Patents

Literature

551 results about "SOLUTION/DROPS" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This is not a list of all drugs or health problems that interact with Maxidex (dexamethasone solution (drops)). Tell your doctor and pharmacist about all of your drugs (prescription or OTC, natural products, vitamins) and health problems. You must check to make sure that it is safe for you to take ...

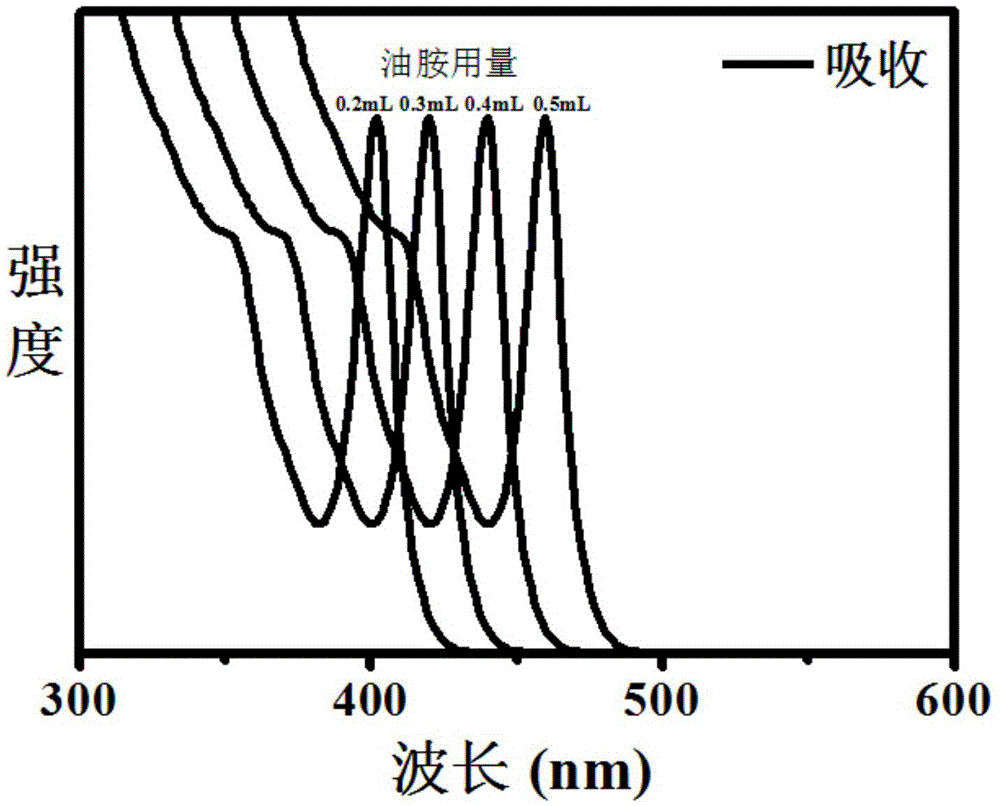

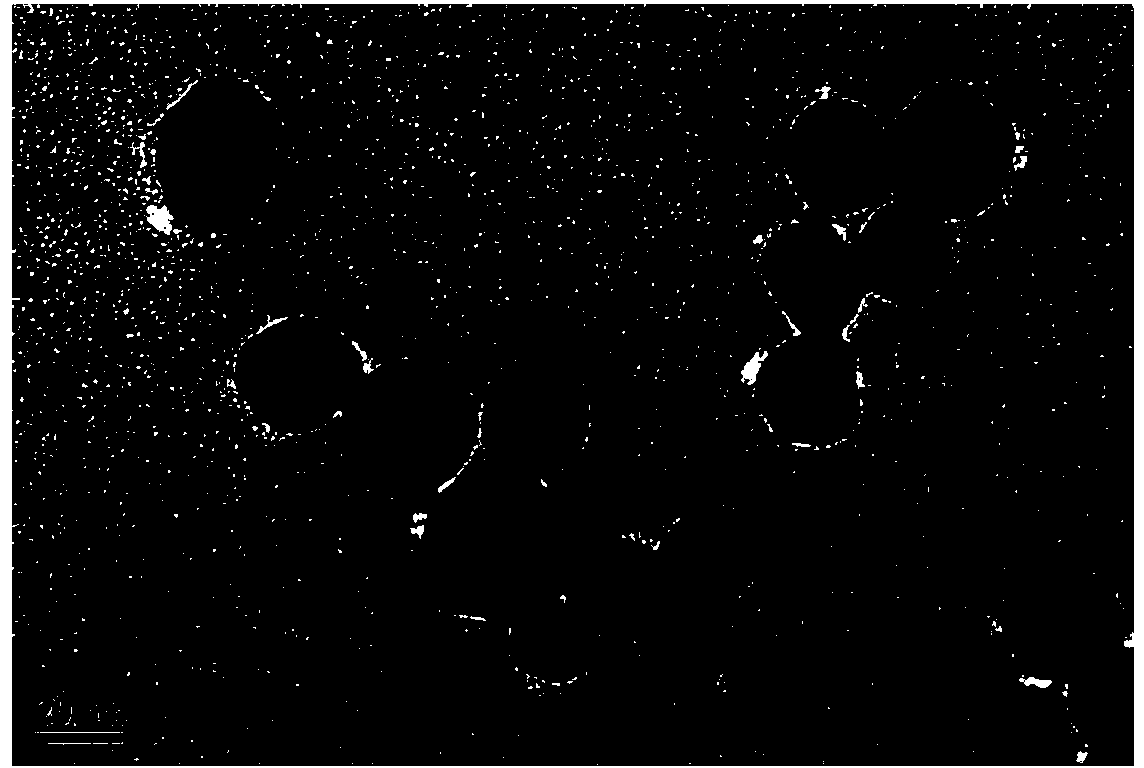

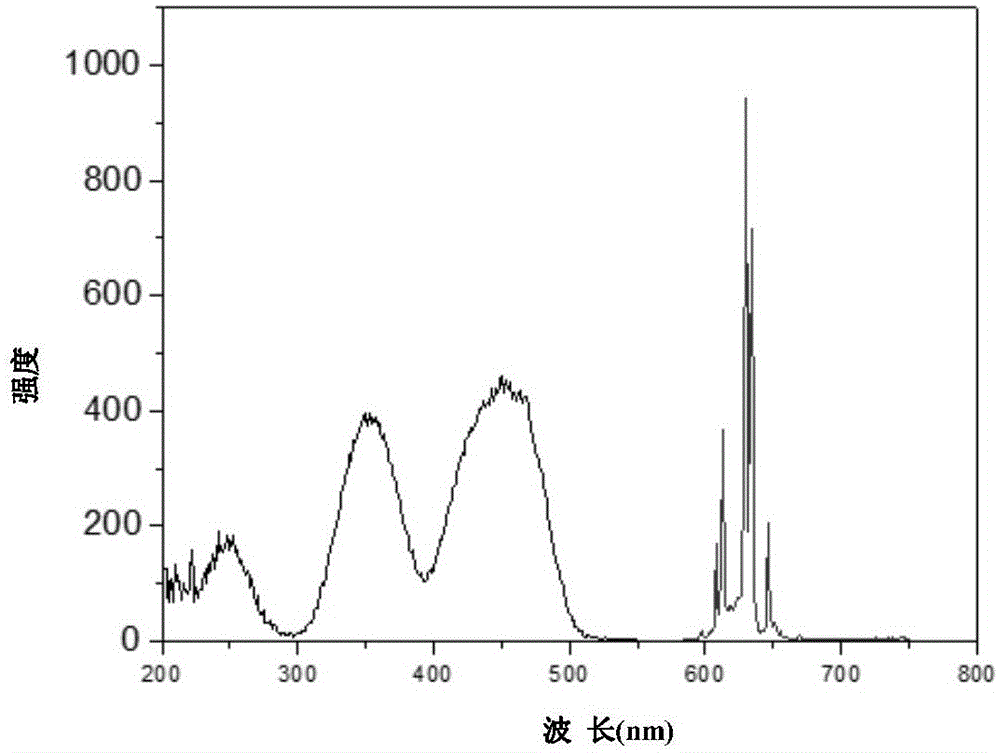

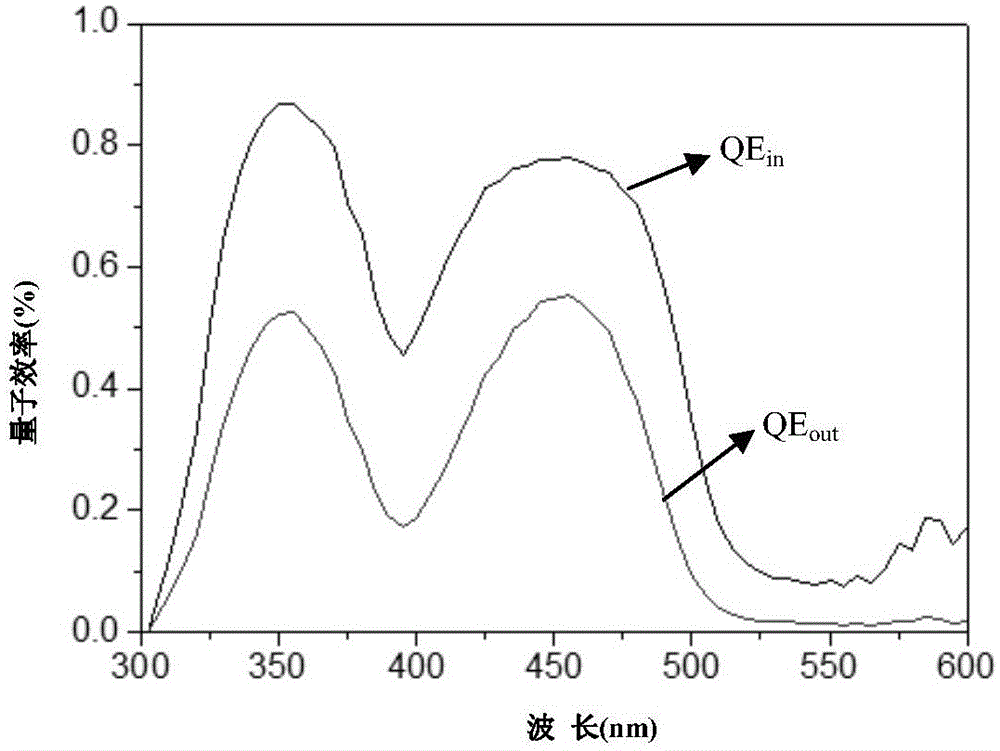

Single-size CsPbX3 perovskite nanocrystalline preparation method

InactiveCN105523581AEasy to adjust sizeEasy to operateLead compounds preparationLead halidesCarboxylic saltLead chloride

The invention belongs to the technical field of preparation of semiconductor nanomaterials and discloses a single-size CsPbX3 perovskite nanocrystalline preparation method. The method includes: adding cesium carboxylate solution into N2 protected lead bromide solution to realize reaction for obtaining single-size CsPbBr3 perovskite nanocrystalline; scattering the single-size CsPbX3 perovskite nanocrystalline into normal hexane, and gradually adding lead chloride solution or lead iodide solution drop by drop to realize reaction for obtaining single-size CsPbBr3 perovskite nanocrystalline. The single-size CsPbX3 perovskite nanocrystalline preparation method has the advantages of simplicity in operation, easiness in size adjustment of products, component controllability and the like.

Owner:JILIN UNIV

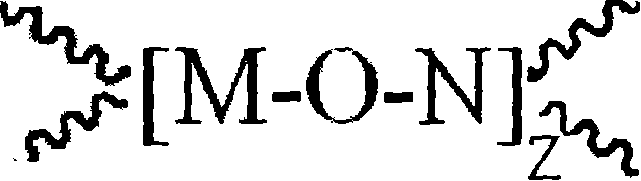

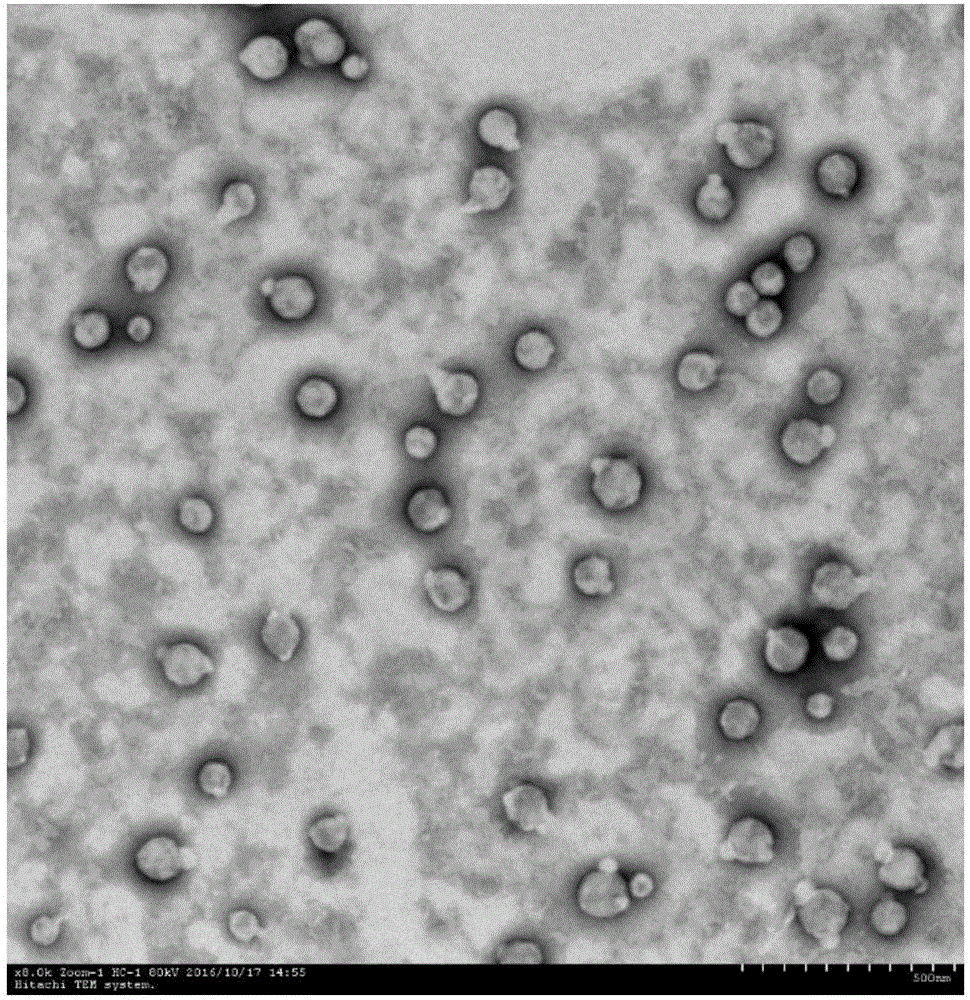

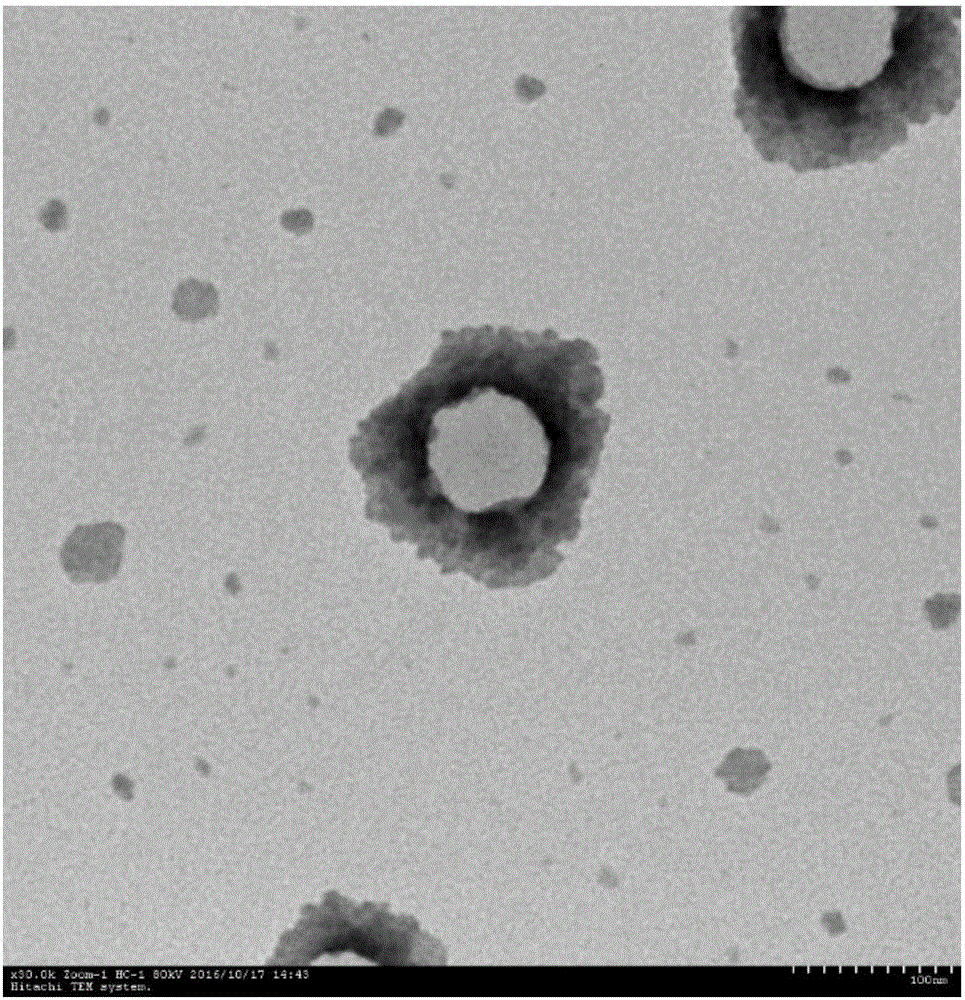

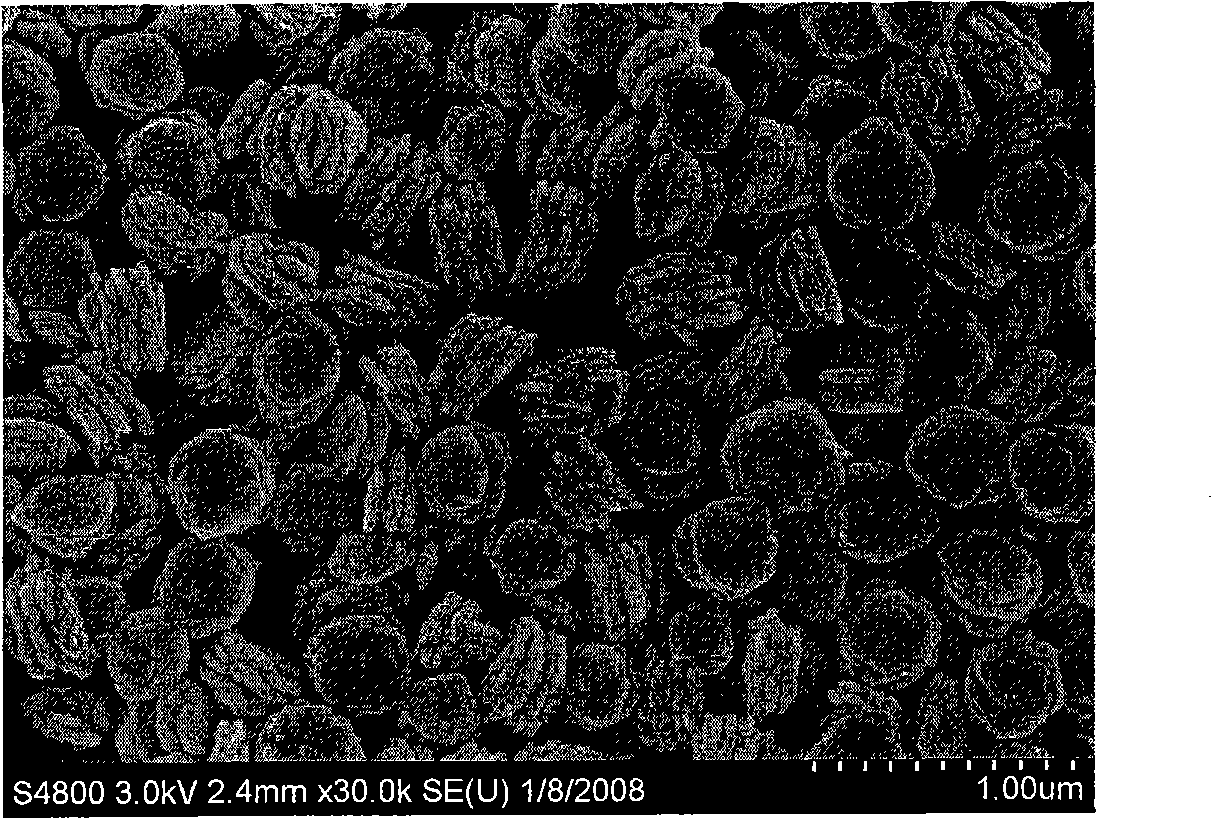

Microgel with nanometer grade sensitivity of temperature and PH value and preparation method thereof

InactiveCN101037494AWith temperatureHas dual pH sensitive propertiesPharmaceutical non-active ingredientsEmulsion polymerizationDrug carrier

The invention relates to a temperature and pH valve sensitive nano microgel and a preparation method thereof. Structure formula of the microgel and copolymer thereof is shown above, wherein temperature sensitive monomer M is amide group containing compound, pH sensitive monomer N is carboxyl group containing compound, crosslinking agent O is acryloyl group containing compound, and mole ratio of amount of the three groups is 50-90 to 40-5 to 10-5. Degree of polymerization Z is 10-500. The method of preparing the microgel under condition of adding no emulsifier includes: employing specific dropping technique and nonsoap emulsion polymerization method, composing reactant water solution by M, N, O and water solvent according proportion, timed adding the reactant water solution to initiator water solution drop by drop, after ruleless copolymerizing and purifying, obtaining the double sensitive nano microgel with equal particle diameter of 40-300 nm and high stability. The microgel is easy to store, convenient for use and widely be used for medicament carrier and coating field. Advantages of the preparing method are: range of applicability is wide, technique is simple, and preparation can be large-scale production.

