Patents

Literature

107 results about "Ammonium adipate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium adipate is a compound with formula (NH₄)₂(C₄H₈(COO)₂). It is the ammonium salt of adipic acid. It is used as a food additive and has the E number E359.

Method for producing solid sheet type electrolytic capacitor

InactiveCN1649053AGood high frequency characteristicsLower equivalent series resistanceSolid electrolytic capacitorsCapacitor electrodesEpoxyAlloy

A manufacturing method for a solid plate electrolytic capacitor is to weld a strip Al foil to a stainless steel technical bar, the Al foil is coated with silicon resin or F resin to be divided into cathode and anode. The cathode part is immersed into a solution containing oxalamine and ammonium biphosphate plus 6-35v voltage, then again immersed in KMno4 solution to be dipped in a solution with Py and sulfosalt to form a pre-conductive layer on its surface as the anode, a stainless steel as the cathode to carry out constant current electrolyte in a mixed solution with Py and sulfosalt. The Al foil cathode is immersed in a solution containing oxalamine, ammonium biphosphate and sulfosalt plus 5-25v voltage to be coated with graphite and Ag to get single chip cores to be laminated, the anode is welded at that of an alloy lead frame, the cathode to the cathode to form a capacitor core to be molded and packaged with epoxy resin.

Owner:XI AN JIAOTONG UNIV

Electrolyte for melting aluminum foil of anode of capacitor and aluminum foil melting method

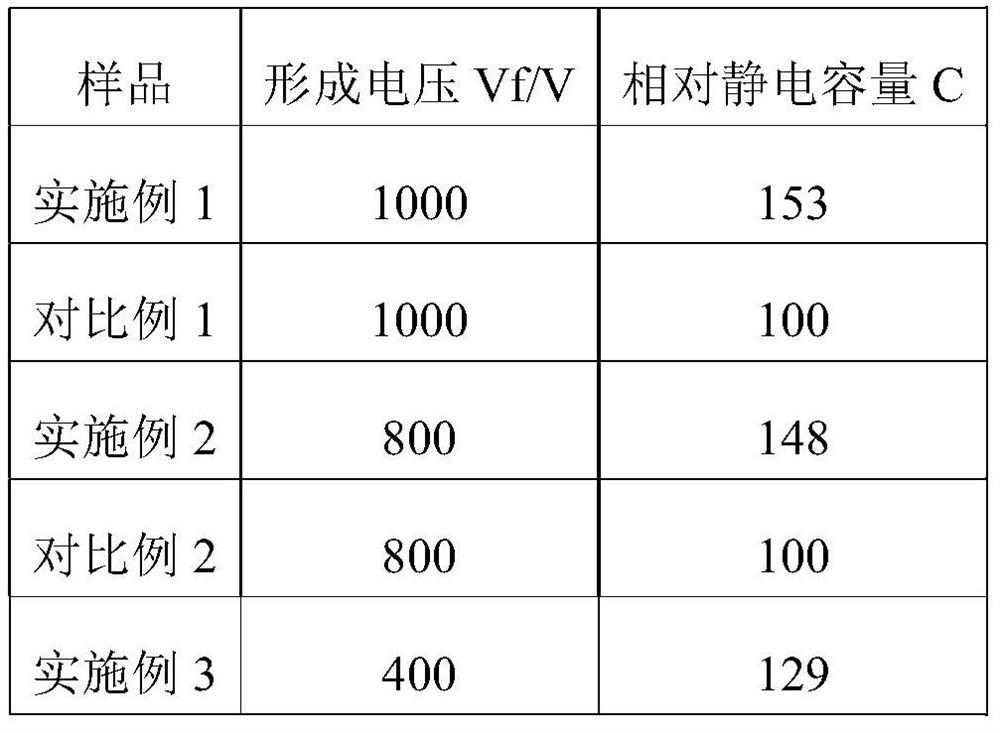

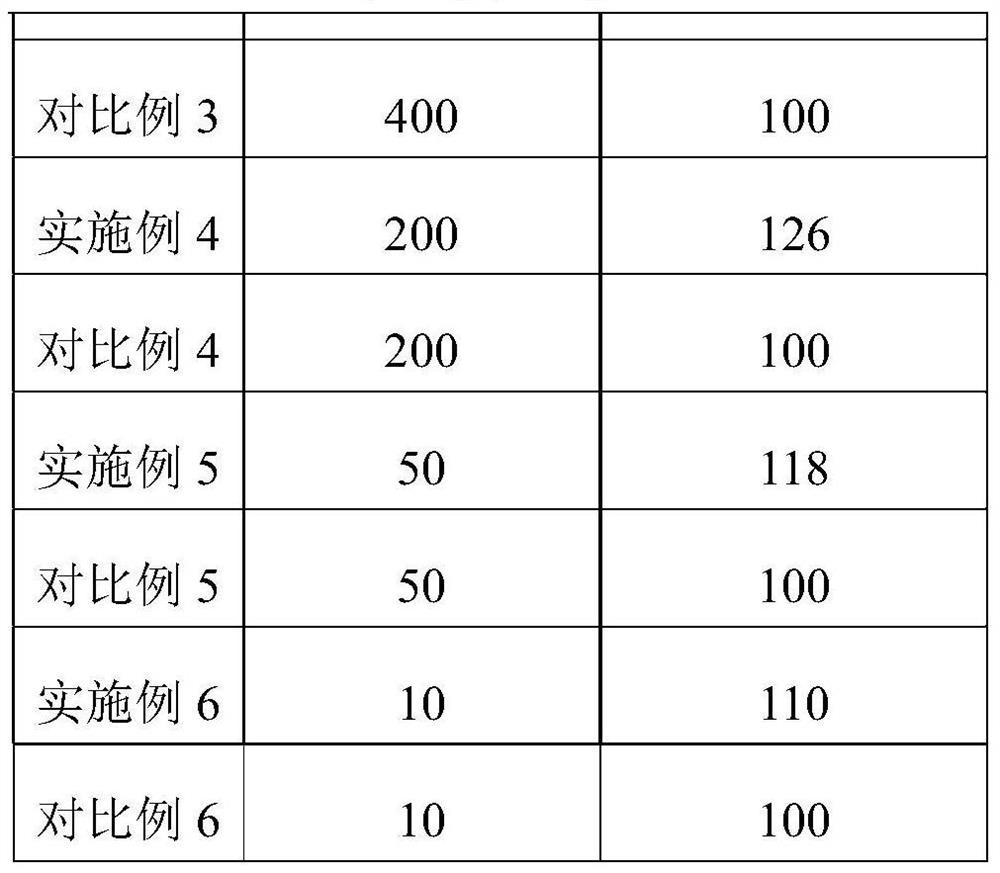

ActiveCN102212861AHigh capacitanceImprove pressure resistanceSurface reaction electrolytic coatingAluminum foilCapacitor

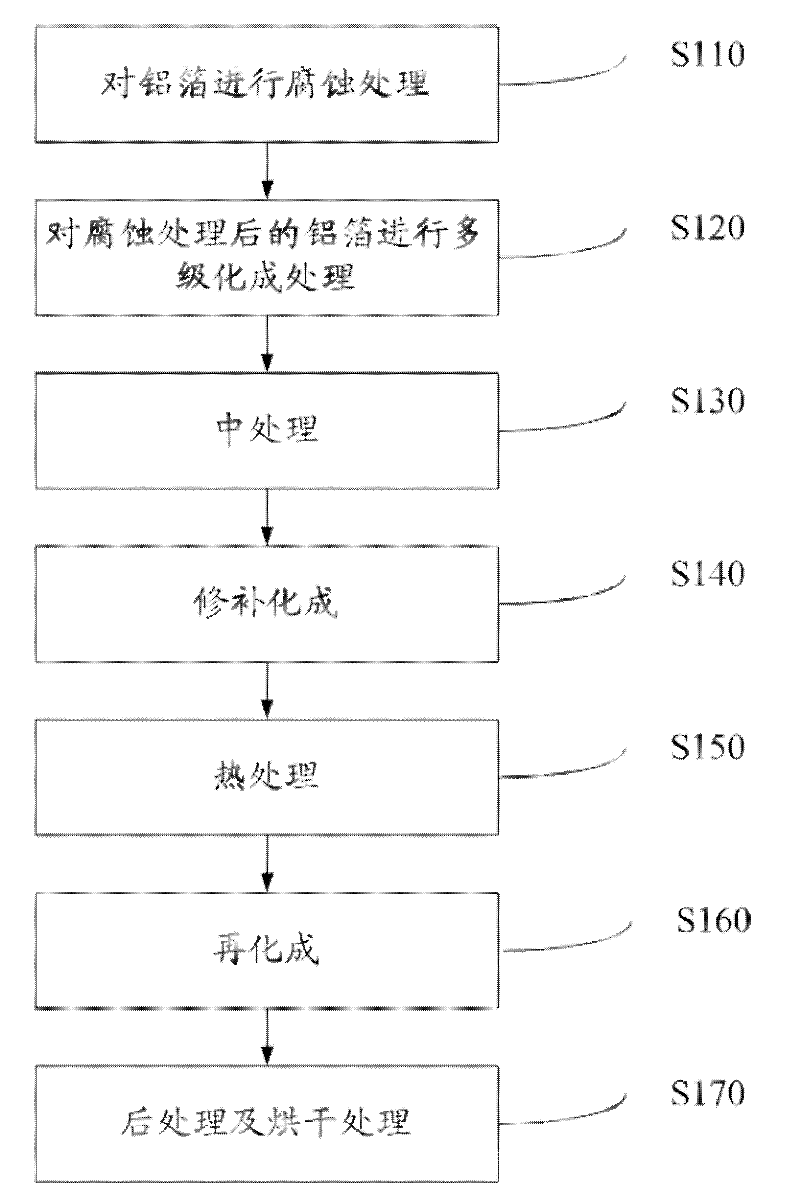

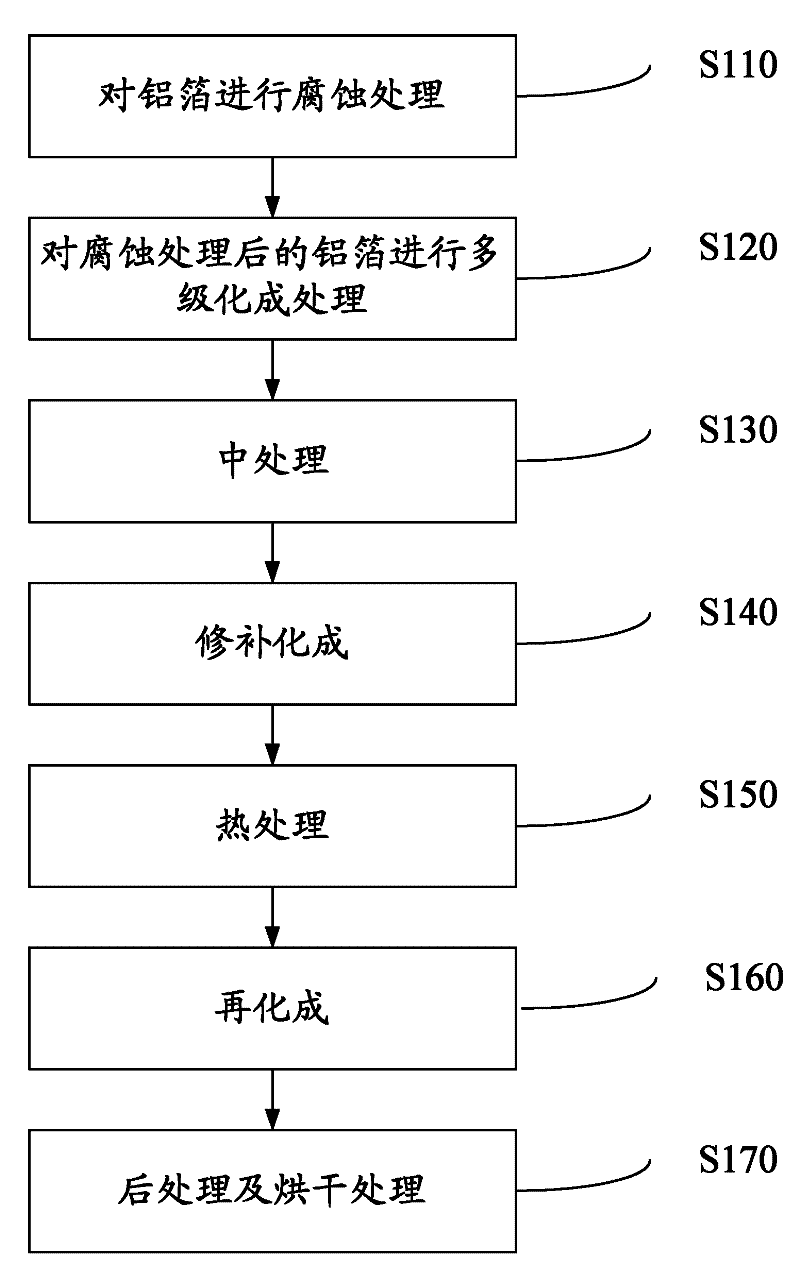

The invention relates to an electrolyte for melting an aluminum foil and an aluminum foil melting method. The capacitor anode aluminum foil melting method comprises the steps of corrosion, multi-stage melting, intermediate treatment, heat treatment, re-melting and post treatment of the aluminum foil. The electrolyte used for melting in the first stage of the multi-stage melting comprises 0.2 to 1.0 percent of oxalate, 3.5 to 7 percent of ammonium adipate and the balance of water according to weight percentage. The aluminum foil of the capacitor anode, which is prepared by the method, has higher electrostatic capacity and withstand voltage.

