Process for preparing high purity acarbose

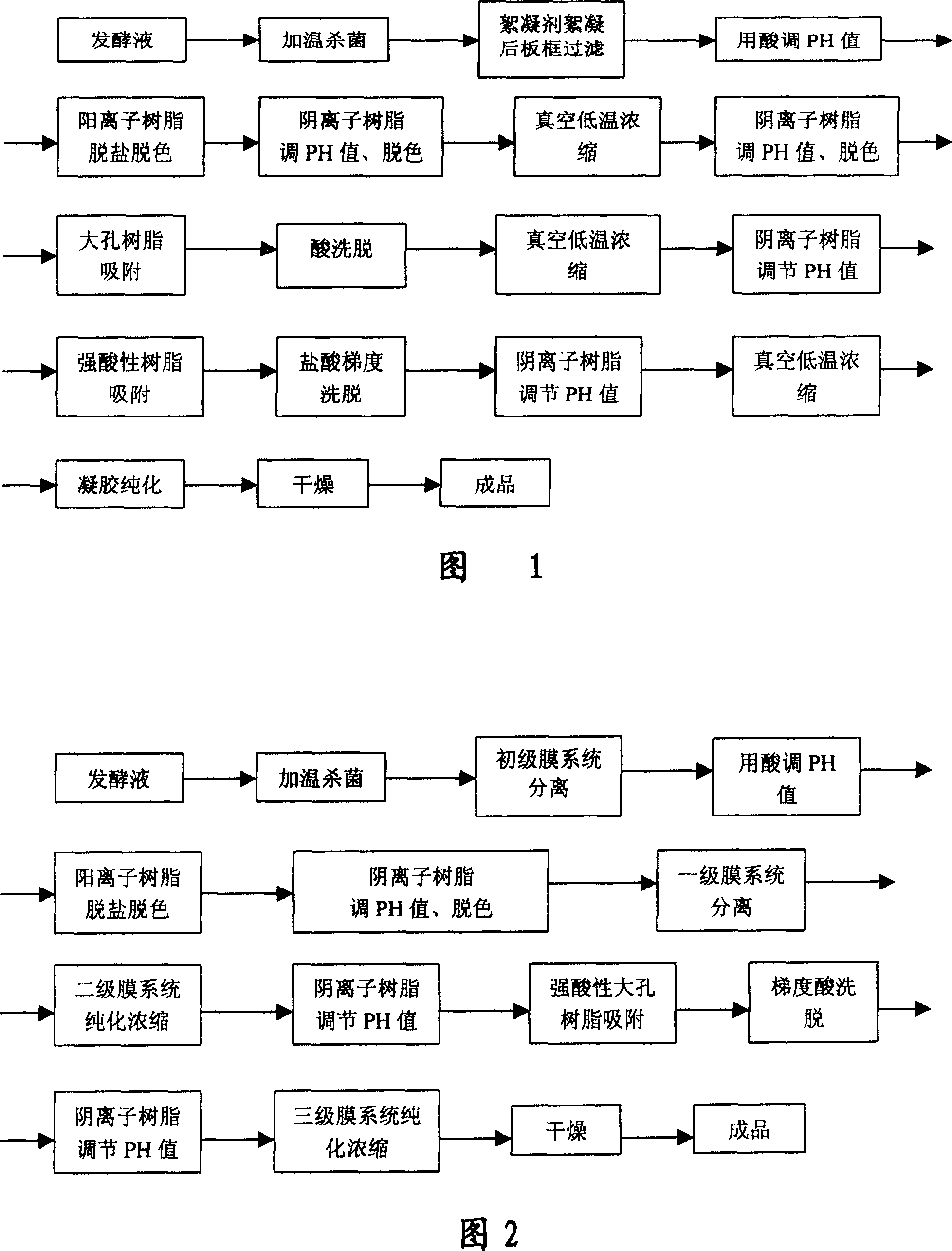

A high-purity acarbose technology, which is applied in the field of preparing high-purity acarbose by membrane technology, can solve the problems affecting the quality of acarbose products, affecting the overall yield of resin extraction process, and long production process routes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