Owner:DONGHUA UNIV

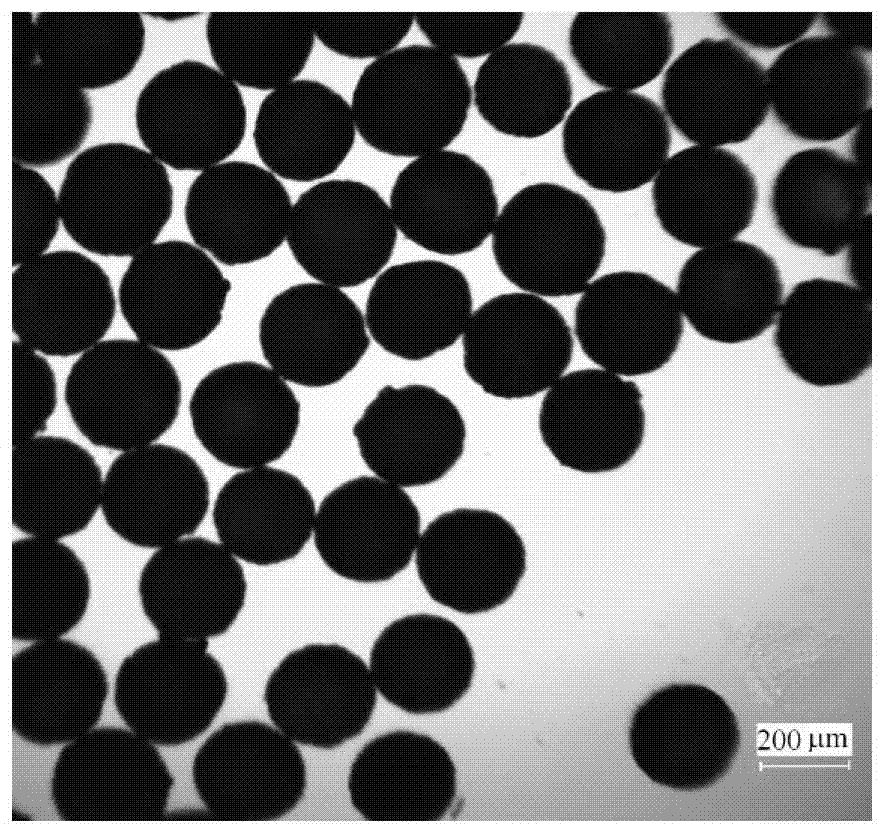

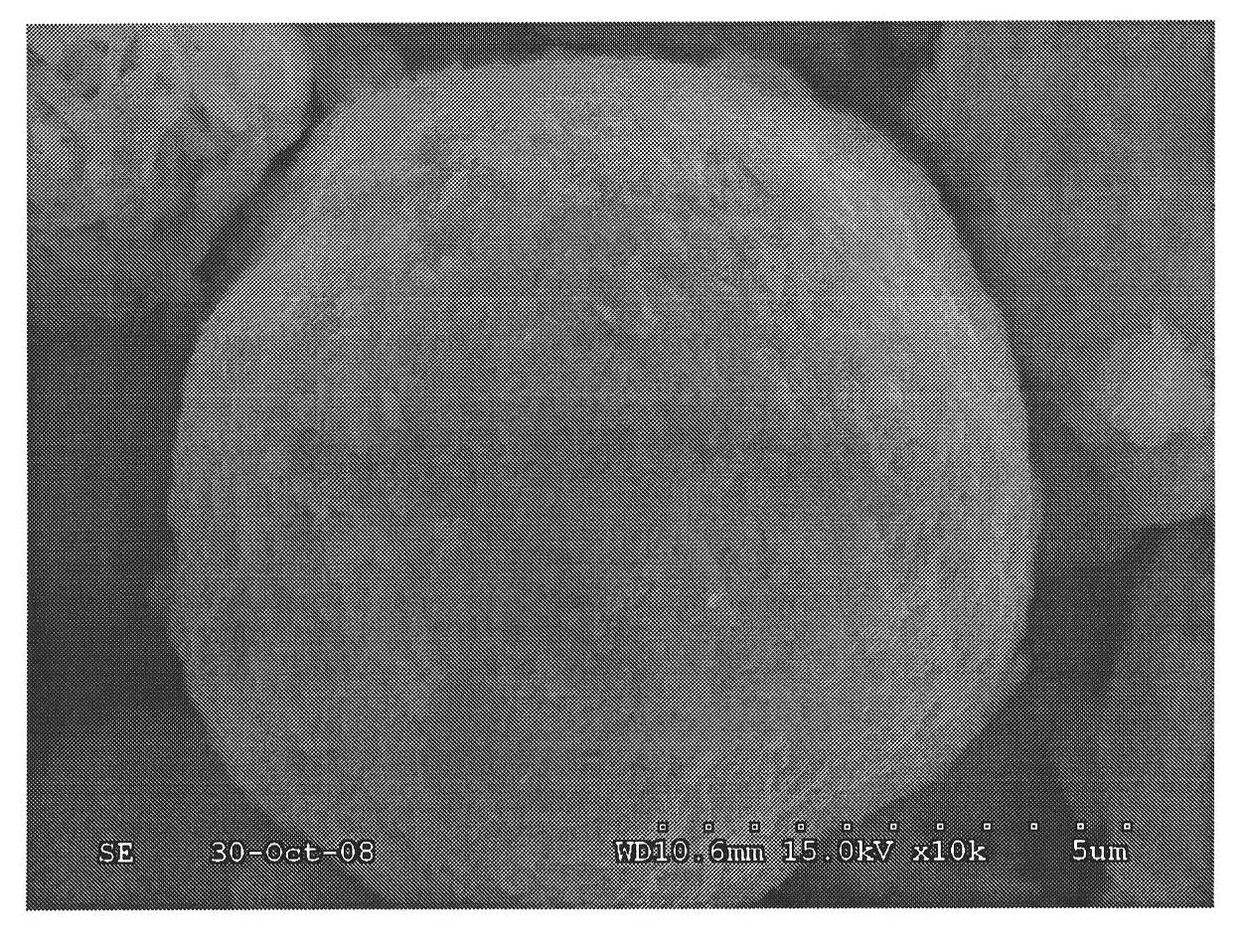

Grain size controllable monodisperse polyvinyl alcohol gel microsphere, preparation method thereof and applied device

InactiveCN102895927AImprove surface morphologySmall sizeMicroballoon preparationMicrocapsule preparationMicrospherePolyvinyl alcohol

The invention relates to a preparation method for a grain size controllable monodisperse polyvinyl alcohol gel microsphere. The preparation method comprises the following steps: preparing a disperse phase solution and a continuous phase solution; controlling the flowing speed, flow and viscosity of the disperse phase and the continuous phase; obtaining polyvinyl alcohol solution drops in different grain sizes and in uniform diameter size after converging the disperse phase with the continuous phase; and solidifying the drops, thereby obtaining the grain size controllable monodisperse polyvinyl alcohol gel microspheres. The invention also relates to a preparation device for the grain size controllable monodisperse polyvinyl alcohol gel microsphere and the prepared monodisperse polyvinyl alcohol gel microsphere. The microsphere prepared according to the invention has a better surface morphology and a grain size range of 50-600 microns. The preparation device is convenient to assemble and disassemble; the size controllable preparation for a monodisperse polyacrylamide microsphere is realized by changing the size of a capillary tube or controlling the flowing speed or viscosity of the disperse phase and the continuous phase; and the grain size distribution coefficient CV is less than 5%.

Owner:UNIV OF SCI & TECH OF CHINA

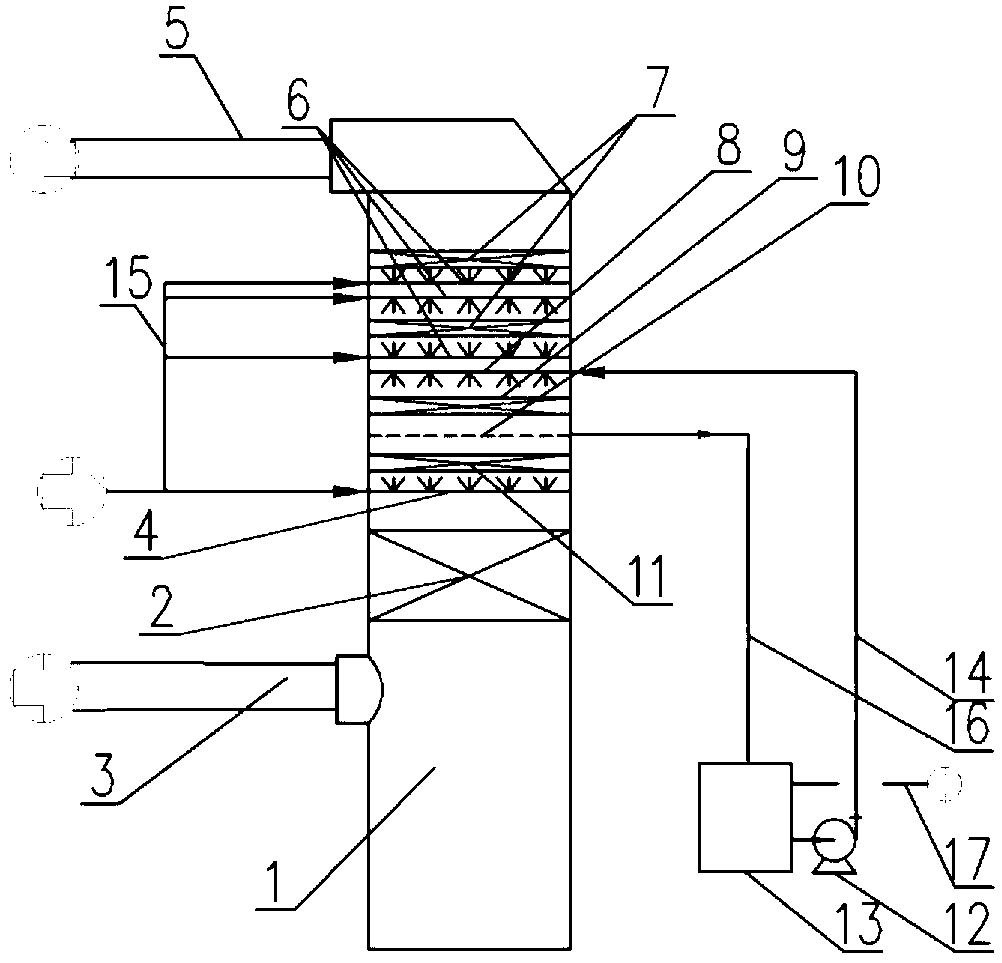

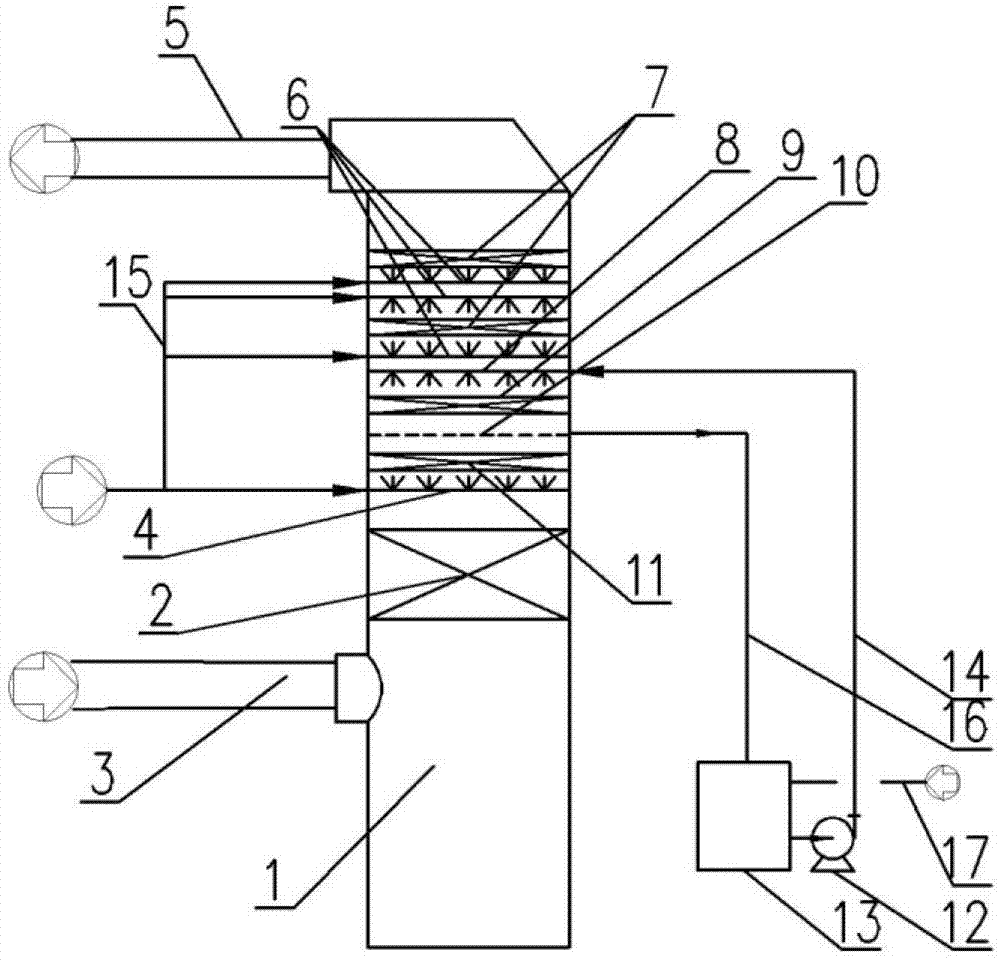

Device and method for controlling fine particulate matter from desulfurized smoke

The invention discloses a device and a method for controlling a fine particulate matter from desulfurized smoke. A raw gas enters an absorption layer (2) from a smoke flue (3) of an absorption tower (1) for desulfurizing smoke; sulfur dioxide in the smoke is absorbed and removed by absorption solution; the smoke with the matters such as absorption solution drops, snoot and an adsorbent ascends inside the absorption tower to enter an absorption solution demister (11) through an absorption solution demister rinsing layer (4); most of liquid drops of which the particle sizes are greater than 10 microns are removed; the smoke enters a washing layer and a gas-liquid distributor (9) and contacts washing solution sprayed from a washing layer distributer (8) through a washing layer partition plate (10); the smoke enters a washing demister (7) to remove liquid drops of which the particle sizes are greater than 10 microns after being washed by a washing demister rinsing layer (6); purified smoke is discharged from a smoke purifying channel (5) at the upper part of a smoke desulfurizing absorption tower after twice rinsing and demisting are orderly carried out. The device is matched with a desulfurizing absorption system. Thus, the device is less in investment and convenient to run.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

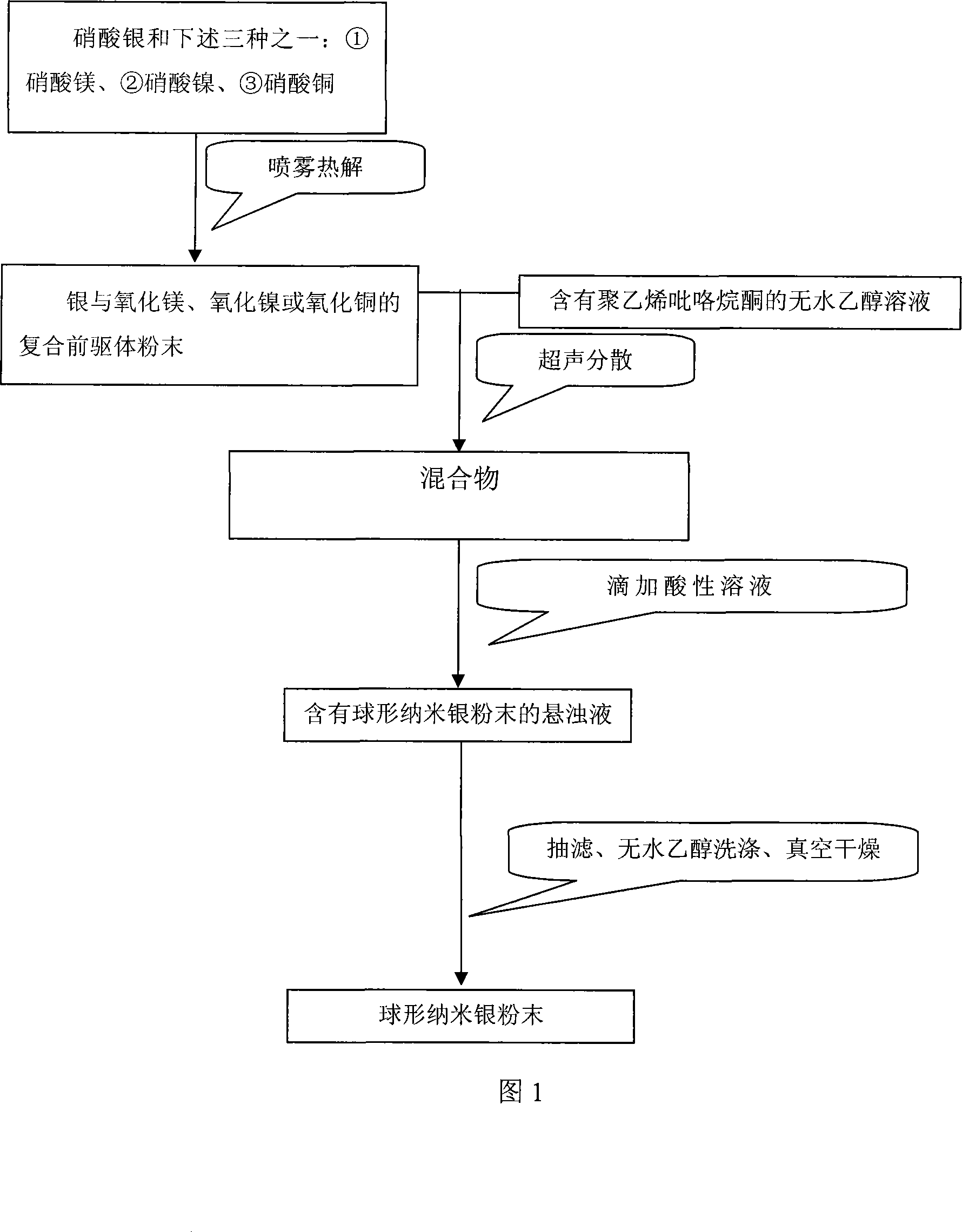

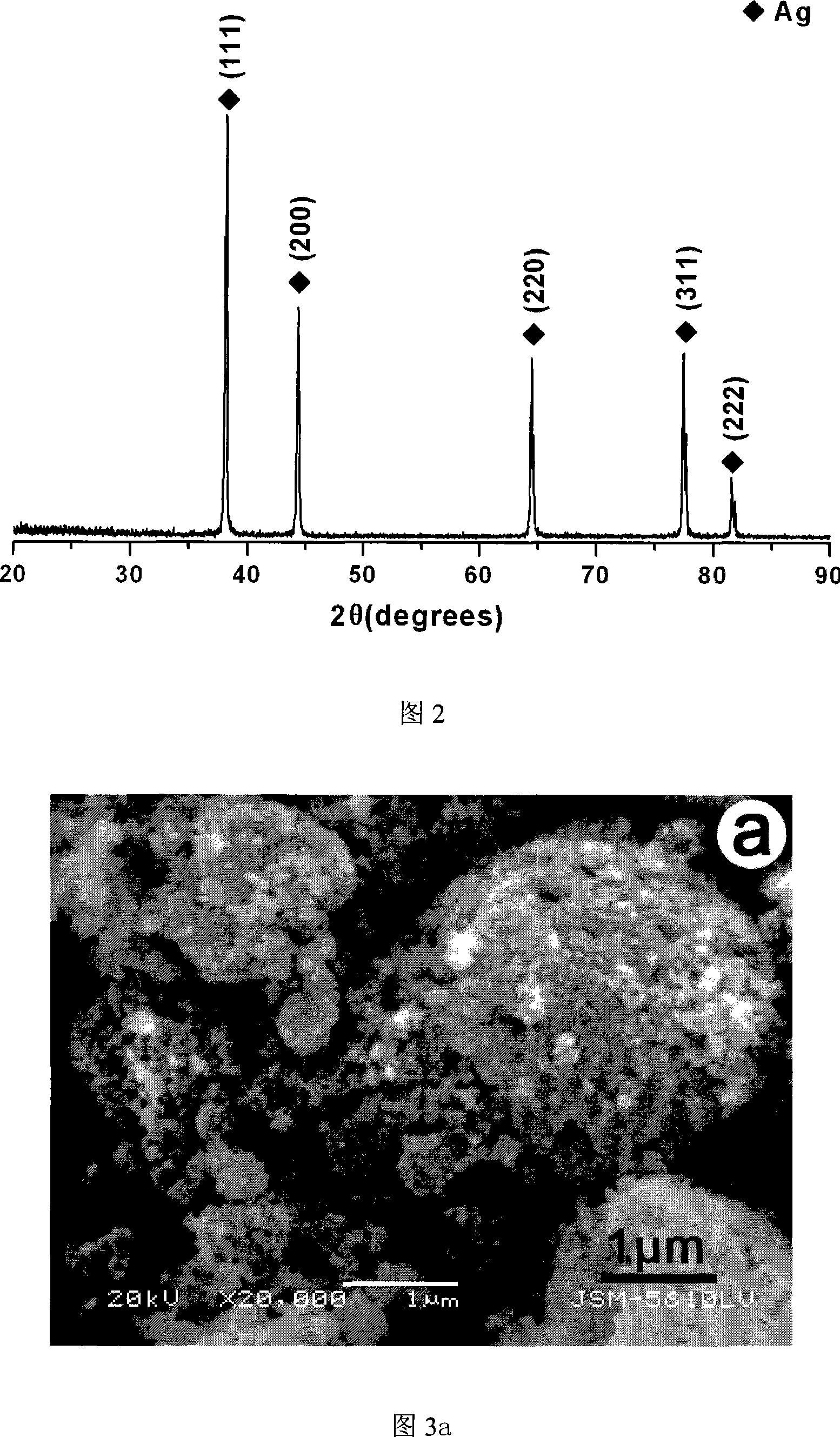

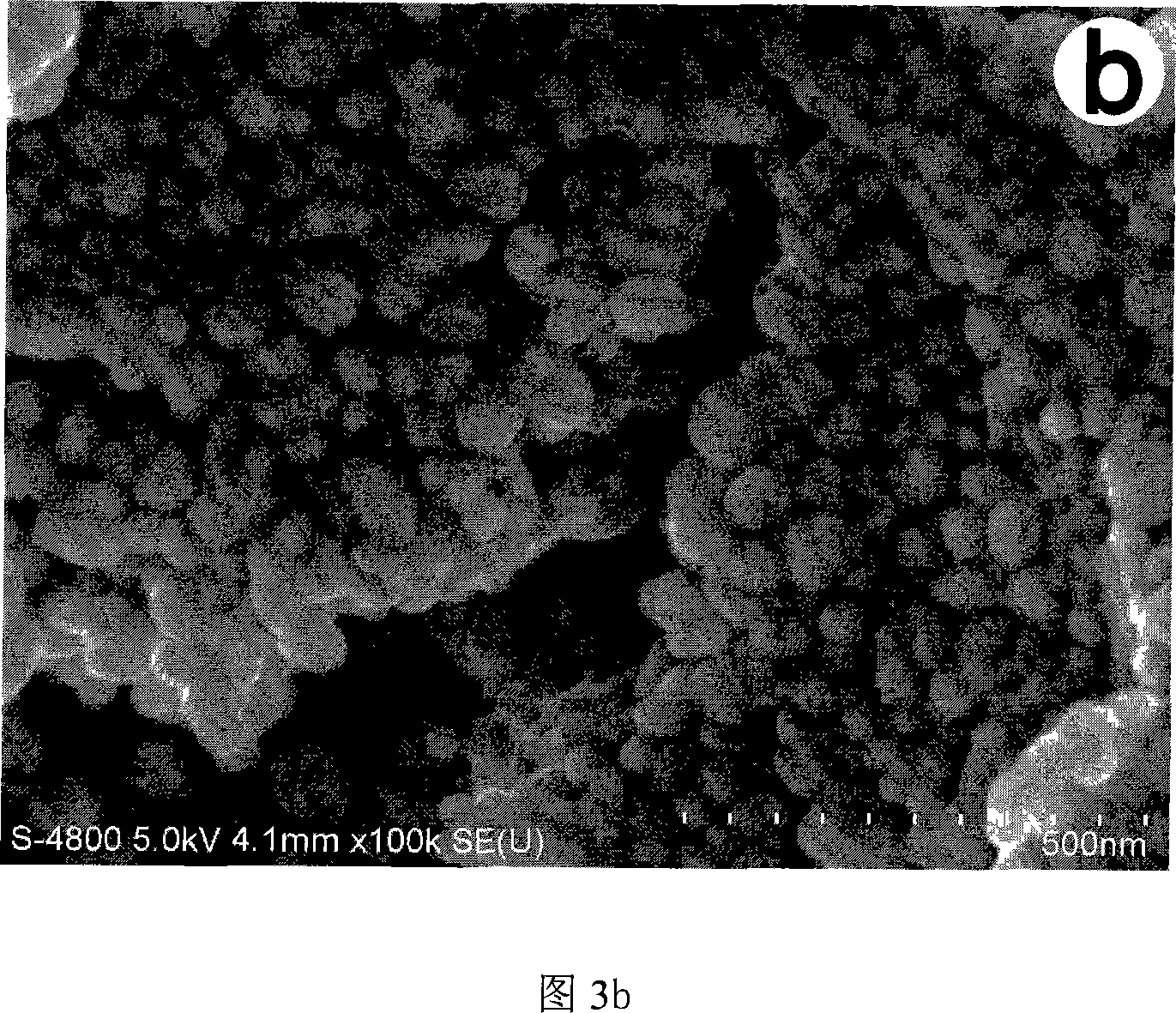

Method for preparing spherical nano silver powder

The invention relates to a method for preparing a spherical nanometer sliver powder. A method for preparing a spherical nanometer sliver powder is characterized in that the invention includes the following steps: 1) spraying and pyrolyzing: a, dissolving silver nitrate with one of the three: {1}magnesium nitrate, {2}nickel nitrate, {3}copper nitrate into water to prepare into a water liquor with a consistency of 10 to 40wt percent; the mol ratio of magnesium ion, nickel ion or copper ion in the liquor is 0.05 to 1 :4; then spraying for pyrogenation; b, under the existence of a dispersant and protecting agent, adding into a non-water ethanol to disperse to acquire a mixture; 2) preparing the spherical nanometer sliver powder: a, dripping acid liquor into the mixture and adjusting a PH value between 3 to 5 to acquire a suspension containing the spherical nanometer sliver powder; b, pumping filtration, washing and drying to acquire the spherical nanometer sliver powder. The preparing method is simple and easy to be controlled, has no pollution and low cost, is suitable for industrialization scale production. The prepared spherical nanometer sliver powder belongs to the nanometer grade and the powder has uniform distribution of the grain diameter, regular shape and high yield.

