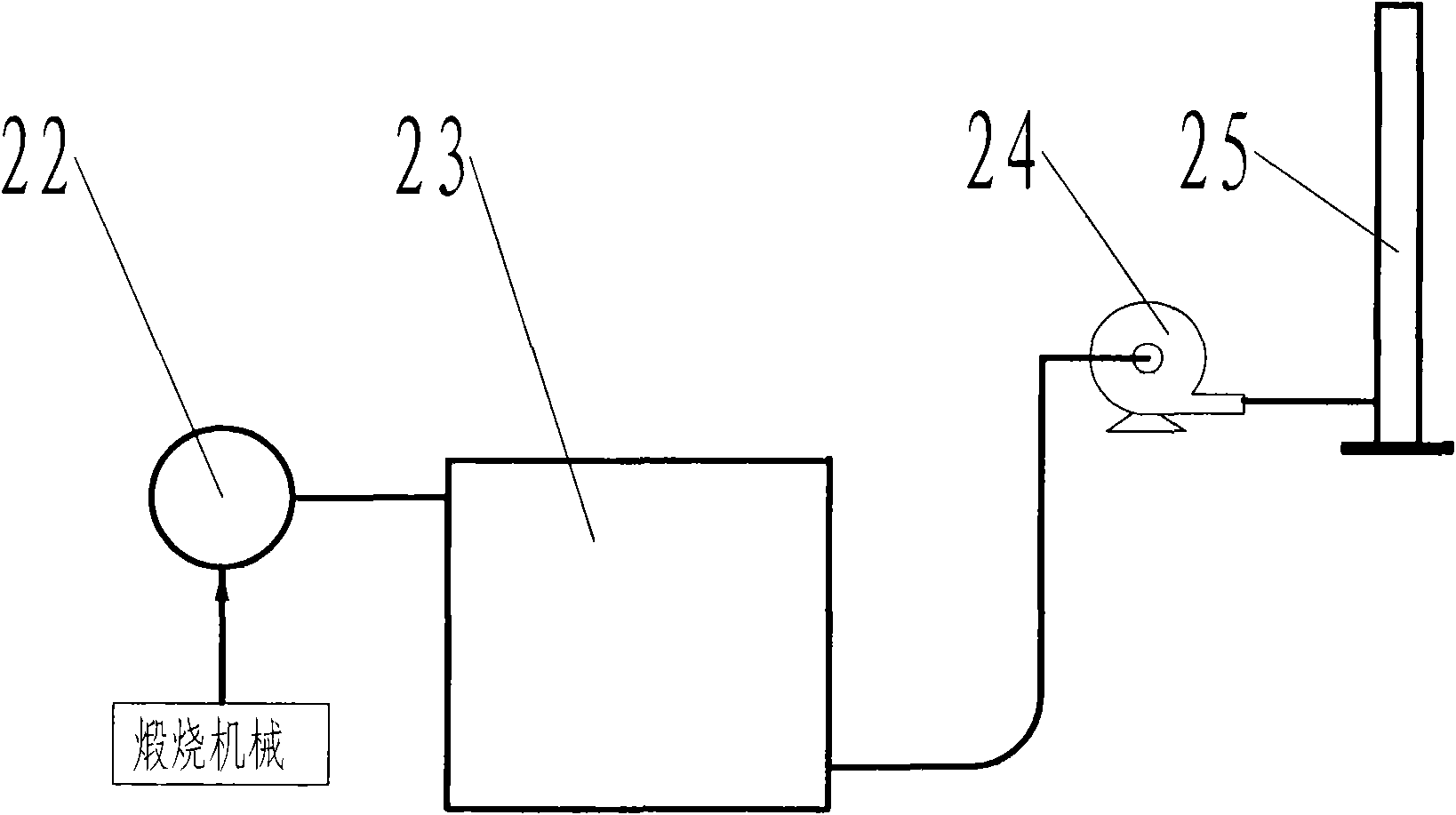

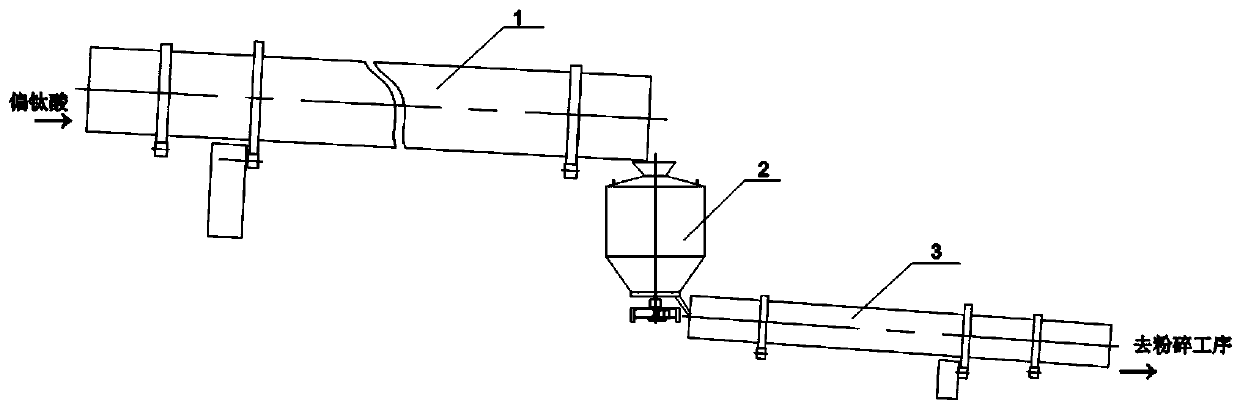

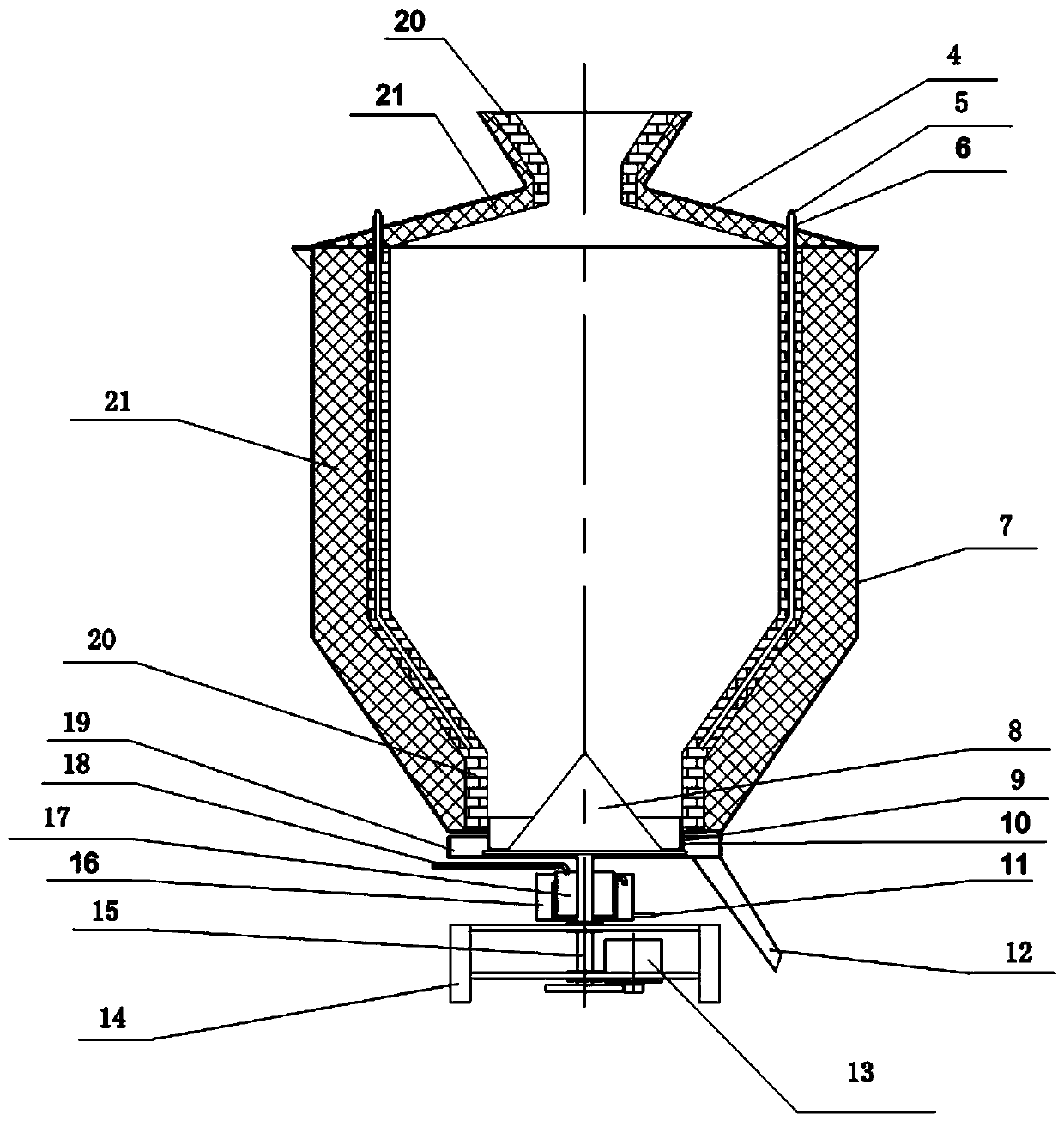

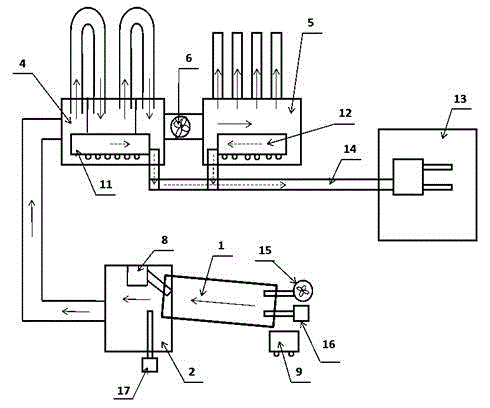

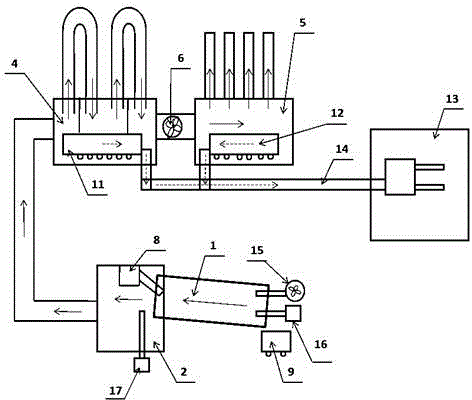

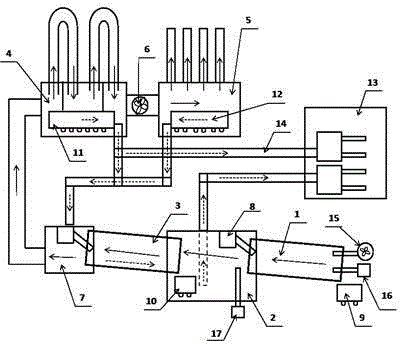

Production and calcination process and equipment of spontaneous-combustion environmental-protection zinc oxide

ActiveCN102874862AReduce manufacturing costImprove energy savingZinc oxides/hydroxidesChemical industryPhysical chemistryRedox

The invention discloses a production and calcination process of spontaneous-combustion environmental-protection zinc oxide. The process adopts a way of continuous production with negative pressure, zinc raw materials and oxygen conduct an oxidation-reduction reaction in an oxidation furnace to generate zinc oxide, a large amount of enthalpy is rejected at the same time, and the zinc oxide is obtained after working procedures of cooling and powder collecting. The outlet end of the oxidation furnace is connected with a calcination furnace, the gaseous zinc raw materials entering the calcination furnace from the oxidation furnace and oxygen conduct the oxidation-reduction reaction again to generate zinc oxide, a large amount of enthalpy is rejected, the directly-collected powder is calcined through a lot of heat from the oxidation furnace, and then the calcined zinc oxide is obtained after the working procedures of cooling and powder collecting. The process utilizes the own enthalpy of the raw materials to produce the zinc oxide and the calcined zinc oxide, and the purposes of saving energy, protecting environment, reducing the production cost, reducing the labor strength and increasing the production efficiency are achieved through a continuous automatic production way.

