Safe carbon electrical calcination furnace

An electric calciner, carbon technology, applied in the field of carbon raw material calcination

Active Publication Date: 2014-12-17

桐乡市恒达经编股份有限公司

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, due to the mutual influence of factors such as raw materials, cooling methods, electric calcination process conditions and management, there are certain unsafe factors in the operation of domestic electric calciners, which are mainly manifested in: 1. The discharge of volatile matter in calcined anthracite is affected. Due to the influence of anthracite particle size and air permeability, when the volatile matter in the furnace is not discharged smoothly, it is easy to cause the volatile matter to burn in the preheating zone of the furnace. Danger

This situation is likely to occur when the anthracite has a large particle size below 10 mm and the negative pressure control of the furnace body is not suitable; 2. When the electric calciner bias current, frequent start-up or improper baking cause damage to the furnace lining refractory bricks and heat insulation materials, The local overheating and redness of the simplified electric calciner appear, and there is a danger of personnel being scalded and the furnace body collapsing; 3. Water leakage in the water cooling parts such as the electrode holder, water cooling round table and water cooling wall, resulting in water entering the furnace, water and furnace The hot carbonaceous material in the interior reacts to generate steam, which enters the furnace to generate carbon monoxide gas and hydrogen gas, and the gas passes through the material layer upwards and enters the high temperature zone between the two electrodes. When the gas reaches the high temperature zone, the volume will expand rapidly and tilt the material layer to Spraying from the furnace mouth forms a spray furnace; when there is a water supply failure, the cooling system of the electric calciner will lack water for a long time, resulting in water shortage and high temperature in high-temperature parts such as the water-cooled round table and water-cooled wall, causing softening and cracking of the water-cooled round table and water-cooled wall 4. The insulation of the DC power supply system and the short circuit caused by the insulation drop between various parts of the furnace body

