Patents

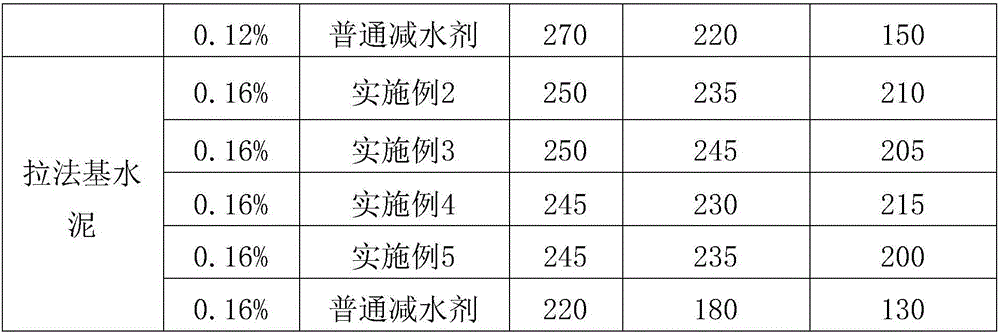

Literature

64results about How to "Avoid competitive adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

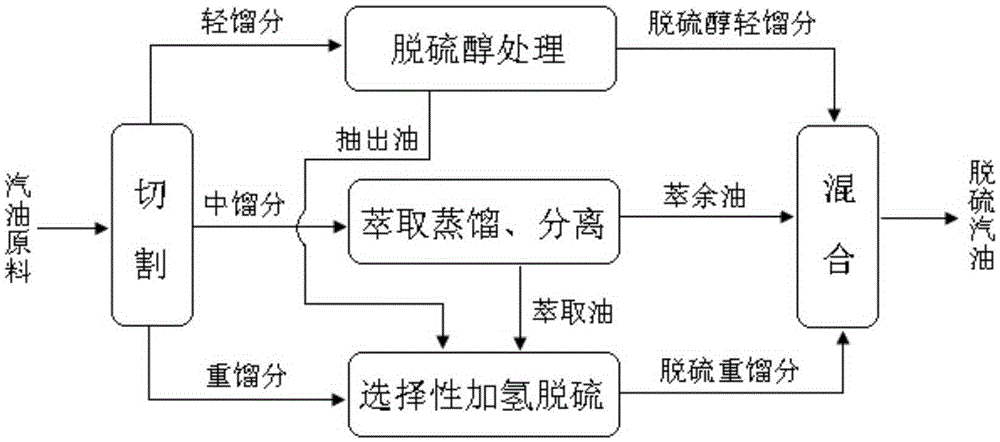

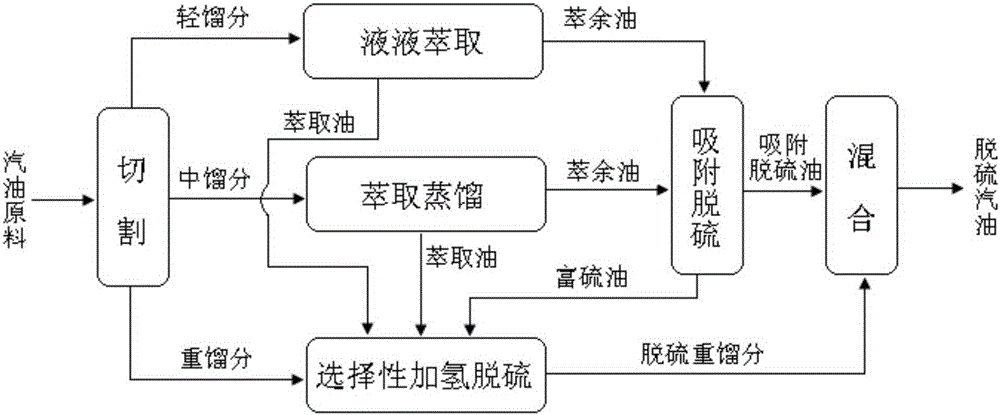

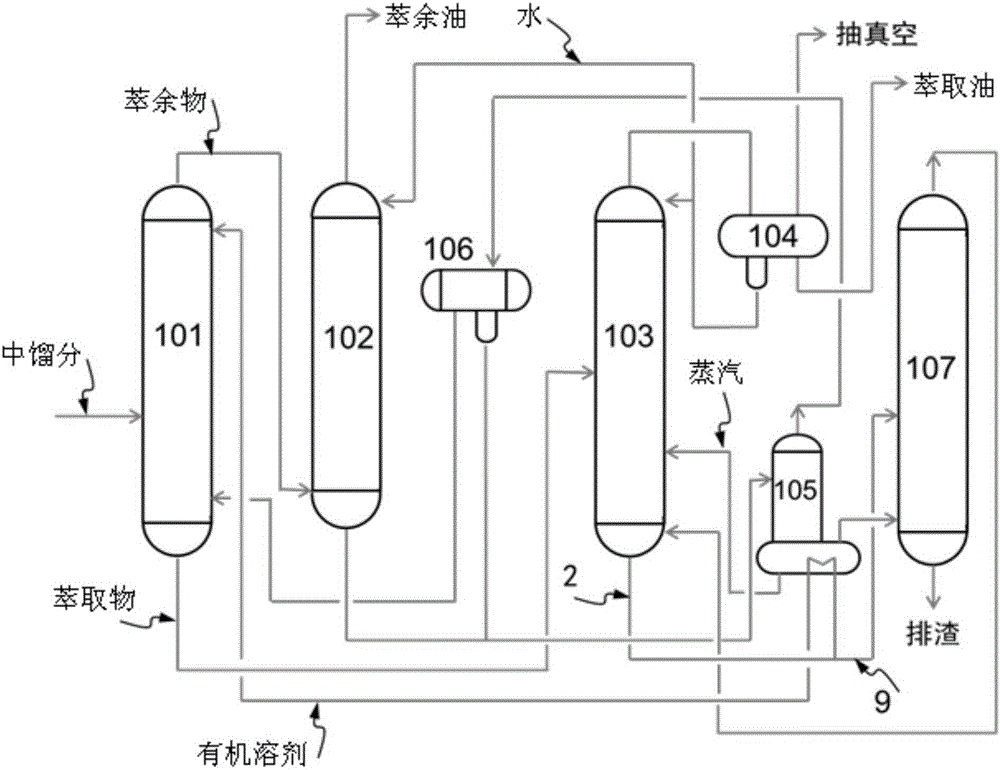

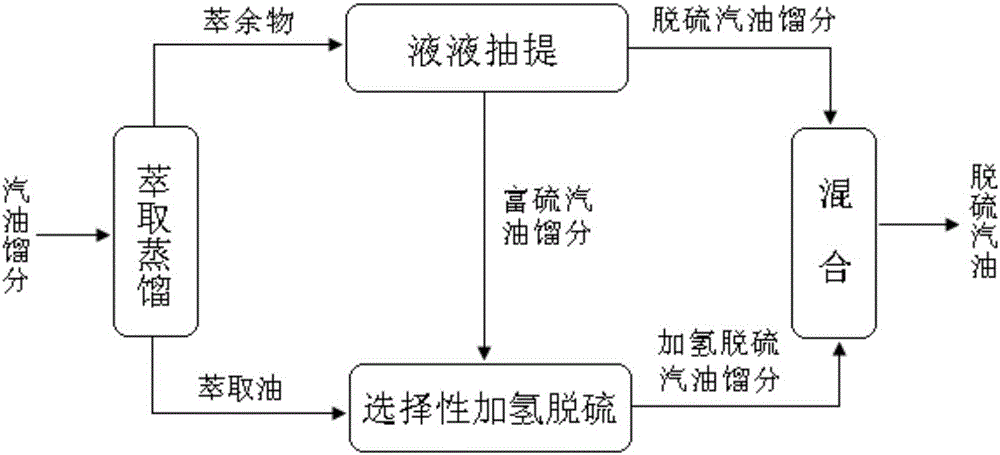

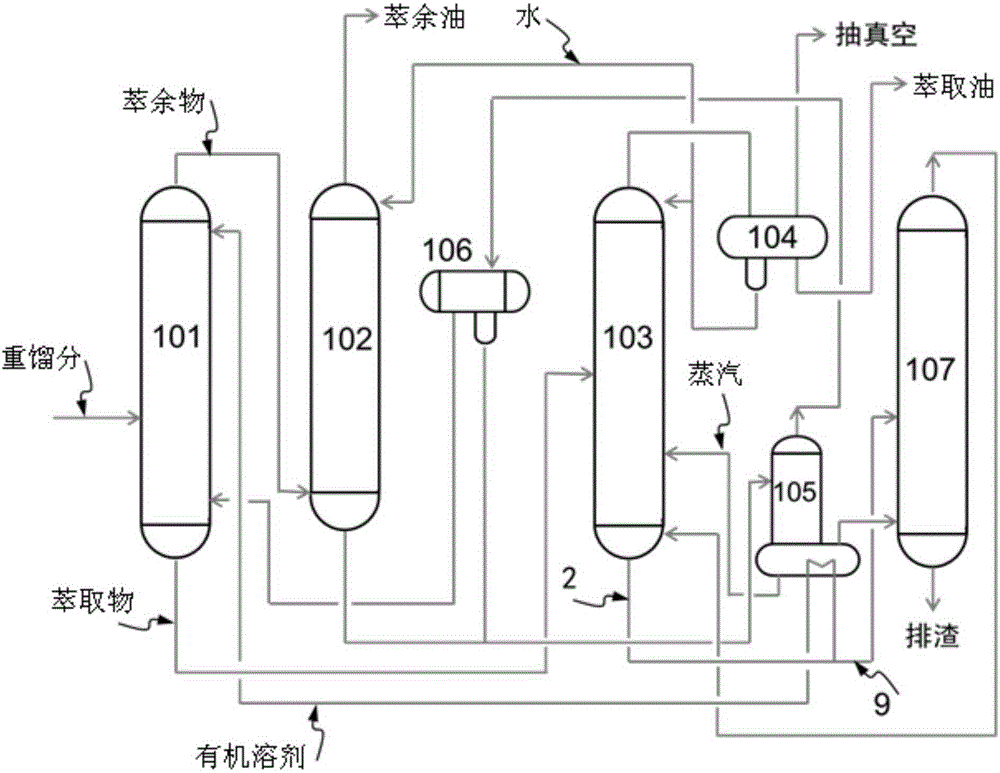

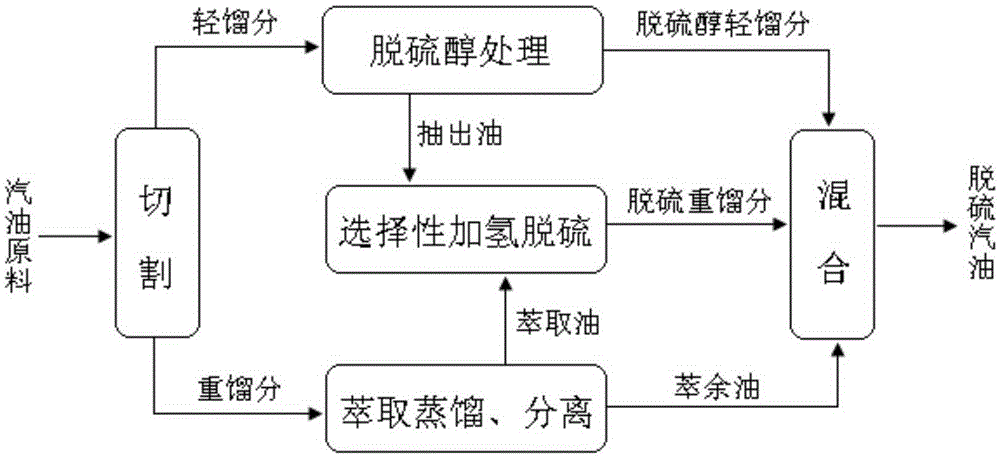

Coupling method of catalytic cracking gasoline desulfurization

ActiveCN105296000AEasy to removeRemoval is not easy to achieveTreatment with hydrotreatment processesOrganic solventExtractive distillation

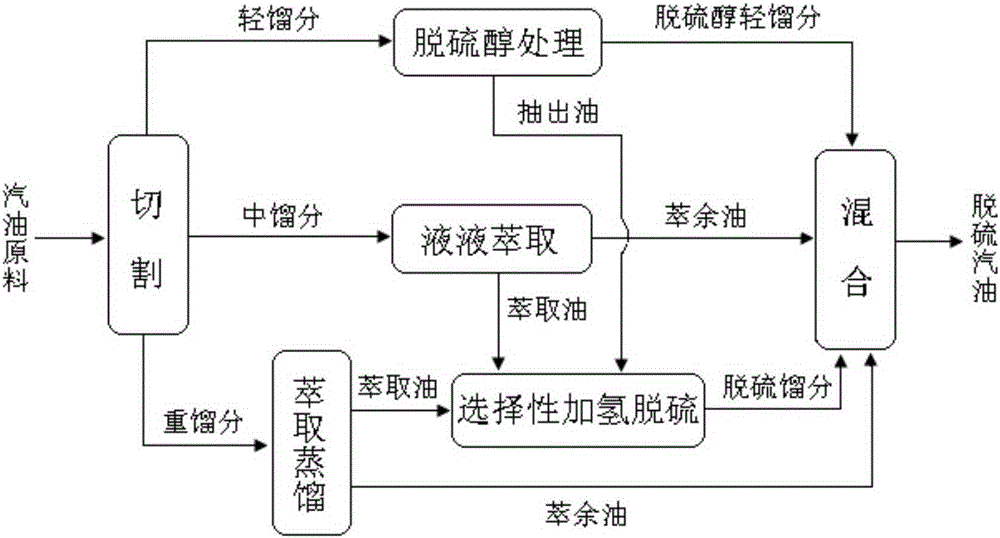

The invention provides a coupling method of catalytic cracking gasoline desulfurization. The coupling method comprises the following steps: cutting gasoline raw materials into light fractions, medium fractions and heavy fractions; carrying out extractive distillation on the medium fractions by an organic solvent to obtain olefin-contained raffinate and extracts which contain sulfide and arene; separating the organic solvent in the extracts to obtain extraction oil; carrying out selective hydrodesulfurization on the extraction oil and the heavy fractions to obtain the desulfurization heavy fractions; mixing the light fractions, the raffinate and the desulfurization heavy fractions to obtain desulfurization gasoline, wherein the cutting temperature of the light fractions and the medium fractions is 35 to 60DEG C, and the cutting temperature of the medium fractions and the heavy fractions is 140 to 160DEG C. According to the coupling method of the gasoline desulfurization, the octane value loss of a gasoline product can be obviously reduced, and desulfurization load is drastically lowered while deep desulfurization is realized. The yield of the product is greater than 95%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing waste water processing materials of organic-inorganic composite bentonite

InactiveCN1569660AImprove the coagulation effectAvoid competitive adsorptionWater/sewage treatment by sorptionClaywaresWater bathsPolymer science

The invention discloses a method for preparing waste water processing materials of organic-inorganic composite bentonite which comprises, (1) disintegrating the alta-mud, passing through 100 mesh sieve, charging into the solution of cationic surface active agent, stiring 1-2 hours in water-bath, (2) charging AlCl3 solution into the suspending liquid, stirring 5-10 minutes, (3) while water-bath stirring, charging NaOH or Na2CO3 solutions into the suspending liquid, stewing for over 10 hrs at room temperature, (4) multitime washing, filtering, drying and grinding.