Owner:WUHAN UNIV OF TECH

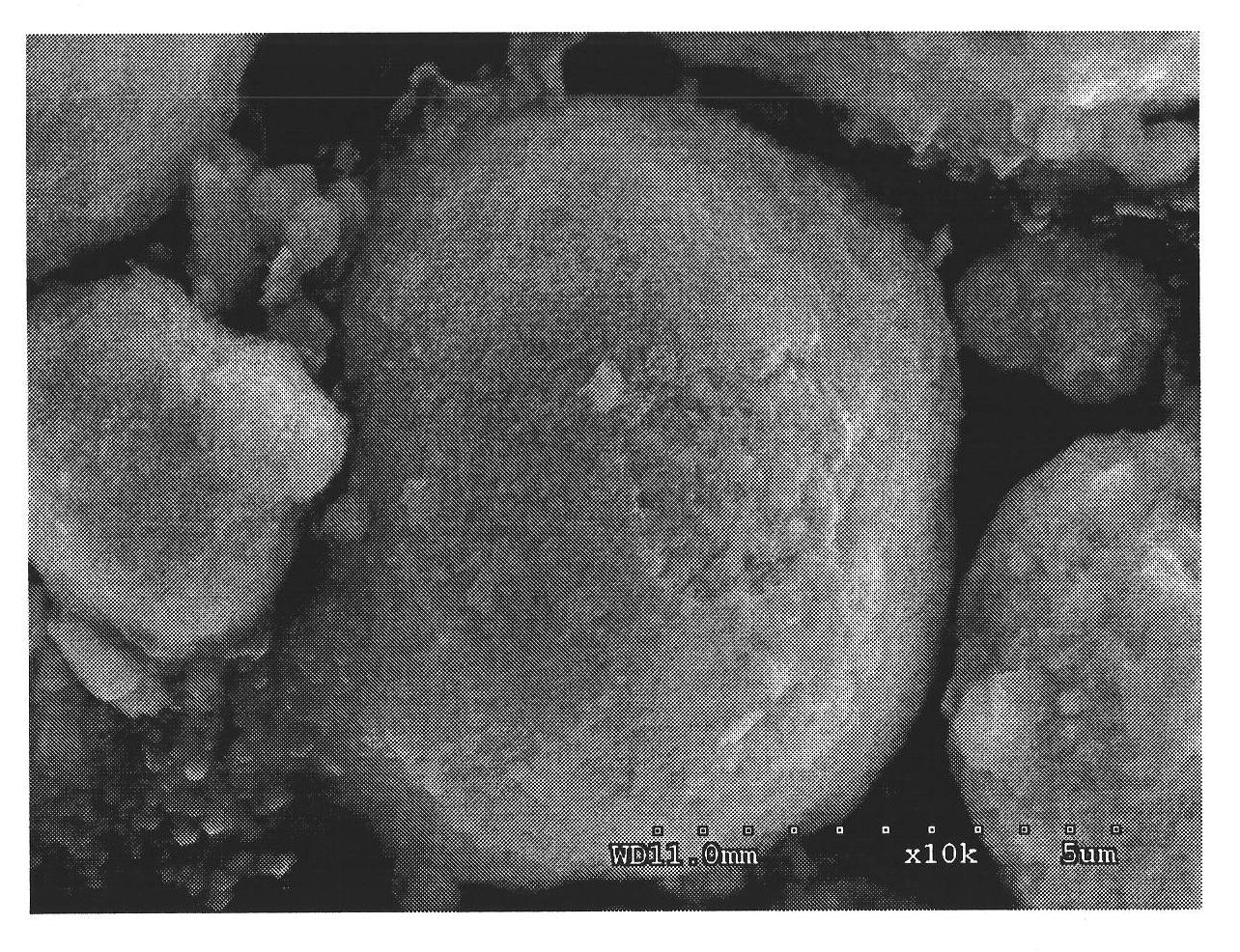

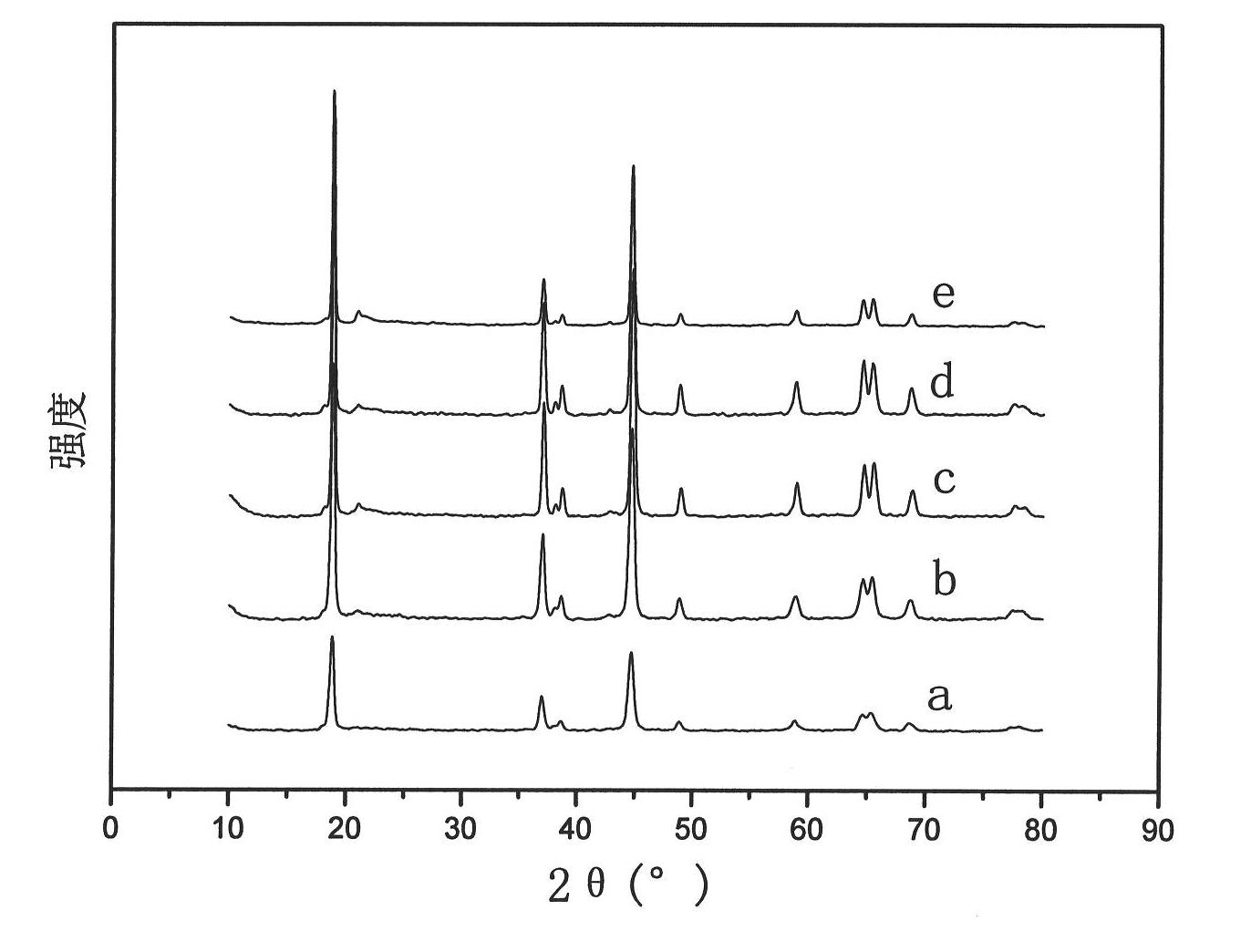

Method for synthesizing spherical gradient lithium-rich anode material

The invention discloses a method for synthesizing a spherical gradient lithium-rich anode material, which comprises the following steps of: adding deionized water into MnSO4 and [Ni0.4Co0.2Mn0.4](OH)2 in a molar ratio of x:1-x to form suspension, and dripping 0.025 to 0.1mol / L NaCO3 solution into the suspension in a 60 DEG C water bath to form a compact manganese carbonate precipitate layer; filtering, washing, and drying at the temperature of between 80 and 120 DEG C; and uniformly mixing precursor particles and lithium hydroxide in a molar ratio of 1:1.15-1.45, performing heat treatment in air at the temperature of between 400 and 500 DEG C for 3 to 5 hours, raising the temperature for 22 to 32 hours, and sintering at the temperature of between 750 and 900 DEG C for 12 to 15 hours. The material synthesized by the method has certain Mn concentration gradient, improves the tap density of lithium-rich materials, has high cyclical stability and specific capacity, and keeps high rate performance.

Owner:BEIJING UNIV OF TECH

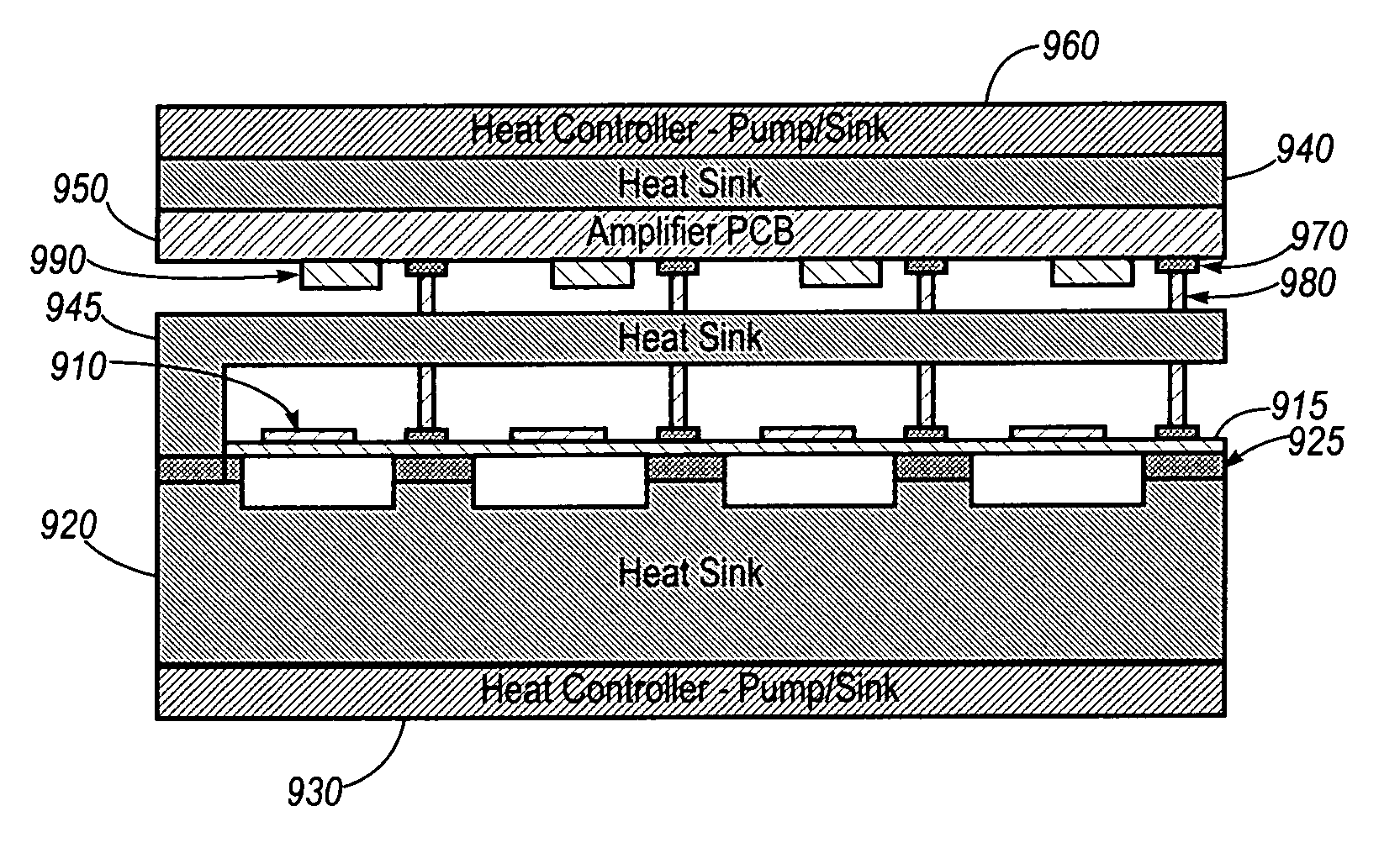

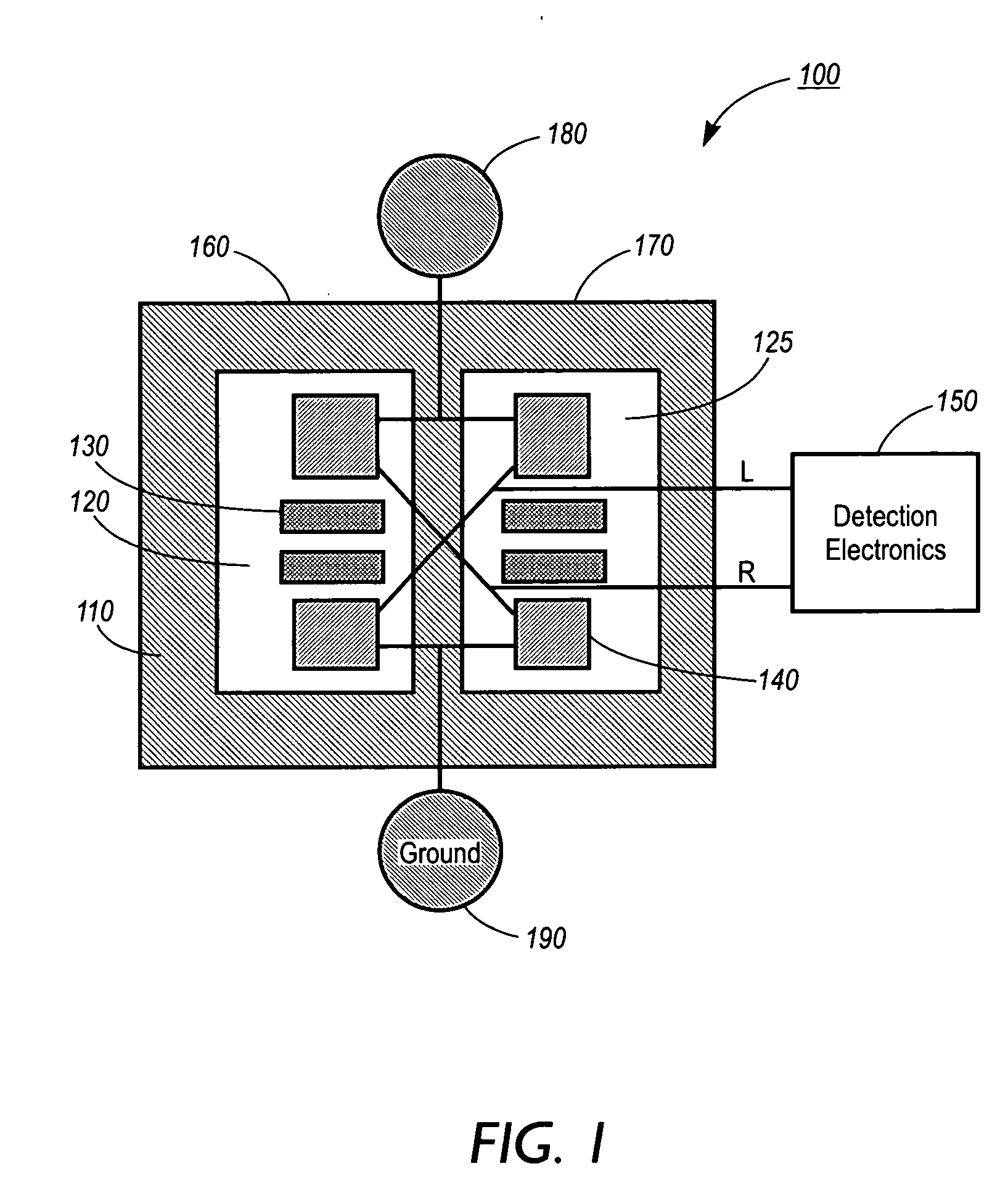

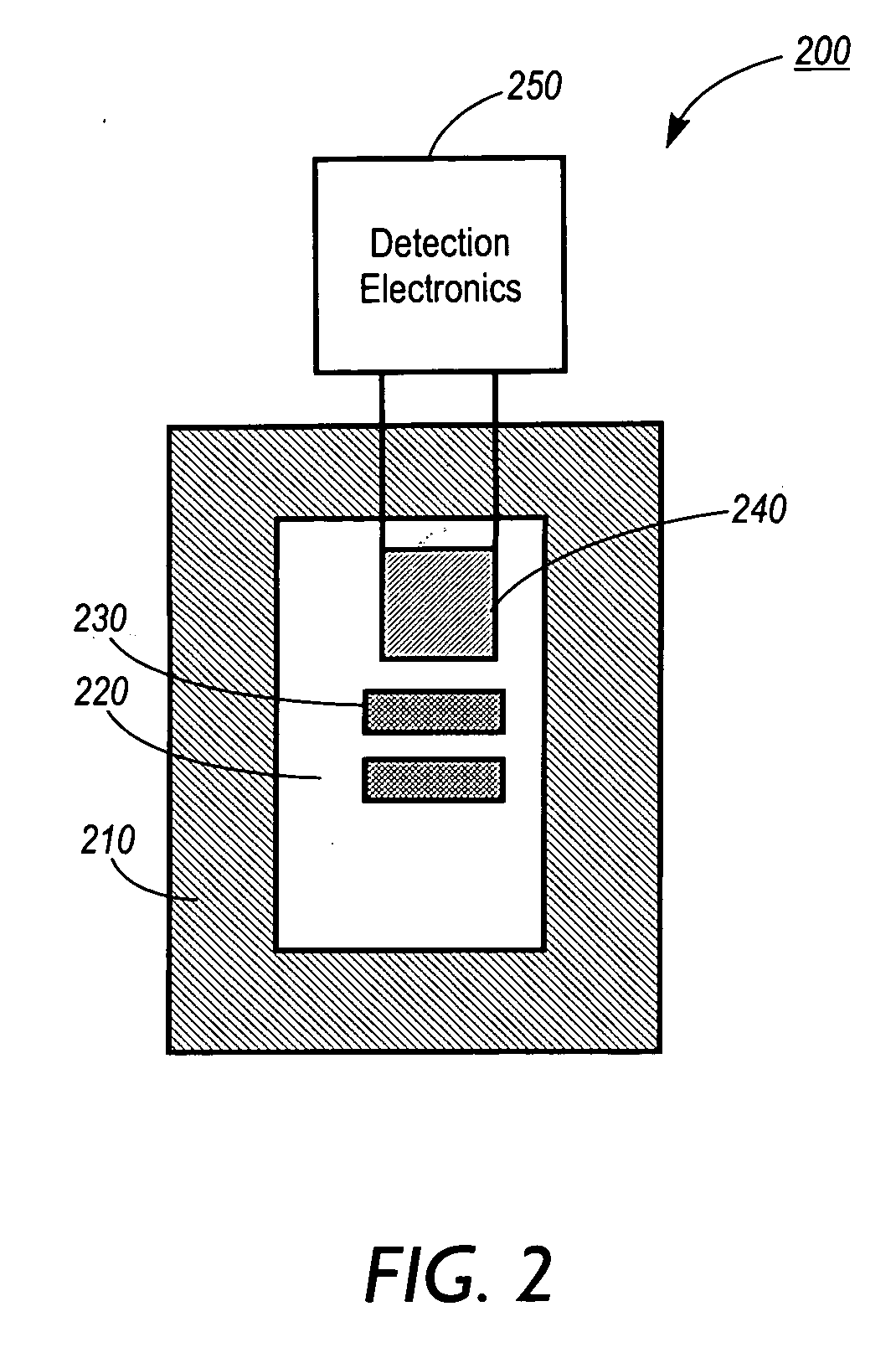

Apparatus and method for a nanocalorimeter for detecting chemical reactions

InactiveUS20060078999A1Easy to solveSimple methodChemical analysis using titrationMaterial heat developmentThermal isolationMeasurement device

A method for detecting chemical reactions uses a nanocalorimeter having a substrate including thermal isolation capability residing on the substrate, thermal equilibration regions residing within the thermal isolation capability, and thermal measurement capability residing within each of the thermal equilibration regions. The thermal measurement device is connected to detection electronics. The method includes depositing drops of potentially reactive chemical solutions within the thermal equilibration region. These potentially reactive solution drops are merged through the use of drop merging electrodes residing within the thermal isolation region. The thermal change occurring within the merged solution drops is then measured with the detection electronics.

