ITO (Indium Tin Oxide) conducting film for touch screen and preparation method thereof

A technology of touch screen and conductive film, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc. It can solve the problems of not meeting production requirements, poor chemical stability, poor transmittance, etc., and achieve low resistivity, Promotes a perfect, high-transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

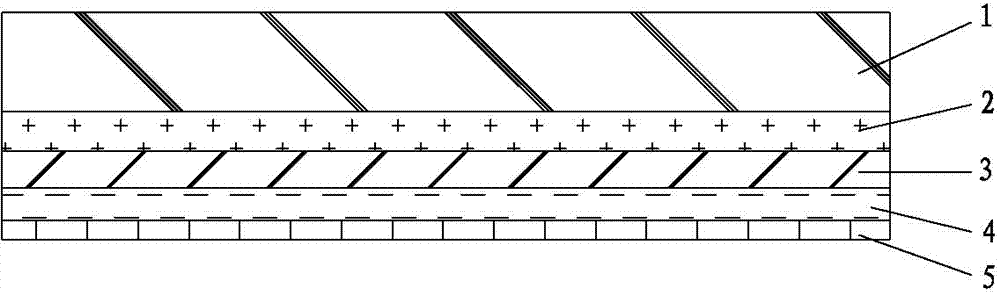

[0047] See figure 1 , an ITO conductive film for a touch screen, comprising a resin base 1 and a first ITO layer 2, a second ITO layer 3, a third ITO layer 4 and a fourth ITO layer 5 deposited on the resin base 1 in sequence, the resin base 1 The thickness of the first ITO layer 2 is 8 nanometers, the thickness of the second ITO layer 3 is 6 nanometers, the thickness of the third ITO layer 4 is 4 nanometers and the thickness of the fourth ITO layer 5 is 2 nanometers.

[0048] Wherein, the resin matrix 1 is a polyethylene terephthalate resin matrix.

[0049] A kind of preparation method of ITO conductive film for touch screen, it comprises following preparation steps successively:

[0050] Step A, put the resin matrix into the loading chamber of the magnetron sputtering equipment, and vacuumize after sealing;

[0051] Step B, the resin substrate is heated to 200°C and then transported to the sputtering chamber, and deposited for the first time by magnetron sputtering, and aft...

Embodiment 2

[0074] See figure 1 , an ITO conductive film for a touch screen, comprising a resin base 1 and a first ITO layer 2, a second ITO layer 3, a third ITO layer 4 and a fourth ITO layer 5 deposited on the resin base 1 in sequence, the resin base 1 The thickness of the first ITO layer 2 is 9 nanometers, the thickness of the second ITO layer 3 is 7 nanometers, the thickness of the third ITO layer 4 is 5 nanometers and the thickness of the fourth ITO layer 5 is 3 nanometers.

[0075] Wherein, the resin matrix 1 is a polyethylene terephthalate resin matrix.

[0076] A kind of preparation method of ITO conductive film for touch screen, it comprises following preparation steps successively:

[0077] Step A, put the resin matrix into the loading chamber of the magnetron sputtering equipment, and vacuumize after sealing;

[0078] Step B, the resin substrate is heated to 210°C and transported to the sputtering chamber, and deposited for the first time by magnetron sputtering, and after th...

Embodiment 3

[0101] See figure 1 , an ITO conductive film for a touch screen, comprising a resin base 1 and a first ITO layer 2, a second ITO layer 3, a third ITO layer 4 and a fourth ITO layer 5 deposited on the resin base 1 in sequence, the resin base 1 The thickness of the first ITO layer 2 is 10 nanometers, the thickness of the second ITO layer 3 is 8 nanometers, the thickness of the third ITO layer 4 is 6 nanometers and the thickness of the fourth ITO layer 5 is 4 nanometers.

[0102] Wherein, the resin matrix 1 is a polyethylene terephthalate resin matrix.

[0103] A kind of preparation method of ITO conductive film for touch screen, it comprises following preparation steps successively:

[0104] Step A, put the resin matrix into the loading chamber of the magnetron sputtering equipment, and vacuumize after sealing;

[0105] Step B, the resin substrate is heated to 200°C and then transported to the sputtering chamber, and deposited for the first time by magnetron sputtering, and af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com