Stirring extraction bar with composite carbon nanofiber coating and preparation method thereof

A nano carbon fiber, extraction rod technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of SBSE technology application limitations, fragile materials, and high SBSE device prices, to expand the range of selectivity, The effect of large specific surface and increased enrichment factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

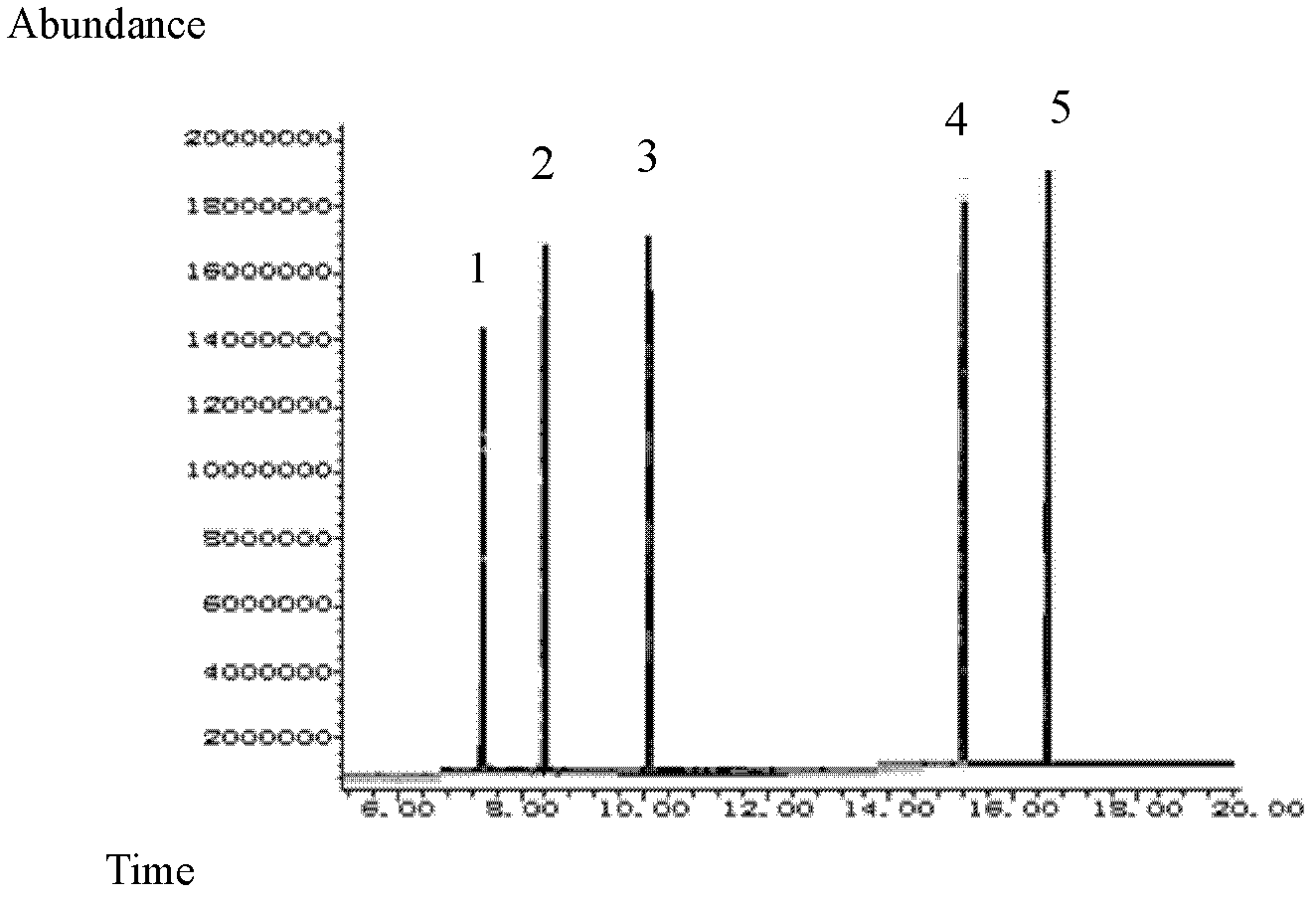

Image

Examples

Example Embodiment

[0029] Example 1 Preparation method of polydimethylsiloxane composite nano carbon fiber coating stirring rod

[0030] Choose a glass tube with a length of 20mm and a diameter of 3mm, and use an alcohol blowtorch to seal the shorter iron core in it, and apply CH to the surface of the rod in turn 2 Cl 2 Treat for 30 minutes, 1mol / L NaOH solution for 8 hours, 0.1mol / L HCl solution for 4 hours, and finally rinse with deionized water to neutrality, and dry at 150°C under nitrogen flow.

[0031] Take 400mg of hydroxy-terminated polydimethylsiloxane diluted with 600μl of dichloromethane, add 100mg of nano carbon fiber, 100mg of hydrogen-containing silicone oil, 100μl of methyltrimethoxysilane and 100μl of trifluoroacetic acid, stir well, and remove the treated The rod is placed in the sol for 30 minutes and taken out, and gelled at room temperature for 12 hours; under the protection of nitrogen, the temperature is programmed to be aged at 120°C for 3 hours, 180°C for 3 hours, and 240°C for...

Example Embodiment

[0032] Example 2 A preparation method of polydimethylsiloxane composite nano carbon fiber coating stirring rod

[0033] Choose a glass tube with a length of 20mm and a diameter of 3mm, and use an alcohol blowtorch to seal the shorter iron core in it, and apply CH to the surface of the rod in turn 2 Cl 2 Treat for 50 minutes, 1mol / L NaOH solution for 6 hours, 0.1mol / L HCl solution for 4 hours, finally rinse with deionized water to neutrality, and dry at 150°C under nitrogen flow.

[0034] Take 400mg of hydroxy-terminated polydimethylsiloxane diluted with 600μl of dichloromethane, add 120mg of carbon nanofiber, 100mg of hydrogen-containing silicone oil, 50μl of glycidoxypropyltrimethylsilane, 50μl of tetraethoxysilane and 100μl Trifluoroacetic acid, stir well to make a sol, put the treated rod in the sol for 30min, take it out, gel at room temperature for 12 hours; under nitrogen protection, carry out temperature-programmed aging at 120℃ for 3h, and 180℃ for 3h 3h, and then kept at 2...

Example Embodiment

[0035] Example 3 Preparation method of polydimethylsiloxane composite nano carbon fiber coating stirring rod

[0036] Choose a glass tube with a length of 20mm and a diameter of 3mm, and use an alcohol blowtorch to seal the shorter iron core in it, and apply CH to the surface of the rod in turn 2 Cl 2 Treat for 30 minutes, 1mol / L NaOH solution for 6 hours, 0.1mol / L HCl solution for 4 hours, and finally rinse with deionized water to neutrality, and dry at 150°C under nitrogen flow.

[0037] Take 400mg of hydroxy-terminated polydimethylsiloxane diluted with 600μl of dichloromethane, add 160mg of carbon nanofibers, 120mg of hydrogen-containing silicone oil, 90μl of methyltrimethoxysilane and 110μl of trifluoroacetic acid, stir well, and remove the treated The rod is placed in the sol for 40 minutes and taken out, and gelled at room temperature for 12 hours; under the protection of nitrogen, the temperature is programmed to be aged at 120°C for 3 hours, 180°C for 3 hours, and 240°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com