Owner:PALO ALTO RES CENT INC

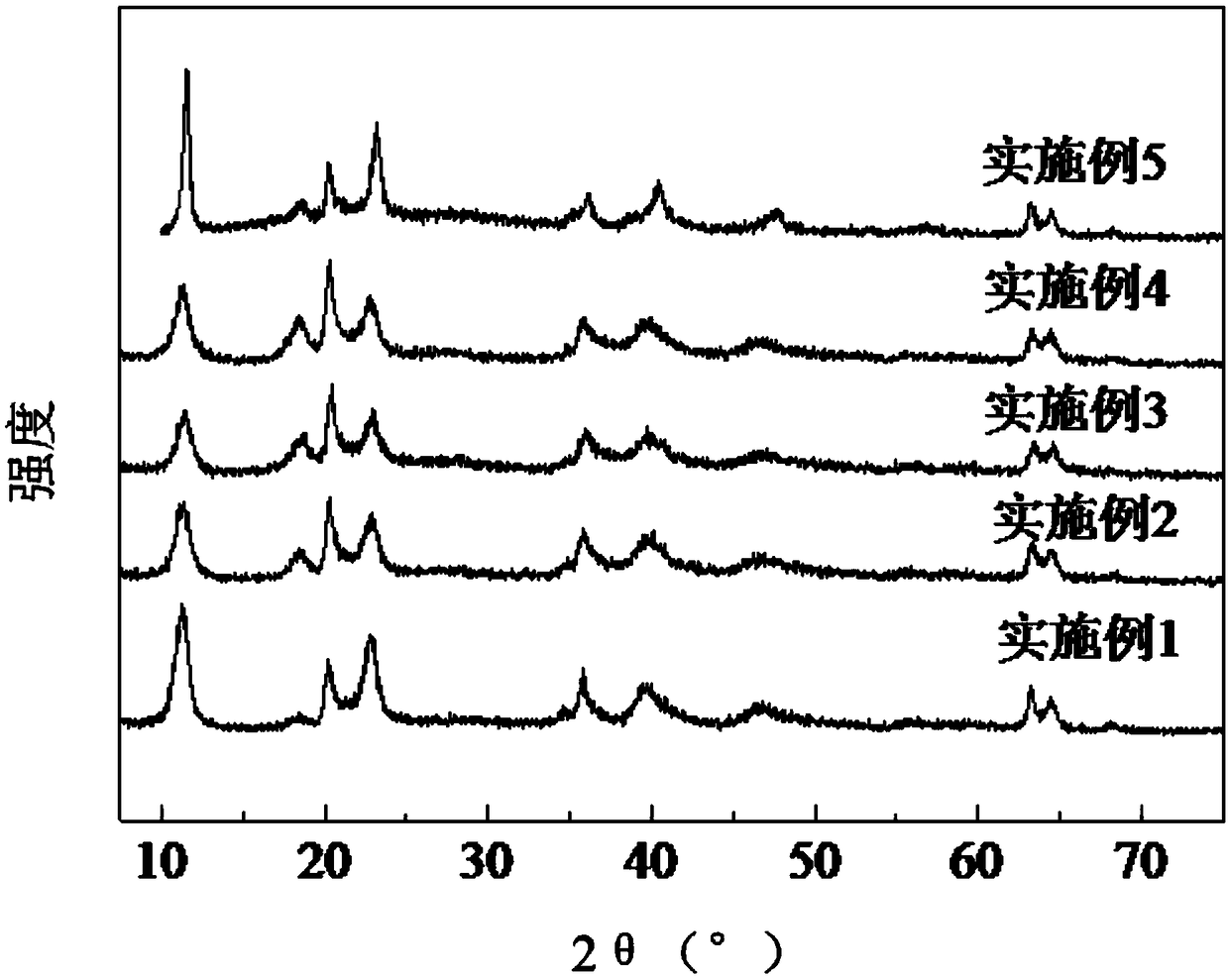

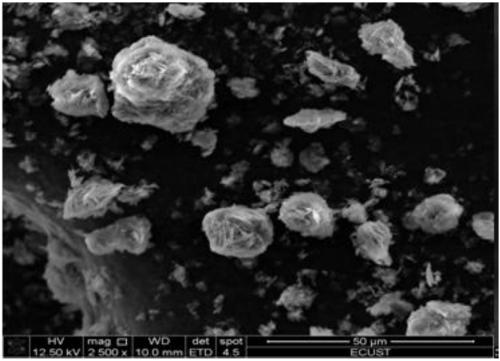

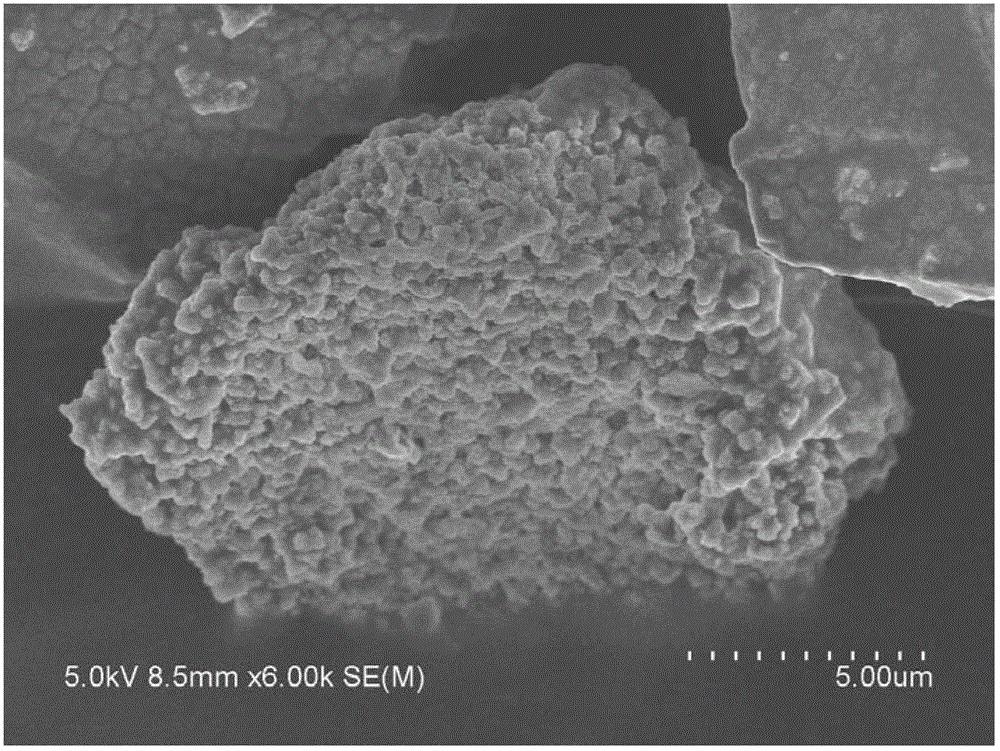

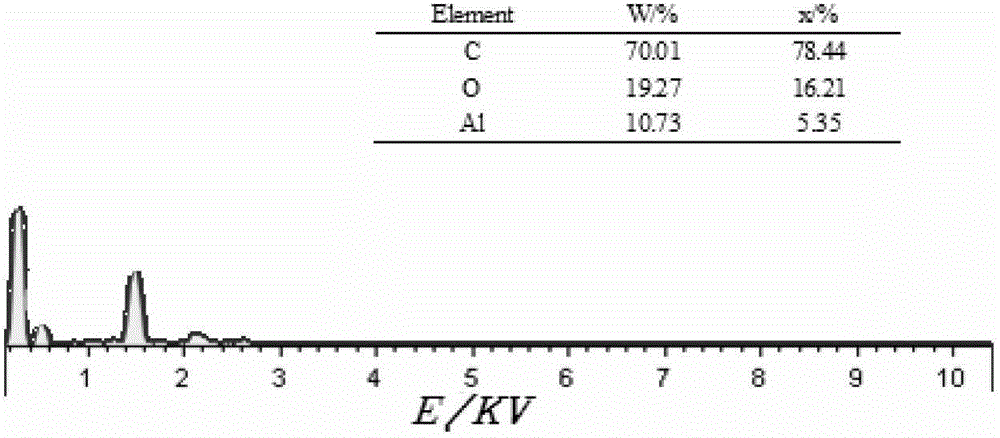

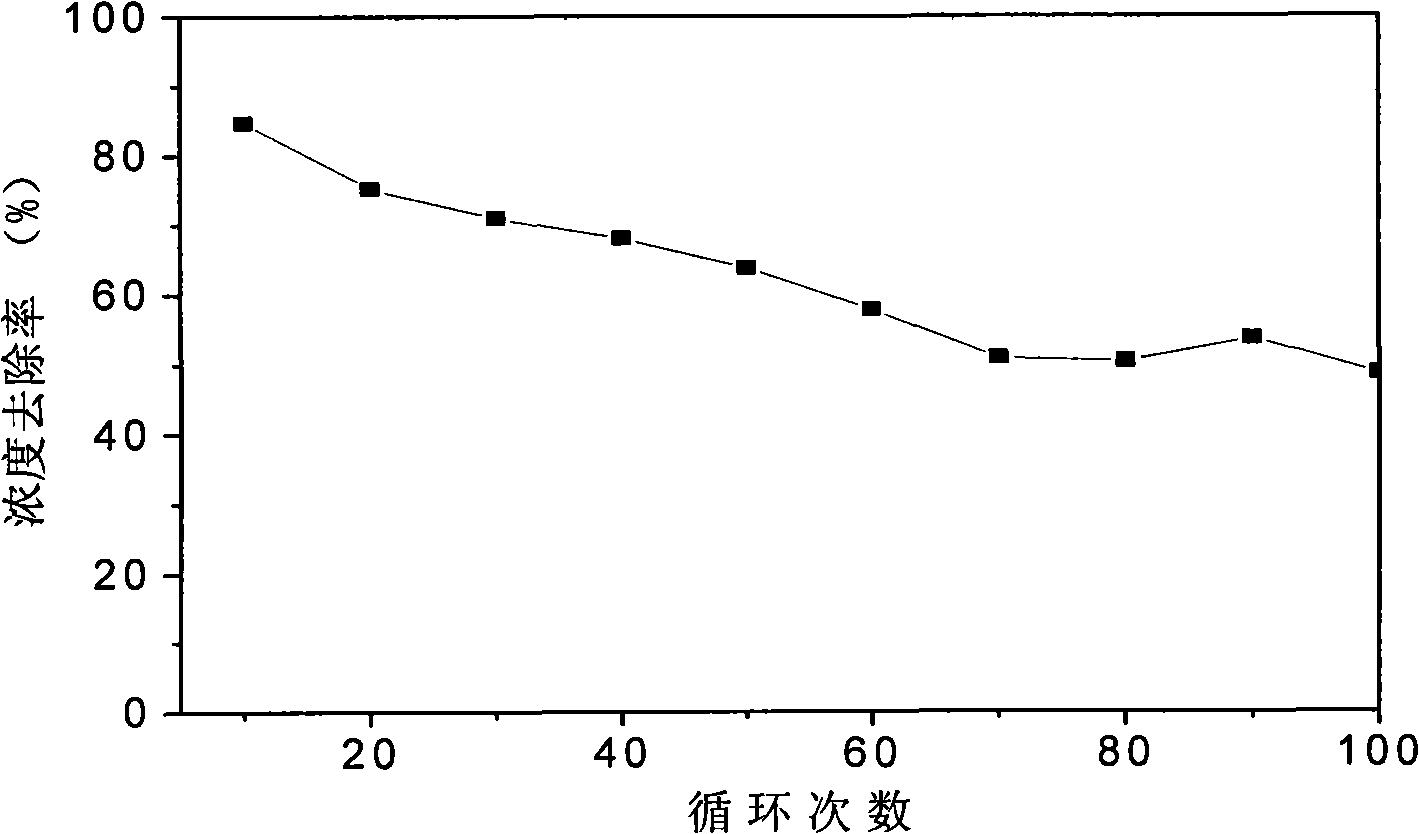

Aluminum salt lithium adsorbent, and preparation method and application thereof

The invention discloses an aluminum salt lithium adsorbent with the molecular formula of LiCl.aAl(OH)3.nH2O, wherein a is 2-5 and n is 0.5-10. The invention also discloses a preparation method of thealuminum salt lithium adsorbent, wherein the preparation method comprises the following steps: mixing an aluminum salt and a lithium salt, then dissolving into deionized water, fully mixing evenly with ultrasound, and then dropwise adding the mixed solution into an alkali solution, or dropwise adding an alkali solution into the mixed solution, or dropwise adding the mixed solution and an alkali solution into a reaction kettle in a manner of parallel flow; and controlling the pH, aging, carrying out hydrothermal reaction, filtering, washing, vacuum-drying, washing with water, and drying to obtain the aluminum salt lithium adsorbent. The invention also discloses an application of the aluminum salt lithium adsorbent in adsorbing lithium in a lithium-containing solution. The prepared aluminumsalt lithium adsorbent has the advantages of stable property, large adsorption capacity, good repeatability and high selectivity.

Owner:EAST CHINA UNIV OF SCI & TECH

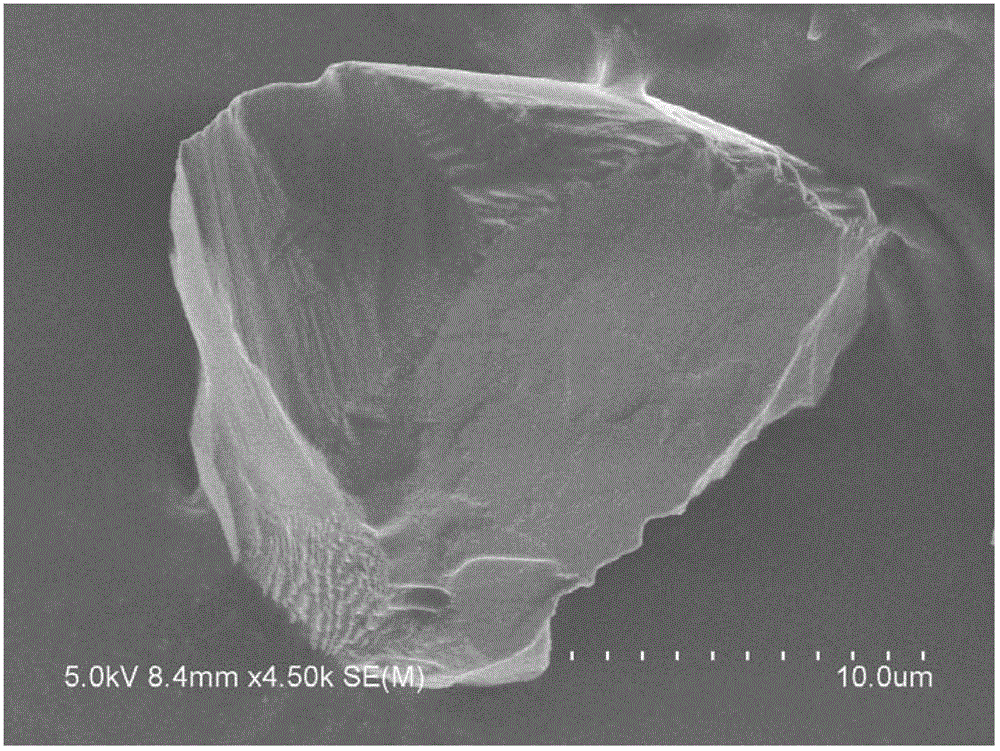

Composite abrasive grain in grain/alumina core-shell structure and preparation method and application of composite abrasive grain

ActiveCN102719220AGood dispersionImprove distribution uniformityOther chemical processesHydrogenCarbide

The invention discloses a composite abrasive grain in a grain / alumina core-shell structure and a preparation method and the application of the composite abrasive grain. An inner core of the composite abrasive grain is selected from diamond, carbide and the like serving as abrasive grains, and an outer shell of the composite abrasive grain is an alumina-coated layer. The preparation method includes: firstly, adding pretreated powder into buffer solution of a certain pH (potential of hydrogen) value, ultrasonically dispersing for 1h, and heating to 50-80 DEG C; secondly, preparing a coating precursor into 0.05-0.4mol / L solution, dripping the solution drop by drop into the buffer solution, violently stirring and keeping the pH value constant; and finally, separating reactants, drying for 24h at 120 DEG C, and performing heat treatment at 300-550 DEG C for more than one hour to obtain the composite abrasive grain in the grain / alumina core-shell structure. Holding power of an abrasive tool base to abrasive grains can be improved to effectively solve the problem of shedding of the abrasive grains, utilization rate of the abrasive grains is increased, the service life of an abrasive tool is prolonged, and uniformity in distribution of the abrasive grains can be remarkably improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Raman probe used for detection of mercury ions and preparation method thereof

InactiveCN103398998ASimple preparation processShort preparation timeRaman scatteringNanoparticlePhytic acid

The invention especially relates to a Raman probe using a gold nanosol as a substrate for detection of mercury ions and a preparation method thereof, which belongs to the technical field of Raman spectrum detection. The preparation method comprises the following steps: adding secondary deionized water into a nano-silver dispersion liquid with phytic acid micelle as a protective agent, carrying out stirring, heating to a temperature of 40 to 60 DEG C, adding a perchloroauric acid solution drop by drop, carrying out stirring for 10 to 20 min, then adding trisodium citrate drop by drop and carrying out stirring for 10 to 20 min and cooling so as to prepare the gold nanosol; and adding crystal violet into the prepared gold nanosol and carrying out uniform mixing. The preparation method for the Raman probe is simple and convenient and needs short preparation time. A gold nanoparticle in the Raman probe has good stability; and the Raman probe has the advantages of capacity of rapid detection of mercury, high sensitivity, good selectivity and a mercury ion detection limit of 0.5*10<-12> mol / L.

Owner:SHANGHAI NORMAL UNIVERSITY

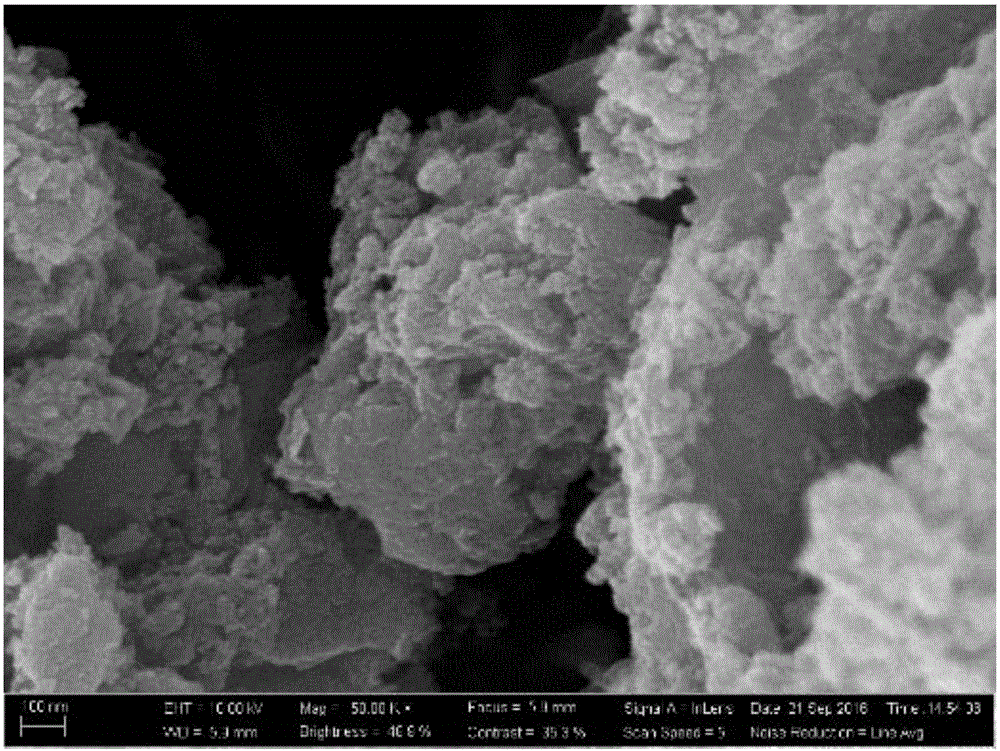

Preparation method of Mn<4+> doped fluoride fluorescent powder material and method for surface modification of Mn<4+> doped fluoride fluorescent powder material

InactiveCN105038776AImprove moisture resistanceLuminescent compositionsHydrofluoric acidHigh humidity

The invention relates to a preparation method of a Mn<4+> doped fluoride fluorescent powder material and a method for the surface modification of the Mn<4+> doped fluoride fluorescent powder material, and belongs to the field of preparation of LED fluorescent powder. The preparation method comprises the following steps: firstly, preparing A2MnF6; then, dropwise adding a second solution, obtained through dissolving fluoride or hydrofluoride of A into a hydrofluoric acid solution, into a first solution containing an HF solution, A2MnF6 and fluoride of a quadrivalent element M, and performing solid-liquid separation, so as to obtain a solid precipitation product generated after reaction. The fluorescent powder prepared by the method is small in particle size and excellent in luminous performance. The invention further provides a method for the surface modification of the Mn<4+> doped fluoride fluorescent powder particles. The surfaces of the prepared A2[MF6]:Mn<4+> fluoride red fluorescent powder particles are coated with an inorganic or organic functional material through a monoatomic deposition technology, a chemical precipitation reaction method and a surface chemical coating modification method, so that the stability of the prepared A2[MF6]:Mn<4+> fluoride red fluorescent powder particles in high-temperature and high-humidity environments is remarkably improved.

Owner:BEIJING YUJI SCI & TECH

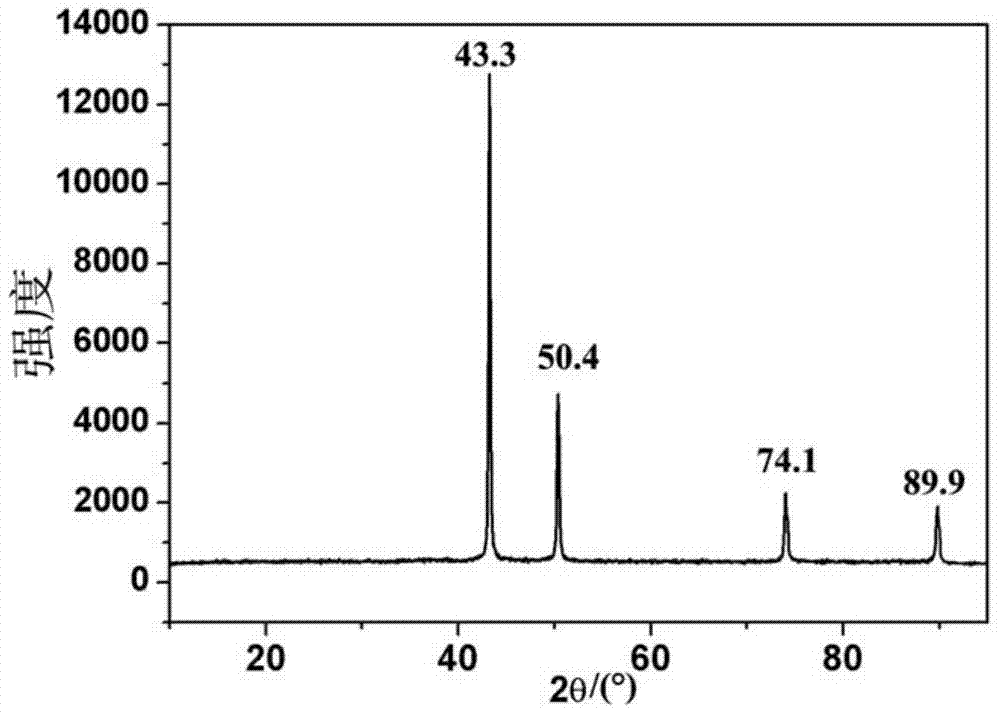

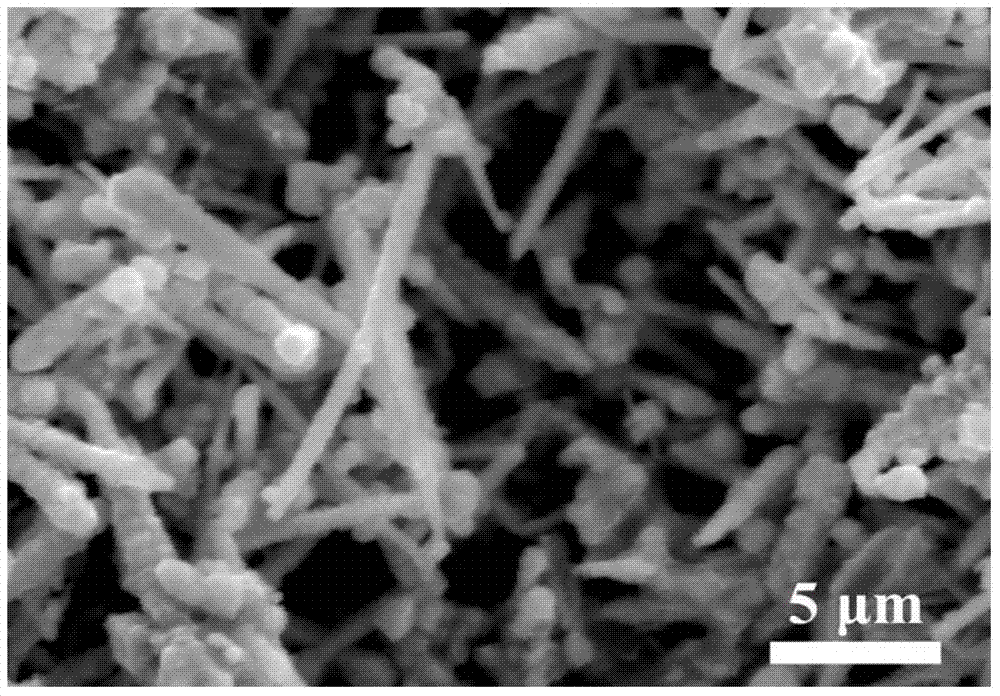

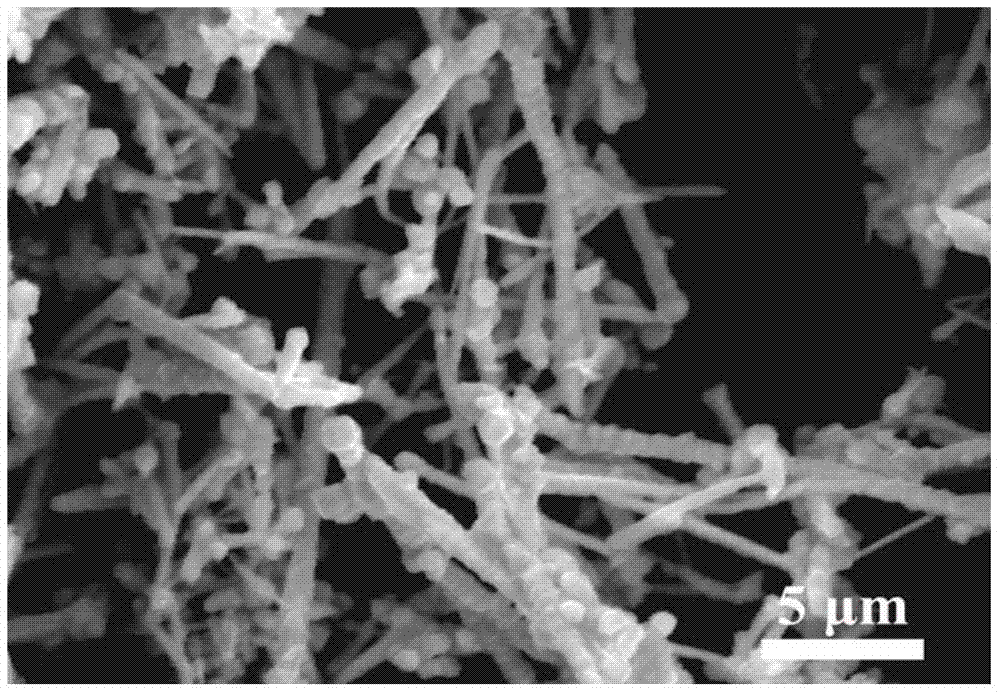

Copper nanowire and preparation method thereof

ActiveCN103658675AMeet savingsMeets requirementsMaterial nanotechnologyDispersityReaction temperature

