Patents

Literature

65results about How to "Crystallization perfect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal shrinkage biaxially oriented film

InactiveCN102059836ACrystallization perfectHigh heat shrinkageSynthetic resin layered productsTime changesAcrylic resin

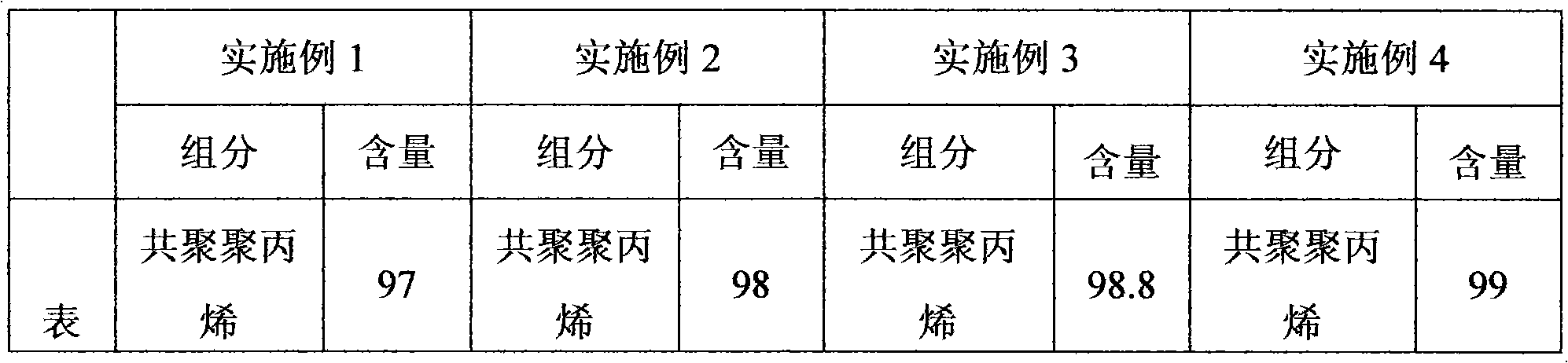

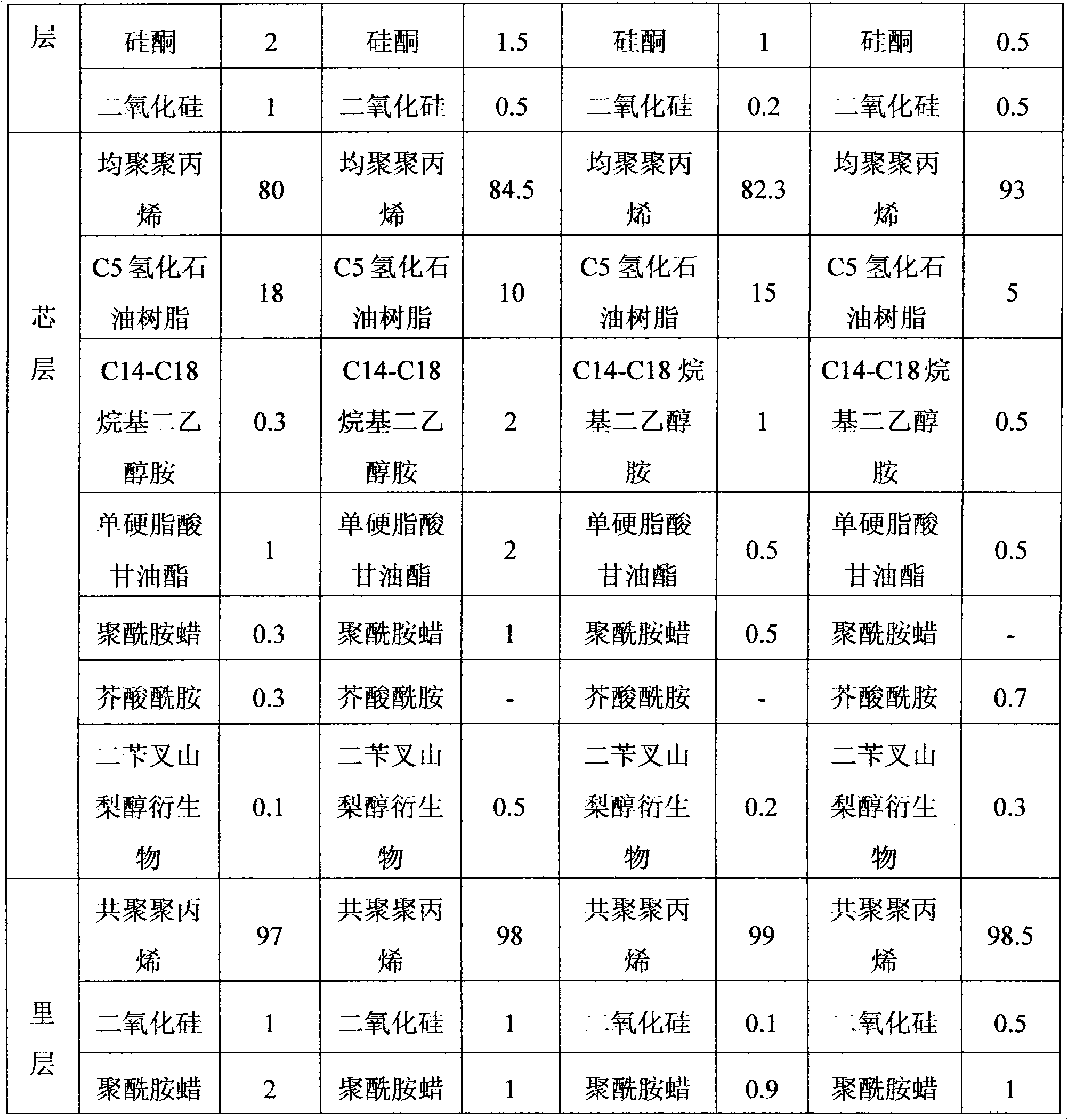

The invention discloses a thermal shrinkage biaxially oriented film which is composed of a surface layer, a sandwich layer and an inner layer, wherein the thickness of the surface layer is 0.5-1.5 micrometers, the thickness of the sandwich layer is 19-22 micrometers, the thickness of the inner layer is 0.5-1.5 micrometers, and the total thickness of the three layers is 20-23 micrometers. The surface layer comprises the following components in percentage by weight: 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The sandwich layer comprises 80-93% of acrylic resin homopolymer, 0.3-3% of anti-static agent, 0.1-0.5% of crystal regulator, 1-2% of surfactant, 5-18% of stiffening agent and 0.5-1% of lubricant. The inner layer comprises 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The film has a stable thermal shrinkage factor which slightly changes as the storage time changes.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

