Patents

Literature

2763 results about "Monosaccharide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monosaccharides (from Greek monos: single, sacchar: sugar), also called simple sugar, are the simplest form of sugar and the most basic units of carbohydrates. They cannot be further hydrolyzed to simpler chemical compounds. The general formula is CₙH₂ₙOₙ. They are usually colorless, water-soluble, and crystalline solids. Some monosaccharides have a sweet taste.

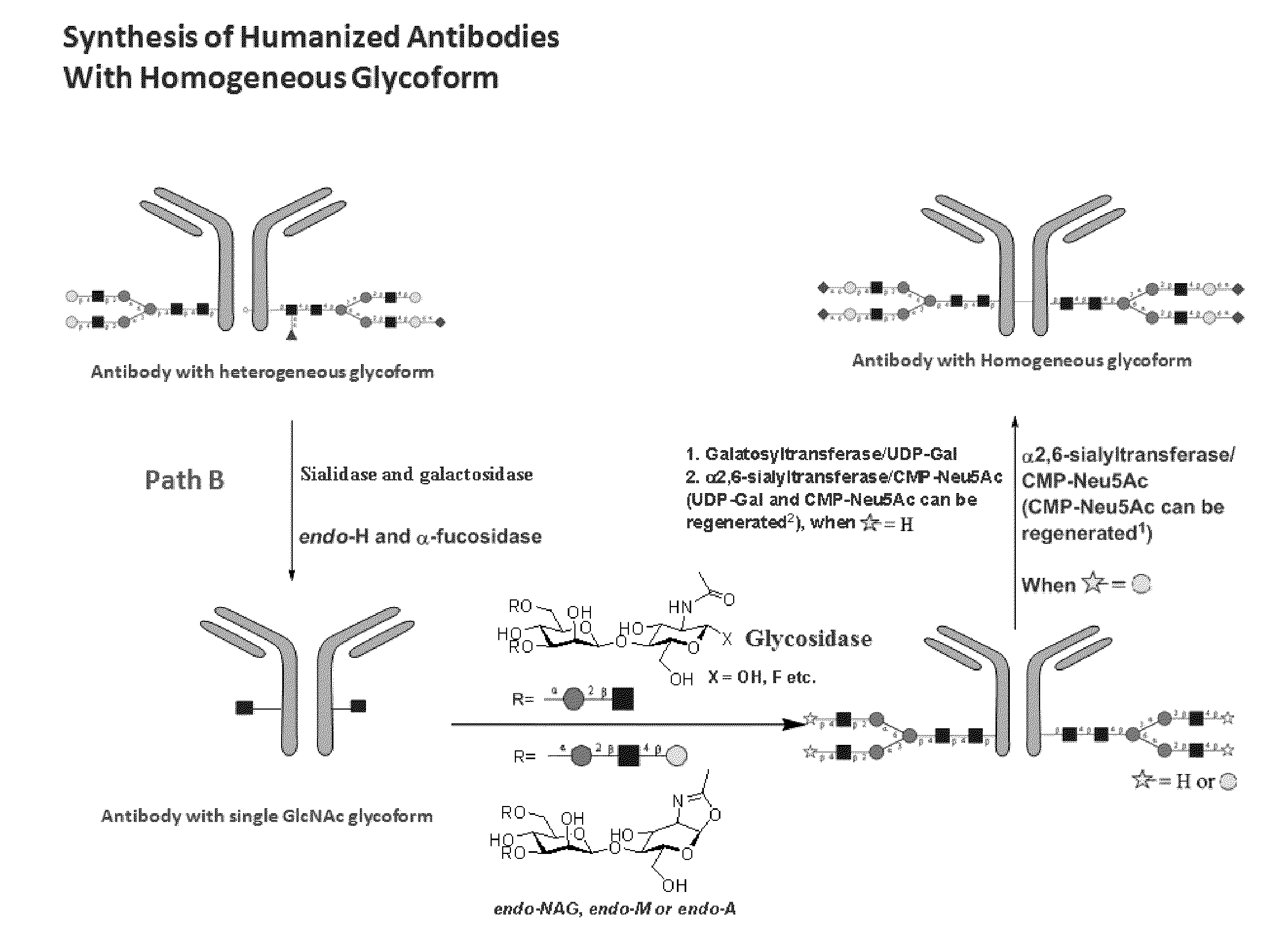

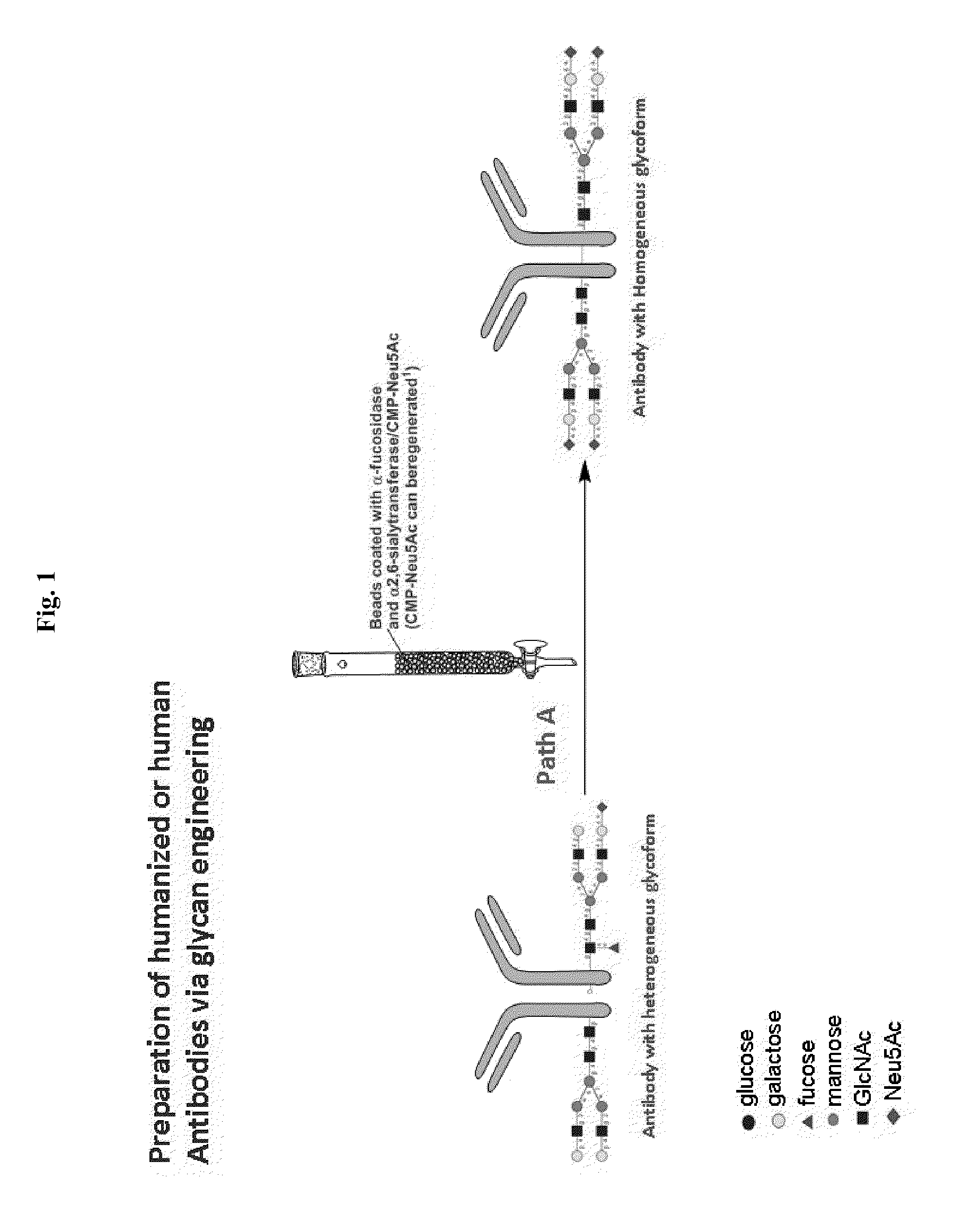

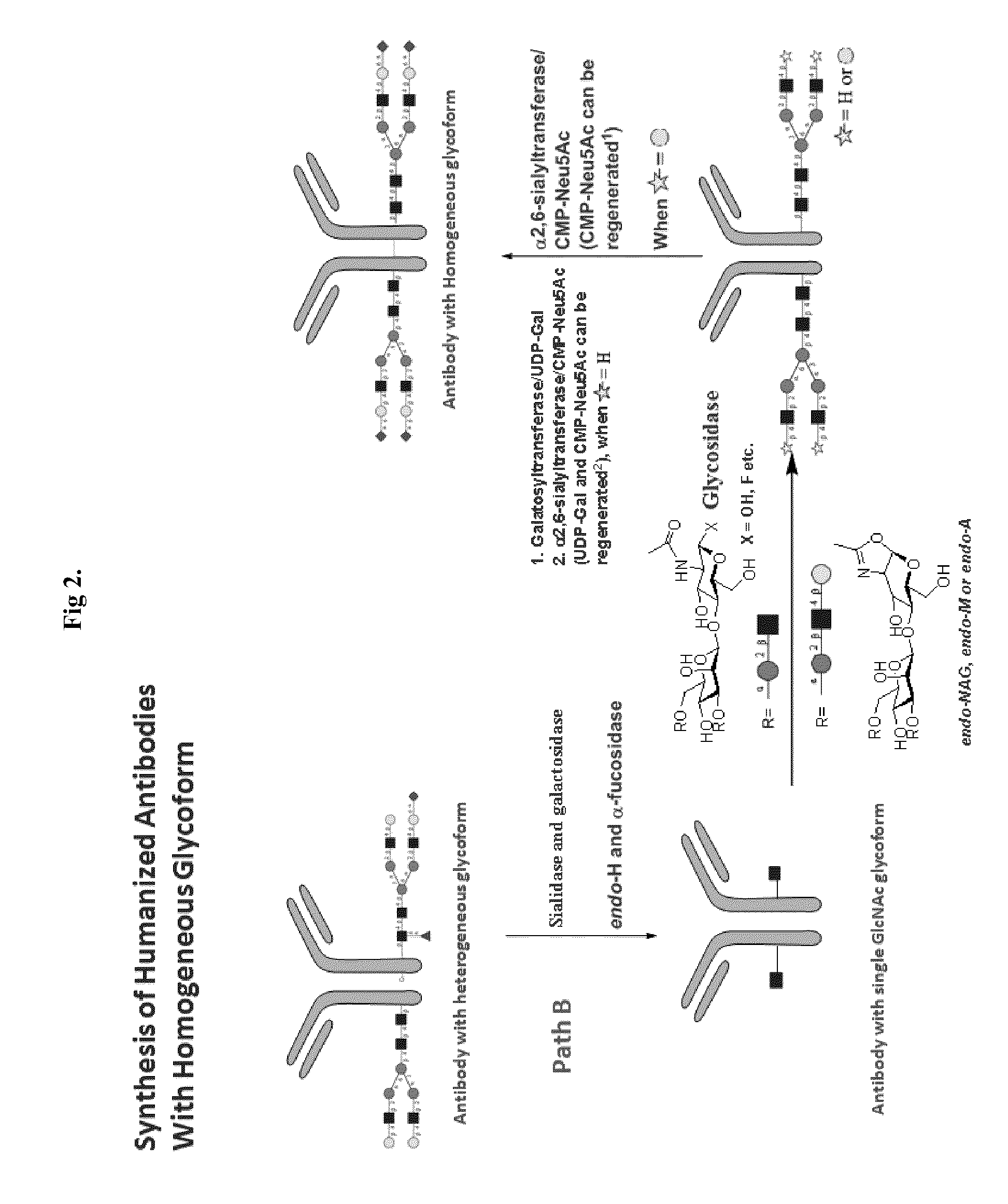

Methods for modifying human antibodies by glycan engineering

ActiveUS20110263828A1Improve efficacyImprove stabilityImmunoglobulinsFermentationGlycanAntibody fragments

Modified Fc regions of antibodies and antibody fragments, both human and humanized, and having enhanced stability and efficacy, are provided. Fc regions with core fucose residues removed, and attached to oligosaccharides comprising terminal sialyl residues, are provided. Antibodies comprising homogeneous glycosylation of Fc regions with specific oligosaccharides are provided. Fc regions conjugated with homogeneous glycoforms of monosaccharides and trisaccharides, are provided. Methods of preparing human antibodies with modified Fc using glycan engineering, are provided.

Owner:ACAD SINIC

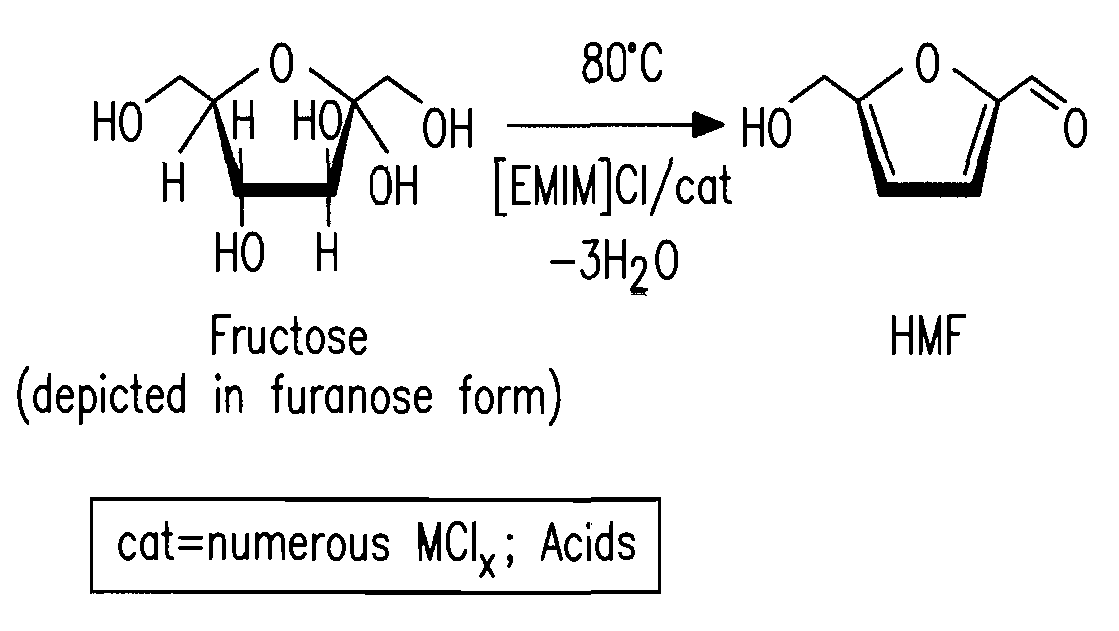

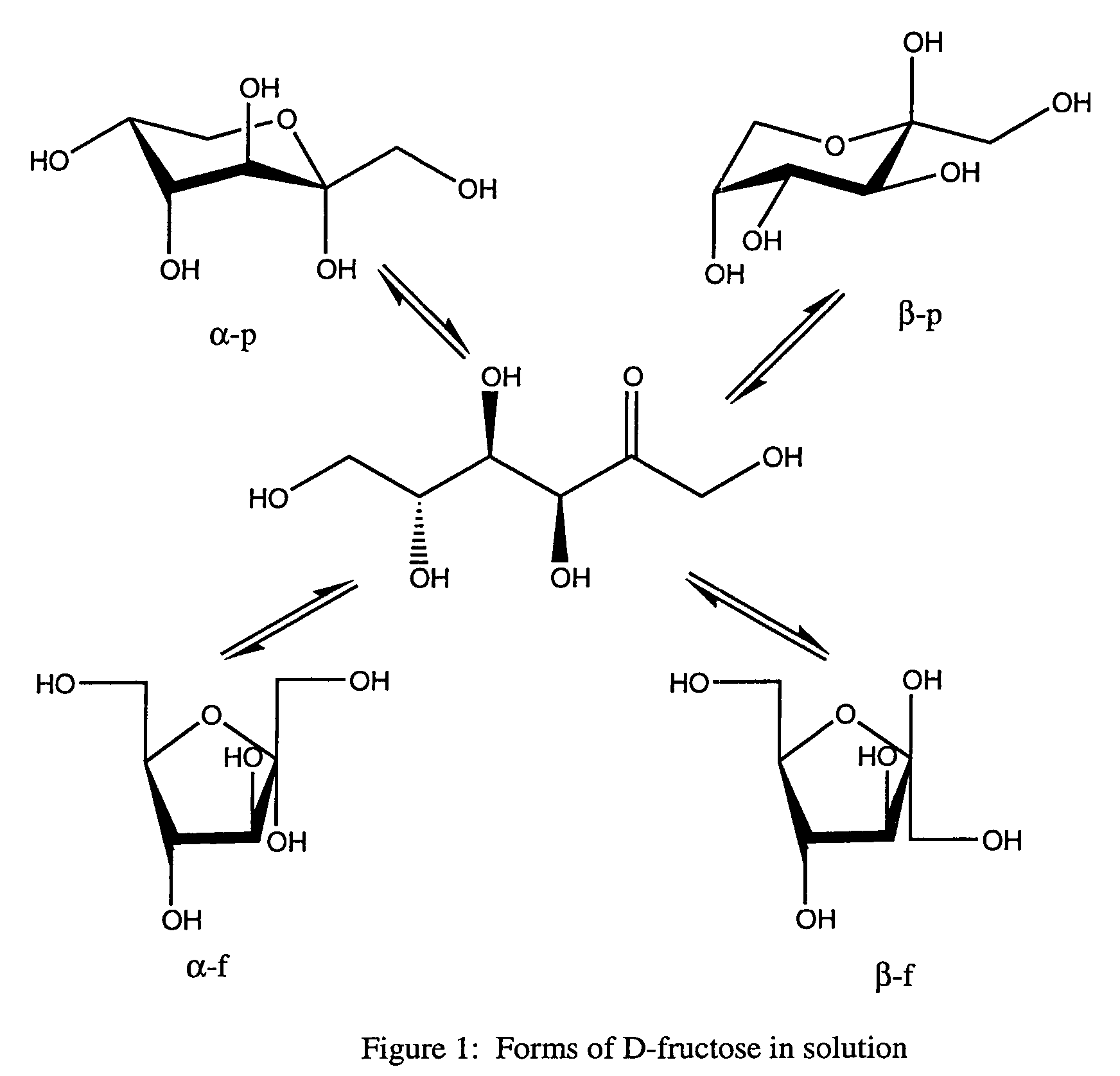

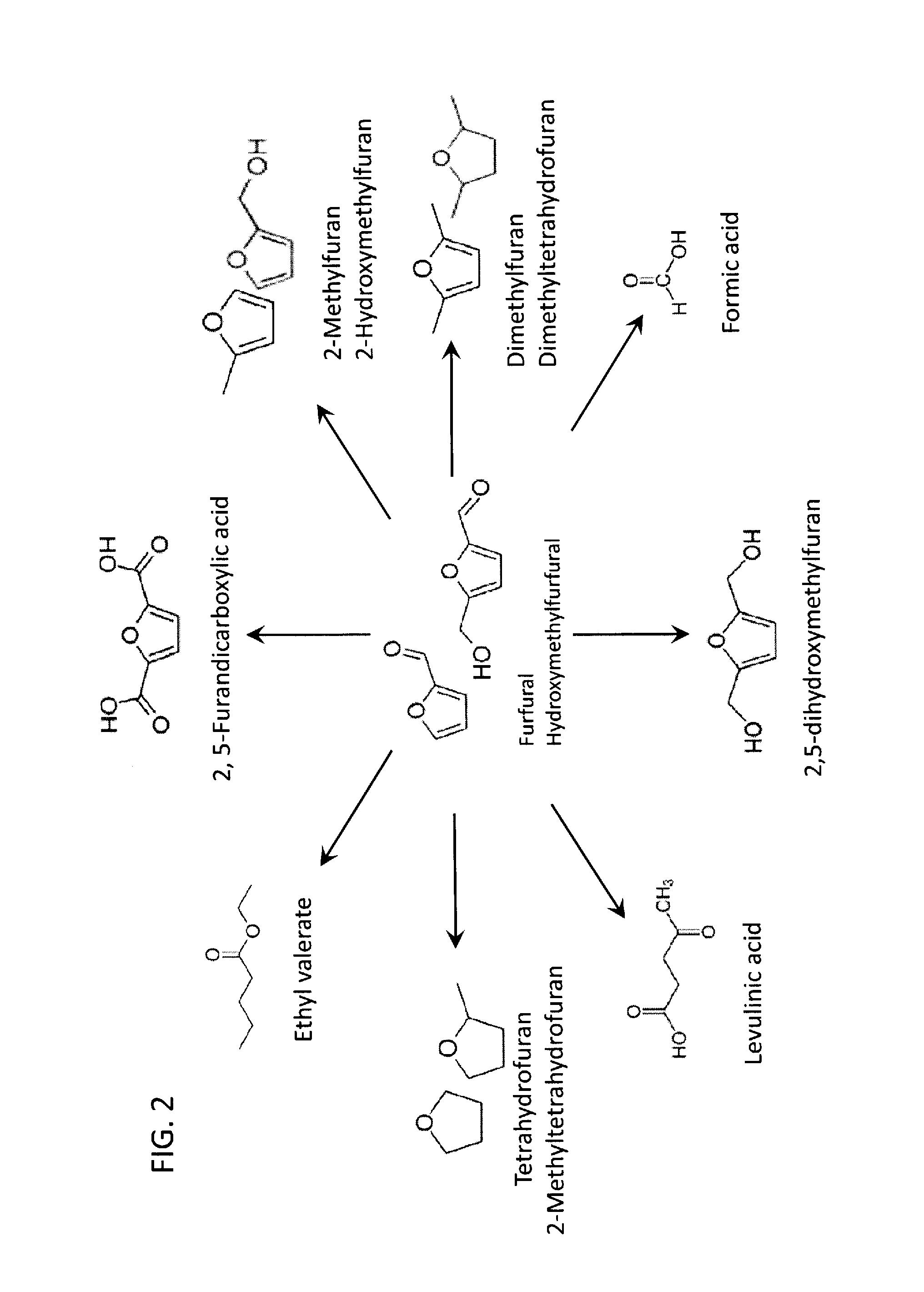

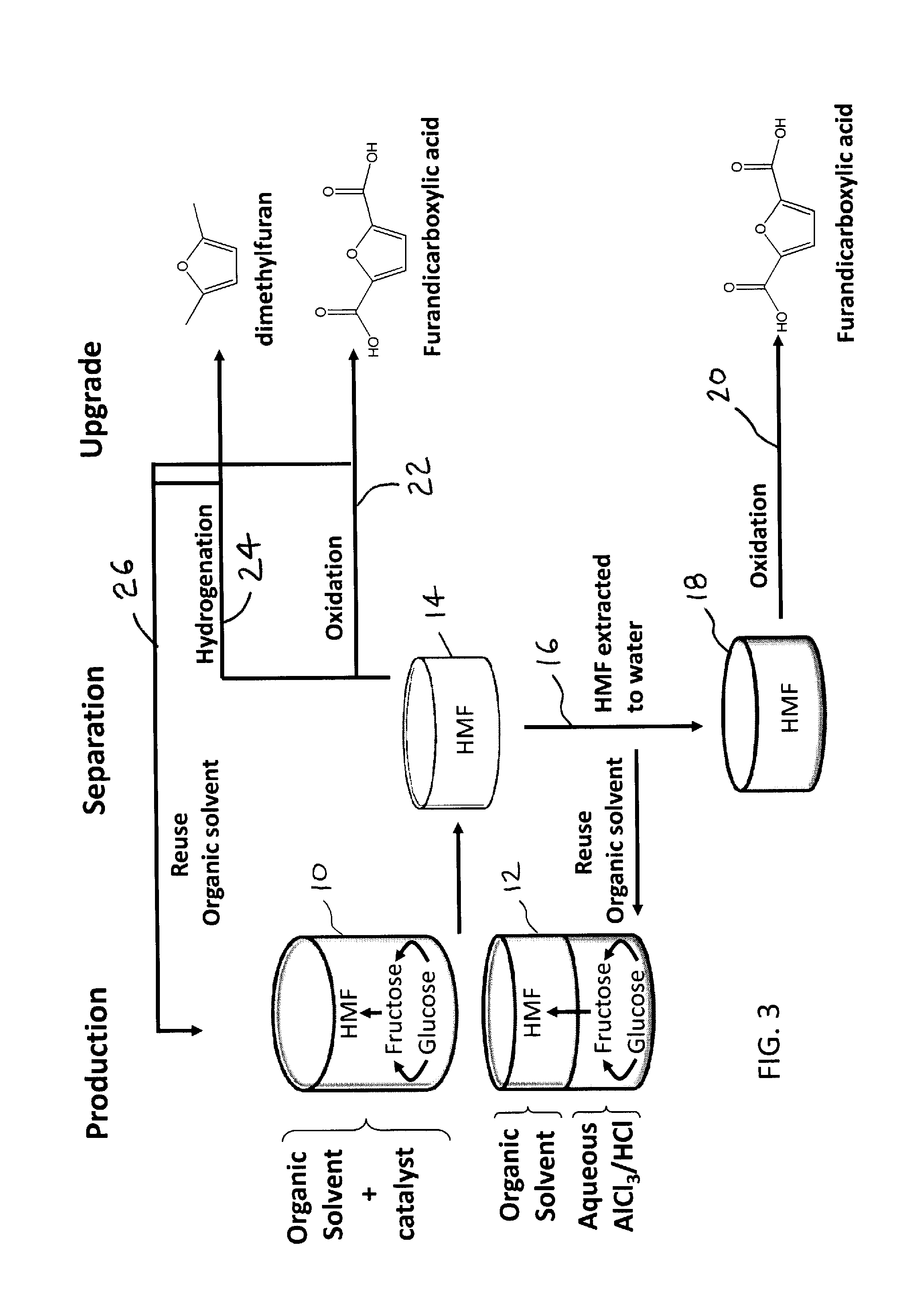

Methods for conversion of carbohydrates in ionic liquids to value-added chemicals