The invention discloses a copper nanowire and a preparation method of the copper nanowire. The method comprises the steps that (1) a copper salt solution is added into an alkali solution, the two solutions are mixed, and the concentration of copper ions in the mixed solution ranges from 1*10<-7>mol / L to 1*10<-5>mol / L; (2) a mixed solution of a reducing agent and a dispersing agent is prepared and added into the mixed solution obtained in the step (1); (3) the copper salt solution is dropwise added into the solution obtained in the step (2) under the conditions of magnetic stirring or ultrasonic dispersing, and reaction is conducted for 0.5-6 hours at the temperature of 40-90 DEG C; (4) products obtained in the step (3) are centrifugally separated and washed, and then the copper nanowire is obtained. The copper nanowire obtained based on the preparation method has the good dispersity and inoxidizability, the particle sizes of the obtained products are uniform, the length of the prepared copper nanowire ranges from 3 micrometers to 15 micrometers, the diameter of the prepared copper nanowire ranges from 20nm to 100nm, and the maximum square resistance value can reach 10.1 ohm per square.

Owner:GUANGDONG TONESET SCI & TECH

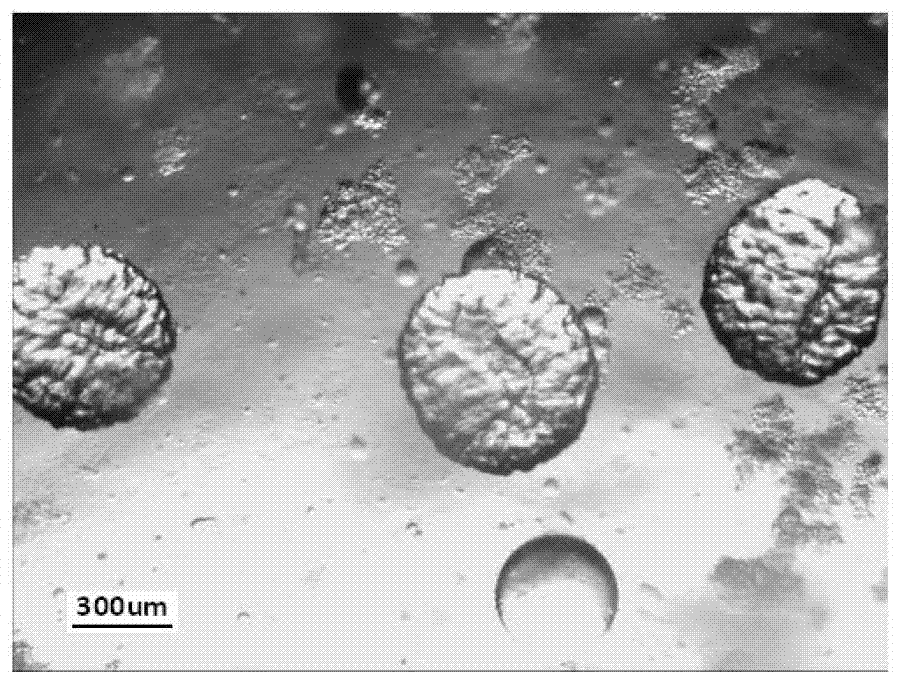

Preparation method of microsphere particles capable of slowly releasing nitrogen and adsorbing-biologically degrading petroleum hydrocarbon

InactiveCN102963959AImprove processing efficiencyCause secondary pollutionFatty/oily/floating substances removal devicesLiquid separationPolyvinyl alcoholMicrosphere

The invention discloses a preparation method of microsphere particles capable of slowly releasing nitrogen and adsorbing-biologically degrading petroleum hydrocarbon. The method comprises the following steps of: weighing a urea aqueous solution and a formaldehyde aqueous solution at a ratio of 6.5:1, and adjusting the pH value of the urea aqueous solution to 7.2-7.4; adding formaldehyde into the urea aqueous solution, stirring for 90-100 minutes, adjusting the pH value to 3.2-3.4, and adding deionized water to obtain mixed liquid M1; mixing the chloroform solutions of poly(beta)hydroxybutyrate and polyethylene glycol at a ratio of 5:1; dropwise adding M1 into the chloroform mixed liquid at a ratio of 1:4; dropwise adding the mixed liquid into a polyvinyl alcohol solution with mass fraction of 3.5% at a ratio of 1:1; dropwise adding a polyvinyl alcohol solution with mass fraction of 0.5% into the mixed liquid at a ratio of 2:1, stirring for 7-8 hours, separating, and freeze-drying to obtain microsphere particles; and culturing the microsphere particles in a petroleum hydrocarbon degrading bacterium culture solution for 24 hours, taking out and air-drying. Through the invention, the preparation technology is simple, the efficiency of the prepared microsphere particles for treating petroleum hydrocarbon pollutants is high, and secondary pollution and damage to the water body are avoided.

Owner:BEIJING NORMAL UNIVERSITY

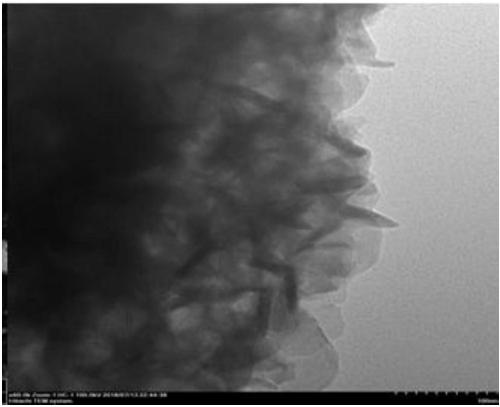

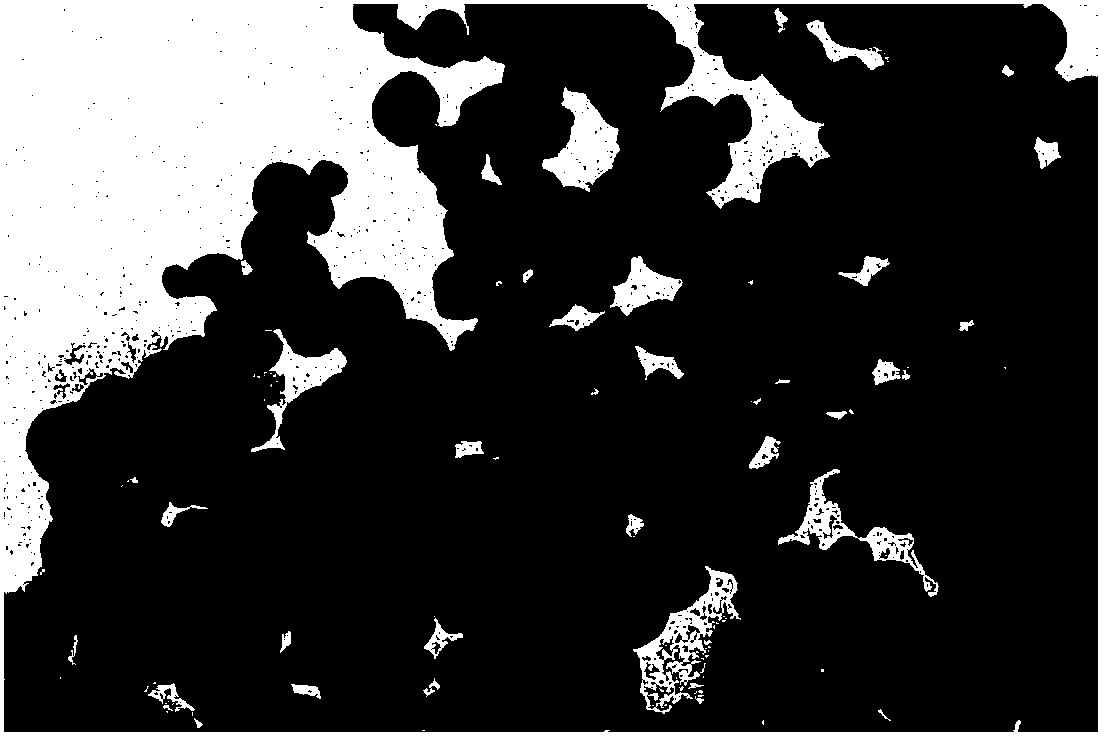

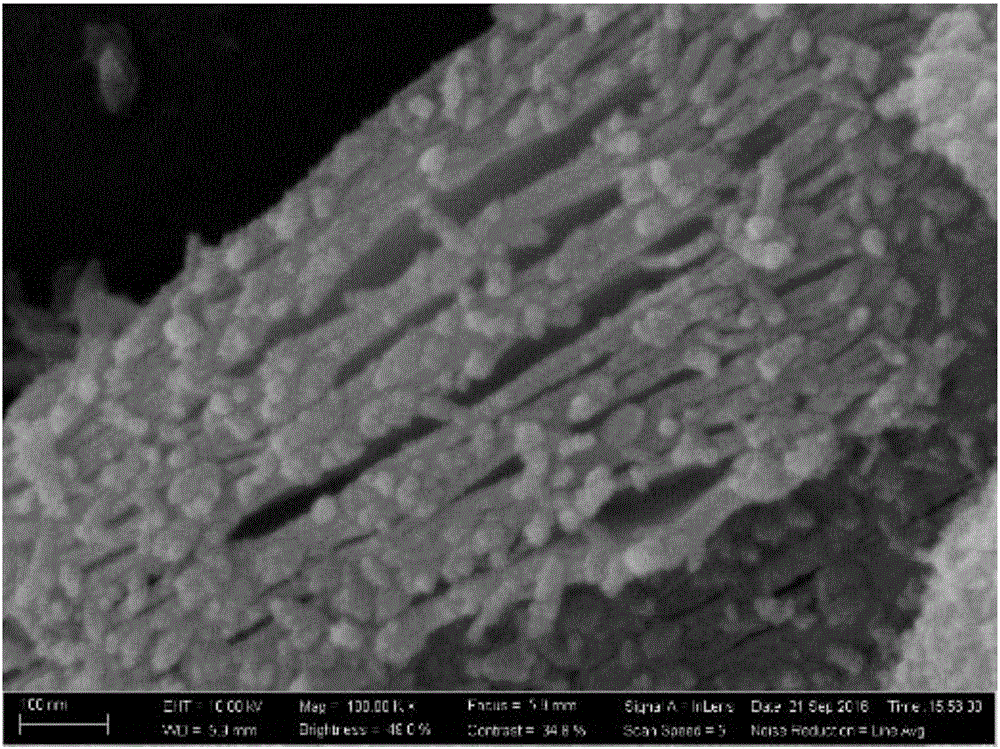

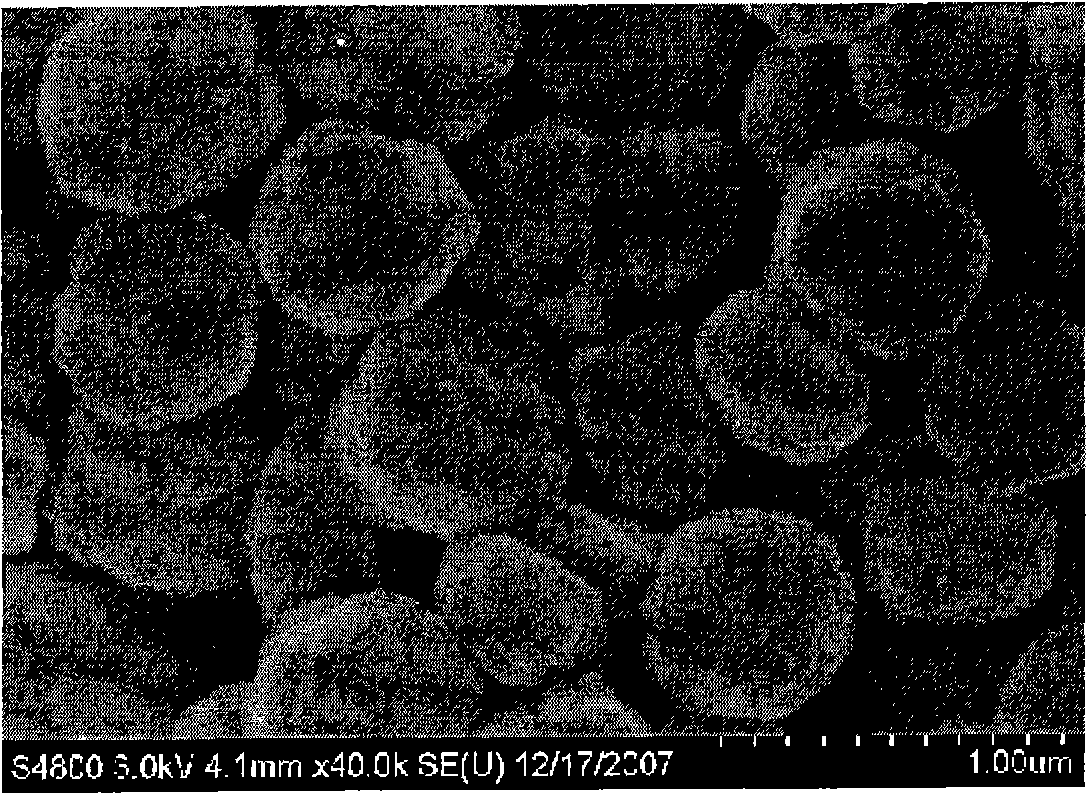

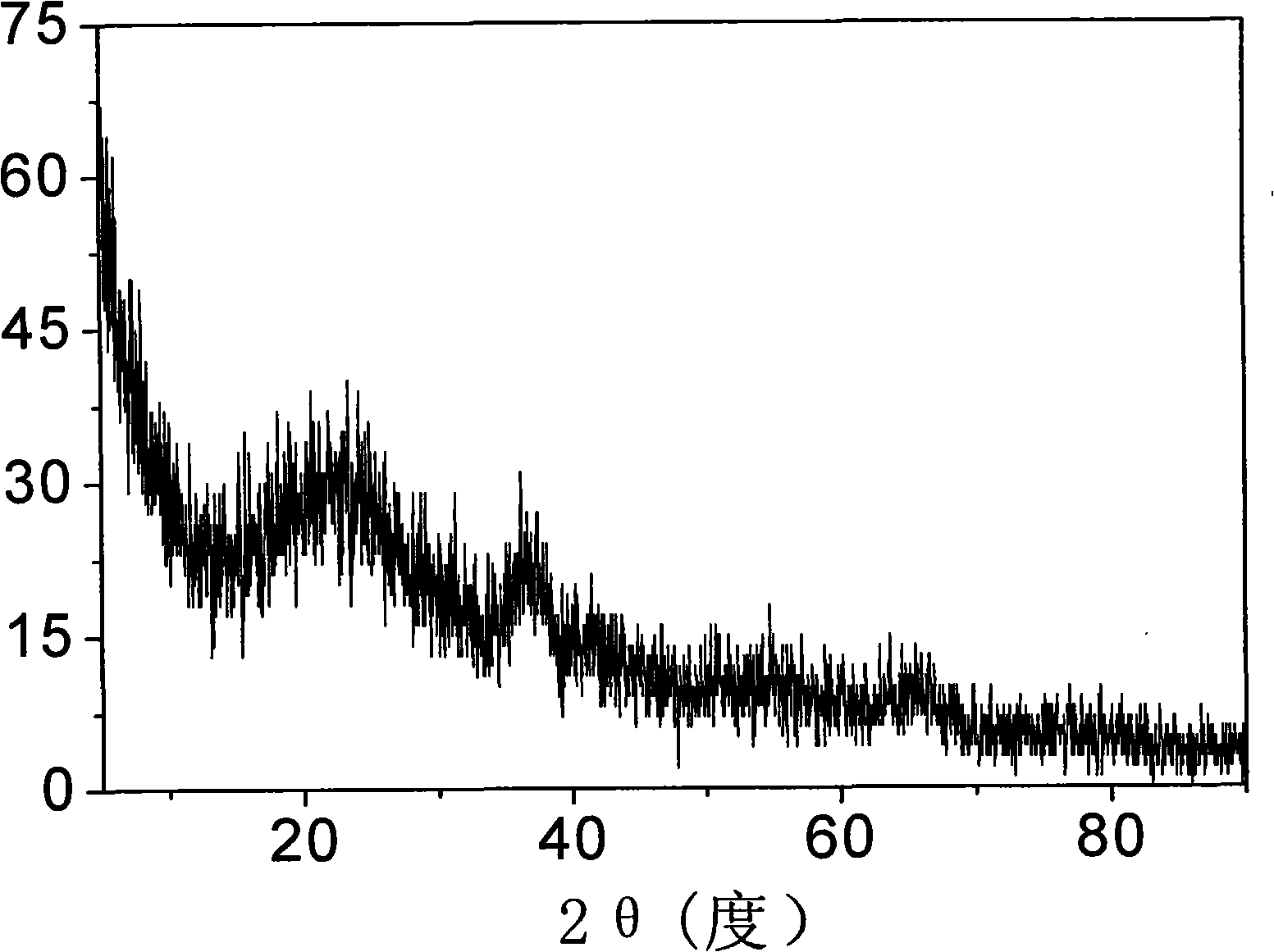

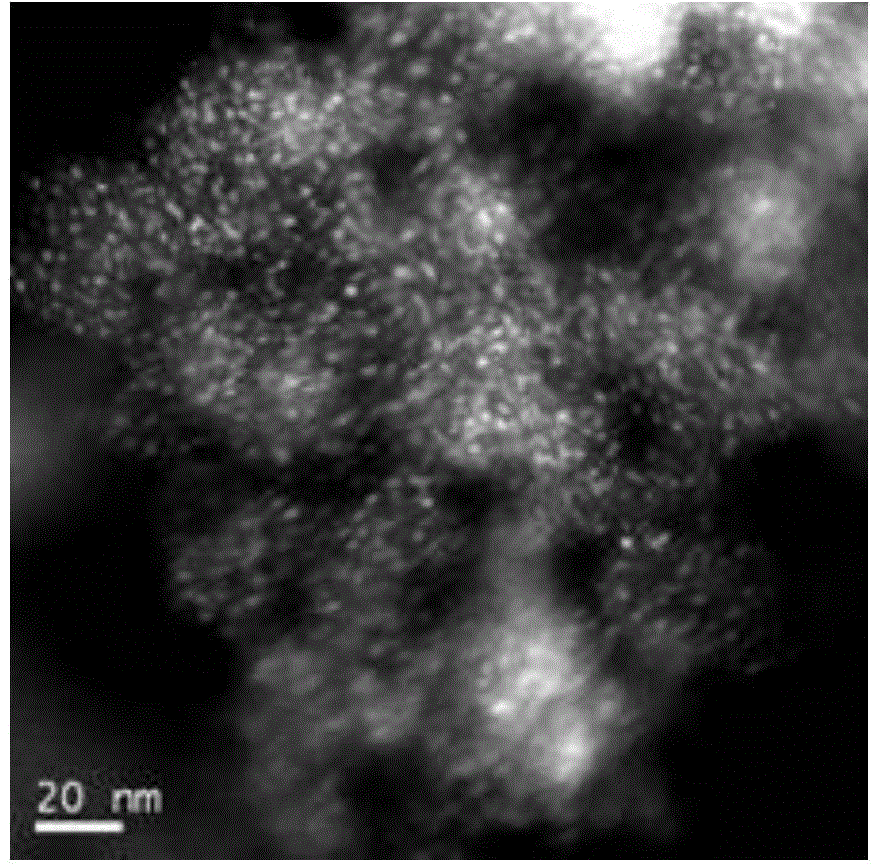

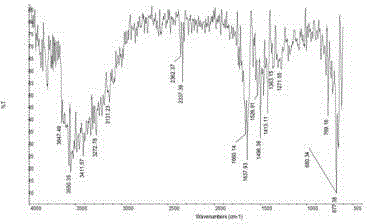

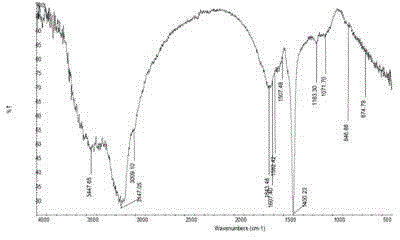

MXene-polyaniline composite material and preparation method thereof

ActiveCN106750277ASolve the technical problem of poor microwave absorption performance of MXeneTitanium carbidePolyaniline compositeSOLUTION/DROPS

The invention provides an MXene-polyaniline composite material and a preparation method thereof, relates to a preparation method of the MXene-polyaniline composite material and aims to solve the technical problem of poor wave absorbing performance of the conventional two-dimensional transition metal carbide MXene. The MXene-polyaniline composite material comprises laminated two-dimensional transition metal carbide and a polyaniline shell coating the surface of the two-dimensional transition metal carbide. The preparation method comprises the following steps: aniline is added to water and stirred, an aniline / water dispersion liquid is obtained, the pH value is regulated to 1.5-2, and a hydrochloride solution of aniline is obtained; the hydrochloride solution of aniline is added to the water dispersion liquid of the two-dimensional transition metal carbide and is stirred and mixed at a low temperature, and an MXene-aniline mixed solution is obtained; an ammonium persulfate solution is added dropwise to the MXene-aniline mixed solution, the mixture is subjected to a stirring reaction at a low temperature, a product is washed and dried, and the MXene-polyaniline composite material is obtained. The MXene-polyaniline composite material can be applied to the field of wave absorption.