Owner:洛阳丹柯锌业有限公司

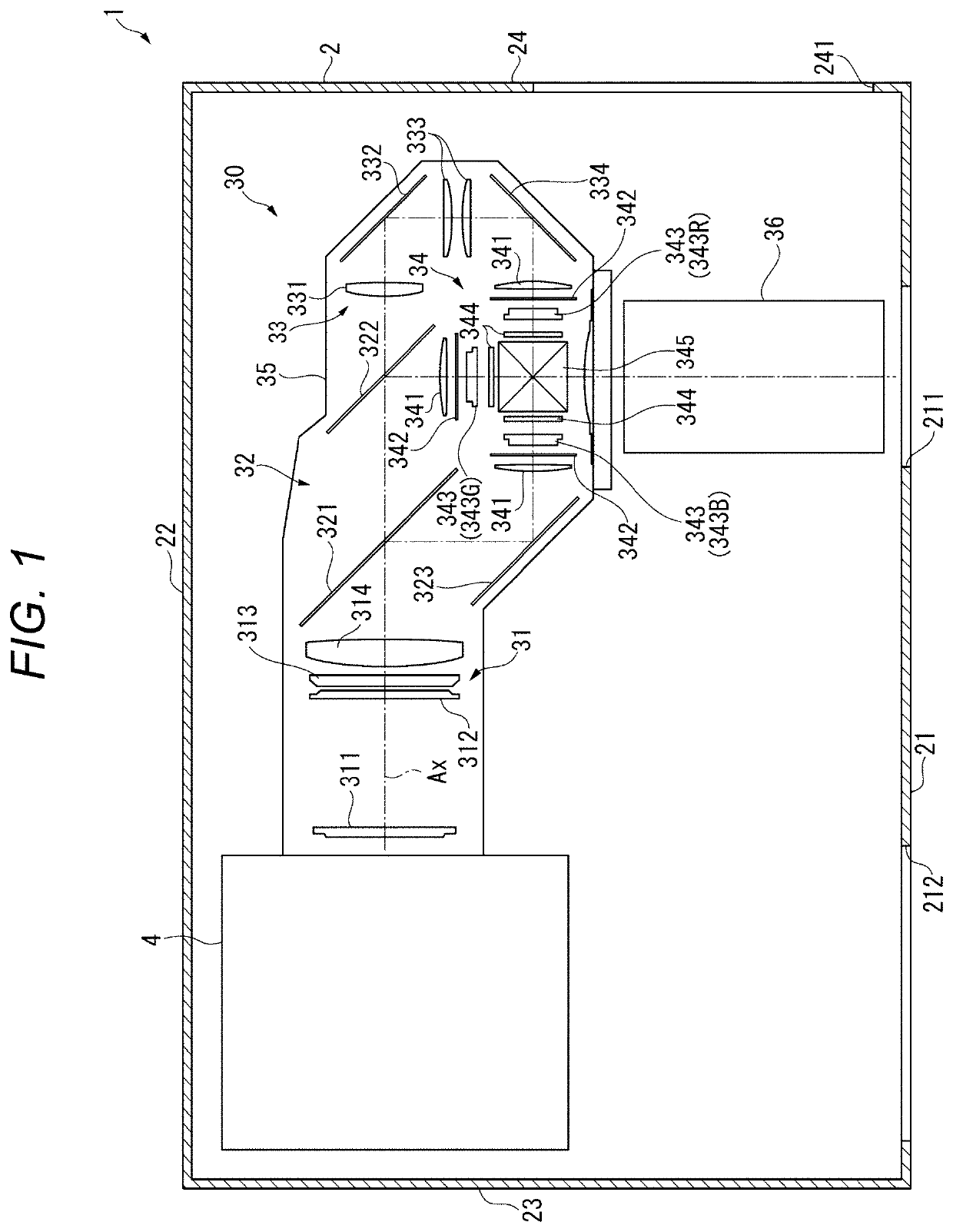

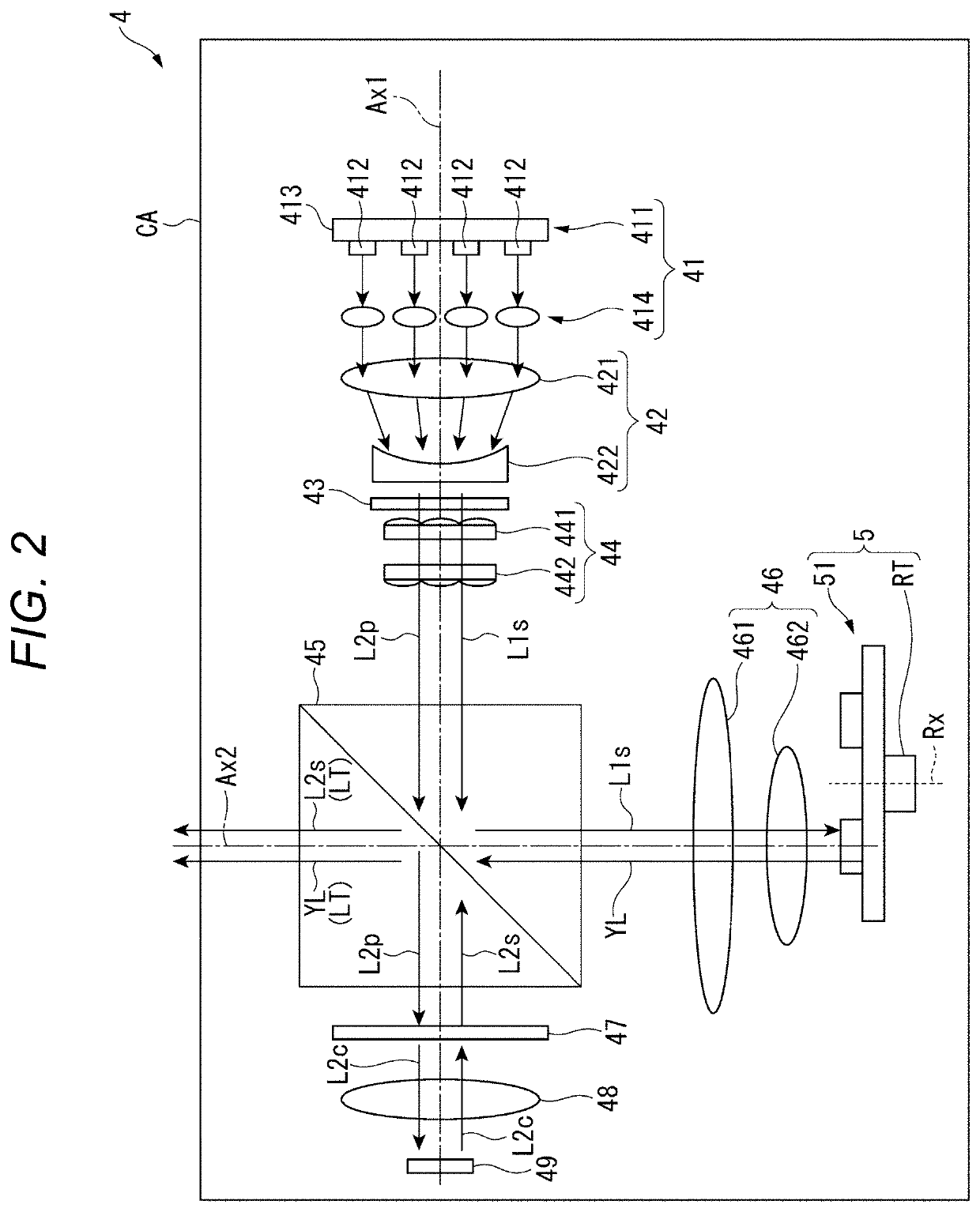

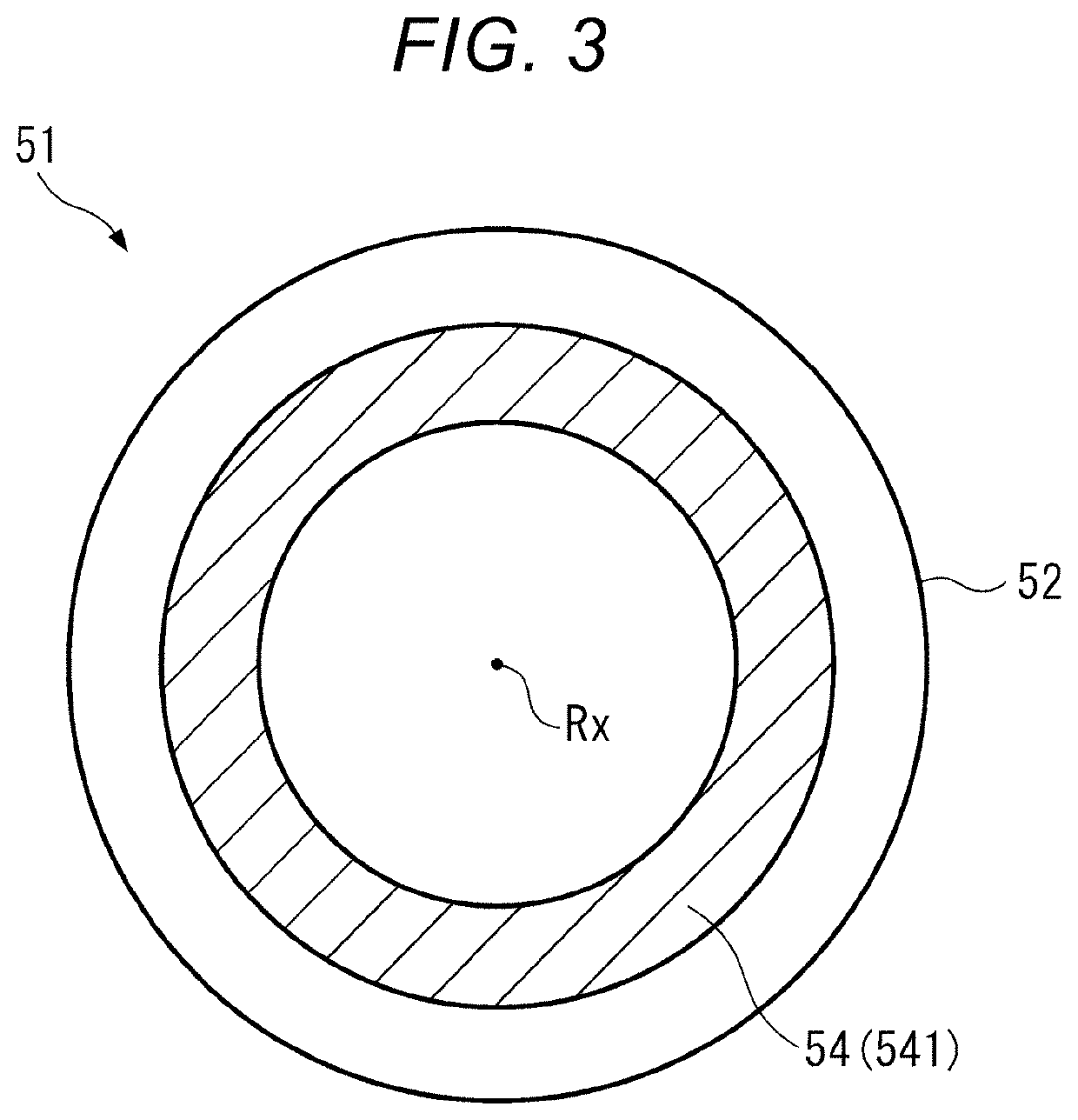

Wavelength conversion element, light source device, projector, and method of manufacturing wavelength conversion element

ActiveUS20200304764A1Calcination temperature is highHigh viscosityProjectorsPicture reproducers using projection devicesPhosphorFluorescence

The wavelength conversion element includes a phosphor layer having a plurality of phosphor particles and a binder configured to bind one of the phosphor particles adjacent to each other and another of the phosphor particles adjacent to each other out of the plurality of phosphor particles, and a substrate provided with the phosphor layer, wherein the binder includes glass, and the binder binds a part of a surface of the one of the phosphor particles and a part of a surface of the another of the phosphor particles to each other.

Owner:SEIKO EPSON CORP

Novel early strength agent for concrete and method for preparing novel early strength agent

The invention discloses a novel early strength agent for concrete and a method for preparing the novel early strength agent. The novel early strength agent comprises, by weight, 20-25 parts of CaO, 20-25 parts of Al2O3, 4-6 parts of Nb2O5, 3-7 parts of MgSO4, 15-20 parts of barite powder, 15-20 parts of zeolite powder, 0.3-0.7 part of Bi2O3, 1-3 parts of Li2CO3, 0.2-0.4 part of NaCl and 0.2-0.4 part of KCl. The method includes carrying out ball-milling on various components; calcining the various components at the temperatures of 850-900 DEG C; carrying out ball-milling on the various components and reagents such as calcium and aluminum hydrotalcite to obtain the novel early strength agent for the concrete. The novel early strength agent and the method have the advantages that excellent early strength effects can be realized by the novel early strength agent, the novel early strength agent is high in strength, has low calcination temperature and is a promising admixture for the concrete, and the like.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing cow dung/coal gangue compound biomass fuels

InactiveCN105400557ATake advantage ofReduce manufacturing costBiofuelsSolid fuelsCalcium hydroxideMicroorganism

The invention discloses a method for preparing cow dung / coal gangue compound biomass fuels, which belongs to the utilization filed of wastes, and aims to the problems that dairy farming in our country rapidly develops at present, a lot of cow dung is produced, and pollutes environment, a traditional cow dung treatment method is easy to produce infectious diseases, low in use ratio and high in cost. Fresh cow dung is dipped in acids to remove parts of metal impurities firstly, and then is mixed with calcium hydroxide, improves combustion value through protection of hydrogen, then is mixed with activated modified coal gangue to ferment, and then is deeply transformed through microorganisms, thereby preparing the cow dung / coal gangue compound biomass fuels with high calorific value and long burning time. The cow dung / coal gangue compound biomass fuels which are prepared through the method for preparing the cow dung / coal gangue compound biomass fuels are higher than common coals 25-35% in burning speed through examples testify, gas which is discharged from chimneys is detected without harmful gas, and the combustion heat value is 22000-26000kJ / kg.