Owner:富德(清远)电子铝箔有限公司

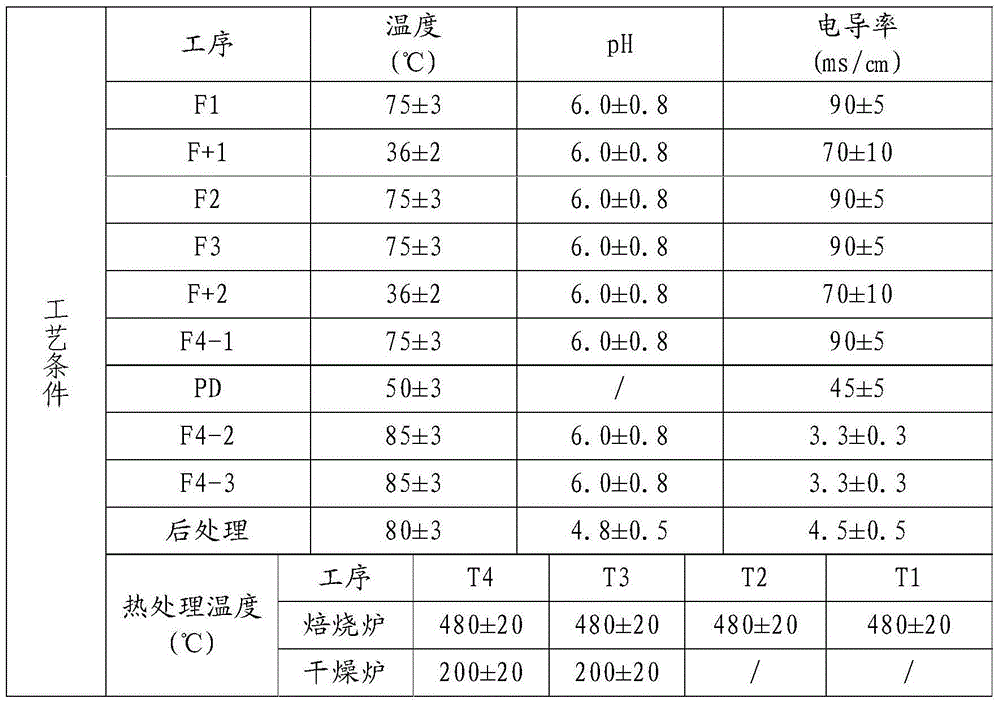

Formation method for anode foil of intermediate-voltage aluminum electrolytic capacitor

InactiveCN102709059AIncrease specific volumeGood hydration resistanceElectrolytic capacitorsPhosphateThree stage

The invention discloses a formation method for an anode foil of an intermediate-voltage aluminum electrolytic capacitor, and belongs to the technical field of manufacture of anode foils of aluminum electrolytic capacitors. According to the formation method for the anode foil of the intermediate-voltage aluminum electrolytic capacitor, ammonium adipate is adopted as four-stage formation electrolyte. The technical scheme is that: the method comprises the following steps of: performing three-stage formation by adopting a solution of ammonium adipate as electrolyte, performing the formation of a fourth stage by using a boric acid and ammonium dihydrogen phosphate, performing high-temperature treatment, performing treatment by using a phosphate solution, and performing drying to obtain the anode foil of the intermediate-voltage aluminum electrolytic capacitor. The ammonium adipate is adopted as the formation electrolyte, so that the obtained anode foil of the capacitor is high in specific capacity and high in hydration resistance, boosting time is shortened, and a Tr60 value is decreased.

Owner:YONGJI SUHAI ALUMINUM

700V high-voltage aluminum electrolytic capacitor electrolyte

InactiveCN106252079AHigh molecular weightLow mobilityLiquid electrolytic capacitorsSalicylic acidGluconic acid

Disclosed is a 700V high-voltage aluminum electrolytic capacitor electrolyte. The electrolyte comprises 50-80% of main solvent, 20-50% of auxiliary solvent, 5-20% of main solute, 2-10% of auxiliary solute, 0.1-1% of auxiliary additive and 5-15% of spark additive, wherein the main solute comprises one or more of azelaic acid, ammonium hydrogen azelate, ammonium sebacate, decane dicarboxylic acid, 7, 9-dimethyl-7, 9-dimethoxy carbonyl-1, 11-dodecane dicarboxylic acid, and 7, 8-dimethyl-7, 8-dimethoxy carbonyl-1, 14 tetradecane dicarboxylic acid; and the auxiliary solvent comprises one or more of ammonium salicylate, salicylic acid, oxalic acid, malonic acid, succinic acid, ammonium benzoate, ammonium maleate, ammonium hydrogen maleate, ammonium adipate and hexanedioic acid. The spark voltage of the electrolyte is greater than 700V; and in addition, the electrolyte is simple to prepare, stable in performance and excellent in related parameters.

Owner:HUNAN AIHUA GRP

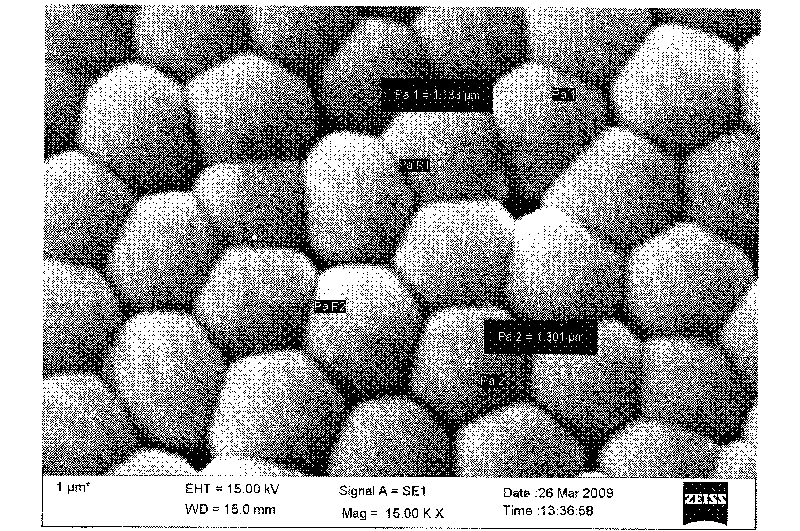

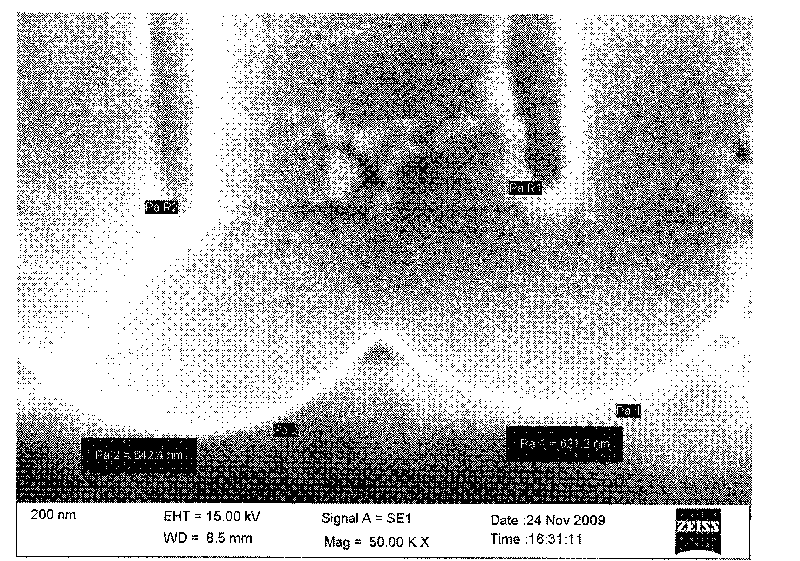

Electrolyte and method for preparing aluminum oxide template with big hole pitch

The invention provide electrolyte and a method for preparing an aluminum oxide template with big hole pitch. The electrolyte consists of oxalic acid, sodium tungstate, ammonium dihydrogen phosphate or boric acid or ammonium adipate and the balance of deionized water. The method comprises the following steps of: 1, pre-treatment; and 2, anodic oxidation. The method can be implemented easily, and the prepared aluminum oxide template with big hole pitch has the characteristics that: the oxidation voltage is high, the hole pitch is big, the maximum hole pitch is 1,3mu m, and the hole pitch is controllable, the limitation existing in the convention preparation method that the membrane with big hole pitch cannot be prepared by porous oxidation, and the application field of the aluminum anodic oxidation membrane is widened; the porous oxidation membrane with different hole size and big cell size is obtained, and the difficulty of filling materials is reduced; and the thickness reaches 8.6mu m in 15 minutes, the membrane coating is thick, the hardness is high, and the surface corrosion resistance and the surface abrasion resistance are enhanced.

Owner:XINJIANG JOINWORLD CO LTD

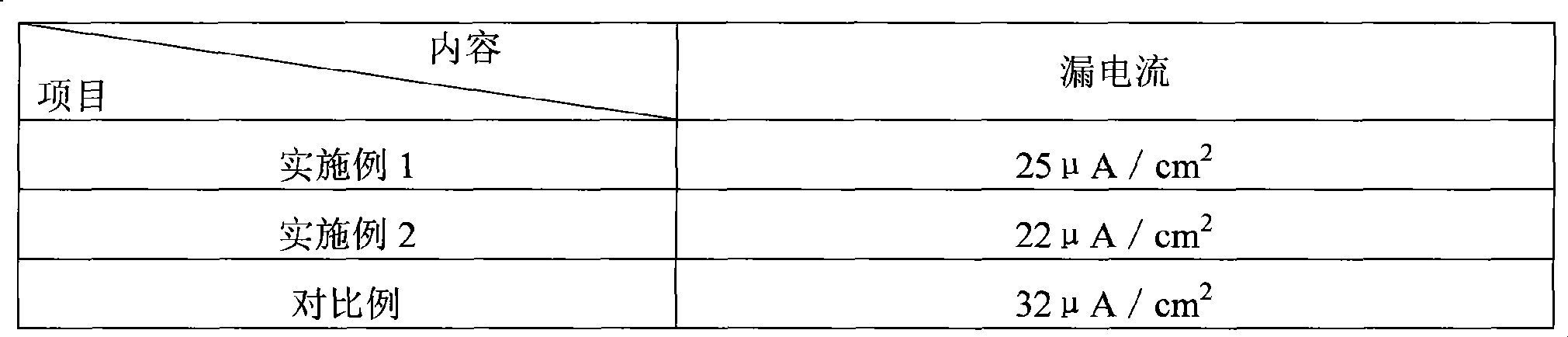

Formation method of electrode foil for low voltage low leakage aluminum electrolysis capacitor

ActiveCN101383228AReduce leakage currentSimple methodElectrolytic capacitorsAluminium electrolysisLow voltage

The invention discloses a formation method of electrode foil for a low-voltage and low leakage current aluminium electrolysis capacitor. The method comprises the following steps: etched foil is put into an ammonium adipate and boric acid aqueous solution at the temperature of 60 to 90 DEG C to carry out first-grade formation and second-grade formation; and after the aluminum foil which carries out the second-grade formation is put into an ammonium biphosphate solution and is dipped, the aluminum foil carries out depolarization treatment and post-formation treatment to form an anode oxide film on the surface of the aluminum foil. The leakage current of the electrode foil for the low-voltage aluminium electrolysis capacitor can be further reduced according to the formation method and can be reduced by 20 to 35 percent. The method of the invention is simple and practical and is easy to implement after being improved on the basis of the prior art and the prior device, the method can produce the electrode foil for the low leakage current and low-voltage aluminium electrolysis capacitor, and the quality of the electrode foil can be increased.