Owner:HARBIN INST OF TECH

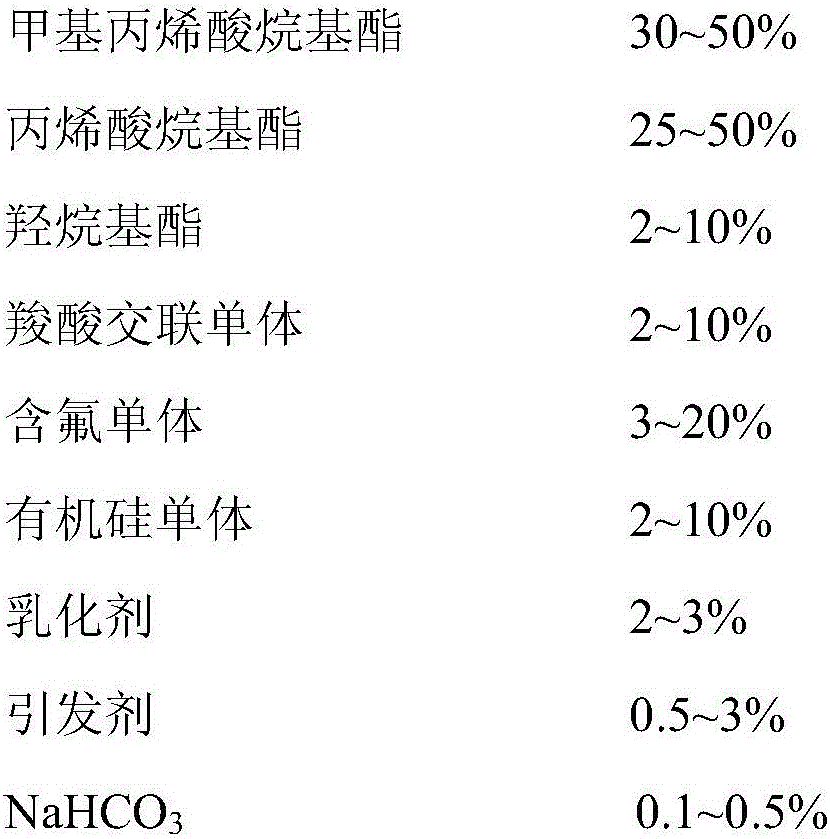

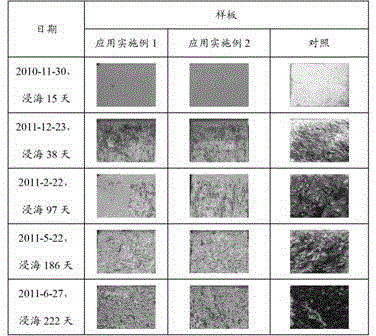

Fluorosilicone-modified polyacrylate emulsion as well as preparing method and application thereof

The invention discloses a fluorosilicone-modified polyacrylate emulsion as well as a preparing method and an application thereof. The preparing method comprises the following steps: first, mixing deionized water, NaHCO3, an emulsifying agent and an initiator solution, stirring, heating, dropwise adding part of core monomers and reacting; then, beginning slowly dropwise adding the rest of core monomers, and after dropwise adding all of the core monomers, reacting to prepare a seed emulsion; then, dropwise adding shell monomers and the rest of initiator solution into the seed emulsion, controlling reaction temperature at 78-82DEG C, filtering after reaction, discharging, and synthesizing a fluorosilicone-modified nanometer acrylic emulsion with a soft-core and hard-shell structure; and adding a protective colloid into the fluorosilicone-modified core-shell emulsion to prepare a spray-dried pre-emulsion and obtain redispersible rubber powder. Compared with common redispersible rubber powder, the redispersible rubber powder has an excellent water resisting property and can be widely applied to the building fields of outer wall paints, dry-mixed mortar and the like. When used for a building paint and mortar, the product can endow the building paint and the mortar with excellent water retention, weather fastness and constructability.

Owner:广东吉美帮新材料有限公司

Device and method for controlling fine particles in desulfurization flue gas

The invention discloses a device and a method for controlling a fine particulate matter from desulfurized smoke. A raw gas enters an absorption layer (2) from a smoke flue (3) of an absorption tower (1) for desulfurizing smoke; sulfur dioxide in the smoke is absorbed and removed by absorption solution; the smoke with the matters such as absorption solution drops, snoot and an adsorbent ascends inside the absorption tower to enter an absorption solution demister (11) through an absorption solution demister rinsing layer (4); most of liquid drops of which the particle sizes are greater than 10 microns are removed; the smoke enters a washing layer and a gas-liquid distributor (9) and contacts washing solution sprayed from a washing layer distributer (8) through a washing layer partition plate (10); the smoke enters a washing demister (7) to remove liquid drops of which the particle sizes are greater than 10 microns after being washed by a washing demister rinsing layer (6); purified smoke is discharged from a smoke purifying channel (5) at the upper part of a smoke desulfurizing absorption tower after twice rinsing and demisting are orderly carried out. The device is matched with a desulfurizing absorption system. Thus, the device is less in investment and convenient to run.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

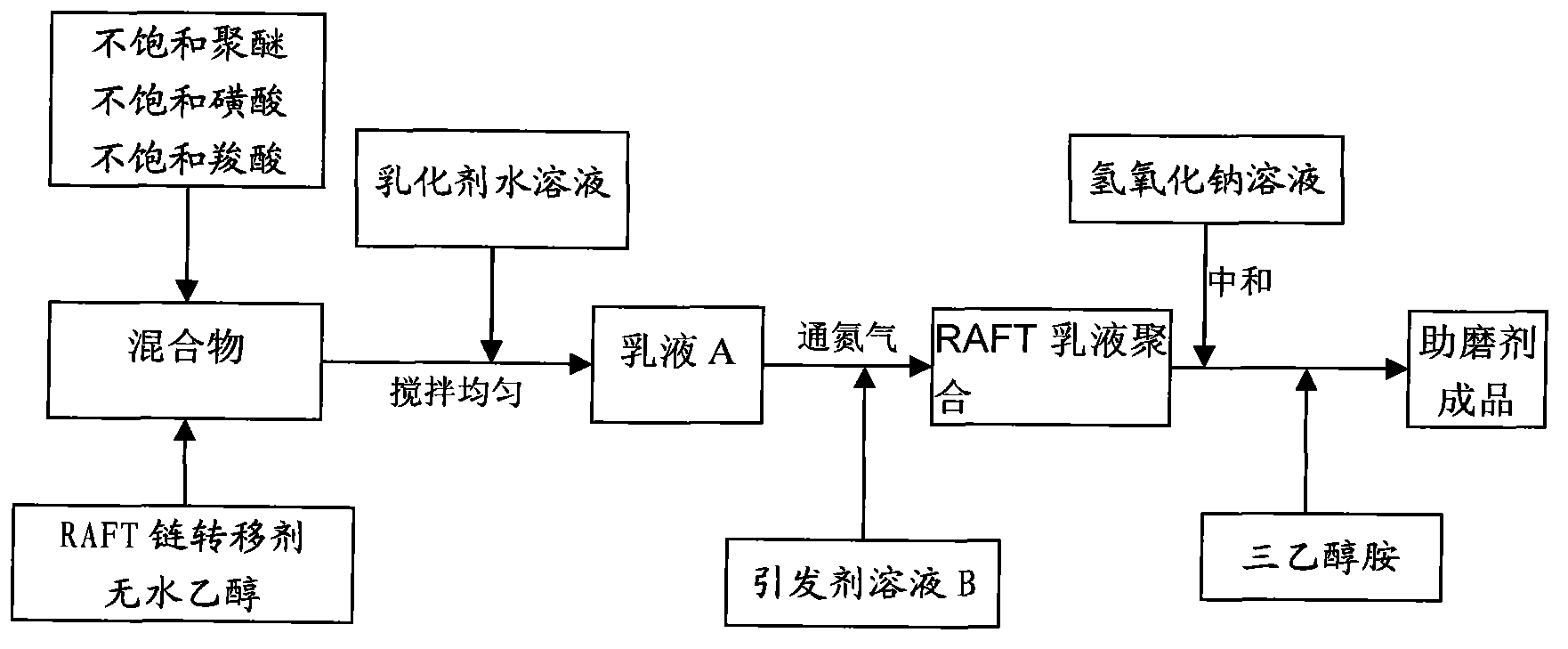

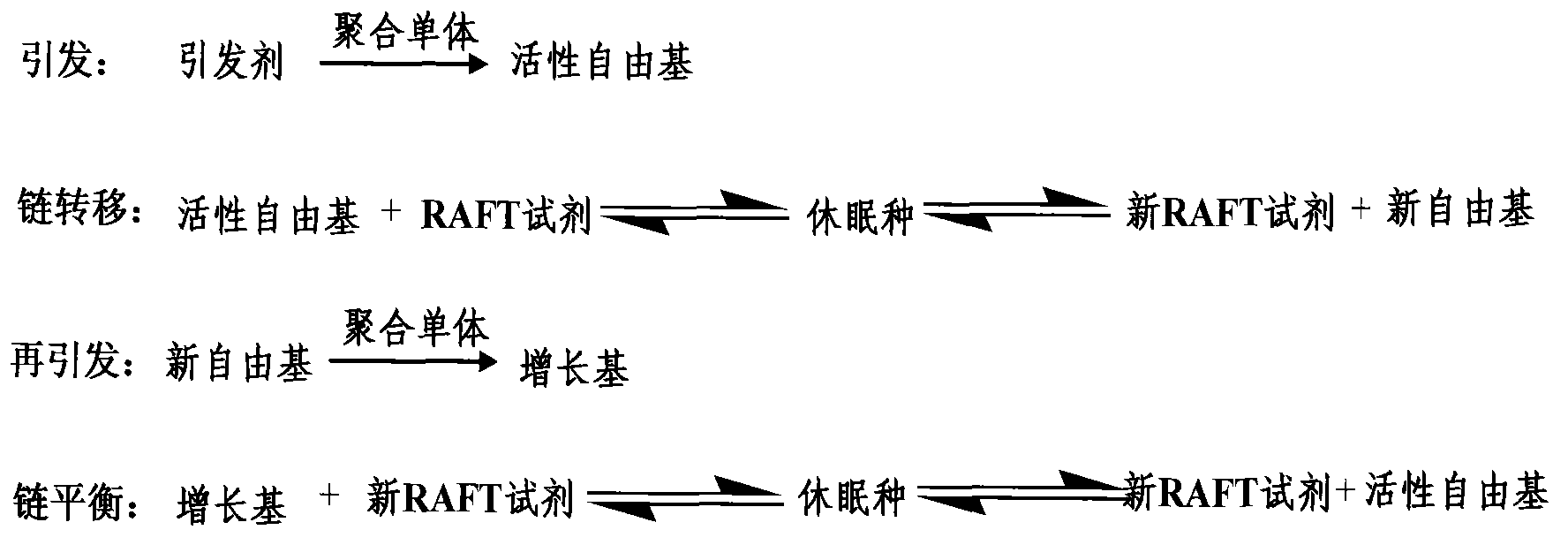

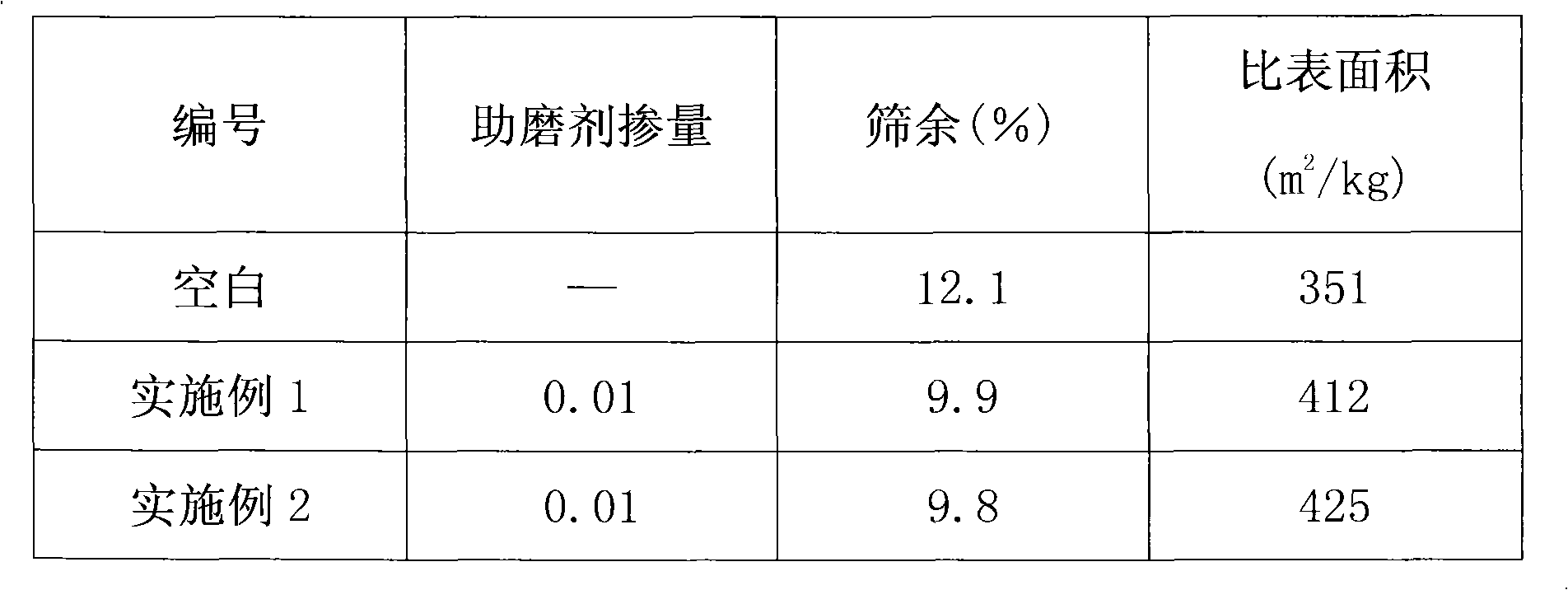

Preparation method of high efficiency controllable polycarboxylic acids series cement grinding aid

The invention relates to a preparation method of a high efficiency controllable polycarboxylic acids series cement grinding aid, which comprises the following steps: mixing nonsaturated polyether, nonsaturated sulfonic acid, unsaturated carboxylic acid, a RAFT chain transferring agent and absolute ethanol, adding an emulsifier aqueous solution, uniformly stirring and mixing to prepare an emulsion A; blending an initiator and water to obtain a solution B; under the condition that nitrogen is introduced in the emulsion A, heating to certain temperature and adding the solution B drop by drop, adjusting a flowmeter by finishing dropping after 1.0-2.5 hours, continuously reacting for 10-15 hours; after the reaction is finished, adding a sodium hydroxide solution with mass fraction of 30% and neutralizing to obtain the pH value between 6.5 and 7.5, adding triethanolamine which accounts for 3-7% of total mass of a reaction system in the solution drop by drop, and uniformly stirring to obtain the polycarboxylic acids series grinding aid product. The preparation principle is RAFT controllable / active free radical emulsion polymerization. The polycarboxylic acids series cement grinding aid has the advantages of low effective mixing amount and stable applicability, and has substantial effects for improving and enhancing the cement grinding aiding and cement physical properties.

Owner:LIAOCHENG TIANCHENG CEMENT TECH RES DEV

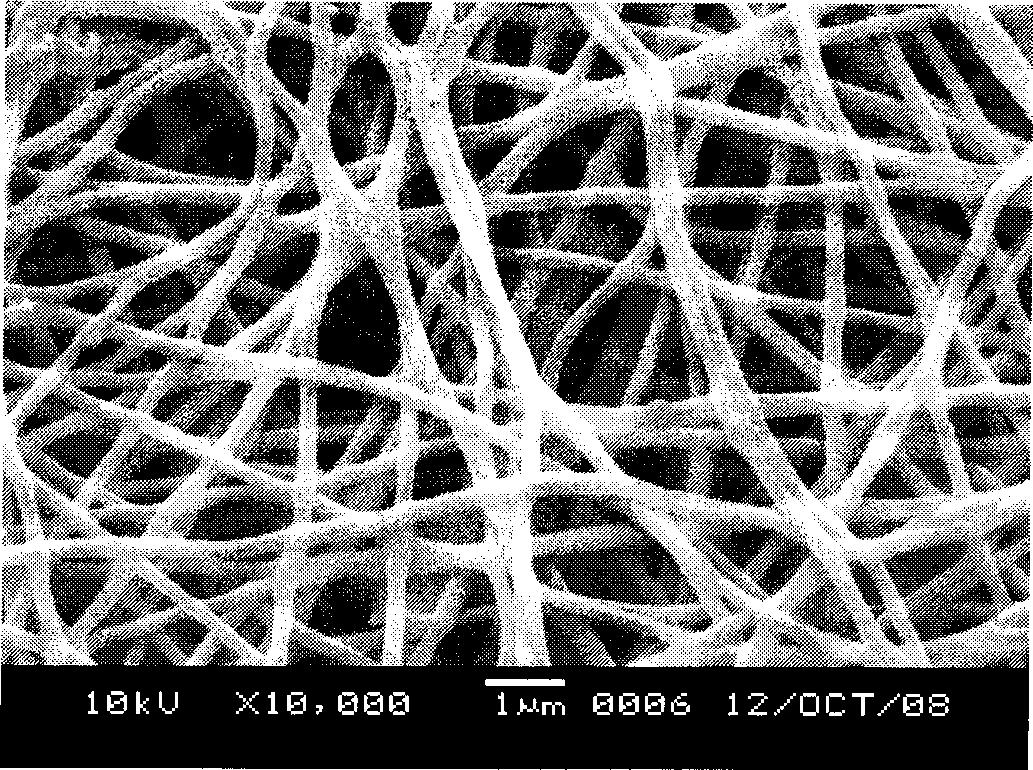

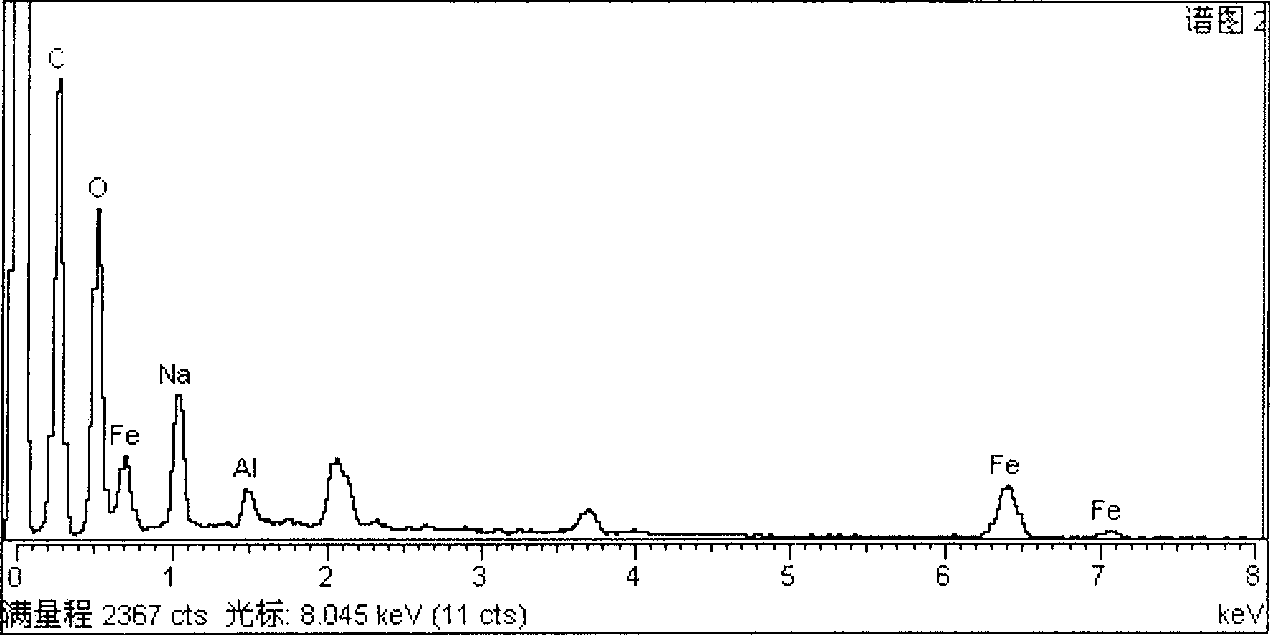

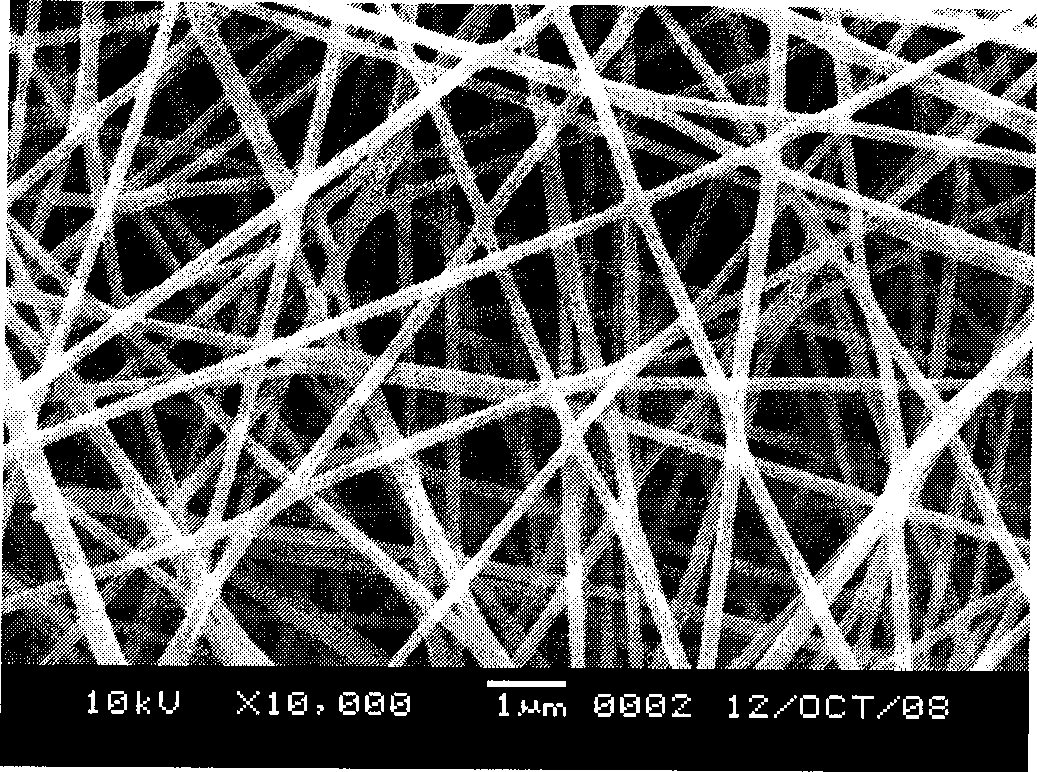

In-situ preparation method for functional nullvalent nano-iron/polyelectrolyte composite fibrofelt

InactiveCN101445291AEvenly dispersedEffectively fixedWater/sewage treatment by sorptionWater/sewage treatment by reductionFiberIron salts

The invention relates to an in-situ preparation method for a functional nullvalent nanometer iron / polyelectrolyte composite fibrofelt. The method comprises the following steps: (1) preparing polyelectrolyte mixed solution with concentration between 7 and 12 percent by polyacrylic acid PAA, and preparing a nanometer fibrofelt according to a principle of electrostatic spinning; (2) carrying out heat treatment on the nanometer fibrofelt to prepare a water-fast polyelectrolyte fibrofelt; (3) preparing soluble iron salt solution, and preparing reducing agent solution with concentration 4 to 6 times of the iron salt solution; (4) dipping the (2) in the iron salt solution; (5) rinsing; (6) dripping the reducing agent solution onto the complex iron ion fibrofelt; (7) rinsing by deionized water; (8) drying and storing. In the fibrofelt prepared by the method, nanometer iron particles are dispersed evenly without aggregation phenomenon, and the fibrofelt can effectively fix nanometer iron particles, thereby ensuring effective recycle of the nanometer iron particles in practical application without secondary pollution.