Owner:雷春生

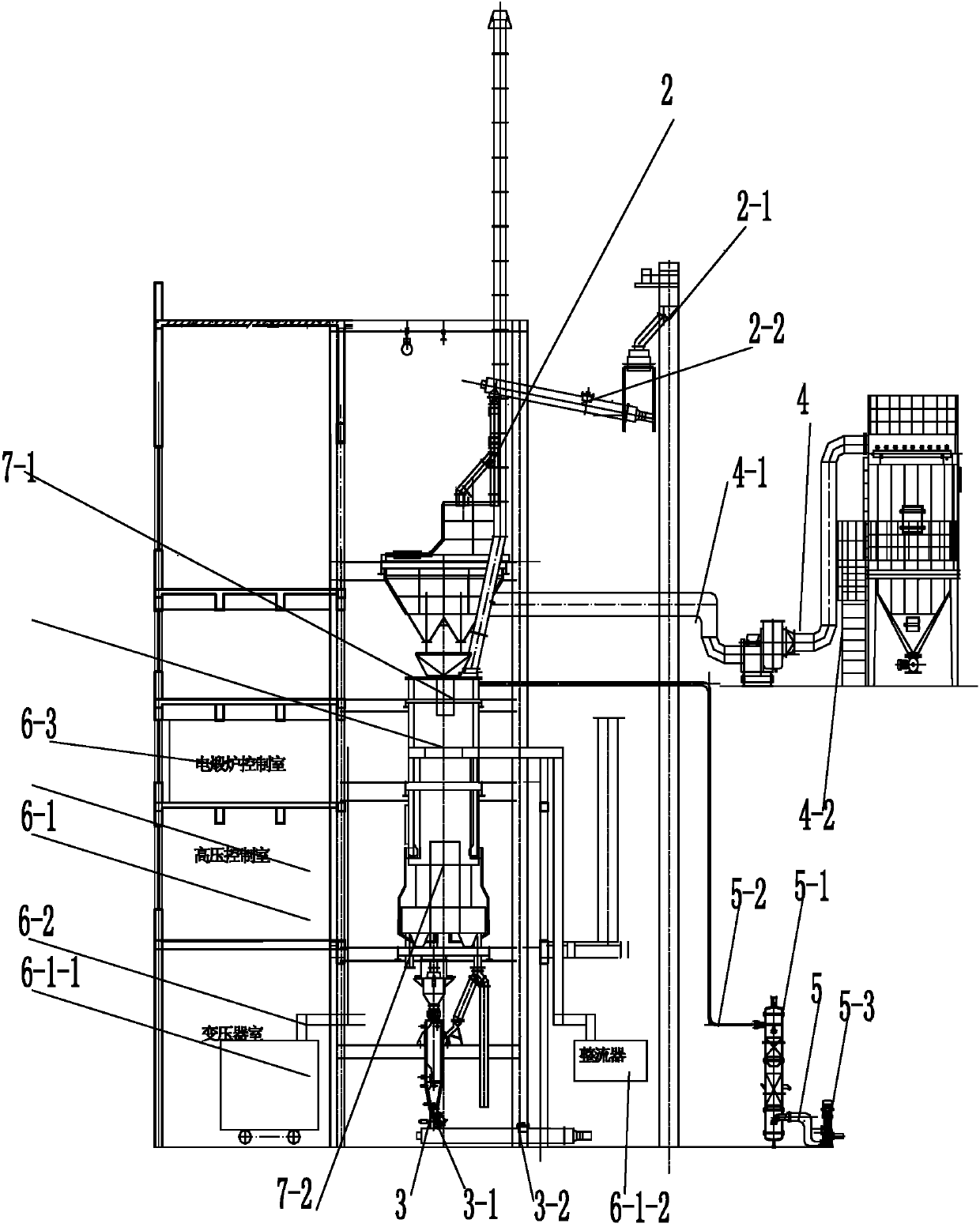

Safe carbon electrical calcination furnace

The invention relates to a safe carbon electrical calcination furnace, and especially relates to a carbon raw material anthracite calcination furnace. The electrical calcination furnace comprises an electrical calcination furnace body 1, a feeding system 2, a discharging system 3, a dust removal system 4, a cooling water system 5, an electric control system 6 and an electrode 7, the electrical calcination furnace continuously adds anthracite into the furnace body 1 from the top of the furnace through the feeding system 2, anthracite passes through a preheating zone at the upper portion of the furnace body 1 and then descends to a calcining zone, a calcined material is cooled, the cooled material is continuously discharged out of the furnace body through the discharging system 3, and high temperature flue gas generated by the electrical calcination furnace enters the dust removal system 4 and is processed. The electrical calcination furnace has the advantages of simple and compact structure, convenient continuous operation, high automation degree andhigh calcination temperature, allows parts of the calcined material to have semi-graphitized property, and is very suitable for high temperature calcination of anthracite; the electrical calcination furnace reasonably controls the granularity and the coal dust content of anthracite by combining the structure and technology characteristics in the operation process, can timely monitor electrical insulation, and realizes the reasonable operation under power, discharge quantity and cooling water supply amount balance maintaining conditions.

Owner:桐乡市恒达经编股份有限公司

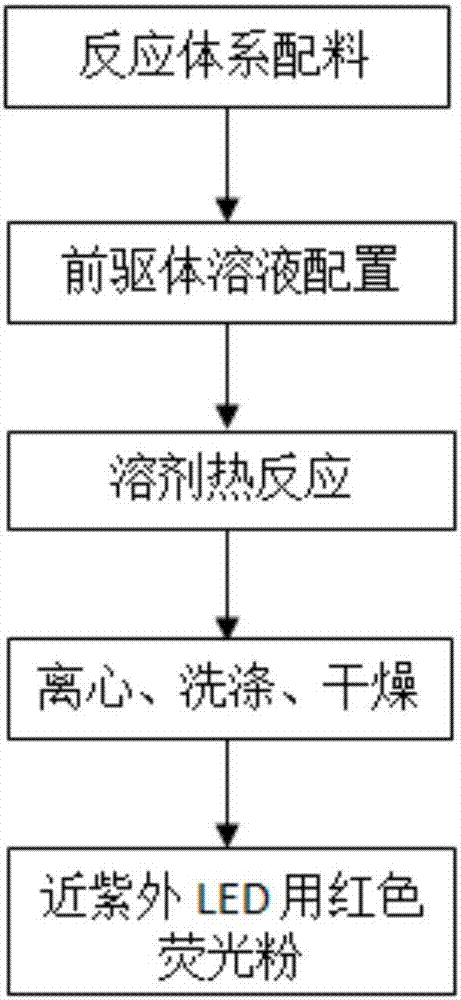

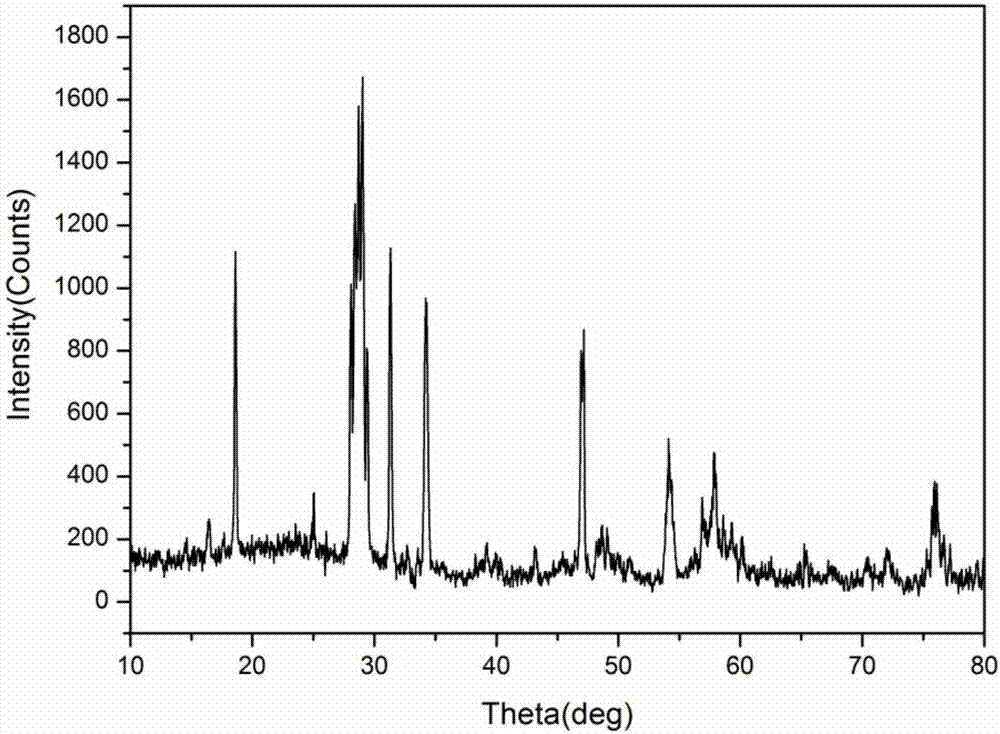

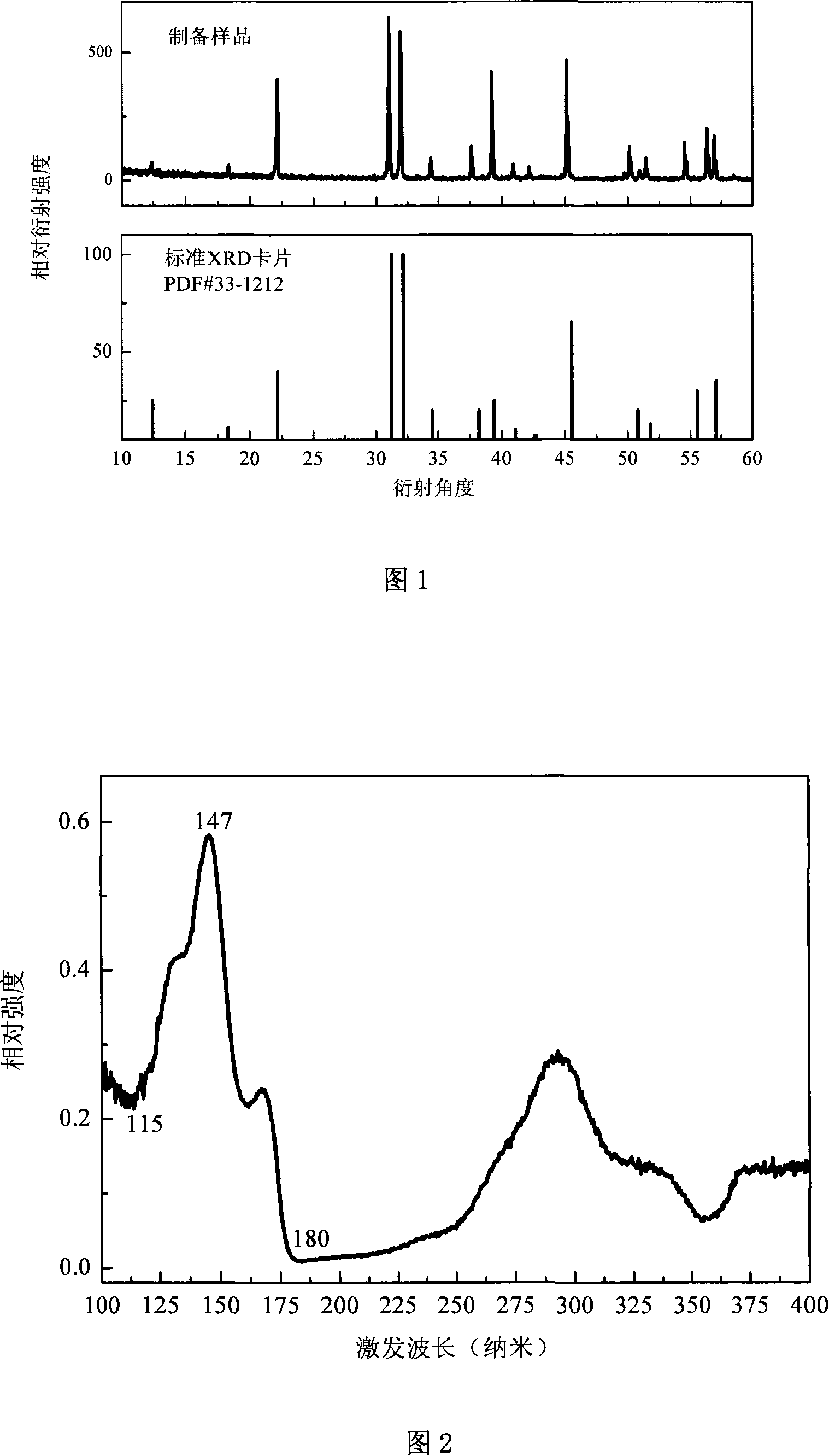

Alkaline earth metal tungstate/ molybdate red fluorescent powder and preparation method thereof

ActiveCN107163941AImprove luminous performanceUniform particlesLuminescent compositionsRare-earth elementAlkaline earth metal

The invention relates to alkaline earth metal tungstate / molybdate red fluorescent powder and a preparation method thereof, and belongs to the technical field of luminescent materials. The fluorescent powder formula is MeLn2-a-b (WO4) 4-x (MoO4)x:aEu<3+>, bRE<3+>, wherein Me is at least one of alkaline earth metal Ca, Sr and Ba; Ln is at least one of rare earth elements Y, Gd, La and Lu; RE is at least one of doped elements Bi, Sm and Tb, 0<x<4, 0<a<0.5 and 0<b<0.1. The design idea is as follows: a solvothermal soft chemical method is used for synthesis of a sample, Eu<3+> is used as a luminescence center, alkaline earth metal rare earth tungstate / molybdate is used as a matrix, Bi<3+> is added as a sensitizer, and by interactions between ions and introduction of defects in the matrix structure, efficient red light emission can be achieved. The alkaline earth metal tungstate / molybdate red fluorescent powder can effectively absorb near ultraviolet light and emit red fluorescence.