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

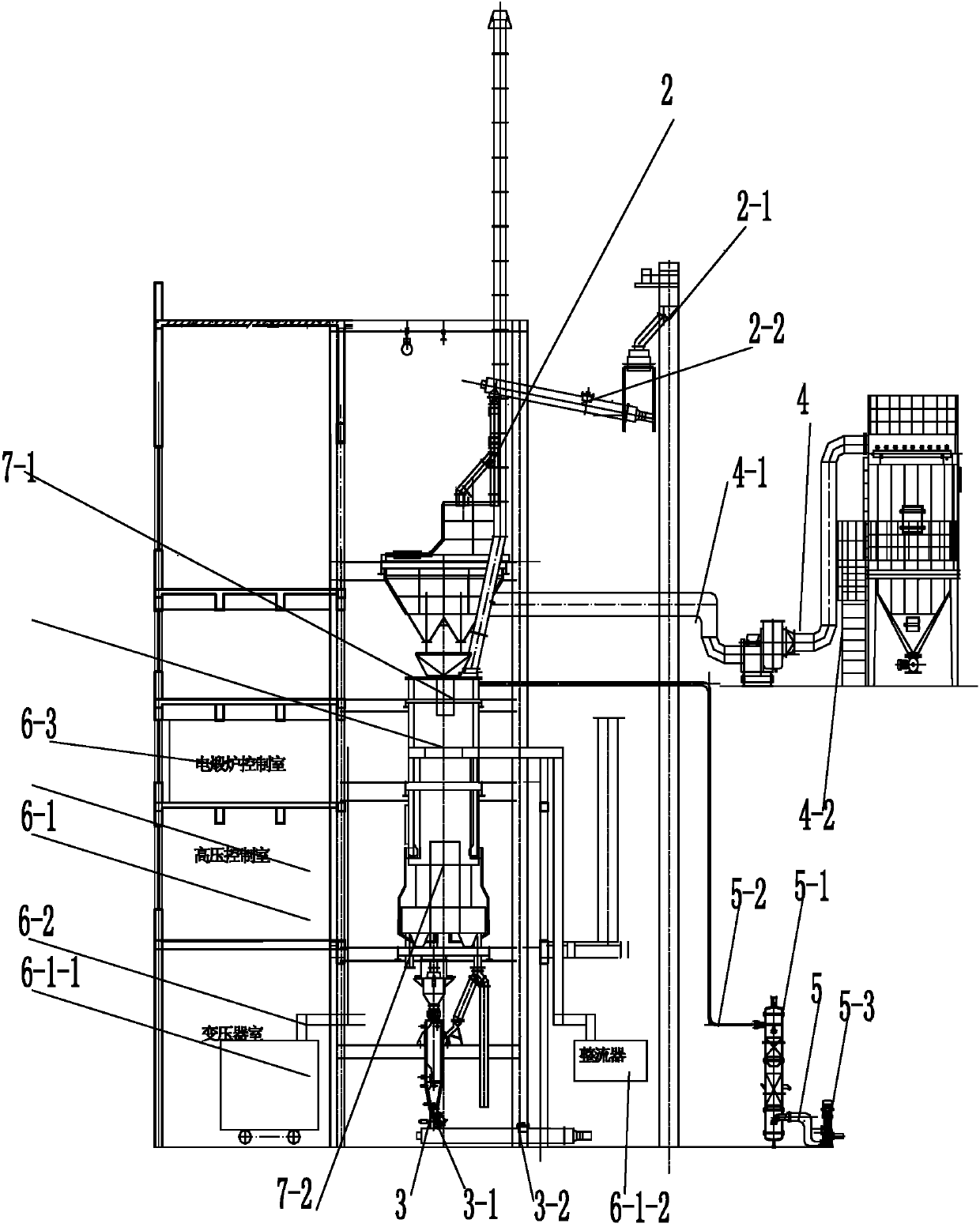

The invention relates to a safe carbon electrical calcination furnace, and especially relates to a carbon raw material anthracite calcination furnace. The electrical calcination furnace comprises an electrical calcination furnace body 1, a feeding system 2, a discharging system 3, a dust removal system 4, a cooling water system 5, an electric control system 6 and an electrode 7, the electrical calcination furnace continuously adds anthracite into the furnace body 1 from the top of the furnace through the feeding system 2, anthracite passes through a preheating zone at the upper portion of the furnace body 1 and then descends to a calcining zone, a calcined material is cooled, the cooled material is continuously discharged out of the furnace body through the discharging system 3, and high temperature flue gas generated by the electrical calcination furnace enters the dust removal system 4 and is processed. The electrical calcination furnace has the advantages of simple and compact structure, convenient continuous operation, high automation degree andhigh calcination temperature, allows parts of the calcined material to have semi-graphitized property, and is very suitable for high temperature calcination of anthracite; the electrical calcination furnace reasonably controls the granularity and the coal dust content of anthracite by combining the structure and technology characteristics in the operation process, can timely monitor electrical insulation, and realizes the reasonable operation under power, discharge quantity and cooling water supply amount balance maintaining conditions.

Description

technical field [0001] The invention belongs to the technical field of calcining carbon raw materials, in particular to a calciner for electric calcining carbon raw materials. Background technique [0002] The electric calcination furnace is a high-temperature calcination equipment used for carbon raw materials. Its heat source is that the current is conducted to the furnace through conductive electrodes. [0003] The anthracite filled with high-temperature treatment has its own resistance to generate heat, so that the calcined carbon raw material can achieve the purpose of corresponding performance indicators. At present, due to the mutual influence of factors such as raw materials, cooling methods, electric calcination process conditions and management, there are certain unsafe factors in the operation of domestic electric calciners, which are mainly manifested in: 1. The discharge of volatile matter in calcined anthracite is affected. Due to the influence of anthracite ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B31/02

Inventor 李黎

Owner 桐乡市恒达经编股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com