Owner:NANTONG HAIYI ELECTRONICS

Electrolyte of high-voltage aluminum electrolytic capacitor and preparation method of electrolyte

The invention discloses electrolyte of a high-voltage aluminum electrolytic capacitor. The electrolyte is characterized by comprising a main solvent, an auxiliary solvent, a solute and a spark voltage increasing agent, wherein the main solvent comprises one or more of ethylene glycol, gamma-butyrolactone, DMF and diglycol monobutylether; the auxiliary solvent comprises two or more of polyethylene glycol 200, polyethylene glycol 400, a nanosilicon dioxide solution, glycerol, propylene carbonate and ethylene carbonate; the solute comprises two or more of ammonium sebacate, ammonium adipate, adipic acid, boracic acid, ammonium pentaborate, ammonium azelate, ammonium dodecanedioate, ammonium formate, ammonium benzoate, mannitol, sorbitol, citric acid and quadrol. The electrolyte can be applied to 600V ultrahigh voltage, is stable in performance, low in viscosity, high in conductivity and beneficial to volume production, and can reduce the production cost.

Owner:HUNAN AIHUA GRP

Method for Enhancing High Temperature and Low Temperature Resistance of Aluminum Electrolytic Capacitors

InactiveCN102280257AGuaranteed low temperature stabilityRaise the ratioElectrolytic capacitorsPhosphorous acidPhosphoric acid

The invention discloses a method for enhancing the high temperature resistance and low temperature resistance of an aluminum electrolytic capacitor, which includes the preparation of an electrolyte, and the electrolyte includes the following raw materials in parts by weight: main solvent: 48-80%; auxiliary solvent: 10-32%, solute : 15-30%, additives: 0.3-3.2%, wherein, the solvent composed of the main solvent and the auxiliary solvent is a liquid with low saturated vapor pressure; the solute is tetramethylammonium maleate, ammonium adipate, triethylamine, One or more of 1,2-dimethylimidazolium phosphoric acid and phosphorous acid. Due to the selection of solvents with low saturated vapor pressure, the ratio of solutes is increased to ensure that the electrolyte does not condense at low temperature and the solutes do not precipitate; adding hydrogen absorbing agents and water suppressing agents reduces the internal pressure of the product; adding inhibitors and low leakage agents, The occurrence of high-temperature characteristic defects such as too fast recovery of electric leakage is prevented; the invention can also effectively ensure the low-temperature stability of the electrolyte, and provide guarantee for the stable operation of the LED driving power supply.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Highly aqueous and high-stability electrolyte used for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469990AGood electrochemical propertiesHigh impedanceElectrolytic capacitorsElectrolytic agentPhosphoric acid

The present invention relates to the technical field of electrolytes, in particular to a highly aqueous and high-stability electrolyte used for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 10-14 parts of ammonium adipate, 6-10 parts of a water-proofing agent, 4.5-7 parts of ammonia, 3-5 parts of ammonium formate, 1-2 parts of p-nitrobenzoic acid, 0.5-1 part of phosphoric acid, 6-10 parts of glycol and 50-70 parts of deionized water. The electrolyte is prepared by means of interaction among the raw materials and by strictly controlling a weight proportion of the raw materials; the sparking voltage of the prepared electrolyte can reach 102 V and the conductivity rate of the prepared electrolyte can reach 100 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high frequency, low impedance and high stability, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

High water system electrolyte with high frequency and low impedance for aluminium electrolytic capacitor and preparation method thereof

ActiveCN105513799AGood electrochemical propertiesHigh Frequency Low Impedance LowElectrolytic capacitor manufactureElectrolysisPhosphoric acid

The invention relates to the electrolyte technical field, and particularly to a high water system electrolyte with high frequency and low impedance for an aluminium electrolytic capacitor and a preparation method thereof. The electrolyte comprises the following raw materials by weight parts: 8-12 parts of ammonium adipate, 8-12 parts of anti-hydrating agents, 1.5-2.5 parts of ammonia water, 1-2 parts of p-nitrobenzoic acid, 0.5-1.5 parts of phosphoric acid, 4-7 parts of glycol, and 60-80 parts of deionized water. Through interaction of the raw materials and strict control of the weight ratio of the various raw materials, the spark voltage of the prepared electrolyte can reach 105V, and the conductivity can reach 50ms / cm. The high water system electrolyte of the invention has good electrochemistry characteristic and high frequency and low impedance, can be applied to the manufacture of the aluminium electrolytic capacitor.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Formation processing method for improving low-voltage formed foil water resistance

ActiveCN103258649AExtend your lifeImprove water resistanceElectrolytic capacitorsMetal surface removal provisionO-Phosphoric AcidPhosphate

The invention discloses a formation processing method for improving low-voltage formed foil water resistance. The formation processing method comprises the steps that an aluminum foil is placed in an adipic acid saline solution for dipping, the aluminum foil is taken out and then placed in an ammonium adipate and adipate water solution, the aluminum foil is taken out for washing after first-level formation, and then high-temperature treatment is carried out; then the aluminum foil is placed in an ammonium adipate and dihydric phosphate mixed water solution for second-level formation, after being taken out and washed, the aluminum foil is placed in a phosphoric acid solution for heat treatment, then high-temperature treatment and washing are carried out, finally, the aluminum foil is placed in a dihydric phosphate water solution, and the aluminum foil is taken out after third-level formation and washed and dried. The formation processing method has the advantages that product water resistance is obviously improved, storage time is prolonged, and capacitor performance is improved.

Owner:NANTONG HAIXING ELECTRONICS

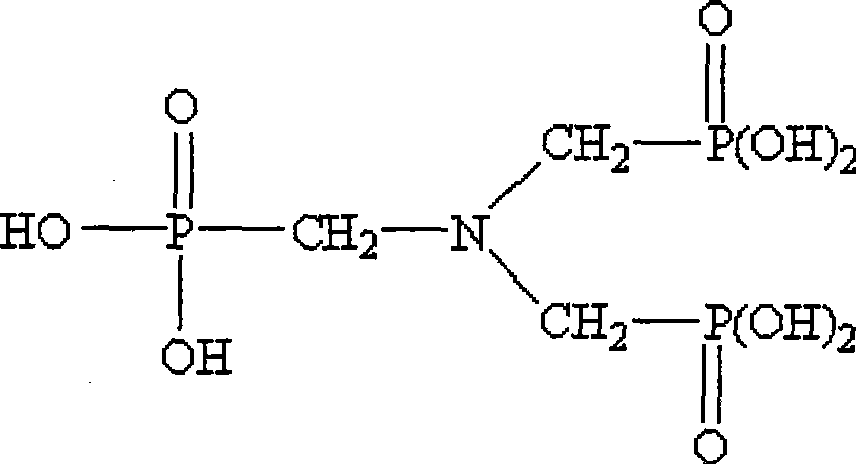

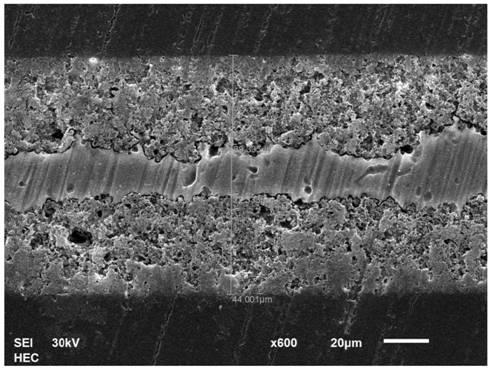

Method for manufacturing foil by composite oxidation film at low pressure

InactiveCN101423964AHigh passivation treatment efficiencyReduce solubilityAnodisationElectrolytic capacitorsLow voltageAluminum silicate

The invention relates to the technical field of formed foils, in particular to a method for manufacturing a composite oxide film low-voltage formed foil. The method is as follows: firstly, a formed foil is treated by sodium silicate, and an aluminum silicate film is generated on the surface of the formed foil, is a good hydration resistant film and can improve the hydration resistance of the formed foil; and secondly, the formed foil is formed in a mixture of ATMP and ammonium adipate, and a hydrous aluminum phosphate film with good water resistance is generated. The aluminum silicate film and the hydrous aluminum phosphate film can effectively prevent reaction of an alumina film and water, improve the hydration resistance of the composite oxide film low-voltage formed foil, and prolong the service life of a capacitor.

Owner:DONGGUAN HEC CONDENSER CO LTD

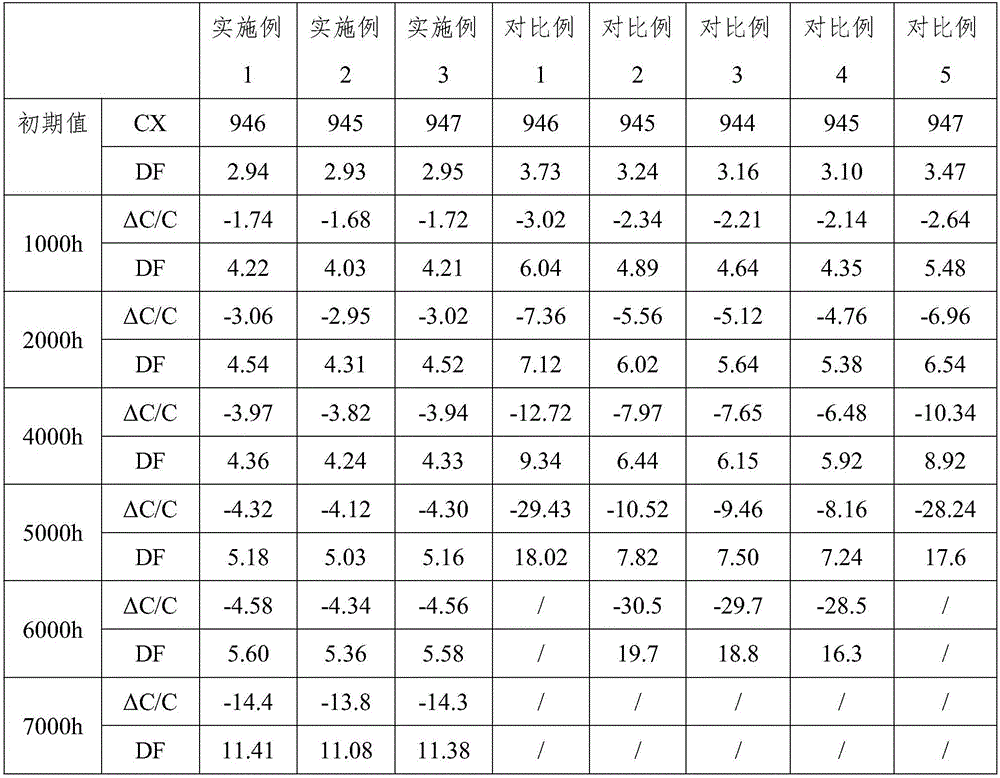

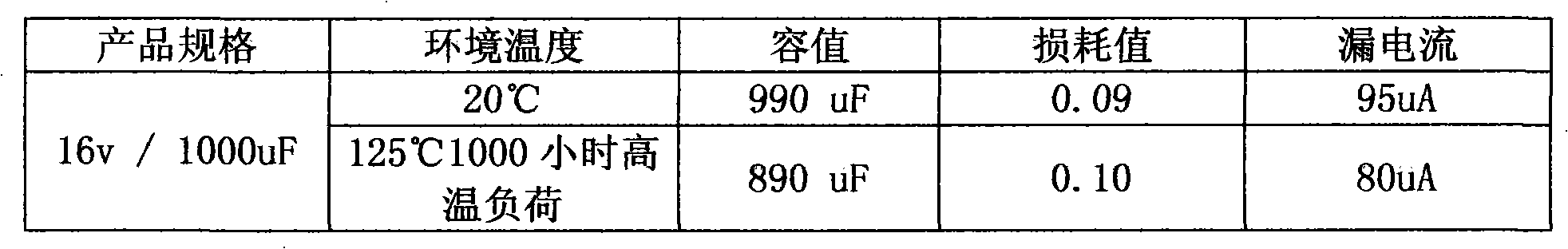

Special aluminum electrolytic capacitor for vehicle-mounted electronics

ActiveCN111029152AExtended service lifeWide operating temperature rangeCapacitor housing/encapsulationCapacitanceElectrolytic agent

The invention discloses a special aluminum electrolytic capacitor for vehicle-mounted electronics. An electrolyte comprises the following components in percentage by weight: 20%-35% of solute, 15%-20%of additive and the balance of solvent, wherein the solute is ammonium azelate, ammonium adipate, ammonium suberate and carboxylate containing a cyclobutane group, the additive is a waterproof mixture, and the solvent is ethylene glycol, ammonium sebacate and branched carboxylate. A core package is soaked with electrolyte with specific composition and proportion; the anode foil is a formed voltage-withstanding aluminum foil adopting 1.6 times of capacitor rated voltage, and the anode foil adopts a corrosion energizing aluminum foil with energizing voltage of 530V; the contact resistance between the positive electrode guide pin and the anode foil is 0.8 momega or less; and the contact resistance between the negative electrode guide pin and electrode cathode foil is 1 momega or less. Through improvement of process materials and conditions and overall cooperation, the aluminum electrolytic capacitor has thermal stability within the temperature range of -40 DEG C to 125 DEG C and is longin service life at 105 DEG C.

