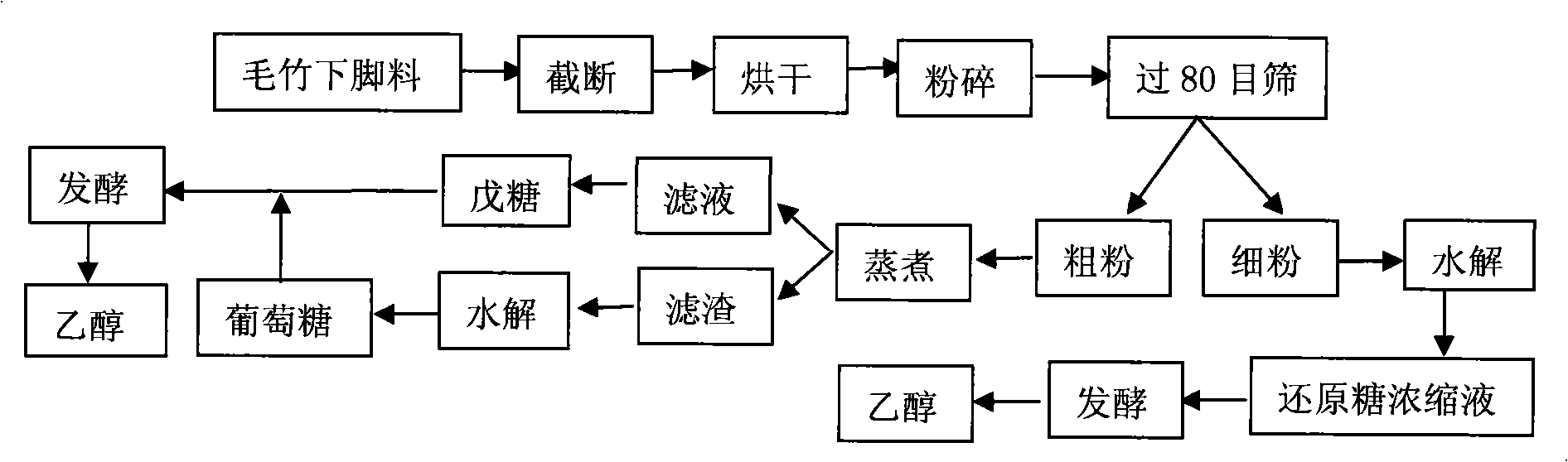

Method for preparing fuel ethanol from bamboo fibers

A technology of fuel ethanol and bamboo, which is applied in the field of preparing fuel ethanol from bamboo fiber, and can solve the problems of high cost of cellulase, long hydrolysis time, high operating cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The moso bamboo leftovers are cut off, dried and crushed. Pass 80 mesh sieves, those that pass through the 80 mesh sieves are bamboo fine powders, those that fail to pass are bamboo coarse powders. Take by weighing 400 grams of bamboo meal and add in the cooking reactor, add the mixed solution of formic acid / acetic acid / water (10 / 70 / 20) with liquid-solid ratio 10:1, cook at 105 DEG C for 2h, filter to get 50.2% filter residue (main component cellulose); the filtrate was diluted with water and precipitated out, and 16% lignin was obtained by filtration; the filtrate was concentrated and tested to contain 20% pentosan.

Embodiment 2

[0026] Add the cellulose obtained in Example 1 into a hydrolysis reactor, add 85% formic acid and 4% hydrochloric acid at a liquid-solid ratio of 25:1, and hydrolyze it at 60° C. for 6 hours. After the formic acid is recovered by distillation under reduced pressure, 55% reducing sugar can be obtained.

Embodiment 3

[0028] Take by weighing 400 grams of bamboo fine powder prepared in Example 1 and add it to a hydrolysis reactor, add 85% formic acid and 4% hydrochloric acid with a liquid-solid ratio of 25:1 and hydrolyze it for 6 hours at 60° C., after formic acid and hydrochloric acid are recovered by distillation under reduced pressure , to obtain 72.7% reducing sugars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com