High-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material

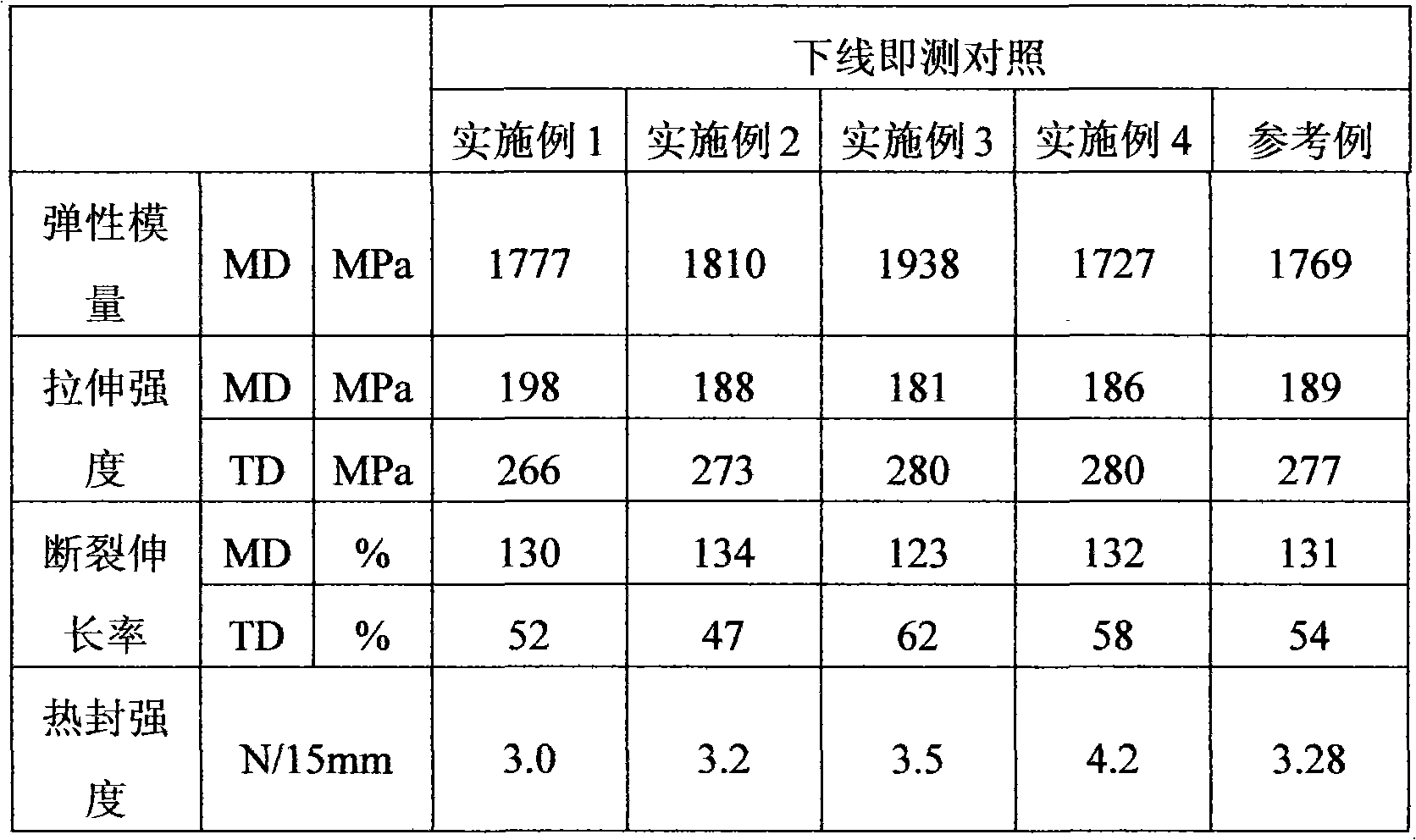

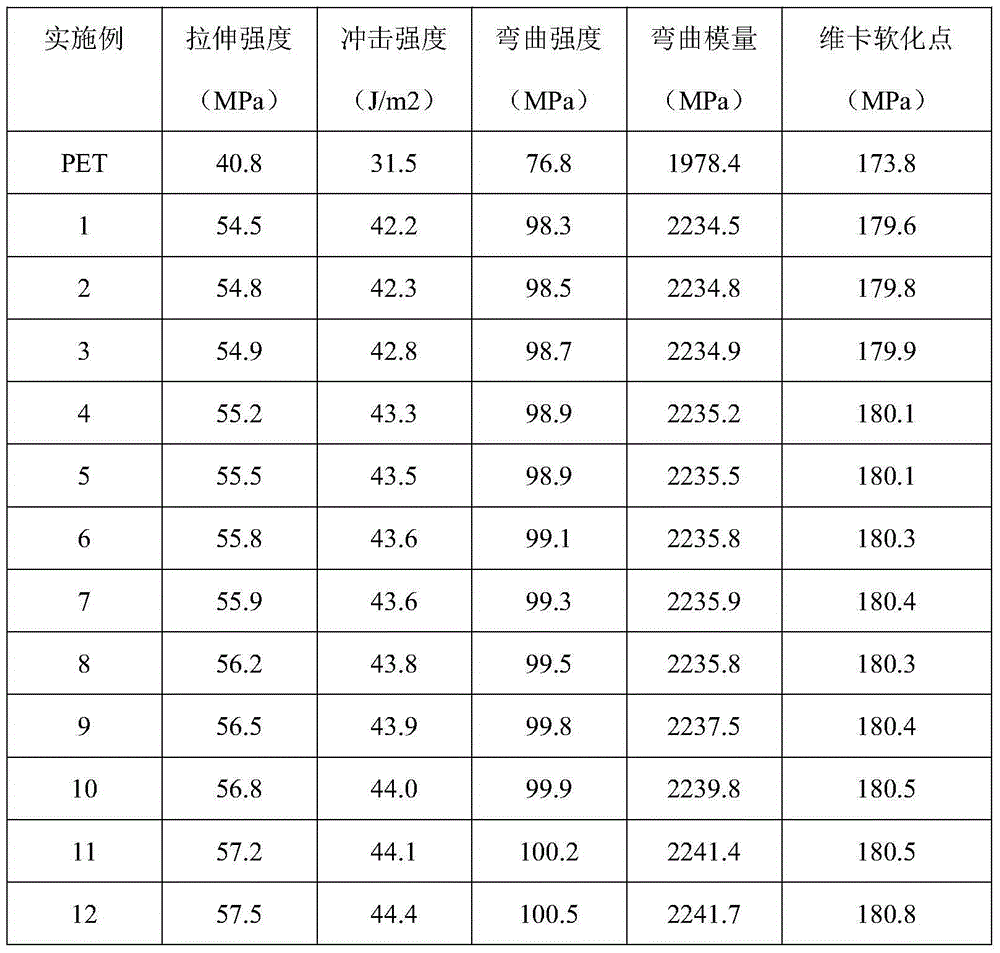

The invention relates to a high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material. The blend material comprises the following raw materials by weight: 60 to 100 parts of UHMWPE, 5 to 12 parts of HDPE, 6 to 16 parts of LLDPE, 0.1 to 3 parts of a high-molecular-weight polymer nucleating agent and 1.5 to 3 parts of a flow modifier. The high-molecular-weight polymer nucleating agent has the advantages of no odor, good dispersibility, good compatibility, capacity of realizing heterogeneous crystallization, a high degree of crystallization and a small application amount; the high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material retains original characteristics of polyethylene UHMWPE and has obviously improved tensile strength, impact strength, bending strength, Vicat softening temperature, elongation at break and Shore hardness and a reduced mortar wear rate.

Owner:漯河科莱堡科技有限公司

Preparation method of aluminium hydroxide micro powder

ActiveCN1927719APerfect crystal developmentFine granularityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium sulfateAluminium hydroxide

The present invention relates to technological process of producing fine aluminum hydroxide powder as fire retardant stuffing, and is especially technological process of producing fine aluminum hydroxide powder with high crystallization degree. The gel seed prepared with sodium aluminate solution through CO2 introducing carbon process and with sodium aluminate solution through aluminum sulfate neutralization process is converted via a special process into fine pure alpha-aluminum hydroxide powder without beta-aluminum hydroxide. The fine pure alpha-aluminum hydroxide powder is coated, modified and stoved to obtain submicron level pure alpha-aluminum hydroxide powder. Or, the completely converted fine powder slurry is added into sodium aluminate solution directly or after being concentrated and further decomposed to obtain fine aluminum hydroxide powder with excellent fire retarding performance.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

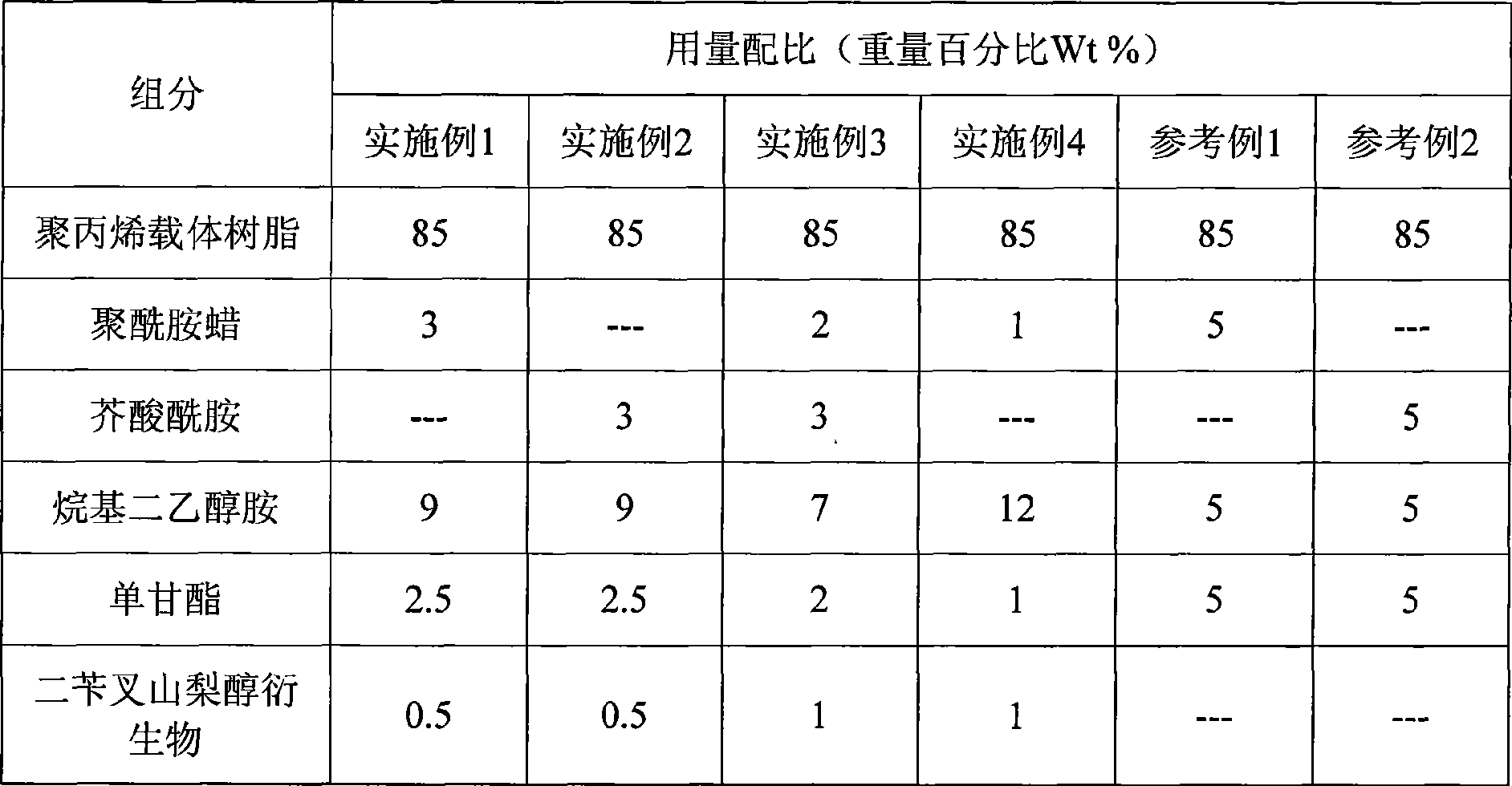

Thermal contraction and antistatic composite master batch, preparation and use thereof

InactiveCN101434726ACrystallization perfectImprove antistatic performanceMasterbatchAntistatic agent

The invention discloses a composite master batch with thermal shrinkable and antistatic functions and a preparation method and an application thereof. The composite master batch comprises the following components according to the following weight percentages: 70 percent to 95 percent of polypropylene carrier resin, 1 percent to 10 percent of lubricant, 2 percent to 20 percent of antistatic agent, 0.1 percent to 5 percent of crystal regulator and 1 percent to 10 percent of surfactant. The preparation method of the composite master batch comprises the following steps: (1) every component is weighed according to weight percentage; (2) all components are added into a twin-screw extruder for fusion, mixing and extruding, the rotating speed of the twin-screw extruder is 200 r / min to 500r / min and the temperature is 180 DEG C to 230 DEG C; and (3) the mixed material extruded is removed of water, granulated and dried so as to obtain the composite master batch. The composite master batch can be applied to the production of polypropylene film, can improve the thermal shrinkage rate and the stability of the thermal shrinkage rate, and has antistatic effect.

Owner:ZHANJIANG PACKAGING MATERIAL ENTERPRISES

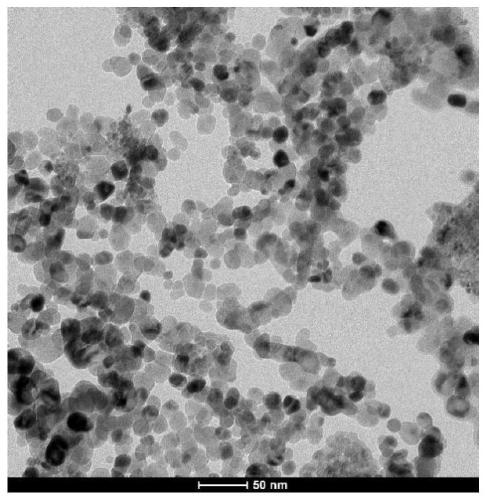

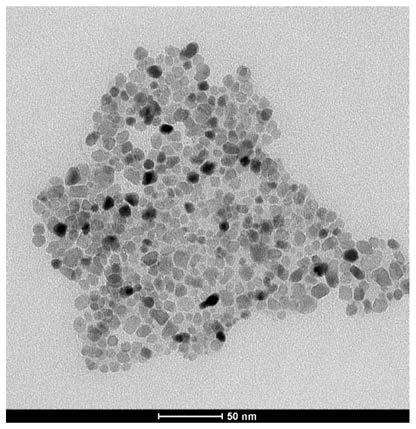

Nano-silver powder, manufacturing method and application thereof

ActiveCN101707062ALarge specific surface areaImprove electrode coverageFixed capacitor electrodesMetal/alloy conductorsNanometreTriethanolamine

The invention relates to nano-silver powder used for DC electrode sizing agents and low-temperature bonding nano-silver paste, and a manufacturing method thereof. The physical properties of nano-silver powder are as follows: particle size distribution between 10 and 100 mu m, average particle size between 20 and 50 nm, specific surface area between 30 and 50 m2 / g, and apparent density between 1.5 and 3.0 g / cm3. The nano-silver powder adopts a chemical reduction method and is prepared by adopting hydrazine hydrate, glycerine or triethanolamine to reduce silver compounds at 90 to 92 DEG C. The nano-silver powder manufactured by the method is applied to the DC electrode sizing agents sintered at 800 DEG C. When the nano-silver powder is applied to the nano-silver paste of SiC or GaN and other chips bonded at 260 to 270 DEG C, electrodes have the advantages of good weldability, high conductivity, stable electrical property, high bonding strength, high reliability and the like.