Owner:ZHAOQING BERYL ELECTRONICS TECH

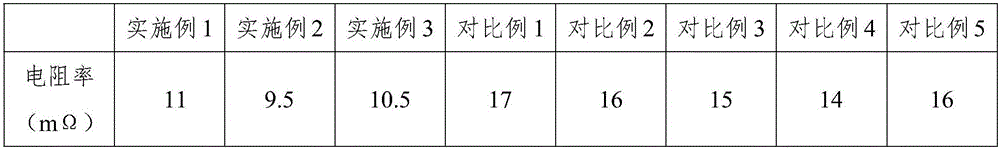

Low-resistivity electrolytic capacitor-used electrolyte and preparation method thereof

ActiveCN105990027AExtended service lifeInhibition of hydrationElectrolytic capacitorsPhosphorous acidElectrolysis

The invention belongs to the technical field of electrolytes, and particularly relates to a low-resistivity electrolytic capacitor-used electrolyte and a preparation method thereof. The low-resistivity electrolytic capacitor-used electrolyte provided by the invention is mainly composed of ethylene glycol, ammonium adipate, ammonium formate, additives and ultrapure water, wherein the additives comprises ethylene glycol, ammonium dihydrogen phosphate, phosphorous acid, silicon dioxide, a complexing agent, a surfactant and a hydrogen removing agent. The low-resistivity electrolytic capacitor-used electrolyte is applicable to a low-voltage electrolytic capacitor, and has the advantages of high frequency, low impedance, low electric leakage and low corrosivity; the electrolyte can restrain a hydration deterioration reaction of an electrode aluminum foil and rebound of leakage current, can also prevent an electrolytic capacitor floor heave phenomenon and can effectively prolong the service life of the electrolytic capacitor.

Owner:湖南建顺电子有限公司

Electrolyte for high-conductance and long-life aluminum electrolytic capacitor and preparation method thereof

ActiveCN105575665ASimple processEasy to operate and controlElectrolytic capacitor manufactureElectrolysisPolyethylene glycol

The invention relates to the technical field of electrolytes and particularly relates to an electrolyte for a high-conductance and long-life aluminum electrolytic capacitor and a preparation method thereof. The electrolyte is composed of the following raw materials in weight part: 8-12 parts of ammonium benzoate, 6-10 parts of ammonium adipate, 4-6 parts of polyethylene glycol, 1.5-2.5 parts of mannitol, 2-3 parts of boric acid, 2.5-3.5 parts of ammonium sebacate, 0.2-0.4 part of ammonium hypophosphite, 0.6-1.0 part of p nitrophenol, 3-5 parts of ammoniacal liquor, 0.1-0.3 part of EDTA and 55-75 parts of glycol. According to the technical scheme of the invention, based on the interaction of the above-described materials, the weight proportion of all the raw materials is strictly controlled, and the scintillation voltage of the prepared electrolyte is up to 380V. The conductivity of the prepared electrolyte is up to 5.5ms / cm. meanwhile, the electrolyte is good in electrochemistry characteristics, high in conductivity and long in service life, thus being applied to the manufacture of aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Preparation method of electrolyte for capacitor, electrolyte and application thereof

ActiveCN102074368ASimple processConditions are easy to controlElectrolytic capacitorsElectrolysisLow voltage