Owner:ZHEJIANG UNIV

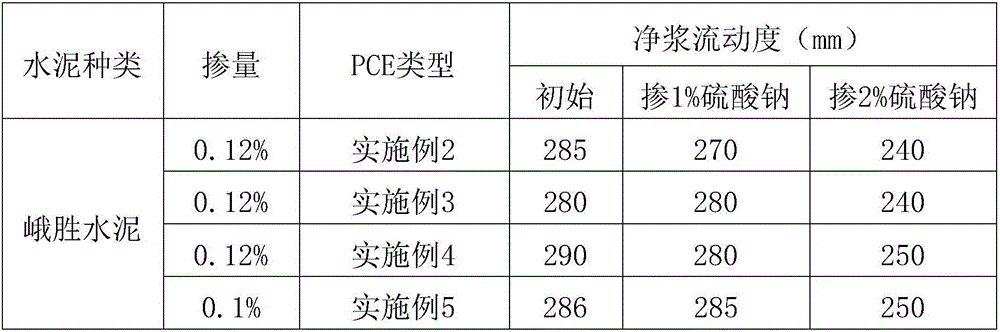

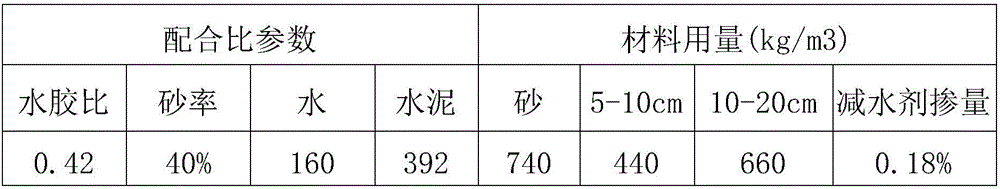

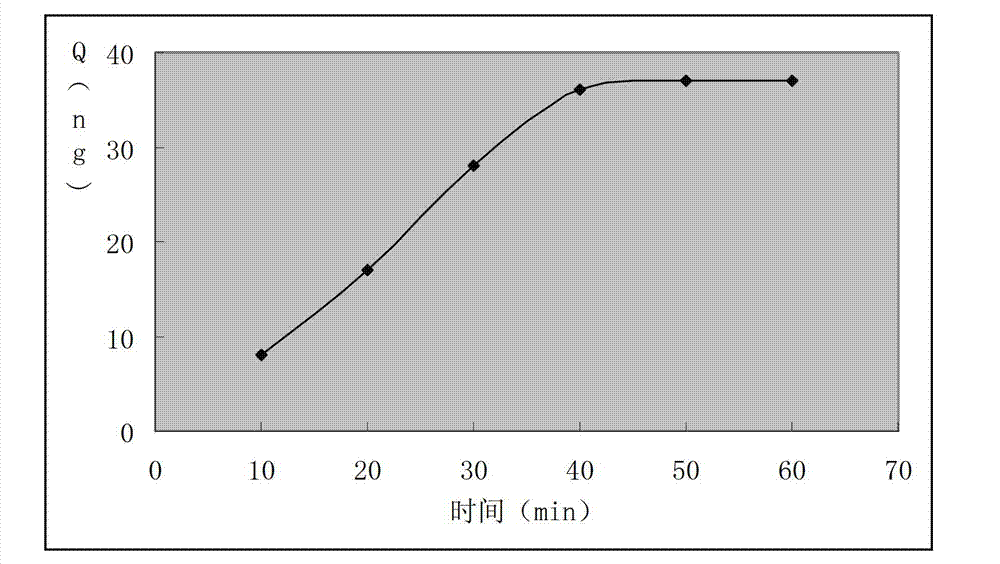

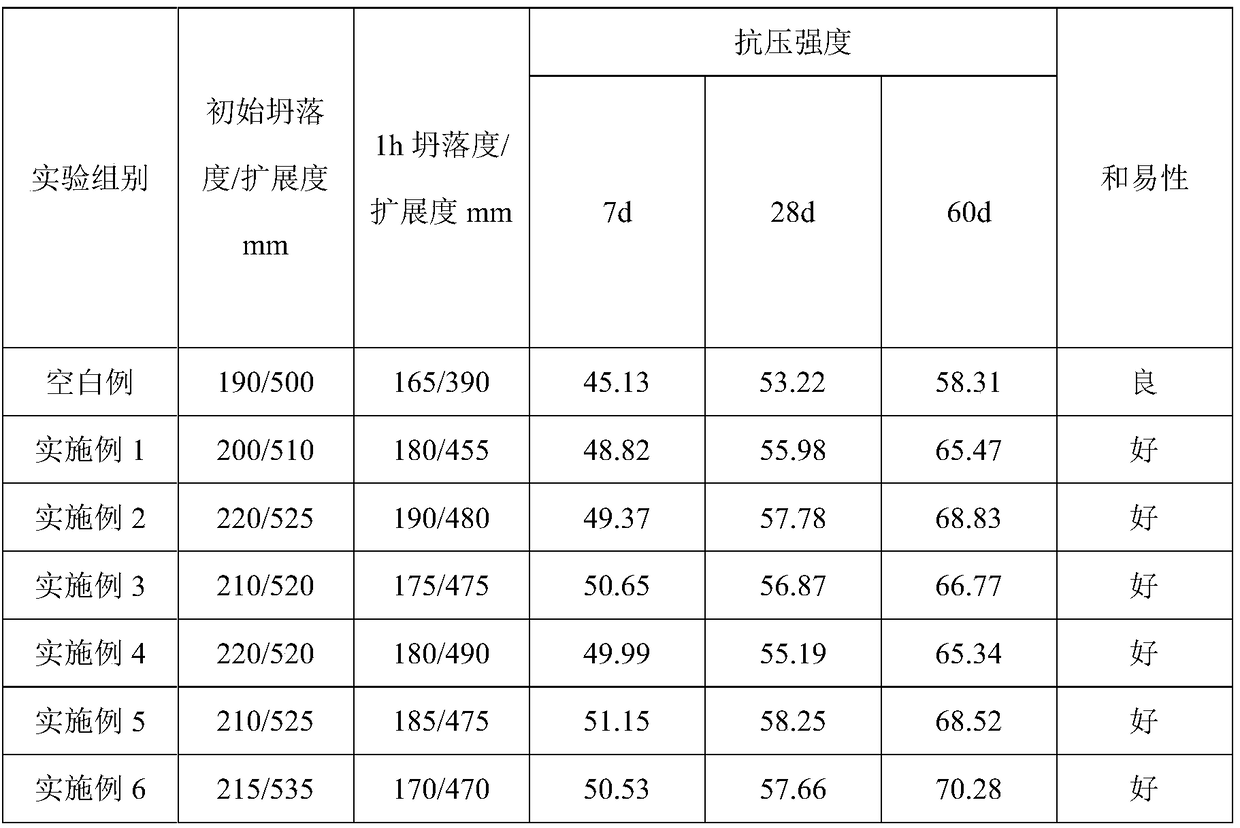

Silane polycarboxylate water-reducing agent and preparation method thereof

The invention relates to a method for preparing a silane polycarboxylate water-reducing agent, relates to a water-reducing agent in a concrete admixture and belongs to the technical field of building materials. The silane polycarboxylate water-reducing agent is prepared from polyoxyethylene ether macromonomer, sodium acrylate or a derivative monomer thereof, chain transfer agents, initiators, a silane functional monomer, 2-acryloyl amino-2-methyl-1-propane sulfonic acid and deionized water. The chain transfer agents are thioglycolic acid, mercaptopropionic acid, sodium methallyl sulfonate and sodium allylsulfonate. The initiators are sodium persulfate and ammonium persulfate. Silane monomer maleic anhydride and triethoxy silane propylamine are prepared through amidation. The silane polycarboxylate water-reducing agent is novel in molecular structure design, high in sulfate resistance and good in concrete material adaptability. The product has an obvious sulfate resistance effect while having a high performance water-reducing effect.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

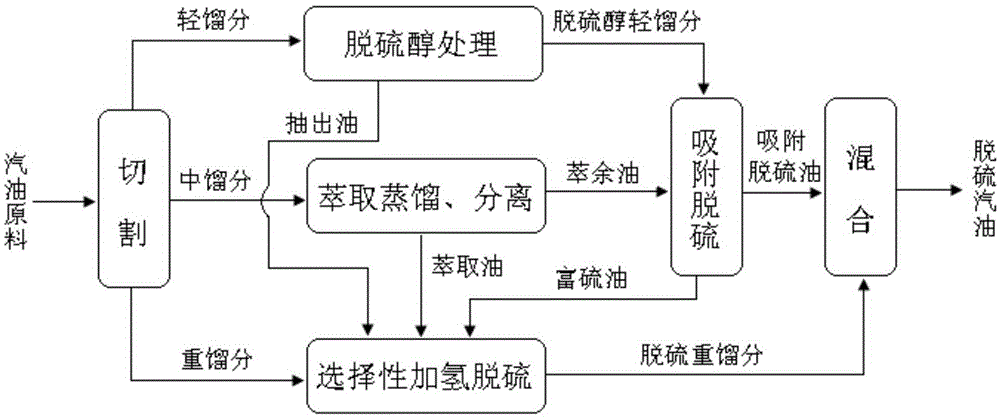

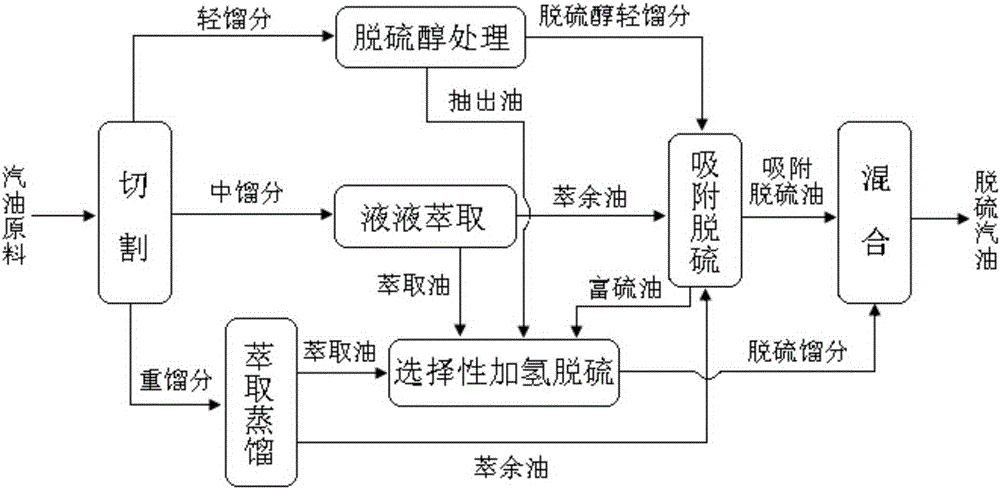

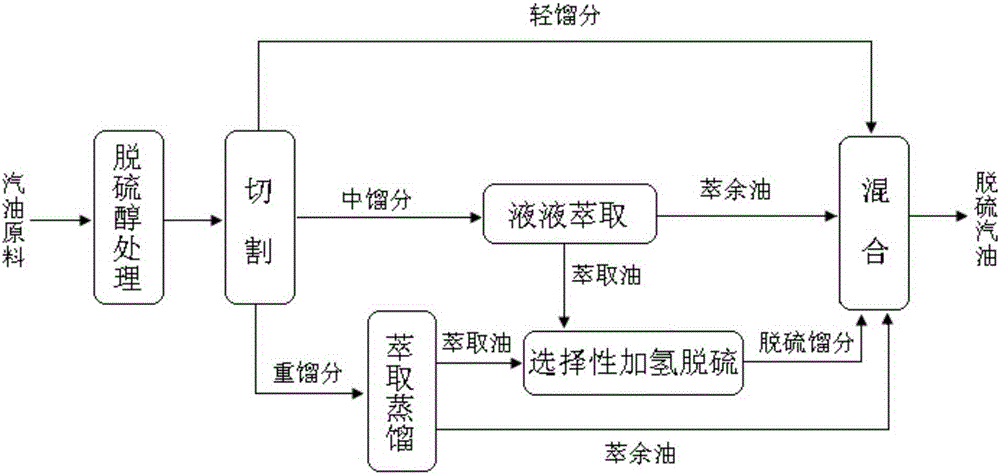

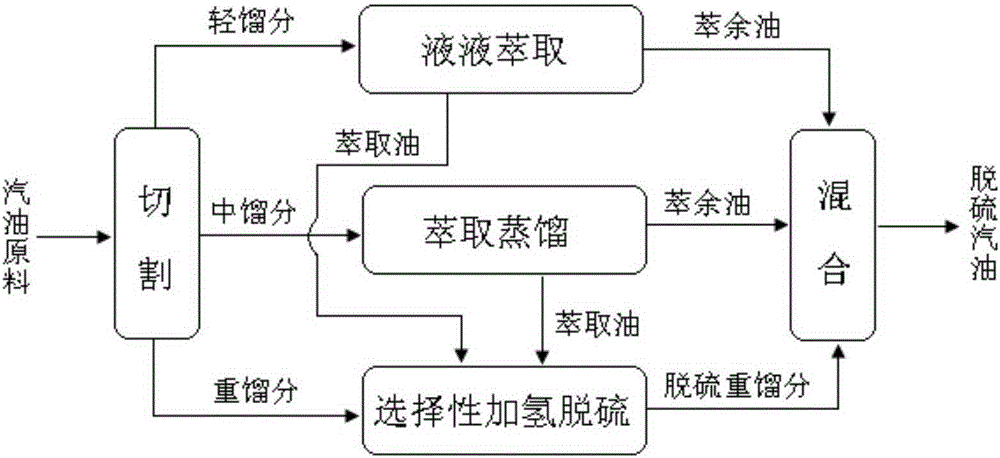

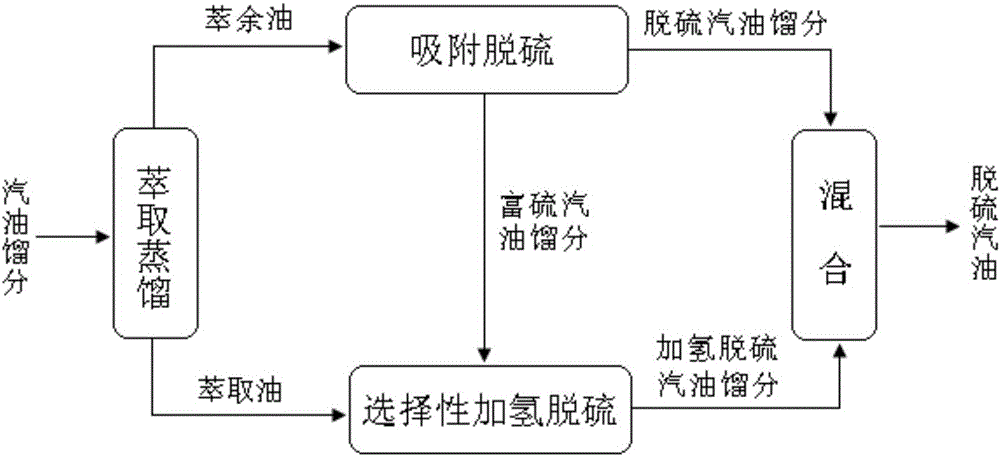

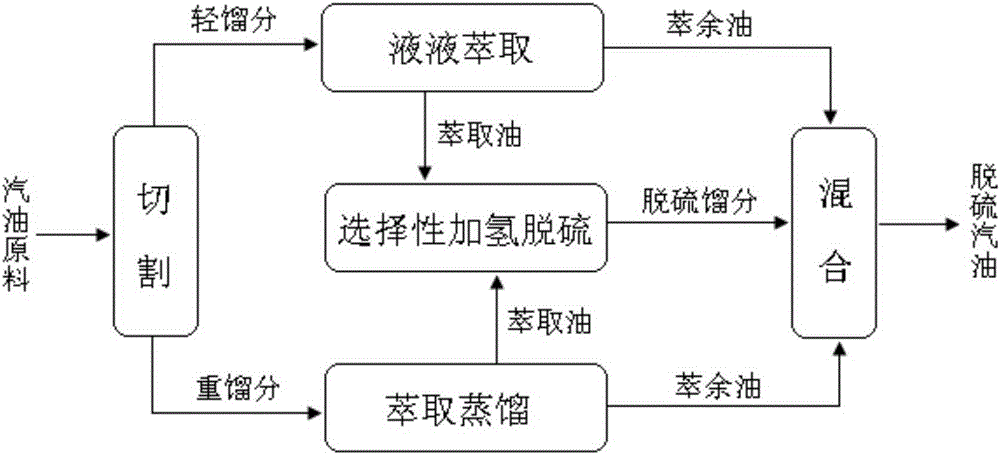

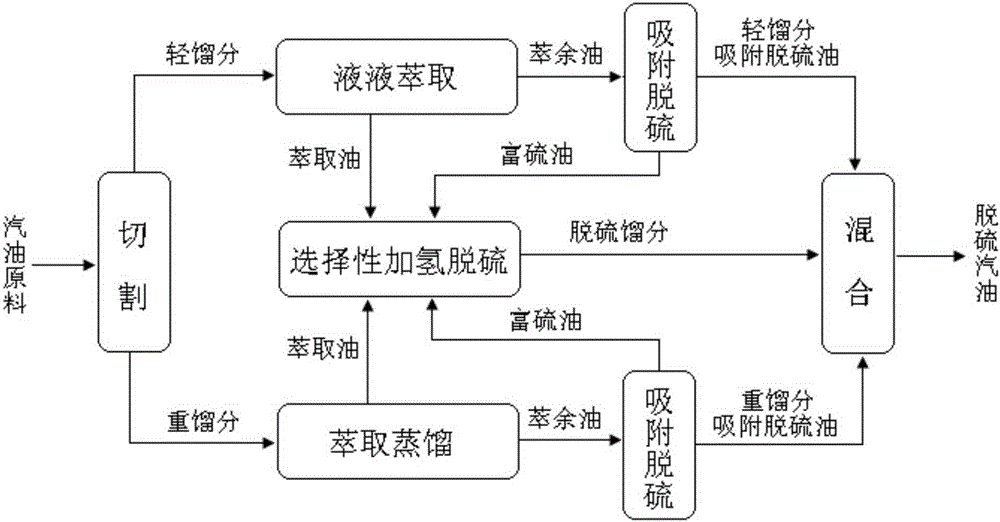

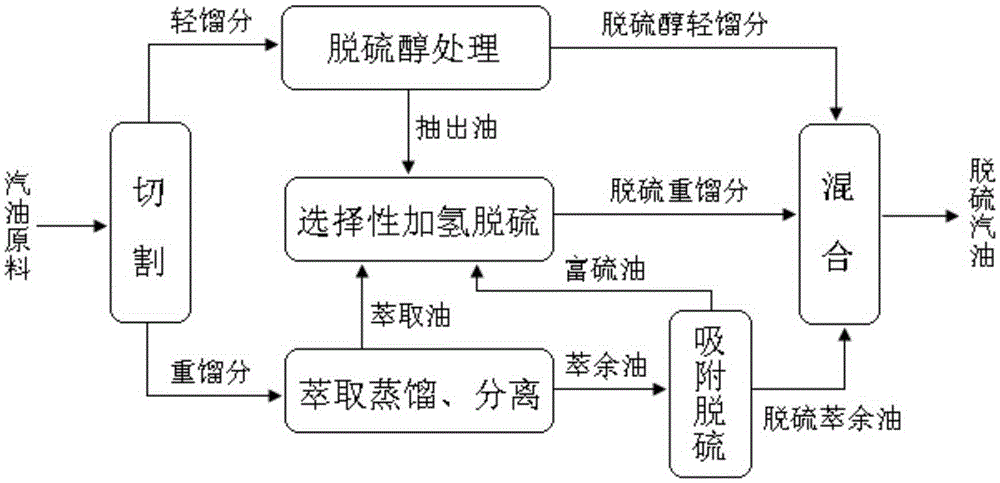

Combination method for producing ultralow sulphur gasoline

ActiveCN105255515AEasy to removeRemoval is not easy to achieveTreatment with hydrotreatment processesChemistrySulfide