Owner:GRIKIN ADVANCED MATERIALS

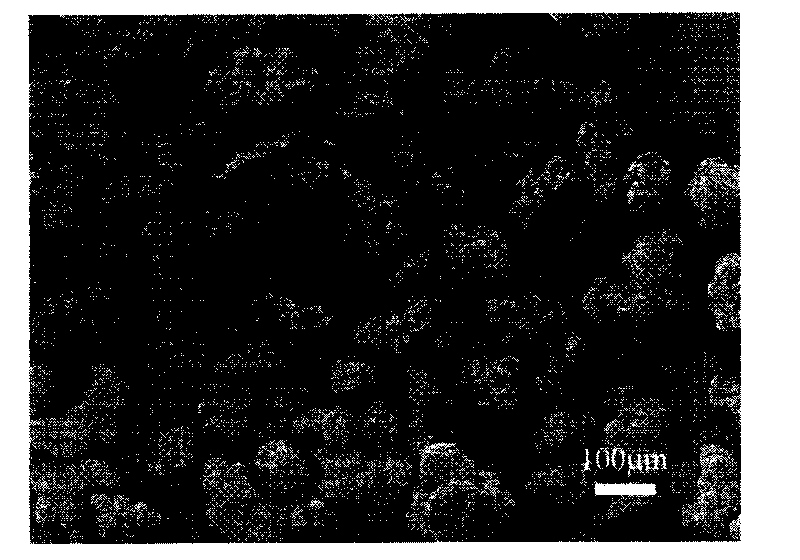

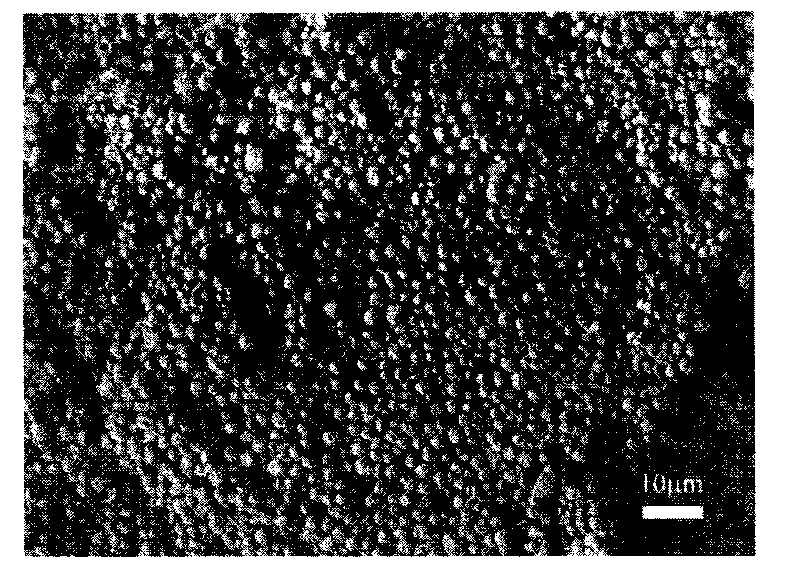

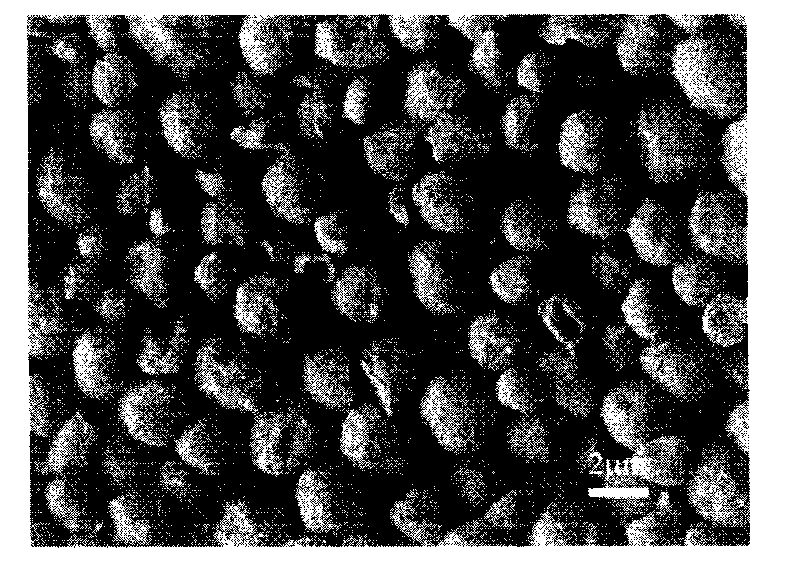

Process for preparing polymer ultra-fine particles by applying supercritical fluid

InactiveCN101693768AHigh crystallinityCrystal stableBulk chemical productionPolymer scienceUltra fine

The invention relates to a process for preparing polymer ultra-fine particles, in particular to a process for preparing polymer ultra-fine particles by applying supercritical fluid, which utilizes the supercritical fluid to process one type of polymer or a mixture of various types of polymers to prepare polymer ultra-fine particles or polymer microcapsule ultra-fine particles. As dissolubility to polymer is increased in a supercritical fluid state, polymer can be precipitated from the supercritical fluid after the supercritical fluid state is eliminated, and then polymer ultra-fine particles or polymer microcapsule ultra-fine particles with high degree of crystallinity and fine shape can be prepared after thermostatic treatment. Besides, the prepared ultra-fine particles are narrow in distribution, and shapes thereof can be controlled into regular spheres. The process is simple in technique and easy in operation without complex devices, the prepared ultra-fine particles are regular in shapes, stable in crystalline form, higher in crystallinity and higher in application value and are adoptable to industrialized production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

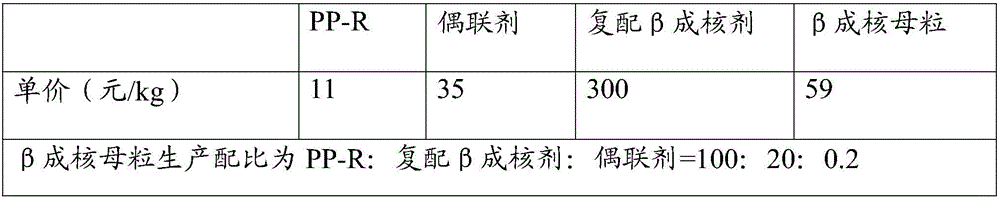

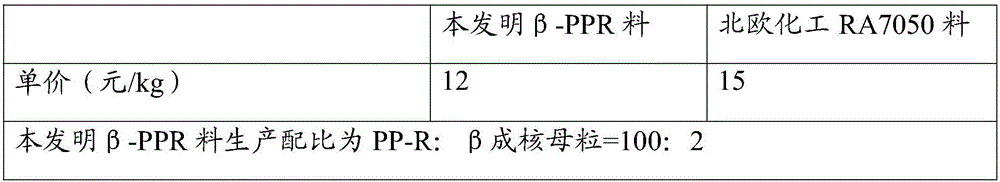

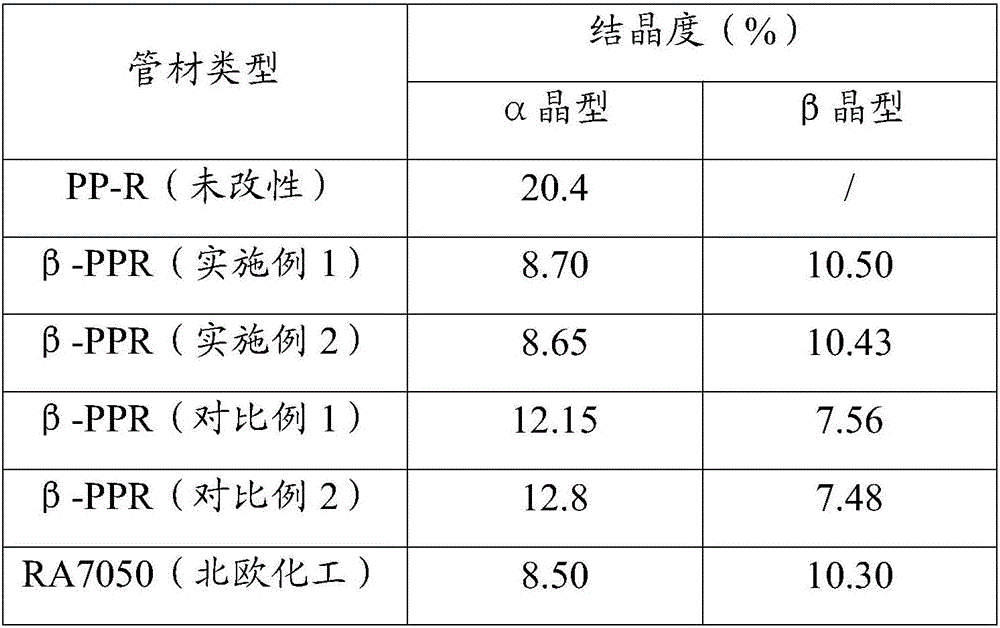

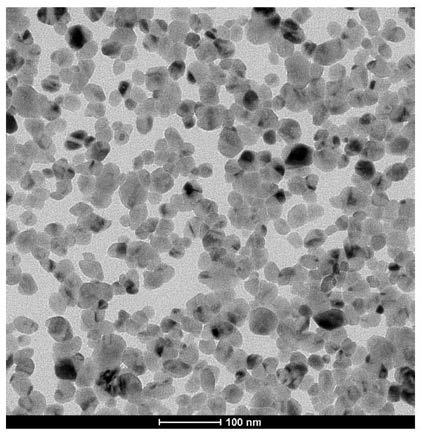

Beta-PPR tube and preparation method thereof

ActiveCN105860275AHigh low temperature impact resistanceReduce brittle crackingShock resistanceMaterials science

The invention relates to a beta-PPR tube and a preparation method thereof. The beta-PPR tube is prepared from the following raw materials in parts by mass: 100 parts of PP-R resin and 1-5 parts of beta nucleated master batch, wherein the beta nucleated master batch is prepared from the following raw materials in parts by mass: 100 parts of PP-R resin, 0.1-1 part of coupling agent and 10-30 parts of beta nucleator. The beta-PPR tube improves the low-temperature shock resistance of the tube and greatly reduces the problem of brittle cracking of the tube, and the preparation method has simple technique, reduces the raw material cost and is favorable for ordinary popularization and use.