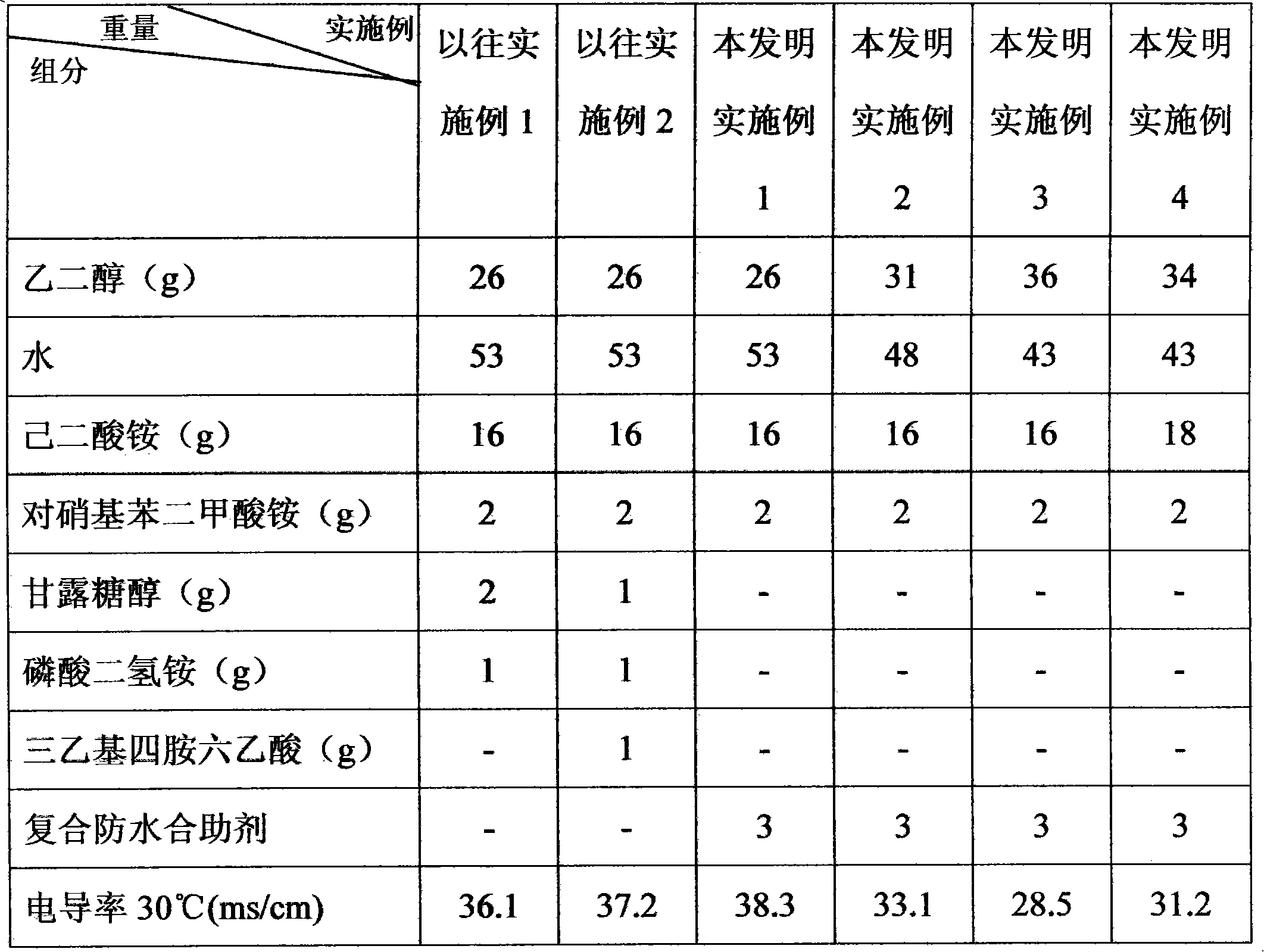

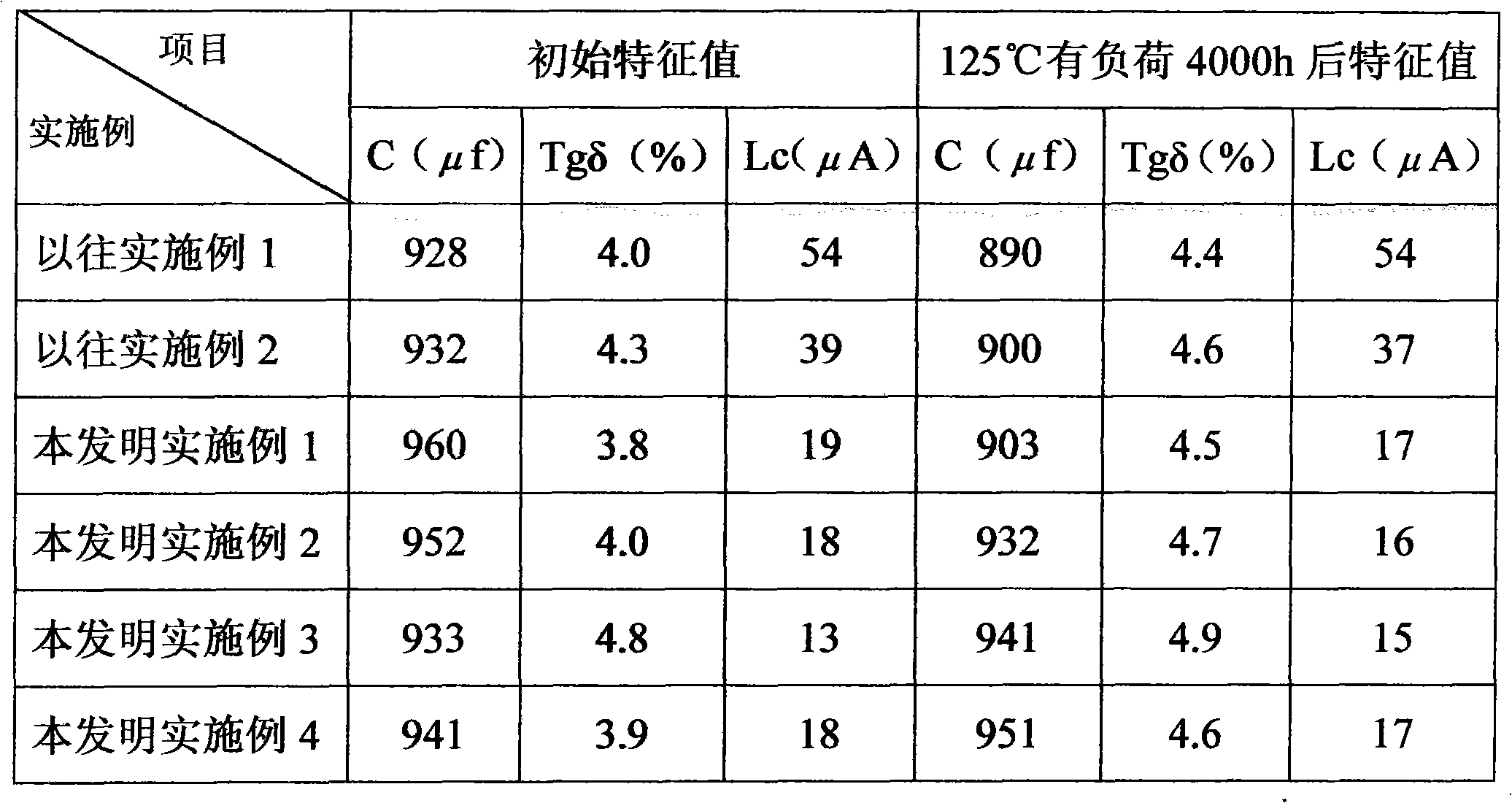

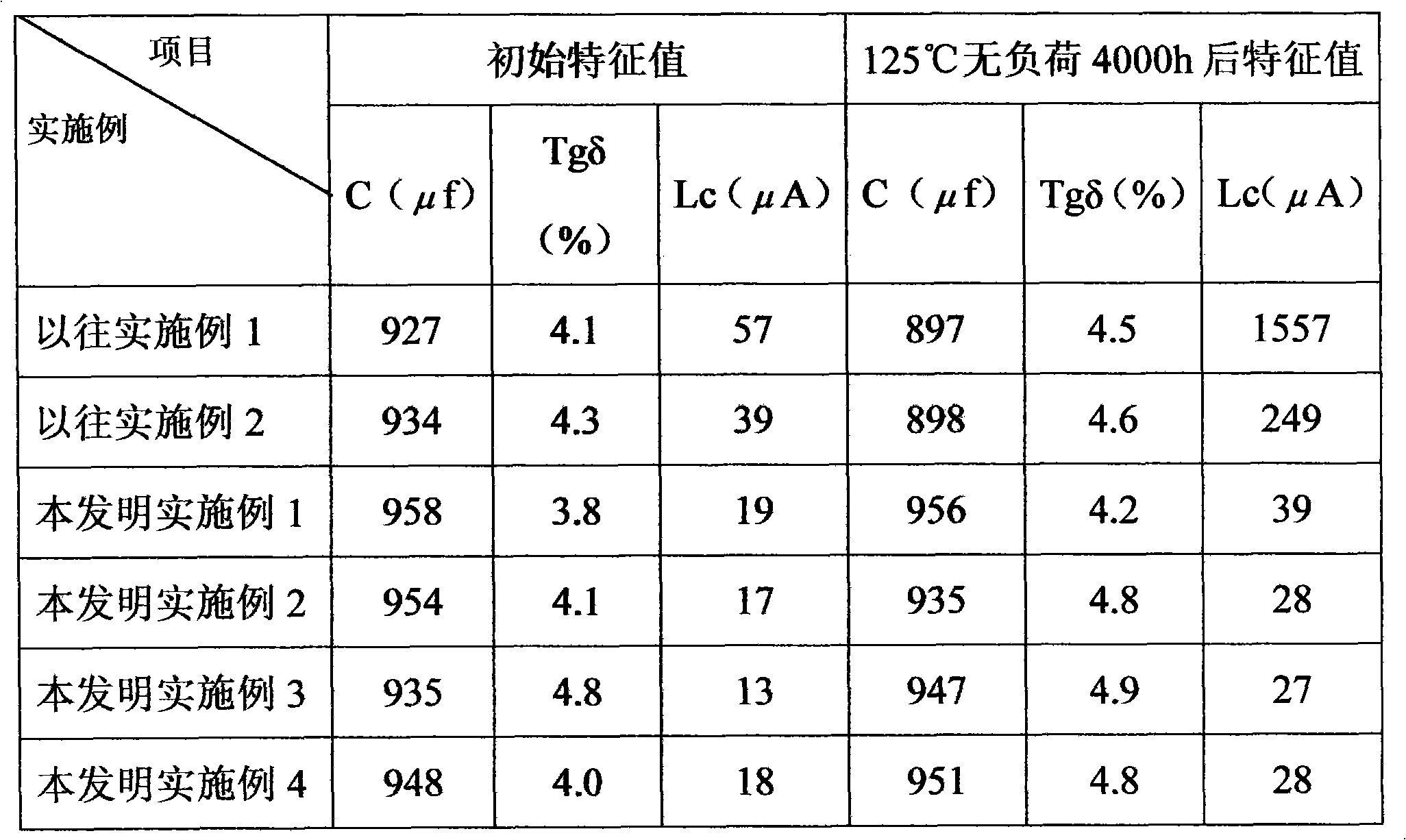

The invention provides a preparation method of electrolyte for a capacitor. The preparation method comprises the following process steps of: adding glycol, water, ammonium adipate, ammonium 4-nitrobenzoate dihydrate and anti-hydration auxiliary agent sequentially into a liquid mixing pot; heating the mixture; controlling the temperature to be 50 to 60 DEG C; stirring for 1 to 2 hours; after the mixture is dissolved completely, cooling to 30 to 40 DEG C; adjusting the pH value to be 6.5 to 7.0 by using ammonia or ammonia water; and discharging to obtain the electrolyte for the capacitor. The invention also provides the electrolyte. The electrolyte consists of the glycol, the water, the ammonium adipate, the ammonium 4-nitrobenzoate dihydrate and the anti-hydration auxiliary agent. The electrolyte is applicable to high-frequency, low-impedance, low-electric-leakage and low-voltage electrolytic capacitors.

Owner:东莞宏强电子有限公司

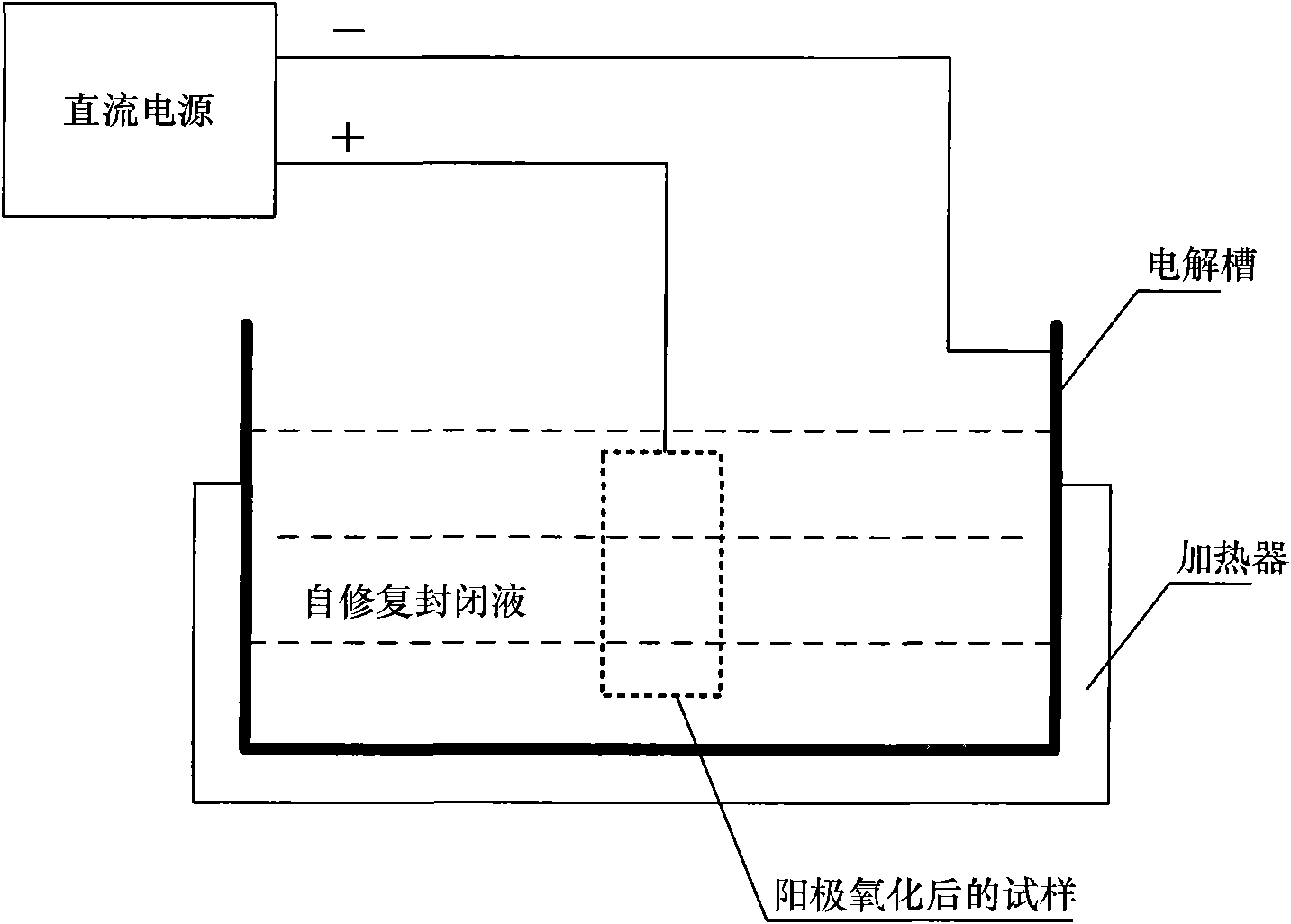

Self-repairing confining liquid and method for confining aluminium alloy anodic oxide film by using the same

InactiveCN101792921AAdvantages of closed processingImprove corrosion resistanceSurface reaction electrolytic coatingAnodic oxidationElectric field

The invention discloses a self-repairing confining liquid and a method for confining an aluminium alloy anodic oxide film by using the same. The self-repairing confining liquid is formed by dissolving 5g-15g of ammonium adipate in 100ml of deionized water. The confining method is to carry out confining treatment on anodized aluminium alloy under the action of an electric field. The confining method confines the micropores of the oxide film, and in the anodic oxide process, since holes caused by the fusion and the dropping of second-phase particles are filled and repaired, a confining bed with a net structure is formed on the surface so that the confined aluminium alloy anodic oxide film has the self-repairing capacity and higher decay resistance.

Owner:BEIHANG UNIV

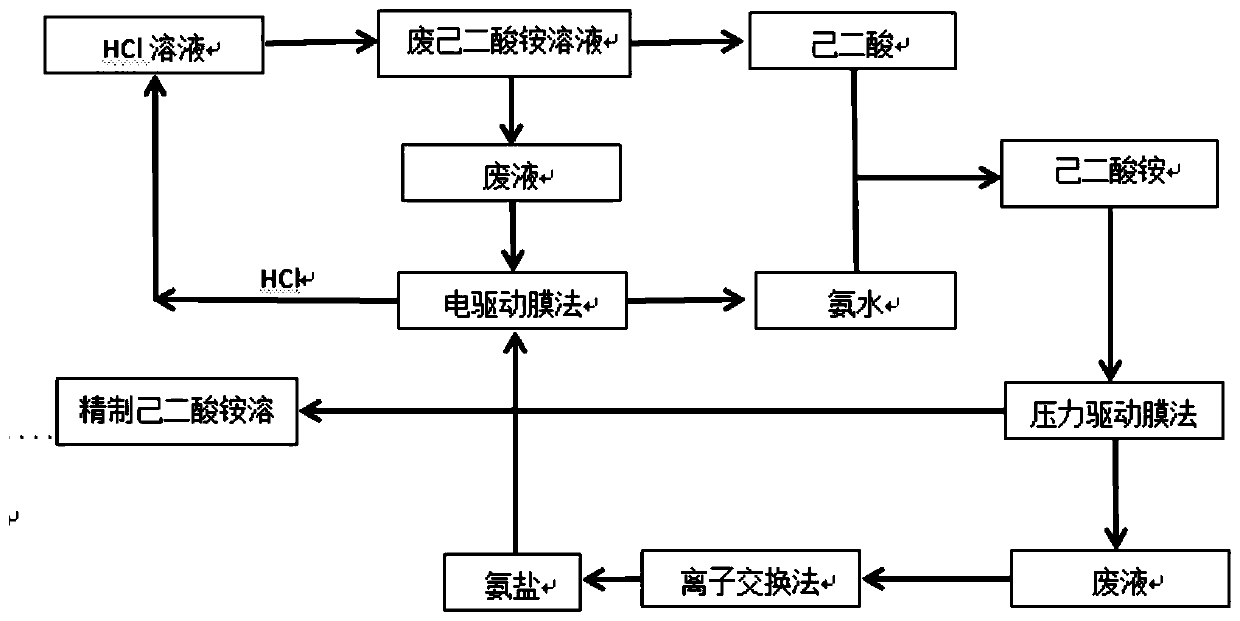

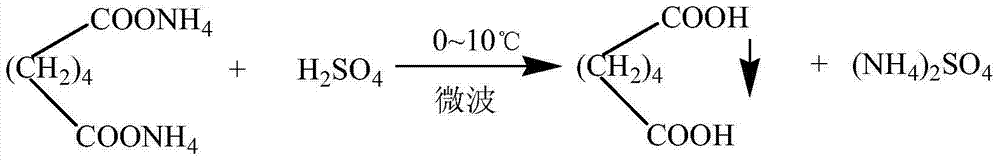

Zero-discharge treatment method for recycling and utilization of aluminum foil formation ammonium adipate wastewater

InactiveCN110759554AAchieve recyclingWater contaminantsTreatment involving filtrationIon exchangeAdipic acid

The invention discloses a zero-discharge treatment method for recycling and utilization of aluminum foil formation ammonium adipate wastewater. The method comprises the following steps: adding an acidliquid into ammonium adipate wastewater, performing acidification treatment, and performing solid-liquid separation so as to obtain an adipic acid crystal and ammonia-containing wastewater; performing ion separation on the ammonia-containing wastewater by using an electric drive membrane method, performing recycling so as to obtain an acid liquid and ammonia water, and circulating and recycling the acid liquid to acidify adipic acid wastewater; mixing and reacting the adipic acid crystal with the ammonia water so as to obtain an ammonium adipate solution; concentrating and refining the ammonium adipate solution by using a pressure drive membrane method so as to obtain a refined ammonium adipate solution, and circulating and recycling the refined ammonium adipate solution to aluminum foilformation; and performing an ion exchange method on a waste liquid generated from concentration and refining of the ammonium adipate solution so as to obtain an ammonium salt solution, conveying the ammonium salt solution to an electric drive membrane, and performing recycling. The method achieves zero-discharge recycling treatment on the ammonium adipate wastewater and is environmentally friendly.