Owner:CHONGQING UNIV OF ARTS & SCI

Novel method for reducing nitrogen oxide emission through preheating calcination

PendingCN112500003AEmission Reduction MethodsSave energyGas treatmentDispersed particle filtrationAir preheaterFresh air

The invention discloses a novel method for reducing nitrogen oxide emission through preheating calcination. The method comprises the following steps of: (1) air supply: preheating fresh air through anair preheater and then feeding the preheated fresh air into a calcination chamber; (2) drying: before calcining, drying a raw material and pulverized coal through high-temperature airflow to reduce the water content of the raw material and the pulverized coal; (3) preheating: preheating the dried raw material and pulverized coal by secondary air, mixing tail gas and air to reduce the air oxygen content of the secondary air, and generating a certain amount of combustible gas with reducibility such as CO to reduce NOx generated through pyrolysis; (4) calcining: calcining the preheated raw material and pulverized coal at high temperature; and (5) cooling: forming clinker from the calcined raw material and pulverized coal, cooling the clinker, and entering the next process. The problems of high consumption of ammonia water and high denitration cost in flue gas denitration treatment corresponding to clinker production are solved.

Owner:兰溪诸葛南方水泥有限公司

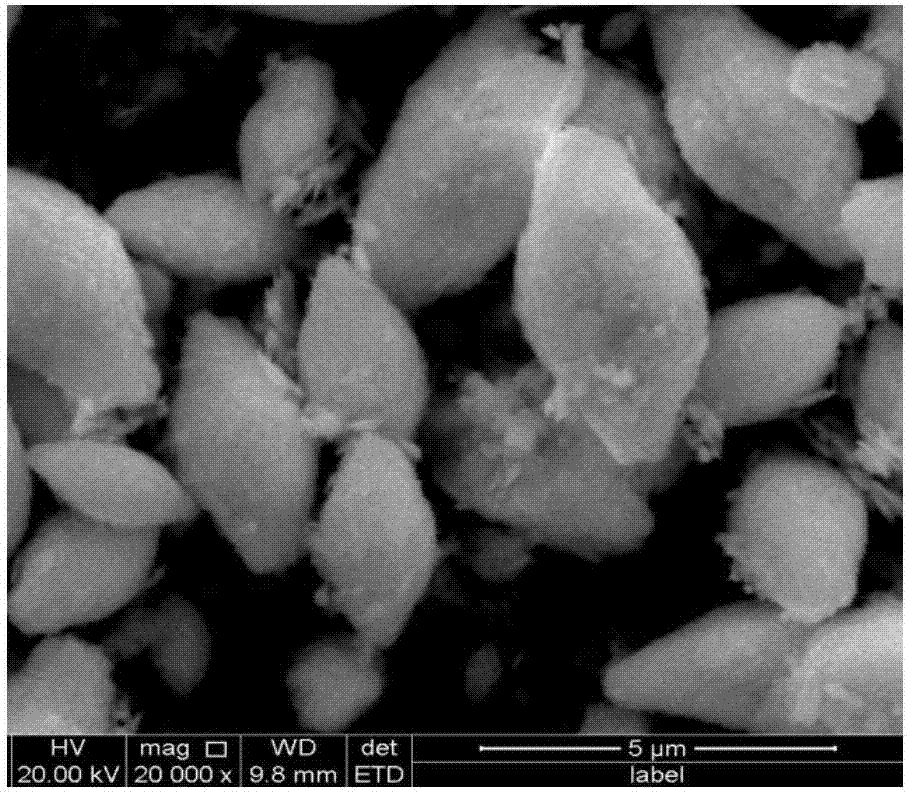

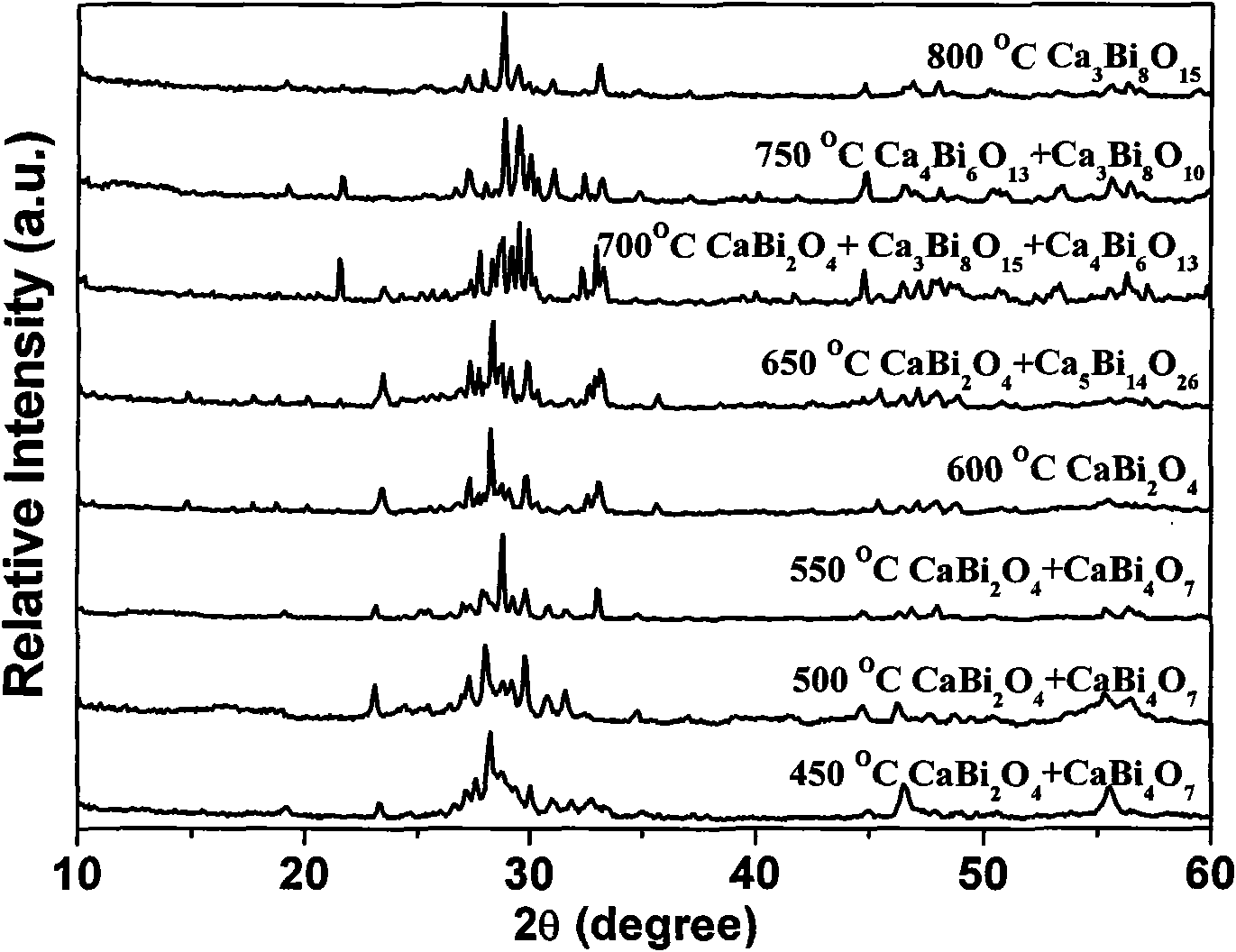

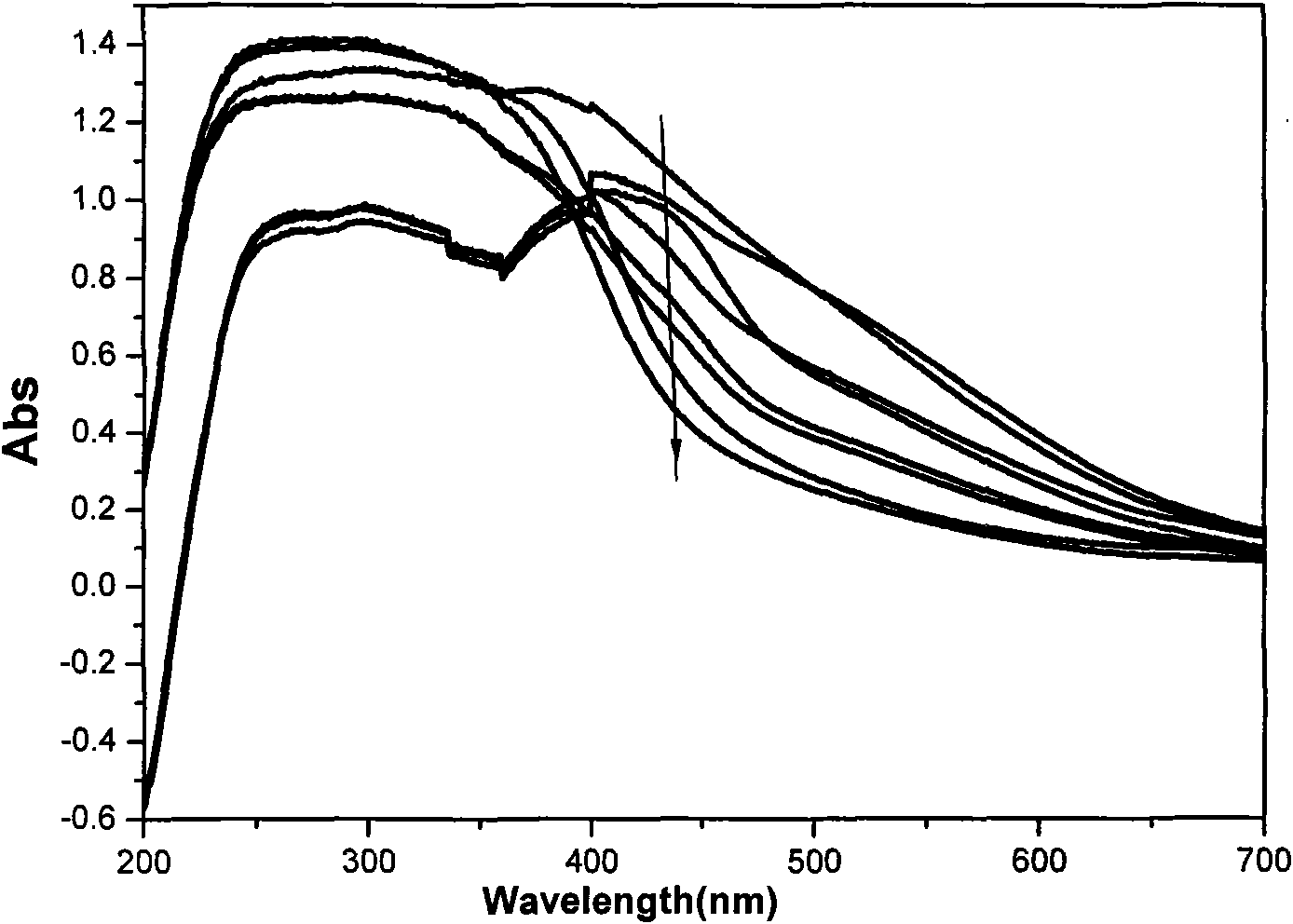

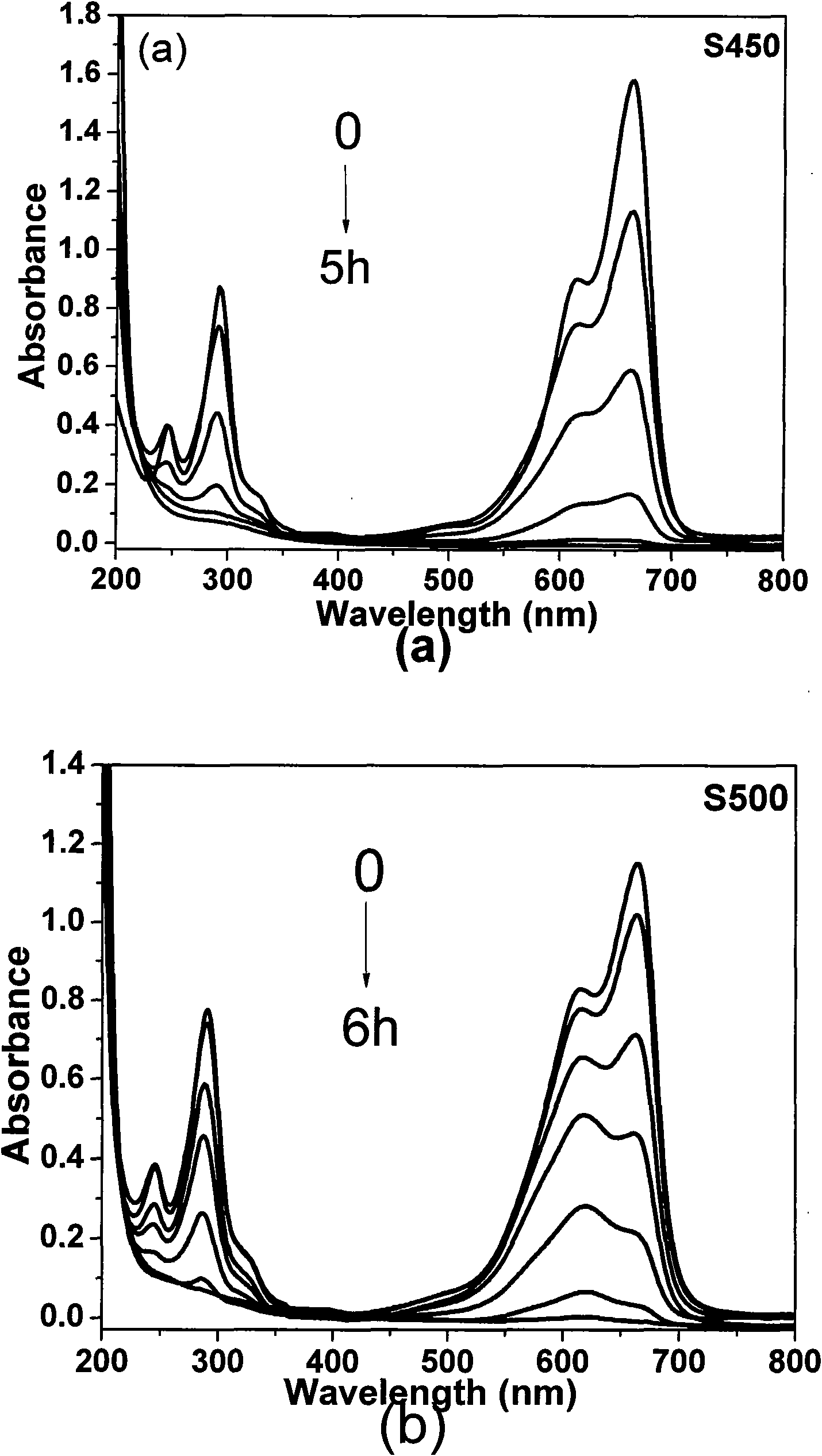

Ca-Bi-O series visible-light photocatalysis material and preparation method thereof