Owner:RIFENG TECH CO LTD +1

Method for preparing small-particle-size cerium-activated yttrium aluminum garnet (YAG) florescent powder

ActiveCN105062482AImprove luminous efficiencyCrystallization perfectEnergy efficient lightingLuminescent compositionsCeriumCrystallinity

The invention discloses a method for preparing small-particle-size cerium-activated yttrium aluminum garnet (YAG) florescent powder. According to the method, first, in fused salt, a wrapping structure of nanometer yttrium oxide (cerium oxide) @ aluminum oxide particles is obtained through controlled synthesis, then the aggregate of small-particle YAG florescent powder particles is generated through reaction in high-temperature fused salt, and finally the small-particle-size YAG: Ce florescent powder is obtained through weak ball milling. It is avoided that in the reaction process, the aluminum oxide particles and intermediate-phase particles abnormally grow, and while the high crystallinity of the particles is kept, final YAG is effectively controlled; the particle size of the Ce florescent powder has important significance for improving light-color quality of white-light LEDs, lowering the complexity of a white-light LED packaging technology and increasing the yield.

Owner:SOUTHEAST UNIV

Metal oxide nanoparticles and preparation method of metal oxide nanoparticles

PendingCN111320193AGood dispersionHigh crystallinityMaterial nanotechnologyAluminium oxide/hydroxide preparationMetal oxide nanoparticlesPhysical chemistry

The invention discloses a metal oxide nanoparticle and a preparation method of the metal oxide nanoparticle, which comprises the following steps: preparing an organosol containing the metal element, mixing the organosol with a water-soluble salt, performing standing or centrifuging to precipitate the water-soluble salt, removing the superfluous organosol at the upper part, and keeping the temperature to convert the organosol into gel; along with evaporation of the solvent, shrinking the gel, and coating the surfaces of the water-soluble salt particles with a layer of xerogel film; and calcining the sample at a high temperature between 400 DEG C and a salt melting point, converting the dry gel film into metal oxide nanoparticles, dispersing and attaching the nanoparticles to the surfaces ofwater-soluble salt particles, cooling, and washing with water to remove the salt, thereby obtaining the high-dispersion metal oxide nanoparticles; if the calcined product is reduced in a reducing atmosphere, converting the metal oxide nanoparticles attached to the surfaces of the water-soluble salt particles into corresponding metal nanoparticles, cooling, and washing with water to obtain the high-dispersion metal nanoparticles. According to the method, the high-crystallinity and high-dispersion metal oxide and metal nanoparticles can be rapidly prepared in batches.

Owner:SOUTHEAST UNIV

Polyetheretherketone hollow fiber preparation method

ActiveCN106591969AWide range of regulationGuaranteed uniformityMonocomponent polyethers artificial filamentHollow filament manufactureFiberHollow fibre

The invention relates to a polyetheretherketone hollow fiber preparation method and belongs to the technical field of organic fiber preparation. The problem that polyetheretherketone fibers prepared by a hollow fiber preparation method in the prior art is mainly to be solved. The polyetheretherketone hollow fiber preparation method includes subjecting special spinning-class polyetheretherketone to melt extrusion by a screw in an extruder, using a melt dosing pump for controlling the discharge amount, filtering melts through a filtering system of a component, and forming polyetheretherketone hollow fiber strips through a hollow spinneret plate; drafting the polyetheretherketone hollow fiber strips, cooling according to different cooling modes, and using a winding device for collecting as-spun fibers; guiding the as-spun fibers into a hot-drawing sizing device so as to obtain polyetheretherketone hollow fibers. The polyetheretherketone hollow fiber preparation method is simple, convenient and high in universality. The polyetheretherketone hollow fibers prepared by the preparation method have the advantages of high quality stability, high strength, high tenacity, high uniformity, excellent wear resistance and the like, and can be used for wear-resisting fabrics, thermal protection, lightweight materials and the like, thereby being quite promising in application prospect.

Owner:SINO HIGH CHINA

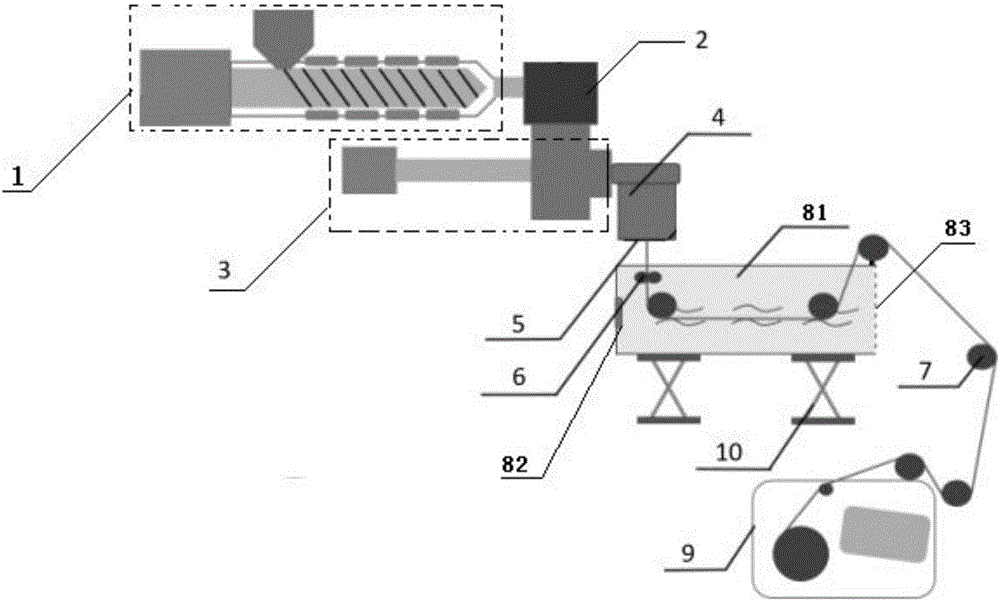

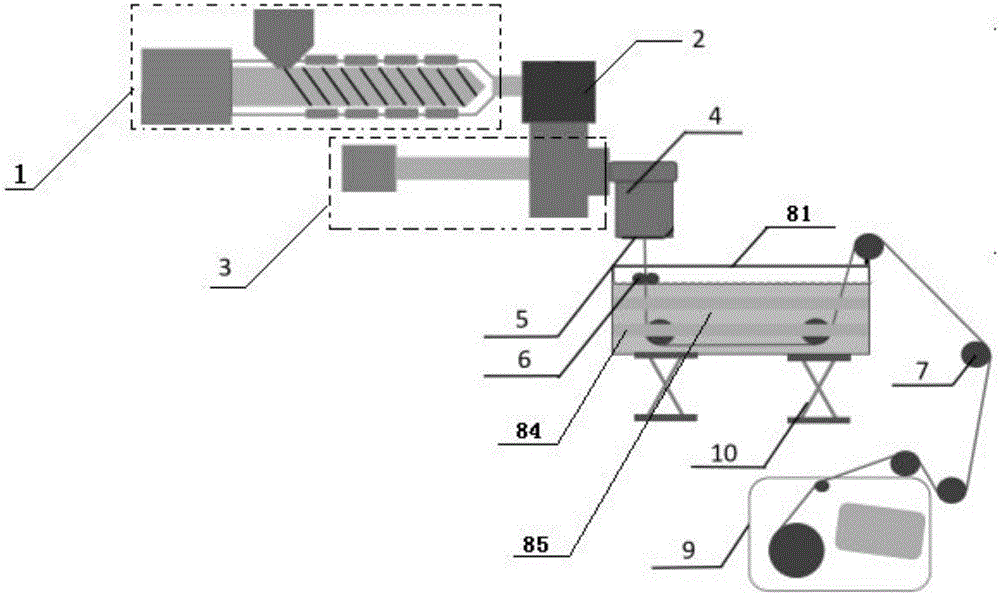

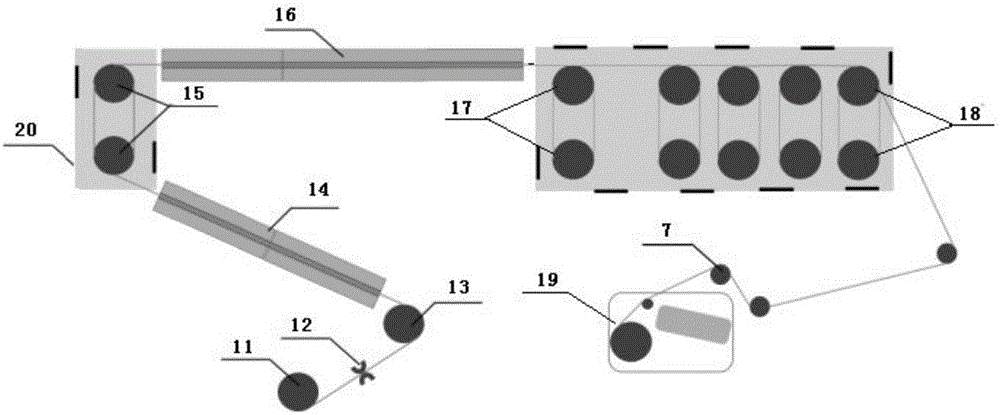

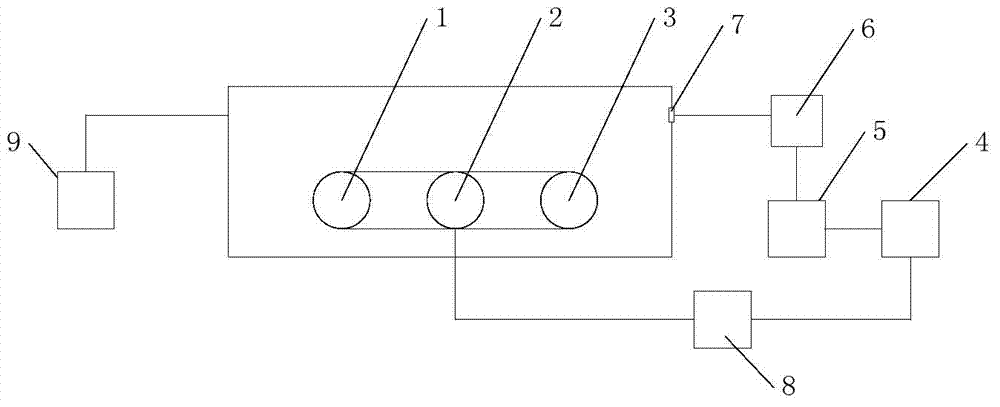

Thermotropic liquid crystal polyarylater monofilament heat treatment device and heat treatment method

ActiveCN104746155ACrystallization perfectHigh strengthArtificial thread manufacturing machinesArtificial filament heat treatmentFiberPolyester

The invention provides a thermotropic liquid crystal polyarylater monofilament heat treatment device and a heat treatment method thereof. The heat treatment device is a heated vacuum airtight box body, and a pay-off roller, a heating tension roller and a take-up roller are sequentially arranged in the box body. A heating device and a vacuum suction device are respectively arranged outside the box body. A monofilament is fed into the heated vacuum heat treatment device to perform heat treatment. The thermotropic liquid crystal polyarylater monofilament is heated and drafted in the closed box body, oxidative degradation of the monofilament is avoided, strength unevenness and drawing irregularity of the monofilament are reduced, and the strength and modulus of the monofilament are improved. The heat treatment method is simple in operation and easy to implement, and the problems of existing complicated polyester fiber heat treatment steps and fiber oxidation degradation are solved.

