Preparation method of colored magnetic pearlescent pigment

A pearlescent pigment and color magnetic technology, applied in the field of pigments, can solve the problems of easy oxidation of magnetic pearlescent, high equipment and operation requirements, and influence on large-scale production, and achieve significant 3D effects, strong magnetic permeability, and bright colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

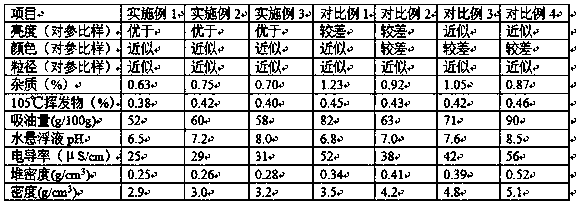

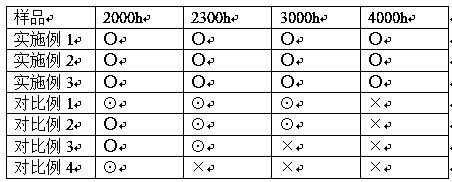

Examples

Embodiment 1

[0028] The preparation method of colored magnetic pearlescent pigment comprises the following steps:

[0029] Step S1: Weigh 100g of the pretreated substrate, add 1000ml of distilled water, adjust the pH to 2.0, raise the temperature to 75°C, add titanium tetrachloride solution at a flow rate of 45ml / min, feed until different colors appear, stop feeding after the feeding is completed Stir for 30 minutes, heat up to 80°C, add alkali to adjust to pH=9.0;

[0030] Step S2: Under the conditions of temperature 80°C and pH=9.0, add 0.2mol / l sodium silicate solution, flow rate 60ml / min, time 2min, stop feeding and stir for 30min, add hydrochloric acid to adjust pH=3.4;

[0031] Step S3: Under the conditions of temperature 80°C and pH=3.4, add ferric chloride solution at a flow rate of 0.7 L / min, stop feeding and stir for 30 minutes after the feeding, and add alkali to adjust the pH to 7.8;

[0032] Step S4: Under the conditions of temperature 80°C and pH=7.8, add the ferrous chlorid...

Embodiment 2

[0043] The preparation method of colored magnetic pearlescent pigment comprises the following steps:

[0044] Step S1: Weigh 100g of the pretreated substrate, add 1000ml of distilled water, adjust the pH to 1.9, raise the temperature to 70°C, add titanium tetrachloride solution at a flow rate of 45ml / min, and feed until different colors appear, stop feeding after the feeding is completed Stir for 30 minutes, heat up to 72°C, add alkali to adjust to pH=8.9;

[0045] Step S2: Under the conditions of temperature 72°C and pH=8.9, add 0.2mol / l sodium silicate solution, flow rate 60ml / min, time 1min, stop feeding and stir for 30min, add hydrochloric acid to adjust pH=3.3;

[0046] Step S3: Under the conditions of temperature 72°C and pH=3.3, add ferric chloride solution with a flow rate of 0.7 L / min, stop feeding and stir for 30 minutes after the feeding, and add alkali to adjust the pH to 7.5;

[0047] Step S4: Under the conditions of temperature 75°C and pH=7.5, add the ferrous c...

Embodiment 3

[0058] The preparation method of colored magnetic pearlescent pigment comprises the following steps:

[0059] Step S1: Weigh 100g of the pretreated substrate, add 1000ml of distilled water, adjust the pH to 1.9-2.1, raise the temperature to 80°C, add titanium tetrachloride solution at a flow rate of 45ml / min, and feed until different colors appear. Stop feeding and stir for 30 minutes, raise the temperature to 82°C, add alkali to adjust the pH to 9.2;

[0060] Step S2: Under the conditions of temperature 82°C and pH=9.2, add 0.2mol / l sodium silicate solution, flow rate 60ml / min, time 2min, stop feeding and stir for 30min, add hydrochloric acid to adjust pH=3.5;

[0061] Step S3: Under the conditions of temperature 82°C and pH=3.5, add ferric chloride solution at a flow rate of 0.7 L / min, stop feeding and stir for 30 minutes after the feeding, and add alkali to adjust the pH to 8.0;

[0062] Step S4: Under the conditions of temperature 82°C and pH=8, add the ferrous chloride m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com