Owner:YANGZHOU HONGYUAN ELECTRONICS

Electrode foil feed liquid, and manufacturing method for high strength and low pressure formed foil

InactiveCN109023474ASpeed up bendingImprove tensile propertiesAnodisationEconomic benefitsHigh intensity

The invention discloses an electrode foil feed liquid, and a manufacturing method for high strength and low pressure formed foil. The electrode foil feed liquid is an ammonium adipate aqueous solutioncontaining alkali metal salt; the manufacturing method for the high strength and low pressure formed foil comprises the steps that the feed liquid is used for supplying the required power for five-stage forming treatment. The formed foil obtained with the feed liquid and the manufacturing method has the features of high bending and tensile strength, and is applicable for reduced capacitors represented by V-CHIP; and meanwhile the production efficiency is high, and the economic benefits are good.

Owner:NANTONG HAIXING ELECTRONICS +2

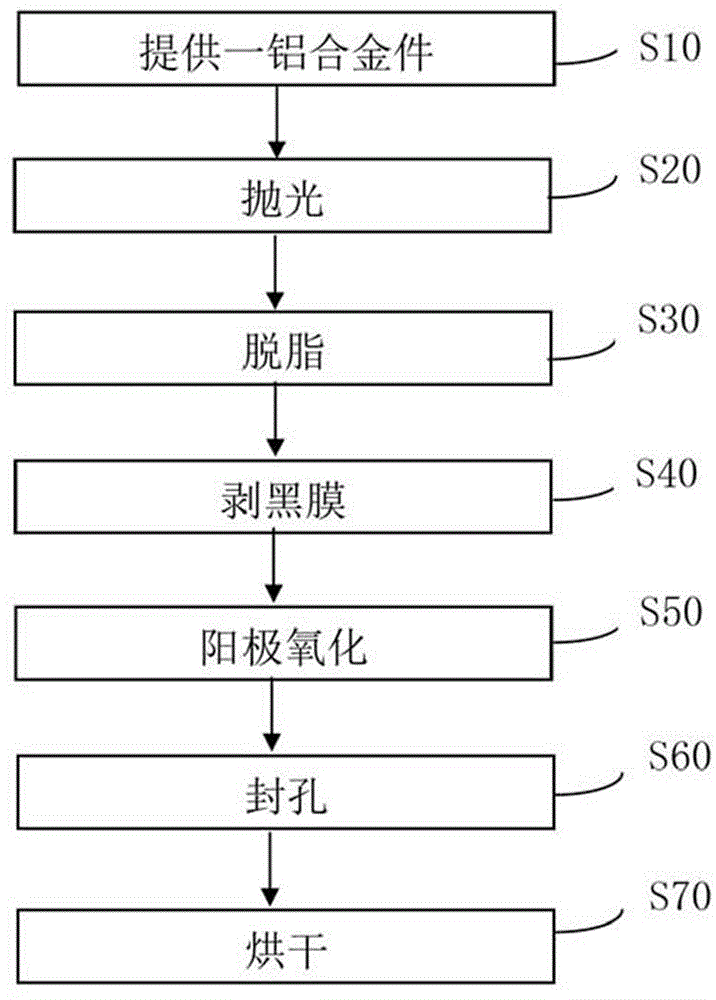

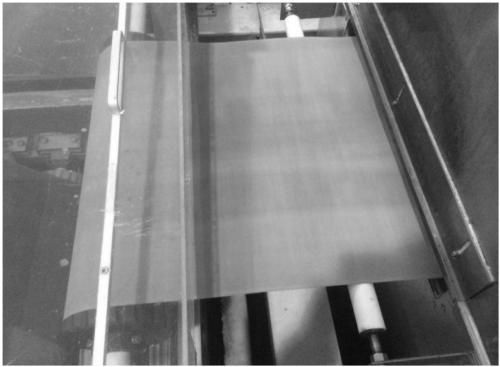

Anodic oxidation and surface treatment method of aluminum alloy part and anodic oxidation treatment liquid thereof

The invention discloses a surface treatment method of an aluminum alloy part containing zinc and magnesium elements. The surface treatment method comprises the following steps: the aluminum alloy part is provided; the aluminum alloy part is polished to reach a mirror surface effect; the aluminum alloy part is degreased by using degreasing solution; the black film stripping treatment is performed tothe aluminum alloy part; anodic oxidation treatment liquid, including acid solution and an additive with a concentration of 0.5 mg / L to 25 g / L, is used for anodically oxidizing the polished aluminum alloy part to form an oxide film on the surface of the aluminum alloy part, wherein the additive is one or several in ammonium adipate, 1, 2, 3-benzotriazole, oxalic acid, sodium malate or glycerin; and closing liquid is used for sealing the anodically oxidized aluminum alloy part. The invention further provides the anodic oxidation treatment liquid applied to the surface treatment method and an anodic oxidation treatment method. The aluminum alloy part, obtained by the surface treatment method, has no bank markon the surface, and has better glossiness.

Owner:富联科技(济源)有限公司

Power supplying electrolyte for organic acidification of aluminum foil

ActiveCN109056024AImprove conductivityImprove pass rateSurface reaction electrolytic coatingElectricityCITRATE ESTER

The invention discloses a power supplying electrolyte for an organic acidification of an aluminum foil. The power supplying electrolyte for the organic acidification of the aluminum foil is composed of a power agent, an additive, and water, wherein the power agent is phosphoric acid, and the concentration is 20-60g / L; the additive is R'-H2PO4 or R'-HPO4, and the concentration is 0.1-1.0 g / L; and the R' is an active metal ion. According to the power supplying electrolyte for the organic acidification of the aluminum foil, a new power agent phosphoric acid is introduced into a feed tank to replace the original power agent ammonium adipate or ammonium dihydrogen citrate to enhance conductivity; the problem of curling and wrinkling of the aluminum foil which occurs during the organic acidification process for producing an electrode foil with high specific volume is completely solved without increasing the unit consumption of the electricity; the product qualification rate is improved by 30%; the stability of production operation is improved; the electrolyte cost is reduced by about 15%; and the invention is suitable for mass production of the electrode foil industry.