The invention provides a combination method for producing ultralow sulphur gasoline. The combination method includes the following steps that gasoline raw materials are cut into light fractions, medium fractions and heavy fractions; the medium fractions are subjected to liquid-liquid extraction, and olefin-containing medium-fraction raffinate and sulfide-and-arene-containing medium-fraction extract oil are obtained; the heavy fractions are extracted and distilled, and olefin-containing heavy-fraction raffinate and sulfide-and-arene-containing heavy-fraction extract oil are obtained; selective hydrogen desulfurization is carried out on the medium-fraction extract oil and the heavy-fraction extract oil, and desulfurized fractions are obtained; the light fractions, the medium-fraction raffinate, the heavy-fraction raffinate and the desulfurized fractions are mixed, and the desulfurized gasoline is obtained. The cutting temperature of the light fractions and the medium fractions ranges from 35 DEG C to 50 DEG C, and the cutting temperature of the medium fractions and the heavy fractions ranges from 80 DEG C to 110 DEG C. By means of the combination method, deep desulfurization is achieved; meanwhile, losses of the octane value of gasoline products can be remarkably reduced, desulfurization loads can be greatly reduced, and the product yield is higher than 95%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

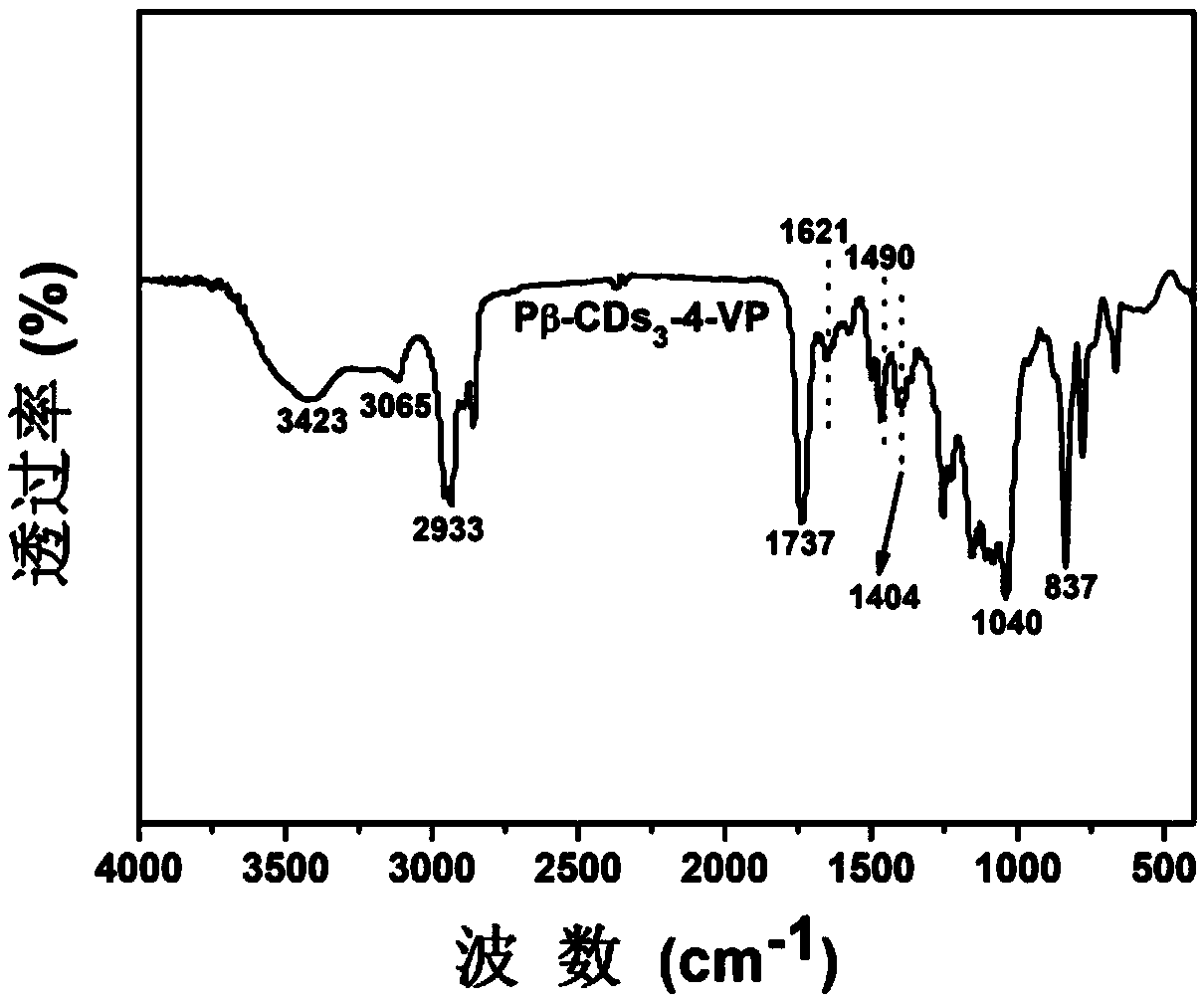

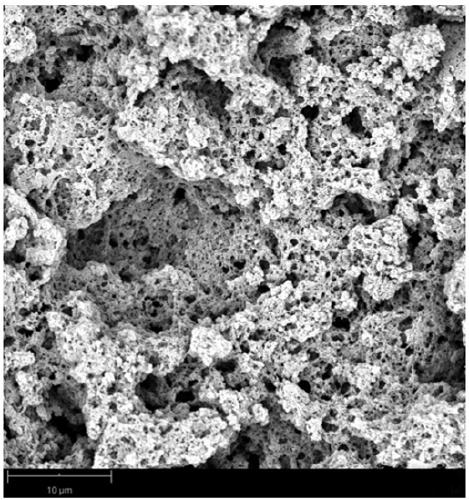

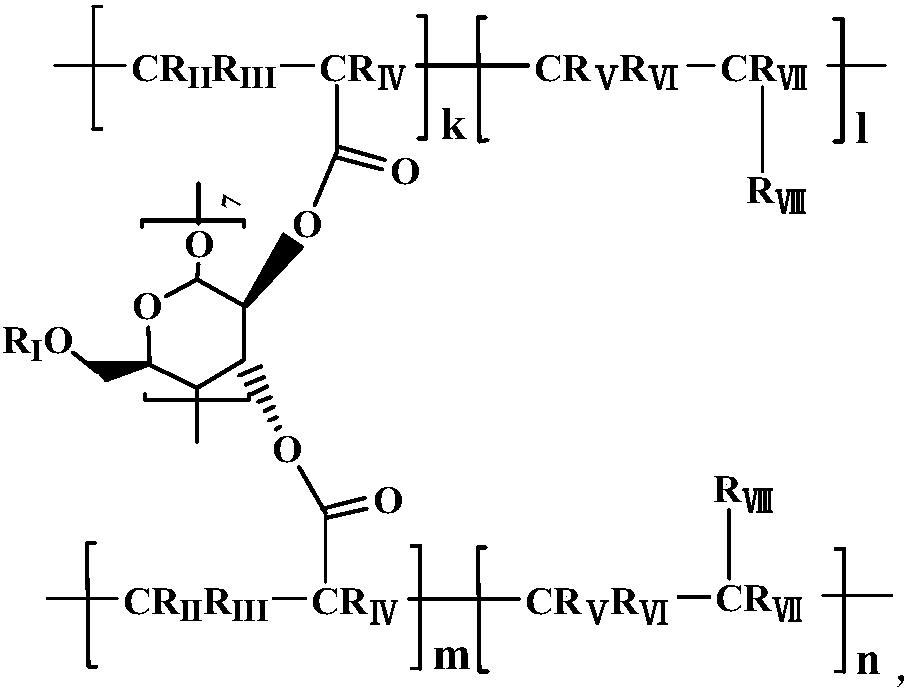

Beta-cyclodextrin polymer adsorbent, and preparation method and application thereof

ActiveCN109046280AAvoid competitive adsorptionIncrease contact areaOther chemical processesWater contaminantsPolymer adsorbentSilanes

The invention discloses a beta-cyclodextrin polymer adsorbent applicable to adsorption of dye and heavy metal ions, and a preparation method and application thereof. According to the method, modifiedbeta-cyclodextrin, obtained by reaction between a silane-protected beta-cyclodextrin derivative and alkenyl anhydride, and heterocyclic olefinic monomers are subjected to free-radical crosslinking copolymerization to obtain the beta-cyclodextrin polymer adsorbent, wherein the structural general formula is shown in the description. The porous large-specific-surface copolymer can be formed during copolymerization between the modified beta-cyclodextrin and the heterocyclic olefinic monomers, and different adsorption sites are provided for the organic dye and the heavy metal ions, so that the adsorption capacity of the adsorbent can be improved greatly, and the mutual inhibition of the organic dye and the heavy metal ions as wells as the poor removal effect can be relieved effectively.

Owner:SICHUAN UNIV

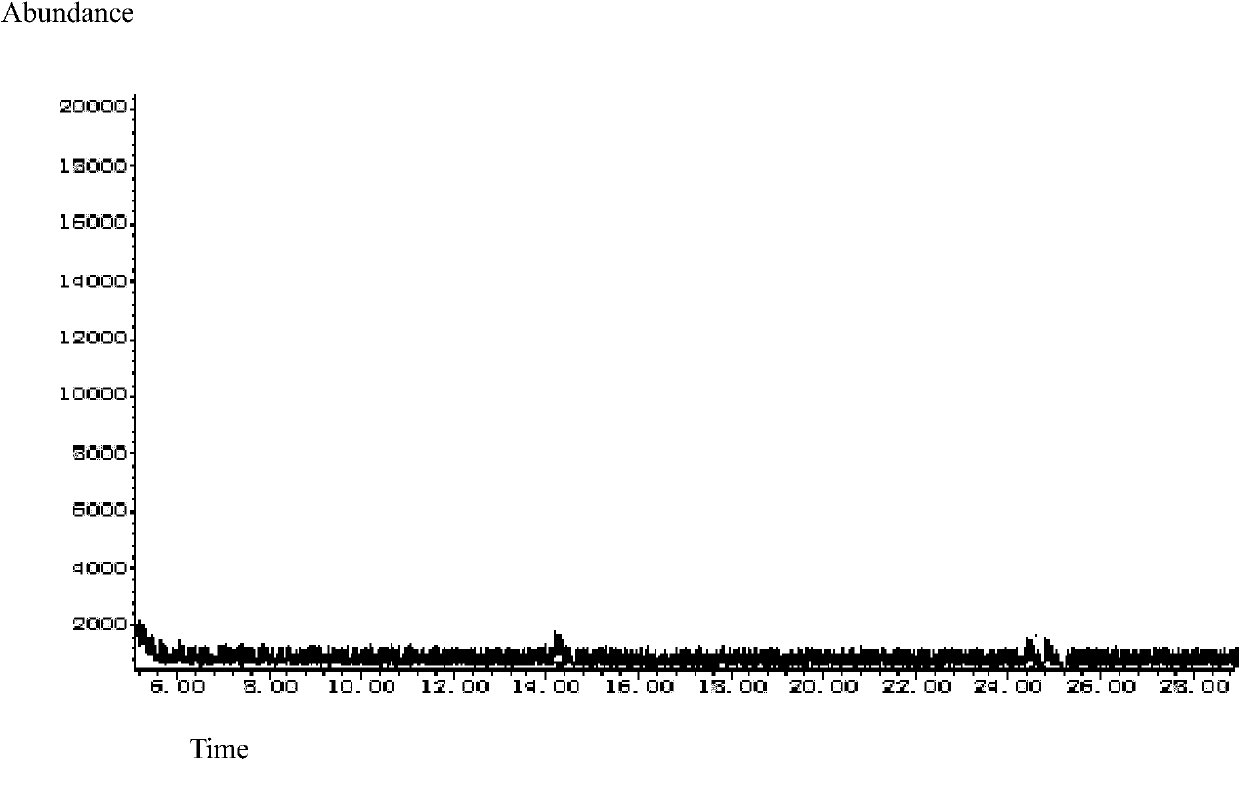

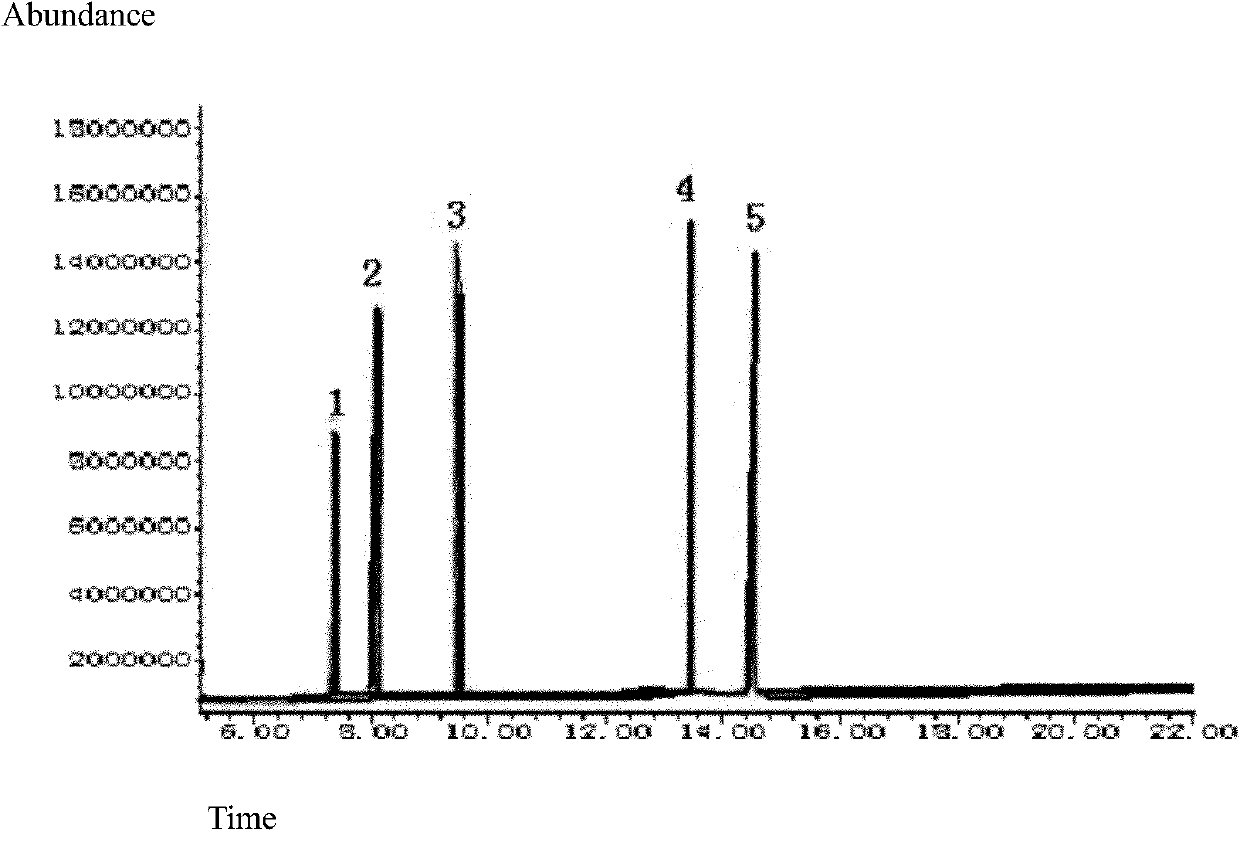

Preparation method of metal carrier Tenax coating stirring and extracting rod

InactiveCN101992069AAchieve enrichmentAvoid competitive adsorptionIon-exchange process apparatusOther chemical processesEpoxyTenax

The invention relates to a preparation method of a metal carrier Tenax coating stirring and extracting rod, which comprises the following steps of: a, selecting and preprocessing a metal rod; b, synthesizing heat-resistant epoxy resin; c, manufacturing a stirring rod coating; d, curing the coating; and e, removing impurities of the extracting rod body, wherein the extracting rod is used in a stirring manner, and the metal is iron, nickel, cobalt, stainless steel or alloy; and when the extracting rod is used in a headspace or ultrasonic manner, the metal is stainless steel, copper, aluminum or alloy. Tenax is fixed on the surface of the metal rod by using the synthesized heat-resistant epoxy resin or organic silicon resin to form a coating material with heat stability and solvent washing resistance, thus the extracting rod realizes the enrichment of trace organic matters. The invention is especially suitable for processing samples of soil, air, essence and spice, indoor air, alcohol, phenol, amine-aldehyde, ketone, aryl halides and the like.