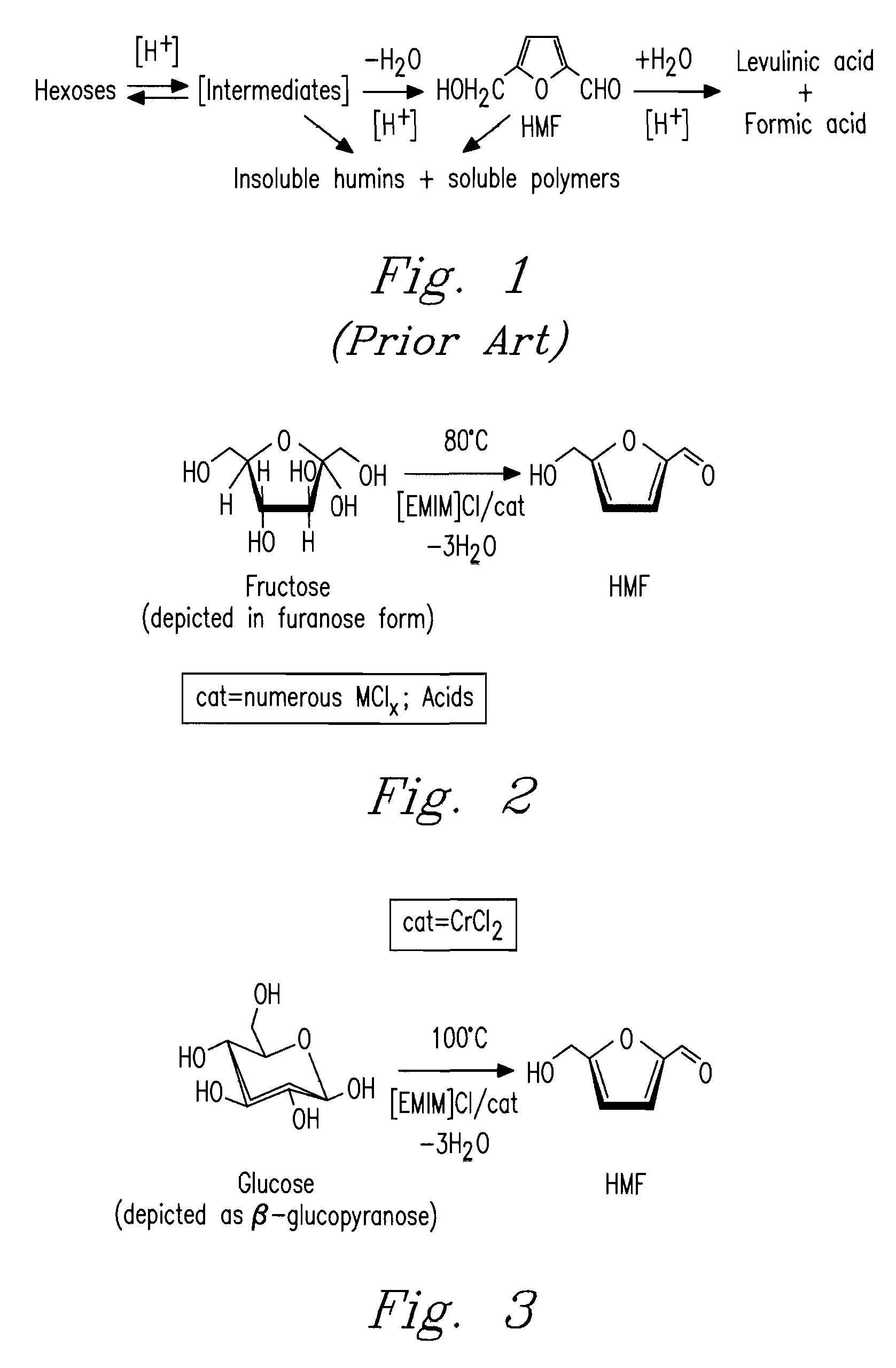

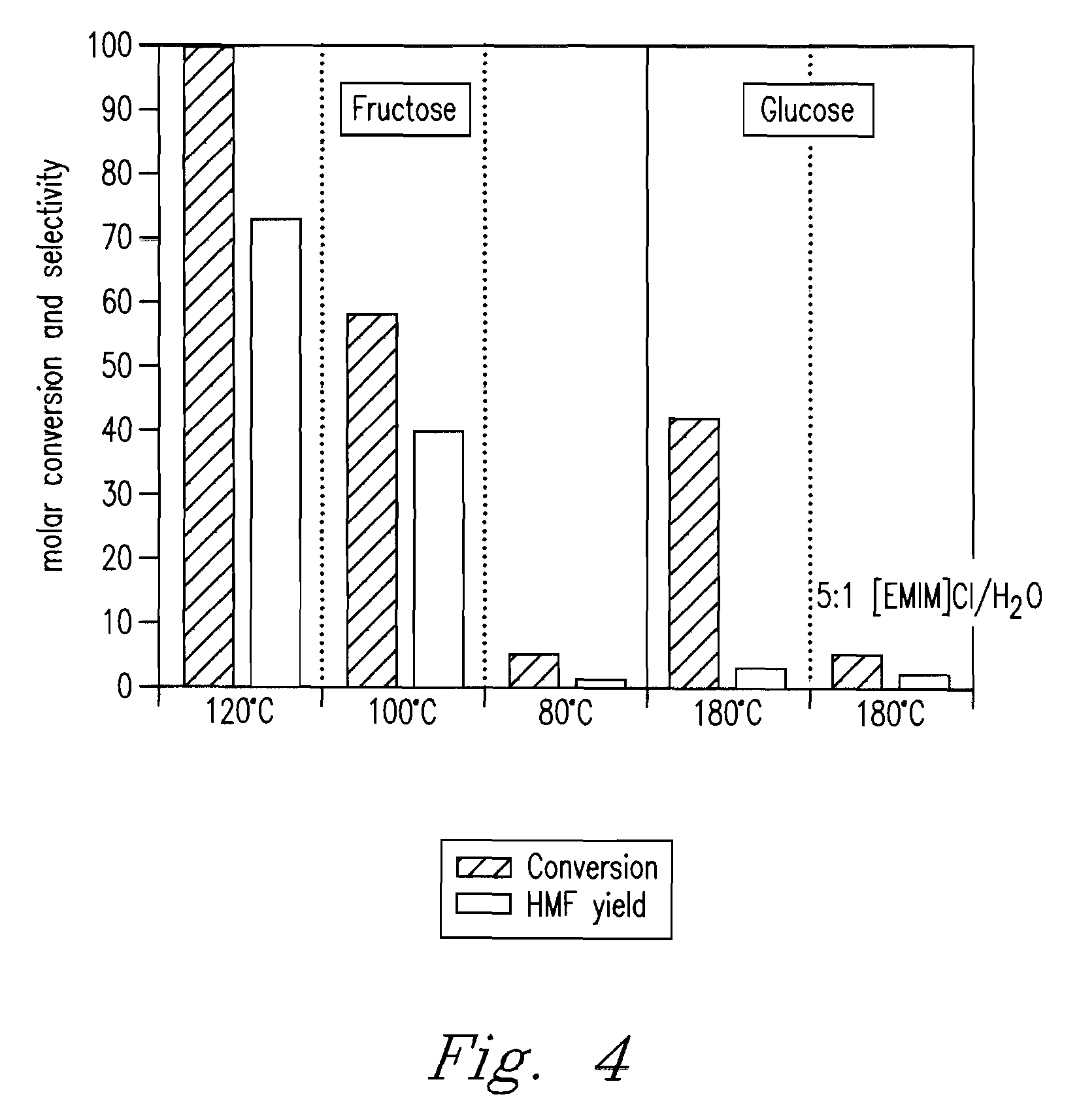

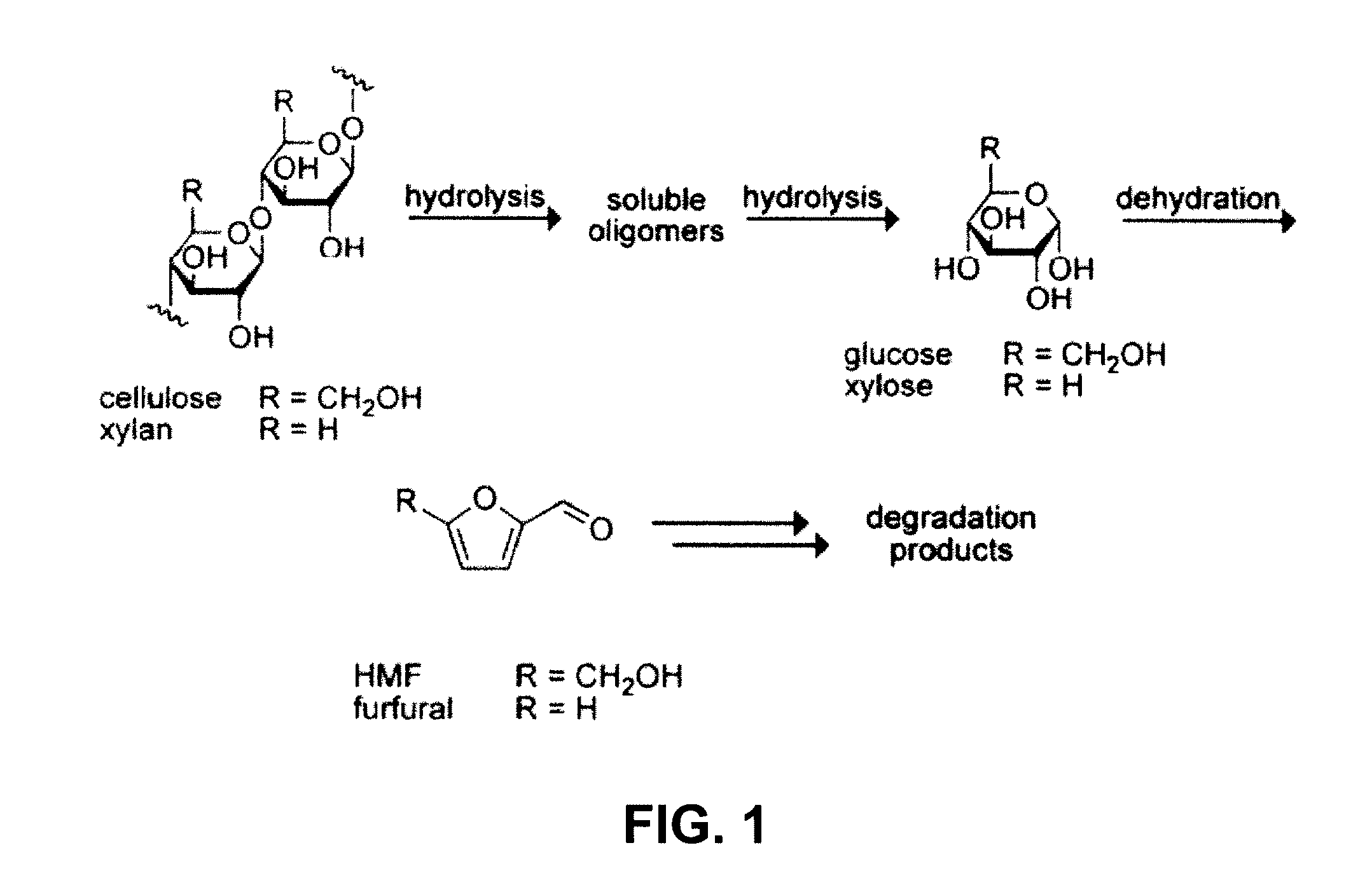

Methods are described for converting carbohydrates including, e.g., monosaccharides, disaccharides, and polysaccharides in ionic liquids to value-added chemicals including furans, useful as chemical intermediates and / or feedstocks. Fructose is converted to 5-hydroxylmethylfurfural (HMF) in the presence of metal halide and acid catalysts. Glucose is effectively converted to HMF in the presence of chromium chloride catalysts. Yields of up to about 70% are achieved with low levels of impurities such as levulinic acid.

Owner:BATTELLE MEMORIAL INST

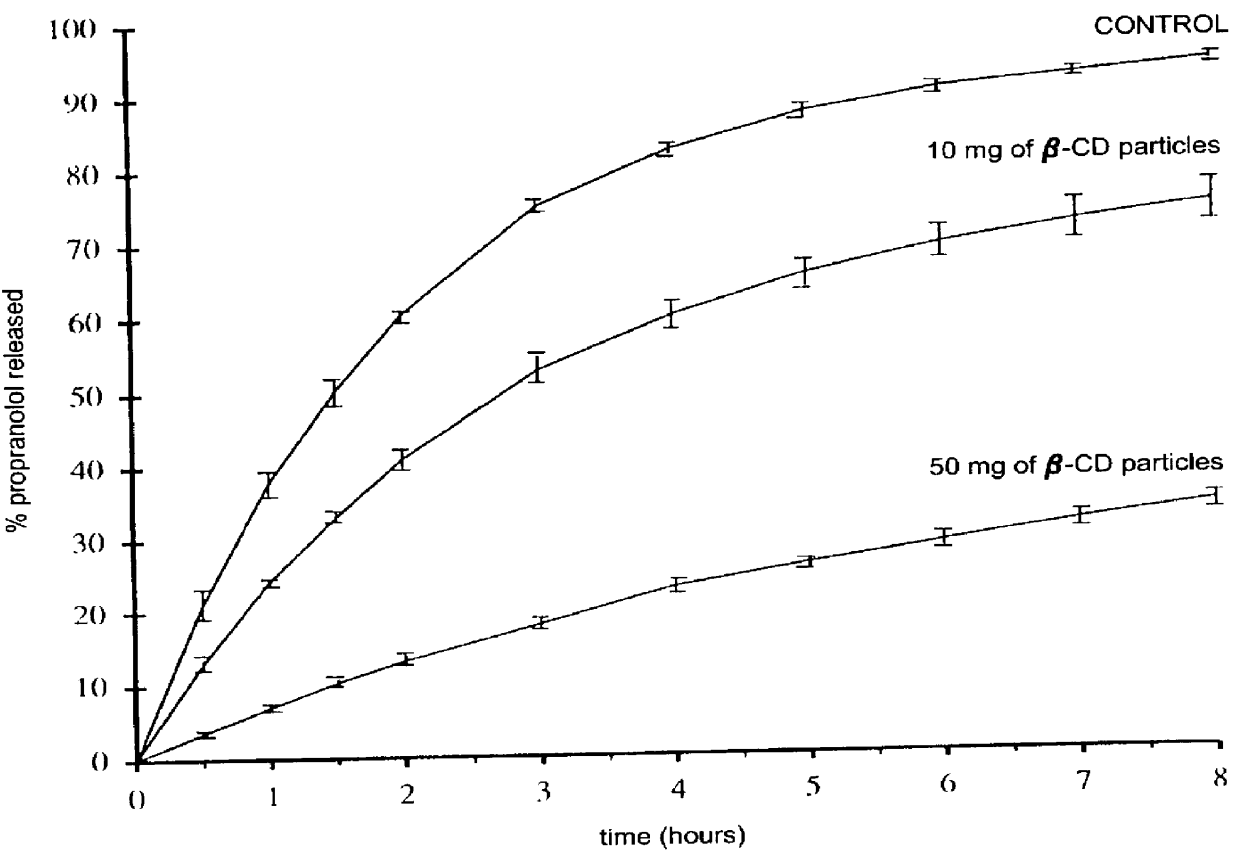

Particles, especially microparticles or nanoparticles, of crosslinked monosaccharides and oligosaccharides, processes for their preparation and cosmetic, pharmaceutical or food compositions in which they are present

InactiveUS6197757B1Demonstrates their biodegradabilityAccurate timingBiocideCosmetic preparationsEmulsionNanoparticle

Particles comprising an outer wall formed of one or more saccharide components selected from the group consisting of monosaccharides and oligosaccharides crosslinked by interfacial crosslinking in emulsion, preferably at room temperature, with a polyfunctional acylating crosslinking agent to produce ester linkages between the acylatable hydroxyl group(s) of the primary alcohol(s) of the saccharide component and the acyl groups of the polyfunctional acylating agent. These particles can be used for the manufacture of cosmetic, pharmaceutical and food compositions.