Owner:WUXI JINTONG CHEM FIBER

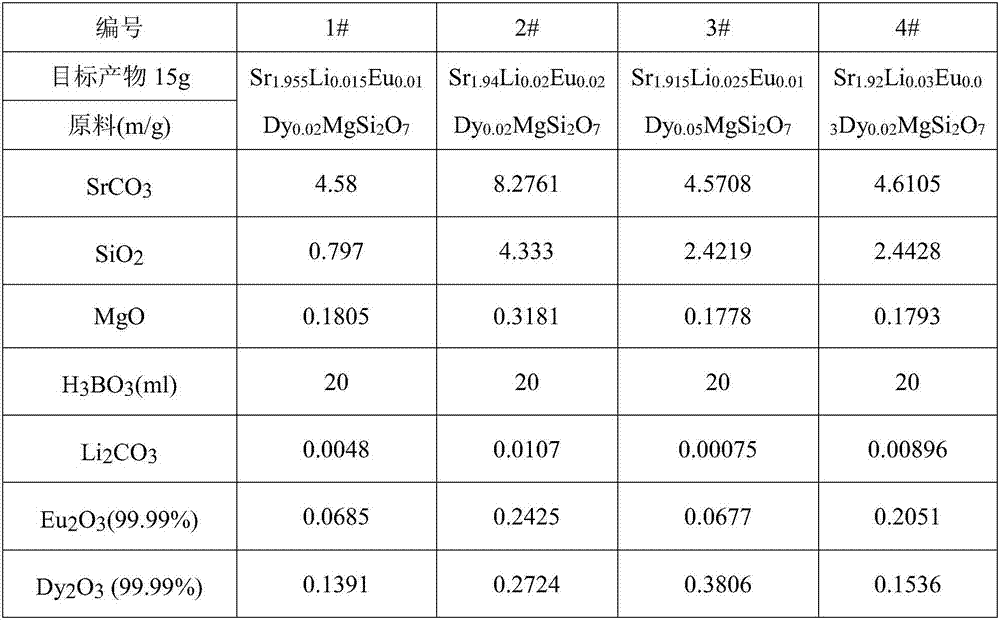

Method for improving long-afterglow characteristics of silicate phosphor powder by means of Li<+> co-doping

InactiveCN107129801AImproved long persistence characteristicsRich oxygen vacanciesLuminescent compositionsOxygen vacancyChemistry

The invention provides a method for effectively improving the afterglow intensity of Sr<2>MgSi<2>O<7>:<x>Eu<2+>, <y>Dy<3+> phosphor powder and prolonging the afterglow time of the Sr<2>MgSi<2>O<7>:<x>Eu<2+>, <y>Dy<3+> phosphor powder by means of do-doping by the aid of Li<+>. The method has the advantages that Sr<2+> sites can be replaced by the Li<+> to form Li'Sr with monovalent negative charge during Li<+> co-doping, and accordingly oxygen vacancy with positive charge can be correspondingly generated to complement charge difference and can be used as a trap for capturing electrons and holes in excited states; captured electrons and holes can be gradually released for heat energy and can be recombined with one another, and phosphorescence can be released and is long-afterglow; oxygen vacancy can be continuously increased along with Li<+> doping, captured electrons can be continuously increased, and accordingly the long-afterglow time can be effectively prolonged; the Li<+> is used for compensating charge, and accordingly the charge is in compensation balance when bivalent Sr<2+> is replaced by trivalent Dy<3+>; the Li<+> further can be used as a fluxing agent, the crystallinity of crystals can be effectively improved, the particle sizes of the crystals can be increased, accordingly, crystallization can be improved, and the luminescence intensity of the long-afterglow can be ultimately improved.

Owner:XUZHOU NORMAL UNIVERSITY

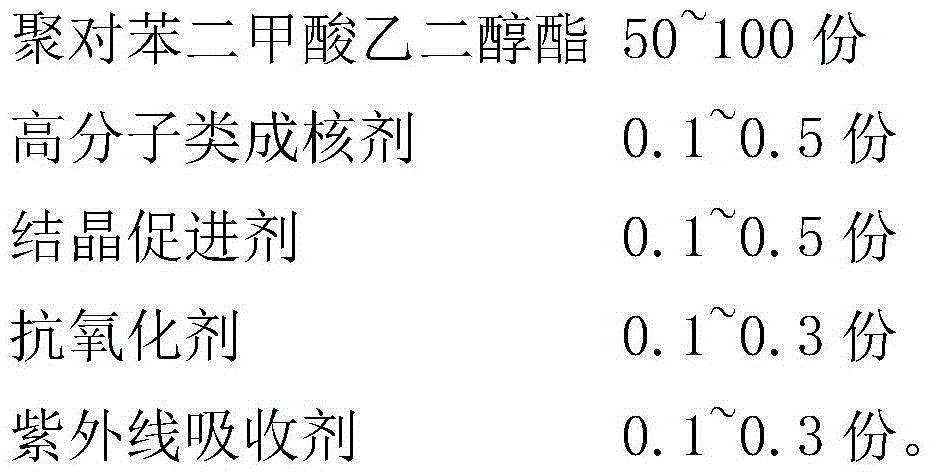

Macromolecule nucleating agent modified polyethylene glycol terephthalate

A macromolecule nucleating agent modified polyethylene glycol terephthalate is characterized by being prepared by the following raw materials in parts by weight: 50-100 parts of polyethylene glycol terephthalate, 0.1-0.5 part of macromolecule nucleating agent, 0.1-0.5 part of crystallization prompter, 0.1-0.3 part of antioxidant and 0.1-0.3 part of ultraviolet light absorber. The macromolecule nucleating agent is none in odor, good in dispersibility and compatibility and high in crystalline degree and the mechanical property of a product is good. The macromolecule nucleating agent is a novel functional assistant for prompting polymer crystallization and improving grain structure thereof, can realize heterogeneous nucleation of polymer, improve rigidity, wearing resistance and processing performance of a material, improve crystalline degree and crystallization rate, reduce the grain size, reduce grain defects, and make crystals be more perfect, and therefore the rigidity, wearing resistance and electricity endurance of a mixer are improved to a certain extent, the melt fluidity is improved, and the extruding and injection molding are prompted.

Owner:JIESHOU CITY TIANHONG PACKAGING MATERIAL

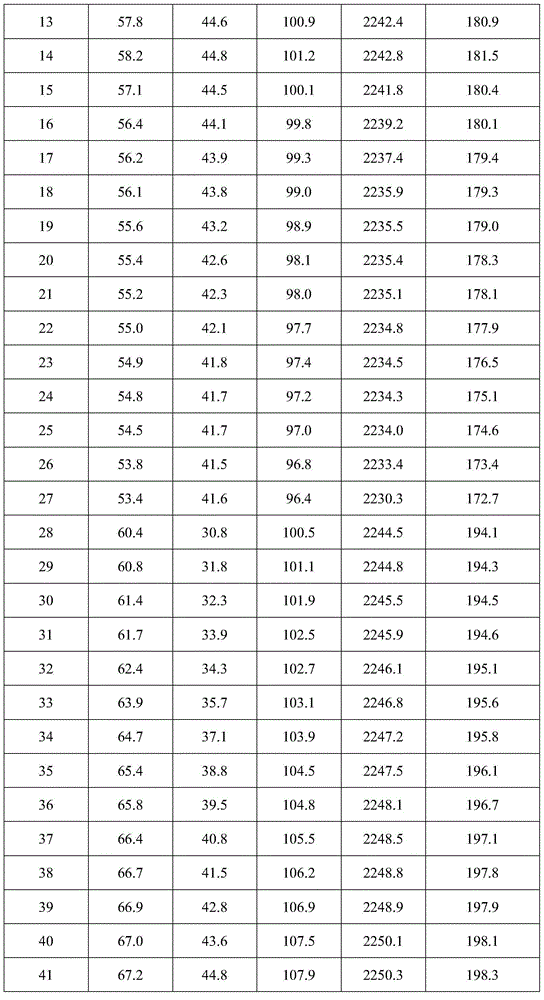

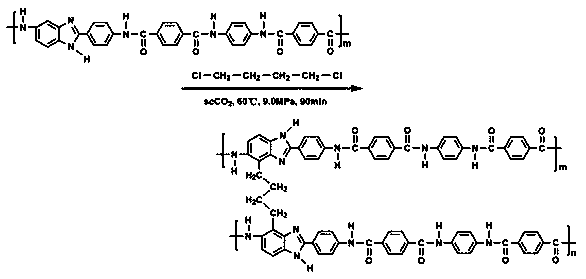

Method modifying aramid fibers in supercritical carbon dioxide environment to increase mechanical performance and surface performance

ActiveCN110761081APromote crystallizationGood orientationFibre typesAramidSupercritical carbon dioxide

The invention discloses a method modifying aramid fibers in a supercritical carbon dioxide environment to increase mechanical performance and surface performance. The method includes the steps of firstly, washing and drying the aramid fibers; secondly, loading the aramid fibers and a reagent into a sealed container, and allowing the aramid fibers to keep tension and not to contact with the reagent; thirdly, feeding carbon dioxide, and heating to rise temperature and pressure to allow the interior of the sealed container to be in a supercritical carbon dioxide state; fourthly, after the swelling reaction, slowly relieving pressure in a constant-speed manner to obtain the modified aramid fibers; fifthly, washing and drying the modified aramid fibers. The method has the advantages surface activation and longitudinal tensile strength increasing of the aramid fibers are achieved, fiber skin layer and core layer combination is reinforced through the crosslinking reaction among molecular chains inside the fibers, the skin-core structure is improved, fiber transverse strength is increased, and the method is of important significance to the modification and use efficiency increasing of thearamid fibers.