Owner:TIANJIN CHUNFA BIO TECH GRP

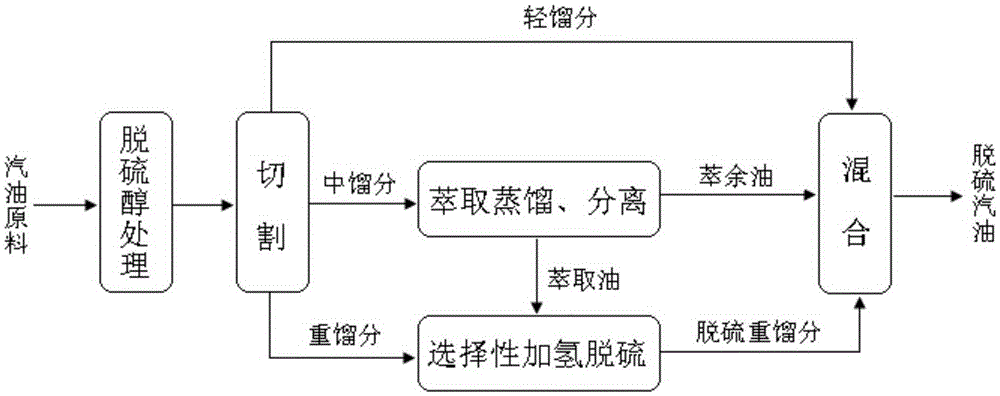

Method for carrying out advanced desulphurization on gasoline

InactiveCN105238441AEasy to removeRemoval is not easy to achieveTreatment with hydrotreatment processesHydrodesulfurizationExtractive distillation

The invention provides method for carrying out advanced desulphurization on gasoline. The method comprises the following steps: cutting a gasoline raw material into light fraction, intermediate fraction and heavy fraction; carrying out liquid-liquid extraction on the light fraction to obtain olefin-containing light fraction raffinate oil and light fraction extraction oil containing sulfide and aromatic hydrocarbon; carrying out extraction distillation on the intermediate fraction to obtain olefin-containing intermediate fraction raffinate oil and intermediate fraction extraction oil containing sulfide and aromatic hydrocarbon; carrying out selective hydrodesulfurization on the light fraction extraction oil, the intermediate fraction extraction oil and the heavy fraction to obtain a desulfurized heavy fraction; and mixing the light fraction raffinate oil, the intermediate fraction raffinate oil and the desulfurized heavy fraction to obtain desulfurized gasoline, wherein the cutting temperature of the light fraction and the intermediate fraction is 80-120DEG C, and the cutting temperature of the intermediate fraction and the heavy fraction is 150-170DEG C. The method has the advantages of realization of advanced desulphurization, great reduction of the loss of the octane number of a gasoline product, and great reduction of the desulphurization load, and allows the yield of the product to be greater than 95%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

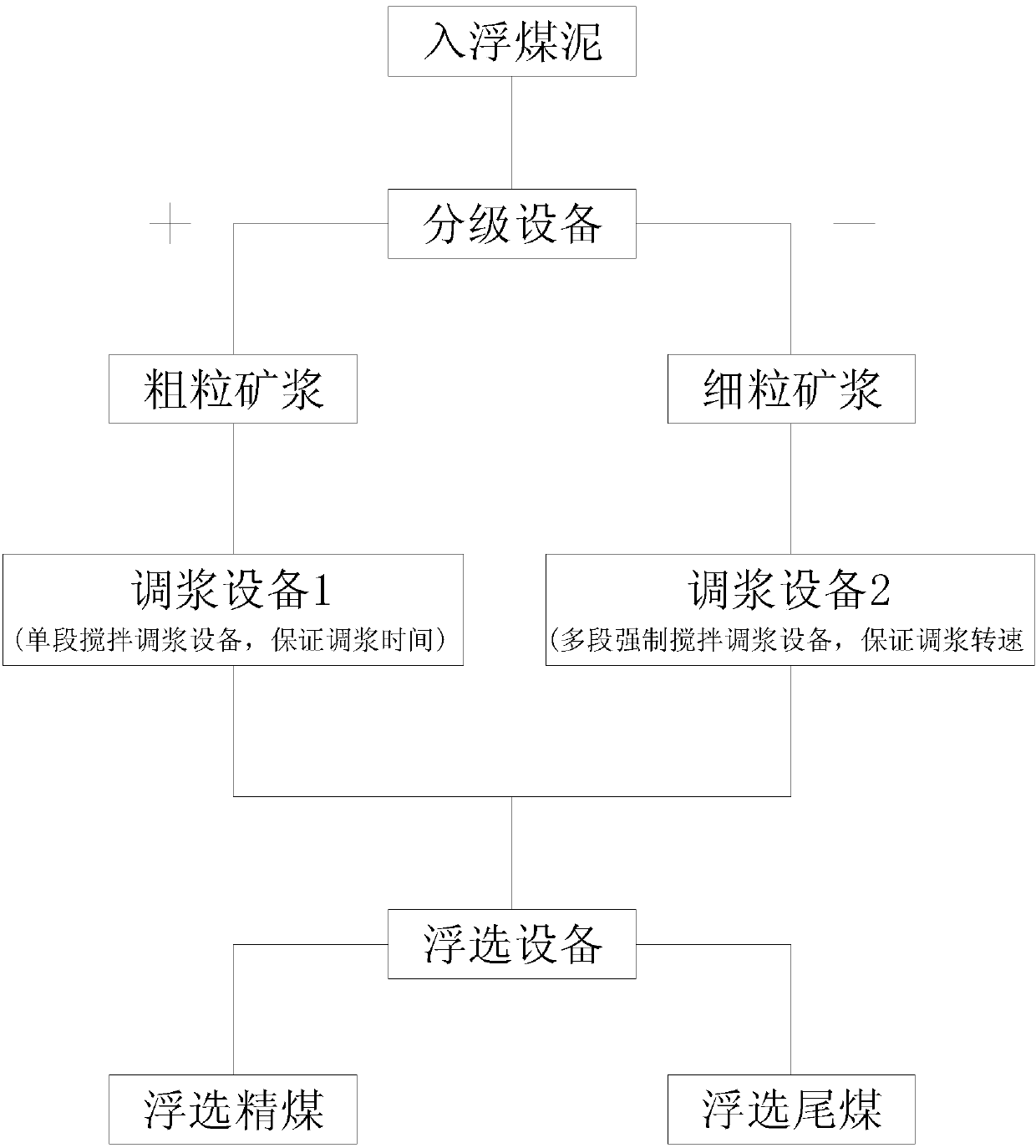

Grading size mixing and bulk flotation separation process

InactiveCN104741211AImprove adsorption capacityGuarantee different needsFlotationWet separationCycloneImpeller

The invention discloses a grading size mixing and bulk flotation separation process. The grading size mixing and bulk flotation separation process comprises the following steps that 1, flotation feeding coal slime is pumped to a grading cyclone to be graded according to a certain granularity (0.074mm or 0.125mm), and coarse pulp and fine pulp obtained after grading enter a size mixing device for size pre-mixing; 2, the coarse pulp enters a single-section impeller size mixing agitator, the size mixing time is no less than 4 min so as to ensure sufficient adsorption of flotation collectors on the surfaces of mine particles, the fine pulp enters a multi-section forced stirring size mixing device provided with three layers of stirring impellers and a high stirring rotation speed, and the linear velocity of the stirring impellers is no less than 6 m / s; 3, the coarse pulp and fine pulp after size pre-mixing are mixed through a pipeline and fed to a flotation column / machine, and flotation clean coal and flotation tailings are obtained after separation of the flotation column / machine. The grading size mixing and bulk flotation separation process is simple in technological process, low in investment, low in energy consumption, low in operation expense, high in separation efficiency and remarkable in economic benefit.

Owner:CHINA UNIV OF MINING & TECH

Catalyst for synthesis of ethanol from synthetic gas, preparation method and application thereof

ActiveCN106513001AEasy to prepareAvoid influenceOrganic compound preparationHeterogenous catalyst chemical elementsPotassium oxideHigh selectivity

The invention relates to a catalyst for synthesis of ethanol from synthetic gas. The catalyst includes the following components by weight percentage: 1.0-20.0% of copper oxide, 5.0-15.0% of zirconia, 1.0-6.0% of potassium oxide, and 60.0-90.0% of a carrier. The catalyst and the method provided by the invention have the advantages of high selectivity, simple preparation process and mild operation process conditions.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

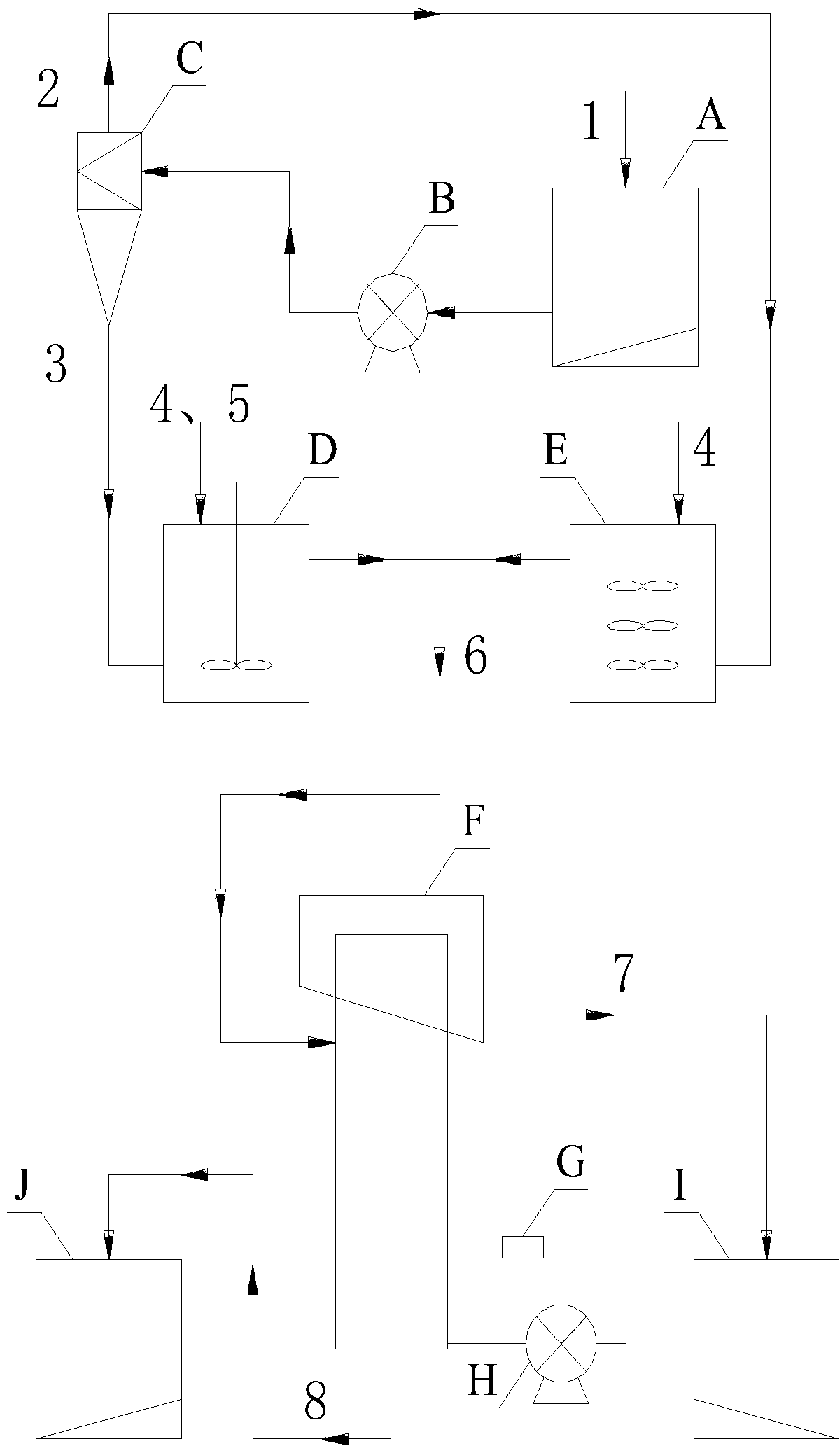

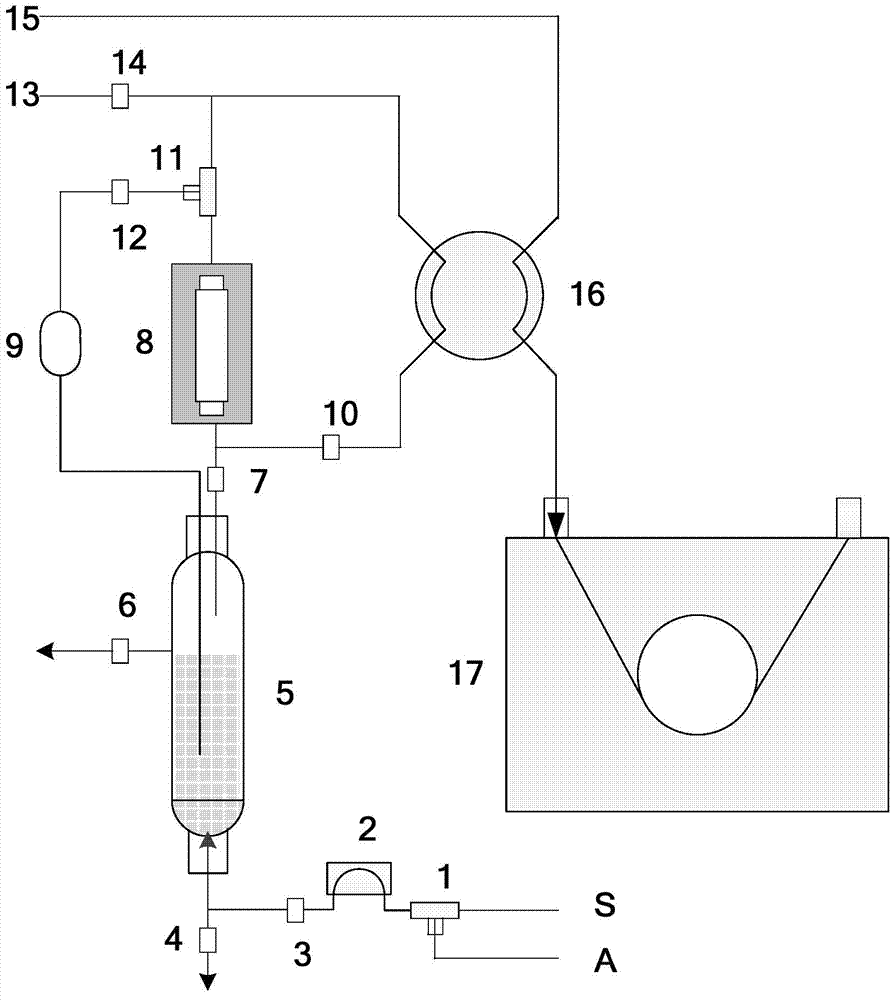

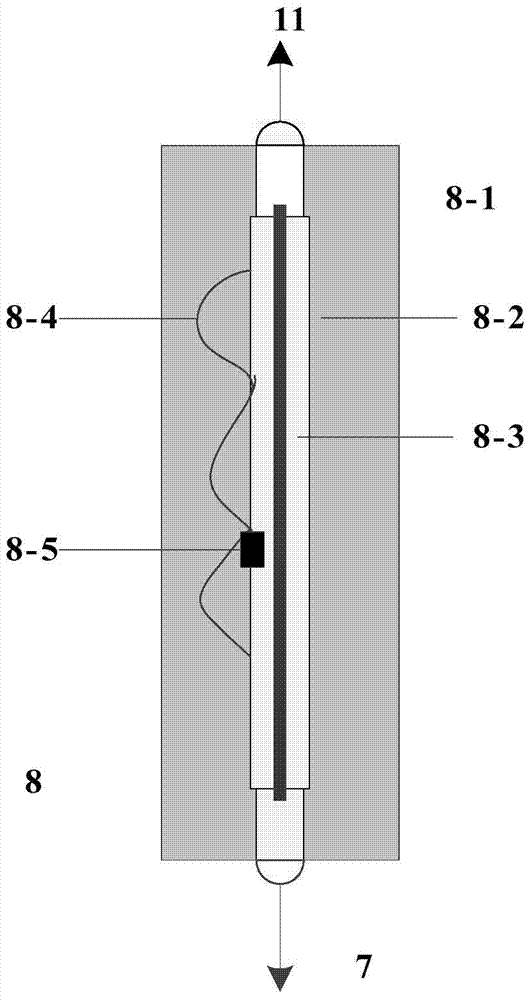

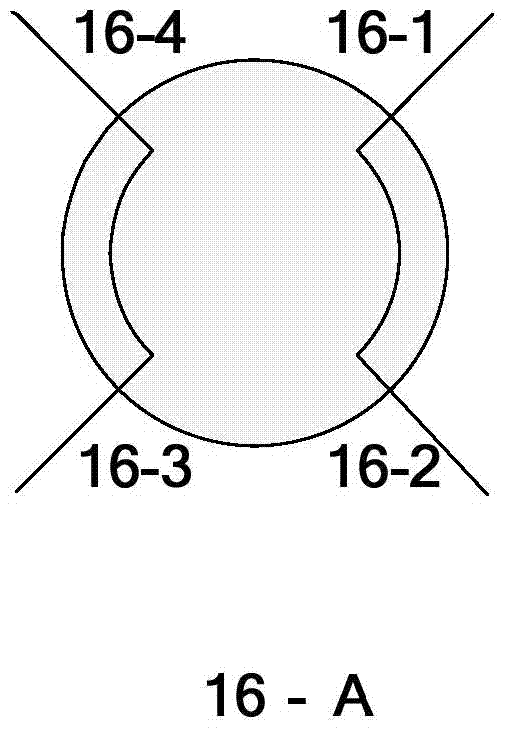

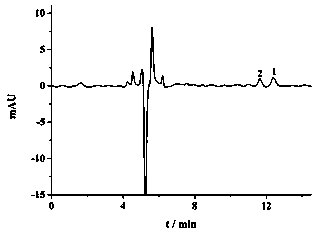

Online pretreatment method and online pretreatment device of SVOCs (Semi Volatile Organic Compounds) in water

ActiveCN103675154AAvoid competitive adsorptionImprove adsorption capacity and enrichment factorComponent separationVolatile organic compoundChemistry

The invention discloses an online pretreatment method and an online pretreatment device of SVOCs (Semi Volatile Organic Compounds) in water. A water sample circulates to carry out contact adsorption with a fixed extracting rod by using an online pulse extraction technology, so that the competitive adsorption of the surface of a stirrer on the sample in solid phase microextraction of fiber is avoided, and the extracting rod is prevented from colliding with a container, thus the service life is prolonged. On the basis of the method, the invention also provides the online pretreatment device of the SVOCs in water, which can be used for realizing procedures of fully-automatic sampling, sampling matching, adsorptive enrichment, analysis and self-washing of a flow passage as well as intermittent pretreatment of the SVOCs in the water sample and is very suitable for online pretreatment of the SVOCs in the water.

