Metal oxide nanoparticles and preparation method of metal oxide nanoparticles

A metal nanoparticle and nanoparticle technology, which is applied in the preparation of alumina/hydroxide, chemical instruments and methods, zirconia, etc., can solve the problems of complex process, uneven particle size, and difficult preparation of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

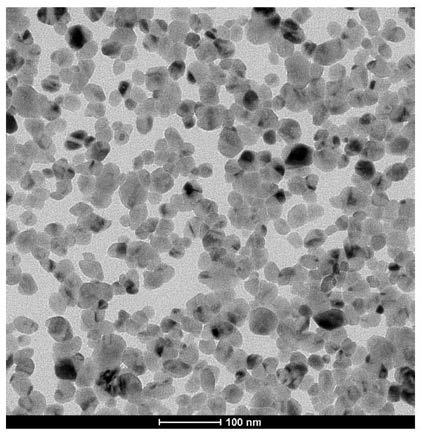

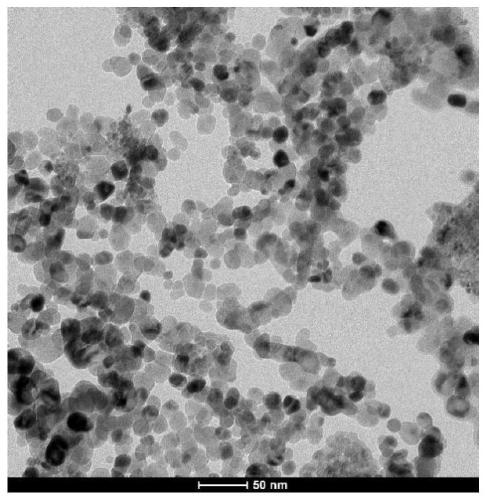

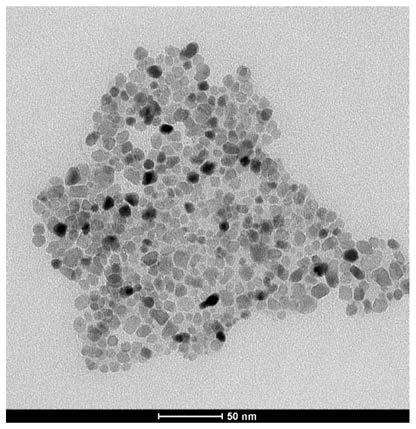

Image

Examples

Embodiment 1

[0039] Example 1: An organosol was prepared by dissolving aluminum nitrate and citric acid in ethylene glycol methyl ether, wherein the molar concentration of aluminum was 0.1M, and the molar ratio of aluminum nitrate and citric acid was 1:0.5. Mix the organosol and potassium sulfate, and pour off the excess organosol after sedimentation to obtain a mixture of the organosol and potassium sulfate. The mixture was kept at 60°C to 120°C and dried to obtain a loose powder. The powder is calcined at 400°C to below the melting point of potassium sulfate, and the calcined product is washed with water and dried to obtain highly crystalline and highly dispersed alumina nanoparticles.

Embodiment 2

[0040] Example 2: An organosol was prepared by dissolving aluminum nitrate and citric acid in ethylene glycol methyl ether, wherein the molar concentration of aluminum was 0.1M, and the molar ratio of aluminum nitrate and citric acid was 1:0.5. Mix the organosol with sodium sulfate, and pour off the excess organosol after sedimentation to obtain a mixture of the organosol and potassium sulfate. The mixture was kept at 60°C to 120°C and dried to obtain a loose powder. The powder is calcined at 400°C to below the melting point of sodium sulfate, and the calcined product is washed with water and dried to obtain highly crystalline and highly dispersed alumina nanoparticles.

Embodiment 3

[0041] Example 3: An organosol was prepared by dissolving aluminum nitrate and citric acid in ethylene glycol methyl ether, wherein the molar concentration of aluminum was 0.1M, and the molar ratio of aluminum nitrate and citric acid was 1:0.5. Mix the organic sol with potassium chloride, and pour off the excess organic sol after sedimentation to obtain a mixture of the organic sol and potassium sulfate. The mixture was kept at 60°C to 120°C and dried to obtain a loose powder. The powder is calcined at 400° C. to below the melting point of potassium chloride, and the calcined product is washed with water and dried to obtain highly crystalline and highly dispersed alumina nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com