Owner:HARBIN INST OF TECH

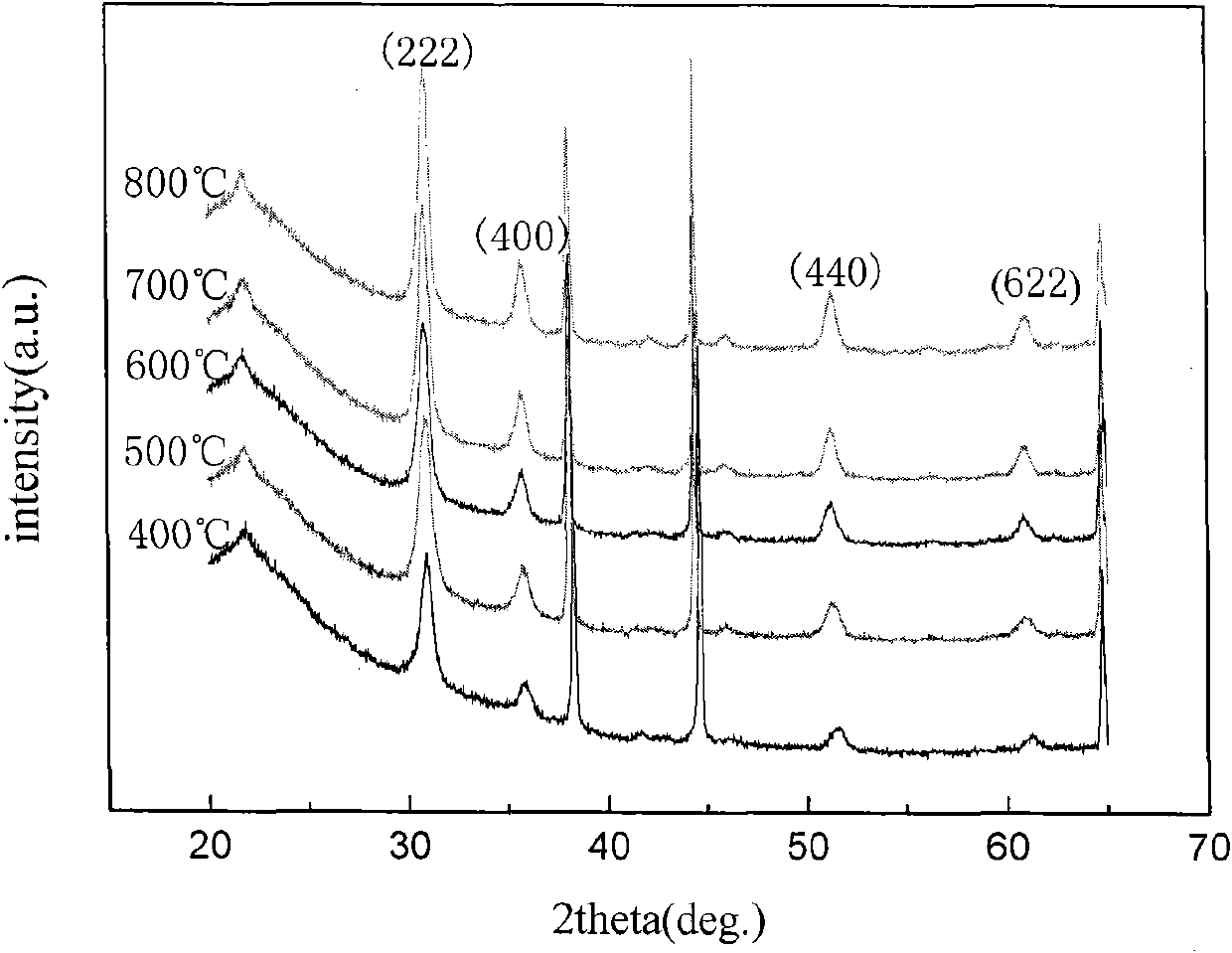

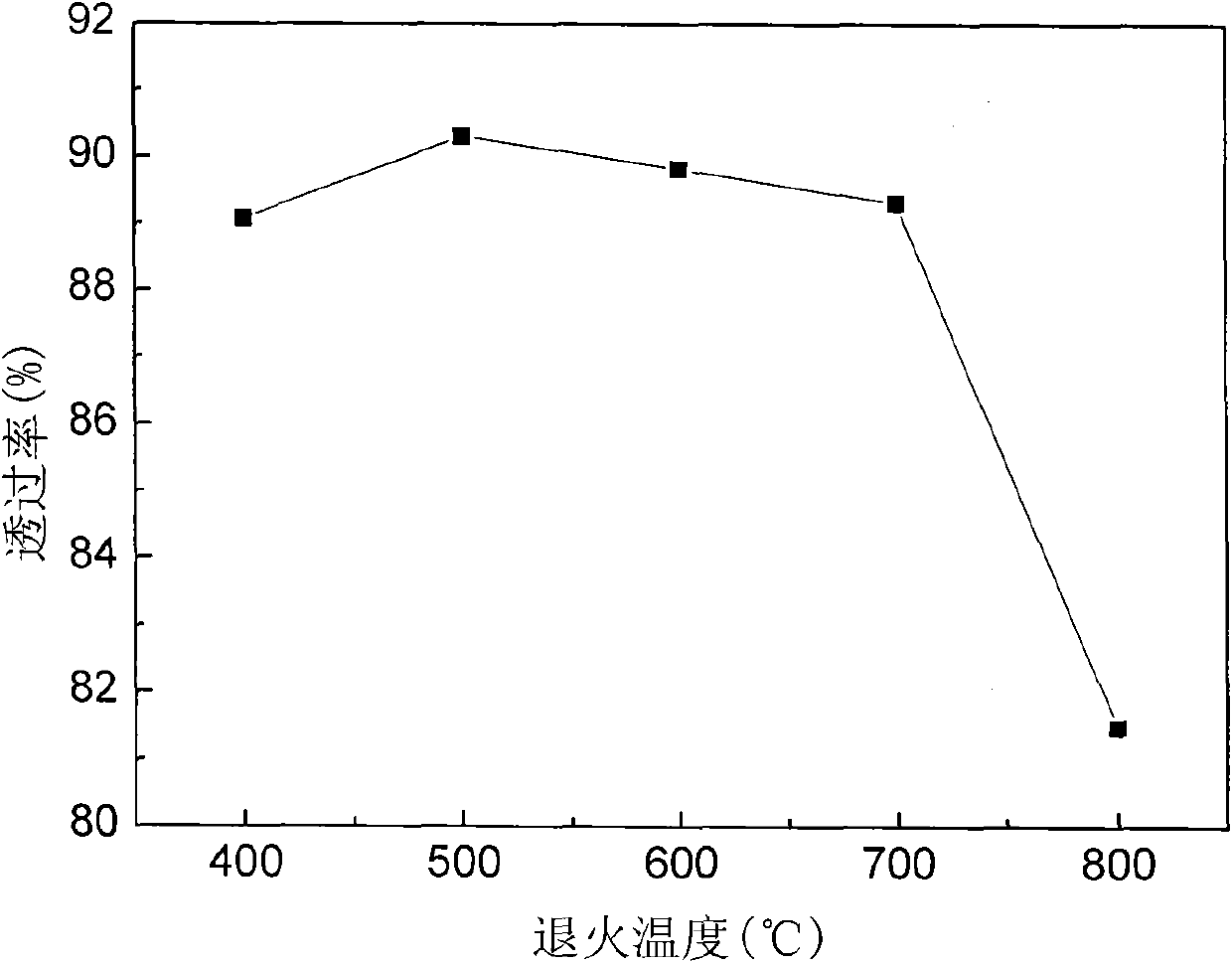

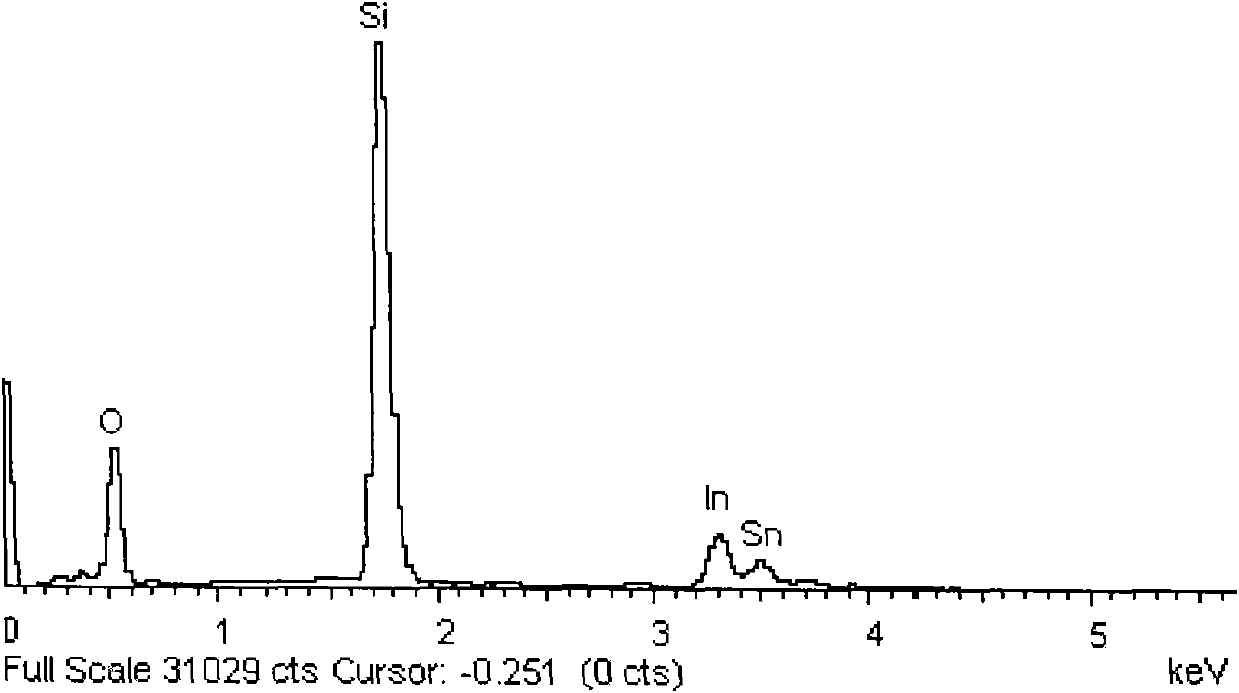

ITO film loaded silica optical fiber and preparation method thereof

ActiveCN101950043AWith light guideConductiveCladded optical fibreOptical waveguide light guideFiberSurface binding

The invention relates to silica optical fiber modification, aiming at providing an ITO film loaded silica optical fiber and a preparation method thereof. The silica optical fiber is taken as base body, and indium tin oxide transparent and conductive film is coated on the surface. In the invention, simple and feasible pre-treatment is carried out on the silica optical fiber, so that ITO film obtained by sol-gel method is firmly combined with the surface of the silica optical fiber, crystallization of film is complete, surface is smooth and compact, and photoelectric properties are good, thus preparing an ITO film loaded silica optical fiber and giving both light guiding property and electrical conductivity to the fiber. The invention can be widely applied to the fields of infrared transmission, current sending and photoelectric response devices, thus greatly widening respective application field.