Owner:LIHE TECH (HUNAN) CO LTD

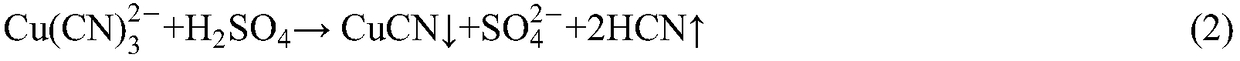

Method for purifying thiocyanate ions in cyanide-containing wastewater by means of flocculation and sedimentation

InactiveCN109502811ASimple processReduce potion consumptionWater contaminantsTreatment involving filtrationIron(III) sulfateChemistry

The invention relates to a method for purifying thiocyanate ions in cyanide-containing wastewater by means of flocculation and sedimentation. By means of research on a purification process of the cyanide-containing wastewater with different concentrations, the process parameters such as solution pH values and the consumption of ferric sulfate and polyferric sulfate are determined; the cyanide-containing wastewater is acidified, and cyanide is recovered; then, the residual cyanide is filtered and removed by means of by precipitation of the ferric sulfate; lime milk is added into the filtrate for adjusting the pH, and the thiocyanate ions are removed by means of flocculation and precipitation of the polyferric sulfate. The method solves the problem that due to the accumulation of the thiocyanate ions in the gold cyanide smelting wastewater, barren liquor can not be reused normally, and the normal smelting process is further influenced; the method guarantees the normal proceeding of goldcyanide leaching and subsequent absorption and replacement processes, and effective improves the smelting recovery rate.

Owner:BACKFILL ENG LAB SHANDONG GOLD MINING TECH CO LTD

Aluminum oxide coating stirring extraction rod of metal carrier

InactiveCN101992072AHigh mechanical strengthImprove thermal stabilityIon-exchange process apparatusOther chemical processesSorbentAlloy

The invention relates to an aluminum oxide coating stirring extraction rod of a metal carrier. The carrier of the extraction rod is metal, and the coating of the extraction rod contains an adsorbent. When the extraction rod is used in a stirring mode, the metal is iron or nickel or cobalt or stainless steel or alloy; when the extraction rod is used in a headspace or ultrasonic mode, the metal is the stainless steel or copper or aluminum or the alloy. The adsorbent is a metal oxide adsorbent. The extraction rod has higher mechanical strength and is sturdy and durable by replacing the traditional glass rod with a metal rod; and a mode that the adsorbent is combined to the stirring rod is more beneficial to the treatment and the static headspace trapping of liquid samples by the adsorbent.

Owner:TIANJIN CHUNFA BIO TECH GRP

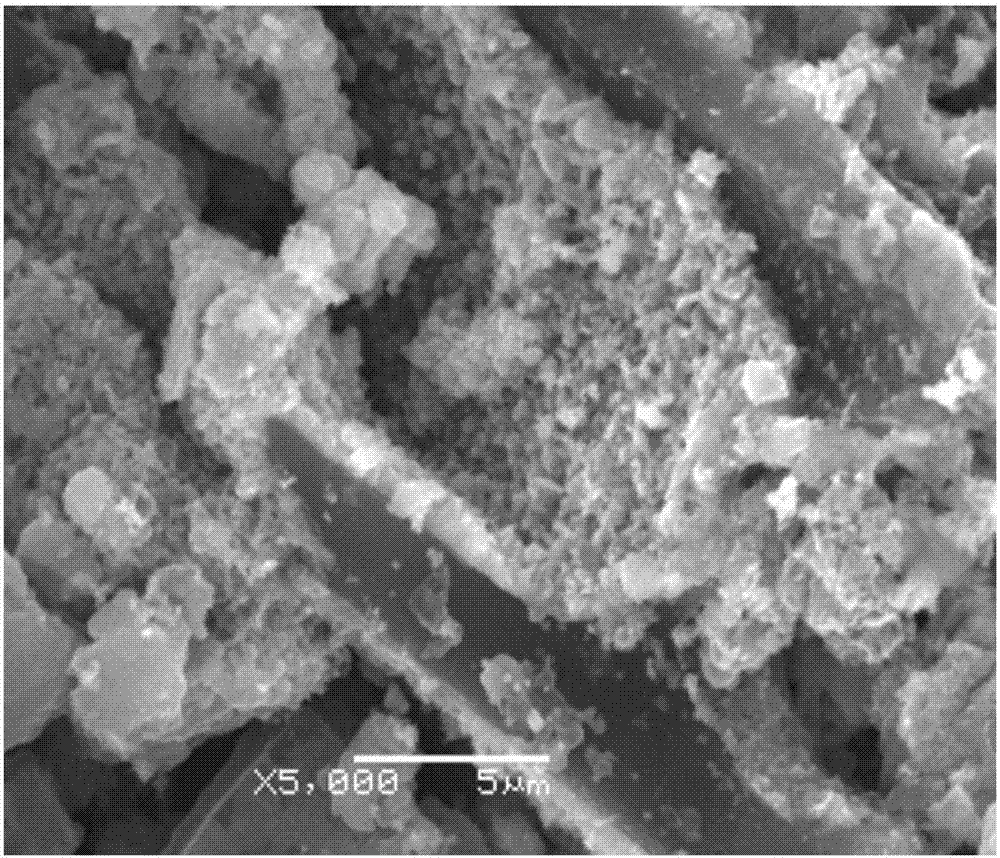

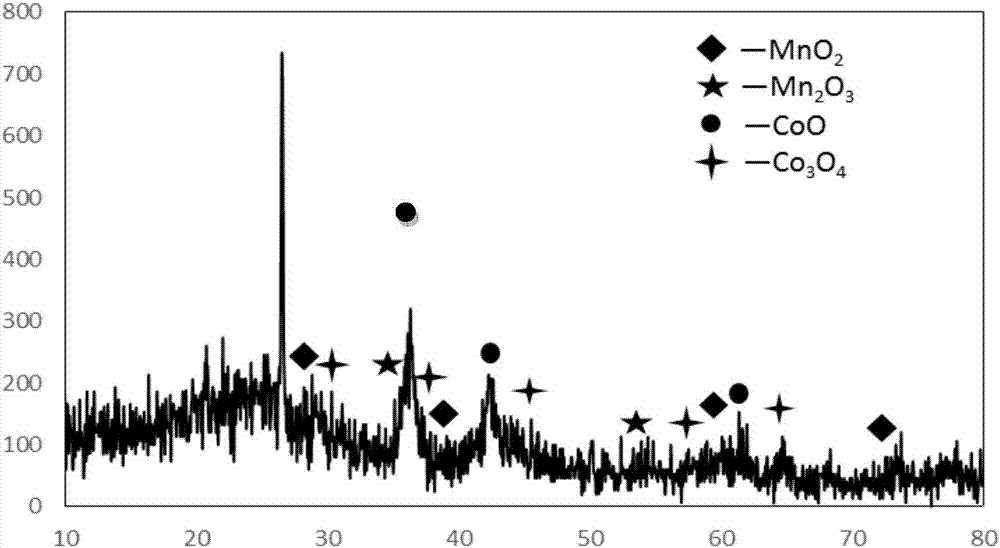

Method for preparing SCO denitration catalyst by virtue of plasma method

InactiveCN107008338AImprove denitrification efficiencyGood catalytic activity at low temperatureGas treatmentDispersed particle separationNitrateManganese

The invention discloses a method for preparing an SCO denitration catalyst by virtue of a plasma method. The method comprises the following steps: (1) sieving brown coal particles by virtue of a sieve, and roasting the brown coal particles in a tubular furnace, so as to obtain pyrolysis coke; (2) dipping the pyrolysis coke into a manganese nitrate solution by virtue of an equivalent-volume impregnation method, so as to obtain pyrolysis coke dipped with manganese nitrate; (3) dipping the pyrolysis coke dipped with manganese nitrate into a cobalt nitrate solution by virtue of the equivalent-volume impregnation method, so as to obtain pyrolysis coke dipped with manganese nitrate and cobalt nitrate; and (4) frying the pyrolysis coke dipped with manganese nitrate and cobalt nitrate by virtue of an electric furnace, putting the pyrolysis coke into a plasma reaction kettle, and carrying out low-temperature plasma roasting, so as to obtain the SCO denitration catalyst. By improving existing preparation methods of denitration catalysts, the catalyst is subjected to pyrolysis coke surface modification by utilizing a plasma method and changing background gas, so that the ratio of a surface pore structure of the catalyst is increased, and the catalytic performance of the SCO denitration catalyst is improved.

Owner:XIAN UNIV OF SCI & TECH

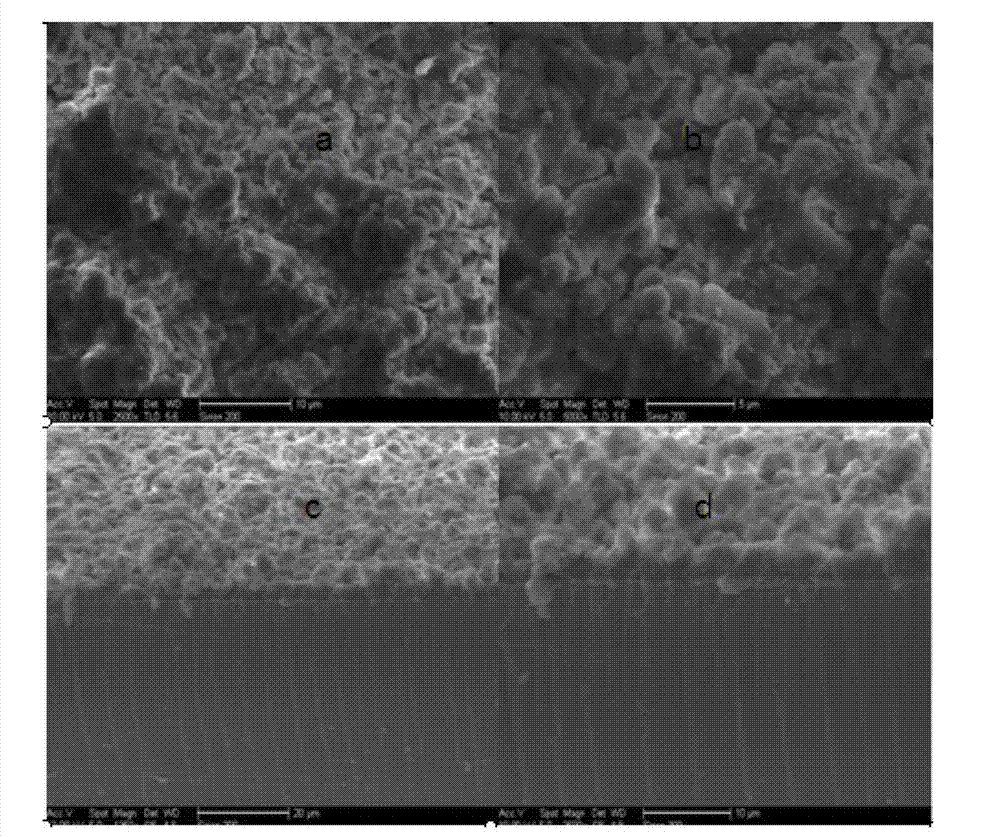

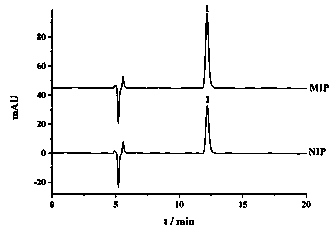

Preparation method of dumbbell-shaped molecular imprinting stirring rod

InactiveCN103111260AImprove thermal stabilityNo sheddingOther chemical processesAlkali metal oxides/hydroxidesCross-linkFunctional monomer

The invention discloses a preparation method of a dumbbell-shaped molecular imprinting stirring rod. The method comprises the following steps of: dipping on the dumbbell-shaped stirring rod in alkali and acid in turn for carrying out activation and silanization reaction; further dipping the dumbbell-shaped stirring rod into a trimethylolpropane tricrylic acid ester solution to carry out grafting reaction; putting a template molecule vardenafil and a functional monomer into a pore-foaming agent for prepolymerization, subsequently adding a cross-linking agent and an initiator and putting into the grafted dumbbell-shaped stirring rod to polymerize; repeating the polymerization reaction of the dumbbell-shaped stirring rod, further aging, and finally washing the template molecules so as to obtain the dumbbell-shaped molecular imprinting stirring rod. The stirring rod prepared by using the preparation method is combined with a chromatograph and can be applied to rapid separation and enrichment of nafil compounds in complex matrixes such as food, medicines and health-care products, so that accurate detection on a sample, with high selectivity and high sensitivity, is achieved.

Owner:NANJING MEDICAL UNIV

Method for preparing cement asphalt (CA) mortar for China railway track system (CRTS) II slab ballastless tracks

InactiveCN102070354AAvoid Competitive AdsorptionAvoid demulsificationCeramicwareElastic modulusEmulsion

The invention discloses a method for preparing cement asphalt (CA) mortar for China railway track system (CRTS) II slab ballastless tracks, which comprises the following steps of: (1) mixing cement with fine sand, an expanding agent and aluminum powder according to proportion to prepare dry CA mortar powder; and (2) sequentially adding a poly carboxylic acid serving as a high-performance water reducing agent, an antifoaming agent and silica sol into water for uniform stirring, adding the dry CA mortar powder for uniform stirring, and adding asphalt emulsion for uniform stirring to obtain the CA mortar for the CRTS II slab ballastless tracks. The method has the advantages of: (1) avoiding cement particles competitively absorbing an emulsifier in the asphalt emulsion, and preventing the asphalt emulsion in the CA mortar from being demulsified to cause bleeding; and (2) reducing the using amount of the asphalt emulsion and the using amount of the water on the basis of ensuring flowability, and strengthening the strength of the CA mortar on the basis of meeting an elastic modulus of the CA mortar.

Owner:ZHEJIANG UNIV

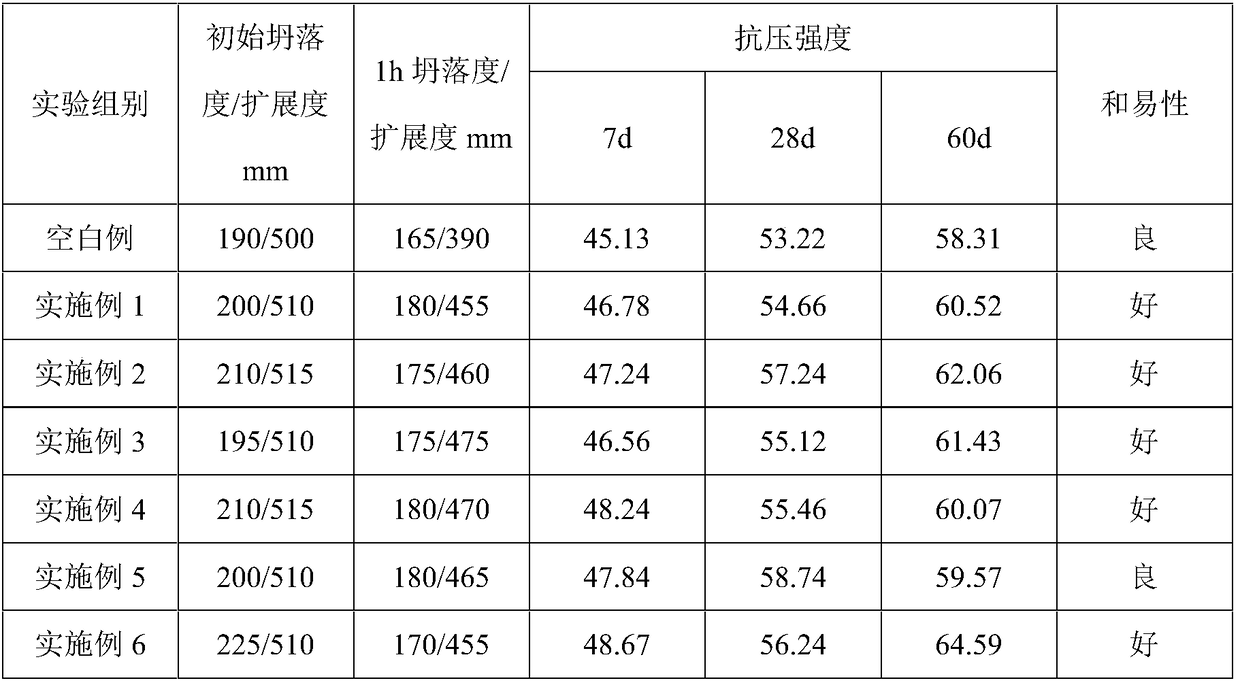

A method for preparing a cementitious material reducing admixture from a cationic polymer

A method for preparing a cementitious material reducing admixture from a cationic polymer is provided. The admixture is prepared from, by weight, 10-20 parts of an alcohol amine compound, 1-5 parts oforganic polyol, 10-25 parts of the cationic polymer, and 0.05-0.1 part of a lubricant, with the balance being water. The admixture is prepared by adding the components into a reactor, and fully stirring the materials for 0.5 h. The cementitious material reducing admixture is prepared by a manner of polymerizing a small cationic monomer to obtain the cationic polymer having a high molecular weight. The cationic polymer has good structure designability and synergistic effect and matches with a water reducing agent well, so that the dosage of a cementitious material can be significantly reduced,and dispersibility, water retention performance and long-term strength of concrete can be improved.