Owner:XINJIANG JOINWORLD CO LTD

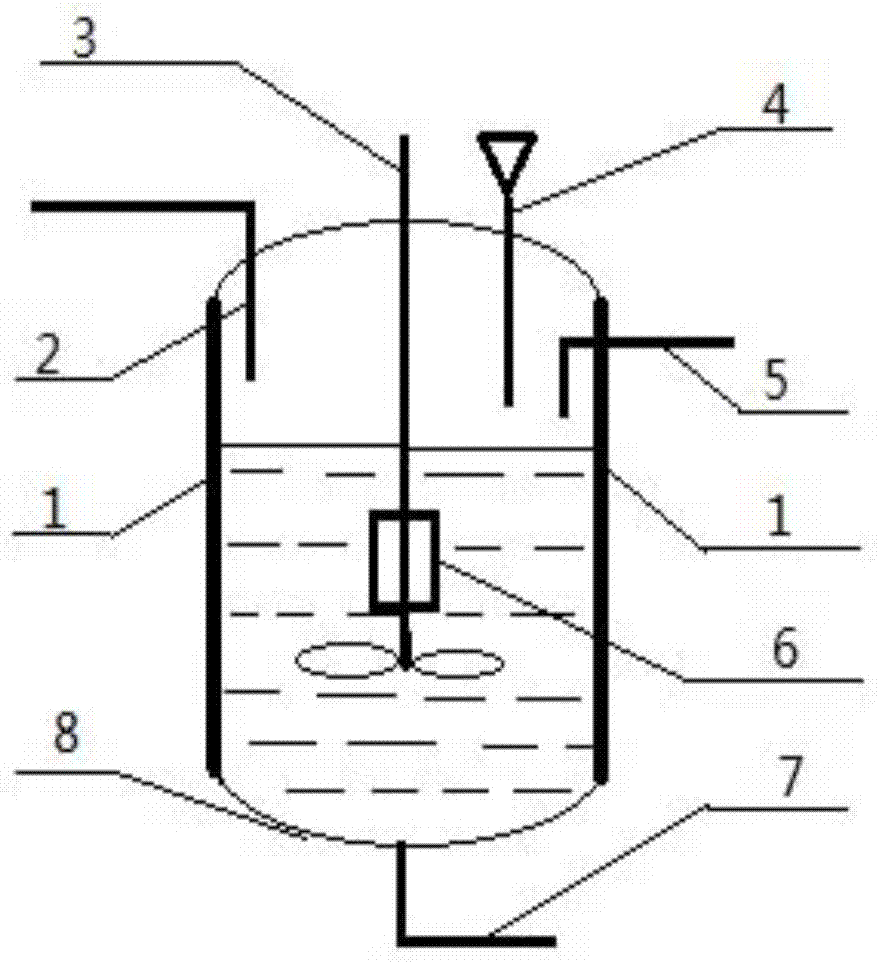

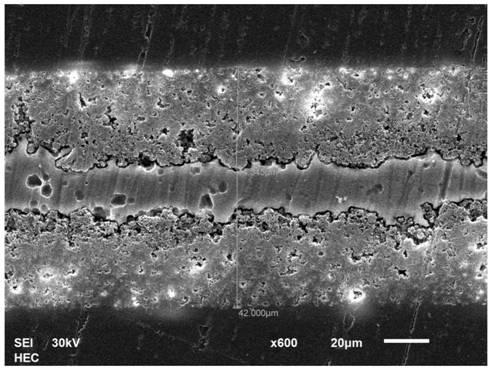

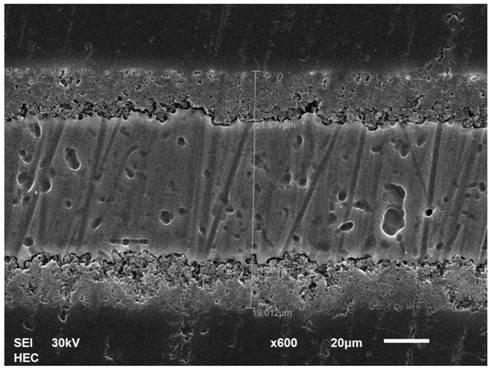

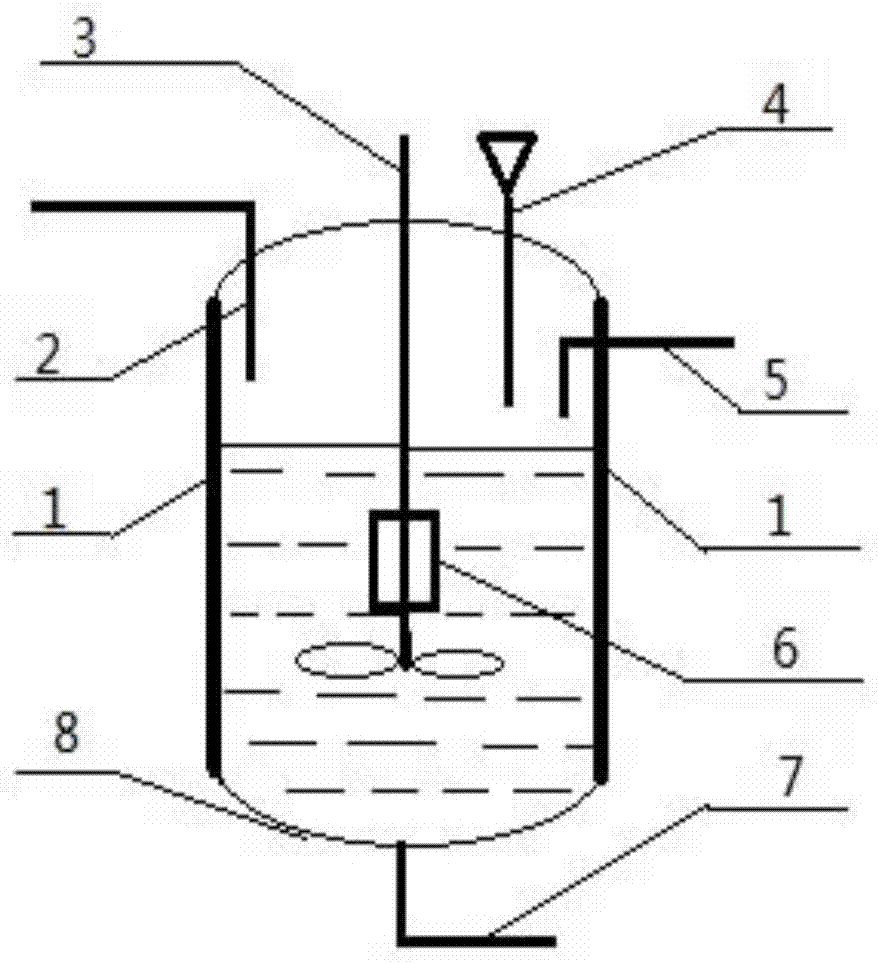

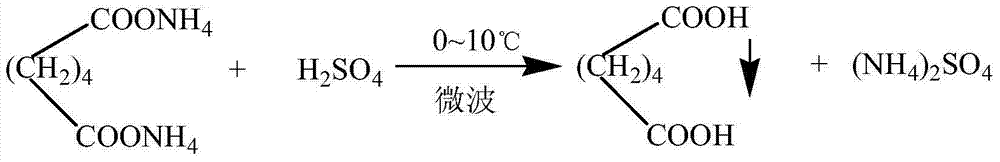

Method and equipment for efficiently synthesizing adipate crystal from ammonium adipate formation waste liquid

ActiveCN103588632AUniform shapeUniform sizePreparation from carboxylic acid saltsSolution crystallizationFiltrationPulse microwave

The invention belongs to the field of adipate preparation and discloses a method and equipment for efficiently synthesizing an adipate crystal from ammonium adipate formation waste liquid. The method comprises the steps: filtering to remove solid impurities in the ammonium adipate formation waste liquid; cooling to 0-10 DEG C; dropwise adding strong acid into a low-temperature ammonium adipate solution under stirring; adding an adipate crystal seed with the particle size of 1-10mm when the pH value of the ammonium adipate solution is reduced to 3.0-4.5; starting a pulse microwave generator with the frequency of 30-40MHz and the energy concentration of 0.01-0.1w / cm<2>, and meanwhile, further dropwise adding the strong acid; when the pH value of the solution is up to 0.9-1.2, ending the dropwise adding of the strong acid, reducing the stirring speed, stopping the pulse microwave generator after 15-30min, and preserving the heat for 1-2h; and carrying out suction filtration, washing and drying in vacuum. The method has the advantages of high product yield, relatively uniform crystal shape, size and density, fewer impurities, simple process and relatively remarkable economic and environment-friendly benefits.

Owner:ZHONGKAI UNIV OF AGRI & ENG +1

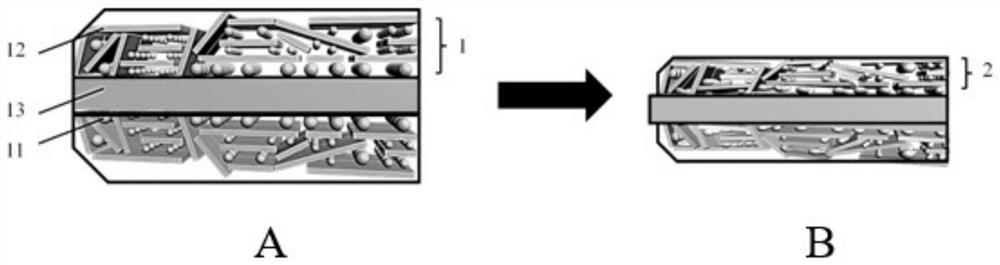

Preparation method of porous anode aluminum foil with multi-stage mixed structure

ActiveCN111627714AReduce pollutionAvoid strong acidsAnodisationElectrolytic capacitorsElectrolytic agentMetal particle

The invention discloses a preparation method of a porous anode aluminum foil with a multi-stage mixed structure, and belongs to the field of aluminum electrolytic capacitors. Large-size aluminum metalhas a large specific surface area and high surface uniformity; small-size aluminum metal particles can play a role in supporting a three-dimensional structure during melting; high porosity of the electrode foil is maintained, meanwhile, an electron transmission channel is added, the aluminum substrate is coated with the large size aluminum and the small size aluminum particles in a mixed mode, anodic oxidation is conducted in an ammonium adipate or boric acid electrolyte, the porous electrode foil of a nano-micron multi-stage mixed structure can be obtained, and the electrode foil has high electrostatic capacity and low leakage current. The method can be used for large-scale industrial manufacturing, the specific volume of the anode aluminum foil for the aluminum electrolytic capacitor can be greatly improved, light weight and miniaturization of the aluminum electrolytic capacitor are promoted, and the comprehensive performance of the aluminum electrolytic capacitor is improved.

Owner:XI AN JIAOTONG UNIV

Method for low-pressure soft-state corrosion of aluminum foil

ActiveCN111048317AReduce usageEmission reductionElectrolytic capacitorsAdipic acidElectrochemical corrosion

The invention discloses a method for the low-pressure soft-state corrosion of an aluminum foil. The method comprises the following steps that: S1, the aluminum foil is prepared, and pretreatment is carried out; S2, electrochemical corrosion is conducted, specifically, the aluminum foil is subjected to electrification corrosion in acid, and water washing is conducted after corrosion is completed; S3, intermediate treatment is performed, specifically, with the aluminum foil adopted as an anode, the aluminum foil is subjected to electrification treatment in an ammonium adipate solution; S4, washing is performed, specifically, the aluminum foil subjected to the intermediate treatment is washed with water; S5, the steps S2 to S4 are repeated until a required aluminum foil corrosion amount is obtained; and S6, after chemical cleaning, water washing is carried out, stabilizing treatment and high-temperature sintering are carried out, so that an etched foil is obtained. In the step S1, the aluminum foil is a to-be-corroded aluminum foil which is also called plain foil. According to the method disclosed by the invention, the ammonium adipate is used for carrying out electrification treatment, so that treatment in a purification chemical method is replaced; the raw materials of the intermediate treatment can be used for a long time, the use of ammonia or phosphorus compounds is avoided,nitrogen and phosphorus emission is reduced, and therefore, cost is low, environmental protection is facilitated, and the specific volume of the etched foil can be increased; compared with the treatment in the purification chemical method, the intermediate treatment can obtain higher specific volume with an aluminum foil with a thickness the same as the thickness of an aluminum foil used in the treatment in the purification chemical method.

Owner:乳源县立东电子科技有限公司

Method and equipment for efficiently synthesizing adipate crystal from ammonium adipate formation waste liquid

InactiveCN103588632BUniform shapeUniform sizePreparation from carboxylic acid saltsSolution crystallizationFiltrationPulse microwave

The invention belongs to the field of adipate preparation and discloses a method and equipment for efficiently synthesizing an adipate crystal from ammonium adipate formation waste liquid. The method comprises the steps: filtering to remove solid impurities in the ammonium adipate formation waste liquid; cooling to 0-10 DEG C; dropwise adding strong acid into a low-temperature ammonium adipate solution under stirring; adding an adipate crystal seed with the particle size of 1-10mm when the pH value of the ammonium adipate solution is reduced to 3.0-4.5; starting a pulse microwave generator with the frequency of 30-40MHz and the energy concentration of 0.01-0.1w / cm<2>, and meanwhile, further dropwise adding the strong acid; when the pH value of the solution is up to 0.9-1.2, ending the dropwise adding of the strong acid, reducing the stirring speed, stopping the pulse microwave generator after 15-30min, and preserving the heat for 1-2h; and carrying out suction filtration, washing and drying in vacuum. The method has the advantages of high product yield, relatively uniform crystal shape, size and density, fewer impurities, simple process and relatively remarkable economic and environment-friendly benefits.

Owner:ZHONGKAI UNIV OF AGRI & ENG +1

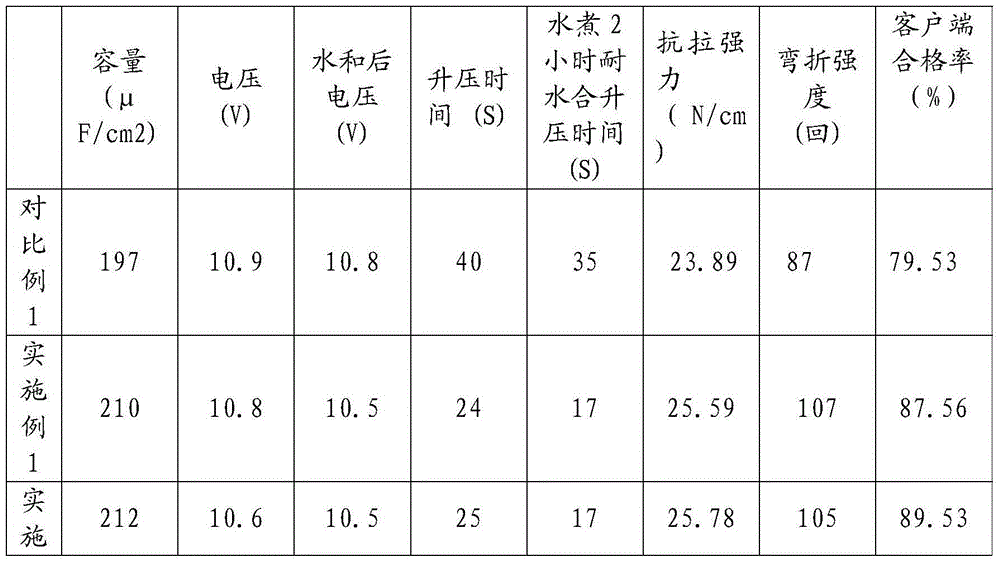

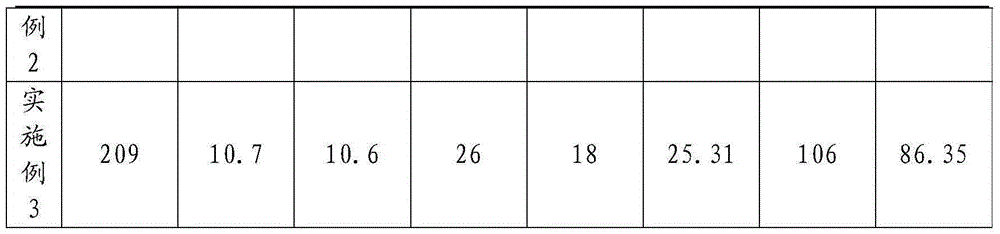

Production method of special aluminum foil for solid-state capacitor

ActiveCN104611747AIncrease temperatureIncrease specific volumeAnodisationElectrolytic capacitorsPrimary repairPhosphoric acid

The invention discloses a production method of a special aluminum foil for a solid-state capacitor. The production method comprises the following steps:1), adding an aluminum foil into an ammonium adipate solution for performing forming treatment to obtain the primarily-formed aluminum foil; 2), performing secondary forming treatment; 3), performing trinary forming treatment; 4), adding the trinarily-formed aluminum foil into a phosphoric acid solution for performing depolarization treatment; 5), performing primary repairing forming treatment; 6), performing secondary repairing forming treatment; 7), posttreating; 8), putting the posttreated aluminum foil into a roasting furnace for performing roasting treatment, putting the roasted aluminum foil into a drying furnace for performing drying treatment to obtain the special aluminum foil. The special aluminum foil produced by the production method has the characteristics of high specific capacity, long service life, long hydration-resisting time and low drain voltage.

