Method and equipment for efficiently synthesizing adipate crystal from ammonium adipate formation waste liquid

A technology of ammonium adipate and adipic acid, which is applied in the field of high-efficiency synthesis of adipic acid crystals, can solve problems such as waste of resources and increased cost of sewage treatment, and achieve energy saving, significant economic and environmental benefits, and balanced growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

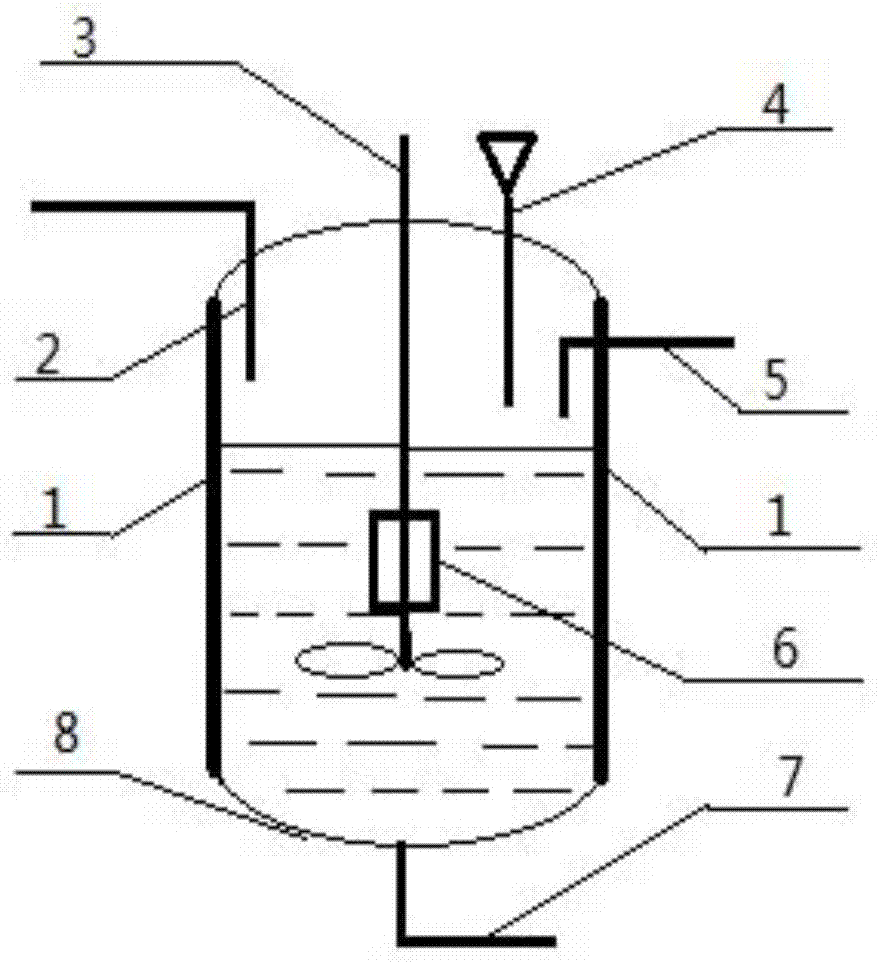

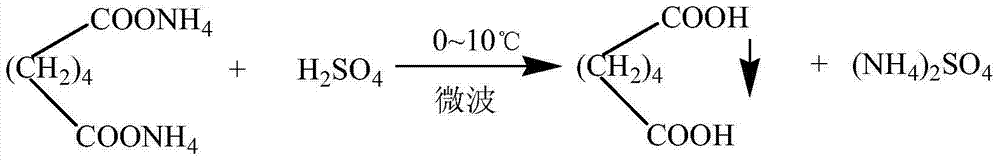

[0029] The pulse microwave assisted reaction crystallizer used in the present invention, its cross-sectional view is as follows figure 1 Shown; the pulse microwave-assisted reaction crystallizer by a cylindrical vessel with a top cover 8, ammonium adipate into a waste liquid feed guide tube 2, adipic acid crystal solid-liquid mixture discharge tube 7, adipic acid The seed crystal introduction port 4, the strong acid introduction port 5, the stirring blade 3 and the pulsed microwave generator 6 are composed; the cylindrical container 8 with a top cover is surrounded by a heat exchange jacket 1; The top cover of the cylindrical container 8 is provided with a feed guide tube 2, adipic acid seed crystal introduction port 4 and a strong acid introduction port 5 for ammonium adipate conversion into waste liquid, all of which extend into the cylindrical container 8 with a top cover Inside; the bottom of the cylindrical container 8 with a top cover is provided with a discharging pipe 7...

Embodiment 2

[0031] Using the pulse microwave-assisted reaction crystallizer described in Example 1 to efficiently synthesize adipic acid crystals from the waste liquid of ammonium adipate:

[0032] (1) Take 800 mL of ammonium adipate with a conductivity of 40ms / cm to convert into waste liquid, filter to remove solid impurities in the waste liquid from ammonium adipate, to obtain an ammonium adipate solution; convert the ammonium adipate solution from adipic acid The ammonium formation waste liquid feed guide tube is introduced into the cylindrical container with a top cover of the pulse microwave assisted reaction crystallizer;

[0033] (2) Cool the ammonium adipate solution to 5°C to obtain a low-temperature ammonium adipate solution;

[0034] (3) Under the condition of stirring at 100rpm, add 95% sulfuric acid to the low-temperature ammonium adipate solution; when the pH value of the ammonium adipate solution drops to about 4.0, the particle size is added 1-10 micron adipic acid seed crystals...

Embodiment 3

[0043] (1) Take 800 mL of ammonium adipate with a conductivity of 40ms / cm to be converted into waste liquid, and filter to remove solid impurities in the waste liquid from the conversion of ammonium adipate to obtain an ammonium adipate solution;

[0044] (2) Cool the ammonium adipate solution to 5°C to obtain a low-temperature ammonium adipate solution;

[0045] (3) Under the condition of stirring at 100 rpm, add dropwise sulfuric acid with a mass concentration of 95% to the low-temperature ammonium adipate solution;

[0046] (4) When the pH value of the solution reaches 0.9, stop adding sulfuric acid with a mass concentration of 95%, the stirring speed is reduced to 20 rpm, and the temperature is kept at 5°C for 2 hours;

[0047] (6) Centrifugal separation of adipic acid crystals, washing with ice water, and vacuum drying at 60°C to obtain adipic acid crystal sample B.

[0048] The particle size, moisture and impurities of the adipic acid crystal sample B were tested, and the results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com