InactiveCN101584985AImprove uniformityCalcination temperature is highCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsChemical solutionReaction temperature

The invention relates to a preparation method for a Ca-Bi-O series visible-light photocatalysis material, and belongs to the technical field of inorganic nano materials. The preparation method comprises the steps of preparing a precursor by using a chemical solution method and annealing for 10 to 15 hours at the temperature of between 450 and 800 DEG C. The method for preparing the Ca-Bi-O series visible-light photocatalysis material by using the chemical solution method through even reaction overcomes the defect of high reaction temperature in the prior art, and can obtain single-phase or heterogenous compound photocatalysis functional materials by controlling the annealing temperature respectively. The method has the advantages of simple operation, easy reaction control and good repeatability; and the obtained heterogenous compound photocatalysis functional material has remarkably-improved photocatalysis activity.

Owner:SHANDONG UNIV

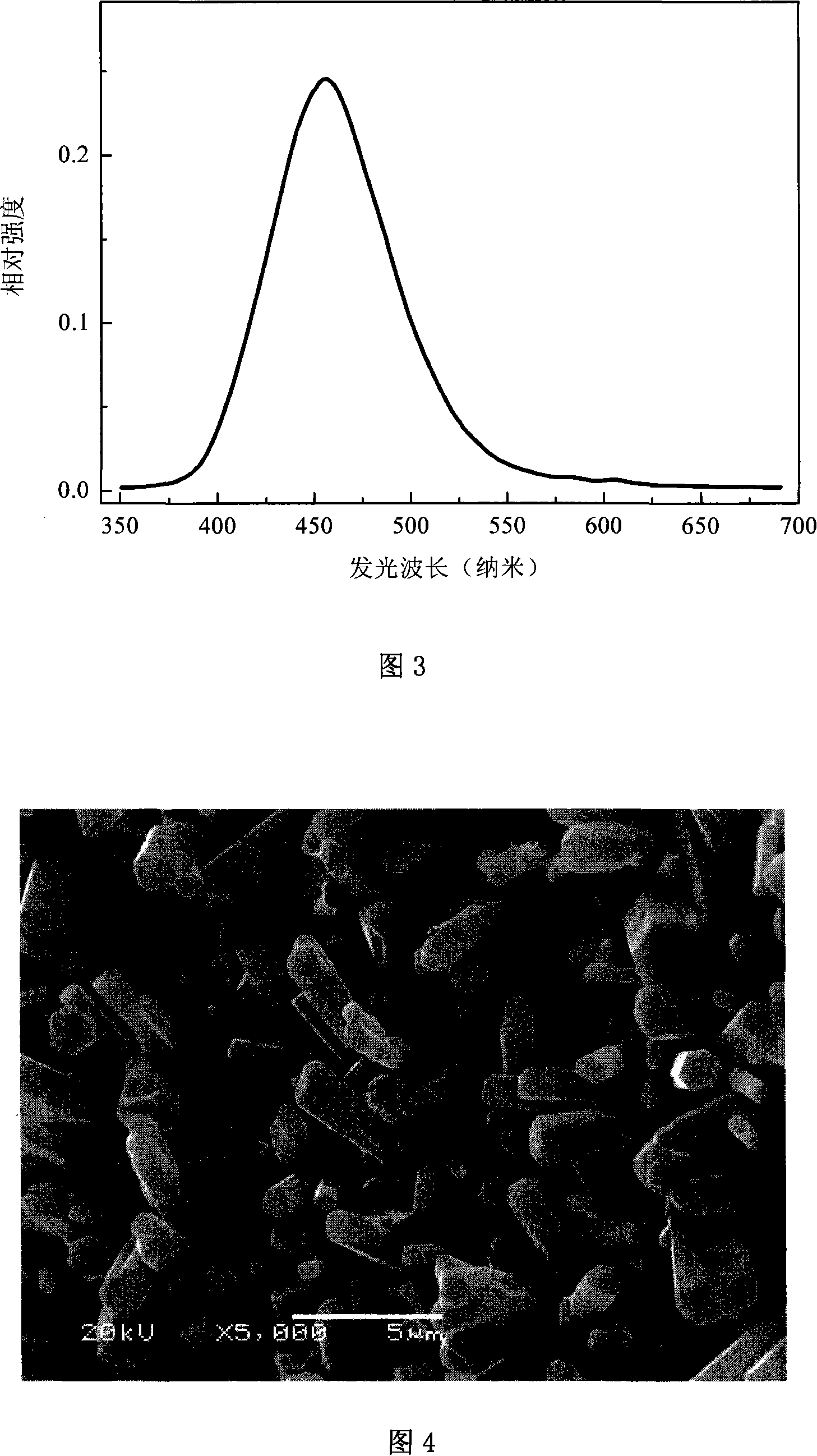

Blue-fluorescence luminescent material and method for making same

InactiveCN101113334APromote reductionSave raw materialsLuminescent compositionsRare-earth elementNoble gas

The invention relates to a blue fluorescence luminescent material and a preparation method thereof, pertaining to the technical field of luminescent material. The technic proposal adopted by the invention is to prepare strontium phosphate barium stone, of which a chemical formula is M(Srx, Ba1-x)PO4:Eu, wherein, M is equal to Li+, Na+, K+, Rb+, x is equal to 0-1, doping content of rare earth element europium (Eu2+) is 0.0005-10 percent mol of the total amount of strontium and barium. An excitation field of the invention tallies closely with vacuum uv (VUV) generated by ionomer such as mixed gas of xenon and ne (Xe plus Ne) which is applied presently. Excited by vacuum uv less than 200nm, the invention emits blue fluorescence; the invention has high crystallinity, good luminescent quality, low cost, simple preparation technique and no pollution and is especially applicable to ionomer plate displaying technology and luminescent and displaying devices with vacuum uv as an excitation source, such as a noble gas discharge lamp, etc.

Owner:SUZHOU UNIV

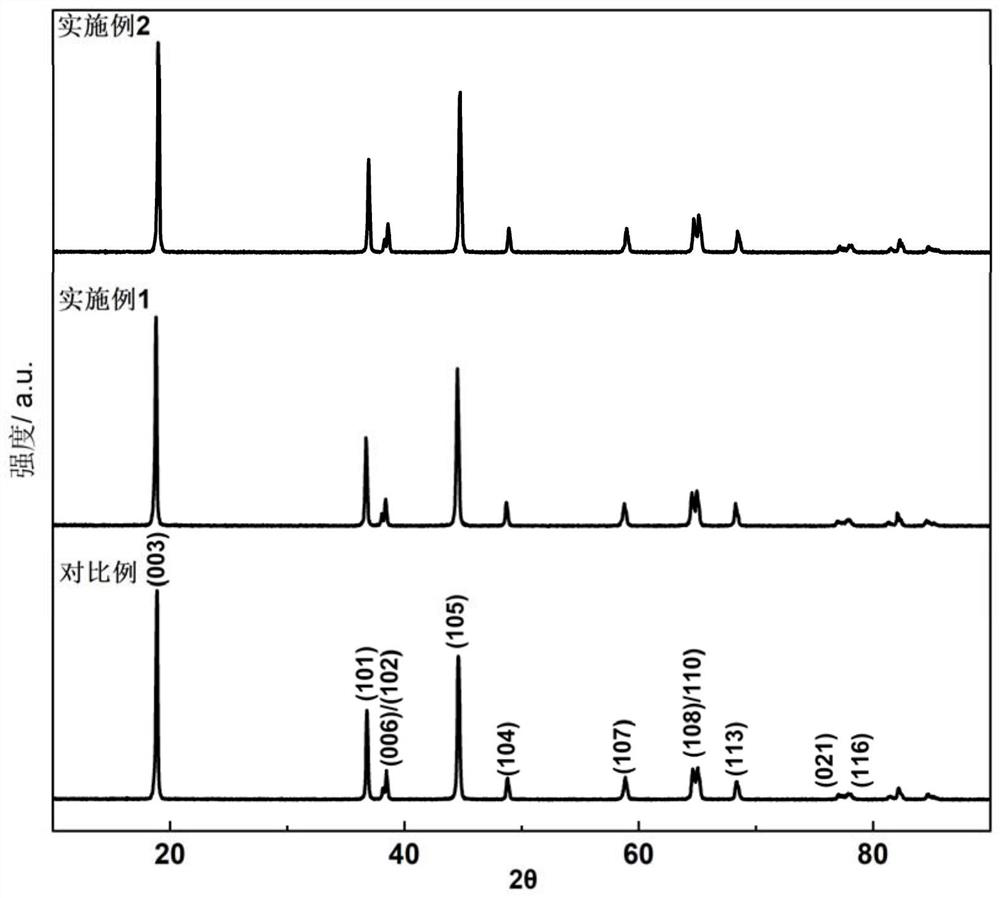

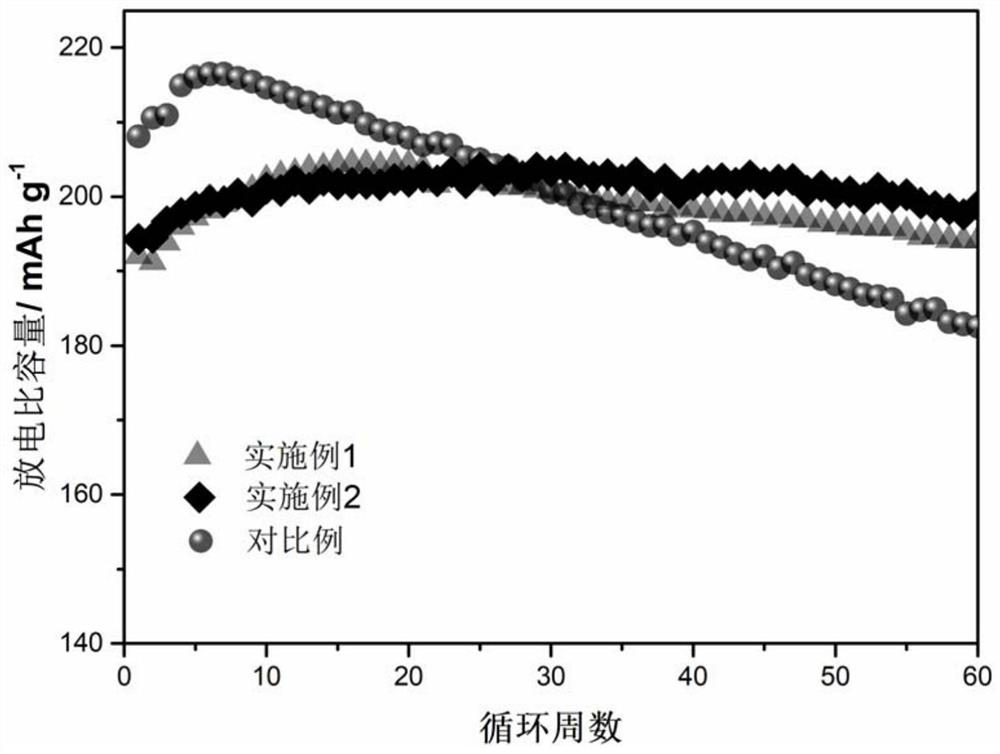

High-nickel positive electrode material with reconstructed primary particle surface layer and preparation method thereof