Owner:HUBEI UNIV OF TECH

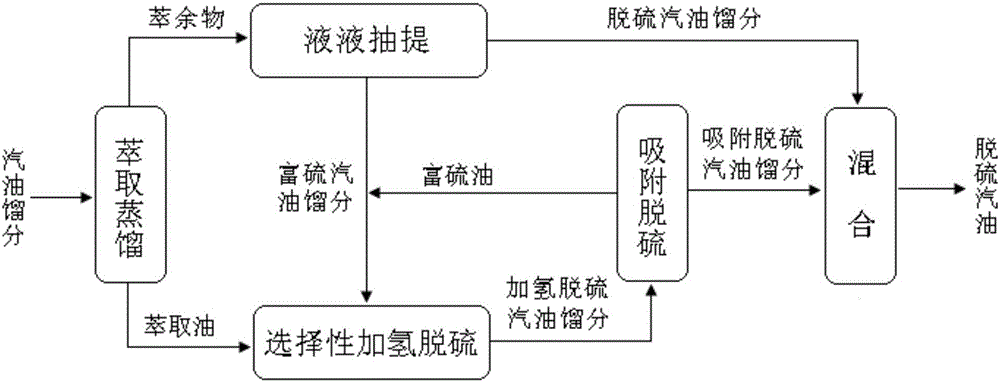

Gasoline desulfurization method

ActiveCN105154132AAvoid lostEasy to desulfurizeHydrocarbon oils treatmentSulfideLiquid–liquid extraction

The invention provides a gasoline desulfurization method which comprises the following steps: performing extractive distillation on gasoline fractions, so as to obtain extraction residues containing olefin and extractives containing sulfides and arene; performing desulfuration treatment on the extractives, so as to obtain desulfurized gasoline fractions and sulfur-rich gasoline fractions, wherein the desulfuration treatment is liquid-liquid extraction or adsorption desulfuration; separating organic solvents in the extractives, so as to obtain extract oil containing sulfides and arene. Through the adoption of the gasoline desulfurization method, the deep desulfurization can be realized, the octane value loss of gasoline products can be remarkably reduced, the desulfuration load can be greatly reduced, and the product yield is greater than 95%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

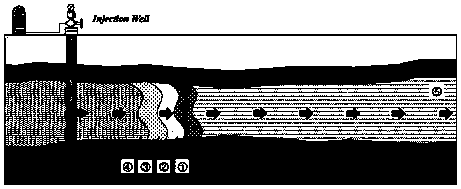

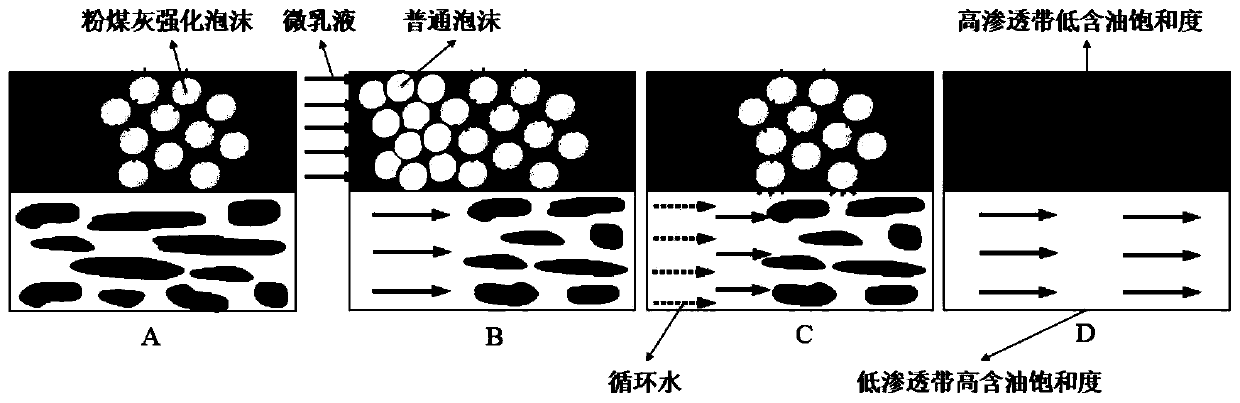

Oil field ultra-high water cut stage fly ash reinforced multiphase composite profile control and flooding method

ActiveCN110984933AEnhanced overall recoveryImprove microscopic heterogeneityFluid removalDrilling compositionActive agentOil phase

The invention discloses an oil field ultra-high water cut stage fly ash reinforced multiphase composite profile control and flooding method. The method comprises the following step: sequentially adopting fly ash reinforced foam, surfactant foam, microemulsion and water for profile control and flooding, wherein the fly ash reinforced foam is prepared from a gas phase and a liquid phase I; the liquid phase I is an aqueous solution of a foaming agent I, fly ash and a gas-liquid interface regulator; the surfactant foam is prepared from a gas phase and a liquid phase II; the liquid phase II is an aqueous solution of a foaming agent II; the microemulsion consists of a compound surfactant, a cosurfactant, an oil phase, an inorganic salt and water; and the compound surfactant is a compound of SDSand Tween 80. According to the method, through the action among the fly ash reinforced foam slug, the surfactant foam slug and the microemulsion slug, the opening and closing of a large pore channel can be regulated and controlled, the flow resistance is reduced, the regulation and flooding effect of blocking without blocking off is realized, the flow and production of crude oil are facilitated, and the purpose of economic and efficient development of an oil reservoir is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Stirring extraction bar with composite carbon nanofiber coating and preparation method thereof

InactiveCN102366717ABroaden your range of optionsAvoid competitive adsorptionIon-exchange process apparatusOther chemical processesCarbon nanofiberPolydimethylsiloxane

Owner:TIANJIN CHUNFA BIO TECH GRP

Method for preparing Beta-cyclodextrin matrix stir extraction bar

InactiveCN102049244AImprove adsorption capacityBroaden your optionsOther chemical processesFiberDimethyl siloxane

A method for preparing Beta-cyclodextrin matrix stir extraction bar relates to the trace analysis field of VOCs (volatile organic compounds) and semi VOCs in food, environment and biological samples. In the method, Beta-cyclodextrin is combined with PDMS (polydimethylsiloxane) to serve as the coating materials of the stir extraction bar coating, a bar body is used to serve as the matrix of the stir extraction bar coating for coating, and the bar body is made of an iron core which is shorter than the bar body and is sealed in a glass tube. As the Beta-cyclodextrin is combined with PDMS to serve as coating materials to make the stir extraction bar, the stir extraction bar enlarges the selection range of polarity of to-be-adsorbed substances selected by the coating, finishes stirring alone in the extraction process, and avoids the competitive adsorption of a stir bar in Fiber SPME (Solid-Phase Micro-Extraction). As the volume of extraction stationary phase is more than 50 times larger than that of SPME, the concentration time is obviously improved, and the stir extraction bar is particularly suitable for trace analysis.

Owner:TIANJIN CHUNFA BIO TECH GRP

Metal carrier stirring and extracting rod

InactiveCN102068966AAchieve enrichmentAvoid competitive adsorptionIon-exchange process apparatusOther chemical processesEpoxyTenax

The invention relates to a metal carrier Tenax coating stirring and extracting rod which uses metal as a carrier, wherein a coating contains a Tenax adsorbing agent, the extracting rod is used in a stirring manner, the metal is selected from iron, nickel, cobalt, stainless steel or alloy; and the extracting rod is used in a head space or ultrasonic manner, the metal is selected from stainless steel, copper, aluminum or alloy. The extracting rod is used for fixing the Tenax on the surface of the metal rod by using synthetic high-temperature epoxy resin or organic silicon resin to form a coating material with good heat stability and solvent rinsing resistance, thus trace organic matters are enriched. The invention is especially suitable for processing samples, such as soil, atmosphere, essence perfume, indoor air, alcohol, phenol, amine and aldehyde, ketone, aryl halides and the like.

Owner:TIANJIN CHUNFA BIO TECH GRP

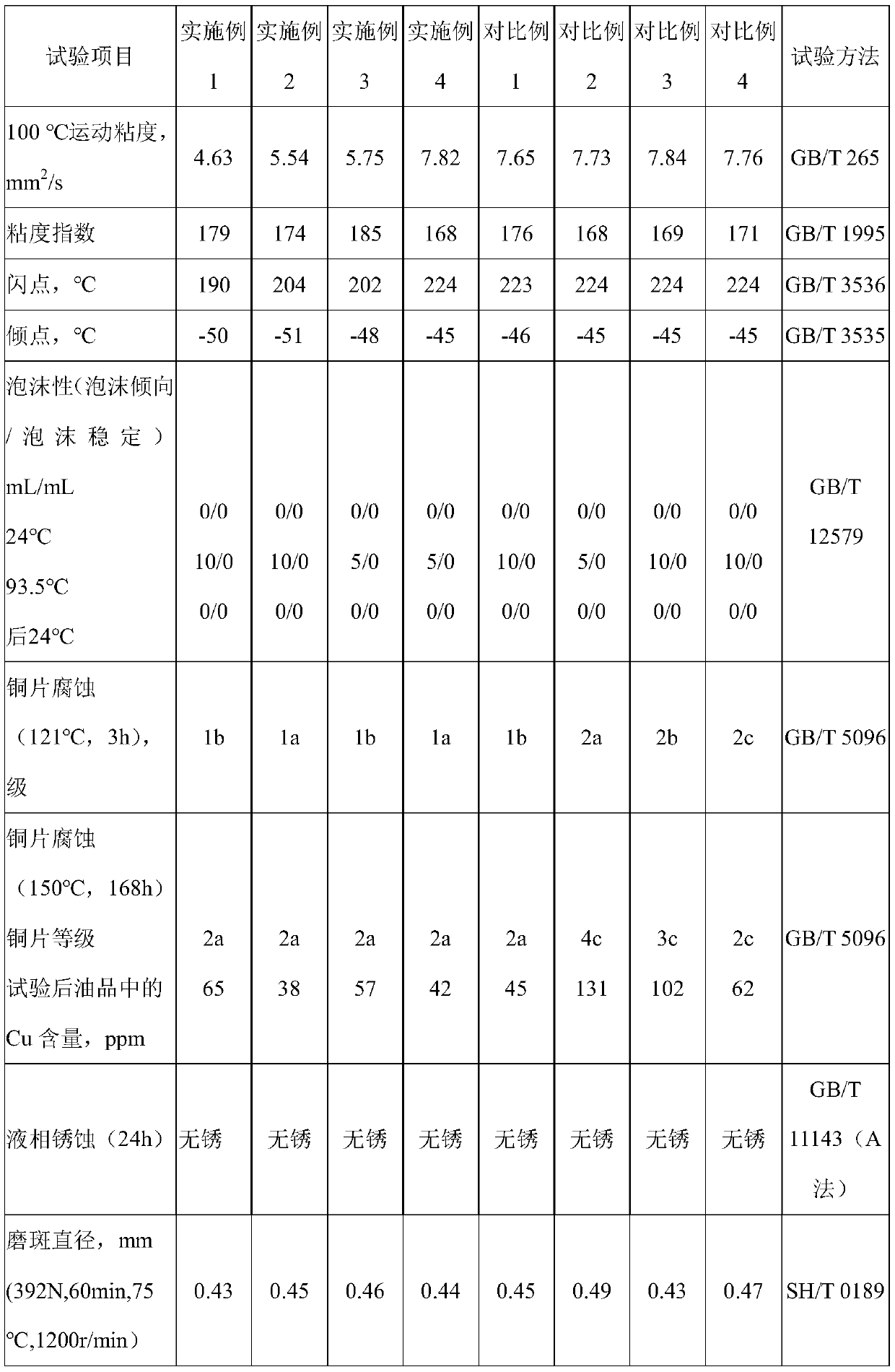

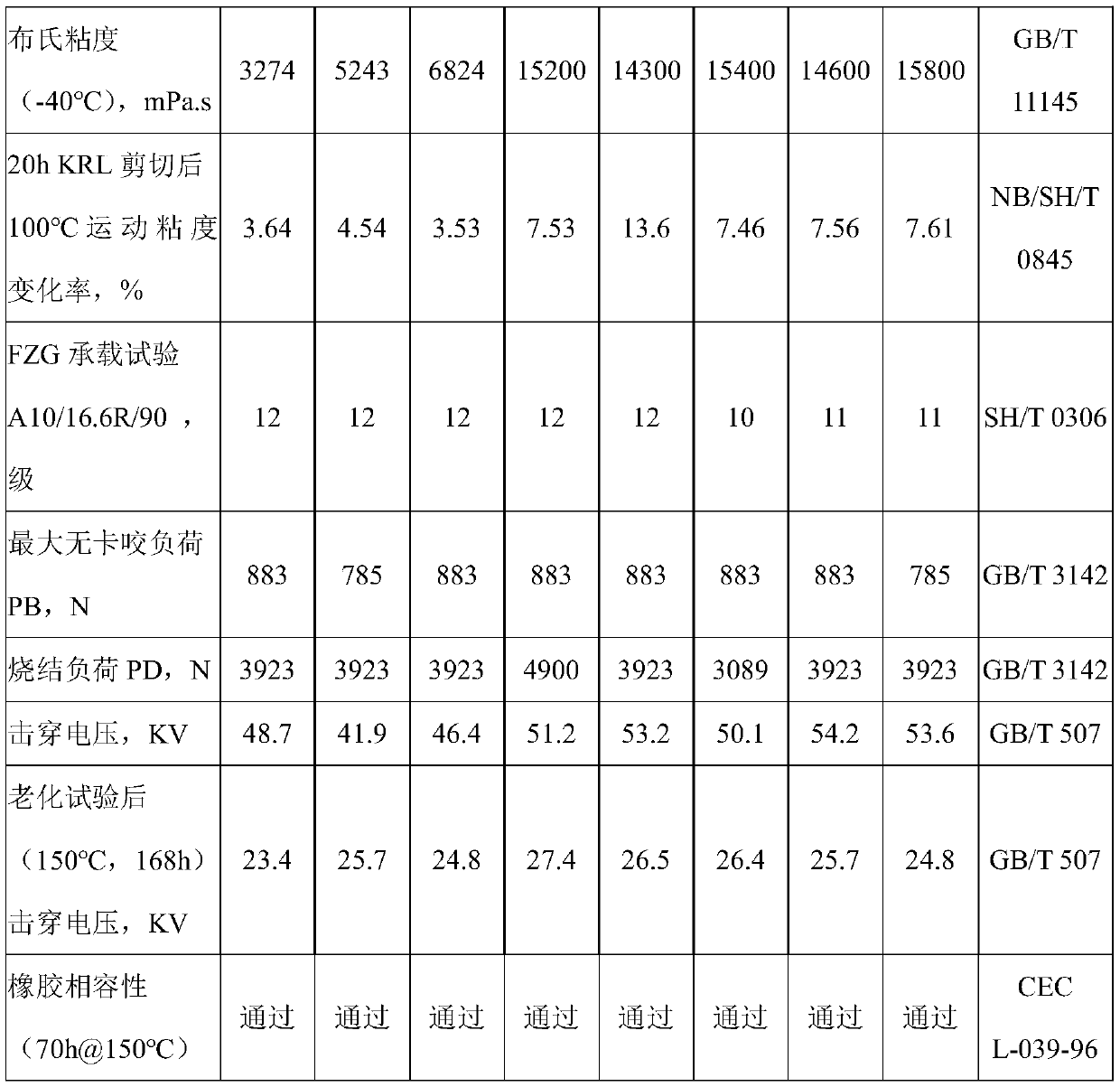

Lubricating oil composition for integrated electric drive assembly speed reducer

InactiveCN111117747AReduced extreme pressure and wear resistanceImproved copper corrosion protectionLubricant compositionReduction driveGear wheel

The invention discloses a lubricating oil composition for an integrated electric drive assembly speed reducer. The lubricating oil composition comprises the following components in percentage by weight: 80%-90% of base oil, 4%-12% of a viscosity index improver, 5.5%-8% of a composite additive, 0.1%-0.5% of a reinforcing agent and 0.3%-0.5% of a pour point depressant. The product provided by the invention has relatively low viscosity, relatively high viscosity index, excellent high-temperature oxidation resistance, extreme-pressure wear resistance, shearing stability, copper corrosion protection and electrochemical characteristics; the lubricating oil provides excellent protection for gears and bearings, has good compatibility with sealing materials and motors, provides excellent protectionand power output efficiency for integrated electric drive assembly reducers, and is especially suitable for lubrication of integrated electric drive transmissions of pure electric buses.

