Preparation method and system of ammonium adipate

An ammonium adipate and preparation system technology, which is applied in the production field of chemical products, can solve the problems of poor application of aluminum foil, uneven particles and high impurity content, and achieves the effects of being conducive to separation, uniform particles and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

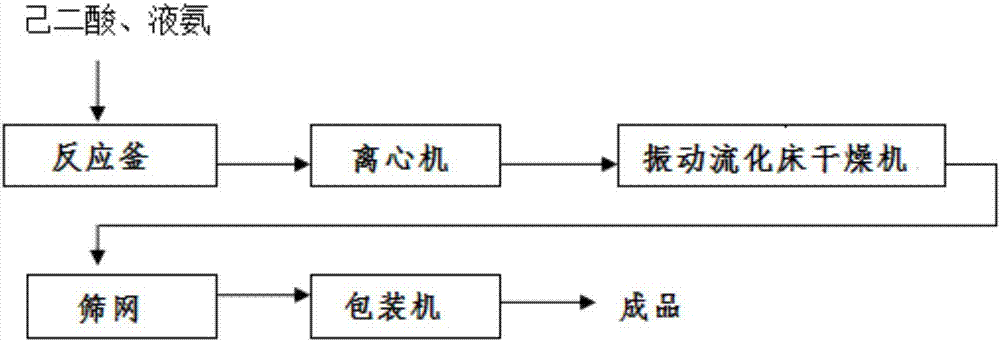

[0051] Such as figure 2 As shown, the invention provides a kind of ammonium adipate preparation system, comprising:

[0052] Reactor 1, centrifuge 2, vibrating fluidized bed dryer 3, screen 4, packaging machine 5 connected in sequence;

[0053] The reaction kettle 4 is provided with a stirring device, a heating device, a water cooling device, a sampling port, an adipic acid feed port, an ammonia gas inlet, and a discharge port;

[0054] The ammonia gas inlet is provided with an ammonia flow rate control valve.

Embodiment 2

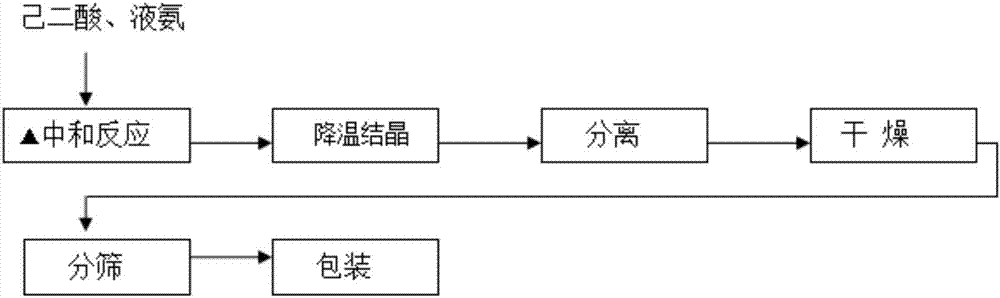

[0056] Such as figure 1 As shown, the present embodiment adopts the ammonium adipate preparation system provided in Example 1 to provide a method for preparing ammonium adipate, which is as follows:

[0057] S1. Inject 30% of the volume of purified water into the reaction kettle, and start stirring; the contents of chloride and iron salt in the above purified water are all less than 1 mg / kg;

[0058] S2. Seal the reaction kettle, turn on the vacuum to suck in adipic acid solids with a purity greater than 99%, then open the steam valve to heat the reaction kettle to 50° C., close the steam valve, continue stirring, and stir the adipic acid evenly;

[0059] S3, open the ammonia gas valve, feed the gasified ammonia gas into the reaction kettle, control the speed of ammonia gas flow, and ensure that the ammonia gas will not overflow; control the opening of the ammonia gas valve to 1 / 3; adipic acid: ammonia gas The molar ratio is 1:2;

[0060] S4, turn on the cooling water, add c...

Embodiment 3

[0068] The difference between this embodiment and embodiment 2 is:

[0069] S1. Inject 40% of the volume of purified water into the reactor;

[0070] S2, making the reaction kettle warm up to 60°C;

[0071] S3. Control the opening of the ammonia valve to 1 / 2; the molar ratio of adipic acid:ammonia is 1:1.8;

[0072] S5, stop passing ammonia, continue to react for 1.5h;

[0073] S6. When the temperature in the tank drops to 55-60°C, stop stirring, and after standing for 5 hours, restart stirring;

[0074] S8. The crystals are directly dried in a vibrating fluidized bed dryer. First, they are blown by hot air at 90°C, and then by natural wind after dehumidification. The total drying time is 3 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com