ActiveCN111755692AImprove cycle stabilityImprove bindingCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention relates to a high-nickel positive electrode material with a reconstructed surface layer and a preparation method thereof, and belongs to the field of chemical energy storage batteries. The chemical formula of the material is Li(Ni<x>Co<1-x>)<1-y-z>M<y>N<z>O<2>, x is larger than 0.7 and smaller than 1, y is larger than 0 and smaller than or equal to 0.1, z is larger than 0 and smallerthan 0.1, the ratio of y to z is m:1-m, and m is larger than 0.6 and smaller than 1. According to the material, a layered nickel-cobalt positive electrode material is used as a matrix, metal elementsM and N are doped in the surface layers of primary particles of the matrix, and the outermost layer of the surface layers of the primary particles is a rock salt phase NiO thin layer. Surface layer doping is performed on the high-valence metal element M and the trivalent metal element N after high-temperature calcinations to enable more Ni on the surface layer to exist in the form of Ni<2+> by utilizing a charge compensation effect, and a rock salt-like phase NiO thin layer is formed on the surface layer of the primary particle, direct contact between the material and an electrolyte can be effectively isolated, and irreversible phase transformation of the material is inhibited, so that the cycling stability of the material is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

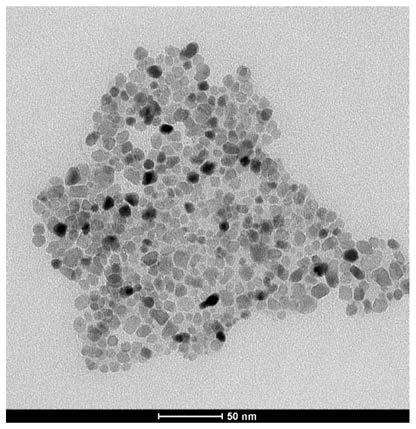

Method for preparing yttrium aluminum garnet nanoparticles

ActiveCN111233022AEasy to prepareEase of mass productionMaterial nanotechnologyRare earth metal compoundsNanoparticlePhysical chemistry

The invention provides a method for preparing yttrium aluminum garnet nanoparticles, which comprises the following steps: preparing organic sol containing aluminum and yttrium, mixing the organic solwith water-soluble salt, performing standing or centrifuging to precipitate the water-soluble salt, removing superfluous organic sol at the upper part, and keeping the temperature to convert the organic sol into gel; along with evaporation of the solvent, contracting the gel, and coating the surfaces of the water-soluble salt particles with a layer of xerogel film, and calcining a sample at a hightemperature between 600 DEG C and a salt melting point, converting a dried gel film into yttrium aluminum garnet nanoparticles, dispersing and attaching the yttrium aluminum garnet nanoparticles to the surfaces of water-soluble salt particles, cooling, and washing with water to remove the salt, thereby obtaining the yttrium aluminum garnet nanoparticles with favorable dispersity and crystallinity. According to the method, the high-dispersion and high-crystallinity yttrium aluminum garnet nanoparticles can be rapidly prepared in batches, and the method is suitable for preparing LED fluorescentpowder, YAG transparent ceramic and other materials.

Owner:SOUTHEAST UNIV

Production and calcination process and equipment of spontaneous-combustion environmental-protection zinc oxide

ActiveCN102874862BReduce manufacturing costImprove energy savingZinc oxides/hydroxidesChemical industryPhysical chemistryRedox

The invention discloses a production and calcination process of spontaneous-combustion environmental-protection zinc oxide. The process adopts a way of continuous production with negative pressure, zinc raw materials and oxygen conduct an oxidation-reduction reaction in an oxidation furnace to generate zinc oxide, a large amount of enthalpy is rejected at the same time, and the zinc oxide is obtained after working procedures of cooling and powder collecting. The outlet end of the oxidation furnace is connected with a calcination furnace, the gaseous zinc raw materials entering the calcination furnace from the oxidation furnace and oxygen conduct the oxidation-reduction reaction again to generate zinc oxide, a large amount of enthalpy is rejected, the directly-collected powder is calcined through a lot of heat from the oxidation furnace, and then the calcined zinc oxide is obtained after the working procedures of cooling and powder collecting. The process utilizes the own enthalpy of the raw materials to produce the zinc oxide and the calcined zinc oxide, and the purposes of saving energy, protecting environment, reducing the production cost, reducing the labor strength and increasing the production efficiency are achieved through a continuous automatic production way.

Owner:洛阳丹柯锌业有限公司

Preparation method of colored magnetic pearlescent pigment

InactiveCN110713736AIncrease brightnessColorfulInorganic pigment treatmentTitanium tetrachlorideTitanium chloride

The invention provides a preparation method of colored magnetic pearlescent pigment, and relates to the technical field of pigment. The method comprises the following steps: weighing 100 g of a pretreated base material, adding 1000 ml of distilled water, adjusting the pH value to 1.9-2.1, heating to 70-80 DEG C, adding a titanium tetrachloride solution until different colors appear, stopping stirring for 30-45 min after addition is finished, heating to 72-82 DEG C, and adding an alkali to adjust the pH value to 8.9-9.2; adding 0.2-0.5 mol / l of a sodium silicate solution, stopping stirring for30-45 minutes, and adding hydrochloric acid to adjust the pH value to 3.3-3.5; adding a ferric trichloride solution, stopping stirring for 30 minutes after addition is finished, and adding alkali to adjust the pH value to 7.5-8.0; and adding a ferrous chloride mixture, stopping feeding when the magnetism is strongest, performing filtration, washing and drying to obtain a finished product. The colored magnetic pearlescent pigment prepared by the preparation method is high in quality and outstanding in stability and has remarkable magnetic conductivity.

Owner:河南凌宝新材料科技有限公司

Preparation method of magnetoplumbite type CH4-CO2 reforming catalyst

ActiveCN105964265AHigh purityGood crystal conditionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNitrateSodium aluminate

The invention discloses a preparation method of a magnetoplumbite type CH4-CO2 reforming catalyst. According to the preparation method, alkaline sodium aluminate NaAlO2 is taken as an aluminum source, nickel nitrate Ni (NO3)2 is taken as a nickel source, strontium nitrate Sr (NO3)2 is taken as a strontium source, a nickel strontium aluminate precipitation copolymer is obtained with an ultrasonic copolymerization method, a hydrothermal reaction is performed for 16-20 h at the temperature of 160-180 DEG C, a pre-crystallization body with a magnetoplumbite structure is prepared, finally, crystallization sintering is performed for 6-8 h at the lower temperature of 750-850 DEG C, and a magnetoplumbite-structured SrNiAl11O19 reforming catalyst material with higher purity and good crystallization condition can be prepared.

Owner:SHAANXI UNIV OF SCI & TECH

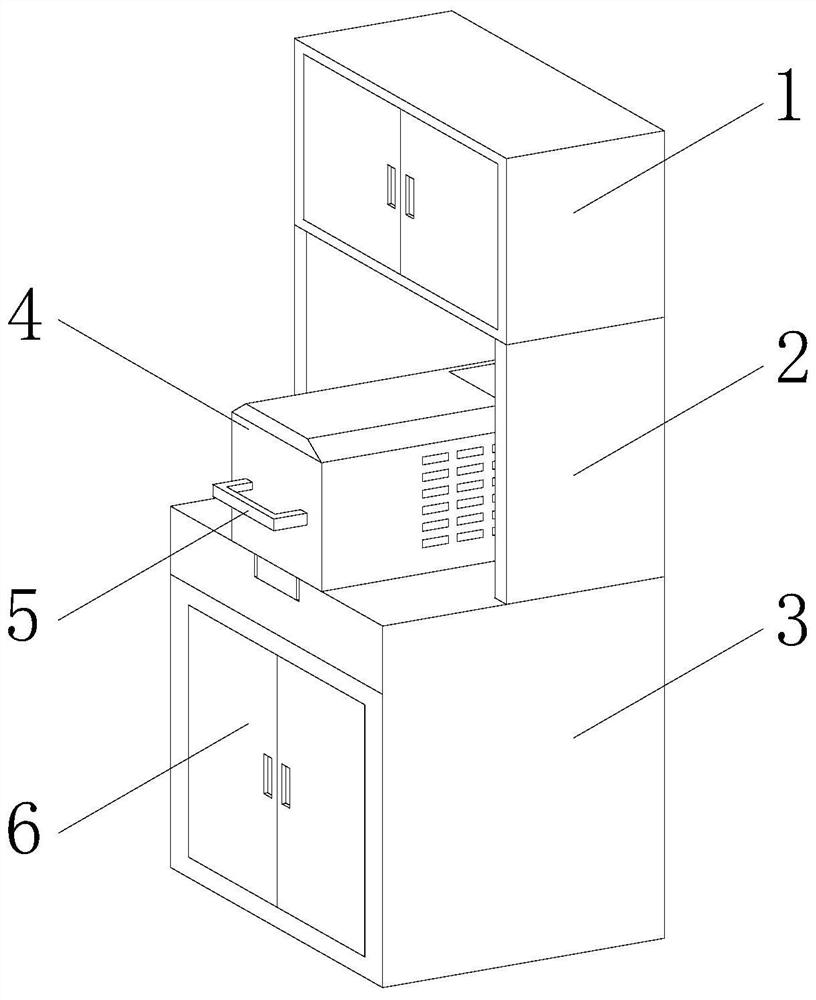

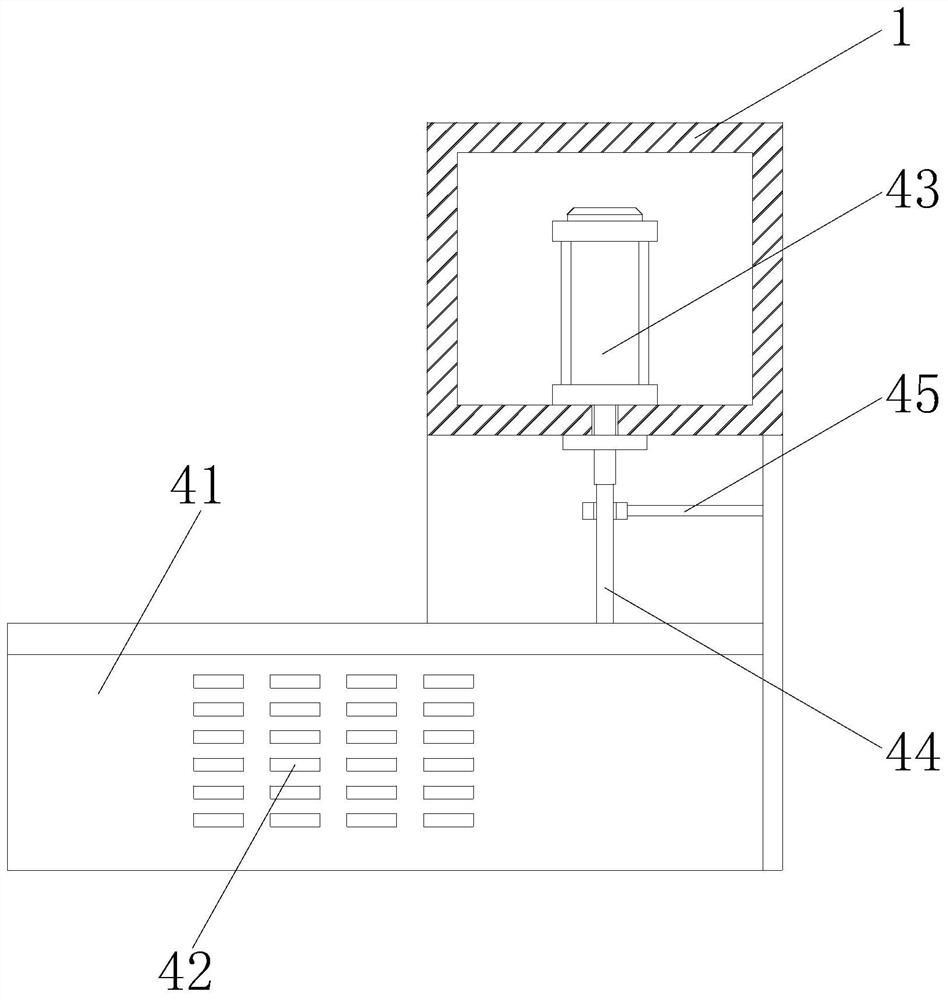

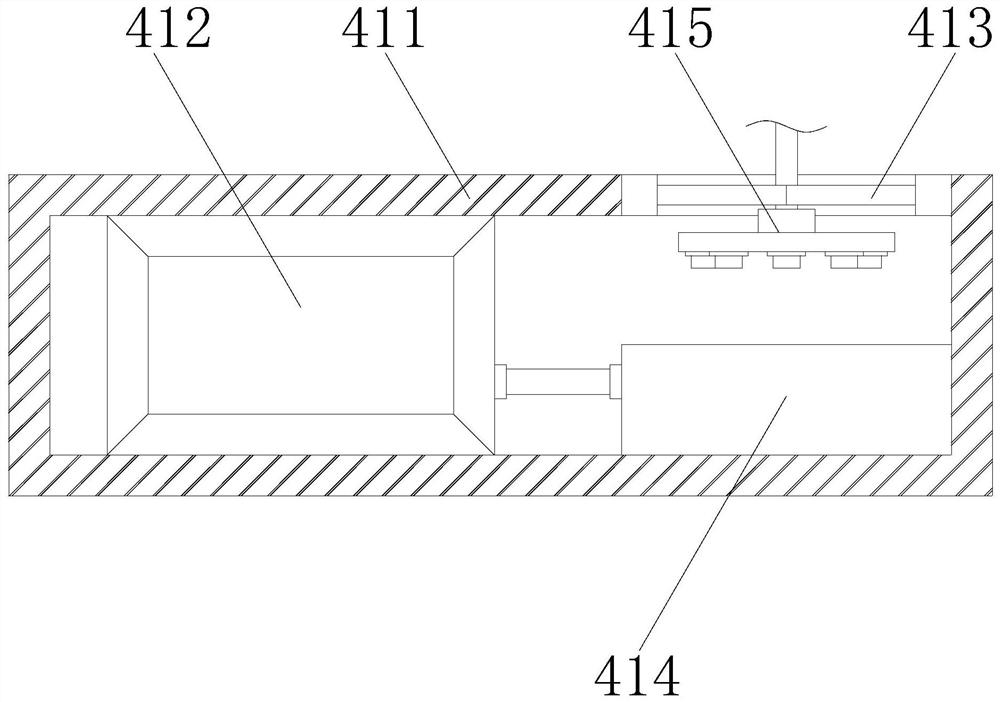

Preparation machine of high-temperature structural ceramic

InactiveCN112374898AUniform high temperatureCalcination temperature is highShaping press ramPipeCeramic

