Ca-Bi-O series visible-light photocatalysis material and preparation method thereof

A photocatalytic material and visible light technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of high reaction temperature, achieve good repeatability, simple operation, and improve photocatalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: The preparation method of Ca-Bi-O visible light photocatalytic nanomaterials, the steps are as follows:

[0035] (1) Preparation of precursors

[0036] Weigh 0.24g Ca(NO 3 ) 2 and 0.97g Bi(NO 3 ) 3 Dissolve in 50mL of ethylene glycol, add 1mL of polymaleic acid dropwise, stir at room temperature for 5 minutes, adjust pH=9 with concentrated ammonia water, and stir at room temperature for 24 hours; wash the resulting product with 100mL of ethanol at room temperature, then centrifuge and separate Dry at 70°C for 24 hours to obtain a precursor.

[0037] (2) Annealing

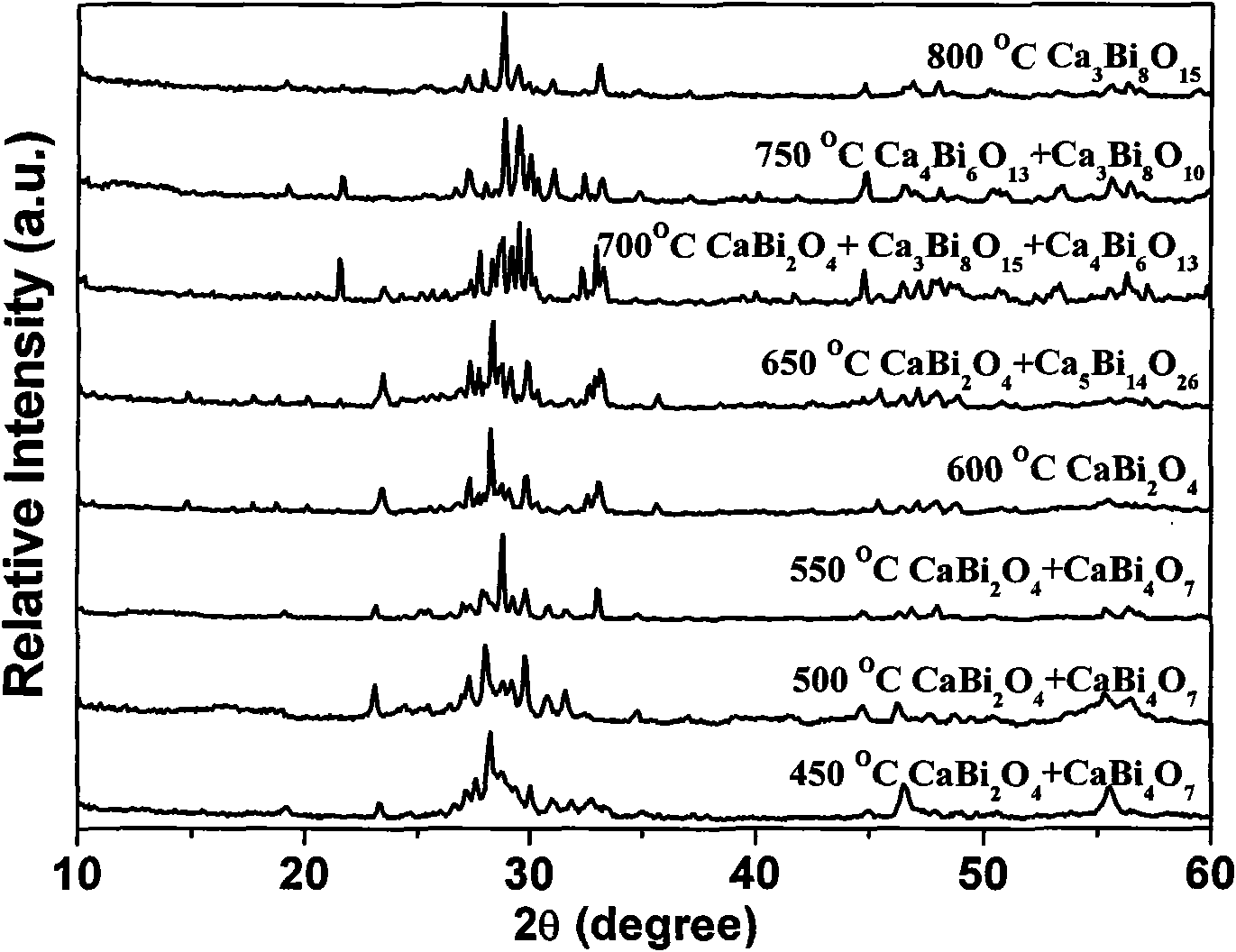

[0038] Take 0.4g of the precursor prepared in step (1), pretreat at 300°C for 8 hours, and cool to room temperature naturally; grind for 20 minutes, anneal at 450-800°C for 10 hours, and cool to room temperature naturally to obtain Ca-Bi-O It is a photocatalytic functional material.

[0039] The reaction described in the steps (1) and (2) is to place the reaction kettle in an oven capable of...

Embodiment 2

[0045] The preparation steps are the same as in Example 1, and the difference is that the calcium salt used in step (1) is Ca(NO 3 ) 2 , the bismuth salt is BiCl 3 .

Embodiment 3

[0047] The preparation steps are the same as in Example 1, and the difference is that the calcium salt used in step (1) is CaCl 2 , the bismuth salt is: Bi(NO 3 ) 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com