Owner:华德士电子(东莞)有限公司

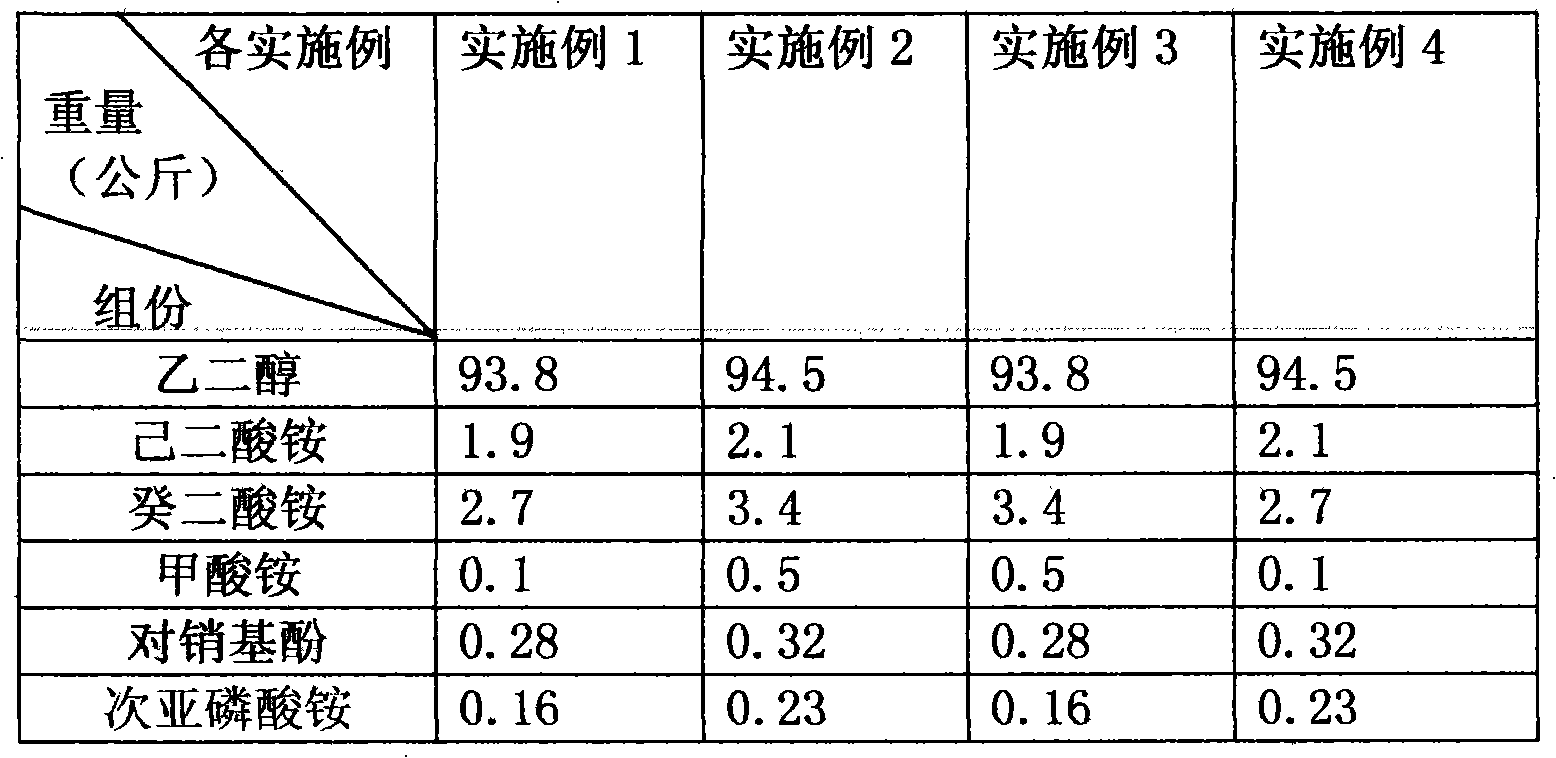

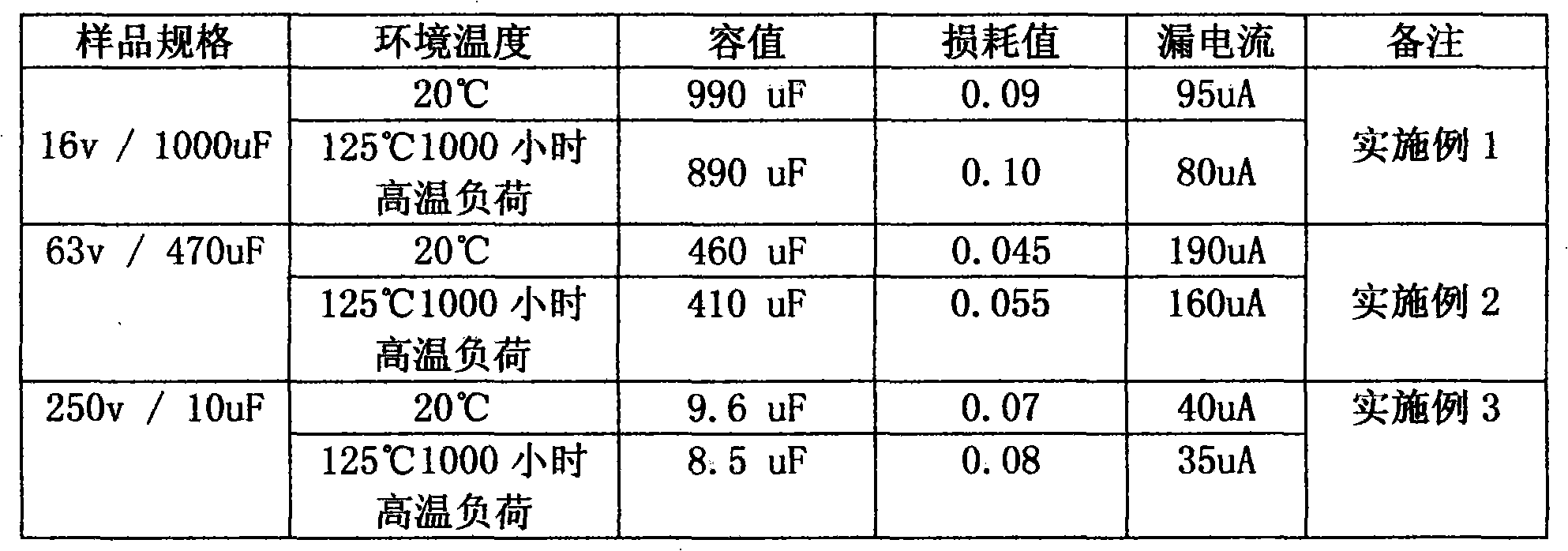

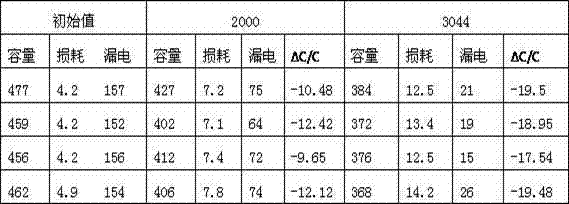

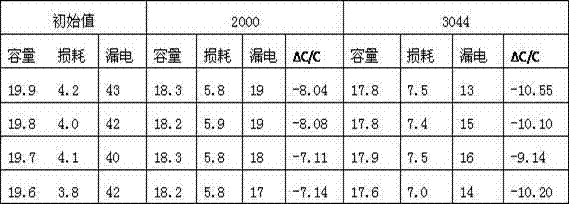

Electrolyte of wide-temperature aluminium electrolytic capacitor and manufacturing method thereof

InactiveCN101814374ANo high pressureImprove performanceElectrolytic capacitorsElectrolysisAmmonium formate

The invention relates to a manufacturing method for electrolyte of a wide-temperature aluminium electrolytic capacitor, comprising the raw materials of ethanediol, ammonium adipate, ammonium sebacate, ammonium formate, p-nitrophenol and ammonium hypophosphite. The method comprises the following steps of heating the ethanediol in parts by weight to 50-60 DEG C, adding the other raw materials in parts by weight in the ethanediol, heating to 130-135 DEG C while stirring, maintaining the constant temperature of 130-135 DEG C for 20-30min, and cooling to the room temperature to prepare the electrolyte of the wide-temperature aluminium electrolytic capacitor. The invention is mainly applied in electric products, electricity control systems, multifunctional meters, power supply parts of computers, various home appliances and other fields. The aluminium electrolytic capacitor prepared from the electrolyte obtained in the invention can produce no high atmospheric pressure and has stable performance in the environment with the temperature no more than 125 DEG C.

Owner:HENGYANG CHUANGJI ELECTRONICS

Working electrolyte for aluminium electrolytic capacitor and preparation method

ActiveCN102779645ALow costImprove oxidation efficiencyElectrolytic capacitorsPolyethylene glycolAdipic acid

Owner:GUANGXI JIGUANG ELECTRONICS TECH CO LTD

Process method for improving water resistance of formed foil

ActiveCN109671568AExtended service lifeImprove water resistanceSurface reaction electrolytic coatingElectrolytic capacitor manufacturePhosphoric acidElectrolyte

The invention discloses a process method for improving the water resistance of a formed foil, which comprises the following steps of: 1, soaking the formed foil into a phosphoric acid aqueous solution, and then washing with ionized water; 2, performing high-temperature heat treatment on the formed foil washed in the step 1; 3, soaking the formed foil subjected to high-temperature heat treatment inthe step 2 into a mixed solution of ammonium adipate and ammonium dihydrogen phosphate, and cleaning the formed foil with ionized water; 4, soaking the formed foil washed in the step 4 into sodium polyacrylate, and then washing the formed foil with ionized water; 5, subjecting the formed foil washed in the step 5 to normal-temperature heat treatment; 6, after cooling the formed foil subjected toheat treatment in the step 5, taking out the treated formed foil. According to the process method, the electrostatic capacity of the aluminum foil is not changed, and the water resistance is better than that of the original process. As a result, the service life of a capacitor in the electrolyte is prolonged. The production cost is reduced, and the market demand is further met.

Owner:YANGZHOU HONGYUAN ELECTRONICS

Formation method suitable for production of small wide electrode foils

ActiveCN110729130AImprove formation efficiencyReduce leakageElectrolytic capacitor manufactureOXALIC ACID DIHYDRATEActive agent

The invention discloses a formation method suitable for small wide electrode foil production. The formation method comprises the following steps that: S1, a surfactant is added into a 1.5 mol / L HCl and AlCl3 mixed solution, an obtained mixture is heated when being stirred, and surface treatment is carried out on an aluminum foil at 50 DEG C; S3, the aluminum foil is soaked in deionized water at the temperature of 100 DEG C for 20 minutes, the aluminum foil is putted in an aqueous solution formed by mixing oxalic acid with the concentration of 1.0% and ammonium adipate with the concentration of6%, and formation is carried put for 200 seconds under the conditions of 95 DEG C temperature, 220V voltage and 100mA / cm <2> current, so that a primary formed electrode foil is obtained; and S4, theprimary formed electrode foil is putted into an aqueous solution formed by mixing boric acid with the concentration of 8%, oxalic acid with the concentration of 0.6% and ammonium pentaborate with theconcentration of 0.8%, and formation is carried out for 180s under the conditions of 85 DEG C temperature, 240V voltage and 0.22 A / cm<2> treatment current density, so that a secondary formed electrodefoil is obtained. A compact oxidation film is formed on the aluminum foil, so that the service life of the aluminum foil is prolonged; a multi-stage formation process is adopted, so that the preparedelectrode foil has excellent performance and low electric leakage, and the quality of the electrode foil is improved.

Owner:南通南辉电子材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com