Owner:BASF BEAUTY CARE SOLUTIONS FRANCE SAS

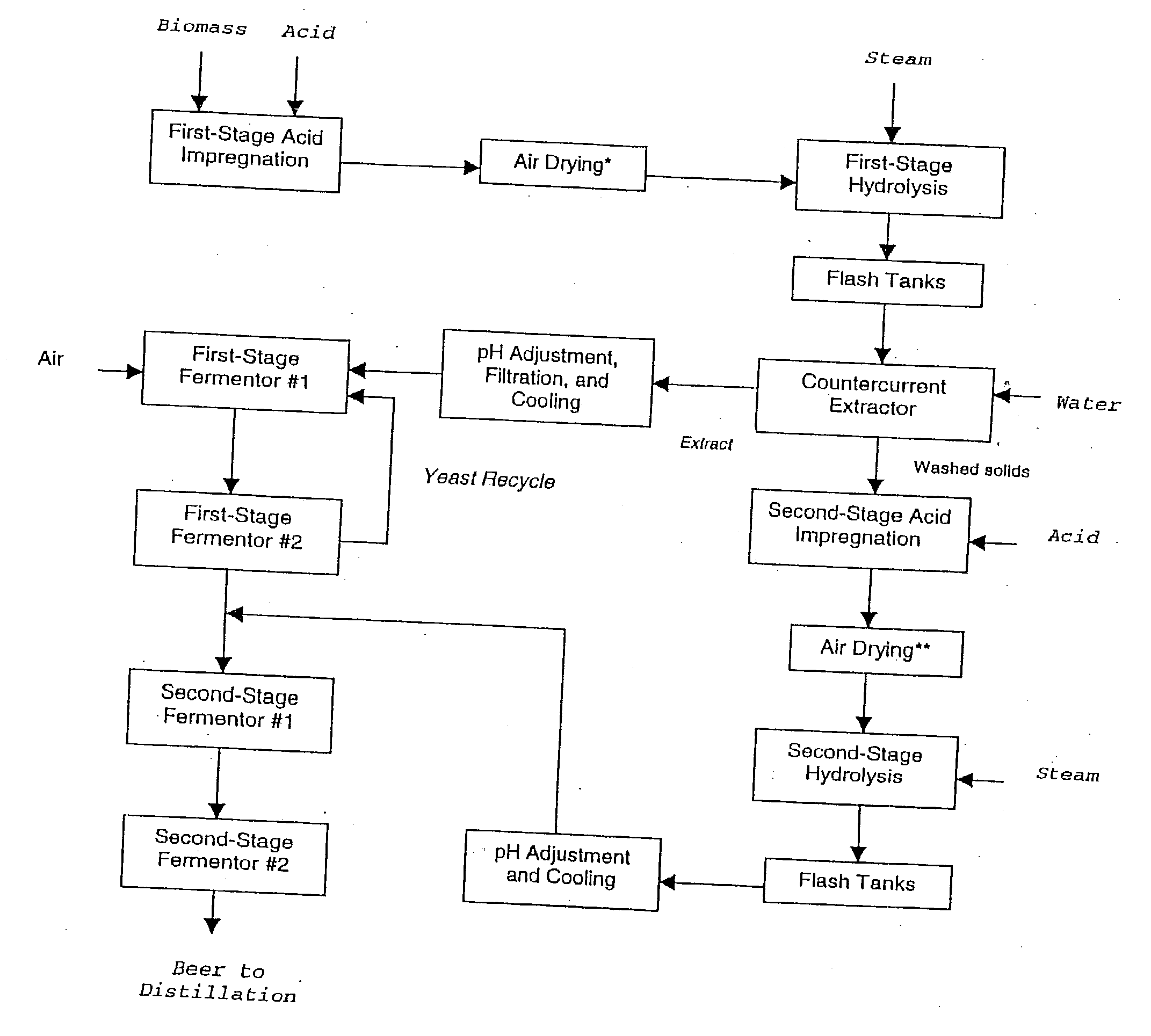

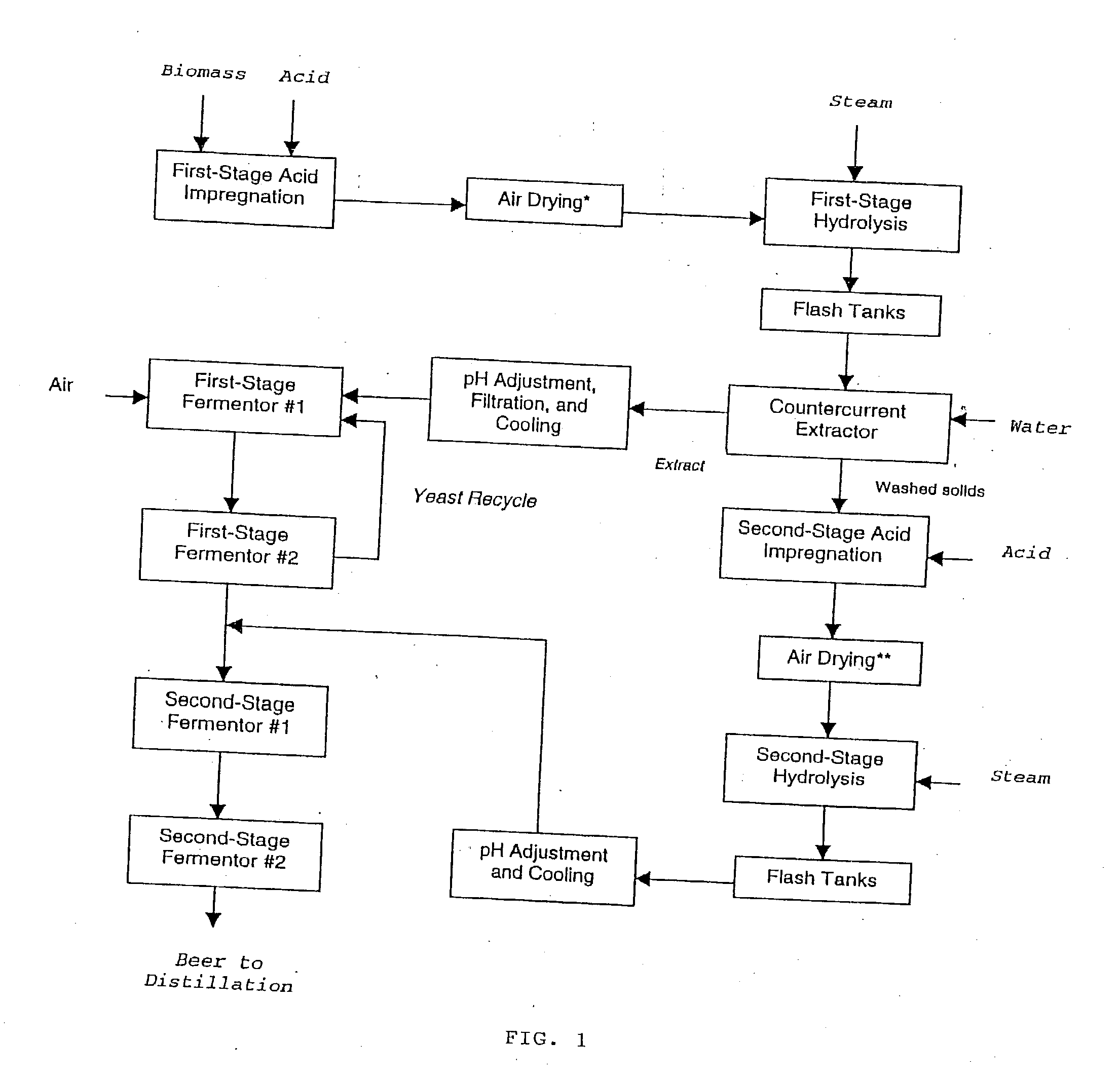

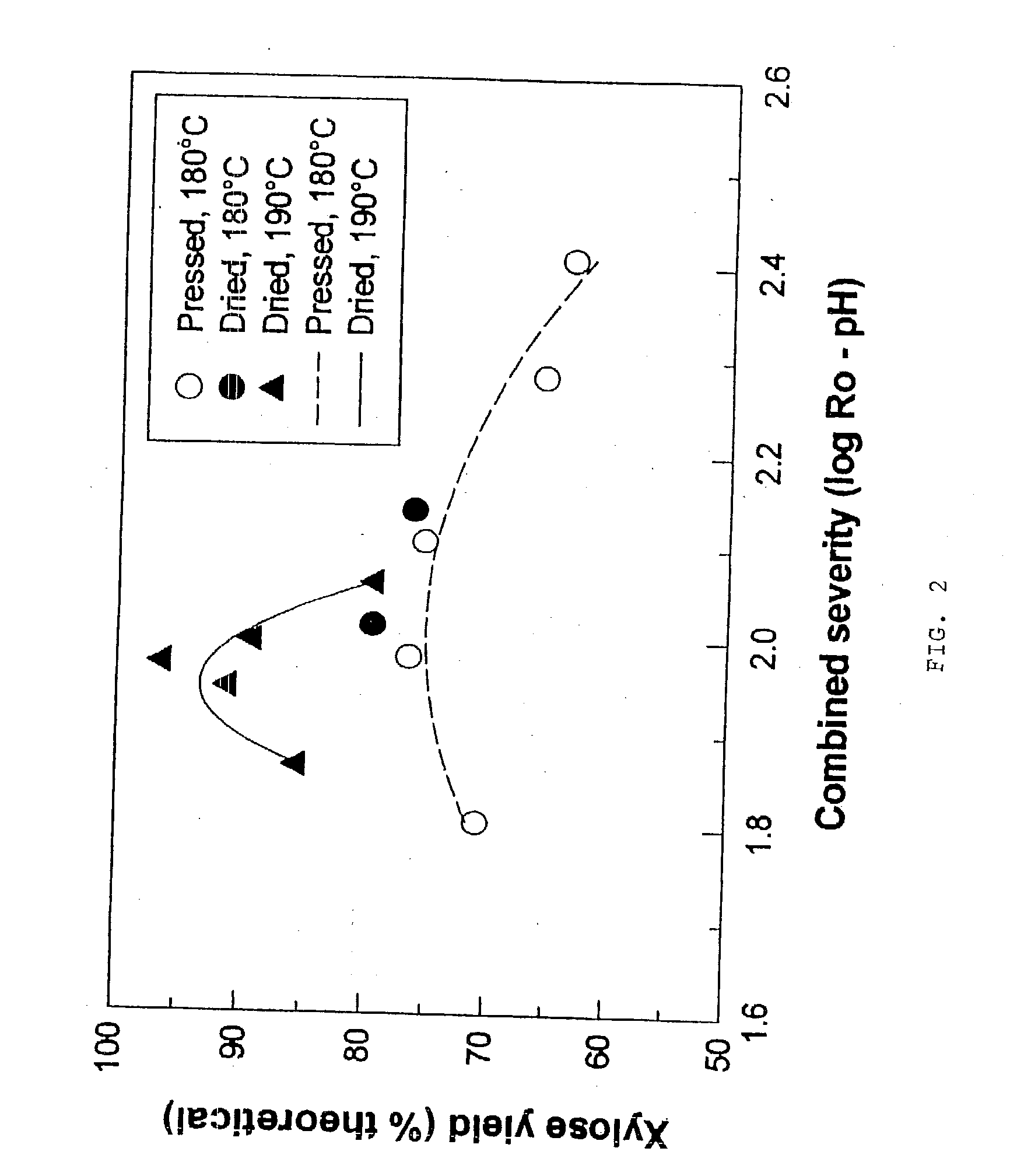

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

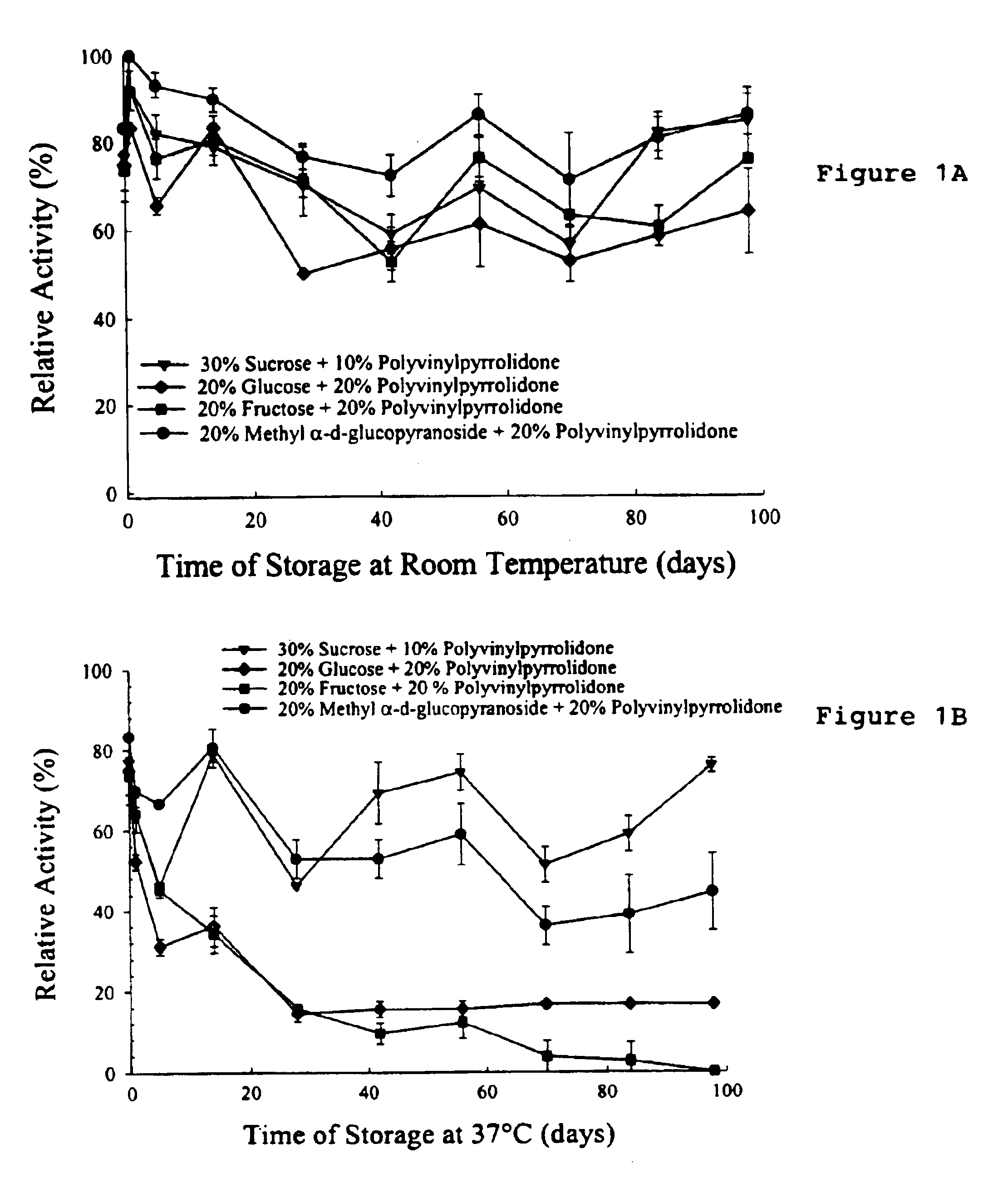

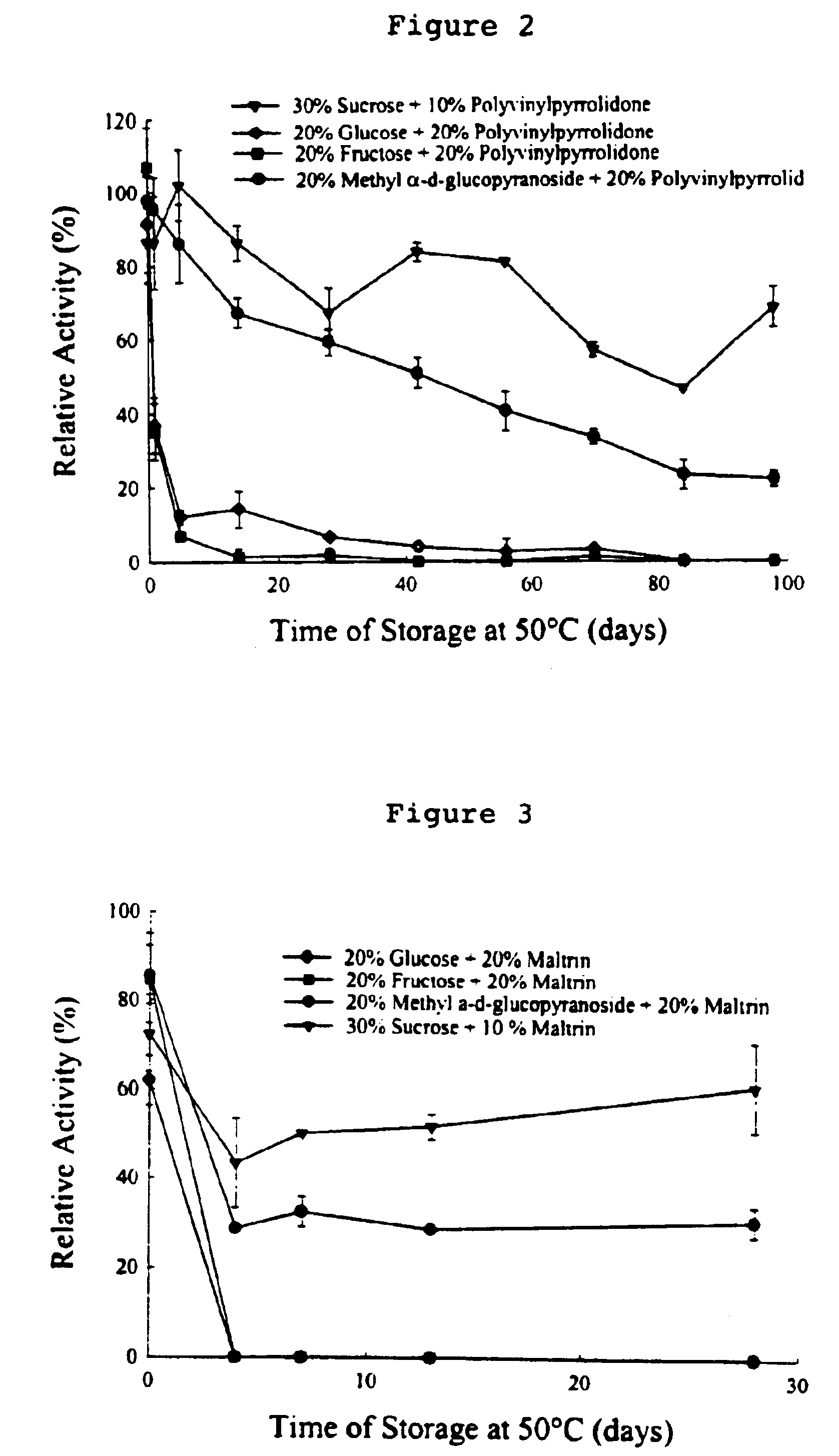

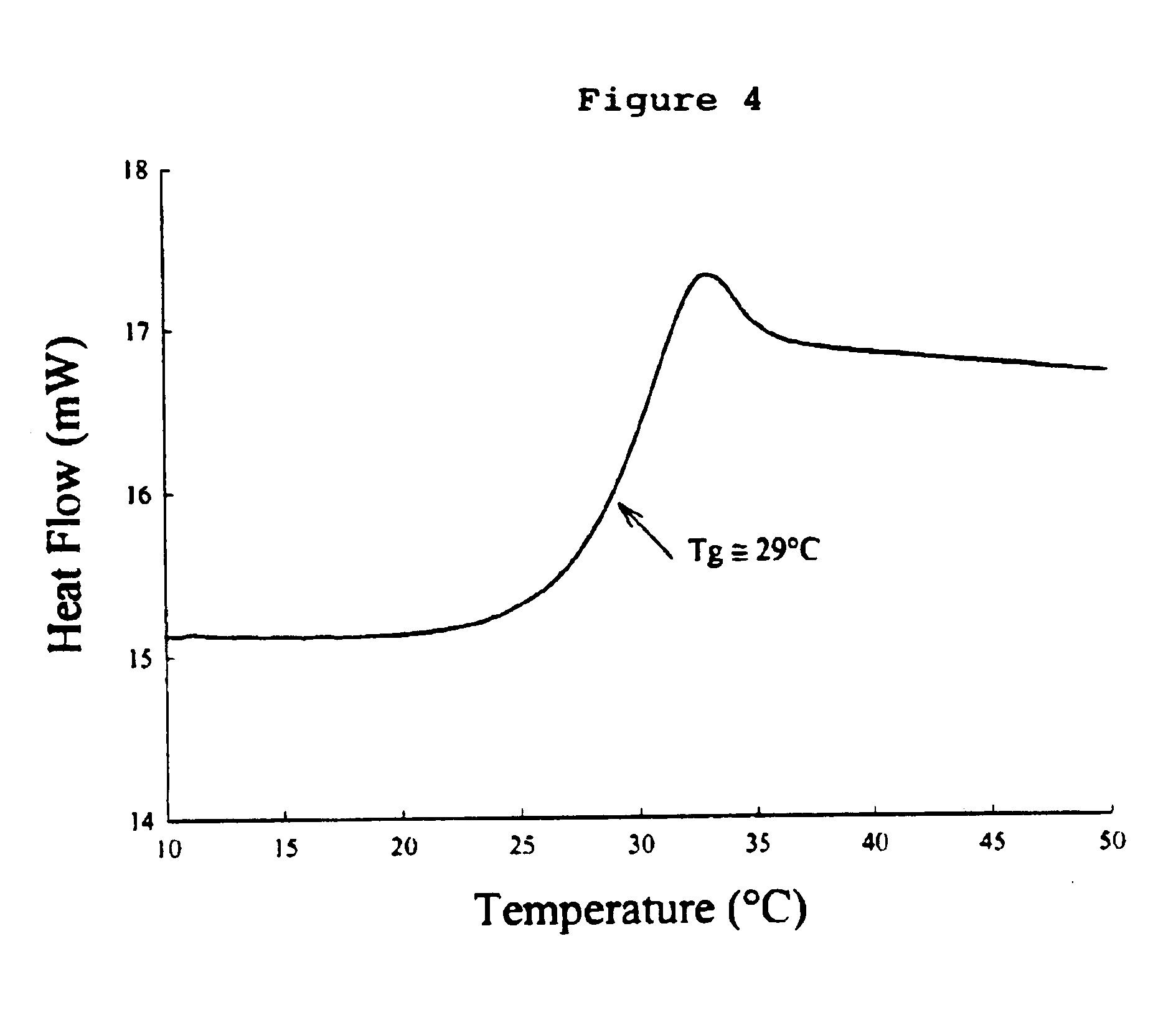

Formulation of preservation mixtures containing sensitive biologicals to be stabilized for ambient temperature storage by drying

This invention relates to formulations and methods for preserving sensitive biologicals, viruses, bacteria and eukaryotic cells by drying. More particularly, the invention relates to preservation mixtures containing viruses or cells and protectants, including a combination of a methylated monosaccharide and a disaccharide, or oligosaccharide, wherein the mixtures are adapted to stabilize these during dehydration and subsequent storage at ambient and higher temperature.

Owner:AVANT IMMUNOTHERAPEUTICS

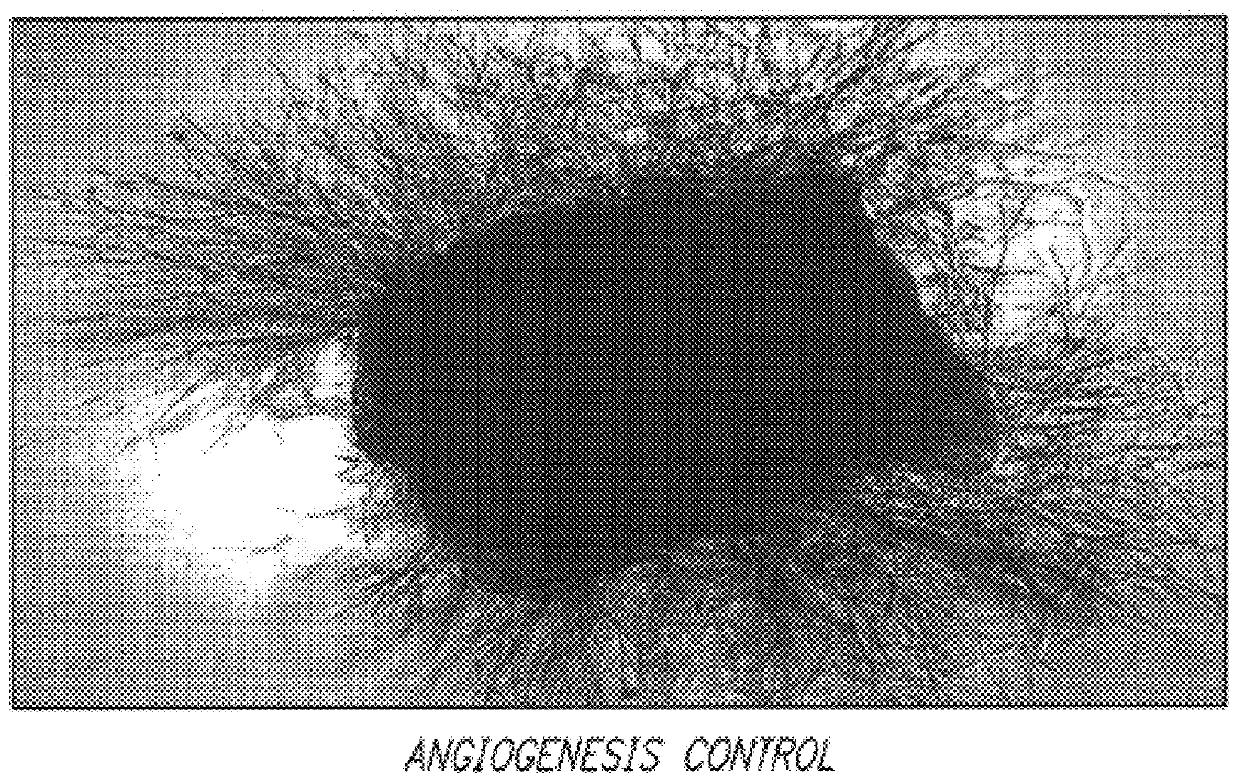

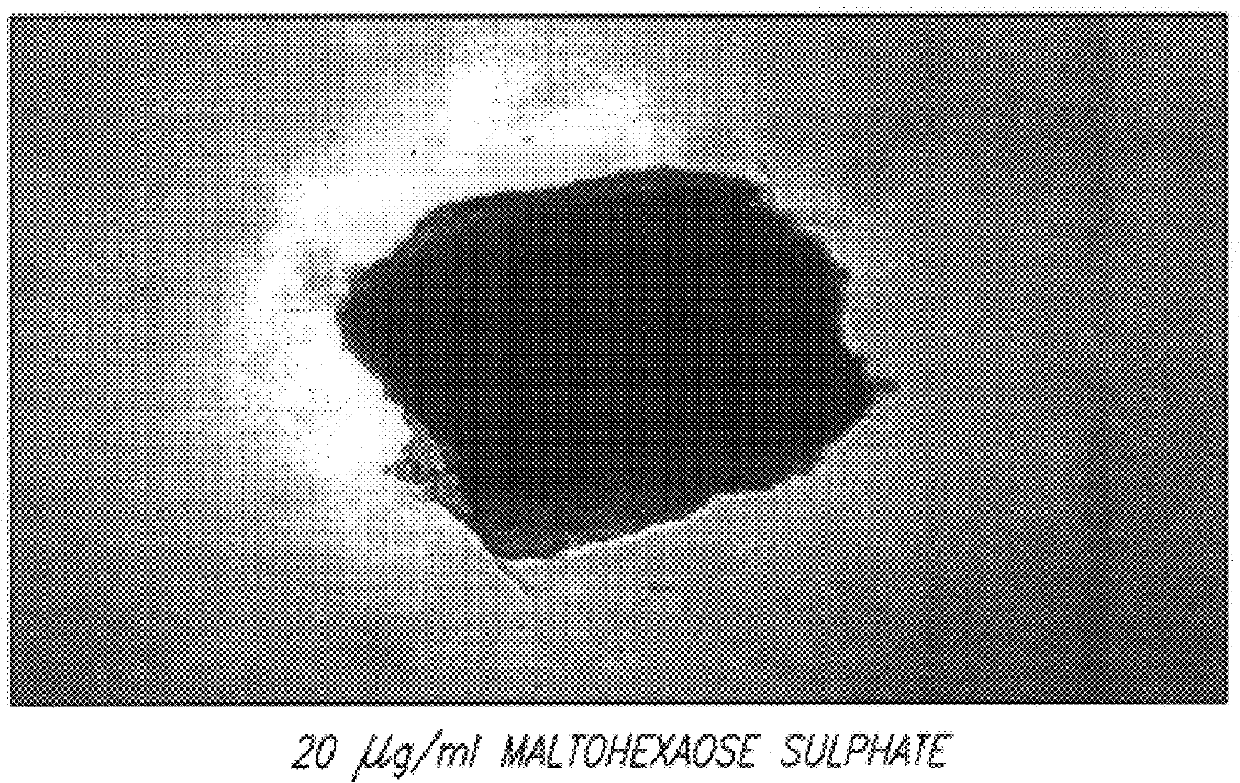

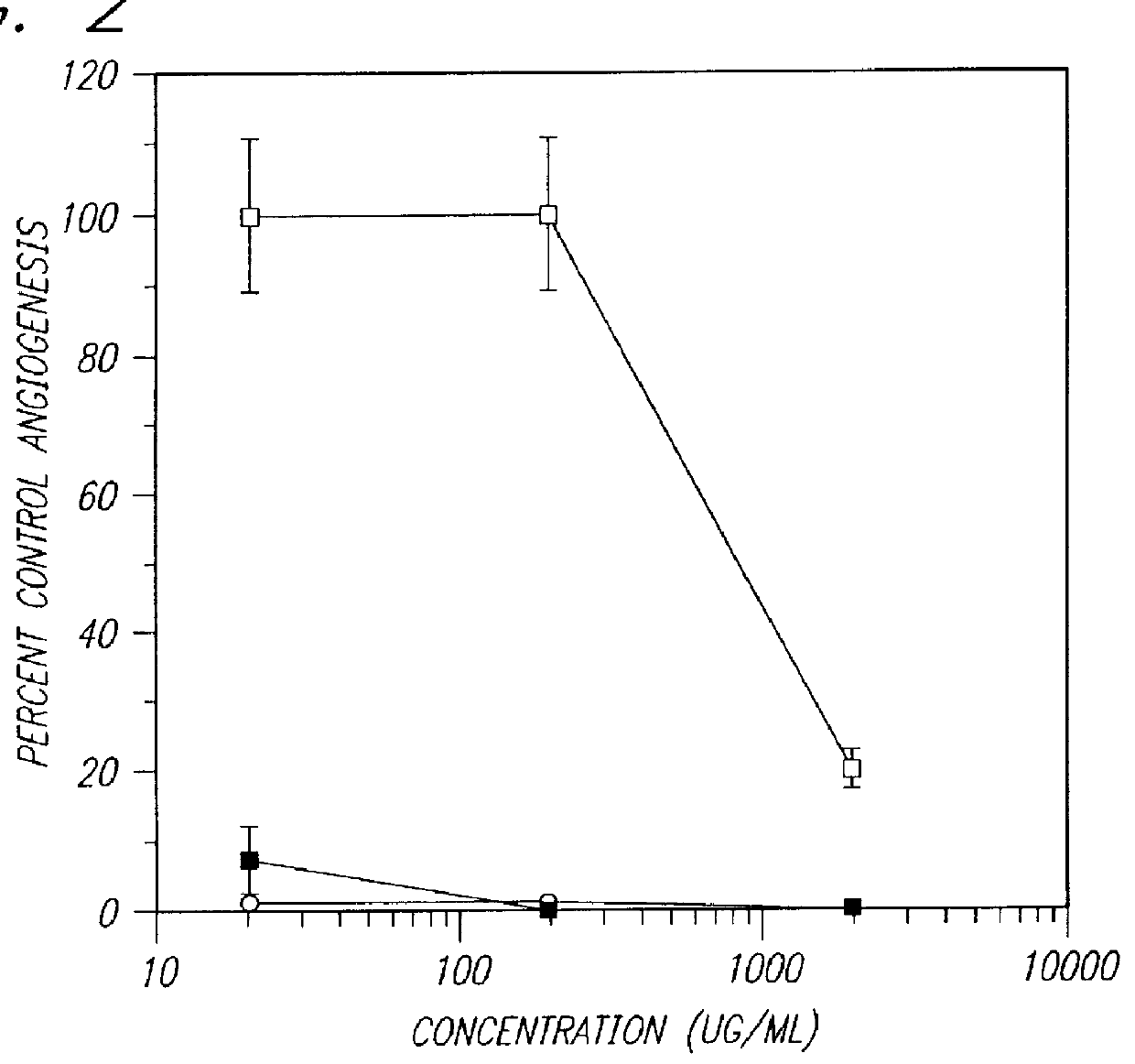

Preparation and use of sulfated oligosaccharides

PCT No. PCT / AU96 / 00238 Sec. 371 Date Oct. 28, 1997 Sec. 102(e) Date Oct. 28, 1997 PCT Filed Apr. 24, 1996 PCT Pub. No. WO96 / 33726 PCT Pub. Date Oct. 31, 1996Sulfated oligosaccharides, wherein the oligosaccharide has the general formula I:R1-(Rx)n-R2(I)wherein R1 and R2 and each Rx represents a monosaccharide unit, all of which may be the same or different, adjacent monosaccharide units being linked by 1->2, 1->3, 1->4 and / or 1->6 glycosidic bonds and n is an integer of from 1 to 6, and use thereof as anti-angiogenic, anti-metastatic and / or anti-inflammatory agents.

Owner:AUSTRALIEN NAT UNIV

Absorbable implants and methods for their use in hemostasis and in the treatment of osseous defects

ActiveUS20050065214A1Stimulate bone healing processLower potentialBiocidePowder deliveryBarium saltTG - Triglyceride

Two (or more), -component, body-implantable, absorbable, biocompatible, putty, and non-putty hemostatic tamponades for use in surgery. Component 1 is a finely powdered bulking material, preferably less than 50 microns, e.g. the calcium, magnesium, aluminum, or barium salts of saturated or unsaturated carboxylic acids containing about 6 to 22 carbon atoms, hydroxyapatite, DBM, polyglycolide, polylactide, poldioxinones, polycaprolactones, absorbable glasses, gelatin, collagens, mono, and polysaccharides starches. Component 2, a dispersing vehicle, may be esters of C8-C18 monohydric alcohols with C2-C6 aliphatic monocarboxylic acids; C2-C18 monohydric alcohols with polycarboxylic acids; C8-C30 monohydric alcohols; tocopherol and esters thereof with C2-C10 aliphatic monocarboxylic acids or polycarboxylic acids; absorbable 10-14C hydrocarbons; free carboxylic acids such as oleic, capric, and lauric; dialkyl ethers and ketones; alkyl aryl ethers and ketones, polyhydroxy compounds and esters and ethers thereof; (ethylene oxide / propylene oxide copolymers), oils e.g. olive oil, castor oil and triglycerides.

Owner:ABYRX

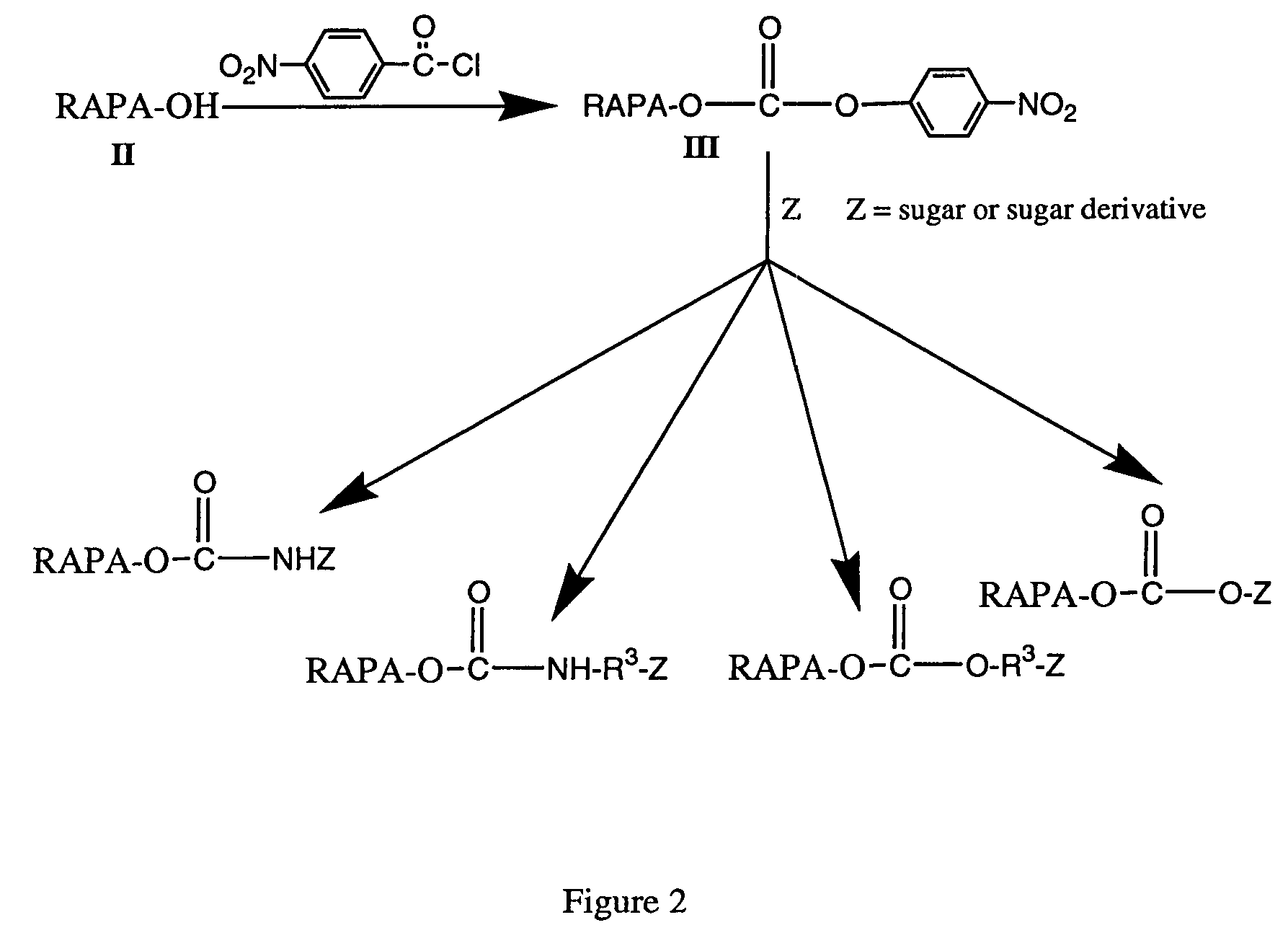

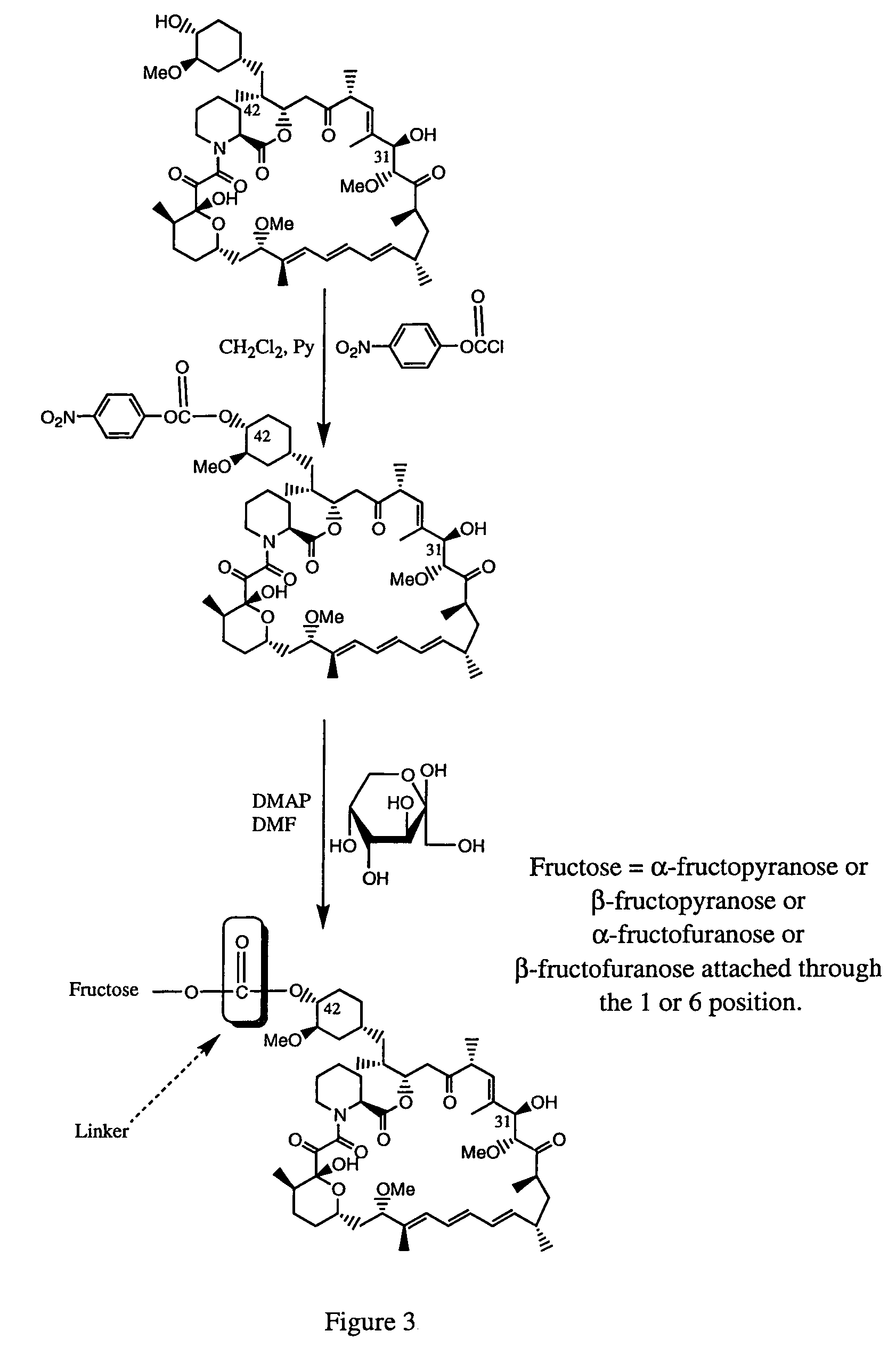

Rapamycin carbohydrate derivatives

InactiveUS7160867B2Low toxicityMore water solubleAntibacterial agentsBiocidePseudosugarsCarbohydrate derivative

This invention provides modified rapamycins that have specific monosaccharide(s), oligosaccharide(s), pseudosugar(s) or derivatives thereof attached through a linker to create rapamycin carbohydrate derivatives having enhanced pharmacokinetic and / or pharmacodynamic profiles. For example, administration of the rapamycin carbohydrate derivative results in altered pharmacokinetic profiles and reduced toxicities. Thus, the present invention provides compounds with characteristics that are distinct from other drugs in its class such as rapamycin.