Owner:LONGPAN LUBRICATION NEW MATERIAL TIANJIN CO LTD +1

Deep desulfurization method for gasoline

InactiveCN105176581AEasy to removeRemoval is not easy to achieveTreatment with hydrotreatment processesHydrodesulfurizationExtractive distillation

The invention provides a deep desulfurization method for gasoline. The method comprises steps as follows: cutting a gasoline raw material into a light fraction and a heavy fraction; performing liquid-liquid extraction on the light fraction to obtain light fraction raffinate containing alkenes and light fraction extract oil containing sulfides and arenes; performing extractive distillation on the heavy fraction to obtain heavy fraction raffinate containing alkenes and heavy fraction extract oil containing sulfides and arenes; performing selective hydrodesulfurization on the light fraction extract oil and the heavy fraction extract oil to obtain a desulfurized fraction; mixing the light fraction raffinate, the heavy fraction raffinate and the desulfurized fraction to obtain desulfurized gasoline, wherein the cutting temperature of the light fraction and the heavy fraction is 80-120 DEG C. With the adoption of the deep desulfurization method for the gasoline, deep desulfurization can be realized, meanwhile, the octane number loss of a gasoline product can be significantly reduced, the desulfurization load can be reduced substantially, and the product yield is higher than 95%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

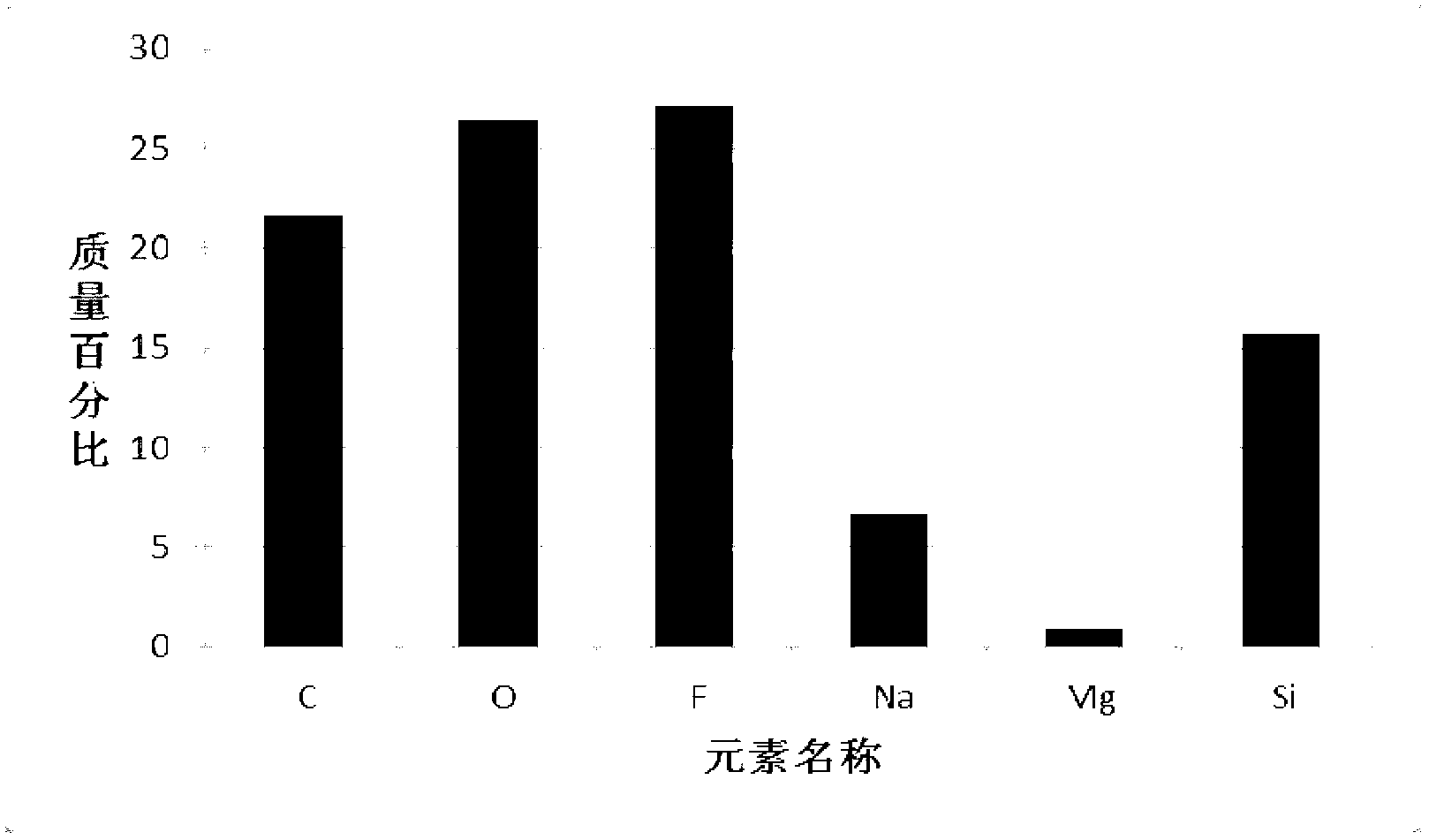

Method for preparing perfluorinated silane modified magnetic extraction stirring stick

InactiveCN103170310AAvoid competitive adsorptionHigh enrichment factorOther chemical processesAlkali metal oxides/hydroxidesStationary phaseFiber

The invention discloses a method for preparing a perfluorinated silane modified magnetic extraction stirring stick. The method comprises the following steps of: preparing a magnetic stirring stick, pretreating the surface of the magnetic stirring stick and preparing the perfluorinated silane modified magnetic extraction stirring stick. The perfluorinated silane modified magnetic extraction stirring stick is prepared by mutual action between fluorine and fluorine; competitive adsorption of stirrers during fiber solid-phase micro extraction is avoided; the volume of extraction solid phase is 50 times more than that of the solid-phase micro extraction; the enrichment time is obviously improved; the adsorption property is high; the selectivity is high; the low efficiency and non-selectivity of enrichment in a complicated substrate are avoided; perfluorinated compounds can be specifically and selectively extracted and separated; and trace analysis is facilitated.

Owner:SHAANXI NORMAL UNIV

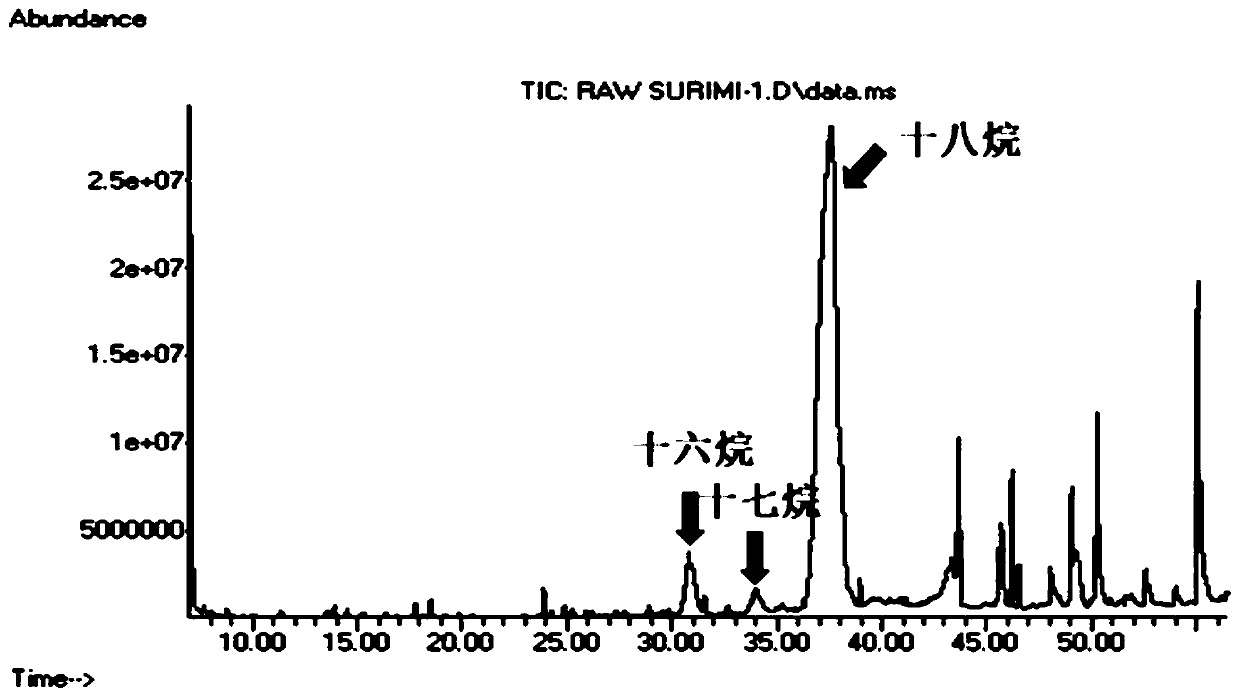

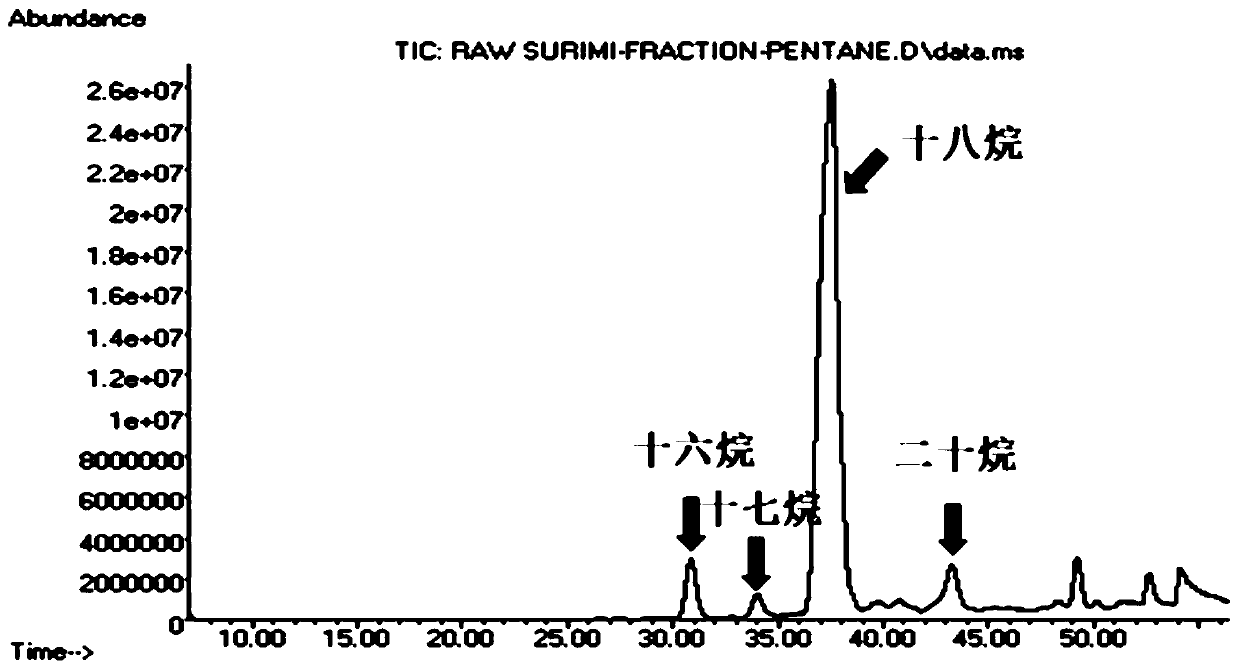

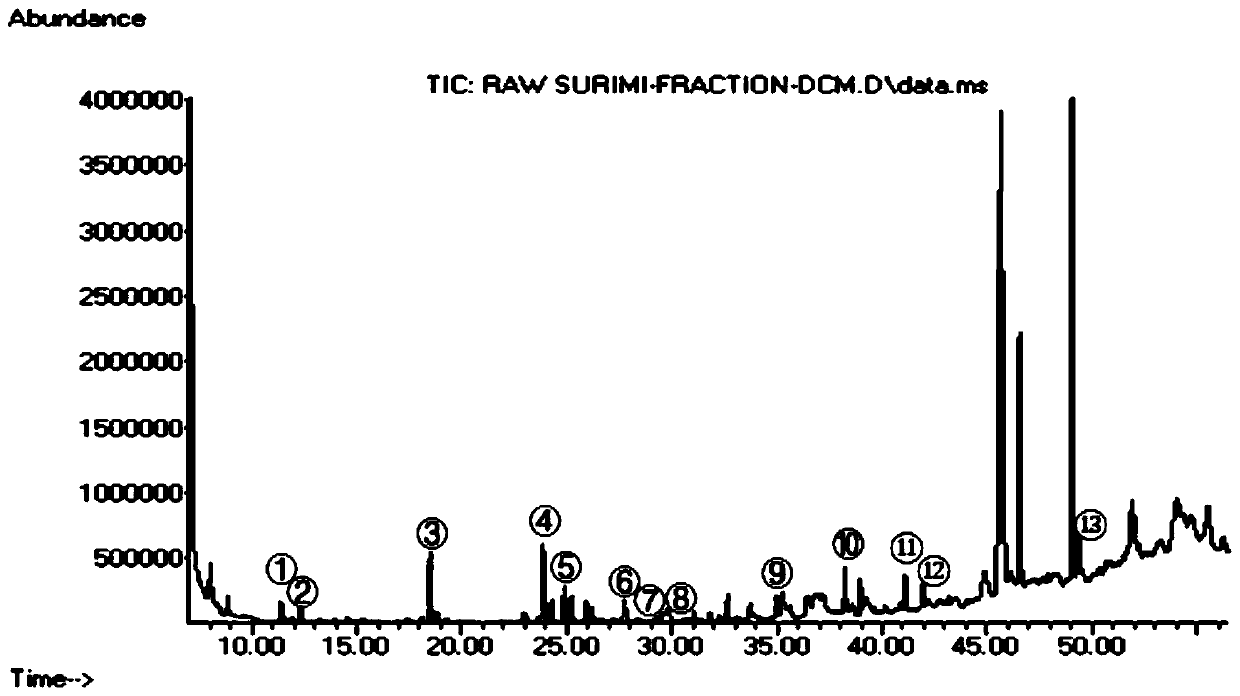

Sample treatment method for detecting volatile substances in minced fillet or products thereof and application thereof

ActiveCN111208238AAvoid competitive adsorptionGuarantee authenticityComponent separationBiotechnologyDistillation

The invention belongs to the technical field of food detection and analysis and particularly relates to a sample treatment method for detecting volatile substances of minced fillet or minced fillet products and application thereof. The method comprises steps of (1) quickly freezing a sample with liquid nitrogen, crushing, oscillating and extracting with dichloromethane, filtering, collecting extracting solution, and carrying out solvent-assisted distillation extraction; (2) concentrating the extracting solution; and (3) fractionating the concentrated solution by using pentane, eluting by usingdichloromethane, collecting volatile odor substances, and carrying out nitrogen blowing concentration. The method is advantaged in that aiming at heat sensitivity of freshwater fish and products thereof, a liquid nitrogen quick-freezing and extraction and concentration method not exceeding 50 DEG C is used, so influence of heat action on a sample and a flavor compound is avoided, and authenticityof a volatile smell extracting solution is reserved, an organic solvent extraction method is used, so selective absorbability of methods such as solid-phase micro-extraction is avoided, through flavor fractionation, influence of non-flavor substances is avoided, and effectiveness of volatile odor component identification is improved.

Owner:HUAZHONG AGRI UNIV

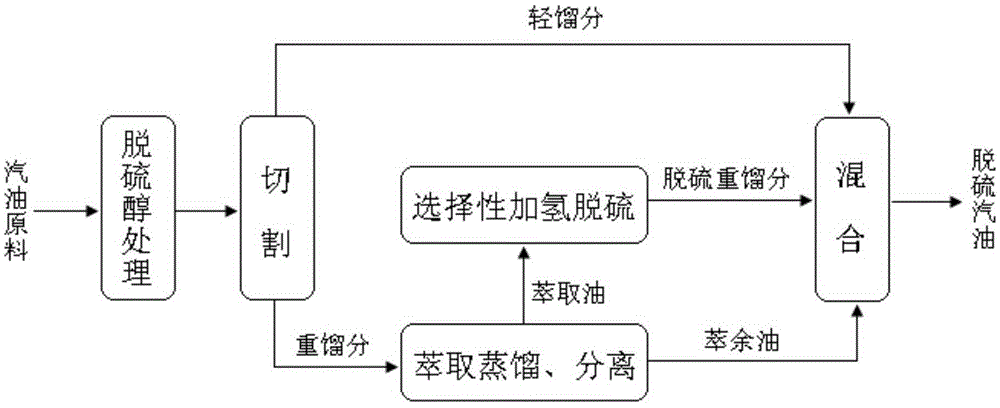

Gasoline desulfurization combination method

InactiveCN105255516AEasy to useSave resourcesTreatment with hydrotreatment processesHydrogenOrganic solvent

The invention provides a gasoline desulfurization combination method. The combination method includes the following steps that gasoline raw materials are cut into light fractions and heavy fractions; the heavy fractions are extracted and distilled through organic solvents, and olefin-containing raffinate and sulfide-and-arene-containing extract are obtained; the organic solvents in the extract are separated, and extract oil is obtained; selective hydrogen desulfurization is carried out on the extract oil, and desulfurized heavy fractions are obtained; the light fractions, the raffinate and the desulfurized heavy fractions are mixed, and desulfurized gasoline is obtained. The cutting temperature of the light fractions and the heavy fractions ranges from 35 DEG C to 60 DEG C. By means of the combination method, losses of the octane value of gasoline products can be remarkably reduced while deep desulfurization is achieved, and the product yield is higher than 95%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

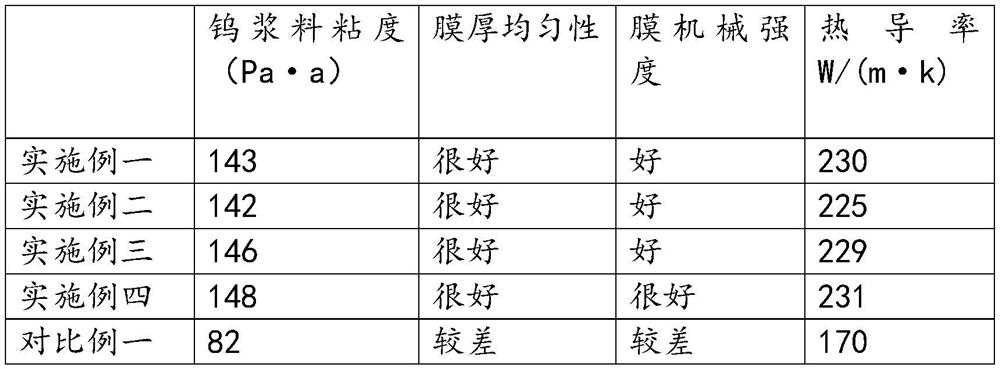

Preparation method of co-fired aluminum nitride ceramic substrate

The invention relates to the field of electronic ceramic substrates, provides a method for co-firing an aluminum nitride ceramic substrate, and solves the defects of low heat conductivity and high energy consumption caused by over-high sintering temperature of co-fired aluminum nitride ceramic in the prior art. Comprising the following preparation steps: (1) batching and ball-milling: feeding aluminum nitride powder and a sintering aid into a ball mill for ball-milling treatment; (2) defoaming: aging the ball-milled slurry for 2-3 hours, and defoaming the slurry in a defoaming machine until the viscosity of the slurry reaches 20000-23000 mPa.s; (3) tape casting: feeding the slurry treated in the step (2) into a tape casting machine for tape casting, and standing for 6-8 hours; (4) punching; (5) laminating: decompressing the printed green sheet according to the thickness requirement; (6) glue discharging is conducted, specifically, the green body pieces treated in the step (5) are placed in a nitrogen protection glue discharging furnace, and glue discharging is conducted under the nitrogen atmosphere till the carbon content is 2000 ppm or below; and (7) sintering.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