The invention discloses a high-temperature structural ceramic preparation machine, which structurally comprises a placement box, a supporting plate, a workbench, a preparation box, a handle and a boxdoor, wherein the bottom of the placement box is welded to the top of the supporting plate, and the lower end of the supporting plate is welded to the upper surface of the workbench. According to theinvention, heat is conducted into a transmission pipe through a pipeline and is conducted through hot air of a conduction rod in a sealed mode, so that the outer side of a forming cavity is subjectedto high temperature more uniformly, and the overall calcining temperature of a ceramic sealing ring is increased; after an extrusion mechanism completely enters a box body, and an opening and closingplate is automatically closed, so that the high-temperature loss in the forming device is reduced; an extrusion round block is subjected to extrusion buffer adjustment through a spring, so that the extrusion round block is prevented from generating excessive extrusion force on the formed ceramic sealing ring; and a sliding outer ring abuts against the ceramic sealing ring through upward lifting ofan air cylinder and downward pressing of the sliding outer ring, and the ceramic sealing ring is prevented from falling off from the extrusion round block, so that the ceramic sealing ring is prevented from being embedded in the outer side of the extrusion round block.

Owner:泉州市勤裕鼎工业设计有限公司

High-nickel positive electrode material with rock salt phase thin layer on primary particle surface layer and preparation method thereof

ActiveCN111740096AInhibition of phase transitionImprove cycle stabilityMaterial nanotechnologyTungsten oxides/hydroxidesElectrolytic agentElectrical battery

The invention relates to a high-nickel positive electrode material with a rock salt phase thin layer on a primary particle surface layer and a preparation method thereof, and belongs to the field of chemical energy storage batteries. The material takes a nickel-cobalt positive electrode material as a matrix, a metal element M is doped on the surface layer of the primary particles of the matrix, and the outermost layer of the surface layer of the primary particles of the material is a rock salt phase NiO thin layer. The method comprises the steps of mixing and stirring a nickel-cobalt positiveelectrode material precursor and a metal organic matter, and enabling the metal organic matter to gradually permeate into the material along the internal cracks of the secondary particles of the precursor in the stirring process and to be attached to the surface layers of the primary particles; and then calcining for the first time to fully mix the lithium salt with the precursor; and 2, calciningfor the second time to uniformly dope the high-valence metal elements attached to the surface layers of the primary particles into the surface layers of the primary particles to form the rock salt phase NiO thin layer on the surface layers of the primary particles. According to the present invention, the rock salt phase NiO thin layer can effectively isolate the direct contact between the material and the electrolyte, and inhibit the irreversible phase transformation of the material, thereby improving the cycling stability of the material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