Owner:ISOTECHNIKA INC

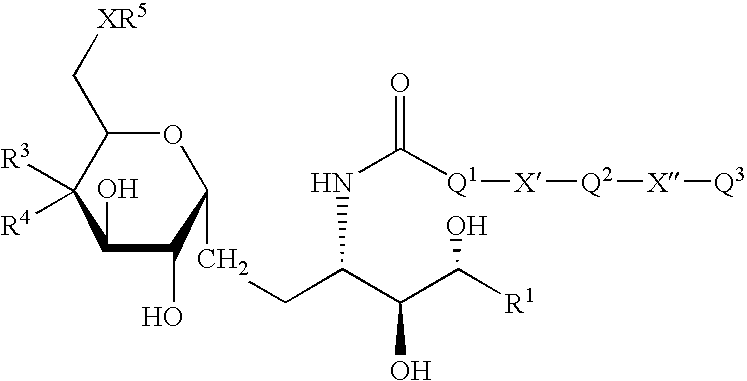

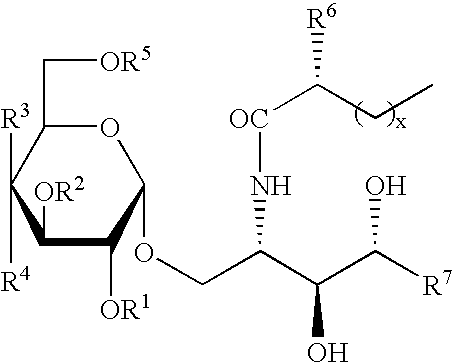

Synthetic C-glycolipid and its use for treating cancer, infectious diseases and autoimmune diseases

The invention is directed to compounds of formula (I) wherein X is O or NH; R' is a hydrocarbon chain; R<3 >and R<4 >are hydrogen, OH or a monosaccharide; R<5 >is hydrogen or a monosaccharide; Q' is optionally present and may be a C1-10 hydrocarbon; X' is optionally present and may be O, S or NR<8>; and Q<3 >may be a hydrocarbon or hydrogen. The invention is also directed to the use of the compounds for treating cancer, infectious diseases and autoimmune diseases. The invention is also directed to syntheses of the compounds of formula (I).

Owner:RES FOUND THE CITY UNIV OF NEW YORK +1

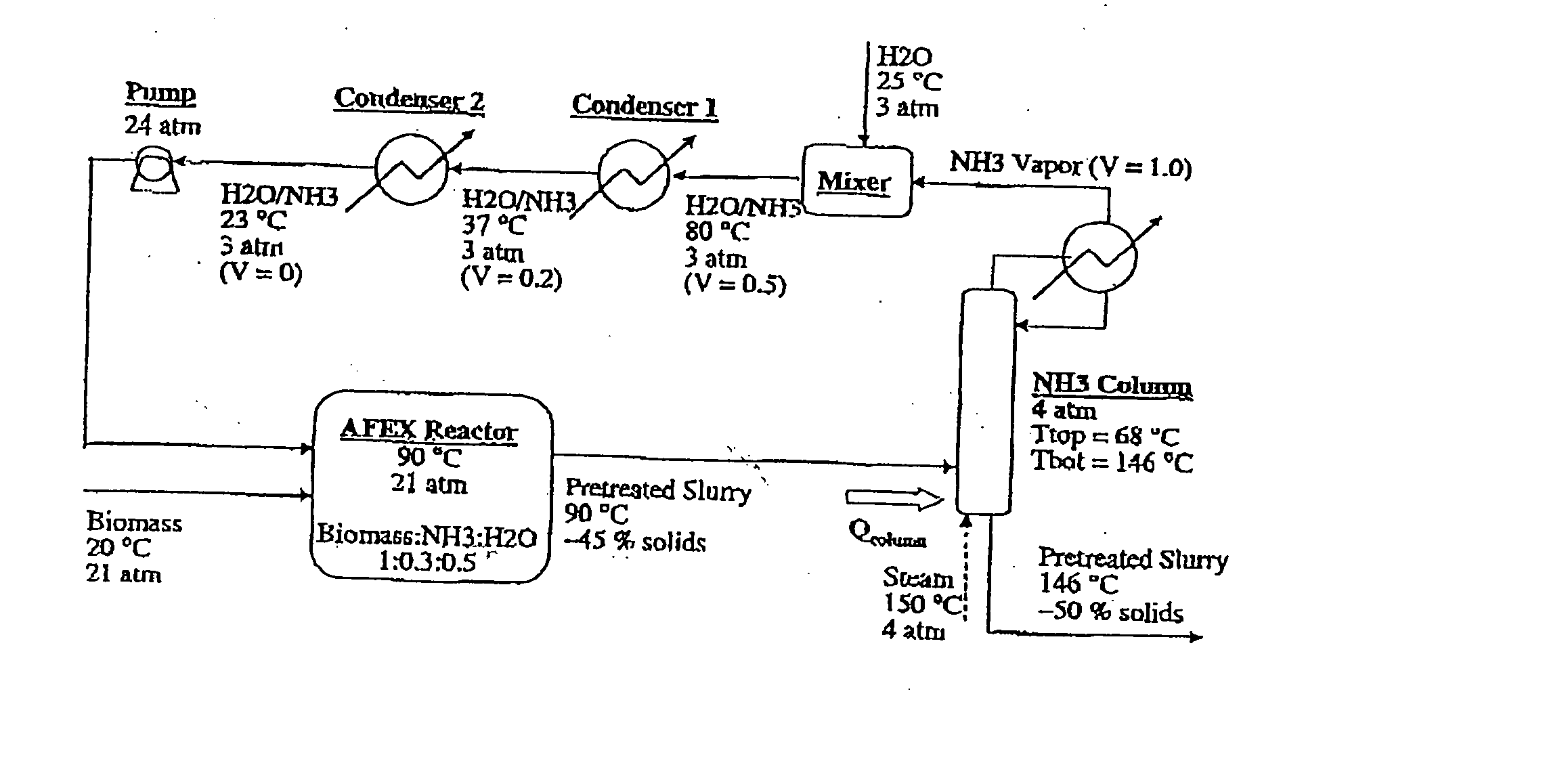

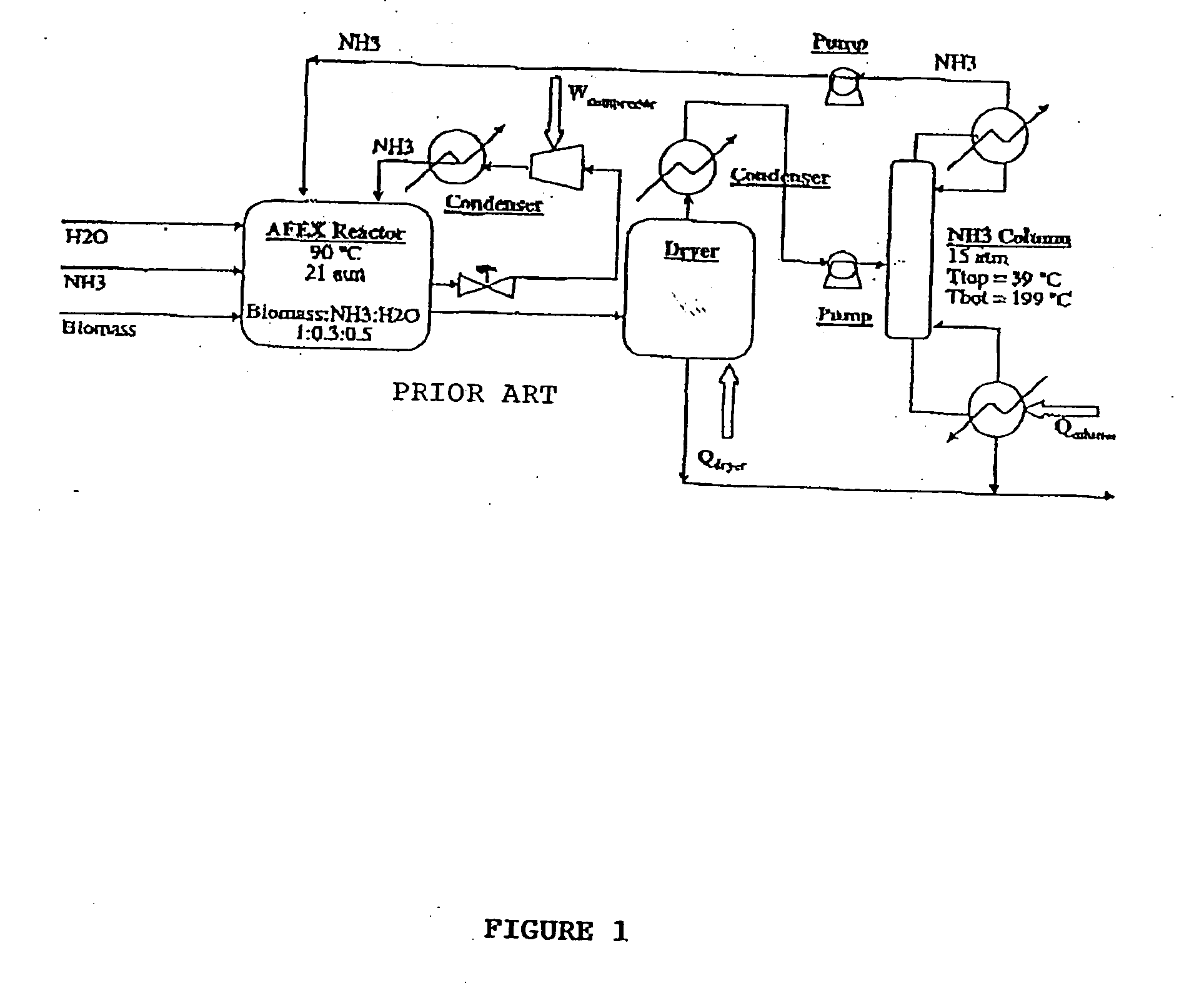

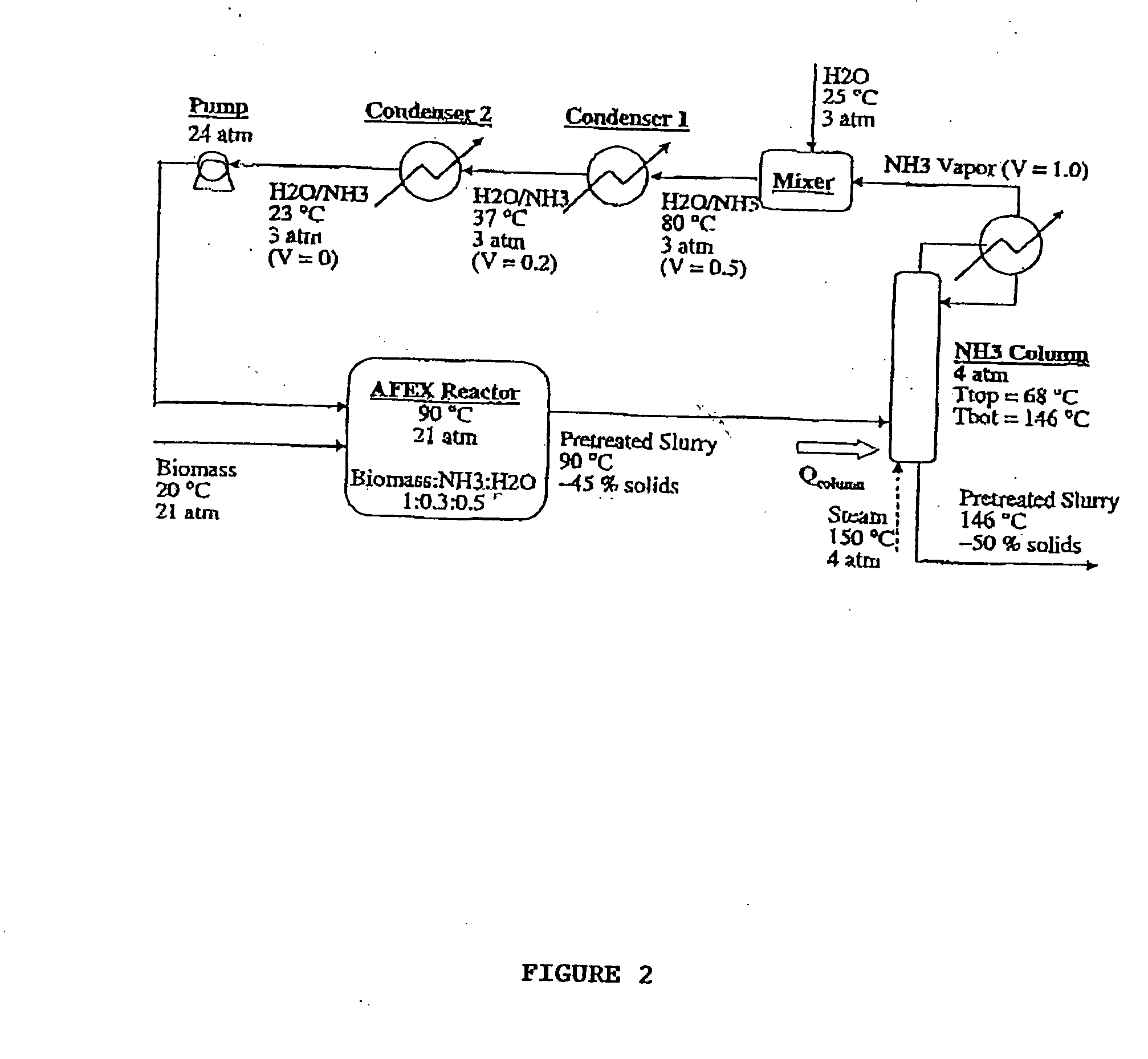

Process for the treatment of lignocellulosic biomass

ActiveUS20080008783A1Lower the volumeIncreasing fractionBiofuelsAnimal feeding stuffCelluloseEnergy source

A process for the treatment of biomass to render structural carbohydrates more accessible and / or digestible using concentrated ammonium hydroxide with or without anhydrous ammonia addition, is described. The process preferably uses steam to strip ammonia from the biomass for recycling. The process yields of monosaccharides from the structural carbohydrates are good, particularly as measured by the enzymatic hydrolysis of the structural carbohydrates. The monosaccharides are used as animal feeds and energy sources for ethanol production.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Absorbable implants and methods for their use in hemostasis and in the treatment of osseous defects

ActiveUS20060013857A1Lower potentialMinimally inhibit osteogenesis and subsequent bone healingSurgical adhesivesSkeletal disorderBarium saltApatite

Two (or more), -component, body-implantable, absorbable, biocompatible, putty, and non-putty hemostatic tamponades for use in surgery. Component 1 is a finely powdered bulking material, preferably less than 50 microns, e.g. the calcium, magnesium, aluminum, or barium salts of saturated or unsaturated carboxylic acids containing about 6 to 22 carbon atoms, hydroxyapatite, DBM, polyglycolide, polylactide, poldioxinones, polycaprolactones, absorbable glasses, gelatin, collagens, mono, and polysaccharides starches. Component 2, a dispersing vehicle, may be esters unsubstituted and N-substituted pyrrolidones of C8-C18 monohydric alcohols with C2-C6 aliphatic monocarboxylic acids; C2-C18 monohydric alcohols with polycarboxylic acids; C8-C30 monohydric alcohols; tocopherol and esters thereof with C2-C10 aliphatic monocarboxylic acids or polycarboxylic acids; absorbable 10-14C hydrocarbons; free carboxylic acids such as oleic, capric, and lauric; dialkyl ethers and ketones; alkyl aryl ethers and ketones, polyhydroxy compounds and esters and ethers thereof; (ethylene oxide / propylene oxide copolymers), oils e.g. olive oil, castor oil and triglycerides.