Owner:ZHEJIANG SCI-TECH UNIV

Wear-resisting and heat-resisting modified polyvinyl chloride composite

The invention discloses a wear-resisting and heat-resisting modified polyvinyl chloride composite. The composite is prepared from components of raw materials as follows: polyvinyl chloride, polyurethane elastomers, chlorosulfonated polyethylene, nitrile rubber, polyvinylidene fluoride, ethylene-methyl methacrylate copolymers, polypropylene fibers, plant fiber, basalt fibers, nano calcium carbonate, diatomite, dipentaerythritol adipate, calcium stearate, zinc stearate, glyceryl stearate, olive oil, polyepichlorohydrin, a coupling agent, polyethylene wax grafted maleic anhydride, adipic acid, acetyl tributyl citrate, diphenyl cresol phosphate, zinc hydroxy stannate and vanadium pentoxide. The wear-resisting and heat-resisting modified polyvinyl chloride composite has high wear resistance, good heat resistance, excellent ageing resistance and long service life.

Owner:ANHUI RUIXIN AUTOMATION INSTR

Preparation method of aluminium hydroxide micro powder

ActiveCN100411991CPerfect crystal developmentFine granularityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideAluminum sulphate

The present invention relates to technological process of producing fine aluminum hydroxide powder as fire retardant stuffing, and is especially technological process of producing fine aluminum hydroxide powder with high crystallization degree. The gel seed prepared with sodium aluminate solution through CO2 introducing carbon process and with sodium aluminate solution through aluminum sulfate neutralization process is converted via a special process into fine pure alpha-aluminum hydroxide powder without beta-aluminum hydroxide. The fine pure alpha-aluminum hydroxide powder is coated, modified and stoved to obtain submicron level pure alpha-aluminum hydroxide powder. Or, the completely converted fine powder slurry is added into sodium aluminate solution directly or after being concentrated and further decomposed to obtain fine aluminum hydroxide powder with excellent fire retarding performance.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for manufacturing high-temp PTC thermosensitive resistor

ActiveCN1624817AGood compatibilityIncrease the degree of cross-linkingPositive temperature coefficient thermistorsPhysical chemistryElectronic component

A manufacturing method of high temperature macromolecule PTC thermal resistor relates to manufacturing method of the electronic component whose material mainly is crystalline hypo-crystalline high polymer and its mixture. A manufacturing method of high temperature PTC thermal resistor is that after the chip is forming, the chip is set in the heating equipment whose high polymer melting point is more than from five centigrade degree to thirty centigrade degree for from five minutes to fifty minutes, then slowly cooled to room temperature, later irradiated, and irradiation dosage range is 0.2- 0.7 times of which is from 20KGy to 5000KGy; after the irradiation , the chip is again set in the heating equipment whose high polymer melting point is more than from five centigrade degree to thirty centigrade degree for from five minutes to fifty minutes, then slowly cooled to room temperature, do the second irradiation, and the irradiation dosage range is 0.4- 0.8 times which is from 20KGy to 5000KGy.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

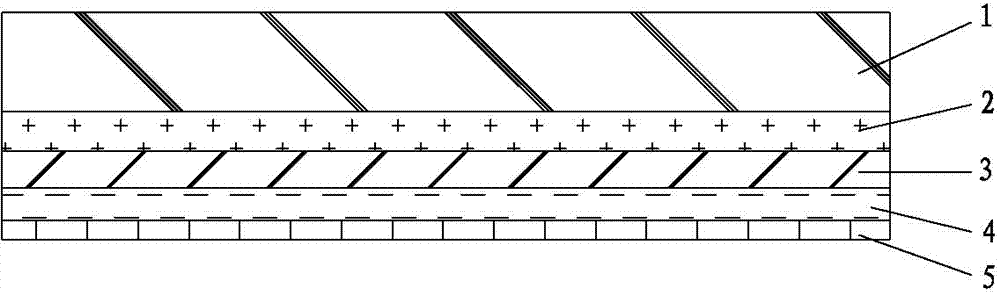

ITO (Indium Tin Oxide) conducting film for touch screen and preparation method thereof

ActiveCN103489505ACrystallization perfectReduce thicknessConductive layers on insulating-supportsOxide conductorsIndium tin oxideResin matrix

The invention relates to the technical field of conducting films of touch screens, and particularly relates to an ITO (Indium Tin Oxide) conducting film for a touch screen and a preparation method thereof. The ITO conducting film comprises a resin matrix of 100-150 micrometers, a first ITO layer of 8-10 nanometers, a second ITO layer of 6-8 nanometers, a third ITO layer of 4-6 nanometers and a fourth ITO layer of 2-4 nanometers, wherein the first ITO layer, the second ITO layer, the third ITO layer and the fourth ITO layer are sequentially deposited on the resin matrix. According to the invention, the resin matrix is heated to 200-240 DEG C every time through four layered deposition and four crystallization processes, and the recrystallization temperature 150 DEG C of the ITO layers is achieved, so that the ITO can be subjected to a crystallization process after being deposited every time, and the perfect crystallization of the ITO layer is effectively promoted; in order to reduce the influence of thickness on the crystallization, the thicknesses of the first ITO layer, the second ITO layer, the third ITO layer and the fourth ITO layer are sequentially reduced. In conclusion, the prepared ITO conducting film for the touch screen has the advantages of high transmittance, low resistivity and good chemical stability.

Owner:DONGGUAN PINGBO ELECTRONICS

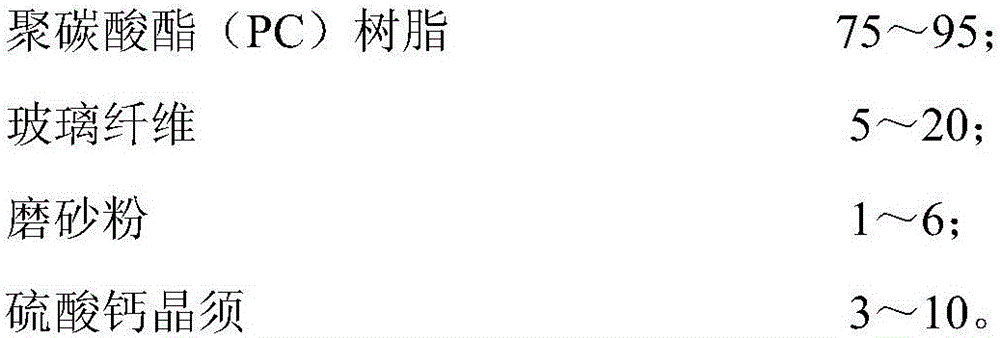

Bending-deformation-resistant frosted PC (polycarbonate) composite material

The invention provides a bending-deformation-resistant frosted PC (polycarbonate) composite material which is prepared from a PC (polycarbonate) resin, glass fibers, frosted powder, calcium sulfate whiskers, an antioxidant, a dispersing agent and a flame retardant. The glass fibers and frosted powder are mixed according to the specific proportion, and the weight ratio of the glass fibers, frosted powder and calcium sulfate whiskers is limited, thereby implementing better dodging effects.

Owner:DONGGUAN XINLONG OPTOELECTRONICS MATERIAL

Low-cobalt hard alloy material and manufacturing method thereof

The invention discloses a low-cobalt hard alloy material and a manufacturing method of the low-cobalt hard alloy material. The manufacturing method specifically comprises the steps that 80 parts of WCpowder, 4-16 parts of carbonyl iron powder, 1-5 parts of carbonyl nickel powder and 2-15 parts of reduced cobalt powder serve as raw materials, the raw materials are preprocessed, presintered, sintered again and subjected to heat treatment after sintering is accomplished, and then low-cobalt hard alloy is obtained, wherein the particle size of the WC powder is 400. The comprehensive performance of the obtained low-cobalt hard alloy is same to the comprehensive performance of conventional WC-20%Co hard alloy, and the hardness and the compactness of the low-cobalt hard alloy are higher than those of the WC-20%Co hard alloy.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Preparation method of PIPD (poly[2,6-diimidazo-(4,5-b:4'5'-e)pyridinylene-1,4-(2,5-dihydroxy)phenylene]) fiber

ActiveCN105350108AStretch smoothlyStretch stopArtificial filament washing/dryingDry-cleaning apparatus for textilesFiberPolyphthalamide

The invention relates to a preparation method of PIPD (poly[2,6-diimidazo-(4,5-b:4'5'-e)pyridinylene-1,4-(2,5-dihydroxy)phenylene]) fiber and belongs to the technical field of preparation of high-performance fiber. The PIPD fiber is obtained through air gap stretching, cooling in a quenching chamber, phosphoric solution curing, washing, multi-level gradual drying, heat treatment and coiling of a PIPD / PPA (polyphthalamide) liquid crystal solution. According to the method, the drawing rate of as-spun fiber can be stably controlled; meanwhile, most of PPA in the as-spun fiber can be rapidly and effectively removed; moisture in the as-spun fiber of PIPD can be slowly removed, and high-performance PIPD fiber with a good structure is obtained.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

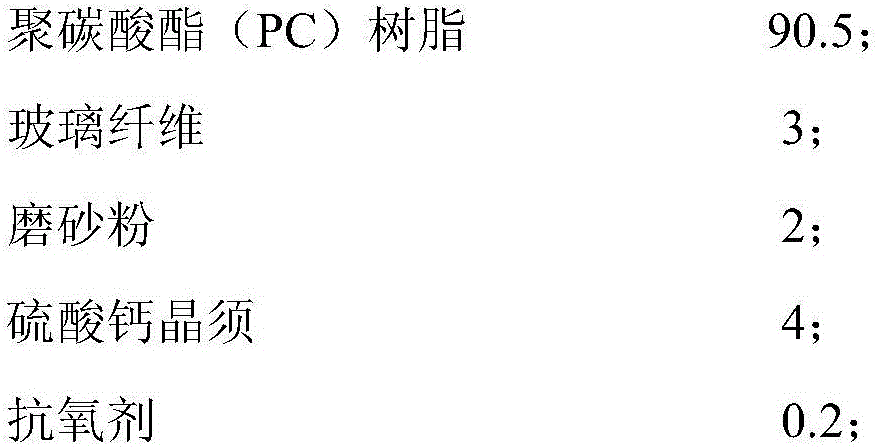

Nano-silver powder, manufacturing method and application thereof

ActiveCN101707062BCrystallization perfectLower sintering temperatureFixed capacitor electrodesMetal/alloy conductorsSilver pasteHigh conductivity

The invention relates to nano-silver powder used for DC electrode sizing agents and low-temperature bonding nano-silver paste, and a manufacturing method thereof. The physical properties of nano-silver powder are as follows: particle size distribution between 10 and 100 mu, average particle size between 20 and 50 nm, specific surface area between 30 and 50 m2 / g, and apparent density between 1.5and 3.0 g / cm3. The nano-silver powder adopts a chemical reduction method and is prepared by adopting hydrazine hydrate, glycerine or triethanolamine to reduce silver compounds at 90 to 92 DEG C. The nano-silver powder manufactured by the method is applied to the DC electrode sizing agents sintered at 800 DEG C. When the nano-silver powder is applied to the nano-silver paste of SiC or GaN and other chips bonded at 260 to 270 DEG C, electrodes have the advantages of good weldability, high conductivity, stable electrical property, high bonding strength, high reliability and the like.