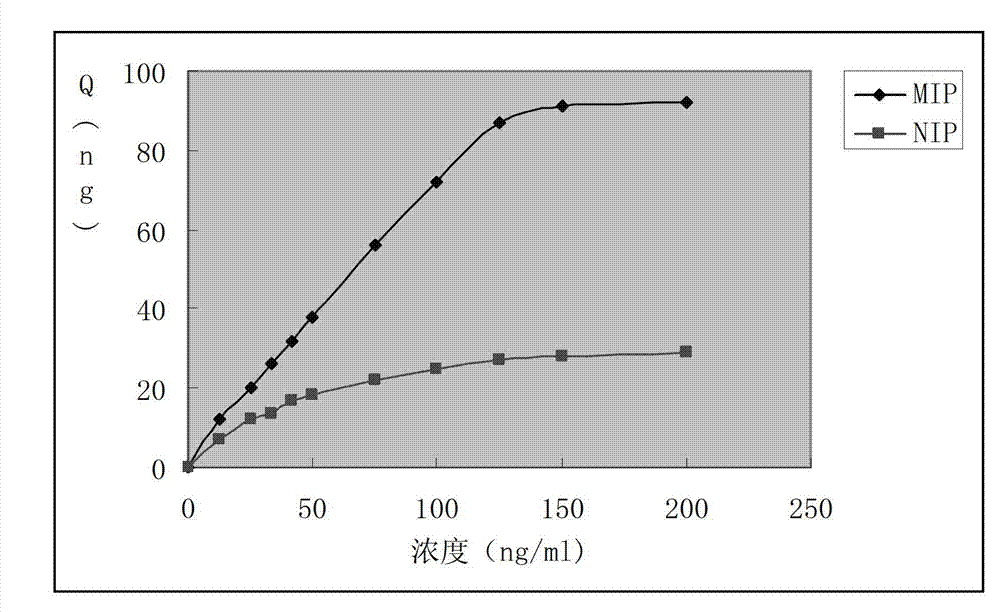

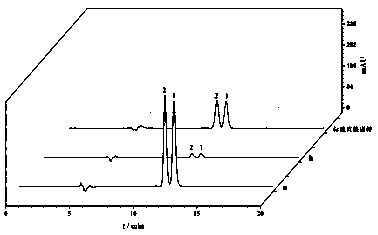

Preparation method of chiral molecularly imprinted adsorption-extraction stirring rod

ActiveCN109939650AAvoid competitive adsorptionHas selective extraction capabilityIon-exchange process apparatusOther chemical processesFunctional monomerSolvent

The invention discloses a preparation method of a chiral molecularly imprinted adsorption-extraction stirring rod and belongs to the technical field of analytical chemistry and sample pretreatment. The preparation method comprises the following steps: first, inserting an iron core into a capillary tube sintered at one end, intercepting a proper length, and then blocking the capillary tube to obtain a stirrer, activating the prepared stirrer, dissolving chiral template modules and a chiral functional monomer in a polymerization solvent, ultrasonically and uniformly mixing the mixture and leaving the mixture to stand, and adding a crosslinking agent and an initiator to obtain an assembling solution and removing oxygen; and injecting the assembling solution without oxygen into the glass capillary tube sintered at one end, inserting the stirrer, carrying out water bath heating and initializing polymerization through a click reaction, removing a jacket of the glass capillary tube after thereaction, and cutting the coating to a proper length by a blade to prepare the chiral molecularly imprinted adsorption-extraction stirring rod. The stirring rod prepared by the preparation method canbe applied to adsorbing a naproxen raceme in a sample.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing metal carrier stirring extraction rod

InactiveCN101992062ALarge adsorption capacityHigh mechanical strengthIon-exchange process apparatusOther chemical processesEpoxySorbent

The invention discloses a method for preparing a metal carrier stirring extraction rod, and relates to the field of trace analysis of organic matters in foods, environment and biological samples. The method comprises the following steps of: (a) selecting a metal rod with the length of 10 to 40mm and the diameter of 0.5 to 5mm, and performing surface pretreatment; and (b) coating a layer of heat-resistant epoxy resin or organic silicon resin on the surface of the metal rod subjected to surface pretreatment, and dipping a layer of adsorbent on the outer layer to obtain a coat, or repeatedly coating and dipping to adjust the thickness of the coat, wherein the adsorbent is one ore more of graphitized carbon black, silica gel and clay. The stirring extraction rod prepared by the method has high mechanical strength, is firm and durable, is favorable for the adsorbent to perform treatment on a liquid sample and static headspace capture, and is particularly suitable for analyzing trace contaminants in water and air.

Owner:TIANJIN CHUNFA BIO TECH GRP

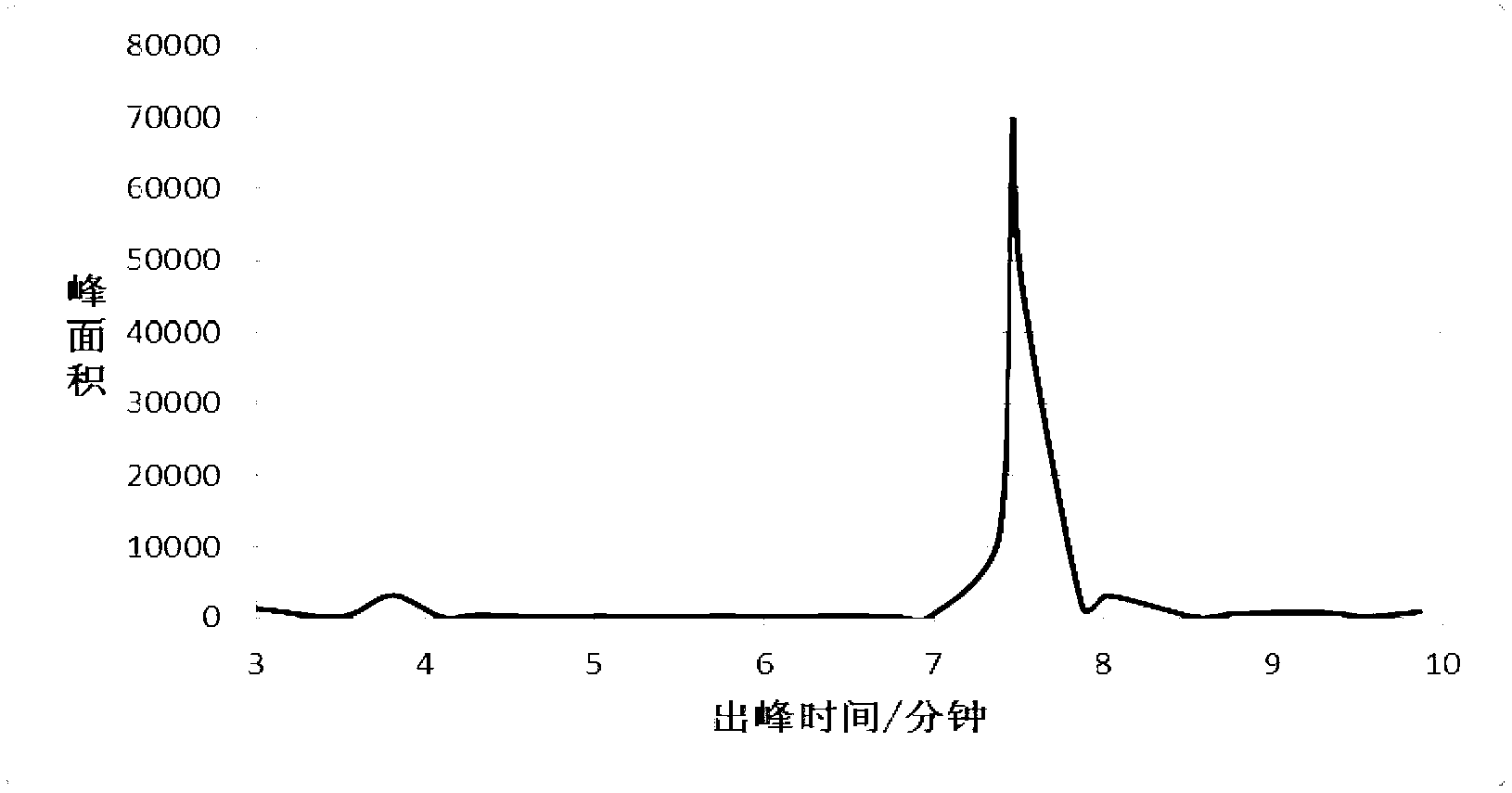

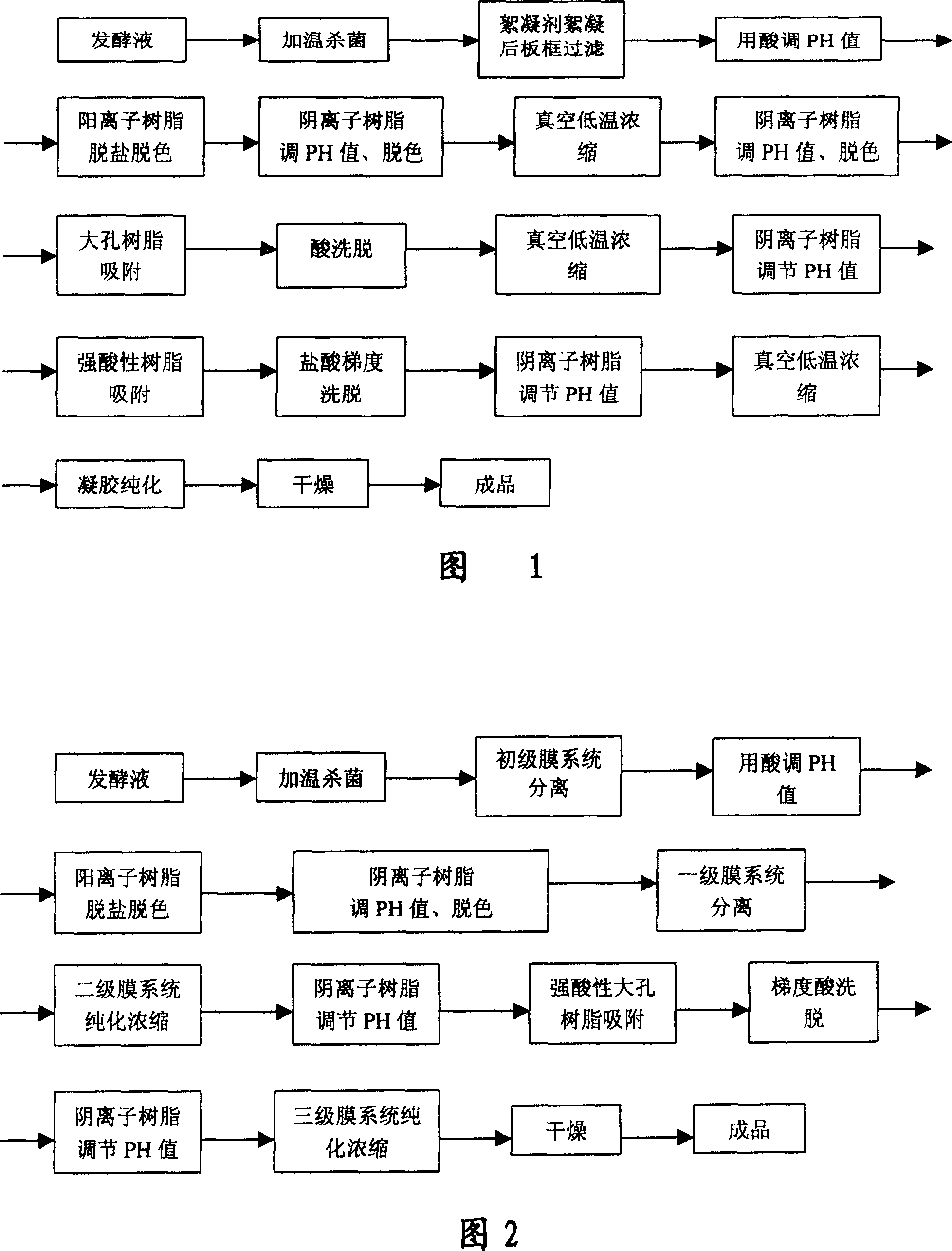

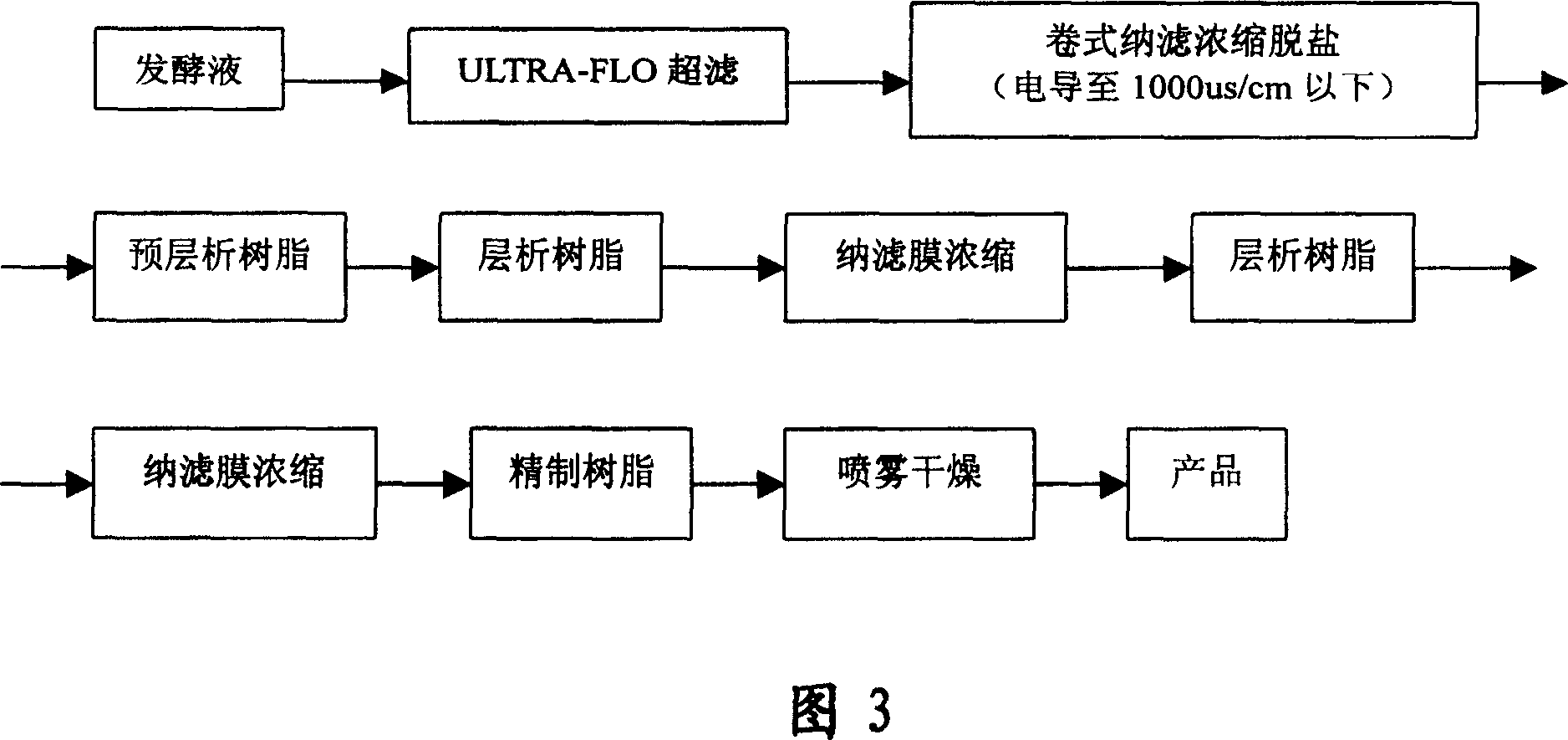

Process for preparing high purity acarbose

ActiveCN1321126CHigh yieldAvoid competitive adsorptionSugar derivativesSugar derivatives preparationInorganic saltsMycelium

The present invention discloses the preparation process of high purity acarbose. The fermented liquid with acarbose is first separated in the first separation system to eliminate mycelium, soluble protein, culture medium and partial pigment to obtain clear acarbose filtrate; the clear acarbose filtrate is then concentrated, decolorized and desalted to eliminate partial monosaccharide, inorganic salt and other small molecular impurity to obtain clear acarbose concentrated solution; and finally through chromatographic resin adsorption, gradient acid pickling, nano filtering film concentration and spray drying, high purity acarbose product is obtained. The present invention has shortened technological path, high total acarbose yield and high product purity.

Owner:SANDA FILM SCI & TECH XIAMEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com