Owner:ABYRX

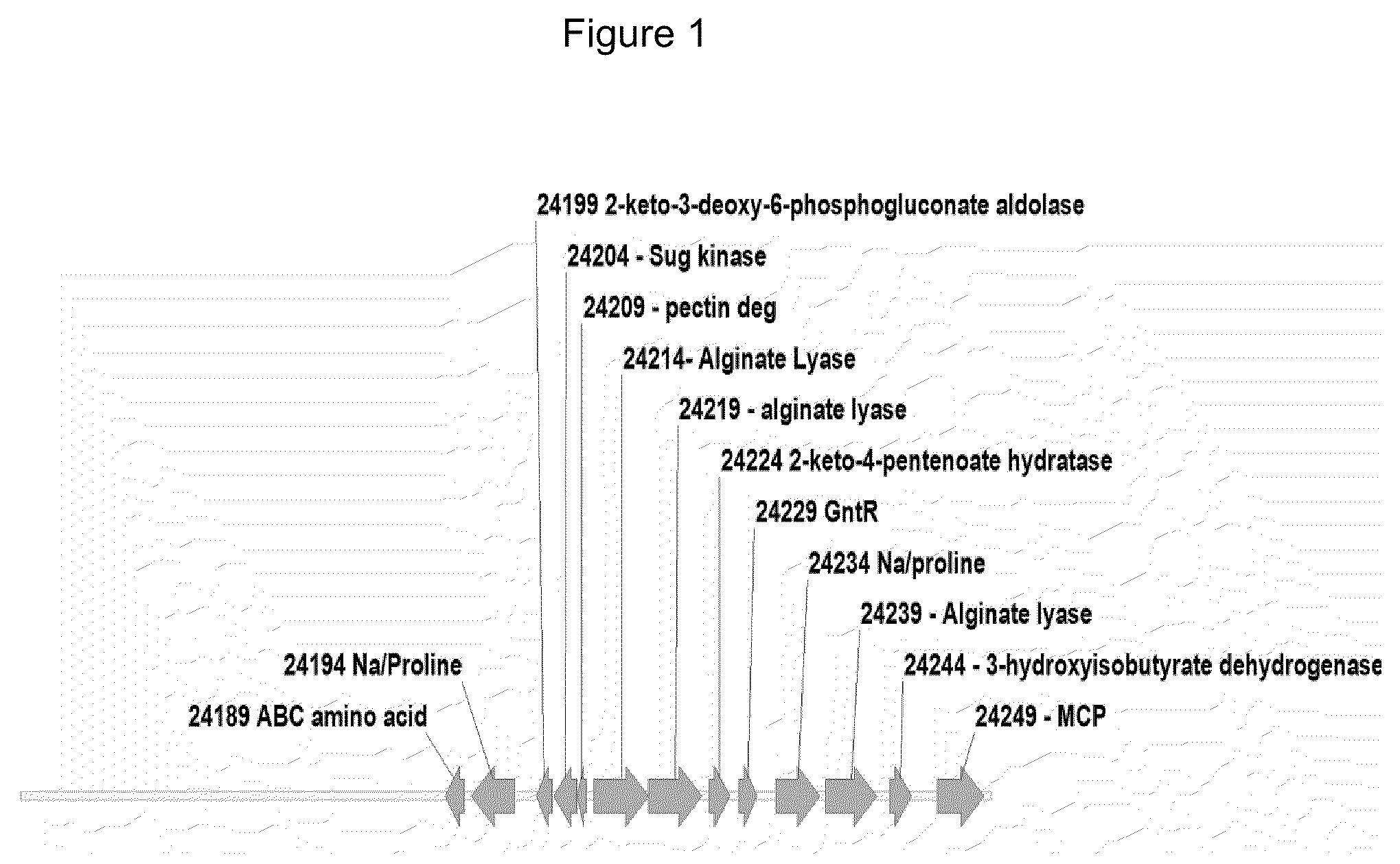

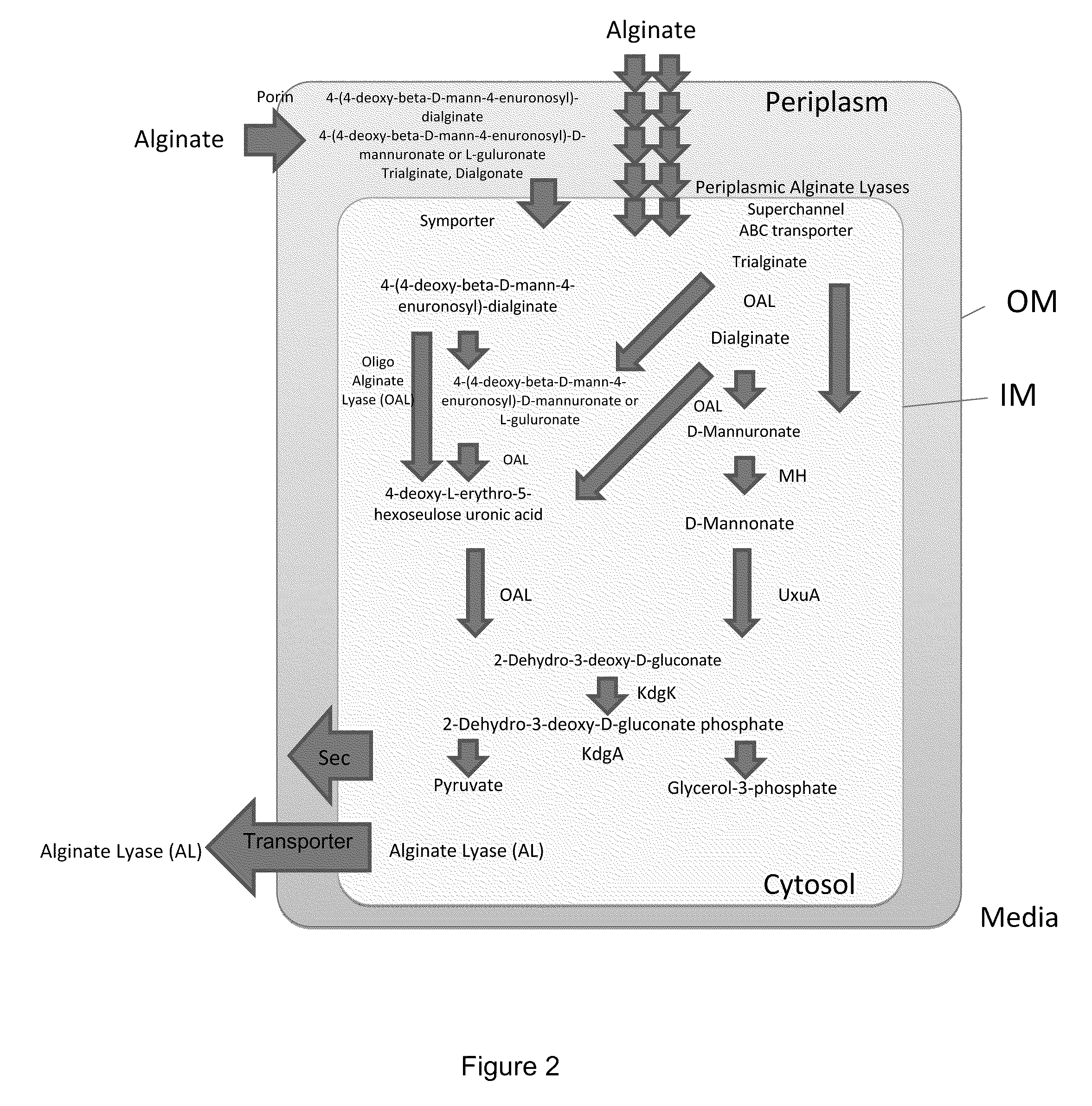

Biofuel production

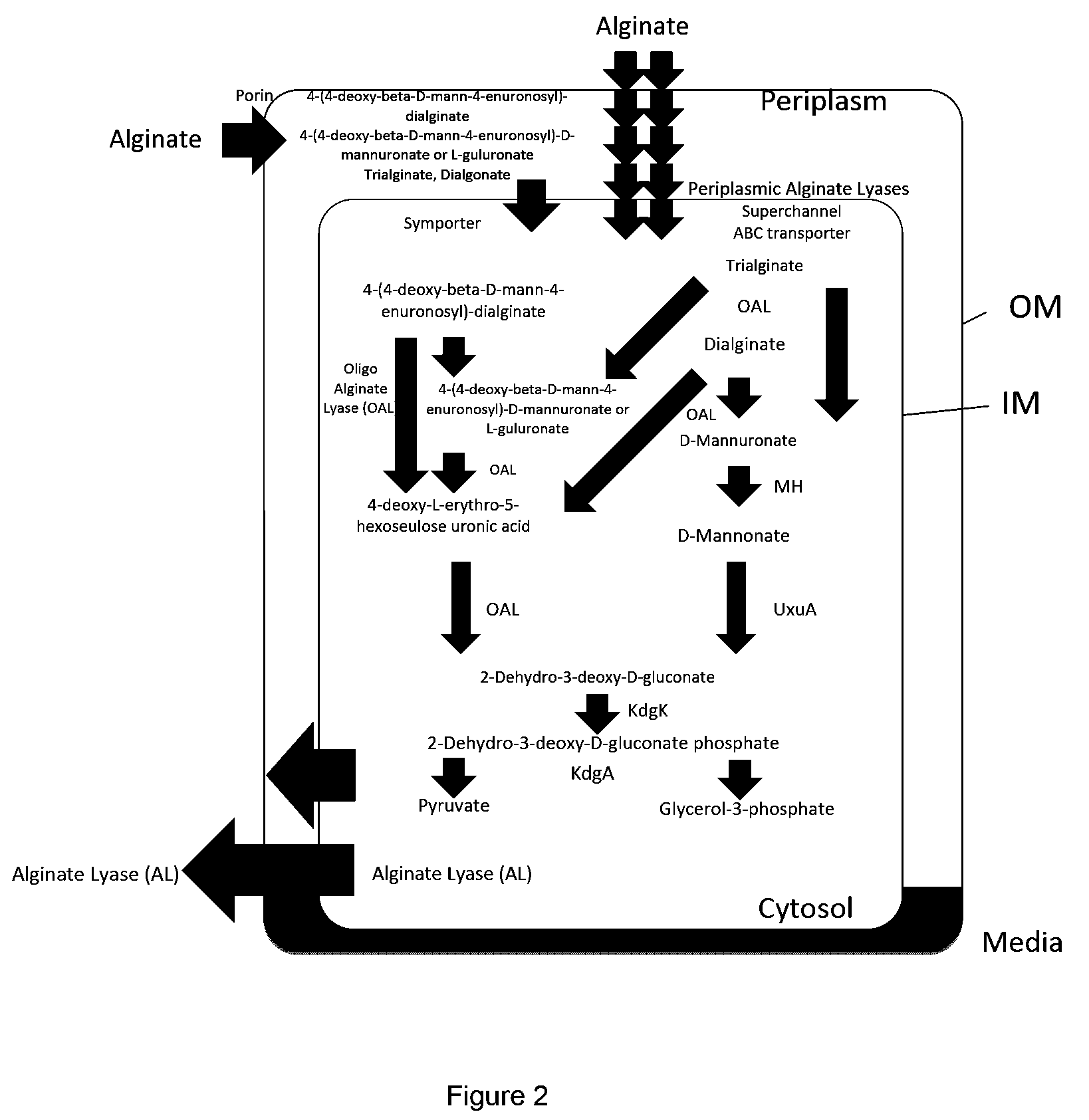

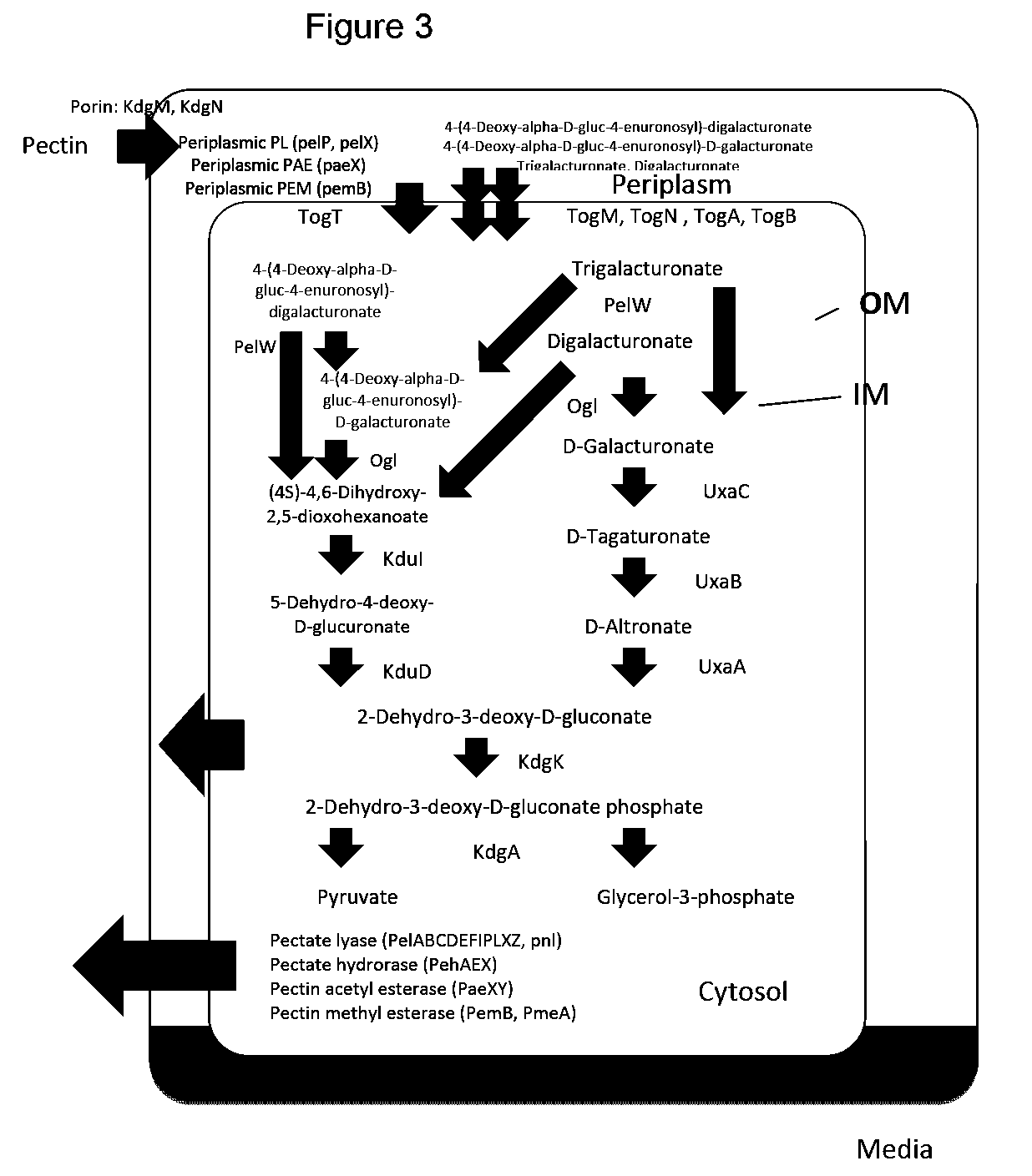

Methods, enzymes, recombinant microorganism, and microbial systems are provided for converting polysaccharides, such as those derived from biomass, into suitable monosaccharides or oligosaccharides, as well as for converting suitable monosaccharides or oligosaccharides into commodity chemicals, such as biofuels. Commodity chemicals produced by the methods described herein are also provided. Commodity chemical enriched refinery-produced petroleum products are also provided, as well as methods for producing the same.

Owner:BIO ARCHITECTURE LAB +1

Biofuel production

Methods, enzymes, recombinant microorganism, and microbial systems are provided for converting polysaccharides, such as those derived from biomass, into suitable monosaccharides or oligosaccharides, as well as for converting suitable monosaccharides or oligosaccharides into commodity chemicals, such as biofuels. Commodity chemicals produced by the methods described herein are also provided. Commodity chemical enriched, refinery-produced petroleum products are also provided, as well as methods for producing the same.

Owner:BIO ARCHITECTURE LAB

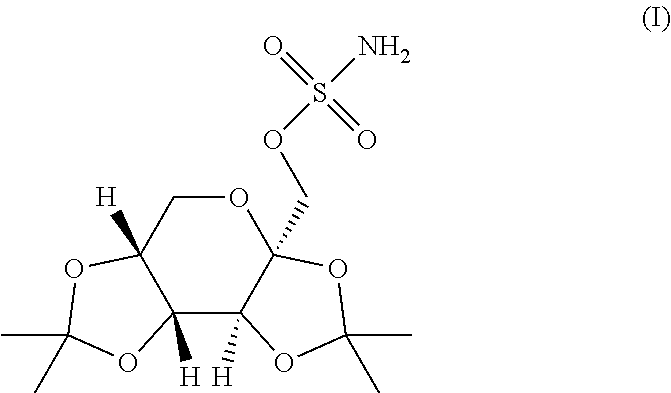

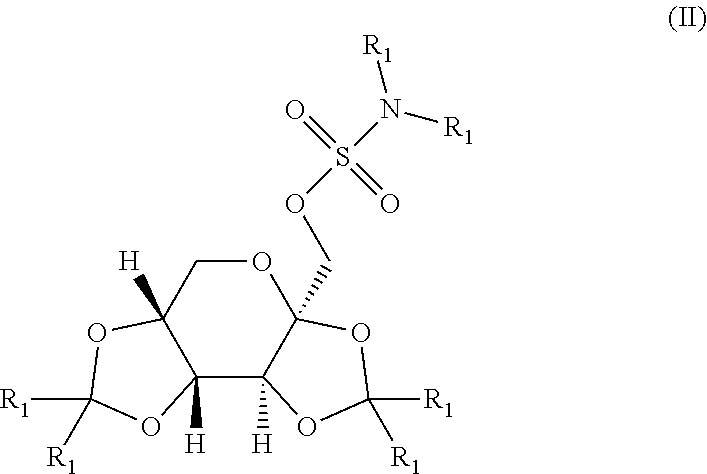

Taste masked topiramate composition and an orally disintegrating tablet comprising the same

In various embodiments, the present invention is directed to a taste masked pharmaceutical composition comprising a therapeutically effective amount of taste masked sulfamate-substituted monosaccharide particles comprising a sulfamate-substituted monosaccharide or a pharmaceutically acceptable salt or derivative thereof that are coated with one or more taste-masking layers, and optionally one or more of taste-masked neltrexone, 5-HT3 receptor antagonist, phentermine, and vitamin B-12. The present invention relates to methods of making the taste masked and ODT compositions, and methods of using the compositions for treating a patient subject to an epileptic condition, migraines, dysphagia, achieving / maintaining weight loss, or alcoholism or drug addiction.

Owner:APTALIS PHARMATECH

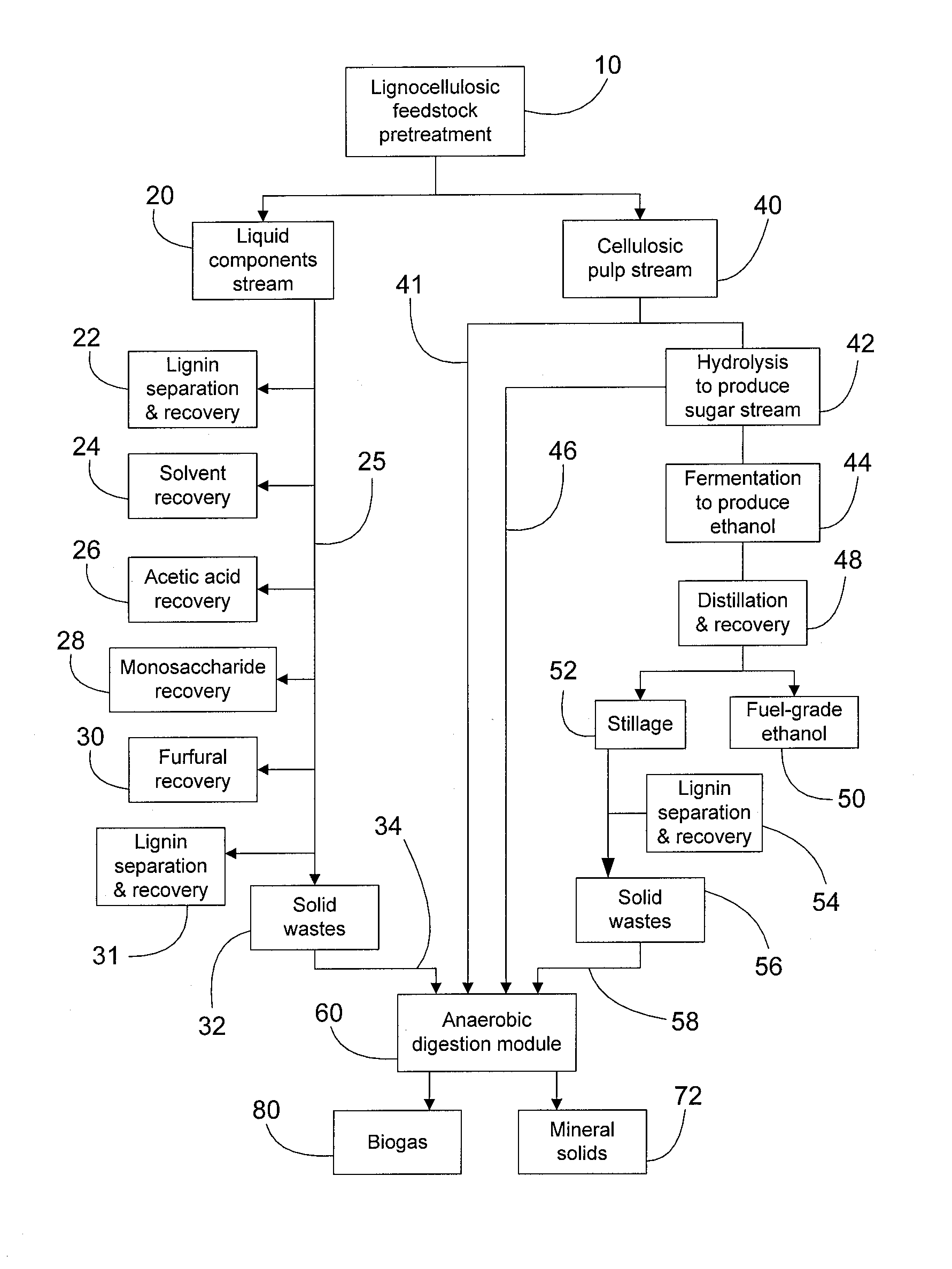

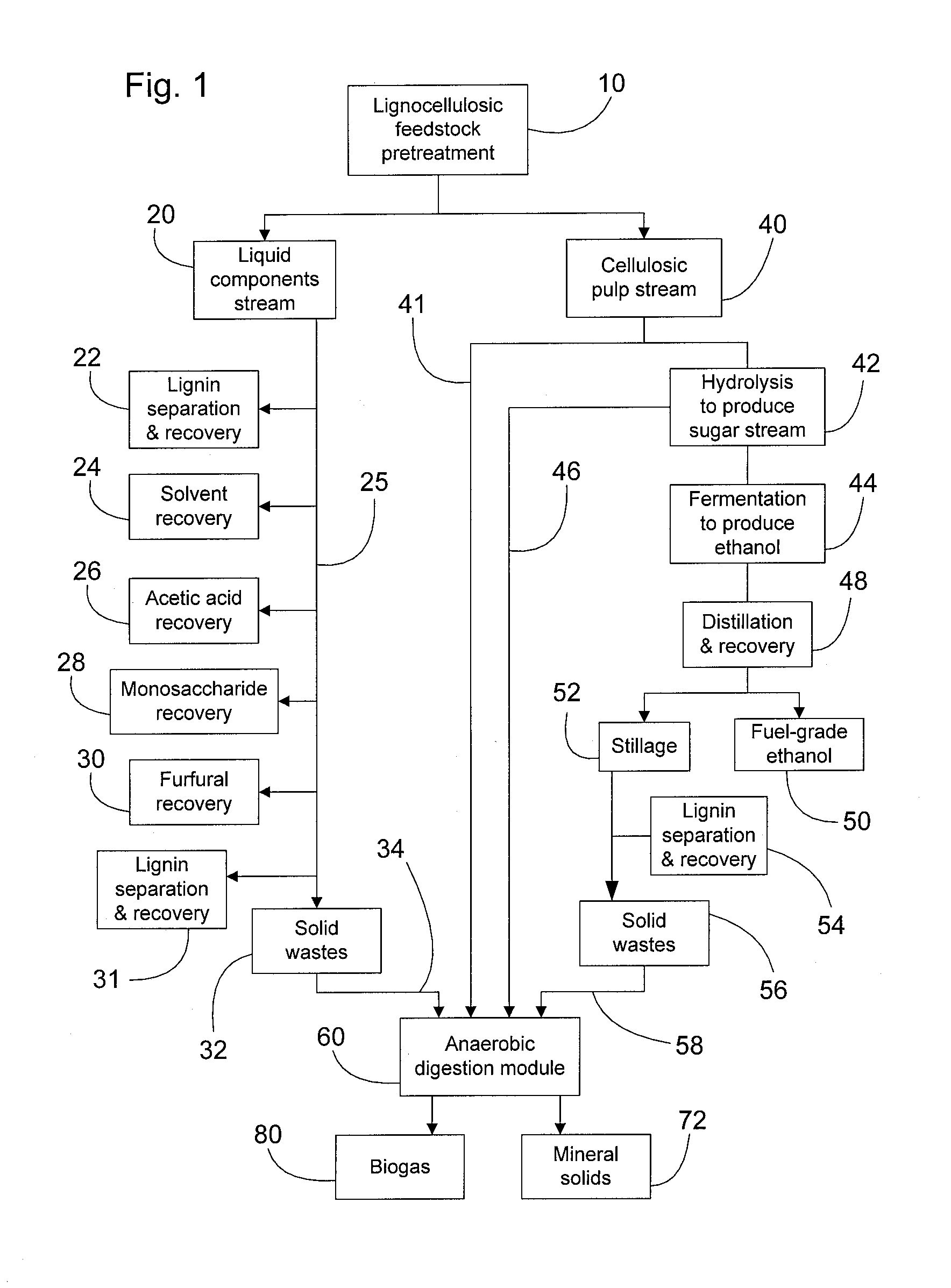

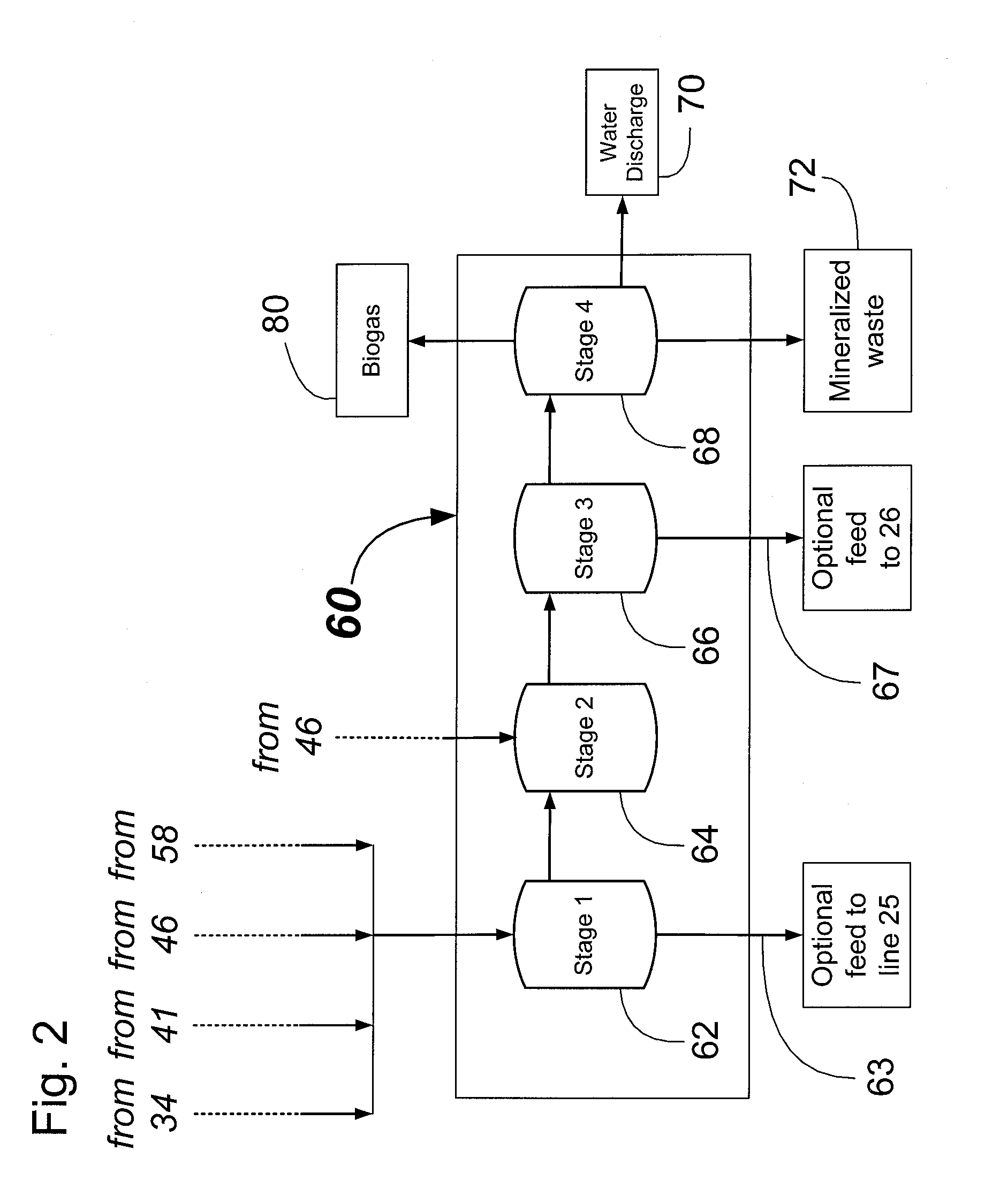

Concurrent Anaerobic Digestion and Fermentation of Lignocellulosic Feedstocks

InactiveUS20110236946A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholSemi solid

A process for concurrent production of lignins, fuel alcohol, and biogas from lignocellulosic feedstocks. The process comprises: (1) pretreating a lignocellulosic feedstock to produce a solubilised liquid components stream comprising lignins, lignin-derived compounds, and a cellulosic pulp stream, (2) separating the liquid stream from the cellulosic pulp stream, (3) processing the liquid stream to separate and recover at least lignins, lignin-derived compounds, and semi-solid waste material, (b) processing the cellulosic pulp stream to saccharify and ferment the cellulose pulp to produce a beer which is then separated into fuel-grade alcohol and a waste stillage material, (4) anaerobically digesting the semi-solid waste material from the liquid stream and the waste stillage material to produce a biogas. The rate of anaerobic digestion can be manipulated by controllably supplying a portion of the monosaccharides produced from the cellulosic pulp. The cellulosic pulp stream may also be anaerobically digested.