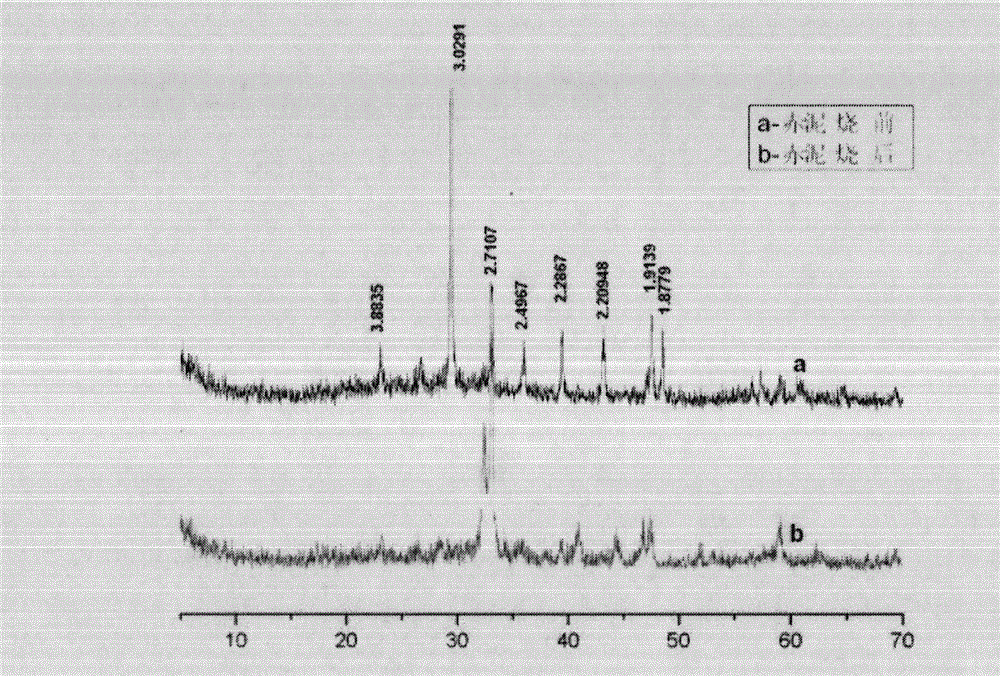

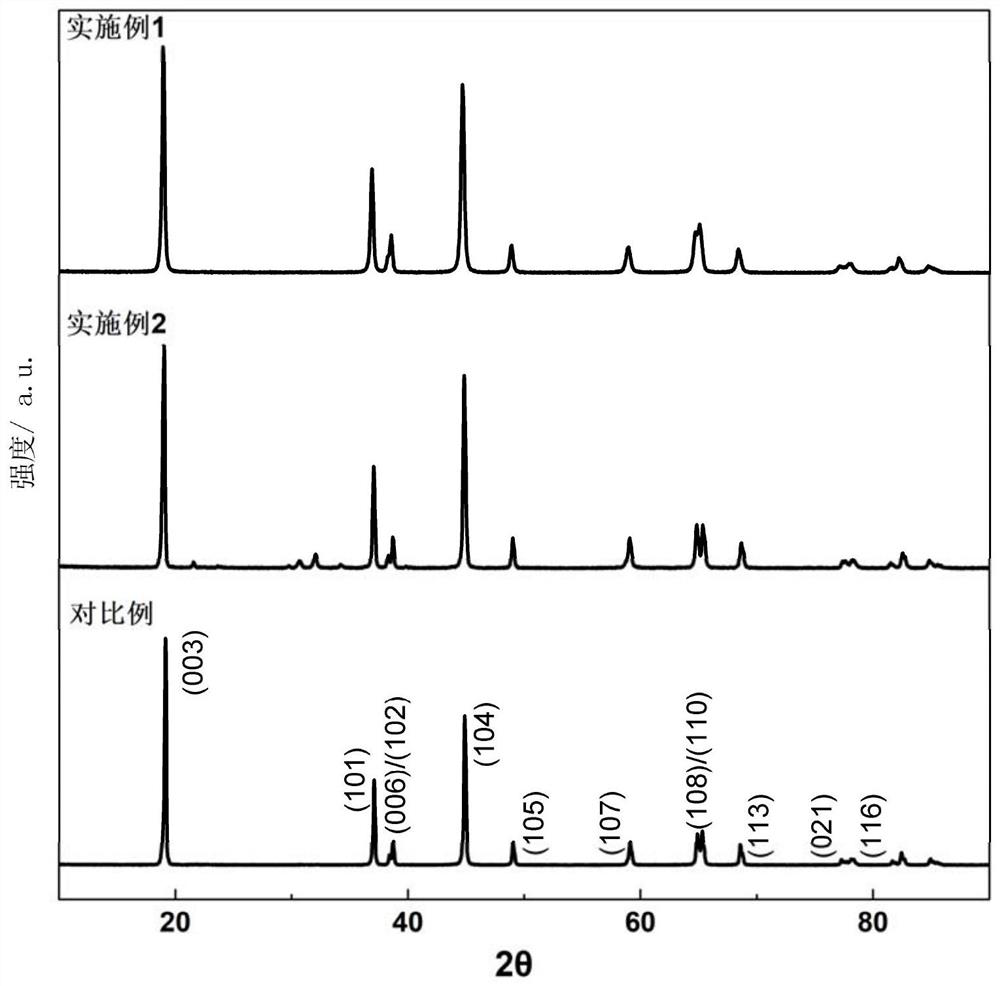

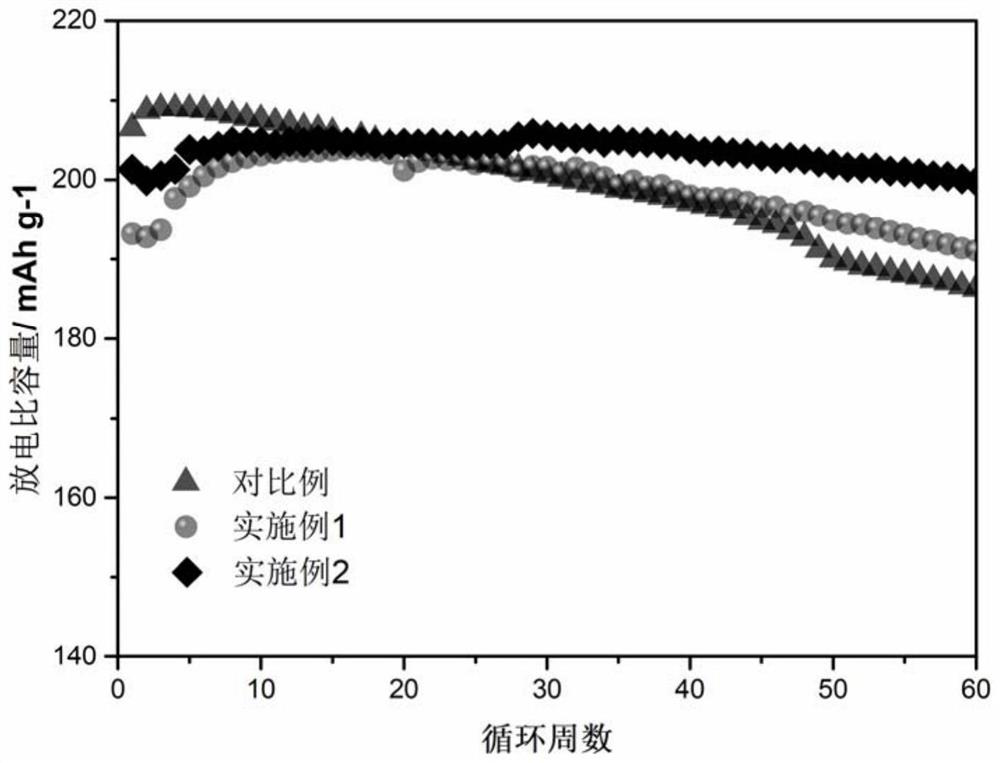

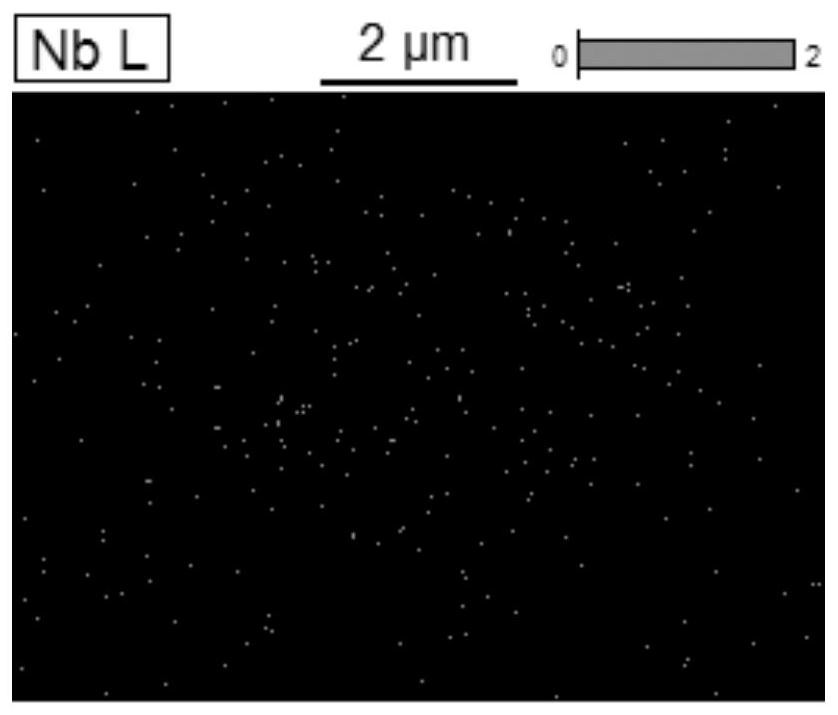

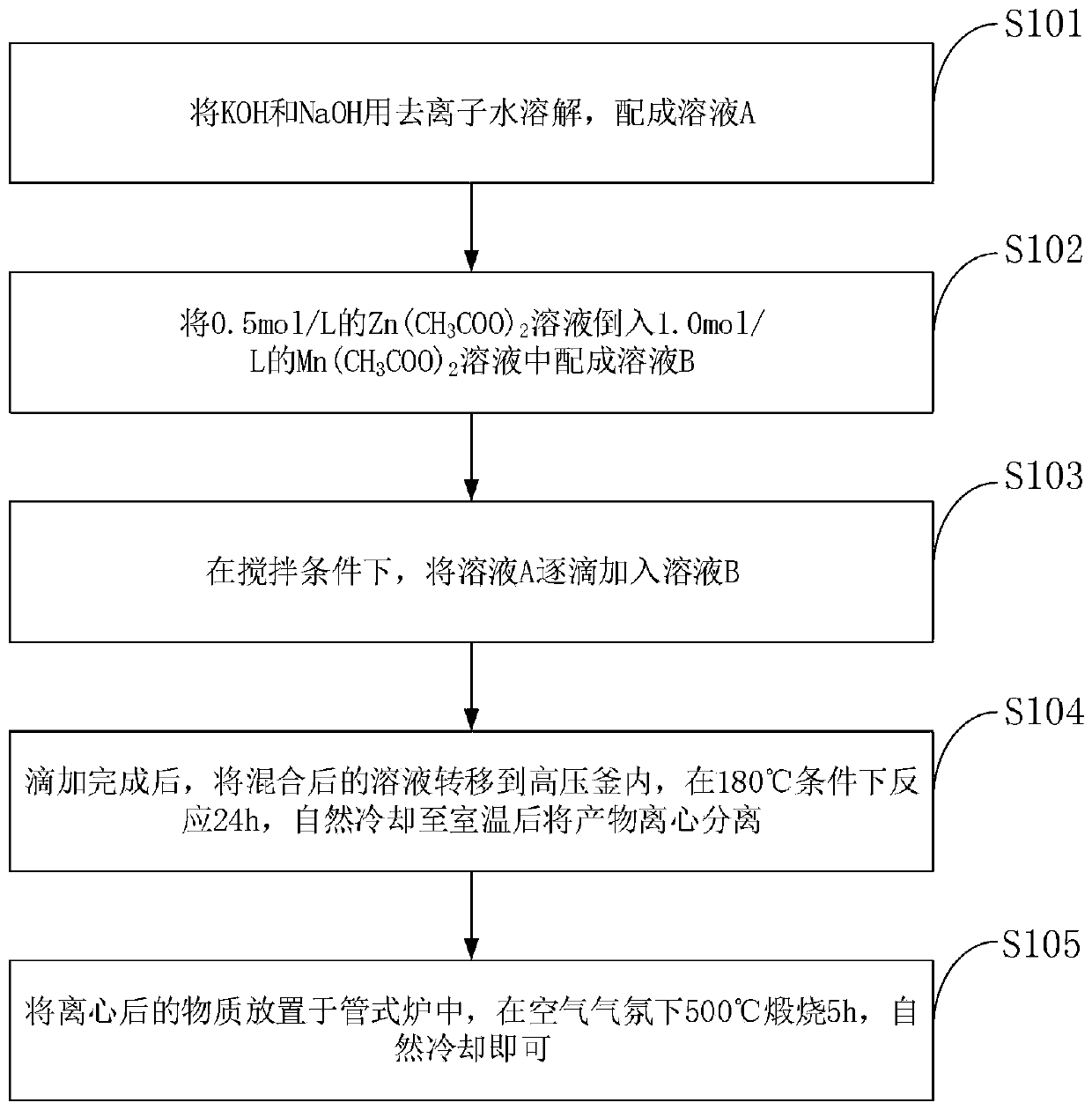

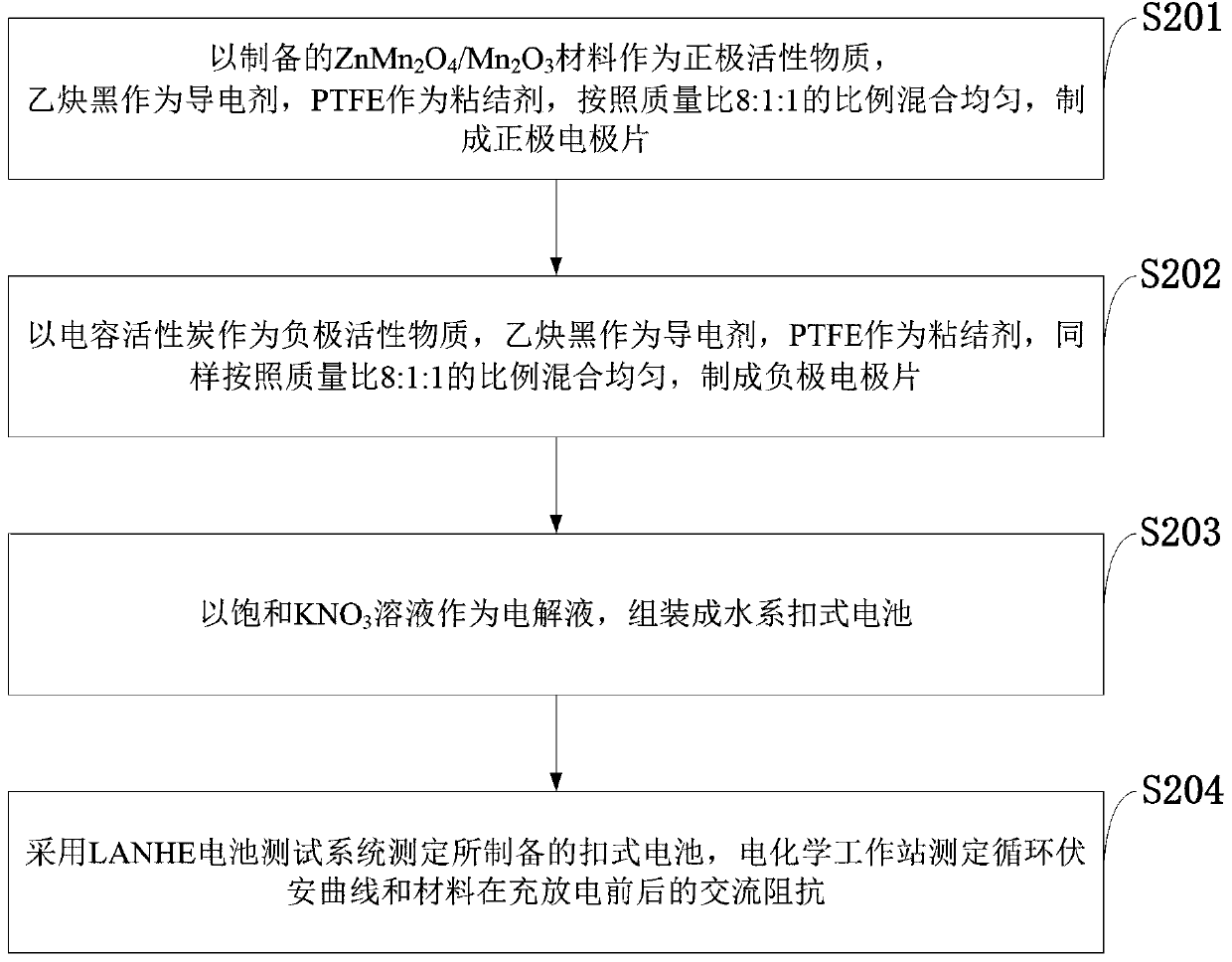

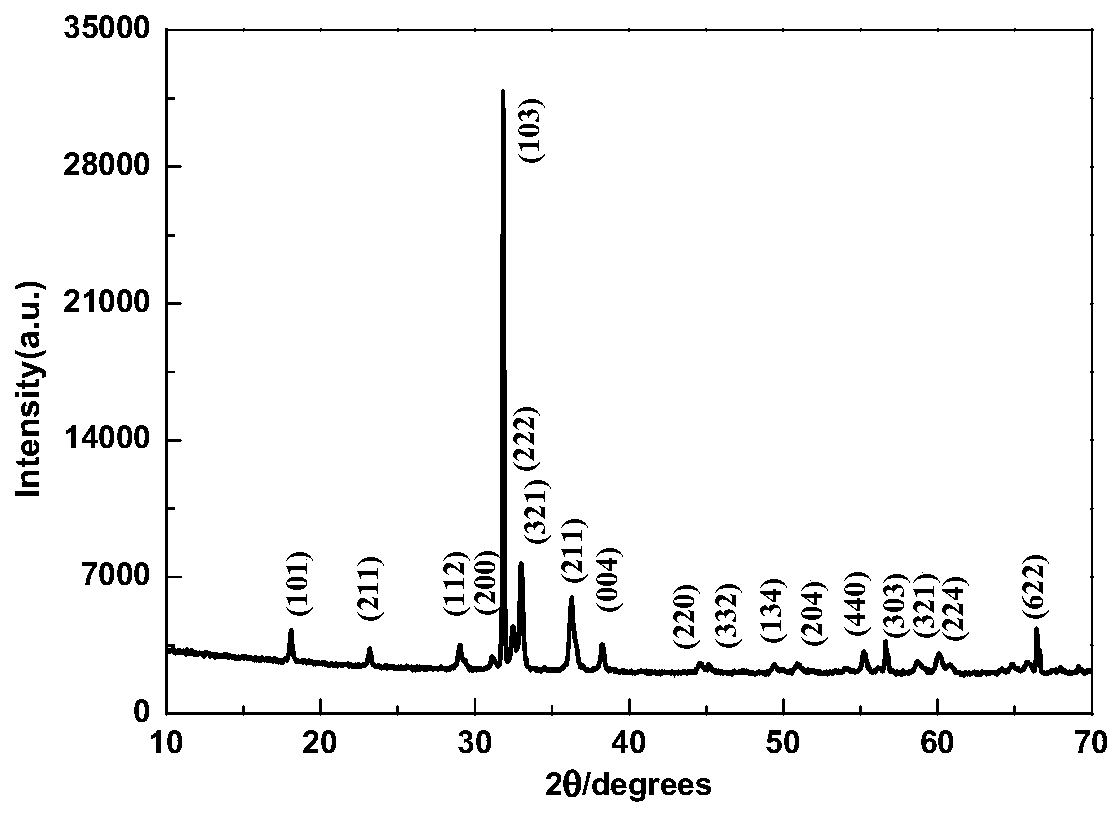

Preparation of ZnMn2O4/Mn2O3 composite material and method for testing electrochemical performance of ZnMn2O4/Mn2O3 composite material

InactiveCN109817905AImprove performanceCalcination temperature is highHybrid capacitor electrodesCell electrodesMaterials preparationAir atmosphere

The invention belongs to the technical field of composite material preparation, and discloses preparation of a ZnMn2O4 / Mn2O3 composite material and a method for testing the electrochemical performanceof the ZnMn2O4 / Mn2O3 composite material. The preparation method of the composite material comprises the following steps: dissolving KOH and NaOH with deionized water to prepare a solution A; pouring0.5 mol / L of Zn (CH3COO) 2 solution into 1.0 mol / L of Mn (CH3COO) 2 solution to prepare a solution B; dropwise adding the solution A into the solution B; transferring the mixed solution into a high-pressure kettle, reacting at 180 DEG C for 24 hours, naturally cooling to room temperature, and centrifugally separating a product; and placing the centrifuged substance in a tubular furnace, calciningfor 5 hours at 500 DEG C in an air atmosphere, and naturally cooling. By comparing the impedance curves of the material before and after charging and discharging, the material has good stability, andan electrochemical test shows that the material has good rate capability and cycle performance.

Owner:SHAOXING UNIVERSITY

Dry distillation charring method for bamboos

InactiveCN101921604BCalcination temperature is highHigh degree of charringCarbon compoundsDirect heating destructive distillationTemperature differenceMoving bed

The invention relates to the bamboo processing field, in particular to a dry distillation charring method for bamboos, which comprises the following steps of: delivering the bamboos in a vertical moving bed through a drying zone, a pre-charring zone, a charring zone, a calcining zone and a cooling zone in turn, exhausting pyrolysis gas from the top to a bamboo vinegar condenser, and condensing the pyrolysis gas to obtain bamboo vinegar; controlling the temperature difference of different positions of a burning zone to perform step temperature rise, heating the bamboos to between 700 and 750 DEG C at the speed of 5 to 15 DEG C per minute during moving downwards in the burning zone and preserving the heat for 40 to 80 minutes, and then heating the bamboos to between 1,000 and 1,500 DEG C atthe speed of 5 to 15 DEG C per minute and preserving the heat for 2 to 8 hours; and preferably, soaking the taken-out bamboo charcoal into solution containing 2 to 4 percent of acid for 1 to 2 hours,taking out the bamboo charcoal and cleaning the bamboo charcoal by using clean water, and then drying the bamboo charcoal in a drying kiln for 0.5 to 1 hour. The bamboo charcoal has high charring degree, strong conductivity and high antistatic capability; the adsorption property of the bamboo charcoal is higher due to the step temperature rise; and the surface of the bamboo charcoal is bright andthe quality is stable due to solution soaking, and the method is suitable for application of health-care bamboo charcoal.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com