Owner:DONGHUA UNIV

Method for preparing waste water processing materials of organic-inorganic composite bentonite

InactiveCN1569660AImprove the coagulation effectAvoid competitive adsorptionWater/sewage treatment by sorptionClaywaresWater bathsPolymer science

The invention discloses a method for preparing waste water processing materials of organic-inorganic composite bentonite which comprises, (1) disintegrating the alta-mud, passing through 100 mesh sieve, charging into the solution of cationic surface active agent, stiring 1-2 hours in water-bath, (2) charging AlCl3 solution into the suspending liquid, stirring 5-10 minutes, (3) while water-bath stirring, charging NaOH or Na2CO3 solutions into the suspending liquid, stewing for over 10 hrs at room temperature, (4) multitime washing, filtering, drying and grinding.

Owner:ZHEJIANG UNIV

Method for preparing high-dispersibility zinc oxide granules and colloid thereof

InactiveCN101544396AShape is easy to controlUniform particle sizeZinc oxides/hydroxidesColloidal chemistry detailsColloidZinc salts

The invention relates to a method for preparing high-dispersibility zinc oxide granules, which comprises the following steps: (1) dissolving soluble zinc salt into deionized water, and stirring the mixture to prepare 0.1 to 10 percent of zinc salt solution in percentage by mass; (2) dissolving alkali in the deionized water according to a molar ratio of the zinc salt to the alkali of 1:2 to prepare alkali solution; (3) dissolving hydrophilic emulsifying agent of which adding amount is 0.5 to 20.0 percent of the mass of the zinc salt into the deionized water; (4) at a temperature of between 20 and 90 DEG C, fully stirring the emulsifying agent solution, adding the zinc salt solution and the alkali solution into the emulsifying agent solution drop by drop to obtain white precipitate, and filtering and separating the white precipitate; and (5) washing the separated white precipitate, drying the washed white precipitate at a temperature of between 40 and 120 DEG C to obtain zinc oxide powder, dispersing the zinc oxide powder into water by ultrasound, and adding 0.1 to 10 percent of stabilizing agent to obtain zinc oxide sol. Compared with the prior art, the method has the advantages that the preparation cost is low, and the size and shape of the zinc oxide granules are easy to control; and the prepared zinc oxide granules have even grain diameter and high dispersibility and do not have the problem of agglomeration.

Owner:上海西源新能源技术有限公司

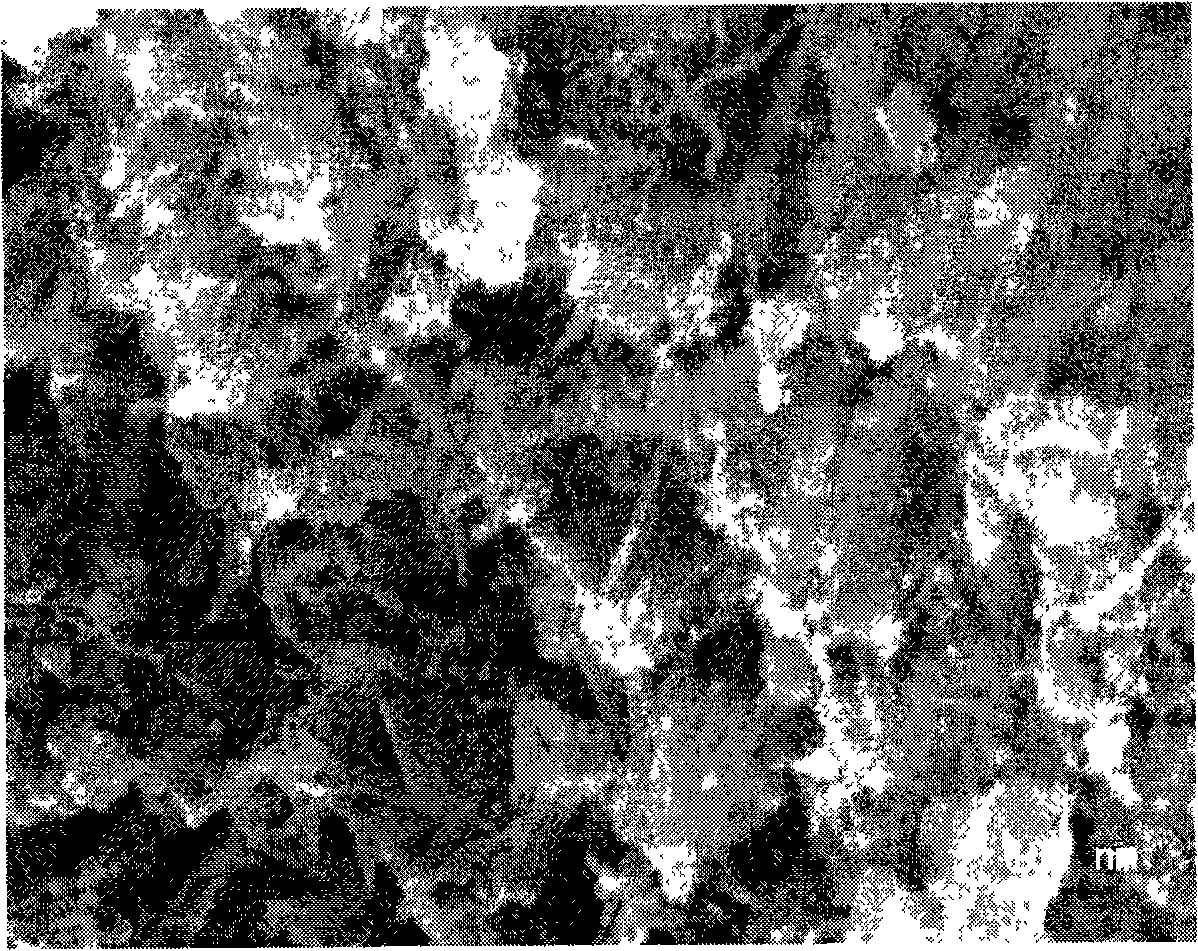

Nano thread-shaped manganese dioxide load carbon silica aerogel as well as preparation method and application thereof

InactiveCN101281821AHigh removal rateThe process steps are simpleElectrolytic capacitorsWater/sewage treatment by electrochemical methodsFiberPorosity

The present invention relates to nanometer fiber-shaped manganese dioxide borne carbon aerogel, a method for producing the aerogel, and an application of the aerogel. The method employs a coprecipitation method, i.e., carbon aerogel grains are dipped in potassium permanganate solution, and manganese acetate solution is added into the potassium permanganate solution drop by drop, then, the precipitate is filtered, washed, and dried. In the resulting nanometer fiber-shaped manganese dioxide borne carbon aerogel, the carbon aerogel is in a three-dimensional mesh structure formed by nanometer grains bonded together; the manganese dioxide in uniform nanometer fiber-shaped distribution; the pore size of the carbon aerogel is 20-30nm; the diameter of the fiber-shaped manganese dioxide is about 5-25nm; wherein, manganese dioxide accounts for 20-50 percent of the total mass. The method utilizes both the high specific surface area, high porosity, and good electrical conductivity features of carbon aerogel and the high specific surface area and high reactivity features of the manganese dioxide in nanometer-level distribution. The nanometer fiber-shaped manganese dioxide borne carbon aerogel can be used in environmental protection and energy domains, such as organic wastewater treatment by three-dimensional electric catalytic oxidation, and manufacturing of electrode materials for super capacitors.

Owner:SUN YAT SEN UNIV

Codoping titanium dioxide nano sol and preparation method thereof

InactiveCN101054202AAchieve UV red shiftPhysical/chemical process catalystsWater/sewage treatment by irradiationUltravioletPolyethylene glycol

The invention discloses a method for preparing co-doped TiO2 nano-sol, which comprises the following steps: 1) dripping butyl titanate into absolute ethyl alcohol followed by continuous stir till the end of drip; then adding in concentrated hydrochloric acid followed by continuous stir, and then still stirring for 25-35min at the end of addition to produce blended solution; 2) dripping the above blended solution into de-ionized water with continuous stir, stirring for further 70-80min after dripping and then vibrating for 13-18min in ultrasonic wave to produce sol; 3) adding polyethylene glycol, urotropine and AgNO3 into the above sol and stirring for 55-65min to produce nano-sol. The co-doped TiO2 nano-sol prepared in the invention has the functions of Einstein shift of ultraviolet ray, photocatalysis after absorption of visible light and light source free antisepsis etc.

Owner:ZHEJIANG UNIV

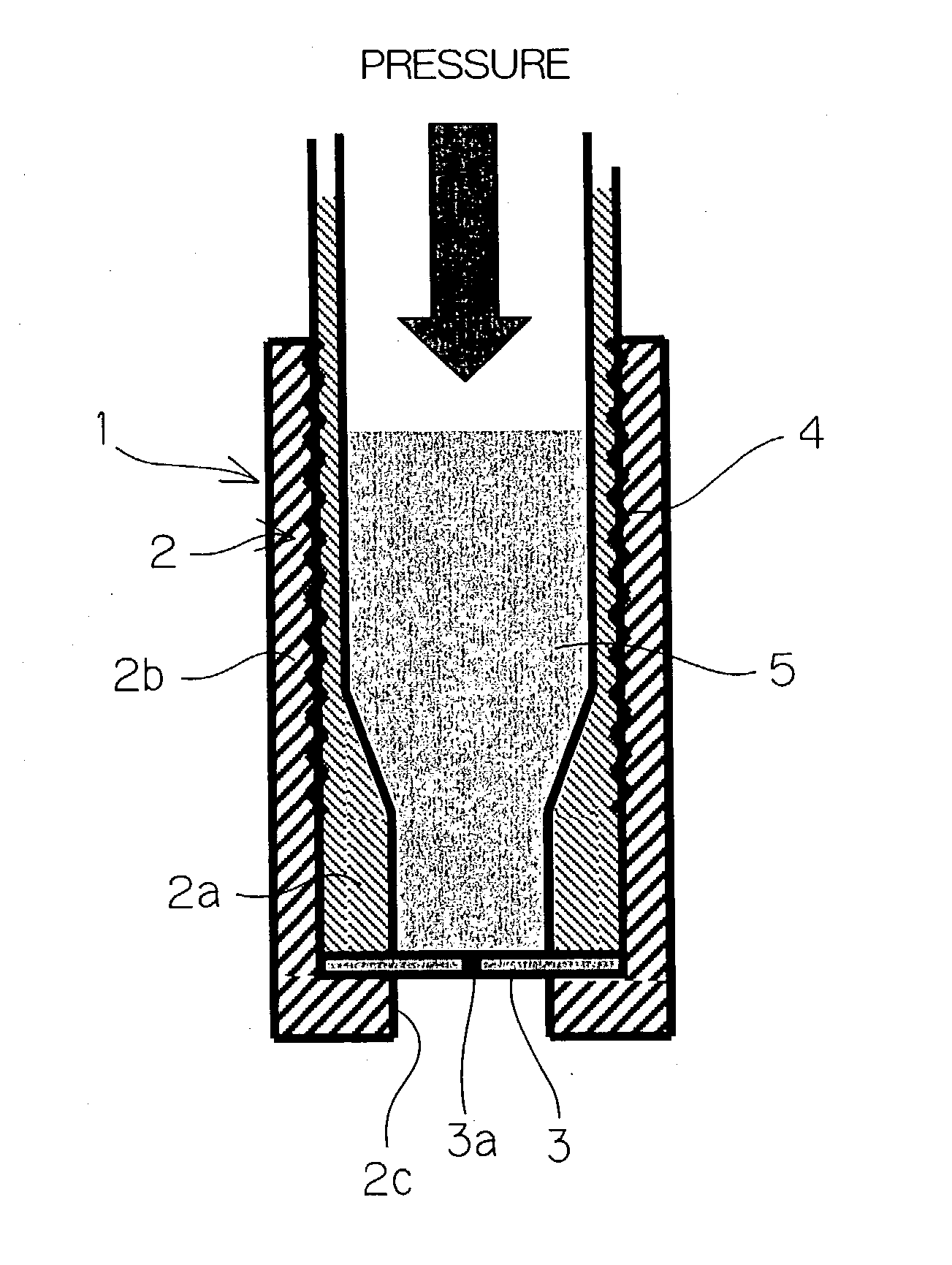

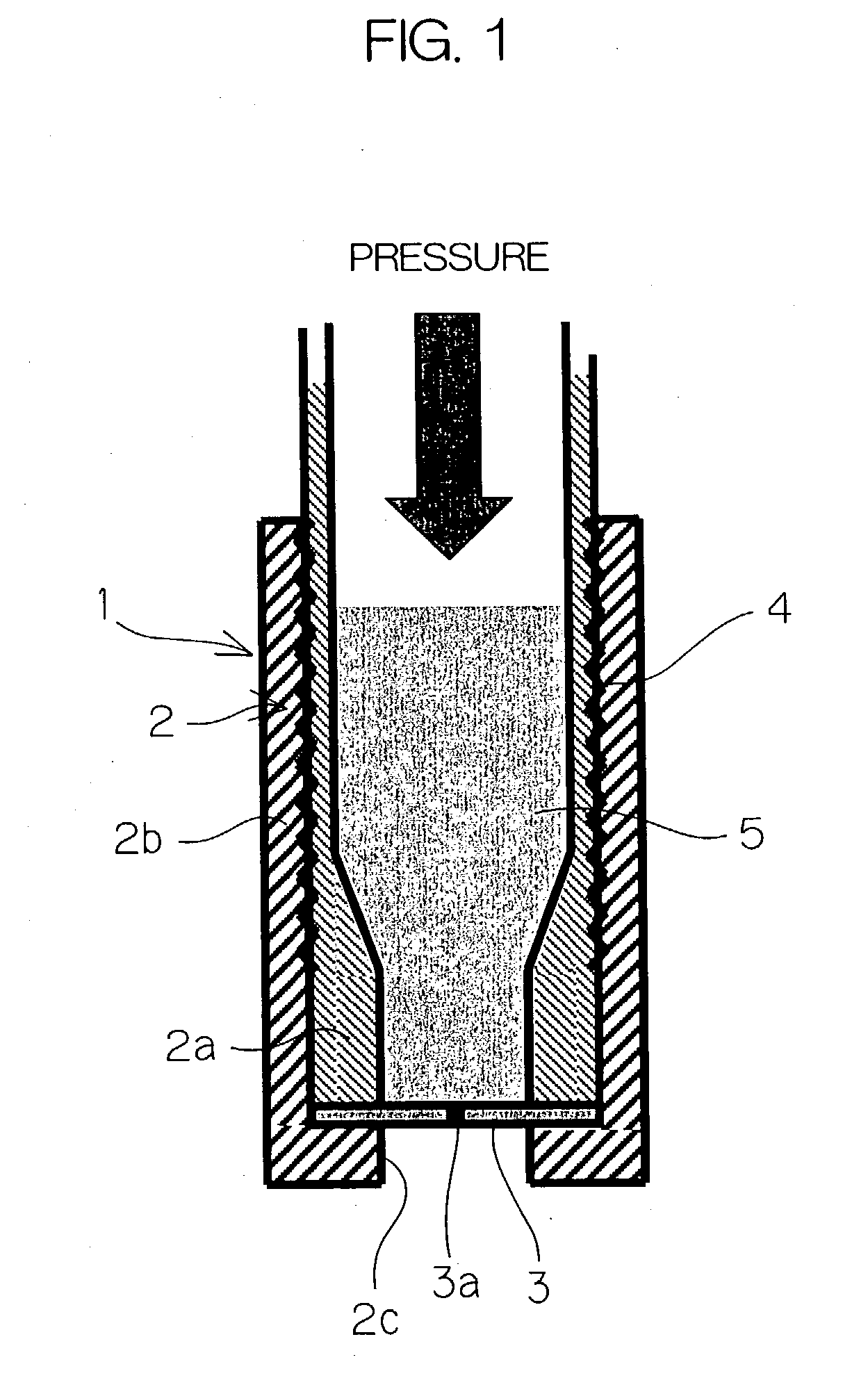

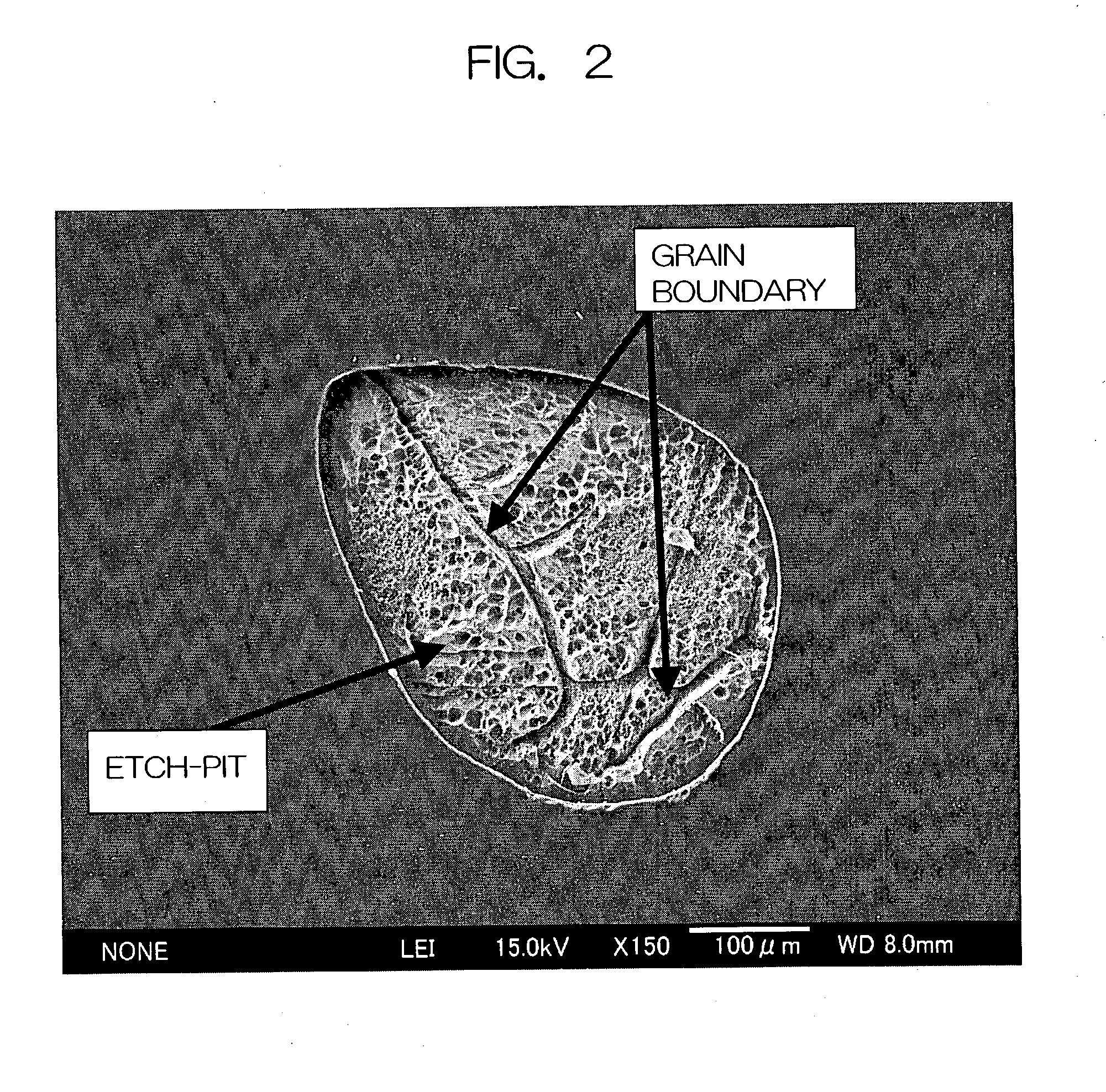

Apparatus and method for manufacturing semiconductor grains

ActiveUS20030080451A1Crystal quality of the grain is more improvedImprove crystal qualityPolycrystalline material growthLayered productsCrucibleSilicon

A crucible is formed of a cylindrical body member and a disk-shaped nozzle member fitted to the bottom portion of the body member, and the nozzle member is provided with a nozzle hole for discharging out a semiconductor molten solution dropwise therethrough. The semiconductor molten solution drops discharged out of the crucible through the nozzle hole are cooled and solidified during falling to become semiconductor grains. Silicon grains having high crystal quality can be manufactured at low cost.