Owner:LIGNOL INNOVATIONS

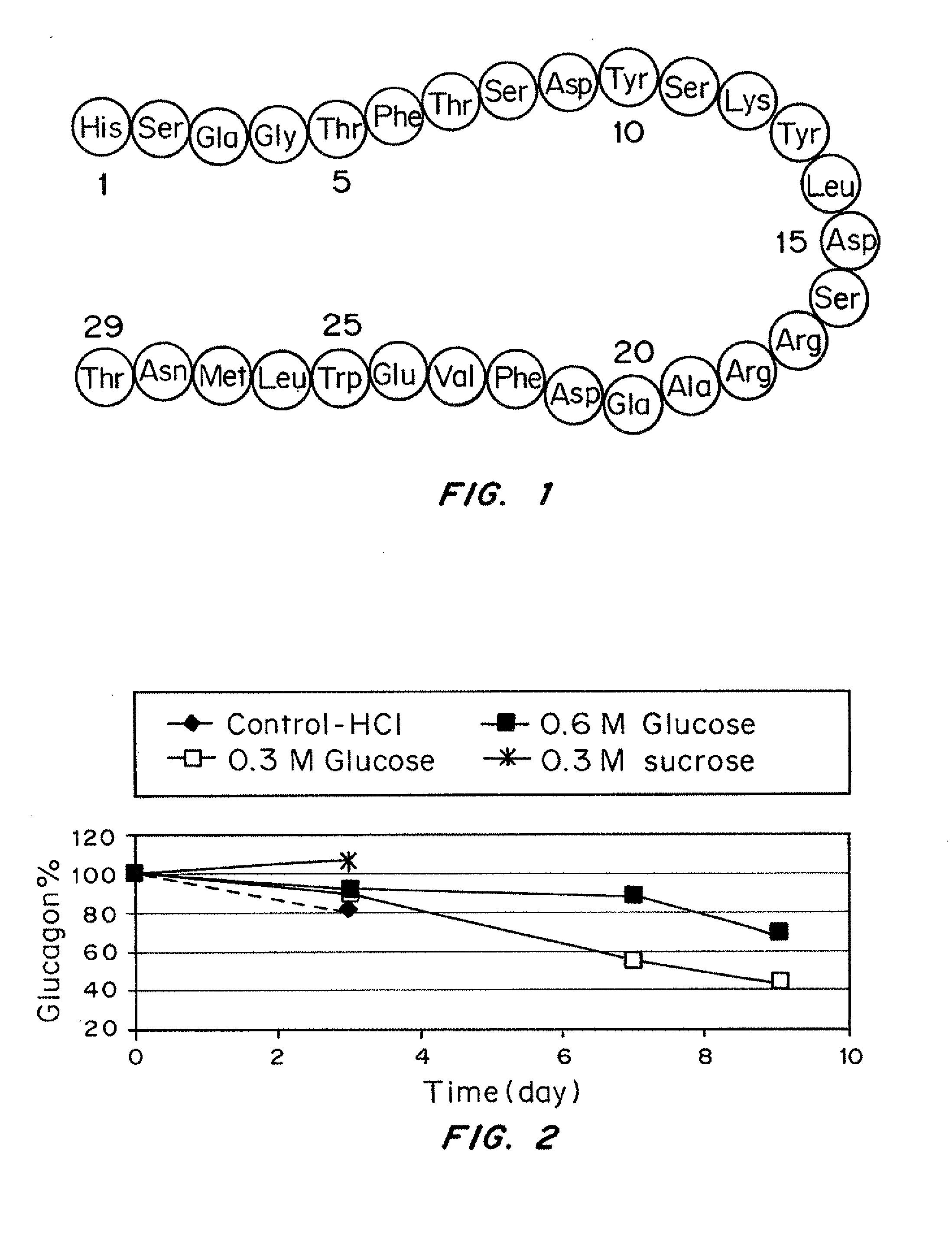

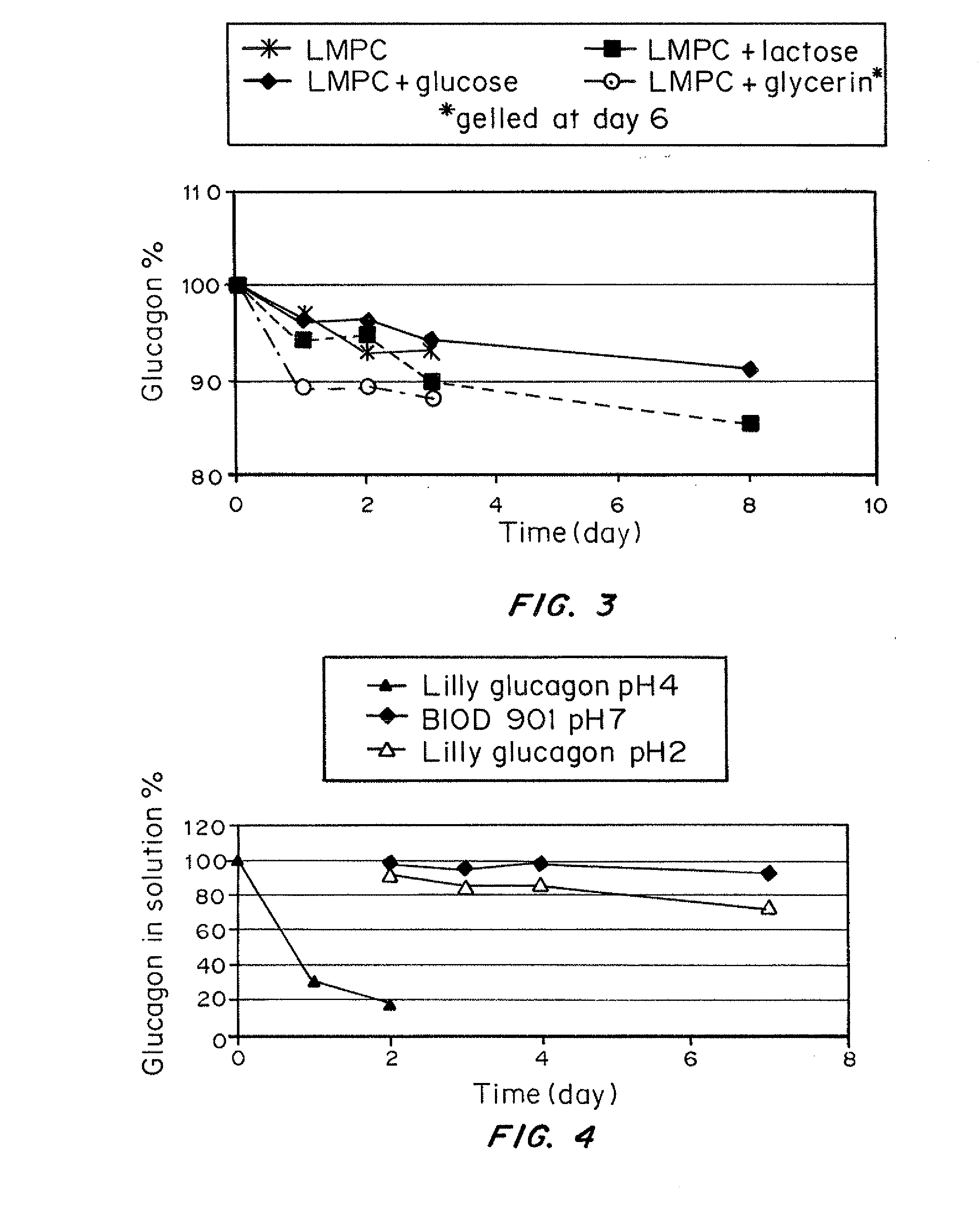

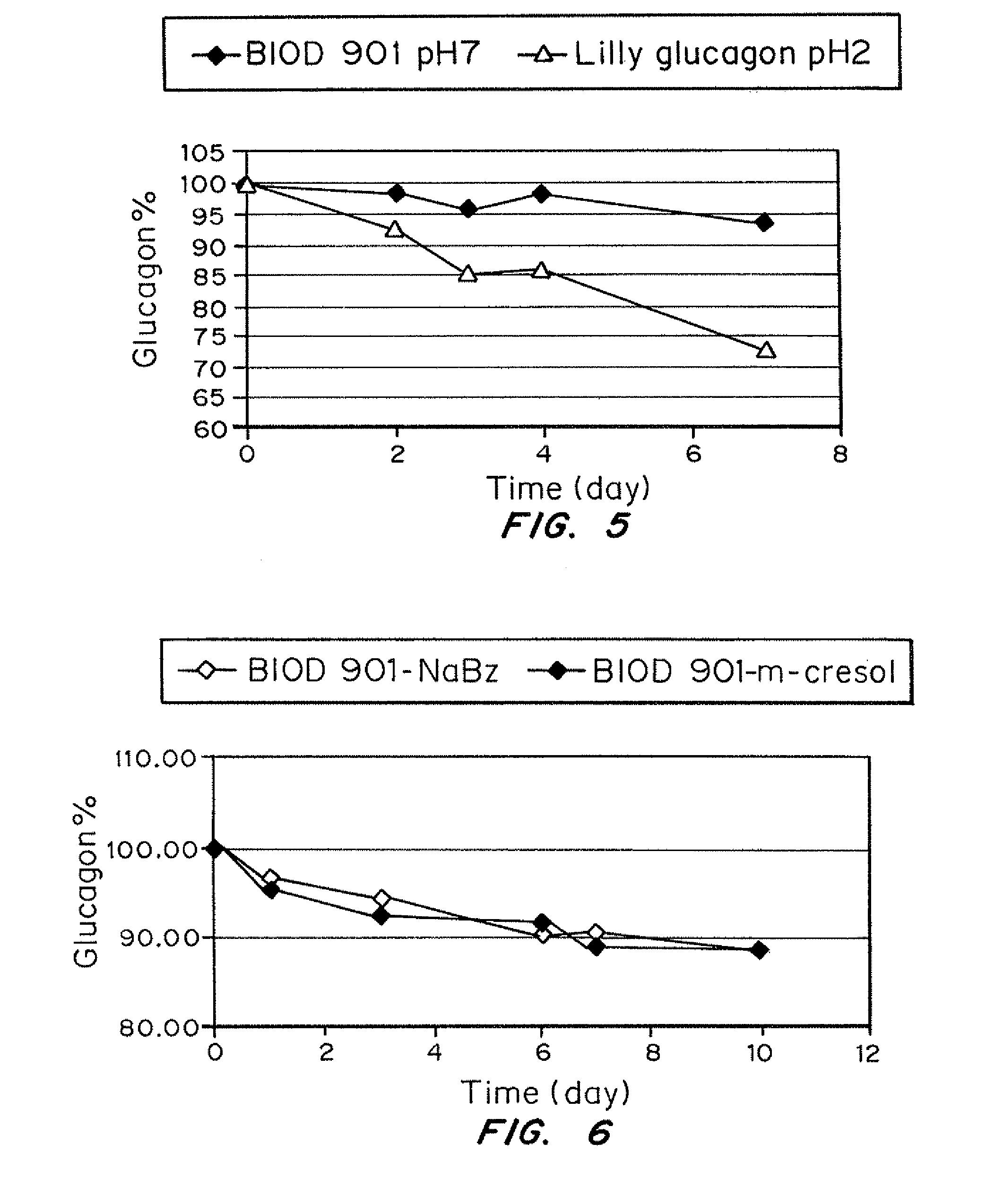

Stabilized glucagon solutions

InactiveUS20110097386A1Assist in elevationStabilize hydrophilic regionPeptide/protein ingredientsMetabolism disorderIrritationGlucose polymers

A formulation composed of a sugar such as glucose and a surfactant such as myristoyl lysophosphocholine (LMPC) has been designed to stabilize both hydrophilic and hydrophobic portions of the glucagon molecule, under prolonged physiological conditions, in a formulation that is sufficiently similar to the pH and osmolarity of plasma so as not to induce or to minimize site irritation. The combination of a simple sugar and an surfactant stabilizes the glucagon molecule in an aqueous solution for seven days at 37° C.

Owner:ALBIREO PHARMA INC

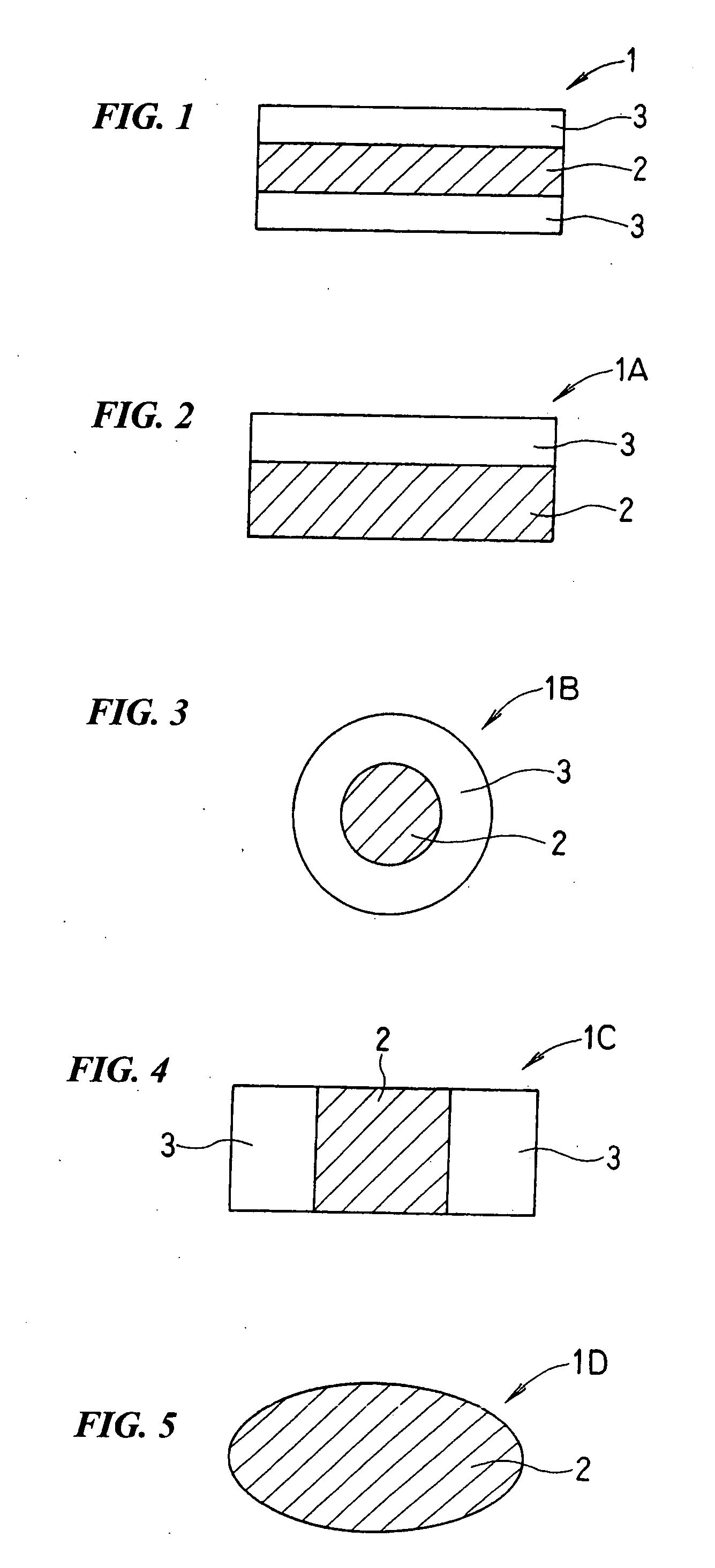

Novel Candy and Process for Producing the Same

InactiveUS20090053390A1Low viscosityImprove liquidityConfectionerySweetmeatsAdditive ingredientAlcohol sugars

A delicious candy in which crystallized xylitol has been molded in a desired shape and which has a beautiful shape and gives a cooling feeling attributable to xylitol; and a process by which the candy can be easily and industrially continuously produced. The novel candy (1) has a layered constitution which comprises two opposed candy part layers (3) and, sandwiched between these, a xylitol crystal part layer (2) comprising xylitol as the main component, at least one ingredient selected among monosaccharides, disaccharides, and sugar alcohols obtained by reducing these, and a viscosity-lowering agent as essential components, the at least one ingredient and the viscosity-lowering agent being contained in given amounts based on the xylitol as the main component.

Owner:MONDELEZ JAPAN

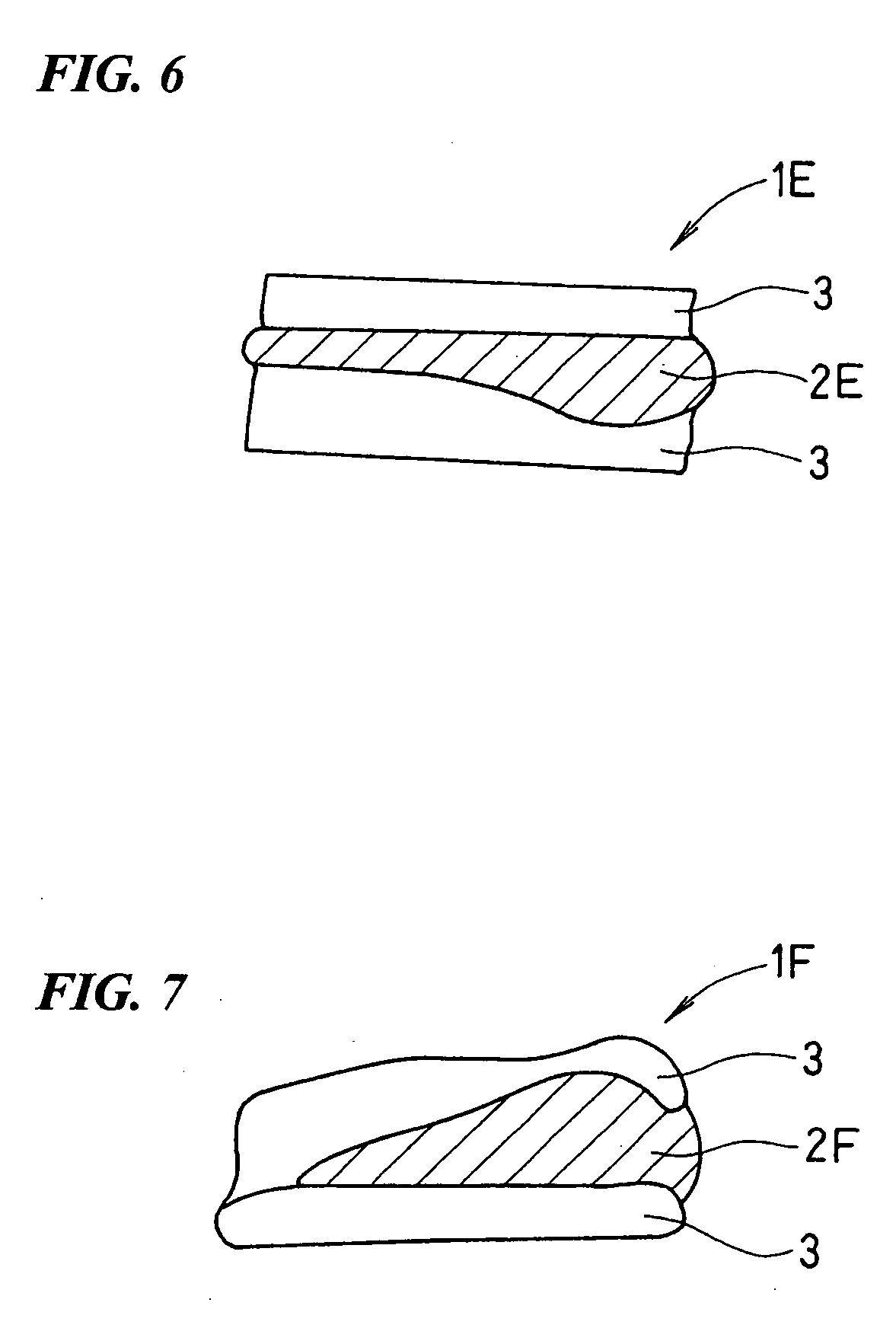

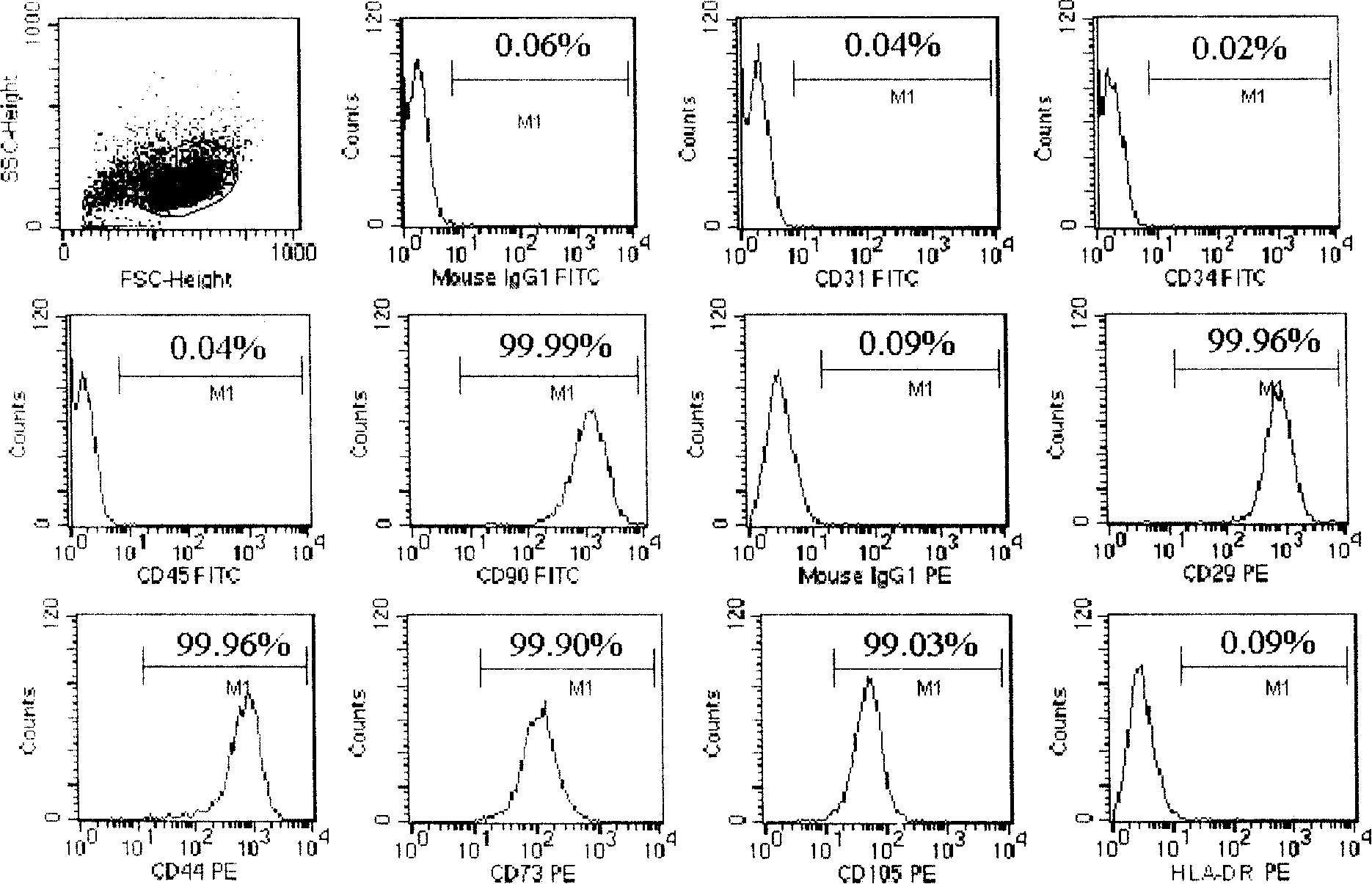

Mesenchyme stem cell preserving fluid and use thereof

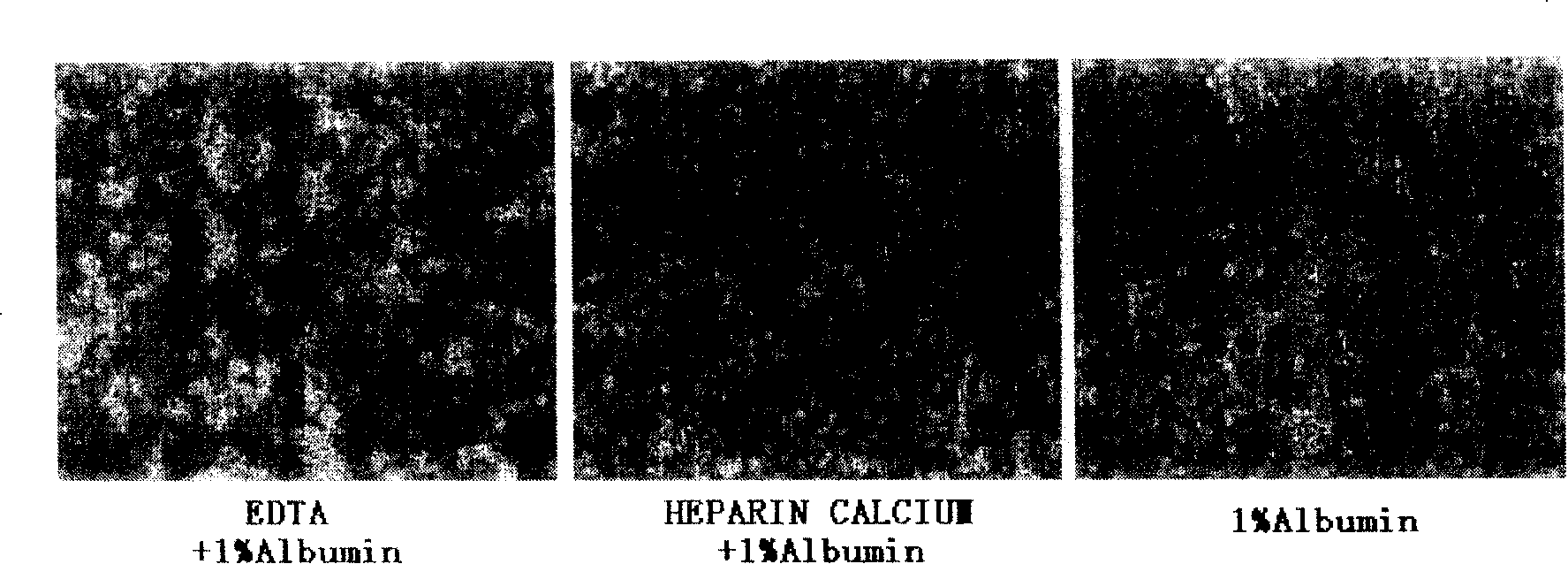

ActiveCN101210232AImprove survival rateReduce adhesionDead animal preservationTissue culturePhosphate ionCell mass

The invention discloses a preservation solution for mesenchymal stem cells and application thereof. The cell preservation solution contains human albumin and heparin as the main components, and other auxiliary reagents such as human cytokine, phosphate ion, metal ions or monosaccharide are contained in a buffer solution for preserving human mesenchymal stem cells. The preservation solution can keep high survival rate of human mesenchymal stem cells in transportation process, reduce adhesion between cells and between the cell and the inner wall of a container, and reduce the possible occurrence of cell mass embolism in blood vessel while clinically infusing human mesenchymal stem cells. The mesenchymal stem cells can be maintained in a state of single-cell suspension at an environment temperature of 4 to 15 DEG C for 24 h, thus greatly enlarging the clinic application range of the human mesenchymal stem cells. The components used in the solution accord with the clinic application, and can meet the requirement for clinic use of the human mesenchymal stem cells.

Owner:TIANJIN AMCELLGENE ENG

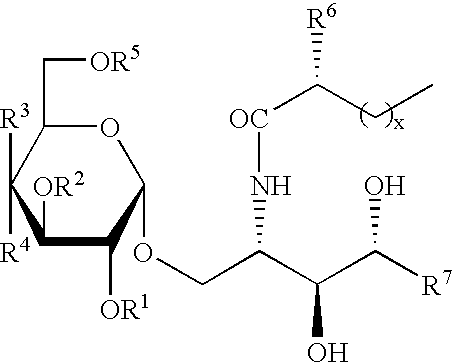

Novel synthetic C-glycolipids, their synthesis and use to treat infections, cancer and autoimmune diseases

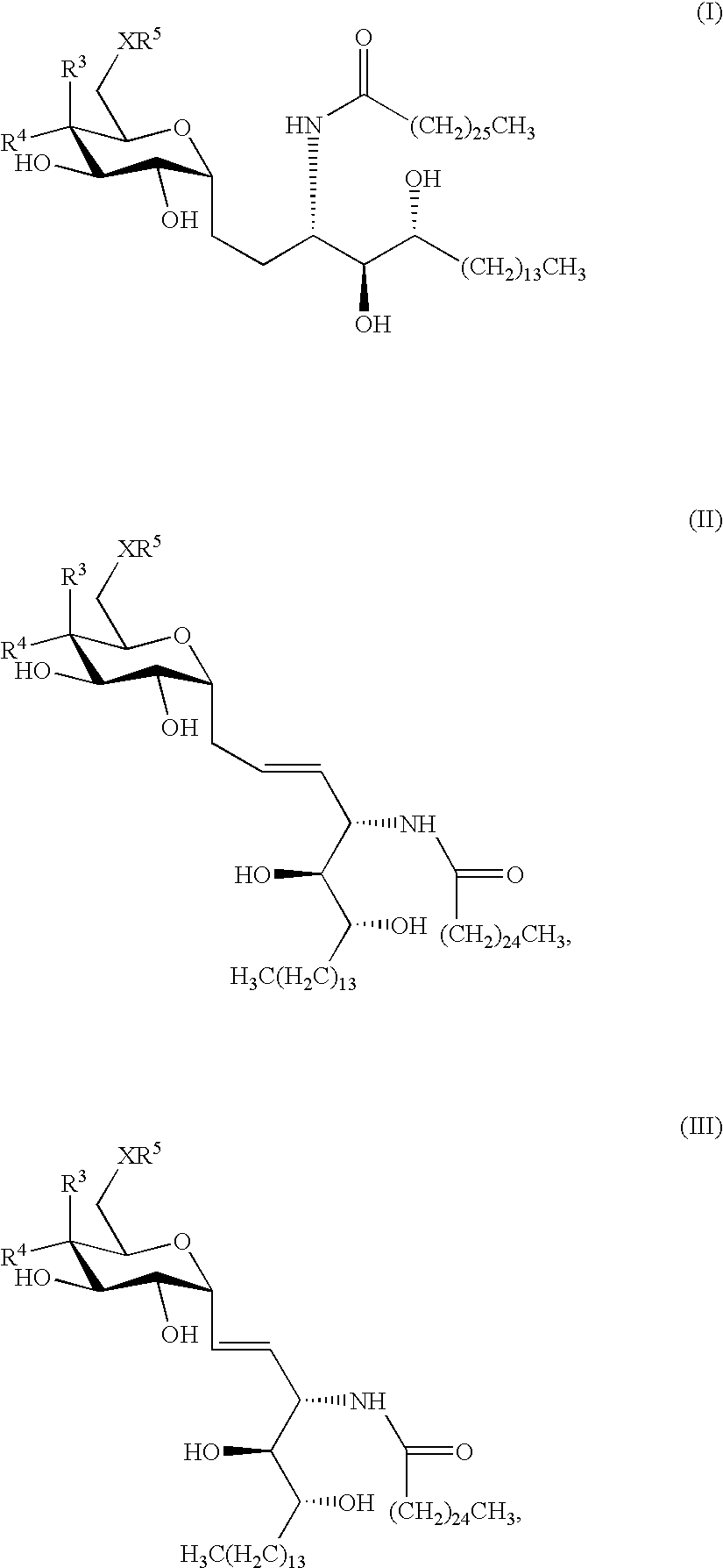

InactiveUS20050222048A1Esterified saccharide compoundsAntibacterial agentsAutoimmune diseaseGlycolipid

The invention is directed to novel compounds of formulae (I), (II) and (III): wherein X is O or NH; R3 is OH or a monosaccharide and R4 is hydrogen, or R3 is hydrogen and R4 is OH or a monosaccharide; R5 is hydrogen or a monosaccharide; and pharmaceutically acceptable salts or esters thereof. The invention is also directed to the use of the compounds both directly and as immune adjuvants for treating cancer, infectious diseases and autoimmune diseases. The invention is also directed to syntheses of the intermediates which can be used to make these novel compounds.

