Combination method for producing ultralow sulphur gasoline

A combined method and ultra-low sulfur technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of complicated operation of desulfurization method, difficulty in achieving deep desulfurization and reducing octane loss at the same time, etc. Loss of octane number, reducing desulfurization load, and satisfying the effect of deep desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] 1. Preparation of selective hydrodesulfurization catalyst

[0095] CoSO first 4 The solution impregnates the ZSM-5 molecular sieve (carrier) with an equal volume, and after washing, drying and roasting, the (NH 4 ) 6 Mo 7 o 24 . 4H 2 O aqueous solution on the impregnated CoSO 4 The ZSM-5 type molecular sieve in the solution is impregnated with equal volume, and after washing, drying and roasting, a selective hydrogenation desulfurization catalyst is prepared.

[0096] The total specific surface area of the selective hydrodesulfurization catalyst prepared above is 168m 2 / g, the total pore volume is about 0.378mL / g, the loading amount of Co on the carrier is about 7%, the loading amount of Mo on the carrier is about 10%, and the mass ratio of Co and Mo loaded on the carrier is 0.7 :1.

[0097] 2. Gasoline desulfurization

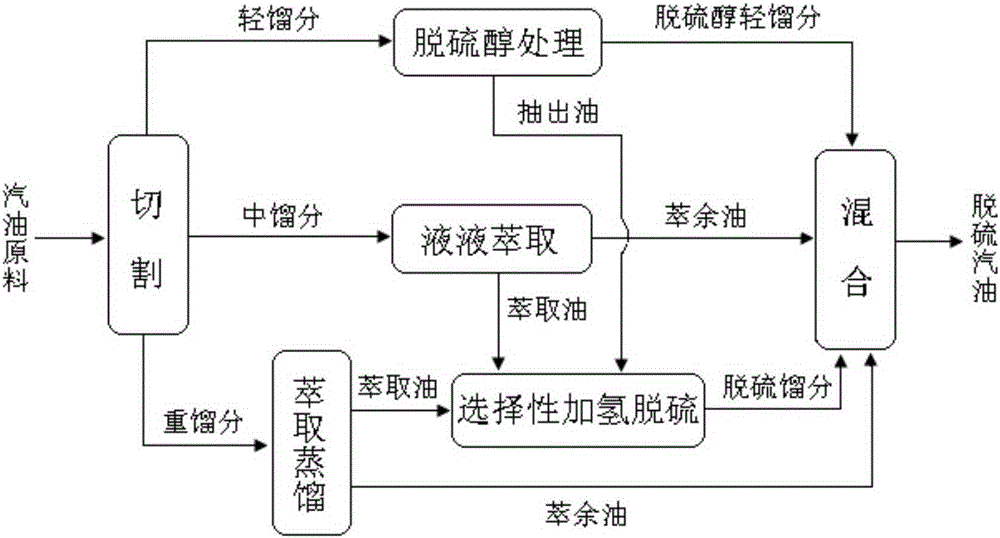

[0098] Using catalytic gasoline produced by Daqing atmospheric heavy oil through catalytic cracking as raw material (see Table 1 for its c...

Embodiment 2

[0124] This embodiment is improved on the basis of Embodiment 1, where the difference is:

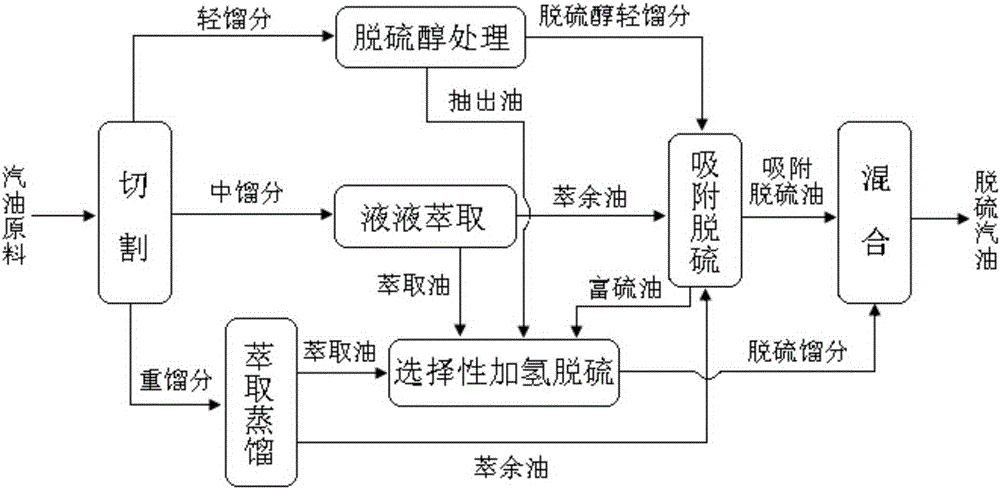

[0125] The sweetened light fraction, middle fraction raffinate and heavy fraction raffinate of Example 1 were combined into a mixed oil, and then the mixed oil was subjected to adsorption desulfurization to obtain adsorption desulfurized oil and sulfur-rich oil, and then the sulfur-rich oil was combined with the The extracted oil, middle distillate extracted oil and heavy distillate extracted oil of Example 1 are combined and then selectively hydrodesulfurized to obtain a desulfurized fraction. The process flow is as follows figure 2 shown.

[0126] The desulfurization adsorbent is used for the above-mentioned adsorption desulfurization. The desulfurization adsorbent is obtained by carrying the active metal components on the ZSM-5 molecular sieve and activated carbon that have been treated with alkali respectively; the mass ratio of the molecular sieve to the activated carbon is 1:1, a...

Embodiment 3

[0131] In addition to extractive distillation, the theoretical plate number of the extractive distillation tower is 25, the temperature of the top of the extractive distillation tower is about 80°C, the temperature of the bottom of the tower is about 150°C, and the absolute pressure of the top of the tower is about 0.2MPa. The material ratio is about 0.4, and the separation degree of olefins and aromatics in the extractive distillation tower reaches about 80% at this time;

[0132] In adsorption desulfurization, the service life of the desulfurization adsorbent is 3.5h, and the adsorption desulfurization efficiency reaches about 85%. The rest are the same as in Example 2 to obtain desulfurized gasoline with a yield of 86%. The composition is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com