Owner:KYOCERA CORP

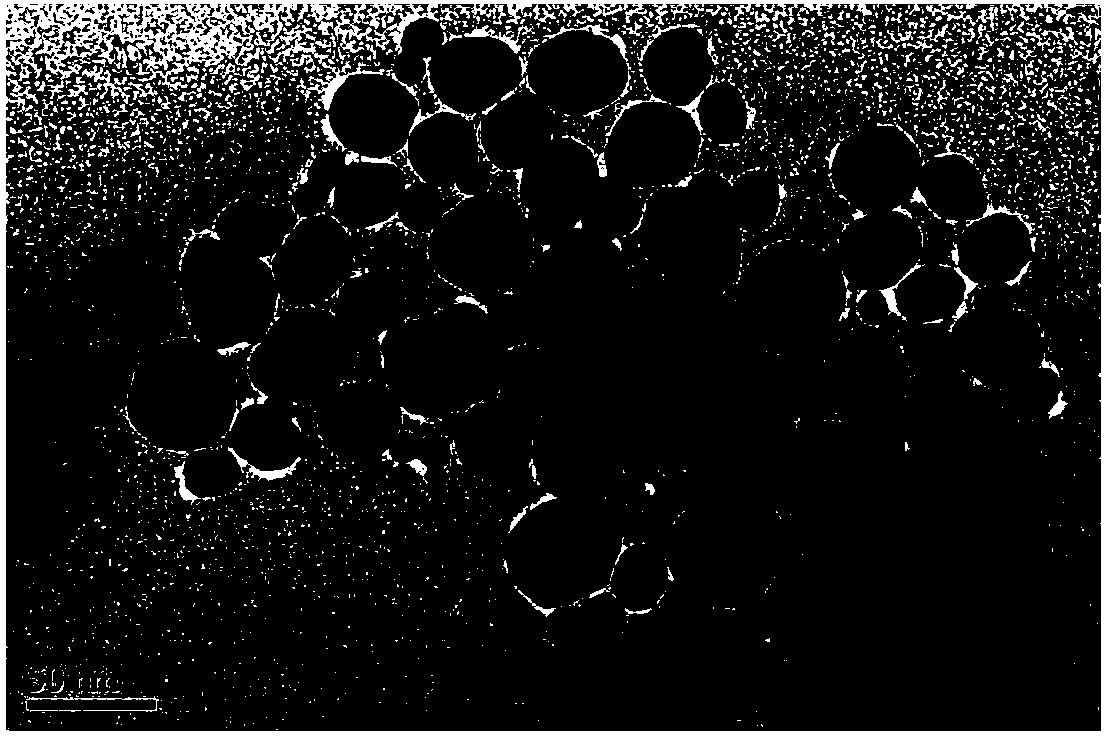

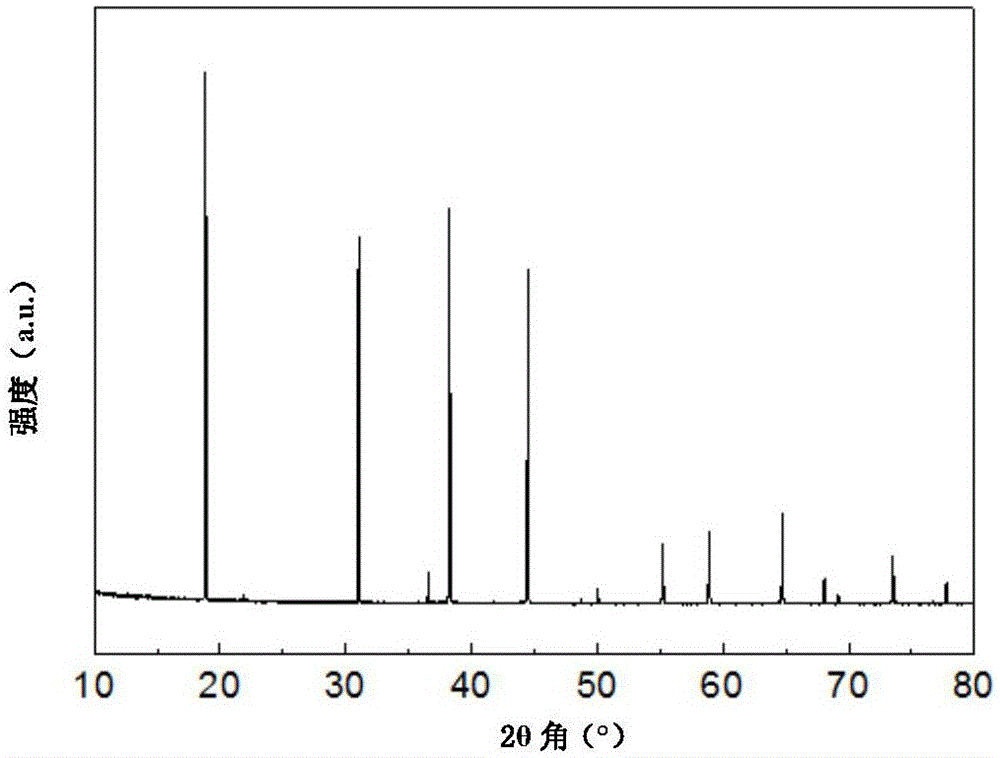

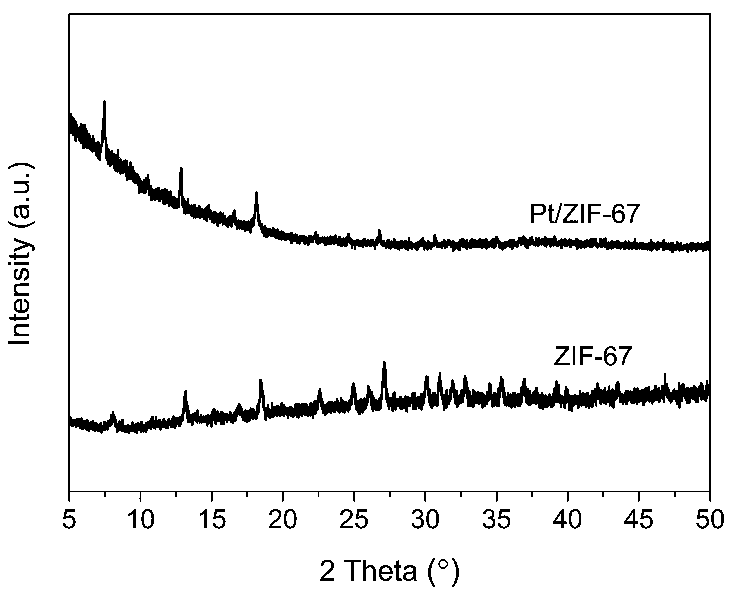

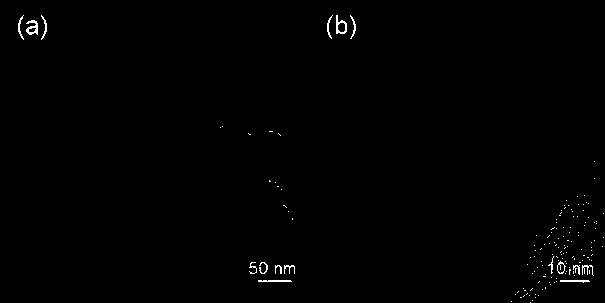

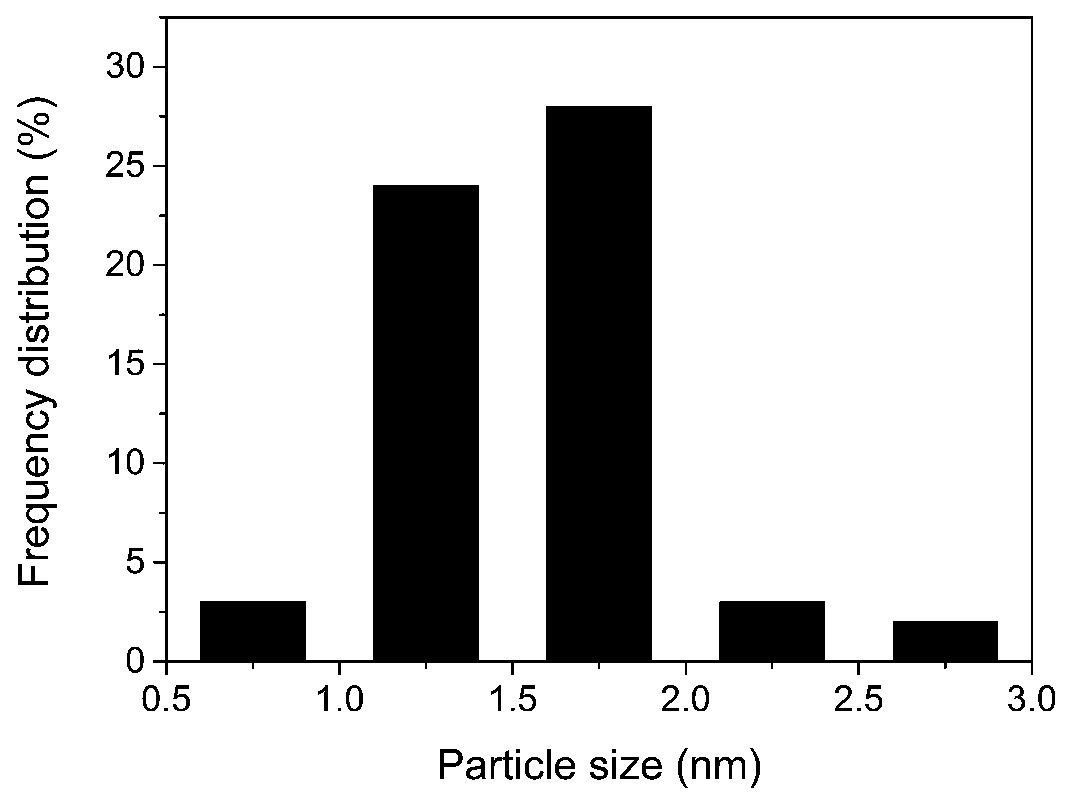

Pt/ZIF-67 composite used for catalyzing hydrolysis of ammonia borane for hydrogen production

InactiveCN107930697AImproved hydrogen release performanceHigh TOF valueOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionReaction rateMetal-organic framework

The invention discloses a Pt / ZIF-67 composite used for catalyzing hydrolysis of ammonia borane for hydrogen production. The Pt / ZIF-67 composite is prepared by mixing chloroplatinic acid with a metal organic framework ZIF-67 and then carrying out one-step reduction. The structure of the Pt / ZIF-67 composite retains the frame structure of ZIF-67; the average size of Pt nanoparticles is 1-2 nm, the Ptnanoparticles are uniformly distributed, and no obvious Pt metal characteristic diffraction peak occurs according to XRD detection results. A preparation method comprises the following steps: step 1)preparation and activation of the ZIF-67; and step 2) loading of the Pt nanoparticles: adding the activated ZIF-67 into water for ultrasonic dispersion, adding chloroplatinic acid, and then adding anaqueous NaBH4 solution drop by drop, and subjecting a product to filtering, washing and drying. As the Pt / ZIF-67 composite is applied to catalysis of the hydrolysis of ammonia borane for hydrogen production, the turn over frequency (TOF) of a reaction rate reaches 70-100 mol H2 min<-1> Pt mol<-1>, and activation energy is 30-40 kJ mol<-1>. The synergistic effect of the ZIF-67 and the Pt nanoparticles brings in better catalytic performance. Therefore, the Pt / ZIF-67 composite has good application prospects in the field of hydrogen production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Preparation method of silver-supported titanium dioxide inorganic antiseptic

ActiveCN104304319AAvoid reunionStop growing upBiocideFungicidesIncipient wetness impregnationSilver ion

The invention discloses a preparation method of a silver-supported titanium dioxide inorganic antiseptic. The method comprises the following steps: sequentially adding sodium hydroxide and ammonia water into a silver salt solution in a dropwise manner to prepare a Tollen's reagent with a certain concentration, controlling the pH value, adding the Tollen's reagent solution into a certain amount of titanium dioxide powder in a dropwise manner through an incipient wetness process, and continuously vibrating to make the powder uniformly wetted, carrying out room temperature drying, and reducing to obtain the silver-supported titanium dioxide inorganic antiseptic. The method has the advantages of simple operation, environmental protection, effective prevention of the agglomeration growth of silver particles in the subsequent processing through inducing the formation of strong interaction between diammine silver ions and the surface of titanium dioxide by adjusting the hydroxy charges on the surface of titanium dioxide via adjusting the pH value, effective guarantee of the high dispersion of the silver particles on the surface of titanium dioxide, and improvement of the antibacterial properties of silver-supported titanium dioxide inorganic antibacterial materials.

Owner:南京丰浩华食品供应链管理有限公司

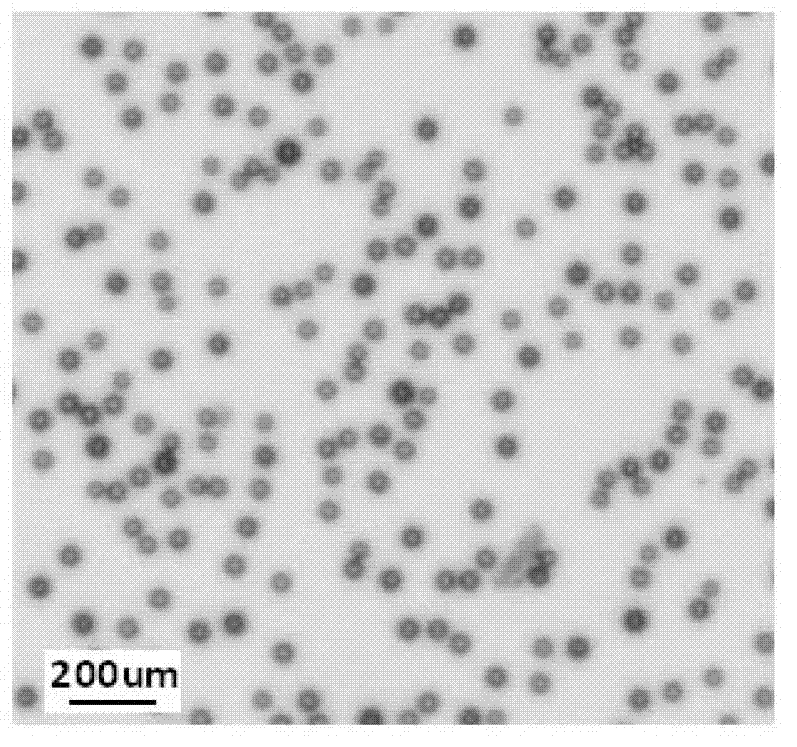

Microspheres for adsorbing heavy-metal cadmium in soil

ActiveCN104226273AObvious adsorption and fixationSimple preparation processOther chemical processesContaminated soil reclamationCross-linkMicrosphere

The invention discloses microspheres for adsorbing heavy-metal cadmium in soil. The microspheres are prepared by the following steps: firstly dissolving powder of sodium alginate and sodium polyacrylate in deionized water, dropwise adding the mixed solution of the sodium alginate and the sodium polyacrylate into a calcium chloride solution by using an injector, and forming water-insoluble microspheres with the sodium alginate and the sodium polyacrylate by cross-linking fixation of Ca<2+> and the sodium alginate. The microspheres prepared are regularly-spherical and are about 100mu m in particle size. The microspheres disclosed by the invention have the advantages that the heavy-metal element (cadmium) in the soil can be effectively adsorbed and fixed, and the adsorbing amount for the heavy-metal cadmium in the soil is 8.7mg / g. The microspheres can be widely applied in restoration of the soil polluted by the heavy-metal cadmium.

Owner:HANGZHOU NORMAL UNIVERSITY

Method for recovering and preparing nano-cobalt oxide from waste lithium ion battery

InactiveCN1594109ASmall particle sizeEasy to manufactureNanostructure manufactureSolid waste disposalLiquid wasteInfrared lamp

The invention discloses a method for recovering and preparing nano-cobalt oxide from waste lithium ion battery which comprises the steps of, cutting the battery, alkaline pickling the Al foil with excess NaOH at room temperature, reacting, filtering to obtain LiCoO2-containing filtering deposit, dissolving the mixture with HNO3 at room temperature, dropping the nitrate solution into NaOH solution, adjusting the pH value to 9-11, thus obtaining fine Co(OH)2 sediment, converting it into hydrated cobalt oxide, removing the foreign ions through filtration and washing, drying the CoO(OH) under infrared lamp, thermal treatment 2h, thus obtaining Co3O4 nano powder.

Owner:TIANJIN UNIV

Waterborne acrylic macromolecular compound as well as preparation method and application thereof

InactiveCN102911309AHigh molecular weightLow priceAntifouling/underwater paintsPaints with biocidesQuaternary ammonium cationAlcohol

The invention relates to a waterborne acrylic macromolecular compound and salts thereof, as well as preparation methods and applications thereof. The method comprises the following steps of: dissolving hydrophilic acrylic monomers containing amino, acrylic monomers containing hydroxyl, acrylic monomers containing quaternary ammonium salts and acrylic monomers containing carboxyl in water, then adding a water-soluble azo compound as an initiator, and dropwise adding the monomer hybrid solution containing the initiator to water or alcohol-water solution for copolymerization reaction. Stain-proof paints prepared by using metal salts of the waterborne acrylic macromolecular compound can effectively prevent adhesion of fouling organism in seawater, and have the advantage of being environment-friendly.

Owner:OCEAN UNIV OF CHINA

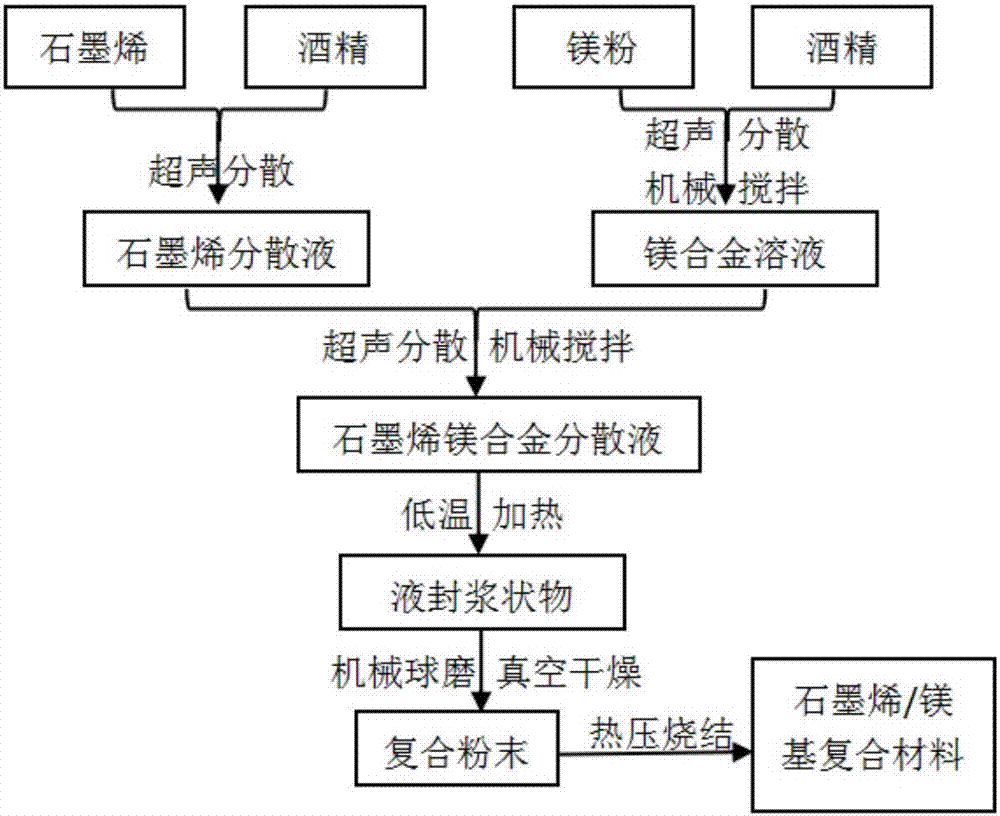

Preparation method for graphene reinforced magnesium matrix composite material

The invention discloses a preparation method for a graphene reinforced magnesium matrix composite material. The preparation method comprises the following steps that magnesium powder is dissolved in ethanol, mechanical stirring and ultrasonic dispersion are conducted, and a magnesium alloy solution is obtained; graphene is added into the ethanol, ultrasonic mixing is conducted, and a graphene dispersion solution is obtained; the graphene dispersion solution is added into the magnesium alloy solution drop by drop, ultrasonic dispersion and mechanical stirring are conducted, and a graphene magnesium alloy dispersion solution is obtained; the graphene magnesium alloy dispersion solution is placed in a low-temperature water bath kettle to be heated; after the solution evaporates to be liquid seal pulp, heating is stopped, the pulp is taken out to be subjected to vacuum ball milling, vacuum pumping is conducted after standing, then high-purity argon is pumped in, and ball milling is conducted; a ball-milled mixture is taken out, subjected to vacuum drying and put into a vacuum glove box to be subjected to manual dispersion grinding; and composite powder is put into a sintering furnace to be sintered. The technological process is simple, practicability is wide, and the graphene reinforced magnesium matrix composite material has wide military and aviation application prospects.

Owner:HARBIN UNIV OF SCI & TECH

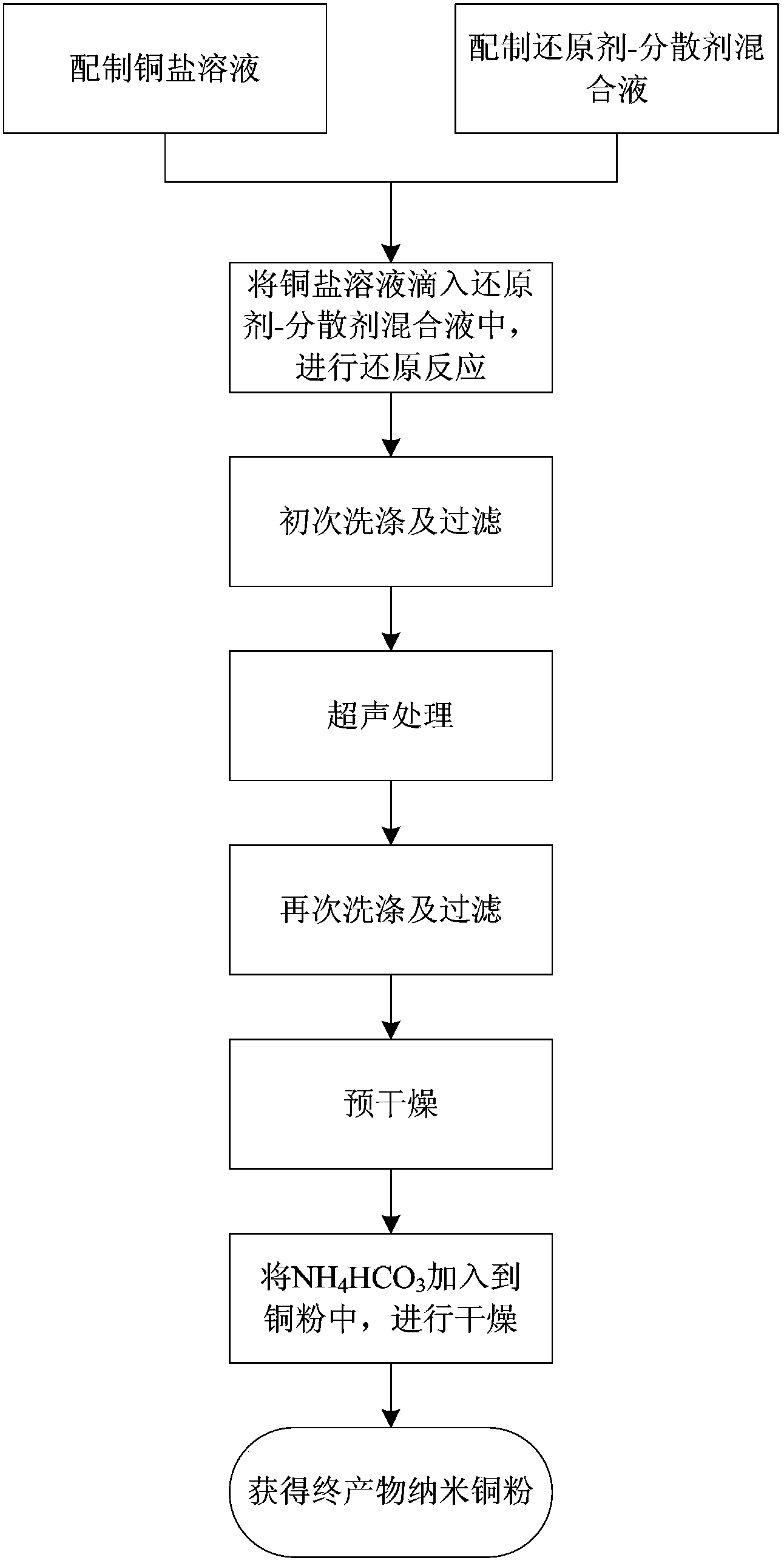

Preparation method for low-agglomeration antioxidant copper nanoparticle powder

The invention discloses a preparation method for low-agglomeration antioxidant copper nanoparticle powder. The preparation method for the low-agglomeration antioxidant copper nanoparticle powder comprises the following steps of preparation: preparing copper salt solution and reductant-dispersant mixed liquor; reaction: dipping the copper salt solution into the reductant-dispersant mixed liquor, regulating the pH (potential of hydrogen) value to 10-13, keeping reaction at the temperature of 70-75DEG C under the ultrasonic oscillating condition until the reaction is finished, and standing to obtain a secondary precipitate; primary washing and filtering: obtaining the secondary precipitate; ultrasonic processing: adding surface protectant into the secondary precipitate, and standing after ultrasonic oscillating processing to obtain third precipitate; secondary washing and filtering: obtaining fourth precipitate; pre-drying: carrying out vacuum drying to the fourth precipitate to obtain copper powder; drying: adding NH4HCO3 into the obtained copper powder to be evenly mixed, putting the mixed copper powder under the flowing nitrogen atmosphere, and drying at the temperature of 70-80DEG C to obtain the copper nanoparticle powder. According to the preparation method for the low-agglomeration antioxidant copper nanoparticle powder, which is disclosed by the invention, the charging sequence is changed, ultrasonic vibration stirring is adopted, NH4HCO3 is added, and therefore the copper nanoparticle powder can be effectively prevented from being agglomerated and oxidized.

Owner:JINGMEN GEM NEW MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com