Owner:RES FOUND THE CITY UNIV OF NEW YORK +1

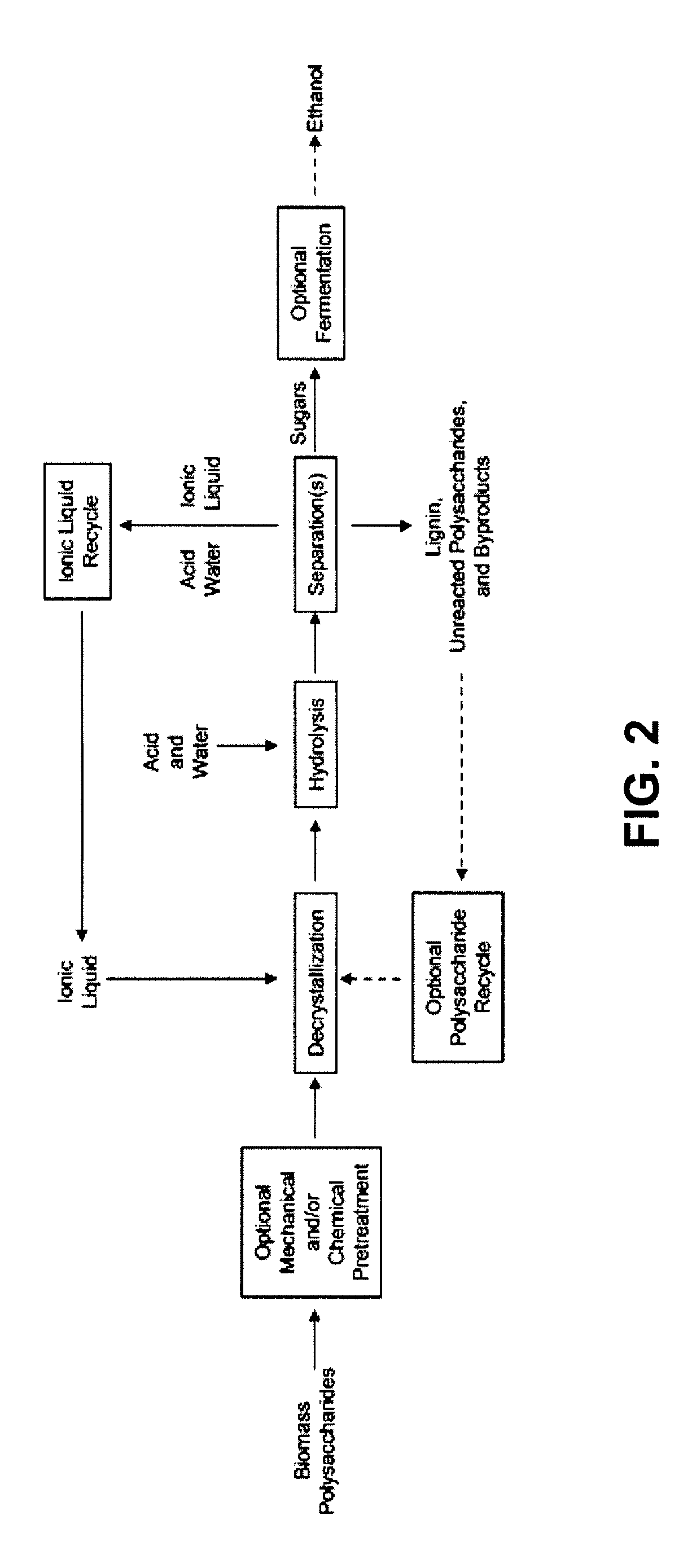

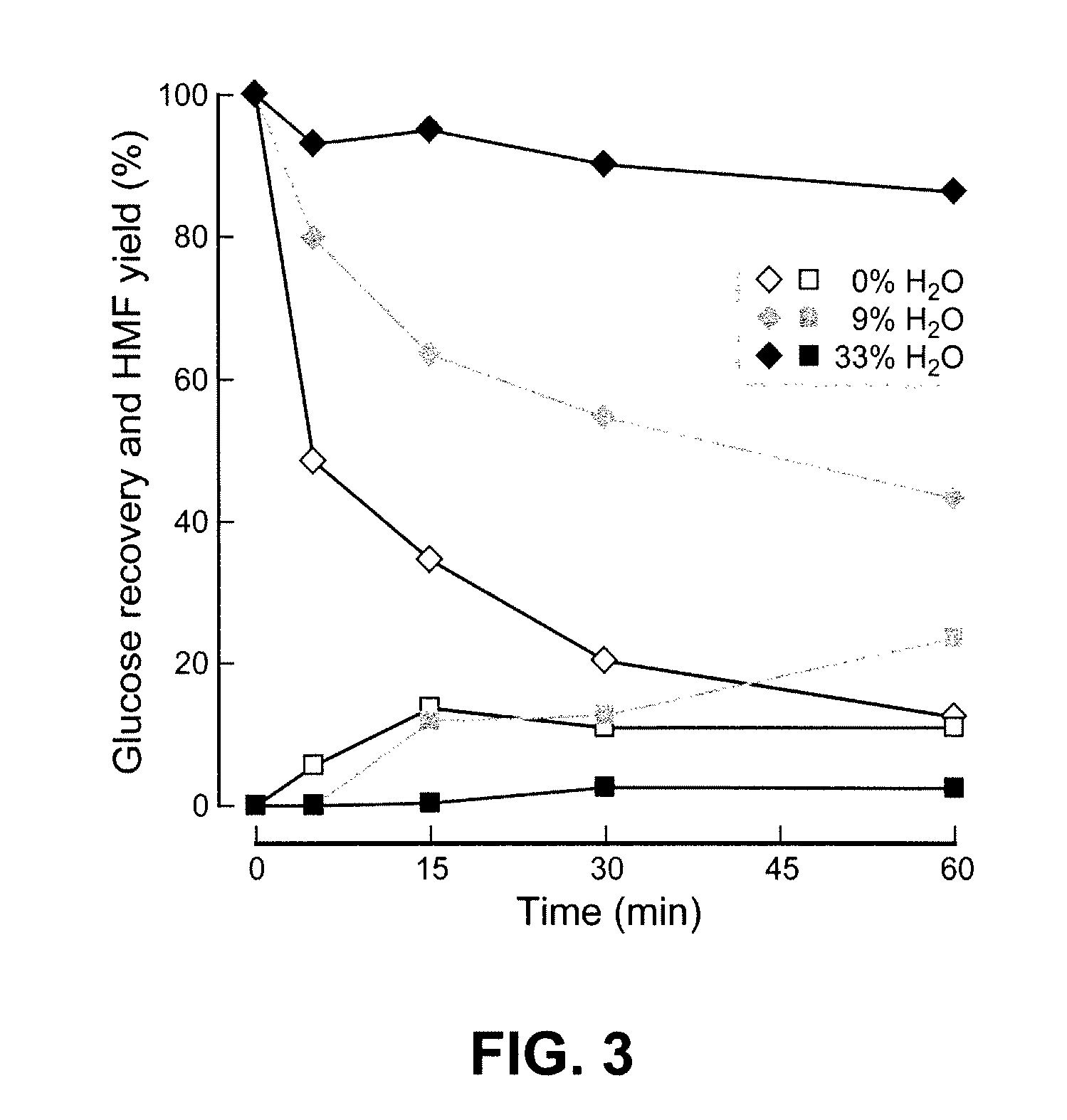

Biomass hydrolysis

ActiveUS20110065159A1Facilitate enhanced yield of glucoseImprove glucose yieldSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsCelluloseHydrolysate

High-yielding method for chemical hydrolysis of lignocellulose into monosaccharides. The process of the invention can additionally be applied to cellulose, xylan and related biomass polysaccharides, such as galactan, mannan, or arabinan. The method is employed for hydrolysis of a biomass polysaccharide substrate. The process is carried out in an ionic liquid in which cellulose is soluble in the presence of catalytic acid at a temperature sufficiently high to initiate hydrolysis. Water is added to the reaction mixture after initiation of hydrolysis at a rate controlled to avoid precipitation yet avoid undesired sugar dehydration products such ad HMF. Hydrolysis product is useful as feedstock for fermentations including fermentation processes for ethanol, butanol and other fuels.

Owner:WISCONSIN ALUMNI RES FOUND

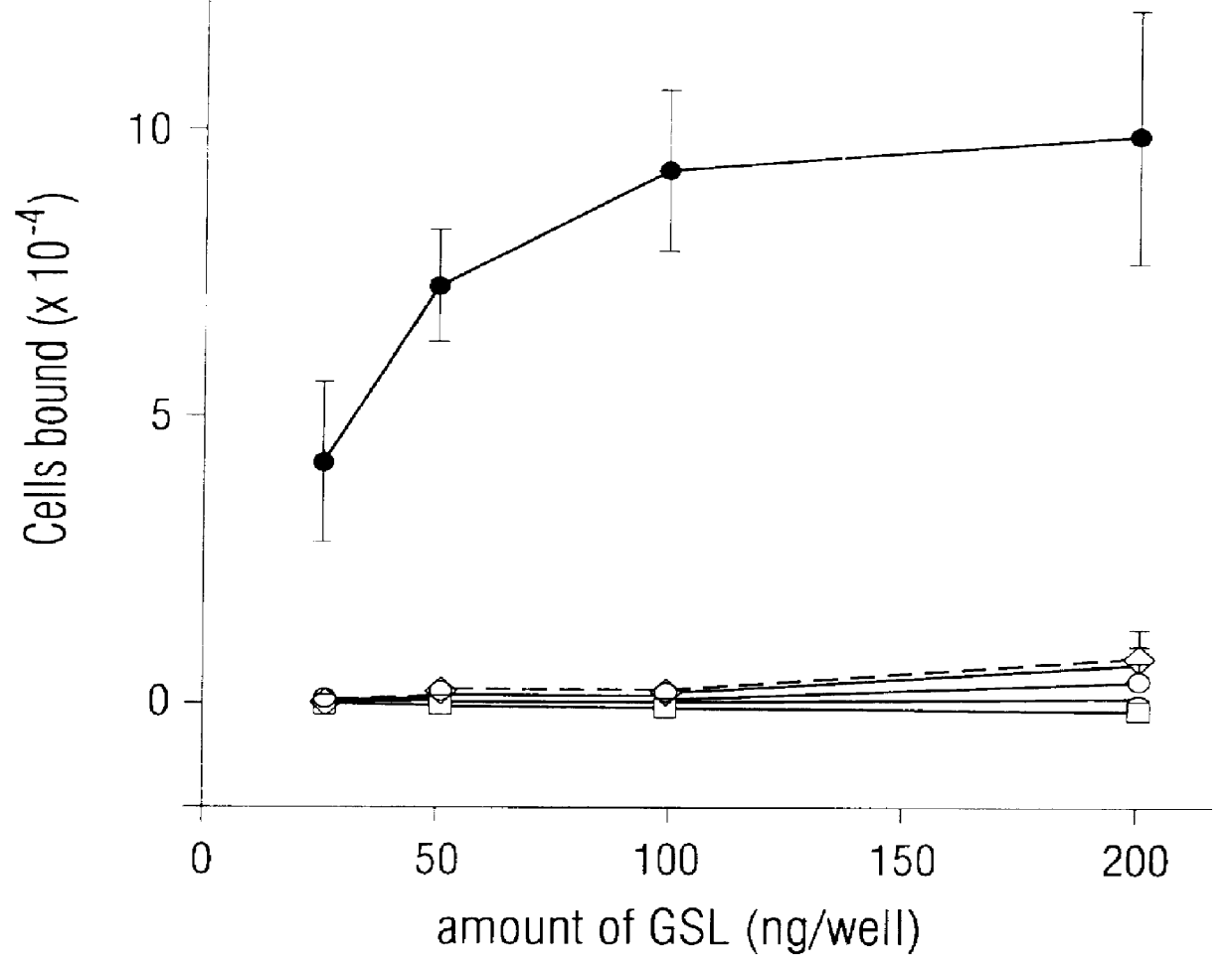

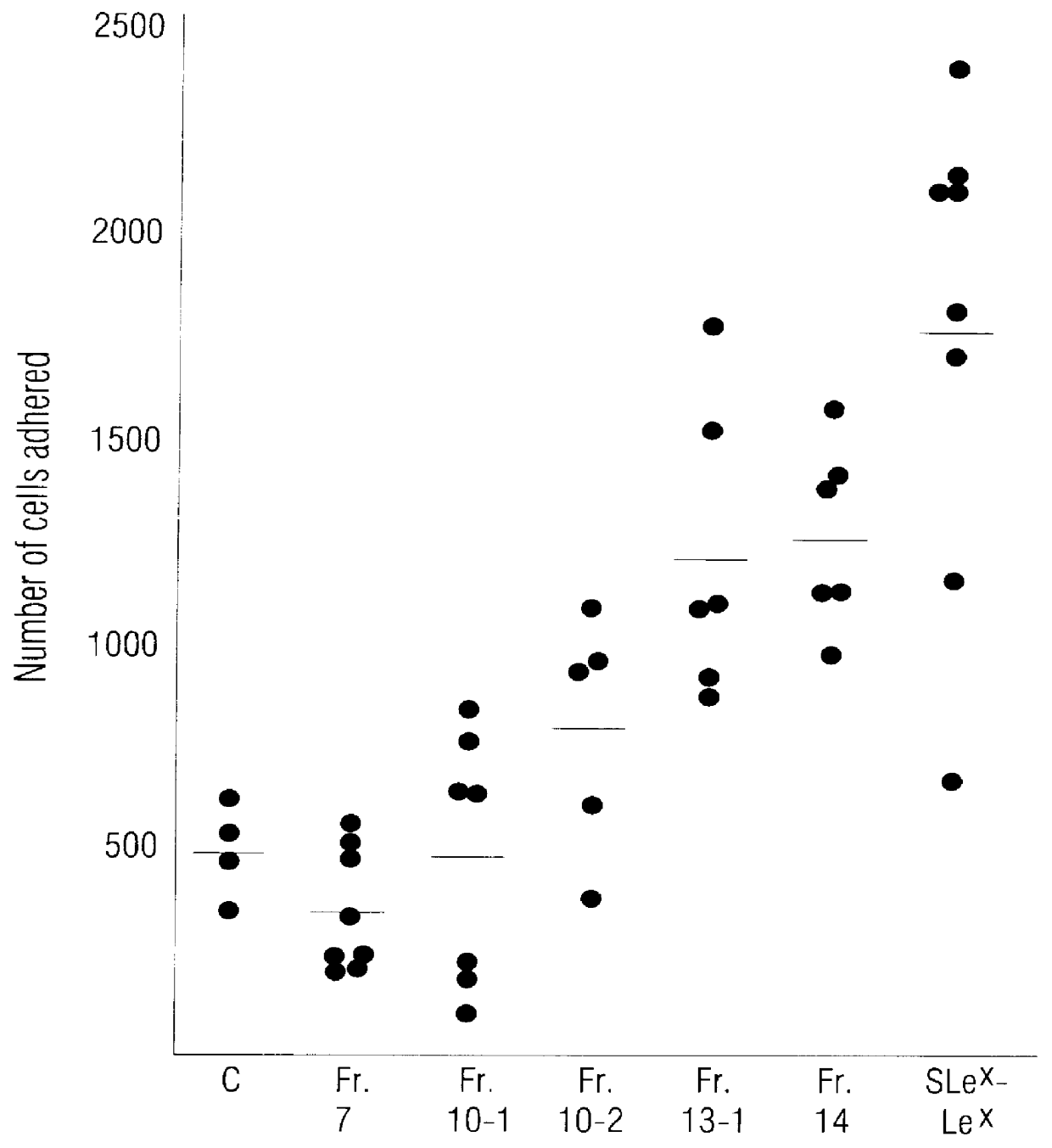

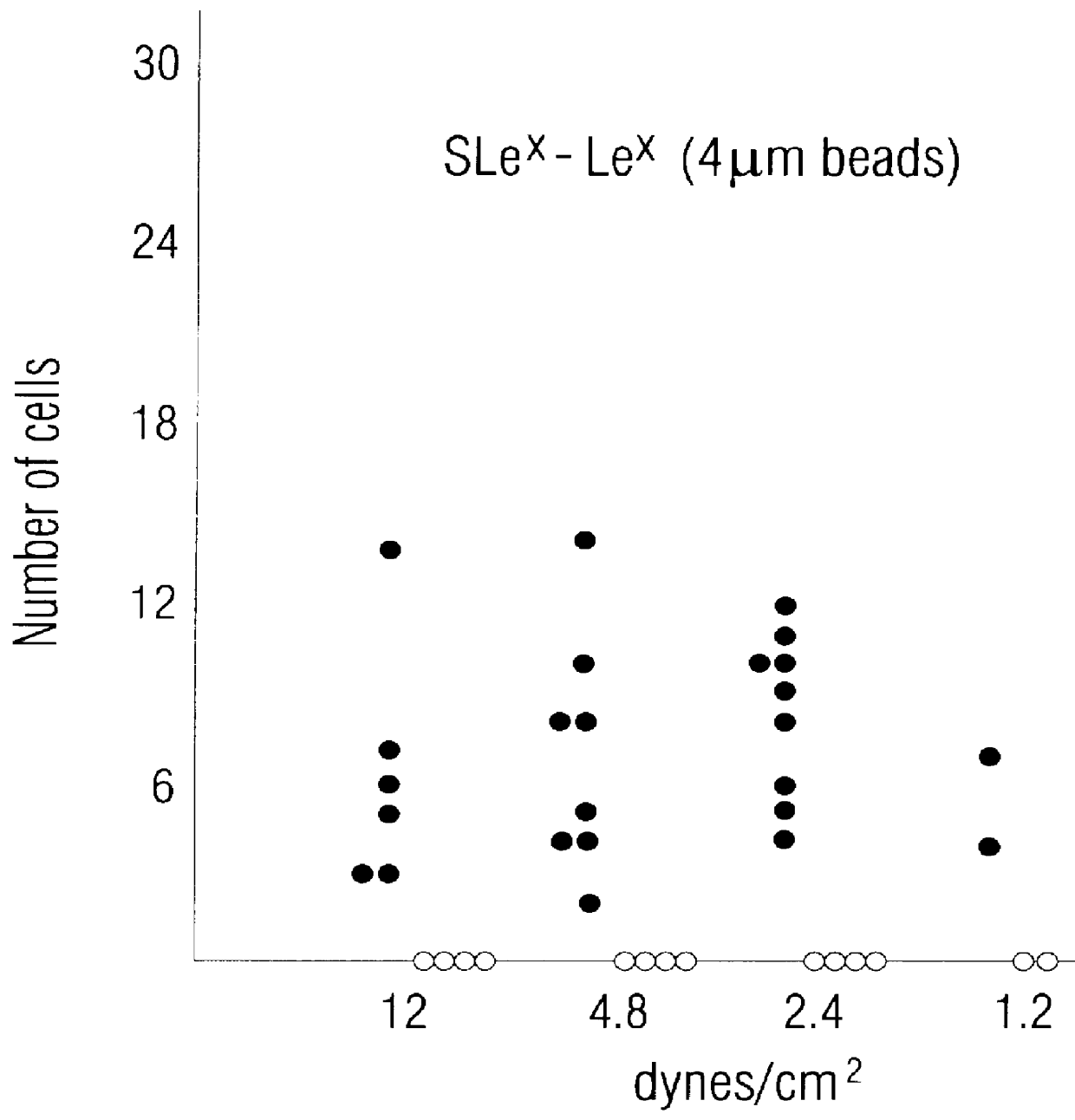

Carbohydrate ligands (myelorollin) that cause E-selectin dependent cell rolling and adhesion under dynamic flow system

InactiveUS6133239AStrong rollingInhibit the inflammatory responseBiocideAntipyreticE-selectinFucosylation

An unbranched polylactosamine comprising at least 6 monosaccharides and having terminal alpha 2->3 sialylation and internal alpha 1->3 fucosylation at various N-acetylglucosamine residues except for solely at the penultimate N-acetylglucosamine residue.

Owner:BIOMEMBRANE INST +1

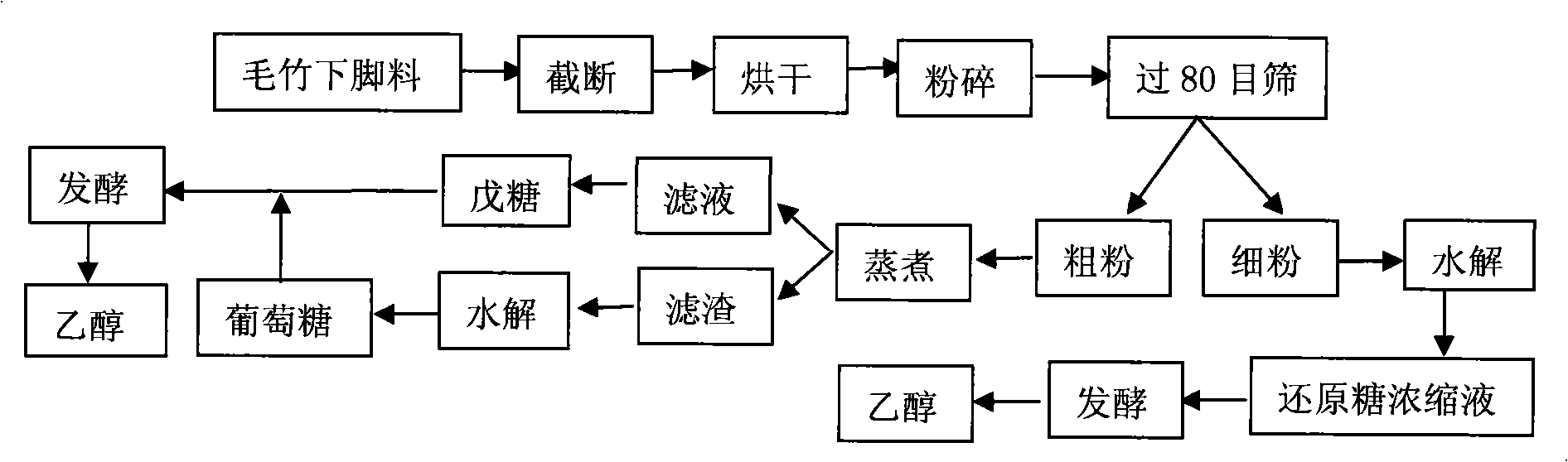

Method for preparing fuel ethanol from bamboo fibers

The invention discloses a method for preparing fuel ethanol from bamboo fibers. The method comprises the following steps that: waste from bamboo (or other non-wood biomass) processing is used as a raw material, the raw material is cut, dried, crushed and passed through a 80-mesh sieve, the powder passing through the 80-mesh sieve is fine bamboo powder and the powder failing to pass through the 80-mesh sieve is coarse bamboo powder; the coarse bamboo powder is cooked in a mixed liquid of formic acid, acetic acid and water for hydrolyzing hemicellulose and delignification, and fibers are obtained and subjected to hydrolysis by an organic acid to form a reducing monosaccharide; the fine bamboo powder is hydrolyzed directly by the organic acid to form the reducing monosaccharide; the reducing monosaccharide obtained from the hydrolysis of the hemicelluloses, the fibers and the fine bamboo powder are detoxicated by an excess amount of Ca(OH)2, the pH of the mixture is reduced, and the fuel ethanol is obtained after fermentation and rectification. The method for producing the fuel ethanol ensures the yield of the fuel ethanol, reduces the energy consumption for hydrolysis, and allows the organic acid used for hydrolysis to be recycled. In addition, the process of the fuel ethanol preparation using the method requires less water, and reduces environmental pollution and cost.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

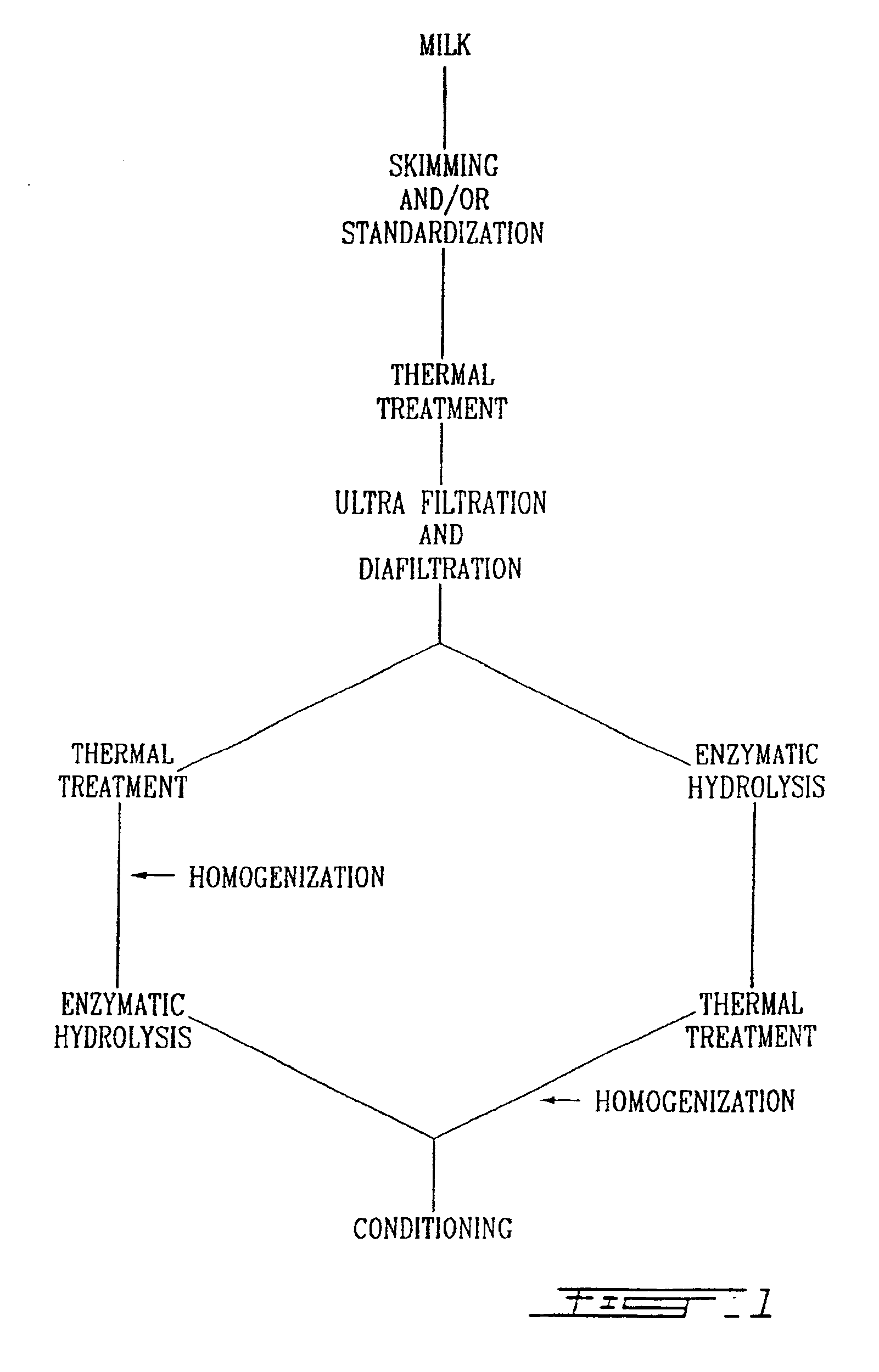

Process for making a lactose-free milk and milk so processed

InactiveUS6881428B2Affecting tasteLactose is reduced or substantially eliminated from milkMilk preparationWort preparationBiotechnologyLactose free milk

This invention relates to a process for producing a lactose-free milk which does not confer a sweet taste to the milk normally resulting from the hydrolysis of lactose into monosaccharides. The process comprises the step of reducing the lactose content of the milk to about 3% prior to hydrolysis with lactase. When the milk is skimmed milk, the protein content may be increased to about 3.8-4.0% or greater, which further improves the organoleptic properties of the milk. Milk so processed and dairy products derived therefrom are also disclosed and claimed.