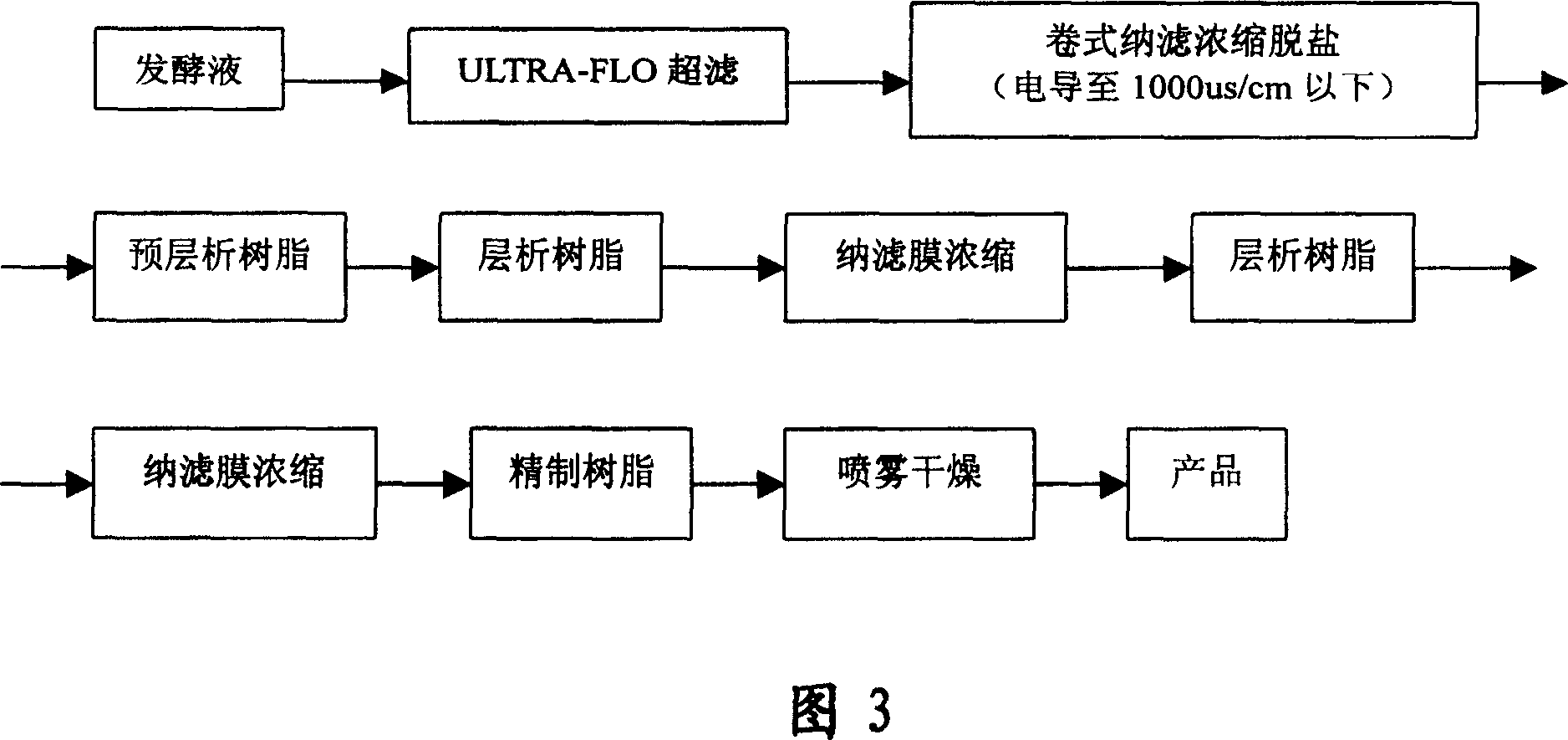

[0028] Firstly, the acarbose fermentation broth is filtered with an organic flat ultrafiltration membrane with a molecular weight cut-off of 50,000, the average membrane flux can reach 58LMH, the amount of water added is 1.5 times the amount of the raw material solution, and the final concentration ratio is 2.0 times. The average yield of ultrafiltration membrane filtration is 99%, far higher than the average yield of 80% of the original plate frame; through the filtration of large molecular weight ultrafiltration system, mycelia and most of the macromolecular proteins (such as soluble protein, culture Base and some pigments, etc.), the filtrate has high clarity and good quality, which can meet the production process requirements.

[0029] Then it is further concentrated by nanofiltration membrane, and desalted and decolorized. The system uses roll-type nanofiltration membrane with a molecular weight cut-off of 200. The average membrane flux is 25LMH. The amount of water added ...

Embodiment 2

[0033] Firstly, the acarbose fermentation broth is filtered with an organic flat ultrafiltration membrane with a molecular weight cut-off of 30,000. The average membrane flux can reach 50LMH. The amount of water added is 2.5 times that of the raw material liquid, and the final concentration is 3 times. The average yield of ultrafiltration membrane filtration is 99%, far higher than the average yield of 80% of the original plate frame; through the filtration of large molecular weight ultrafiltration system, mycelia and most of the macromolecular proteins (such as soluble protein, culture Base and some pigments, etc.), the filtrate has high clarity and good quality, which can meet the production process requirements.

[0034] Then it is further concentrated by nanofiltration membrane, and desalted and decolorized. The system uses roll-type nanofiltration membrane with a molecular weight cut-off of 300. The average membrane flux is 32LMH. The amount of water added can be controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com