Owner:GRIKIN ADVANCED MATERIALS

A kind of preparation method of poly[2,5-dihydroxy-1,4-phenylenepyridodiimidazole] fiber

ActiveCN105350108BStretch smoothlyStretch stopArtificial filament washing/dryingDry-cleaning apparatus for textilesFiberPolyphthalamide

The invention relates to a preparation method of PIPD (poly[2,6-diimidazo-(4,5-b:4'5'-e)pyridinylene-1,4-(2,5-dihydroxy)phenylene]) fiber and belongs to the technical field of preparation of high-performance fiber. The PIPD fiber is obtained through air gap stretching, cooling in a quenching chamber, phosphoric solution curing, washing, multi-level gradual drying, heat treatment and coiling of a PIPD / PPA (polyphthalamide) liquid crystal solution. According to the method, the drawing rate of as-spun fiber can be stably controlled; meanwhile, most of PPA in the as-spun fiber can be rapidly and effectively removed; moisture in the as-spun fiber of PIPD can be slowly removed, and high-performance PIPD fiber with a good structure is obtained.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Method for preparing yttrium aluminum garnet nanoparticles

ActiveCN111233022AEasy to prepareEase of mass productionMaterial nanotechnologyRare earth metal compoundsNanoparticlePhysical chemistry

The invention provides a method for preparing yttrium aluminum garnet nanoparticles, which comprises the following steps: preparing organic sol containing aluminum and yttrium, mixing the organic solwith water-soluble salt, performing standing or centrifuging to precipitate the water-soluble salt, removing superfluous organic sol at the upper part, and keeping the temperature to convert the organic sol into gel; along with evaporation of the solvent, contracting the gel, and coating the surfaces of the water-soluble salt particles with a layer of xerogel film, and calcining a sample at a hightemperature between 600 DEG C and a salt melting point, converting a dried gel film into yttrium aluminum garnet nanoparticles, dispersing and attaching the yttrium aluminum garnet nanoparticles to the surfaces of water-soluble salt particles, cooling, and washing with water to remove the salt, thereby obtaining the yttrium aluminum garnet nanoparticles with favorable dispersity and crystallinity. According to the method, the high-dispersion and high-crystallinity yttrium aluminum garnet nanoparticles can be rapidly prepared in batches, and the method is suitable for preparing LED fluorescentpowder, YAG transparent ceramic and other materials.

Owner:SOUTHEAST UNIV

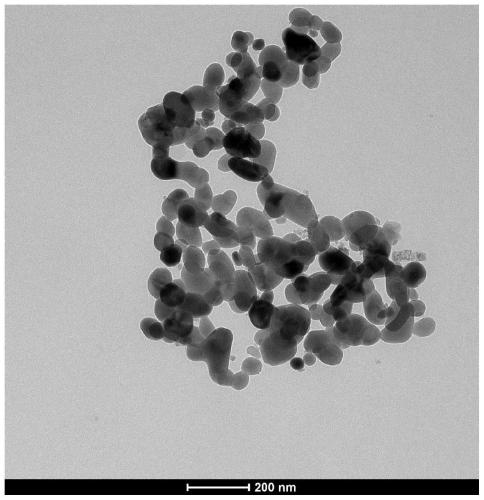

High Molecular Weight Polymer Nucleating Agent Modified Ultra High Molecular Weight Polyethylene Blends

The invention relates to a high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material. The blend material comprises the following raw materials by weight: 60 to 100 parts of UHMWPE, 5 to 12 parts of HDPE, 6 to 16 parts of LLDPE, 0.1 to 3 parts of a high-molecular-weight polymer nucleating agent and 1.5 to 3 parts of a flow modifier. The high-molecular-weight polymer nucleating agent has the advantages of no odor, good dispersibility, good compatibility, capacity of realizing heterogeneous crystallization, a high degree of crystallization and a small application amount; the high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material retains original characteristics of polyethylene UHMWPE and has obviously improved tensile strength, impact strength, bending strength, Vicat softening temperature, elongation at break and Shore hardness and a reduced mortar wear rate.

Owner:LUOHE KELAIBAO TECH CO LTD

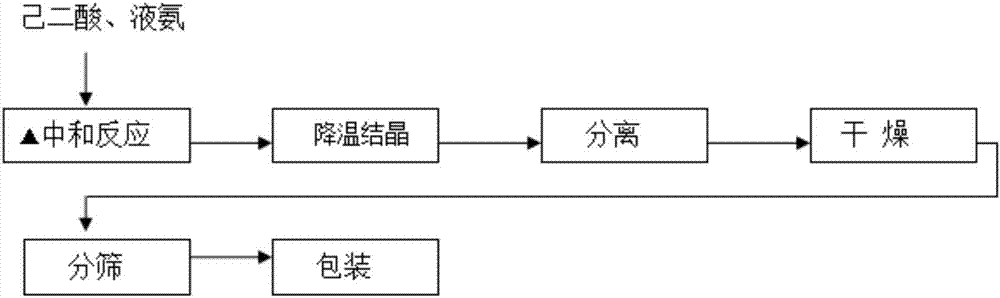

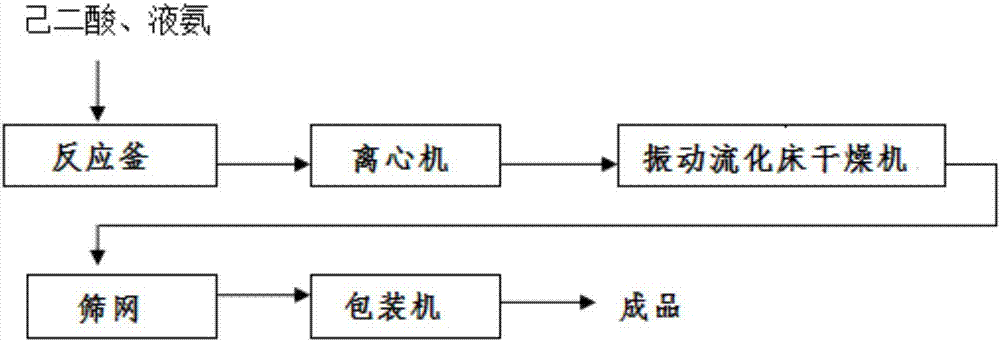

Preparation method and system of ammonium adipate

ActiveCN107986959ALess impuritiesHigh purityOrganic compound preparationCarboxylic acid salt preparationFluidized bed dryingReaction temperature

The invention relates to a preparation method and a preparation system of ammonium adipate. The preparation method comprises the following steps: enabling adipic acid in a reaction kettle to react with gasified ammonia gas; controlling the reaction temperature at 60-70 DEG C; monitoring whether the pH value of a solution reaches a reaction endpoint, opening a lid at a tank hole of the reaction kettle, carrying out sampling for reaction, stopping the introduction of ammonia, continuing to react for 1-1.5 hours, and introducing cooling water for cooling; after the temperature is decreased to bebelow 40 DEG C, carrying out sampling, starting discharging while detecting that the content of crystals is 50% or above, and carrying out solid-liquid separation by virtue of a centrifugal machine; and directly introducing the crystals into a vibrated fluidized bed drying machine, drying, and sieving by virtue of a screen, so as to obtain a finished product. The invention further provides a preparation method for preparing ammonium adipate by virtue of the preparation method. The ammonium adipate product prepared by virtue of the preparation method is white powder or a transparent crystal andhas low toxicity; and the product has good dissolving property in glycol and water, can be used as formation and middle-low-voltage electrolyte solute in the production processes of low-pressure aluminum foils and solid-state capacitors, and a water solution can be used as an electrifying agent for middle-high-pressure aluminum foils.

Owner:NINGXIANG XINYANG CHEM

Preparation method of hard elastic polypropylene film

InactiveCN101698352AGood orientationHigh crystallinityFlat articlesPolymer scienceVolumetric Mass Density

The invention relates to a preparation method of hard elastic polypropylene film and is characterized in that the method includes the following steps: extrusion grade polypropylene resin with the degree of isotacticity more than or equal to 96% and density of 0.9 plus or minus 0.05g / cm<3> is extruded by flat die gap of an extruder at the temperature of 180-250 DEG C, the width of die gap is 1.5-3.0mm, then the resin is drawn by a drawing roller at drawing speed of 20-40m / min and drawing ratio of 1:100-300, then the film is cooled by a cooling roller and the temperature of the cooling roller is 30-110 DEG C, and the cooled thin film is annealed at 120-150 DEG C for 5-60min. The hard elastic polypropylene film prepared by the preparation method of the invention has high recovery rate, and the recovery rate can reach more than 95%.

Owner:JIANGSU SHENLONG VENTURE GROUP

Preparation method of fast-fired colorful starry-sky bright glaze ceramic container

The invention relates to a preparation method of a fast-fired colorful starry-sky bright glaze ceramic container. The preparation method comprises the following steps: (1) preparation of a blank; (2) biscuiting; (3) preparation of a glaze; (4) glazing; (5) glaze firing; and (6) inspecting. According to the invention, a glaze surface is good in quality, unique in color and texture, short in a firing period and integrally environment-friendly and safe.

Owner:JIANGSU YIXIANG CERAMIC TECH CO LTD

Polyester resin composition as well as preparation method and application thereof

The invention discloses a polyester resin composition which comprises the following components in parts by weight: 100 parts of PCT resin; 0-50 parts of a reinforcing material; and 0.1-0.8 part of a hyperbranched polyester; wherein the molecular weight of the hyperbranched polyester is 600-10000 g / mol, and the hydroxyl value of the hyperbranched polyester is 200-600 mg KOH / g. By adding specific parameters and a specific amount of hyperbranched polyester, the defect of insufficient dimensional stability of the PCT resin can be improved, and cold crystallization is inhibited.

Owner:KINGFA SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com