Owner:AGROPUR COOP

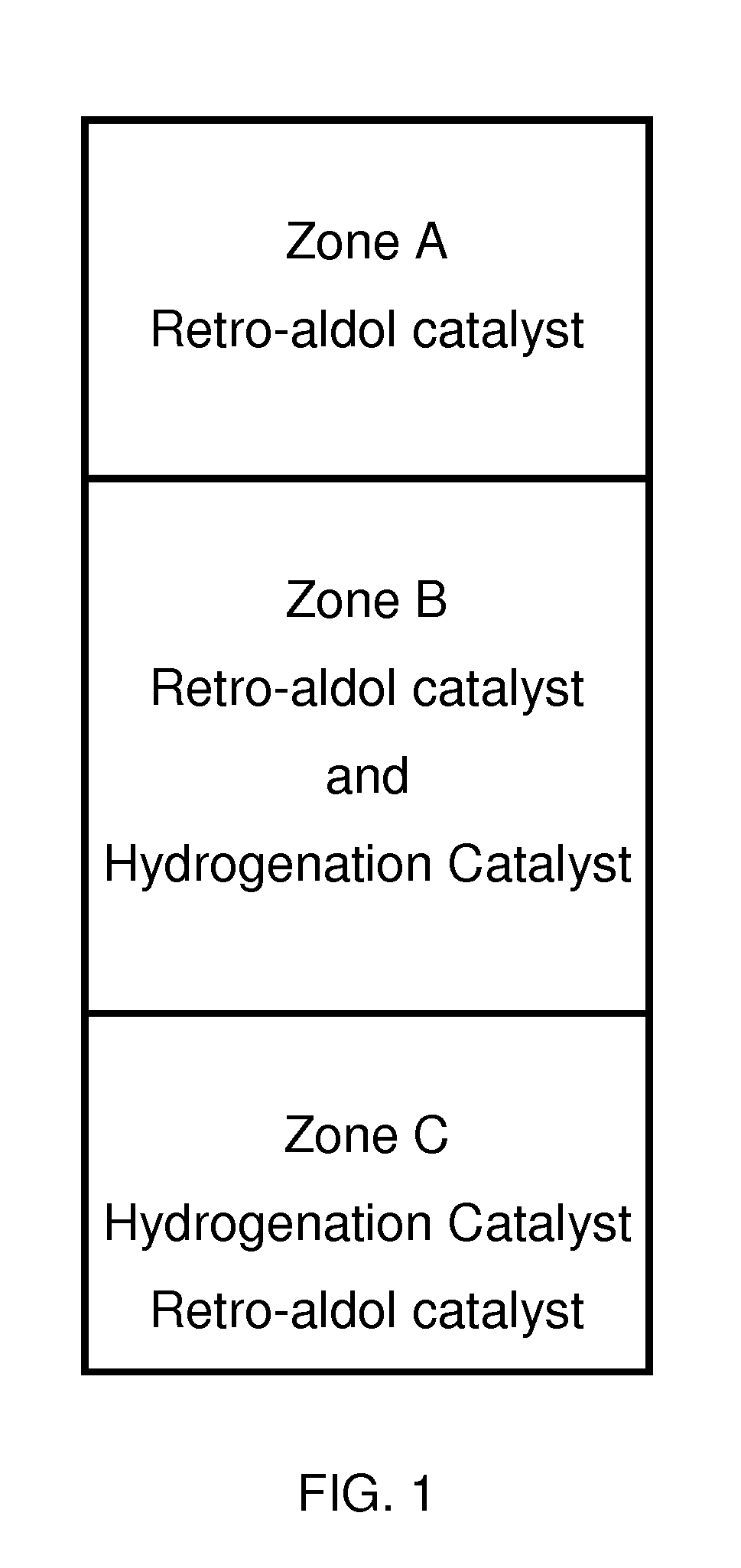

Process for the continuous production of ethylene glycol from carbohydrates

ActiveUS20150329449A1Organic compound preparationOxygen compounds preparation by reductionHydrogenPropylene glycol

A continuous process for converting carbohydrates to ethylene and propylene glycol. The carbohydrates are mixed with water and passed through a reactor at a temperature that hydrolyzes the carbohydrate mixture at least partially to monosaccharides. The reactor has a first zone comprising a retro-aldol catalyst and a second zone comprising a reducing catalyst. The aldose is converted in the first zone into glycolaldehyde by the retro-aldol catalyst and the glycolaldehyde, in the presence of hydrogen, is converted to ethylene glycol in the second zone of the reactor. The reaction products are removed from the reactor and the ethylene glycol is recovered. The selectivity to propylene glycol can be enhanced via feeding ketose as the carbohydrate.

Owner:TECH PRECESS TECH INC

Sweetener composition

A sweetener composition containing less than 1 gram of carbohydrates includes a monosaccharide derive polyol such as erythritol, a reduced calorie sweetener such as tagatose, a bulking agent such as polydextrose or maltodextrin and a high intensity, non-nutritive sweetener such as sucralose. The sweetness profile of the sweetener composition may be customized by adjusting the level of high intensity, non-nutritive sweetener included in the compositon.

Owner:MILES LOREN

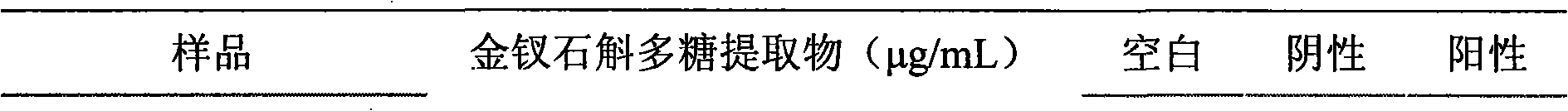

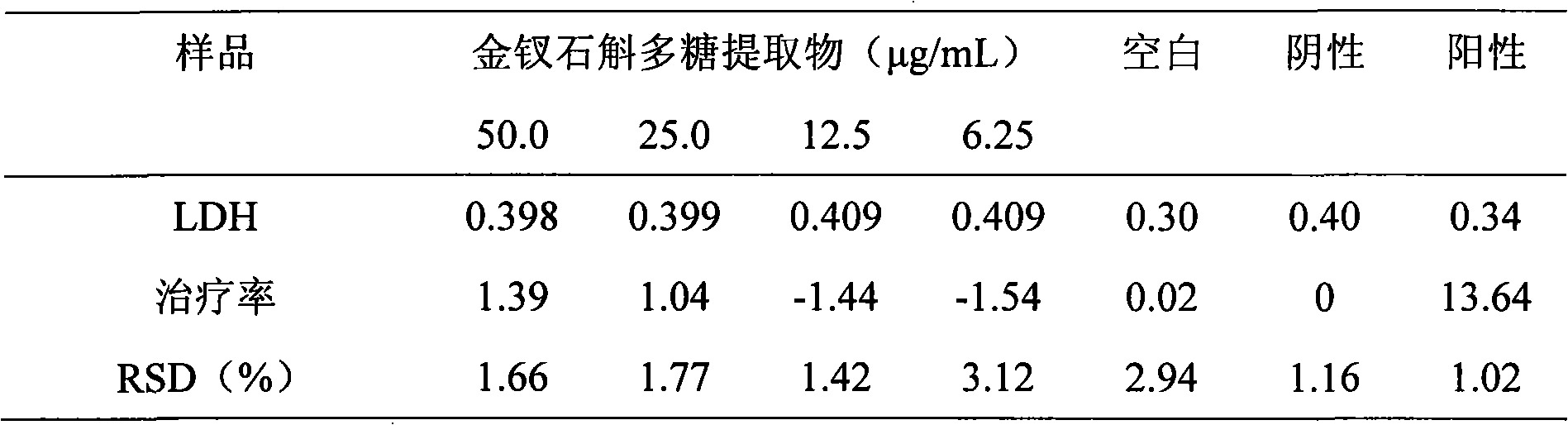

Preparation and use of Dendrobium nobile polysaccharide extract

InactiveCN101407557AQuality is easy to controlIncrease contentOrganic active ingredientsMetabolism disorderAlcoholMedicine

The invention provides a preparation method of dendrobium nobile polysaccharide extracts, which is realized by steps of degreasing, extracting, alcohol precipitating, protein removing, monose and oligosaccharide removing and purifying gel columns and the like. The polysaccharide content in the polysaccharide extract is more than 93 percent. The polysaccharide extract has remarkable oxidation prevention activity, can be combined with medicament excipients and carriers permitted by preparation agents, and can be applied in preparing medicaments or medicament combinations for treating and preventing cardiovascular diseases. The preparation method of the dendrobium nobile polysaccharide extracts is reasonable in design and convenient in operation.

Owner:ZHEJIANG UNIV

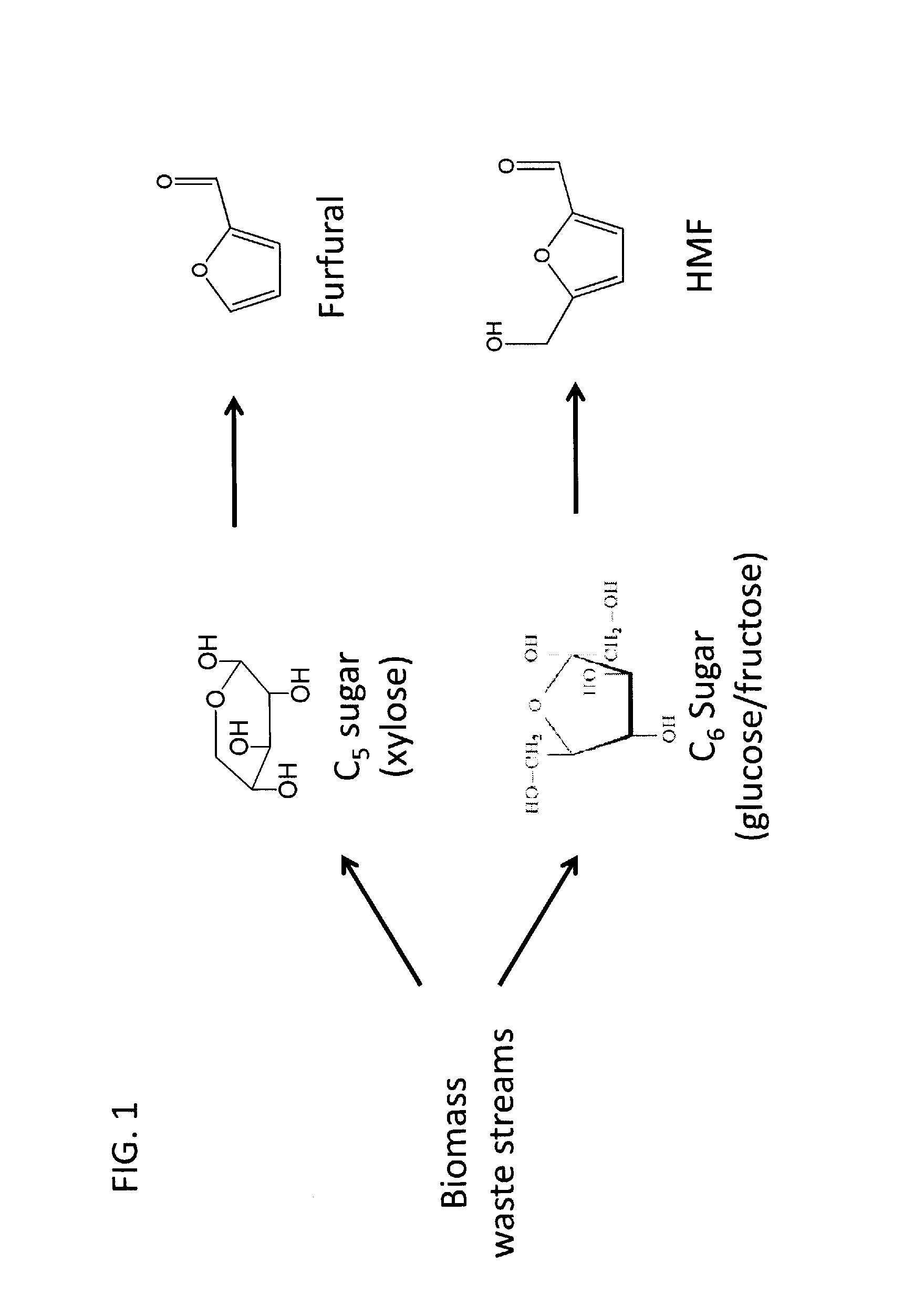

Method to convert monosaccharides to 5-(hydroxymethyl) furfural (HMF) using biomass-derived solvents

Described is a process to produce hydroxymethyl furfural (HMF) from biomass-derived sugars. The process includes the steps of reacting a C5 and / or C6 sugar-containing reactant derived from biomass in a monophasic or biphasic reaction solution comprising water and a co-solvent. The co-solvent can be beta-, gamma-, and / or delta-lactones derived from biomass, tetrahydrofuran (THF) derived from biomass, and / or methyltetrahydrofuran (MTHF) derived from biomass. The reaction takes place in the presence of an acid catalyst and a dehydration catalyst for a time and under conditions such that at least a portion of glucose or fructose present in the reactant is converted to HMF.

Owner:WISCONSIN ALUMNI RES FOUND

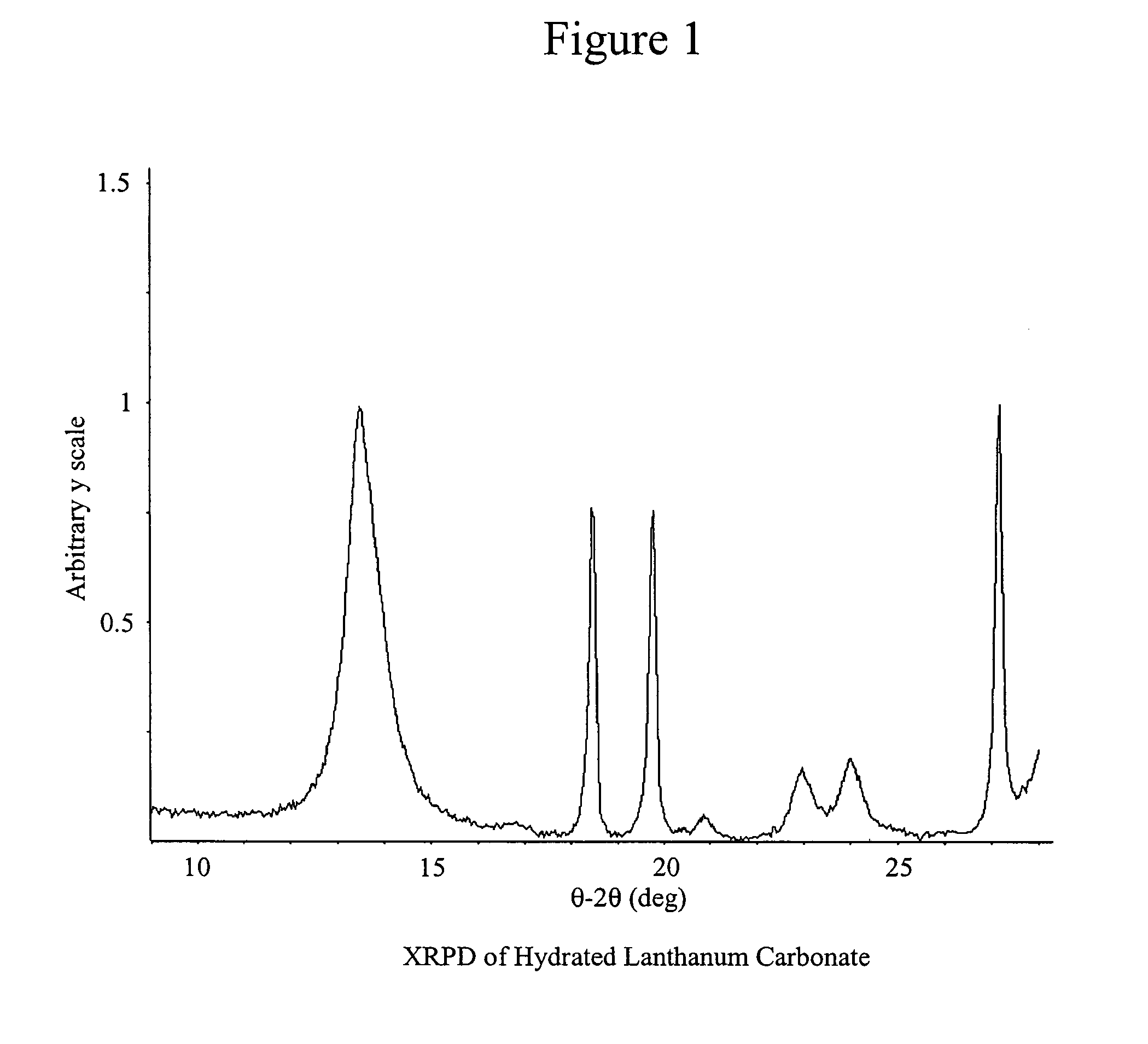

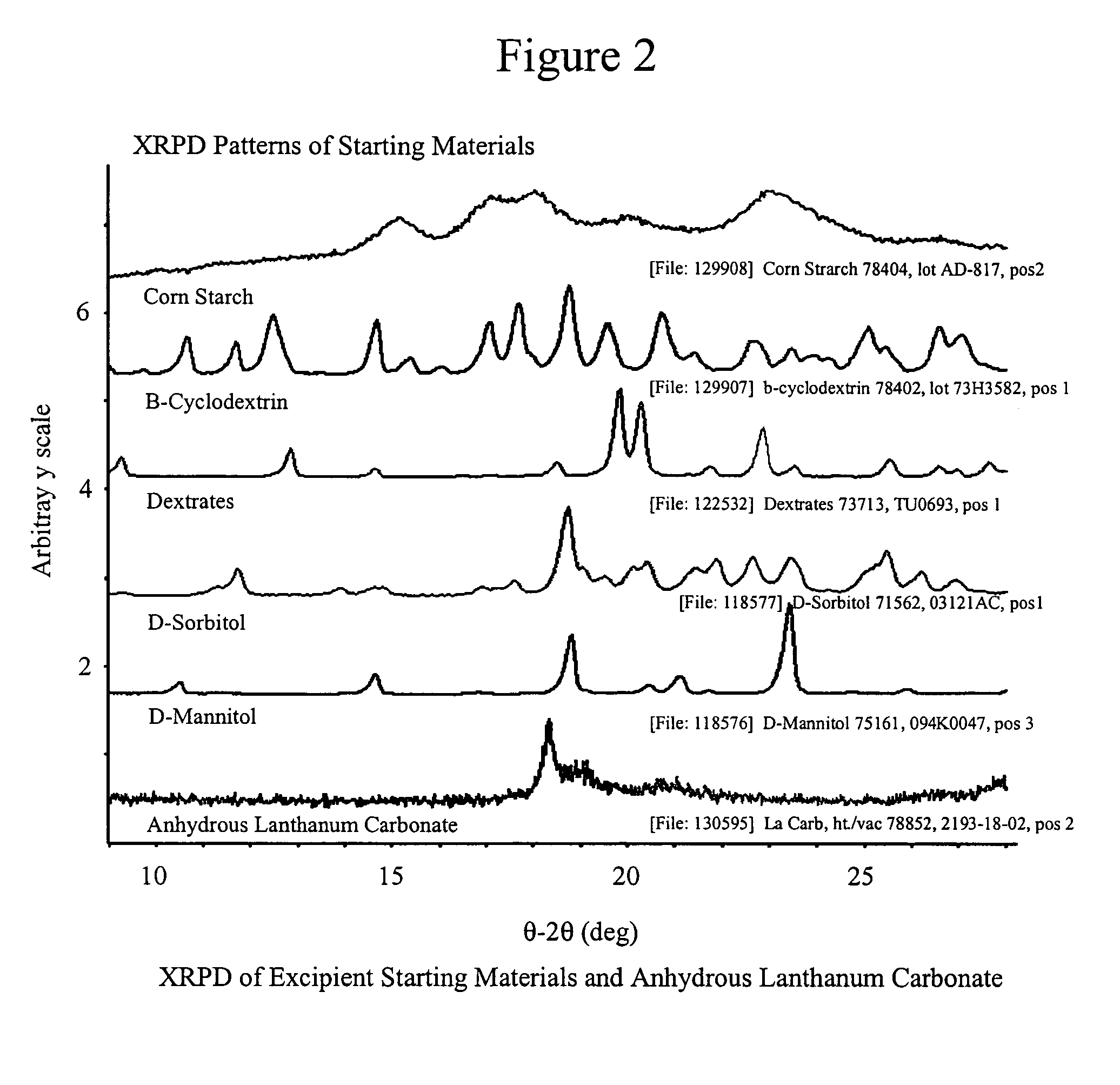

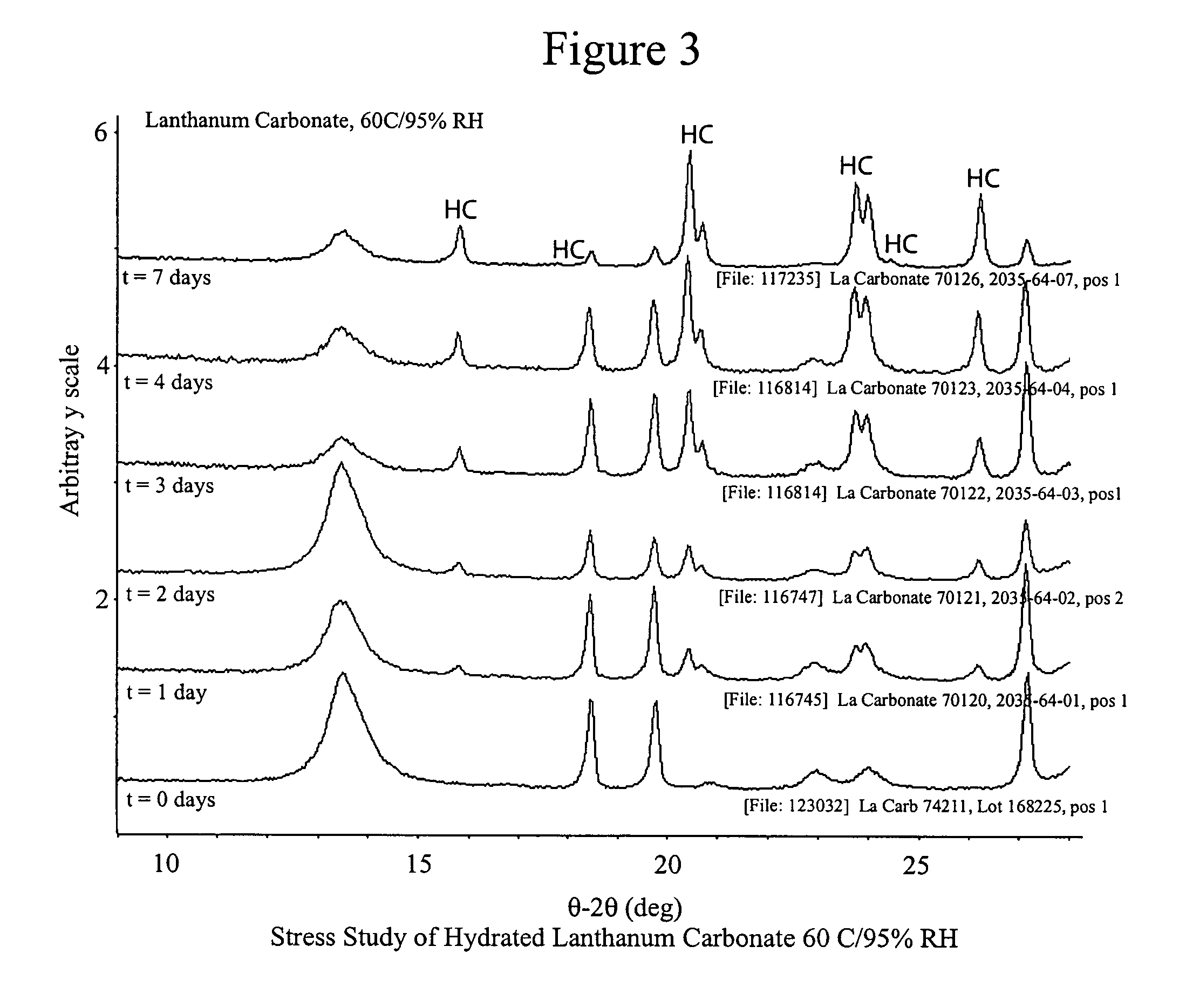

Stabilized lanthanum carbonate compositions

Owner:TAKEDA PHARMA CO LTD

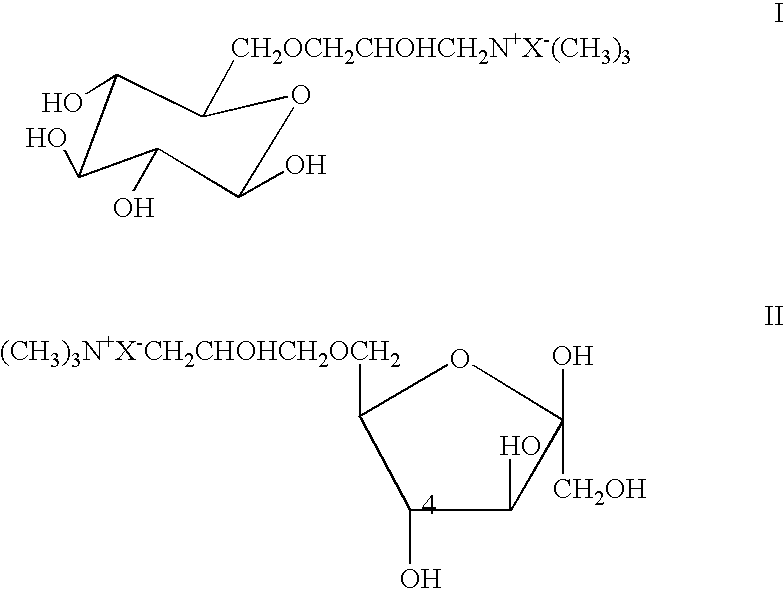

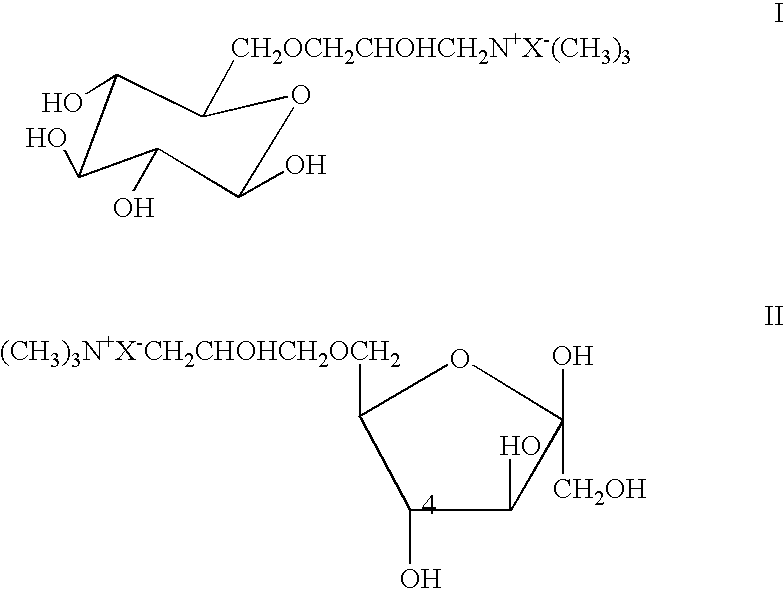

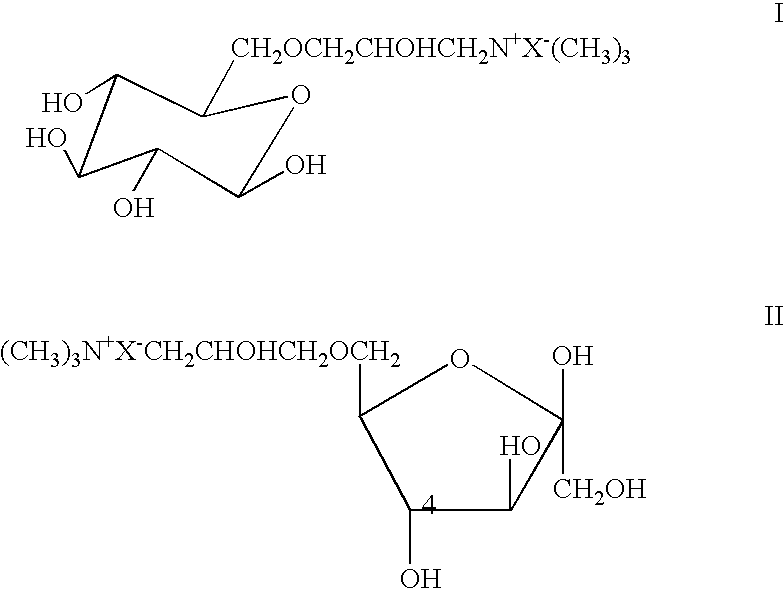

Quaternary ammonium polyol salts as anti-aging actives in personal care compositions

A personal care product is provided which includes a package filed with a personal care composition and instructions printed on or associated with the package indicating topical use of the composition on skin for purposes of controlling the signs of aging. The composition includes a quaternary ammonium compound selected from (a) salts of hydroxypropyltri(C1-C3 alkyl)ammonium mono-substituted mono-saccharide; (b) salts of hydroxypropyltri(C1-C3 alkyl)ammonium mono-substituted polyols, the salts having a cation of an average molecular weight no higher than about 450 and the salt having a Tg no higher than about 10° C.; (c) dihydroxypropyltri(C1-C3 alkyl)ammonium salts; (d) chlorohydroxypropyltri(C1-C3 alkyl)ammonium salts; and (e) mixtures thereof.

Owner:UNILEVER HOME & PERSONAL CARE USA DIVIOSN OF CONOPCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com